Page 1

DATA SHEET

MOS INTEGRATED CIRCUIT

µ

PD77016

16 bits, Fixed-point Digital Signal Processor

µ

PD77016 is a 16 bits fixed-point DSP (Digital Signal Processor) developed for digital signal processing with its

demand for high speed and precision.

FEATURES

• FUNCTIONS

• Instruction cycle: 30 ns (MIN.) with 33 MHz clock

• Dual load/store

• Hardware loop function

• Conditional execution

• Executes product-sum operation in one instruction cycle

• PROGRAMMING

• 16 bits × 16 bits + 40 bits → 40 bits multiply accumulator

• 8 general registers (40 bits each)

• 8 ROM/RAM data pointer: each data memory area has 4 registers

• 10 source interrupts (external: 4, internal: 6)

• 3 operand instructions (example: R0 = R0 +R1L∗R2L)

• Nonpipeline on execution stage

• MEMORY AREAS

• Program memory area: 64K words × 32 bits

• Two independent data memory areas: 64K words × 16 bits (X/Y memory)

• ON-CHIP PERIPHERAL

• I/O port: 4 bits

• Serial I/O (16 bits): 2 channels

• CMOS

• +5 V single power supply

ORDERING INFORMATION

Part Number Package

µ

PD77016GM-KMD 160-pin plastic QFP (FINE PITCH) (24 × 24 mm)

Document No. U10891EJ5V0DS00 (5th edition)

Date Published April 1998 N CP(K)

Printed in Japan

The information in this document is subject to change without notice.

The mark shows major revised points.

©

1992, 1994, 1995

Page 2

2

X–Bus

BLOCK DIAGRAM

External

Memory

Serial

I/O #1

Serial

I/O #2

Ports

Host I/O

X Memory

Data

Pointers

Interrupt

Control

X Memory

2KW–RAM

Loop

Control

Stack

CPU Control

Main Bus

Y Memory

Data

Pointers

PC Stack

Y–Bus

Y Memory

2KW–RAM

Instruction

Memory

(1.5 KW–RAM)

MPY

16 × 16 + 40 → 40

R0–R7

ALU (40)

Wait

Controller

IE

I/O

INT1–INT4 RESET CLKOUT CLKIN

External Instruction MemoryWAIT

µ

PD77016

Page 3

FUNCTIONAL PIN GROUPS

SO1

SORQ1

SOEN1

SCK1

SI1

SIEN1

SIAK1

Serial

Interface #1

SO2

SORQ2

SOEN2

SCK2

SI2

SIEN2

SIAK2

Serial

Interface #2

HCS

HA0,HA1

HRD

HRE

HWR

HWE

HD0 - HD7

Host Interface

P0 - P3Ports

(2)

(4)

(8)

V

DD

+5 V

GND

RESET

INT1

INT2

INT3

INT4

IA0 - IA15

ID0 - ID31

HOLDRQ

BSTB

X/Y

DA0 - DA15

D0 - D15

WAIT

MRD

MWR

HOLDAK

External Instruction

Memory

Data Bus Control

Interrupts

(16)

(32)

(16)

External Data Memory

(16)

(2)

(3)

TDO,TICE

TCK,TDI,TMS

CLKIN

CLKOUT

PWR

Debugging

Interface

µ

PD77016

3

Page 4

4

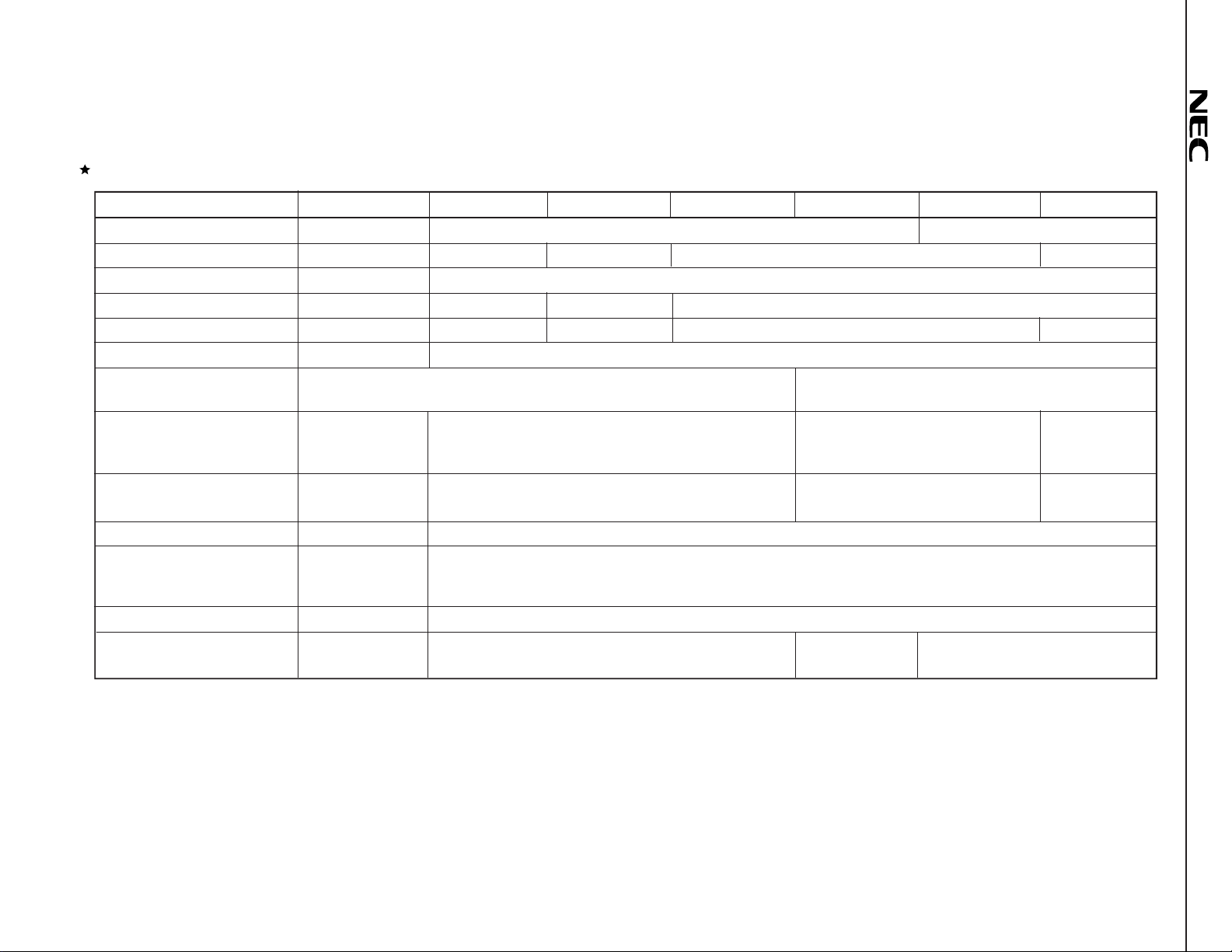

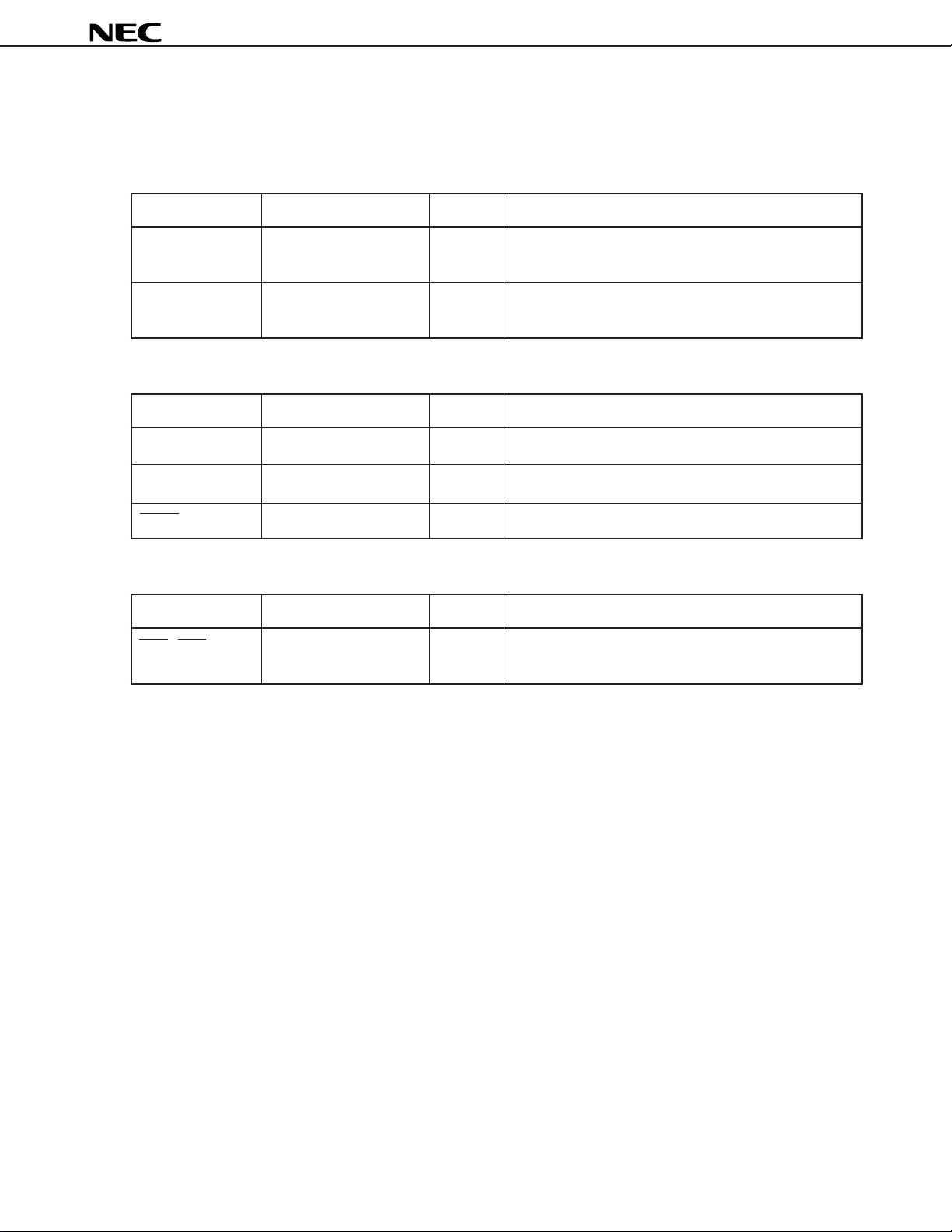

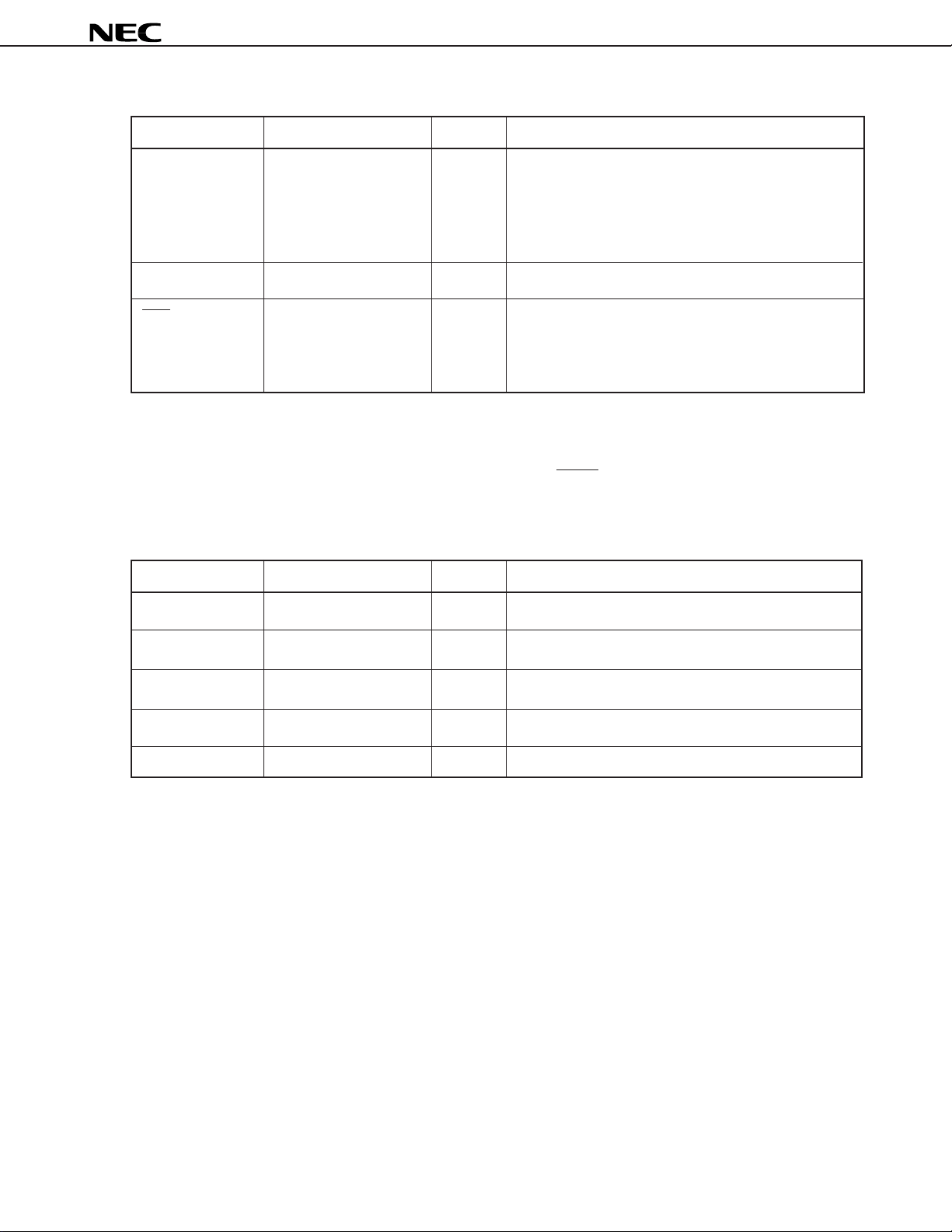

Functional Differences among the

Item

Internal instruction RAM 1.5K words 256 words 4K words

Internal instruction ROM None 4K words 12K words 24K words None

External instruction memory 48K words None

Data RAM (X/Y memory) 2K words each 1K words each 2K words each 3K words each

Data ROM (X/Y memory) None 2K words each 4K words each 12K words each None

External data memory 48K words each 16K words each

Instruction cycle

(Maximum operation speed)

External clock

(at maximum operation speed)

Crystal

(at maximum operation speed)

Instruction – STOP instruction is added.

