Page 1

DATA SHEET

MOS INTEGRATED CIRCUIT

µ

PD72107

LAP-B CONTROLLER

Link Access Procedure Balanced mode

The µPD72107 is an LSI that supports LAP-B protocol specified by the ITU-T recommended X.25 on a single

chip.

FEATURES

• Complied with ITU-T recommended X.25 (LAP-B84

edition)

HDLC frame control

Sequence control

Flow control

• ITU-T recommended X.75 supported

• TTC standard JT-T90 supported

• Optional functions

Option frame

Global address frame

Error check deletion frame

• Powerful test functions

Data loopback function

Loopback test link function

Frame trace function

• Abundant statistical information

• Detailed mode setting function

• Modem control function

• On-chip DMAC (Direct Memory Access Controller)

24-bit address

Byte/word transfer enabled (switch with external pin)

• Memory-based interface

Memory-based command

Memory-based status

Memory-based transmit/receive data

• MAX.4 Mbps serial transfer rate

• NRZ, NRZI coding

ORDERING INFORMATION

Part Number Package

µ

PD72107CW 64-pin plastic shrink DIP (750 mils)

µ

PD72107GC-3B9 80-pin plastic QFP (14 x 14 mm)

µ

PD72107L 68-pin plastic QFJ (950 x 950 mils)

The information in this document is subject to change without notice.

Document No. S12962EJ5V0DS00 (5th edition)

Date Published October 1998 N CP(K)