Serial interface (2 Channels)

Power supply 5V 3 V

Package

µ

PD7701× Family

µ

PD77016

66 MHz

–

Channel 1 has the

same functions

as channel 2.

160-pin plastic QFP 100-pin plastic TQFP

µ

PD77015

30 ns (33 MHz)

Variable multiple rate (1, 2, 4, 8 ) by mask option.

Channel 1 has the same functions as that of the

Channel 2 has no SORQ2 or SIAK2 pin (Channel 2 is used for CODEC connection).

µ

PD77017

33/16.5/8.25/4.125 MHz

33 MHz

µ

PD77018

µ

PD77016.

µ

PD77018A

60/30/20/15/7.5 MHz

Variable multiple rate (1, 2, 3, 4, 8 ) by

mask option.

60 MHz

100-pin plastic TQFP

116-pin plastic BGA

µ

PD77019

16.6 ns (60 MHz)

100-pin plastic TQFP

µ

PD77019-013

15 MHz

Multiple rate is

fixed to 4.

–

Remark The

µ

PD77019-013 internal ROM area is masked already by the void code to use as RAM based DSP without mask code ordering process.

µ

PD77016

Page 5

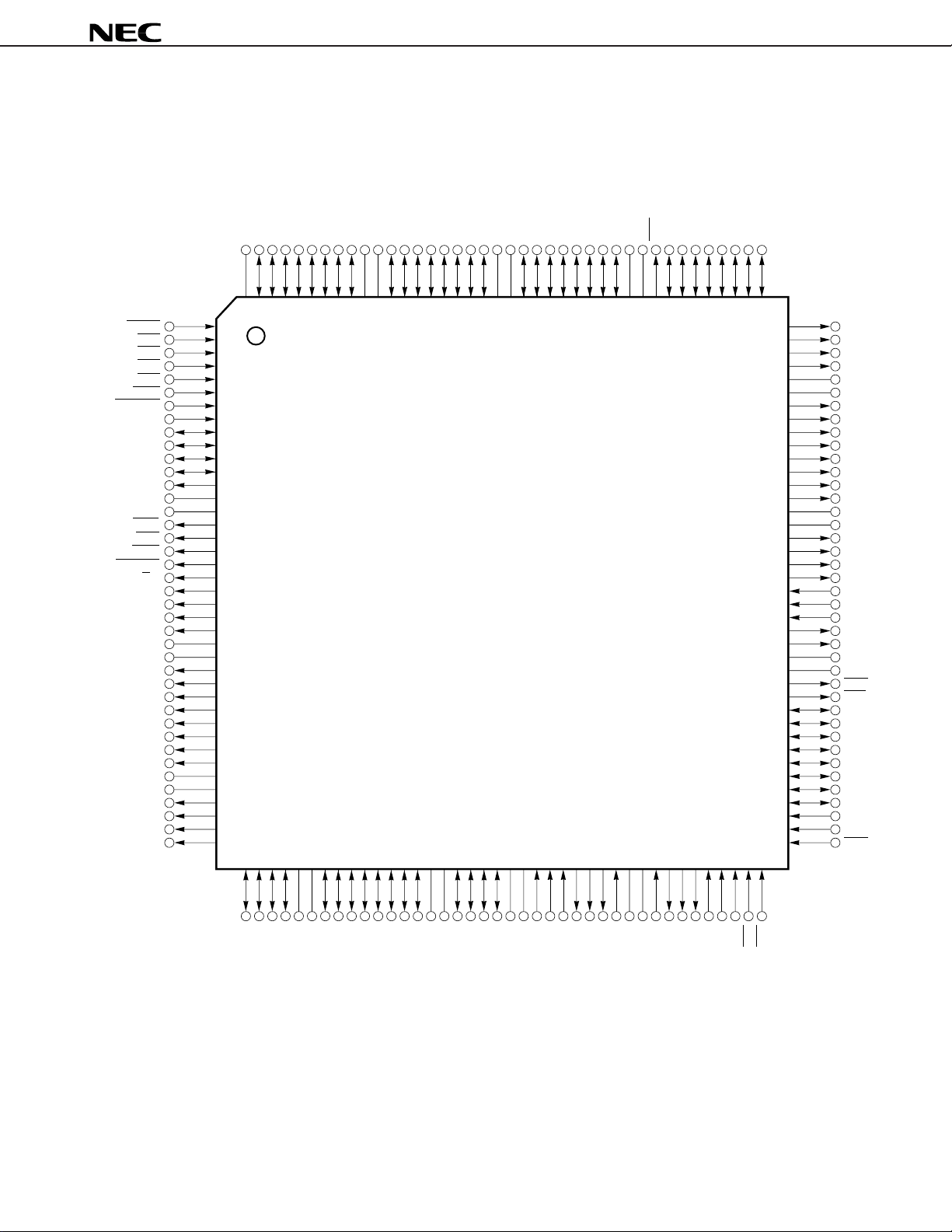

PIN CONFIGURATION

µ

PD77016GM-KMD

160-pin plastic QFP (FINE PITCH) (24 × 24 mm) (Top View)

µ

PD77016

RESET

INT4

INT3

INT2

INT1

WAIT

HOLDRQ

CLKIN

P3

P2

P1

P0

CLKOUT

GND

V

MWR

MRD

BSTB

HOLDAK

X/Y

DA15

DA14

DA13

DA12

GND

V

DA11

DA10

DA9

DA8

DA7

DA6

DA5

DA4

GND

V

DA3

DA2

DA1

DA0

NC

ID0

ID1

ID2

ID3

ID4

ID5

ID6

ID7

VDDGND

ID8

ID9

ID10

ID11

ID12

ID13

ID14

ID15

VDDGND

ID16

ID17

ID18

ID19

ID20

ID21

ID22

ID23

DD

PWR

ID24

GND

V

ID25

ID26

ID27

ID28

ID29

ID30

ID31

121122123124125126127128129130131132133134135136137138139140141142143144145146147148149150151152153154155156157158159160

1

2

3

4

5

6

7

8

9

10

11

12

13

14

DD

15

16

17

18

19

20

21

22

23

24

25

DD

26

27

28

29

30

31

32

33

34

35

DD

36

37

38

39

40

120

119

118

117

116

115

114

113

112

111

110

109

108

107

106

105

104

103

102

101

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

IA0

IA1

IA2

IA3

V

DD

GND

IA4

IA5

IA6

IA7

IA8

IA9

IA10

IA11

DD

V

GND

IA12

IA13

IA14

IA15

TMS

TDI

TCK

TIC

TDO

DD

V

GND

HWE

HRE

HD0

HD1

HD2

HD3

HD4

HD5

HD6

HD7

HA1

HA0

HWR

80797877767574737271706968676665646362616059585756555453525150494847464544434241

D15

D14

D13

D12

GND

DD

V

D11

D9D8D7D6D5

D10

D4

GND

DD

D3D2D1

V

D0

GND

DD

V

SI1

SCK1

SIEN1

SO1

SIAK1

GND

SOEN1

SORQ1

DD

V

SOEN2

SORQ2

SO2

SCK2

SIAK2

SI2

SIEN2

HCS

HRD

5

Page 6

PIN IDENTIFICATION

BSTB: Bus Strobe

CLKIN: Clock Input

CLKOUT: Clock Output

D0-D15: 16 Bits Data Bus

DA0-DA15: External Data Memory Address Bus

GND: Ground

HA0,HA1: Host Data Access

HCS: Host Chip Select

HD0-HD7: Host Data Bus

HOLDAK: Hold Acknowledge

HOLDRQ: Hold Request

HRD: Host Read

HRE: Host Read Enable

HWE: Host Write Enable

HWR: Host Write

IA0-IA15: Instruction Memory Address Output

ID0-ID31: Instruction Data Input

INT1-INT4: Interrupt

MRD: Memory Read Output

MWR: Memory Write Output

N.C: No Connection

P0-P3: Port

PWR: Program Memory Write Strobe

RESET: Reset

SCK1,SCK2: Serial Clock Input

SI1,SI2: Serial Data Input

SIAK1,SIAK2: Serial Input Acknowledge

SIEN1,SIEN2: Serial Input Enable

SO1,SO2: Serial Data Output

SOEN1,SOEN2: Serial Output Enable

SORQ1,SORQ2: Serial Output Request

TCK: Test Clock Input

TDI: Test Data Input

TDO: Test Data Output

TICE: Test In-Circuit Emulator

TMS: Test Mode Select

DD: Power Supply

V

WAIT: Wait Input

X/Y: X/Y Memory Select

µ

PD77016

6

Page 7

µ

PD77016

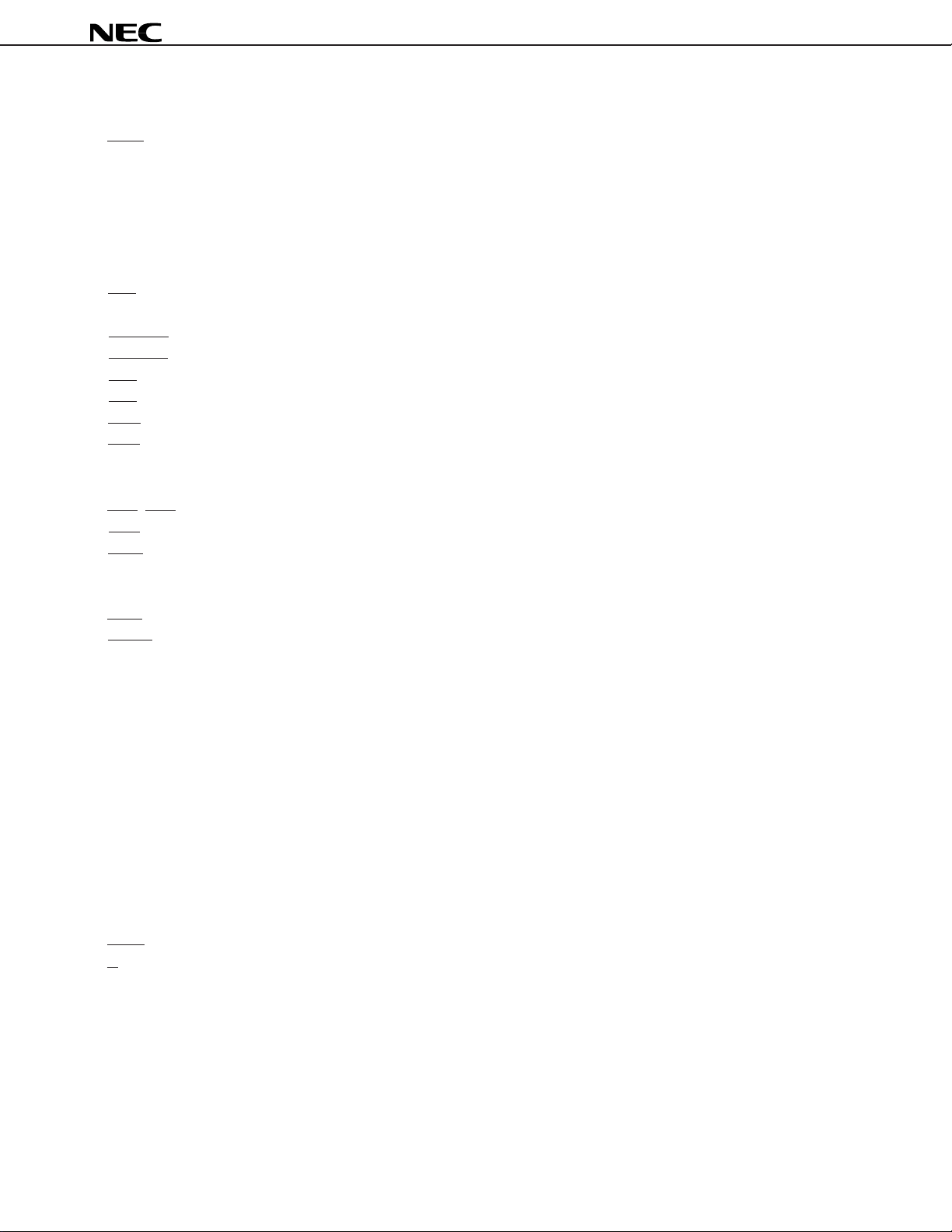

Pin No. Symbol

1 RESET

2 INT4

3 INT3

4 INT2

5 INT1

6 WAIT

7 HOLDRQ

8 CLKIN

9P3

10 P2

11 P1

12 P0

13 CLKOUT

14 GND

15 VDD

16 MWR

17 MRD

18 BSTB

19 HOLDAK

20 X/Y

21 DA15

22 DA14

23 DA13

24 DA12

25 GND

26 VDD

27 DA11

28 DA10

29 DA9

30 DA8

31 DA7

32 DA6

33 DA5

34 DA4

35 GND

36 VDD

37 DA3

38 DA2

39 DA1

40 DA0

Pin No. Symbol

41 D15

42 D14

43 D13

44 D12

45 GND

46 VDD

47 D11

48 D10

49 D9

50 D8

51 D7

52 D6

53 D5

54 D4

55 GND

56 VDD

57 D3

58 D2

59 D1

60 D0

61 GND

62 VDD

63 SI1

64 SIEN1

65 SCK1

66 SIAK1

67 SO1

68 SORQ1

69 SOEN1

70 GND

71 VDD

72 SOEN2

73 SORQ2

74 SO2

75 SIAK2

76 SCK2

77 SIEN2

78 SI2

79 HCS

80 HRD

Pin No. Symbol

81 HWR

82 HA0

83 HA1

84 HD7

85 HD6

86 HD5

87 HD4

88 HD3

89 HD2

90 HD1

91 HD0

92 HRE

93 HWE

94 GND

95 VDD

96 TDO

97 TICE

98 TCK

99 TDI

100 TMS

101 IA15

102 IA14

103 IA13

104 IA12

105 GND

106 VDD

107 IA11

108 IA10

109 IA9

110 IA8

111 IA7

112 IA6

113 IA5

114 IA4

115 GND

116 VDD

117 IA3

118 IA2

119 IA1

120 IA0

Pin No. Symbol

121 ID31

122 ID30

123 ID29

124 ID28

125 ID27

126 ID26

127 ID25

128 ID24

129 PWR

130 GND

131 VDD

132 ID23

133 ID22

134 ID21

135 ID20

136 ID19

137 ID18

138 ID17

139 ID16

140 GND

141 VDD

142 ID15

143 ID14

144 ID13

145 ID12

146 ID11

147 ID10

148 ID9

149 ID8

150 GND

151 VDD

152 ID7

153 ID6

154 ID5

155 ID4

156 ID3

157 ID2

158 ID1

159 ID0

160 NC

7

Page 8

µ

PD77016

CONTENTS

1. PIN FUNCTIONS............................................................................................................................... 9

1.1 Pin Functions........................................................................................................................................... 9

1.2 Recommended Connection for Unused Pins .......................................................................................14

2. FUNCTIONS...................................................................................................................................... 15

2.1 Pipeline Processing ................................................................................................................................ 15

2.1.1 Outline........................................................................................................................................... 15

2.1.2 Instructions with Delay .................................................................................................................. 15

2.2 Program Control Unit.............................................................................................................................. 16

2.3 Operation Unit ......................................................................................................................................... 16

2.3.1 General register (R0 to R7)........................................................................................................... 16

2.3.2 MAC: Multiply ACcumulator ......................................................................................................... 17

2.3.3 ALU: Arithmetic Logic Unit ........................................................................................................... 17

2.3.4 BSFT: Barrel ShiFTer................................................................................................................... 17

2.3.5 SAC: Shifter And Count Circuit .................................................................................................... 17

2.3.6 CJC: Condition Judge Circuit ....................................................................................................... 17

2.4 Memory..................................................................................................................................................... 18

2.4.1 Instruction RAM Outline ................................................................................................................ 19

2.4.2 Data Memory Outline .................................................................................................................... 19

2.4.3 Data Memory Addressing.............................................................................................................. 19

2.5 On-chip Peripheral Circuit...................................................................................................................... 20

2.5.1 Serial Interface Outline.................................................................................................................. 20

2.5.2 Host Interface Outline.................................................................................................................... 20

2.5.3 General Input/output Ports Outline................................................................................................ 20

2.5.4 Wait Cycle Register....................................................................................................................... 20

3. INSTRUCTIONS................................................................................................................................ 21

3.1 Outline...................................................................................................................................................... 21

3.2 Instruction Set and Operation................................................................................................................ 22

4. ELECTRICAL SPECIFICATIONS.....................................................................................................29

5. PACKAGE DRAWING ...................................................................................................................... 50

6. RECOMMENDED SOLDERING CONDITIONS................................................................................ 51

8

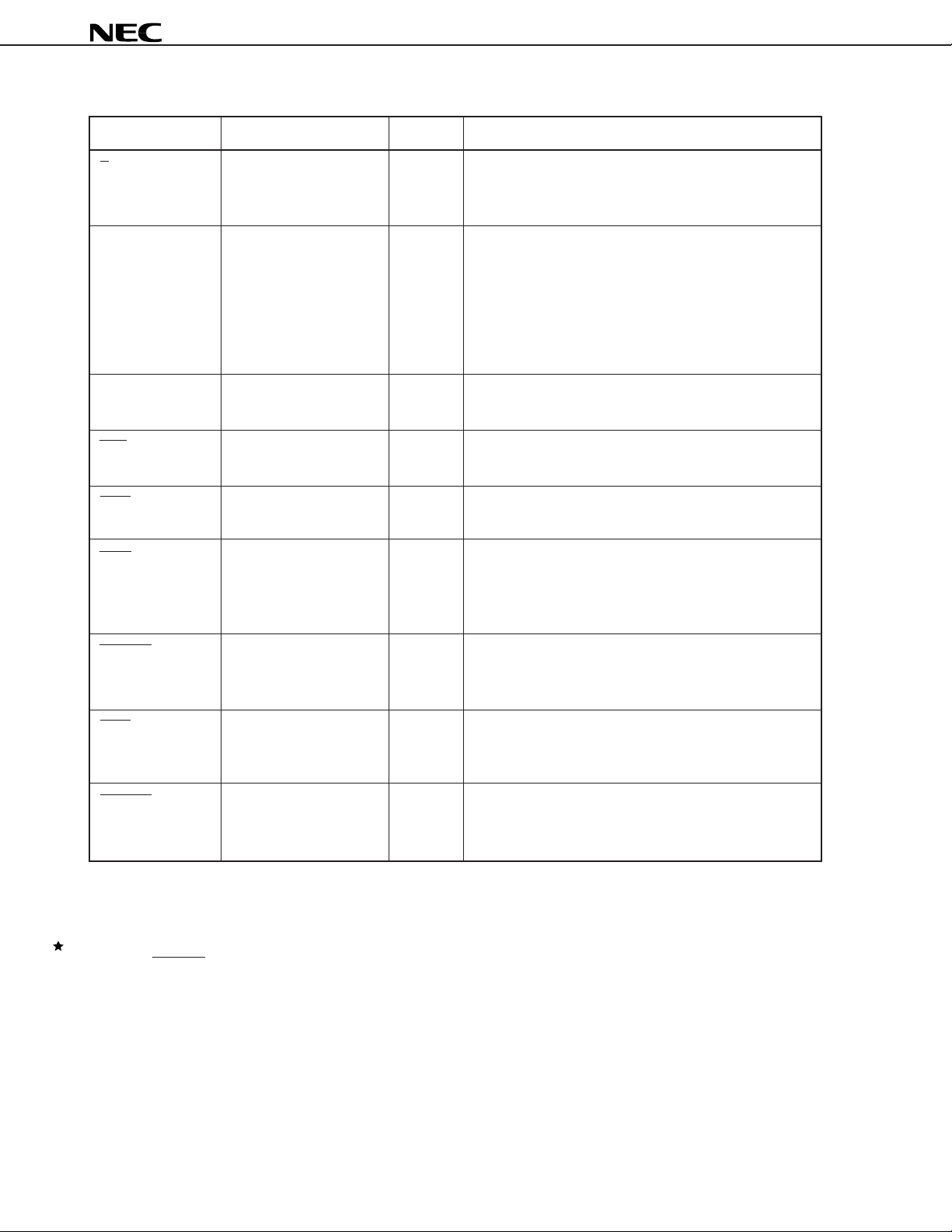

Page 9

1. PIN FUNCTIONS

1.1 Pin Functions

• Power supply

Symbol Pin No. I/O Function

µ

PD77016

VDD – +5V power supply

GND – Ground

15, 26, 36, 46, 56, 62, 71,

95, 106, 116, 131, 141, 151

14, 25, 35, 45, 55, 61, 70,

94, 105, 115, 130, 140, 150

• System control

Symbol Pin No. I/O Function

CLKIN 8 I External clock input

CLKOUT 13 O Internal system clock output

RESET 1 I Internal system reset signal input

• Interrupt

Symbol Pin No. I/O Function

INT4 - INT1 2, 3, 4, 5 I Maskable external interrupt input

• Falling edge detection

9

Page 10

• External data memory interface

Symbol Pin No. I/O Function

X/Y 20 O Memory select signal output

(3S) • 0: X memory is used.

• 1: Y memory is used.

DA15 - DA0 Note 1. O Address bus to external data memory

(3S) • External data memory is accessed.

• During the external memory is not accessed, these pins

keep the previous level.

These pins are set to low level; 0x0000, by reset.

They continue outputting low level until the first external

memory access.

D15 - D0 Note 2. I/O 16 bits data bus to external data memory

(3S) • External data memory is accessed.

MRD 17 O Read output

(3S) • Reads external memory

µ

PD77016

MWR 16 O Write output

(3S) • Writes external memory

WAIT 6 I Wait signal input

• Wait cycle is input when external memory is read.

1: No wait

0: Wait

HOLDRQ 7 I Hold request signal input

• Input low level when external data memory bus is

expected to use.

BSTB 18 O Bus strobe signal output

• Outputs low level while the µPD77016 is occupying

external memory bus.

HOLDAK 19 O Hold acknowledge signal output

• Outputs low level when the µPD77016 permits external

device to use external data memory bus.

Note 1. DA15 to DA0 pins are located on Pin No. 21 - 24, 27 - 34, 37 - 40.

2. D15 to D0 pins are located on Pin No. 41 - 44, 47 - 54, 57 - 60.

Remark The state of the pins added 3S becomes high impedance when the external memory is not accessed or bus release signal

(HOLDAK = 0) is output.

10

Page 11

• Serial interface

Symbol Pin No. I/O Function

SCK1 65 I Clock input for serial 1

SORQ1 68 O Serial output 1 request

SOEN1 69 I Serial output 1 enable

SO1 67 O (3S) Serial data output 1

SIEN1 64 I Serial input 1 enable

SI1 63 I Serial data input 1

SCK2 76 I Clock input for serial 2

SORQ2 73 O Serial output 2 request

SOEN2 72 I Serial output 2 enable

µ

PD77016

SO2 74 O (3S) Serial data output 2

SIEN2 77 I Serial input 2 enable

SI2 78 I Serial data input 2

SIAK1 66 O Serial input 1 acknowledge

SIAK2 75 O Serial input 2 acknowledge

Remark The state of the pins added 3S becomes high impedance, when data output have been finished or RESET is input.