Printed in Japan

©

1998

Page 2

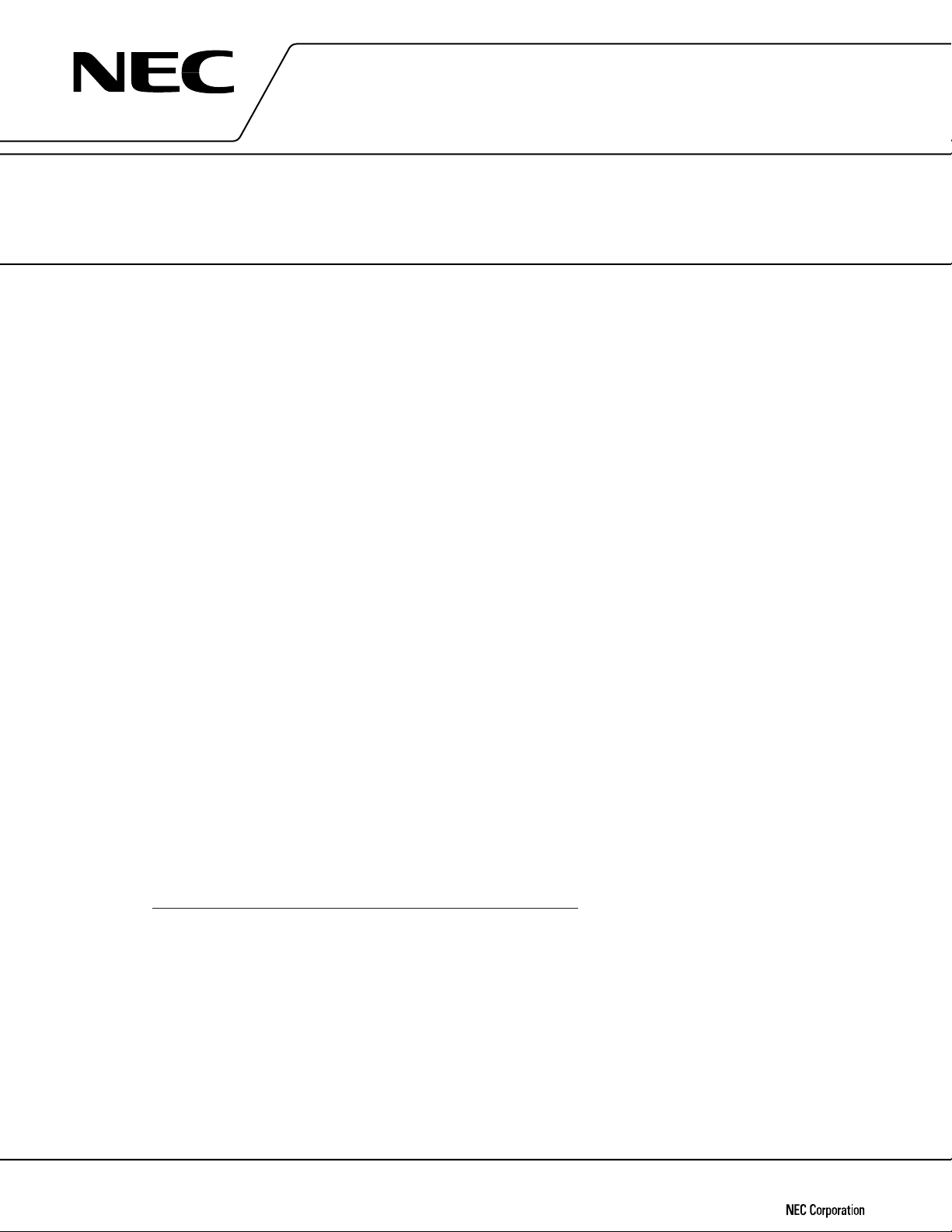

BLOCK DIAGRAM

D0-D7

A16D8

-A23D15

A0-A15

IORD

IOWR

MRD

MWR

UBE

CS

ASTB

AEN

READY

HLDRQ

HLDAK

CRQ

INT

CLRINT

B/W

PU

VCC

GND

RESET

CLK

Bus

interface

Internal controller

Internal bus

DMAC

TxFIFO

RxFIFO

Transmitter

Receiver

µ

TxC

TxD

RTS

CTS

CD

RxC

RxD

PD72107

Name Function

Bus interface An interface between the µPD72107 and external memory or external host processor

Internal controller Manages LAP-B protocol including control of the DMAC block, transmitter block, and receiver block

DMAC Controls the transfer of data on the external memory to the internal controller or transmitter block,

(Direct Memory and controls the writing of data in the internal controller or receiver block to the external memory

Access Controller)

TxFIFO A 16-byte buffer for when transmit data is sent from the DMAC to the transmitter block

RxFIFO A 32-byte buffer for when receive data is sent from the receiver block to the DMAC

Transmitter Converts the contents of TxFIFO into an HDLC frame and transmits it as serial data

Receiver Receives HDLC frame and writes internal data to RxFIFO

Internal bus An 8-bit address bus and 8-bit data bus that connect the internal controller, DMAC, FIFO, serial block,