11

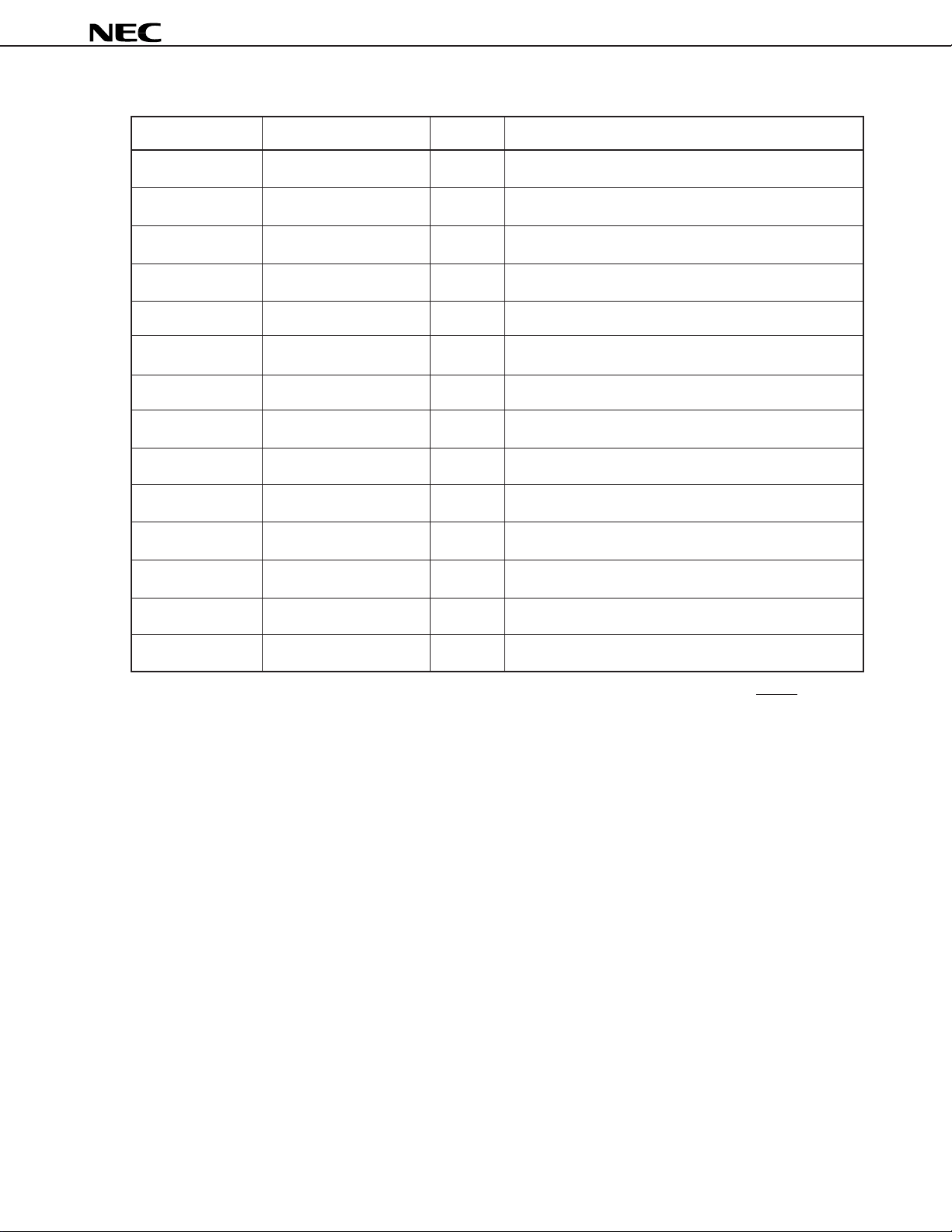

Page 12

• Host interface

Symbol Pin No. I/O Function

HA1 83 I Specifies register which HD7 to HD0 access

1: Accesses HST: Host interface status register

when HA1 = 0

0: Accesses HDT(out): Host transmit data register when

HRD = 0

0: Accesses HDT(in): Host receive data register when

HWR = 0

HA0 82 I Specifies bits of registers which HD7 to HD0 access

• 1: Accesses bits 15-8 of HST, HDT (out), HDT (in)

• 0: Accesses bits 7-0 of HST, HDT (out), HDT (in)

HCS 79 I Chip select input

HRD 80 I Host read input

HWR 81 I Host write input

µ

PD77016

HRE 92 O Host read enable output

HWE 93 O Host write enable output

HD7 - HD0 84 - 91 I/O (3S) 8 bits host data bus

Remark The state of the pins added 3S becomes high impedance when the host does not access host interface.

• I/O port

Symbol Pin No. I/O Function

P3 - P0 9 - 12 I/O I/O port

12

Page 13

• External instructions memory interface

Symbol Pin No. I/O Function

IA15 - IA0 Note 1. O (3S) Address bus to external instruction memory

• Even the internal instruction memory is accessed, the

address is output to the external instruction memory.

In this case, the µPD77016 ignores data of external

instruction memory output.

ID31 - ID0 Note 2. I/O (3S) 32 bits instruction input

PWR 129 O (3S) Program memory write strobe

• Write strobe for external instruction memory. This pin

loads program to external instruction memory (not

internal memory) while µPD77016 is in boot operation.

Note 1. IA15 to IA0 pins are located on these pins: 101 to 104, 107 to 114, 117 to 120

2. ID31 to ID0 pins are located on these pins: 121 to 128, 132 to 139, 142 to 149, 152 to 159

Remark The state of the pins added 3S becomes high impedance when RESET is input.

µ

PD77016

• Debugging interface

Symbol Pin No. I/O Function

TDO 96 O For debugging

TICE 97 O For debugging

TCK 98 I For debugging

TDI 99 I For debugging

TMS 100 I For debugging

13

Page 14

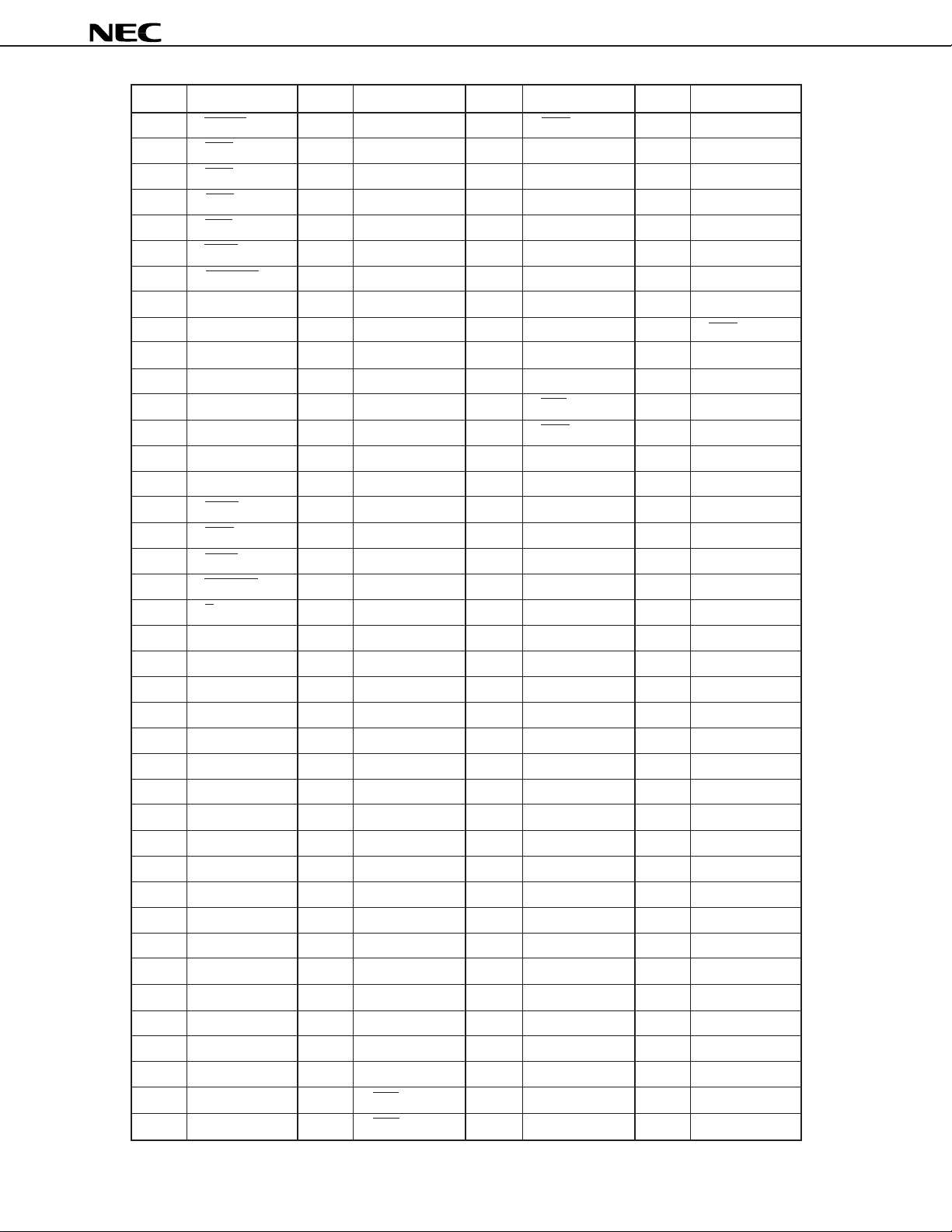

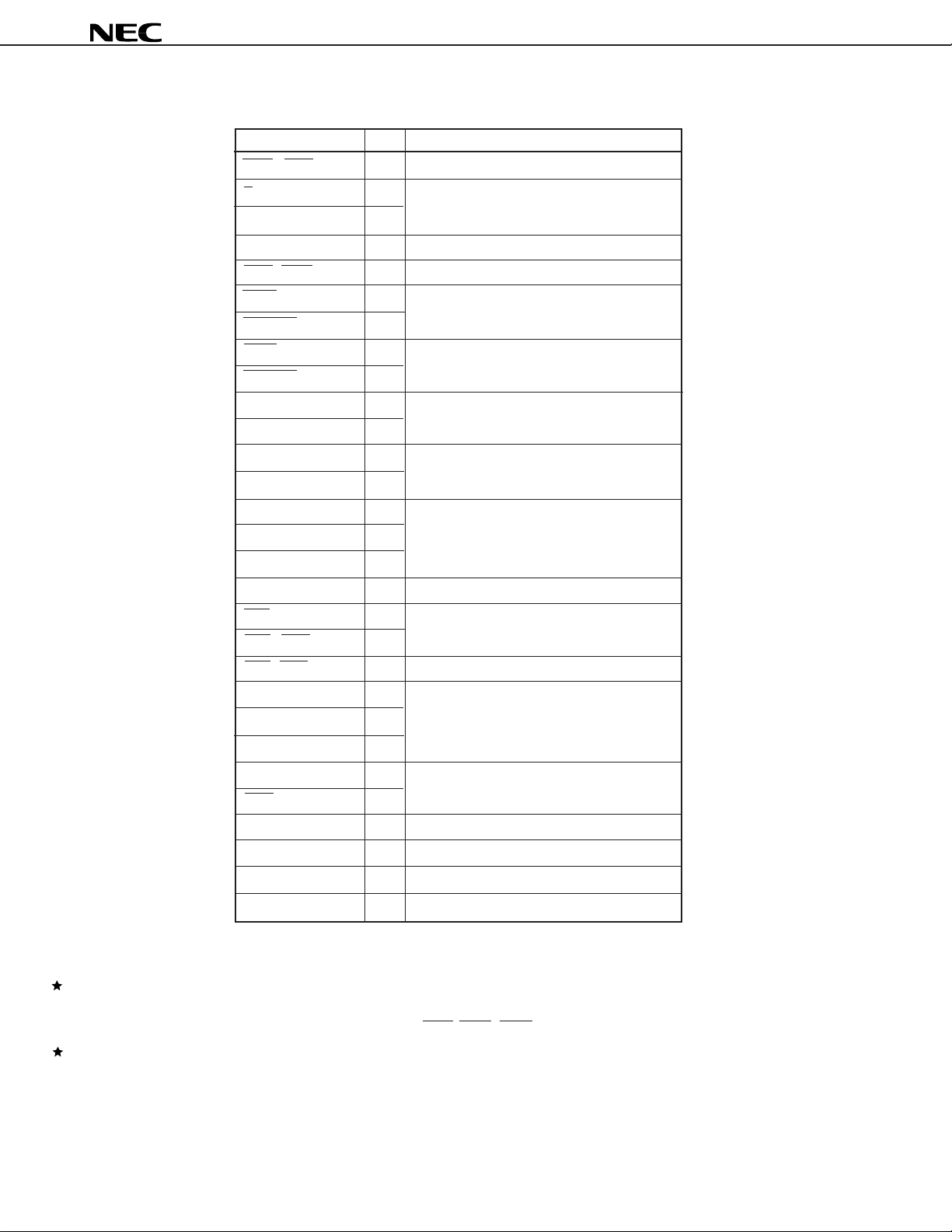

1.2 Recommended Connection for Unused Pins

µ

PD77016

Pin I/O

INT1 - INT4 I

X/Y O

DA0 - DA15 O

D0 - D15

MRD, MWR O

WAIT I

HOLDRQ I

BSTB O

HOLDAK O

SCK1, SCK2 I

SI1, SI2 I

SOEN1, SOEN2 I

SIEN1, SIEN2 I

SORQ1, SORQ2 O

SO1, SO2 O

SIAK1, SIAK2 O

HA0, HA1 I

HCS I

HRD, HWR I

Note 1

I/O

Recommended connection

connect to VDD

open

connect to VDD or GND, via a resistor

open

connect to VDD

open

connect to VDD or GND

connect to GND

open

connect to VDD or GND

connect to VDD

HRE, HWE O

HD0 - HD7

P0 - P3 I/O

ID0 - ID31 I/O

IA0 - IA15 O

PWR O

TCK I

TDO, TICE O

TMS, TDI I

CLKOUT O

Note 2

open

I/O

connect to VDD or GND, via a resistor

open

connect to GND, via a resistor

open

open(pull-up internally)

open

Notes 1. Can leave open, if no access to external data memory is

executed in the whole of program.

But in the HALT mode when the current consumption is

reduced, connect a pin as recommended connection.

2. Can leave open, if HCS, HRD, HWR are fixed to high level.

But in the HALT mode when the current consumption is

reduced, connect a pin as recommended connection.

Remark I: Input pin, O: Output pin, I/O: Input/Output pin

14

Page 15

µ

PD77016

2. FUNCTIONS

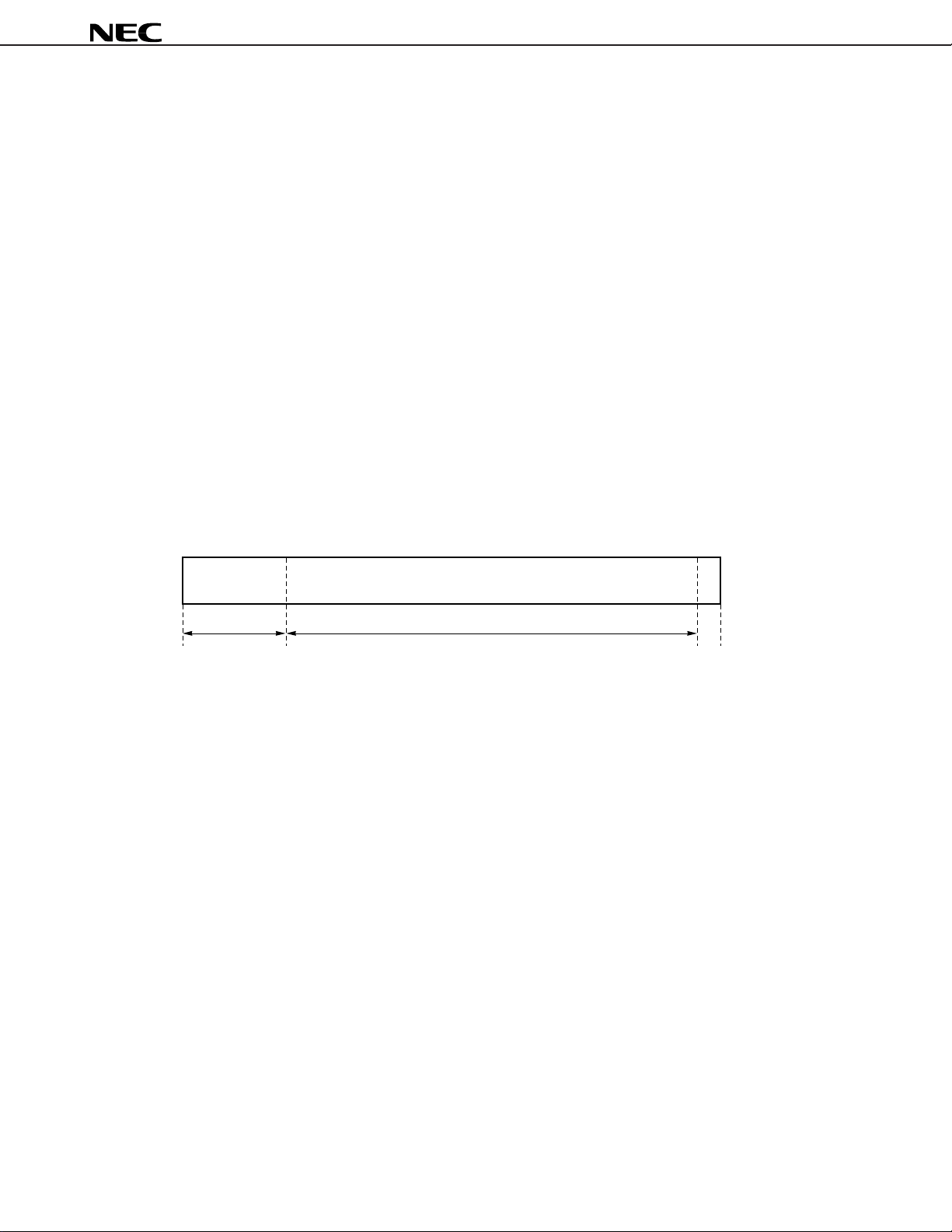

2.1 Pipeline Processing

This section describes the µPD77016 pipeline processing.

2.1.1 Outline

µ

PD77016 basic operations are executed in following 3-stage pipeline.

The

(1) instruction fetch; if

(2) Instruction decoding; id

(3) execution; ex

µ

When the

with written back to general registers. Pipeline processing actualizes programming without delay time to execute

instructions and write back data. Three successive instructions and their processing timing are shown below.

PD77016 operates a result of a instruction just executed before, the data is input to ALU in parallel

Pipeline Processing Timing

if1 id1 ex1

if2 id2 ex2

if3 id3 ex3

1 instruction cycle

2.1.2 Instructions with Delay

The following instructions have delay time in execution.

(1) Instructions to control interrupt

2 instruction cycles have been taken between instruction fetch and execution.

(2) Inter-register transfer instructions and immediate data set instructions

When data is set in data pointer, it needs 2 instruction cycles before the data is valid.

15

Page 16

µ

PD77016

2.2 Program Control Unit

Program control unit controls not only count up of program counter in normal operation, but loop, repeat,

branch, halt and interrupt.

In addition to loop stack of loop 4 level and program stack of 15 level, software stack can be used for multi-

loop and multi-interrupt/subroutine call.

µ

PD77016 has external 4 interruptions and internal 6 interruptions from peripheral, and specifies interrupt

The

enable or disable independently.

The HALT instruction causes the µPD77016 to place in low power standby mode.

When the HALT instruction is executed, power consumption decreases. HALT mode is released by interrupt

input or hardware reset input. It takes several system clock to recover.

2.3 Operation Unit

Operation unit consists of the following five parts.

– 40 bits general register × 8 for data load/store and input/output of operation data

– 16 bits × 16 bits + 40 bits → 40 bits multiply accumulator

– 40 bits Data ALU

– 40 bits barrel shifter

– SAC: shifter and count circuit.

Standard word length is 40 bits to make overflow check and adjustment easy, and to accumulate the result

of 16 bits × 16 bits multiplication correctly.

SSSSSSSS

Head room

2.3.1 General register (R0 to R7)

µ

PD77016 has eight 40 bits registers for operation input/output and load/store with memory. General

The

register consists of the following three parts.

– R0L to R7L (bit 15 to bit 0)

– R0H to R7H (bit 31 to bit 16)

– R0E to R7E (bit 39 to bit 32)

But each of RnL, RnH and RnE are treated as a register in the following conditions.

(1) General register used as 40 bits register

General registers are treated as 40 bits register, when they are used for the following aims.

(a) Operand for triminal operation (except for multiplier input)

(b) Operand for dyadic operation (except for multiplier and shift value)

(c) Operand for monadic operation (except for exponent instructions)

(d) Operand for operation

(e) Operand for conditional judge

(f) Destination for load instruction (with sign extension and 0 clear)

Result of multiplication among two's complement data

0

1313239

0

(2) General register used as 32 bits register

Bit 31 to bit 0 of general register are treated as 32 bits register, when it is used for a operand of exponent

instruction.

16

Page 17

µ

PD77016

(3) General register used as 24 bits register

Bit 39 to bit 16 of general register are treated as 24 bits register, when it is used for destination with extended

sign for a load/store instruction.

(4) General register used as 16 bits register

Bit 31 to bit 16 of general register are treated as 16 bits register, when it is used for the following aims.

(a) Signed operand for multiplier

(b) Source/destination for load/store instruction

Bit 15 to bit 0 of general register are treated as 16 bits register, when it is used for the following aims.

(c) Unsigned operand for multiplier

(d) Shift value for shift instruction

(e) Source/destination for load/store instruction

(f) Source/destination for inter-register transfer instruction

(g) Destination for immediate data set instruction

(f) Hardware loop times

(5) General register used as 8 bits register

Bit 39 to bit 32 of general register are treated as 8 bits register, when it is used for source/destination of load/

store instruction.

2.3.2 MAC: Multiply ACcumulator

MAC multiplies a pair of 16 bits data, and adds or subtract the result and 40 bits data. MAC outputs 40 bits

data.

MAC operates three types of multiplication: signed data × signed data, signed data × unsigned data and

unsigned data × unsigned data.

Result of multiplication and 40 bits data for addition can be added after 1 or 16 bits arithmetic shift right.

2.3.3 ALU: Arithmetic Logic Unit

ALU performs arithmetic operation and logic operation. Both input/output data are 40 bits.

2.3.4 BSFT: Barrel ShiFTer

BSFT performs shift right/left operation. Both input/output data are 40 bits. There are two types of shift right

operations; arithmetic shift right which sign is extended, and logic shift right which is input 0 in MSB first.

2.3.5 SAC: Shifter And Count Circuit

SAC calculates and outputs shift value for normalization. SAC is input 32 bits data and outputs the 40 bits

data. Then, bit 39 to bit 5 of output data is always 0.

2.3.6 CJC: Condition Judge Circuit

CJC judges whether condition is true or false with 40 bits input data. A conditional instruction is executed

when the result is true, and not executed when the result is false.

17

Page 18

µ

PD77016

2.4 Memory

µ

PD77016 has one instruction memory area (64K words × 32 bits) and two data memory areas (64K words

The

× 16 bits each). It adopts Harvard-type architecture, with instruction memory area and data memory areas

separated.

µ

PD77016 has 2 sets of data addressing units, which are dedicated for addressing data memory area.

The

Each addressing unit consists of four data pointers, four index registers, a modulo register and addressing ALU.

Memory areas are shown below.

X memory area addresses are specified by DP0 to DP3, and Y memory area addresses are specified by DP4

to DP7. After memory access, DPn (with the same subscript), can be modified by DNn value. Modulo operation

is performed with DMX for DP0 to DP3, with DMY for DP4 to DP7.

Data Memory Area (X/Y Memory) Instruction Memory Area

0xFFFF

0x4000

0x3FFF

0x3840

0x383F

0x3800

0x37FF

0x0800

0x07FF

0x0000

External Data Memory

(48 K words)

System

Peripheral (64 words)

System

Data RAM (2 K words)

0xFFFF

0x4000

0x3FFF

0x0800

0x07FF

0x0240

0x023F

0x0200

0x01FF

0x0100

0x00FF

0x0000

External Instruction Memory

(48 K words)

System

Internal Instruction RAM (1.5 K words)

Vector (64 words)

System

Bootup ROM (256 words)

Caution When any data is accessed or stored to system address, normal operation of the

not assured.

18

µ

PD77016 is

Page 19

µ

PD77016

2.4.1 Instruction RAM Outline

The µPD77016 has an instruction RAM (1.5 words × 32 bits). A system vector area is assigned to 64 words

of the instruction RAM. Internal RAM is initialized and rewritten by boot program.

µ

Additionally external memory expansion is available as the

instruction memory. When RAM is used as the external memory, it can be initialized and rewritten by boot

program.

Boot up ROM contains the program loading instruction code to internal and external instruction RAM.

When the external instruction memory area is accessed, instruction cycle can be 2 or more by wait function.

2.4.2 Data Memory Outline

µ

PD77016 has two data memory areas (64 words × 16 bits each) in X and Y memory areas.

The

Each memory areas consists of 2K words × 16 bits data RAM. Additionally, data memory expansion is

µ

available as the

Each data memory area includes on-chip peripheral area which consists of 64 words.

When the external data memory area is accessed, instruction cycle can be 2 or more by wait function.

2.4.3 Data Memory Addressing

There are following two types of data memory addressing.

• Direct addressing

The address is specified in the instruction field.

• Indirect addressing

The address is specified by the data pointer (DP). DP can get a bit reverse before addressing. It can update

the DP value after accessing data memory.

PD77016 has interface with the external data memory.

PD77016 has interface with the external

19

Page 20

µ

PD77016

2.5 On-chip Peripheral Circuit

µ

PD77016 includes serial interface, host interface, general input/output ports and wait cycle registers.

The

They are mapped in both X and Y memory areas, and are accessed as memory mapped I/O by the µPD77016

CPU.

2.5.1 Serial Interface Outline

µ

PD77016 has 2 channel serial interfaces. Serial I/O clock must be provided from external. Frame length

The

can be programmed independently to be 8 bits or 16 bits. MSB first or LSB first can also be selected. Data is

input/output by hand shaking for an external device, and by interrupts, polling or wait function in internal.

2.5.2 Host Interface Outline

µ

PD77016 has 8 bits parallel ports as host interface to input/output data to and from host CPU and DMA

The

controller. When an external device accesses host interface, HA0 and HA1 pins; which are host address input

µ

pins; specifies bit 15 to bit 8 and bit 7 to bit 0. The

are dedicated for input data, output data and status. The µPD77016 has three types of interface method for

internal and external data; interrupts, polling and wait function.

2.5.3 General Input/output Ports Outline

General input/output ports consist of 4 bits. User can set each port as input or output. The

two registers. One is 4 bits register for input/output data, and the other is 16 bits for control.

PD77016 includes 3 registers consisting of 16 bits, which

µ

PD77016 includes

2.5.4 Wait Cycle Register

The wait cycle registers consist of 16 bits. It is used to set wait cycle number when external memory is

accessed. 0, 1, 3, or 7 wait cycle can be set in every data area which is divided into 8, and in every X and Y

memory area which is divided into 4.

When data area is accessed, wait cycle can be also set by WAIT pin.

20

Page 21

µ

PD77016

3. INSTRUCTIONS

3.1 Outline

All µPD77016 instructions are one-word instructions, consisting of 32 bits. And they are executed in 30 ns

(min.) per instruction. There are following 9 instruction types.

(1) Trinomial instructions

: specify the Acc operation. 3 of general registers are specified optionally as the operation object.

(2) Dyadic operation instructions

: specify the Acc, ALU or shifter operation. 2 of general registers are specified optionally as the operation

object. Some instructions can specify a general register and immediate data.

(3) Monadic operation instructions

: specify operations by ALU. 1 general register is specified optionally as the operation object.

(4) Load/store instructions

: transfer 16 bits data from memory to general registers, from general registers to memory and between general

registers.

(5) Inter-register transfer instructions

: transfer data between general register and other registers.

(6) Immediate data set instructions

: set immediate data at general registers or each registers of address operation unit.

(7) Branch instructions

: specify the direction of the program flow.

(8) Hardware loop instructions

: specify times of instruction repeating.

(9) Control Instructions

: specify the control program.

21

Page 22

µ

PD77016

3.2 Instruction Set and Operation

An operation is written according to the rules for expressing. An expression of instructions having two or more

descriptions can have only one selected.

(a) Expressions and selectable registers

Expression and selectable registers are shown as follows.

Expression Selectable registers

ro, ro', ro" R0 - R7

rl, rl' R0L - R7L

rh, rh' R0H - R7H

re R0E - R7E

reh R0EH - R7EH

dp DP0 - DP7

dn DN0 - DN7

dm DMX, DMY

dpx DP0 - DP3

dpy DP4 - DP7

dpx_mod DPn, DPn++, DPn– –, DPn##, DPn%%, !DPn## (n = 0 - 3)

dpy_mod DPn, DPn++, DPn– –, DPn##, DPn%%, !DPn## (n = 4 - 7)

dp_imm DPn##imm (n = 0 - 7)

∗××× content of memory address ×××

Example When the content of DP0 register is 1000, ∗DP0 shows the content of memory

address 1000.

22

Page 23

µ

PD77016

(b) Modifying data pointers

Data pointers are modified after memory access. The results are valid immediately after instruction execution.

It is impossible to modify without memory access.

Description Operation

DPn No operation: DPn value does not change.

DPn++ DPn ← DPn+1

DPn–

– DPn ← DPn–1

DPn## DPn ← DPn + DNn: Adds DN0-DN7 corresponding to DP0-DP7

Example DP0 ← DP0 + DN0

DPn%% (n = 0 - 3) DP

(n = 4 - 7) DPn = ((DPL + DNn ) mod (DMY + 1)) + DPH

!DPn## Access memory after DPn value is bit-reversed

After memory access, DPn ← DPn + DNn

DPn##imm DPn ← DPn + imm

(c) Concurrent processing instructions

●● shows concurrent processing instruction.

Instruction names are shown in abbreviation.

TRI : Trinomial

DYAD : Dyadic

MONAD : Monadic

TRANS : Inter-register transfer

IMM : Immediate data set

BR : Branch

LOOP : Hardware loop

CTR : Control

(d) State of Overflow flag (OV)

The following marks show the

: Not affected

: 1 is set when the result of operation is overflow.

↔

n = ((DPL + DNn ) mod (DMX + 1)) + DPH

µ

PD77016 overflow flag state.

Caution If overflow does not occur after operation, OV is not reset, and keeps the state before operation.

23

Page 24

24

µ

PD77016 INSTRUCTION SET

Name Mnemonic Operation

Multiply add ro = ro + rh∗rh' ro ← ro+rh∗rh'

Multiply sub ro = ro–rh∗rh' ro ← ro–rh∗rh'

Sign unsign ro = ro + rh∗rl ro ← ro+rh∗rl

Multiply add (rl should be a plus

Trinomial

Unsign unsign ro=ro+rl∗rl' ro ← ro+rl∗rl'

Multiply add (rl and rl' should be a plus

1 bit shift Multiply add ro=(ro>>1)+rh∗rh' ro ← +rh∗rh'

16 bits shift Multiply add ro = (ro>>16)+rh∗rh' ro ← +rh∗rh'

Multiply ro=rh∗rh' ro ← rh∗rh'

Add ro"=ro+ro' ro" ← ro+ro'

Immediate add ro'=ro+imm ro' ← ro+imm (imm 1)

Sub ro"=ro–ro' ro" ← ro–ro'

integral number.)

integral number.)

Concurrent Writing Processing Flag

TRI. DYAD. MONAD. Load/ TRANS. IMM. BR. LOOP. CTL. OV

store

↔↔ ↔ ↔ ↔ ↔↔↔↔

ro

2

ro

16

2

Dyadic

Immediate sub ro'=ro–imm ro' ← ro–imm (imm 1)

Arithmetic right shift ro'=ro SRA rl ro' ← ro >> rl

Immediate arithmetic ro'=ro SRA imm ro' ← ro >> imm

right shift

Logic right shift ro'=ro SRL rl ro' ← ro >> rl

Immediate Logic right shift ro'=ro SRL imm ro' ← ro >> imm

Logic left shift ro'=ro SLL rl ro' ← ro << rl

Immediate logic left shift ro'=ro SLL imm ro' ← ro << imm

µ

PD77016

Page 25

Name Mnemonic Operation

And ro" = ro & ro' ro" ← ro & ro'

Immediate and ro' = ro & imm ro' ← ro & imm

Or ro" = ro | ro' ro" ← ro | ro'

Concurrent Writing Processing Flag

TRI. DYAD. MONAD. Load/ TRANS. IMM. BR. LOOP. CTL. OV

store

25

Dyadic

Monadic

Immediate or ro' = ro | imm ro' ← ro | imm

Exclusive or ro" = ro ^ ro' ro" ← ro ^ ro'

Immediate exclusive or ro = ro ^ imm ro ← ro ^ imm

Less than ro" = LT(ro, ro') if(ro<ro')

Clear CLR(ro) ro ← 0x0000000000

Increment ro' = ro + 1 ro' ← ro + 1

Decrement ro' = ro – 1 ro' ← ro – 1

Absolute ro' = ABS (ro) if (ro<0)

One's complement ro' =

Two's complement ro' = –ro ro' ← –ro

Clip ro' = CLIP (ro) if (ro>0x007FFFFFFF)

Round ro' = ROUND (ro) if (ro>0x007FFF0000)

Exponent ro' = EXP (ro) ro' ← log

Substitution ro' = ro ro' ← ro

~

ro ro' ←

{ro" ← 0x0000000001}

else {ro" ← 0x0000000000}

{ro' ← –ro}

else {ro' ← ro}

~

ro

{ro' ← 0x007FFFFFFF]

else if, (ro<0xFF80000000)

{ro' ← 0xFF80000000}

else {ro' ← ro}

{ro' ← 0x007FFF0000}

else if, (ro>0xFF80000000)

{ro' ← 0xFF80000000}

else {ro' ←

(ro + 0x8000) & 0xFFFFFF0000}

1

2

( )

ro

↔↔ ↔ ↔↔ ↔

µ

PD77016

Page 26

26

Name Mnemonic Operation

Cumulation ro'+ = ro ro' ← ro'+ro

Degression ro'– = ro ro' ← ro'–ro

Concurrent Writing Processing Flag

TRI. DYAD. MONAD. Load/ TRANS. IMM. BR. LOOP. CTL. OV

store

↔↔ ↔

Monadic

Load/store

Division ro'/ = ro if (sign(ro')==sign(ro))

{ro' ← (ro'–ro)<<1}

else

{ro' ← (ro'+ro)<<1}

if (sign(ro')==0

{ro' ← ro'+1}

Parallel load/store ro=∗dpx_mod ro'=∗dpy_mod ro ← ∗dpx, ro' ← ∗dpy

Note1, Note2.

ro=∗dpx_mod ∗dpy_mod=rh ro ← ∗dpx, ∗dpy ← rh

∗dpx_mod=rh ro=∗dpy_mod ∗dpx ← rh, ro ← ∗dpy

∗dpx_mod=rh ∗dpy_mod=rh' ∗dpx ← rh, ∗dpy ← rh'

Section load/store dest=∗dpx_mod dest'=∗dpy_mod dest ← ∗dpx, dest' ← ∗dpy

Note1, Note2, Note 3.

dest=∗dpx_mod ∗dpy_mod=source dest ← ∗dpx, ∗dpy ← source

∗dpx_mod=source dest=∗dpy_mod ∗dpx ← source, dest ← ∗dpy

∗dpx_mod=source ∗dpy_mod=source' ∗dpx ← source, ∗dpy ← source'

Note 1. One or both of a mnemonic pair can be written.

2. After execution of load/store, data is modified by mod.

3. One of following mnemonic should be selected: dest, dest' = {ro, reh, re, rh, rl}, source, source' = {re, rh, rl}.

µ

PD77016

Page 27

Load/store

Name Mnemonic Operation

Direct addressing dest = ∗addr dest ← ∗addr

load/store Note 1.

∗addr = source ∗addr ← source

Immediate index dest = ∗dp_imm dest ← ∗dp

load/store Note 2.

∗dp_imm = source ∗dp ← source

Concurrent Writing Processing Flag

TRI. DYAD. MONAD. Load/ TRANS. IMM. BR. LOOP. CTL. OV

store

Inter-register

transfer

Immediate

data set

Note 1. One of following mnemonic should be selected: dest = {ro, reh, re, rh, rl}, source = {re, rh, rl}, add = .

Inter-register transfer dest = rl dest ← rl

Note 3.

rl = source rl ← source

Immediate data set rl = imm rl ← imm

(provided imm = 0-0xFFFF)

dp = imm dp ← imm

(provided imm = 0-0xFFFF)

dn = imm dn ← imm

(provided imm = 0-0xFFFF)

dm = imm dm ← imm

(provided imm = 1-0xFFFF)

2. One of following mnemonic should be selected: dest = {ro, reh, re, rh, rl}, source = {re, rh, rl}.

0: X-0xFFFF:X memory

0: Y-0xFFFF:Y memory

3. Any register except general registers should be selected as dest or source.

µ

PD77016

27

Page 28

28

Branch

Hardware

loop

Control

Name Mnemonic Operation

Jump JMP imm PC ← imm

Inter-register indirect jump JMP dp PC ← dp

Subroutine call CALL imm SP ← SP + 1

STK ← PC +

PC ← imm

Inter-register indirect CALL dp SP ← SP + 1

subroutine call STK ← PC + 1

PC ← dp

Return RET PC ← STK

SP ← SP – 1

Return from interrupt RETI PC ← STK

STK ← SP – 1 Restore the

interrupt enable flag

Repeat REP count start RC ← count

RF ← 0

repeat PC ← PC

RC ← RC – 1

end PC ← PC + 1

RF ← 1

Loop LOOP count start RC ← count

(Mnemonics more than two lines) RF ← 0

repeat PC ← PC

RC ← RC – 1

end PC ← PC + 1

RF ← 1

Loop pop LPOP LC ← LSR3

LE ← LSR2

LS ← LSR1

LSP ← LSP–1

No operation NOP PC ← PC + 1

Halt HALT CPU stop

If IF (ro cond) Conditional judge

Forget interrupt FINT Forget interrupt request

Concurrent Writing Processing Flag

TRI. DYAD. MONAD. Load/ TRANS. IMM. BR. LOOP. CTL. OV

store

µ

PD77016

Page 29

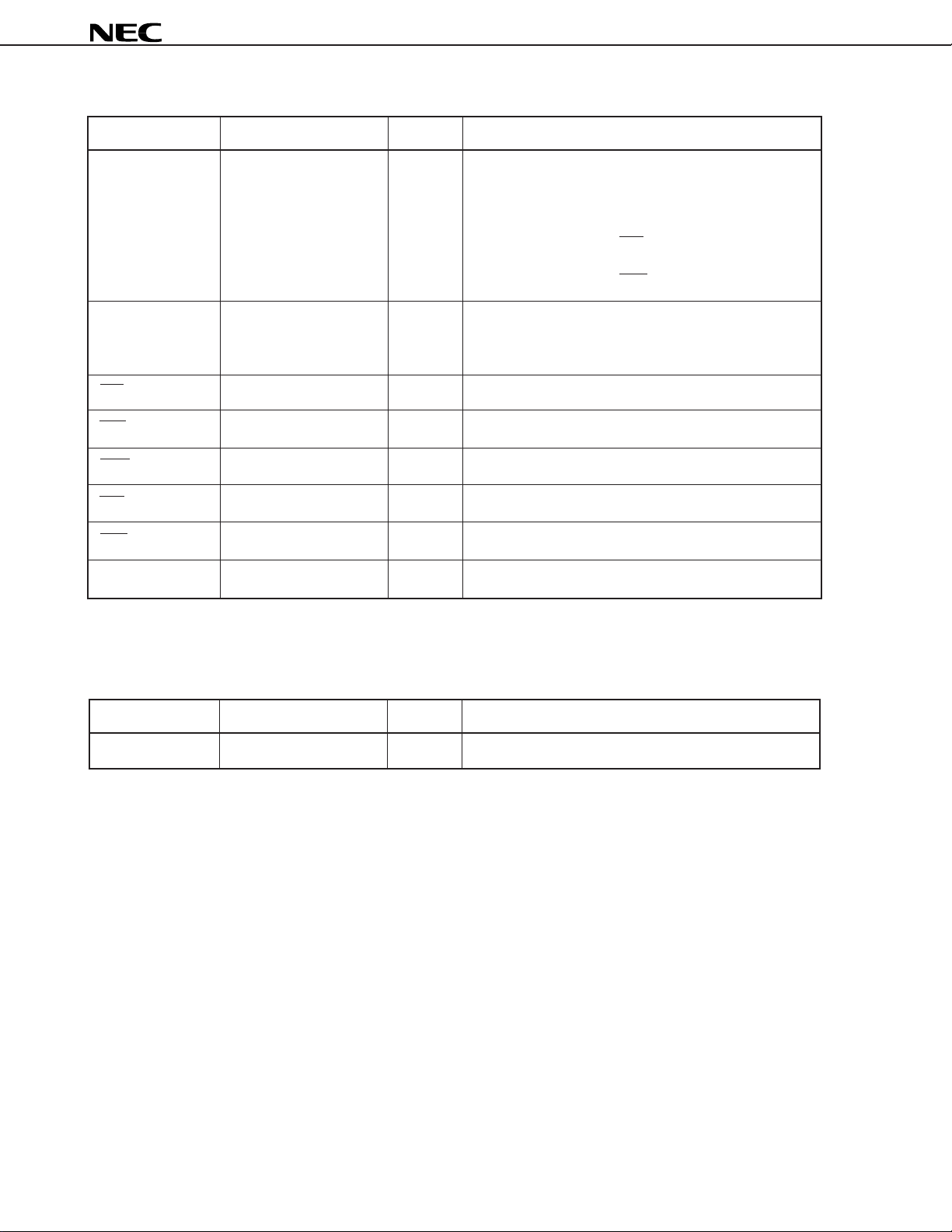

µ

PD77016

4. ELECTRICAL SPECIFICATIONS

Absolute maximum ratings (TA = +25 ˚C)

Parameters Symbol Conditions Ratings Unit

Power supply voltage VDD –0.5 to +7.0 V

Input voltage VI –0.5 to VDD + 0.5 V

Output voltage VO –0.5 to VDD + 0.5 V

Storage temperature Tstg –65 to +150 ˚C

Operating ambient temperature TA –40 to +85 ˚C

Caution Exposure to Absolute Maximum Ratings for extended periods may affect device reliability;

exceeding the ratings could cause permanent damage. The parameters apply independently.

The device should be operated within the limits specified under DC and AC Characteristics.

Capacitance (T

Input capacitance CI 15 pF

Output capacitance CO 15 pF

A = +25 ˚C, VDD = 0 V)

Parameters Symbol Conditions MIN. TYP. MAX. Unit

fc = 1 MHz

Unmeasured pins returned to 0

V.

DC characteristics (TA=–40 to +85 ˚C, VDD = 5 V ±10 %)

Parameters Symbol Conditions MIN. TYP. MAX. Unit

High level input voltage

Low level input voltage

High level CLKIN voltage

Low level CLKIN voltage

High level output voltage

Low level output voltage

Low level input current

High level input leak current

Low level input leak current

Power supply current

VIH

VIHC

VIL

VILC

VIHX

VILX

VOH

VOL

IIL

ILIH

ILIL

IDD

IDDH

IDDS

except for RESET, CLKIN,

INT1 - INT4, WAIT, HCS,

HRD, HWR, TCK, TDI, TMS

RESET, INT1 - INT4, WAIT, HCS,

HRD, HWR, TCK, TDI, TMS

except for RESET, CLKIN,

INT1 - INT4, WAIT, HCS,

HRD, HWR, TCK, TDI, TMS

RESET, INT1 - INT4, WAIT, HCS,

HRD, HWR, TCK, TDI, TMS

IOH = –2.5 mA

IOL = 2.5 mA

TDI, TMS, VI = 0 V

VI = VDD

except for TDI, TMS, VI = 0 V

Note

Active mode, tcCI = 15 ns

VIH = VDD, VIL = 0 V, no load

HALT mode, tcCI = 15 ns,

VIH = VDD, VIL = 0 V, no load

CLKIN = 0 V

VIH = VDD, VIL = 0 V, no load

2.2

0.7VDD

–0.5

–0.5

0.8VDD

–0.5

0.8VDD

140

80

10

VDD + 0.5

VDD + 0.5

+0.8

0.2VDD

VDD + 0.5

0.2VDD

0.4

–400

10

–10

300

V

V

V

V

V

V

V

V

µ

µ

µ

mA

mA

µ

A

A

A

A

Note The TYP. value is measured when a general program is executed, and VDD = 5 V conditon. The MAX.

value is measured when a special program that max. switching required is executed, and VDD = 5.5 V

condition

.

29

Page 30

Measurement Standards Common to Switching Characteristics

0.8 V

0.5 V

0.2 V

DD

DD

DD

Test pointsCLKIN

0.8 V

0.5 V

0.2 V

µ

PD77016

DD

DD

DD

(except for CLKIN)

Input

2.2 V

1.5 V

0.8 V

2.2 V

1.5 V

0.8 V

Test points

Test pointsOutput

2.2 V

1.5 V

0.8 V

2.2 V

1.5 V

0.8 V

AC Characteristics (TA = –40 to +85 ˚C, VDD = 5 V ±10%, CL = 30 pF)

Clock

Required Timing Condition

Parameters Symbol Conditions MIN. TYP. MAX. Unit

CLKIN cycle time tcCI 15 500 ns

CLKIN high level width t wCIH 6.75 0.55 tcCI ns

CLKIN low level width twCIL 6.75 0.55 tcCI ns

CLKIN rise/fall time trfCI 6ns

Switching Characteristics

Parameters Symbol Conditions MIN. TYP. MAX. Unit

CLKOUT cycle time tcCO 2tcCI ns

CLKOUT level width twCO tcCI – 3 ns

CLKOUT rise/fall time trfCO 3ns

30

Page 31

µ

PD77016

Reset, Interrupt

Required Timing Condition

Parameters Symbol Conditions MIN. TYP. MAX. Unit

RESET low level width tw(RL) 4tcCO ns

RESET recovery time trec(R) 4tcCO ns

INT1-INT4 low level width tw(INTL) 3tcCO ns

INT1-INT4 recovery time trec(INT) 3tcCO ns

Clock Input/Output Timing

t

CLKIN

t

wCIH

cCI

t

wCIL

t

cCO

t

wCO

t

rfCI

t

wCO

t

rfCI

t

rfCO

t

rfCO

CLKOUT

Reset, Interrupt Timing

RESET

Interrupt Timing

INT1 - INT4

t

w(RL)

t

w(INTL)

t

rec(R)

t

rec(INT)

31

Page 32

µ

PD77016

External Data Memory Access

Required Timing Condition

Parameters Symbol Conditions MIN. TYP. MAX. Unit

Read data setup time tsuDDRD 14 ns

Read data hold time thDDRD 0ns

WAIT setup time tsuWA 8ns

WAIT hold time thWA 0ns

Switching Characteristics

Parameters Symbol Conditions MIN. TYP. MAX. Unit

Address output delay time tdDA 06ns

MRD output delay time tdDR 08ns

MRD hold time thDR 08ns

Write data setup time tsDDWD

Write data output hold time thDDWD 015ns

MWR output delay time tdDW twCIH – 4 ns

MWR setup time tsuDW twCIL – 4 ns

MWR low level width twDWL tcCI – 4 ns

MWR high level width twDWH tcCI – 4 ns

tcCI + twCIH –

+ tcDW

Note

Note

15 + tcDW

ns

Note tcDW: Data wait cycle

32

Page 33

External Data Memory Read Operation

CLKOUT

tdDA

DA0 DA15,

X/Y

µ

PD77016

D0 - D15

tdDR

MRD

tsuWA

WAIT

External Data Memory Write Operation

CLKOUT

thWA

tsuWA thWA

tsuDDRD

thDDRD

thDR

DA0 - DA15,

X/Y

D0 - D15

MWR

WAIT

t

dDA

t

sDDWD

Hi-Z Hi-Z

t

t

suWA

dDW

t

wDWL

t

hWA

t

suWA

t

hWA

t

wDWH

t

suDW

t

hDDWD

33

Page 34

µ

PD77016

External Instruction Memory Access

Required Timing Condition

Parameters Symbol Conditions MIN. TYP. MAX. Unit

ID setup time (to CLKOUT ↑)tsuID 14 ns

ID hold time (to CLKOUT ↑)thID 0ns

Switching Characteristics

Parameters Symbol Conditions MIN. TYP. MAX. Unit

IA output delay time tdIA 10 ns

IA hold time thIA 06ns

ID write setup time tsIDW

ID write hold time thIDW 0ns

PWR output delay time tdIW 10 ns

Address → PWR setup time td(IAV-IWV) tcCI + twCIH ns

PWR setup time tsuIW twCIL – 4 ns

PWR width twIW tcCO – 4 ns

tcCI + twCIH

– 15

– 4

+ tcIW

ns

Remark tcIW: Instruction wait cycle

34

Page 35

External Instruction Memory Read Operation

CLKOUT

µ

PD77016

t

t

dIA

hIA

IA0 - IA15

Hi-Z

ID0 - ID31

PWR

Hi-Z

RESET

External Instruction Memory Write Operation

t

suID

t

dIW

t

hID

CLKOUT

IA0 - IA15

ID0 - ID31

PWR

t

hIA

t

t

hIDW

Hi-Z

suIW

Hi-Z

t

d(IAV-IWV)

t

wIW

t

sIDW

35

Page 36

µ

PD77016

Bus Arbitration

Required Timing Condition

Parameters Symbol Conditions MIN. TYP. MAX. Unit

HOLDRQ setup time tsuHRQ 8ns

HOLDRQ hold time thHRQ 0ns

Switching Characteristics

Parameters Symbol Conditions MIN. TYP. MAX. Unit

BSTB hold time thBS 06ns

BSTB output delay time tdBS 06ns

HOLDAK output delay time tdHAK 06ns

HOLDAK hold time thHAK 06ns

Data hold time when bus arbitration th(BS-D) 15 ns

Data valid time after bus arbitration tv(BS-D) 15 ns

36

Page 37

Bus Arbitration Timing (Bus idle)

CLKOUT

BSTB

HOLDRQ

HOLDAK

X/Y, DA0 - DA15,

MRD, MWR

(Bus busy) Bus idle

thBS

suHRQ

t

t

dBS

tdHAK

th(BS-D)

Bus release Bus idle (Bus busy)

thHRQ tsuHRQ

thHAK

tv(BS-D)

Hi-Z

thHRQ

µ

PD77016

37

Page 38

38

Bus Arbitration Timing (Bus busy)

CLKOUT

BSTB

HOLDRQ

HOLDAK

X/Y, DA0 - DA15,

MRD, MWR

(Bus busy) Bus busy

suHRQ

t

Bus idle Bus idle (Bus busy)

t

hBS

t

dBS

Bus release

t

hHRQ

t

dHAK

t

h(BS-D)

t

suHRQ

Hi-Z

t

hHAK

t

v(BS-D)

t

hHRQ

µ

PD77016

Page 39

Bus Arbitration Timing (Bus slave)

CLKOUT

BSTB

HOLDRQ

Load/store External Memory

Bus idle Bus hold Bus idle

39

X/Y, DA0 - DA15,

MRD, MWR

HOLDAK

Hi-ZHi-Z

µ

PD77016

Page 40

µ

PD77016

Serial Interface

Required Timing Condition

Parameters Symbol Conditions MIN. TYP. MAX. Unit

SCK input cycle time tcSC 2tcCO ns

SCK input high/low level width twSC 25 ns

SCK input rise/fall time trfSC 320ns

SOEN recovery time trecSOE 10 ns

SOEN hold time thSOE 5ns

SIEN recovery time trecSIE 10 ns

SIEN hold time thSIE 5ns

SI setup time tsuSI 10 ns

SI hold time thSI 0ns

Switching Characteristics

Parameters Symbol Conditions MIN. TYP. MAX. Unit

SORQ output delay time tdSOR 030ns

SORQ hold time thSOR 030ns

SO valid time tvSO 030ns

SO hold time thSO 60 ns

SIAK output delay time tdSIA 030ns

SIAK hold time thSIA 030ns

Notes for Serial Clock

Serial clock inputs SCK1 and SCK2 are sensitive to any kind of interfering signals (noise on power supply,

induced voltage, etc.). Spurious signals can cause malfunction of the device. Special care for the serial clock

design should be taken. Careful grounding, decoupling and short wiring of SCK1 and SCK2 are recommended.

Intersection of SCK1 and SCK2 with other serial interface lines or close wiring to lines carrying high frequency

signals or large changing currents should be avoided.

It considers for the serial clock to make a waveform stable especially about the rising and falling.

Example 1. good example

Straight rising form and falling

form

Example 2. no good example

It doesn’t bound. It doesn’t make

noise one above another.

Example 3. no good example

It doesn’t make a stair stepping.

40

Page 41

Serial Output Timing 1

t

wSC

SCK1,

SCK2

t

dSOR

SORQ1,

SORQ2

SOEN1,

SOEN2

t

cSC

t

recSOE

t

rfSC

t

wSC

t

hSOR

t

recSOE

t

hSOE

t

hSOE

t

rfSC

41

SO1,

SO2

Hi-Z

t

t

vSO

vSO

1st Last

hSO

t

Hi-Z

µ

PD77016

Page 42

42

Serial Output Timing 2 (Continual output)

t

cSC

t

wSC

SCK1,

SCK2

SORQ1,

SORQ2

SOEN1,

SOEN2

t

wSC

t

dSOR

t

recSOE

t

hSOE

rfSC

t

t

hSOR

t

vSO

t

rfSC

SO1,

SO2

Last

1st Last

Hi-Z

µ

PD77016

Page 43

Serial Input Timing 1

SCK1,

SCK2

t

dSIA

SIAK1,

SIAK2

SIEN1,

SIEN2

t

wSC

t

recSIE

t

cSC

t

wSC

t

hSIE

t

recSIE

t

hSIE

t

hSIA

t

suSI

t

hSI

t

rfSC

t

rfSC

43

SI1,

SI2

1st

2nd

3rd

µ

PD77016

Page 44

44

Serial Input Timing 2 (Continual input)

t

cSC

t

wSC

SCK1,

SCK2

SIAK1,

SIAK2

SIEN1,

SIEN2

t

wSC

t

dSIA

t

recSIE

t

hSIE

t

hSIA

t

rfSC

t

suSI

t

hSI

t

rfSC

SI1,

SI2

LastLast–1 2nd

1st

3rd

µ

PD77016

Page 45

µ

PD77016

Host Interface

Required Timing Condition

Parameters Symbol Conditions MIN. TYP. MAX. Unit

HRD delay time tdHR 0ns

HRD width twHR 2tcCO ns

HCS, HA0, HA1 read hold time thHCAR 5ns

HCS, HA0, HA1 write hold time thHCAW 5ns

HRD, HWR recovery time trecHS 2tcCO ns

HWR delay time tdHW 0ns

HWR width twHW 2tcCO ns

HWR hold time thHDW 5ns

HWR setup time tsuHDW 20 ns

Switching Characteristics

Parameters Symbol Conditions MIN. TYP. MAX. Unit

HRE, HWE output delay time tdHE 30 ns

HRE, HWE hold time thHE 20 ns

HRD valid time tvHDR 30 ns

HRD hold time thHDR 0ns

45

Page 46

46

Host Read Interface Timing

CLKOUT

HCS, HA0, HA1

HRD

HD0 - HD7

t

hHCAR

t

dHR

t

vHDR

t

wHR

t

hHDR

t

recHS

Hi-ZHi-Z

HRE

t

dHE

t

hHE

µ

PD77016

Page 47

Host Write Interface Timing

CLKOUT

HCS, HA0, HA1

HWR

HD0 - HD7

t

dHW

t

wHW

t

suHDW

t

hHCAW

t

hHDW

t

recHS

47

HWE

t

dHE

t

hHE

µ

PD77016

Page 48

µ

PD77016

General Input/Output Ports

Required Timing Condition

Parameters Symbol Conditions MIN. TYP. MAX. Unit

Port input setup time tsuPI 10 ns

Port input hold time thPI 10 ns

Switching Characteristics

Parameters Symbol Conditions MIN. TYP. MAX. Unit

Port output delay time tdPO 030ns

General Input/Output Ports Timing

CLKOUT

P0 - P3

(Output)

P0 - P3

(Input)

t

dPO

t

suPI

t

hPI

48

Page 49

µ

PD77016

Debugging Interface (JTAG)

Required Timing Condition

Parameters Symbol Conditions MIN. TYP. MAX. Unit

TCK cycle time tcTCK 4tcCO ns

TCK high level width twTCKH 50 ns

TCK low level width twTCKL 50 ns

TCK rise/fall time trfTCK 320ns

TMS, TDI setup time tsuDI 10 ns

TMS, TDI hold time thDI 15 ns

Input pin setup time tsuJIN 10 ns

Input pin hold time thJIN

Switching Characteristics

Parameters Symbol Conditions MIN. TYP. MAX. Unit

TDO output delay time tdDO 030ns

Output pin output delay time tdJOUT 30 ns

0

ns

Debugging Interface Timing

t

cTCK

t

wTCKH

TCK

TMS,

TDI

dDO

t

TDO

Capture

state

t

wTCKL

t

rfTCK

t

suDI

t

hDI

Valid Valid Valid

t

suJIN

hJIN

Valid

t

t

rfTCK

t

dJOUT

Update

state

Remark For the details of JTAG, refer to “IEEE1149.1.”

49

Page 50

5. PACKAGE DRAWING

160 PIN PLASTIC QFP (FINE PITCH) ( 24)

A

B

µ

PD77016

120

121

160

F

G

1

H

M

I

P

N

NOTE

Each lead centerline is located within 0.10 mm (0.004 inch) of

its true position (T.P.) at maximum material condition.

81

40

80

41

detail of lead end

C D

S

J

K

M

L

ITEM MILLIMETERS INCHES

26.0±0.2

A

24.0±0.2

B

24.0±0.2

C

26.0±0.2

D

2.25

F

2.25

G

+0.05

0.22

H

I

J

K

L

M

N

P

–0.04

0.10

0.5 (T.P.)

1.0±0.2

0.5±0.2

+0.03

0.17

–0.07

0.10

2.7

0.4±0.1Q

+7°

3°R3°

–3°

3.3 MAX.S 0.130 MAX.

S160GM-50-JMD,KMD

Q

+0.008

1.024

–0.009

0.945±0.008

0.945±0.008

+0.008

1.024

–0.009

0.089

0.089

0.009±0.002

0.004

0.020 (T.P.)

+0.009

0.039

–0.008

+0.008

0.020

+0.001

0.007

0.004

0.106

+0.004

0.016

–0.005

+7°

–3°

R

–0.009

–0.003

50

Page 51

µ

PD77016

6. RECOMMENDED SOLDERING CONDITIONS

When soldering this product, it is highly recommended to observe the conditions as shown below. If other

soldering processes are used, or if the soldering is performed under different conditions, please make sure to

consult with our sales offices.

For more details, refer to our document “SEMICONDUCTOR DEVICE MOUNTING TECHNOLOGY MANUAL”

(C10535E).

Surface mount device

µ

PD77016GM-KMD: 160-pin plastic QFP (FINE PITCH) (24 × 24 mm)

Process Conditions Symbol

Infrared ray reflow Peak temperature: 235 °C or below (Package surface temperature), IR35-207-1

Reflow time: 30 seconds or less (at 210 °C or higher),

Maximum number of reflow processes: 1 time,

Exposure limit

afterwards).

VPS Peak temperature: 215 °C or below (Package surface temperature), VP15-207-1

Reflow time: 40 seconds or less (at 200 °C or higher),

Maximum number of reflow processes: 1 time,

Exposure limit

afterwards).

Partial heating method Pin temperature: 300 °C or below, –

Heat time: 3 seconds or less (Per each side of the device).

Note

: 7 days (20 hours pre-baking is required at 125 °C

Note

: 7 days (20 hours pre-baking is required at 125 °C

Note Maximum allowable time from taking the soldering package out of dry pack to soldering.

Storage conditions: 25 °C and relative humidity of 65 % or less.

Caution Apply only one kind of soldering condition to a device, except for “partial heating method”,

or the device will be damaged by heat stress.

51

Page 52

[MEMO]

µ

PD77016

52

Page 53

[MEMO]

µ

PD77016

53

Page 54

[MEMO]

µ

PD77016

54

Page 55

NOTES FOR CMOS DEVICES

1 PRECAUTION AGAINST ESD FOR SEMICONDUCTORS

Note: Strong electric field, when exposed to a MOS device, can cause destruction

of the gate oxide and ultimately degrade the device operation. Steps must

be taken to stop generation of static electricity as much as possible, and

quickly dissipate it once, when it has occurred. Environmental control must

be adequate. When it is dry, humidifier should be used. It is recommended

to avoid using insulators that easily build static electricity. Semiconductor

devices must be stored and transported in an anti-static container, static

shielding bag or conductive material. All test and measurement tools

including work bench and floor should be grounded. The operator should

be grounded using wrist strap. Semiconductor devices must not be touched

with bare hands. Similar precautions need to be taken for PW boards with

semiconductor devices on it.

µ

PD77016

2 HANDLING OF UNUSED INPUT PINS FOR CMOS

Note: No connection for CMOS device inputs can be cause of malfunction. If no

connection is provided to the input pins, it is possible that an internal input

level may be generated due to noise, etc., hence causing malfunction. CMOS

device behave differently than Bipolar or NMOS devices. Input levels of

CMOS devices must be fixed high or low by using a pull-up or pull-down

circuitry. Each unused pin should be connected to VDD or GND with a

resistor, if it is considered to have a possibility of being an output pin. All

handling related to the unused pins must be judged device by device and

related specifications governing the devices.

3 STATUS BEFORE INITIALIZATION OF MOS DEVICES

Note: Power-on does not necessarily define initial status of MOS device. Produc-

tion process of MOS does not define the initial operation status of the device.

Immediately after the power source is turned ON, the devices with reset

function have not yet been initialized. Hence, power-on does not guarantee

out-pin levels, I/O settings or contents of registers. Device is not initialized

until the reset signal is received. Reset operation must be executed immediately after power-on for devices having reset function.

55

Page 56

µ

PD77016

[MEMO]

No part of this document may be copied or reproduced in any form or by any means without the prior written

consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which may appear in

this document.

NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual property

rights of third parties by or arising from use of a device described herein or any other liability arising from use

of such device. No license, either express, implied or otherwise, is granted under any patents, copyrights or other

intellectual property rights of NEC Corporation or others.

While NEC Corporation has been making continuous effort to enhance the reliability of its semiconductor devices,

the possibility of defects cannot be eliminated entirely. To minimize risks of damage or injury to persons or

property arising from a defect in an NEC semiconductor device, customers must incorporate sufficient safety

measures in its design, such as redundancy, fire-containment, and anti-failure features.

NEC devices are classified into the following three quality grades:

"Standard", "Special", and "Specific". The Specific quality grade applies only to devices developed based on a

customer designated "quality assurance program" for a specific application. The recommended applications of

a device depend on its quality grade, as indicated below. Customers must check the quality grade of each device

before using it in a particular application.

Standard: Computers, office equipment, communications equipment, test and measurement equipment,

audio and visual equipment, home electronic appliances, machine tools, personal electronic

equipment and industrial robots

Special: Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support)

Specific: Aircrafts, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems or medical equipment for life support, etc.

The quality grade of NEC devices is "Standard" unless otherwise specified in NEC's Data Sheets or Data Books.

If customers intend to use NEC devices for applications other than those specified for Standard quality grade,

they should contact an NEC sales representative in advance.

Anti-radioactive design is not implemented in this product.

M4 96.5

2

Loading...

Loading...