and bus interface block

2

Page 3

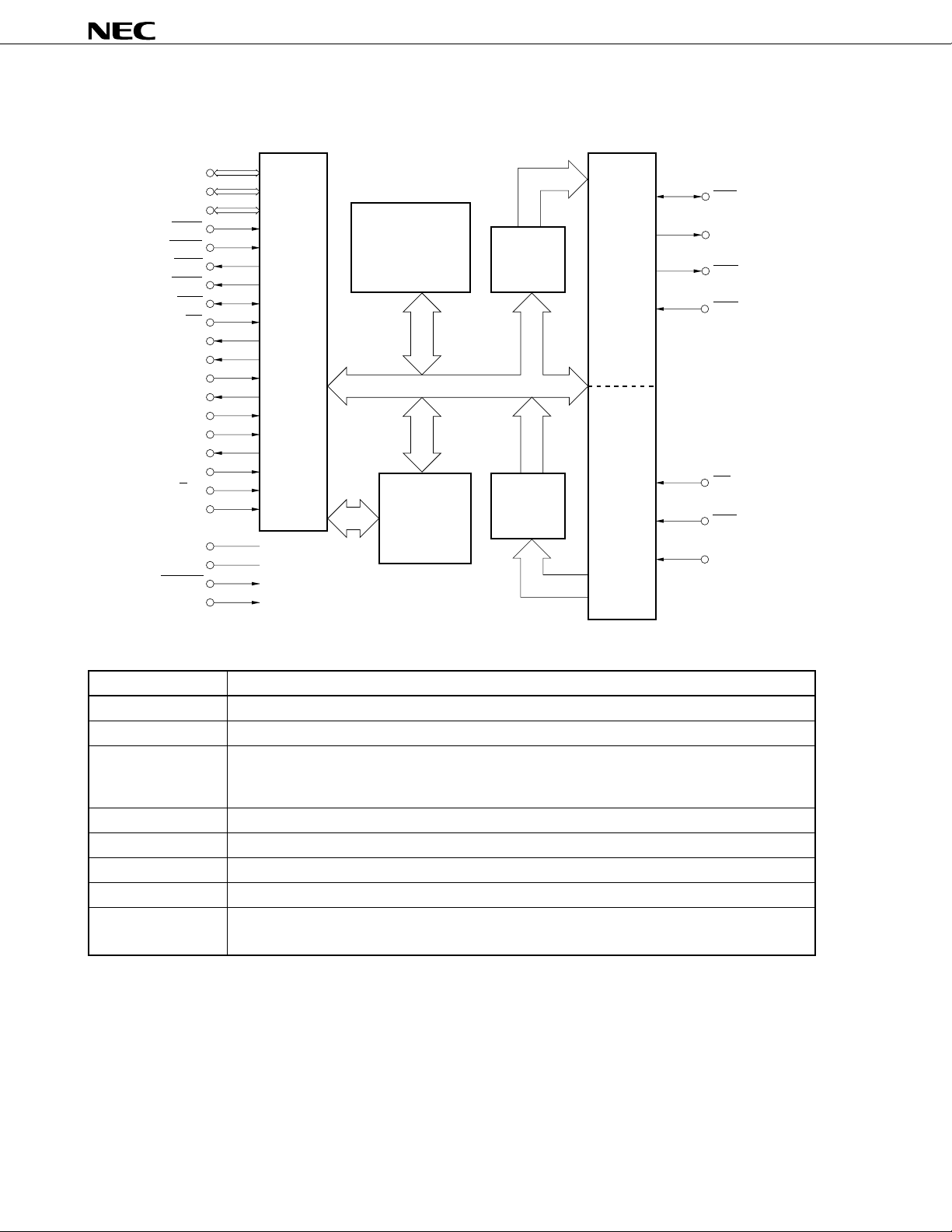

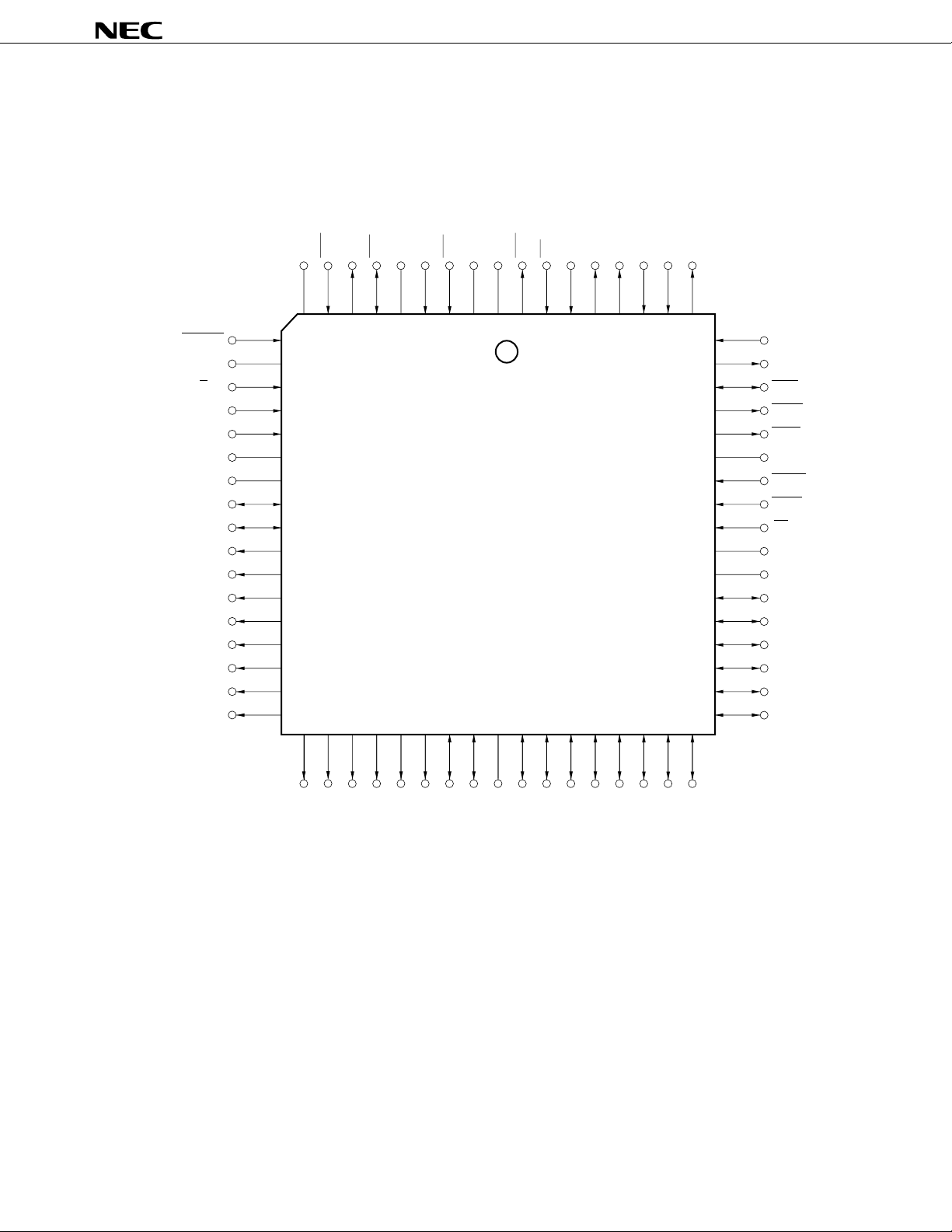

PIN CONFIGURATION (Top View)

64-pin plastic shrink DIP (750 mils)

µ

PD72107CW

µ

PD72107

RxC

RxD

TxC

TxD

CTS

RESET

NC

B/W

PU

CLK

GND

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16D8

A17D9

IC

IC

IC

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

RTS

CD

CRQ

AEN

ASTB

READY

HLDAK

HLDRQ

CLRINT

INT

UBE

MWR

MRD

GND

IOWR

IORD

CS

CC

V

D7

D6

D5

D4

D3

D2

D1

D0

A23D15

A22D14

A21D13

A20D12

A19D11

A18D10

3

Page 4

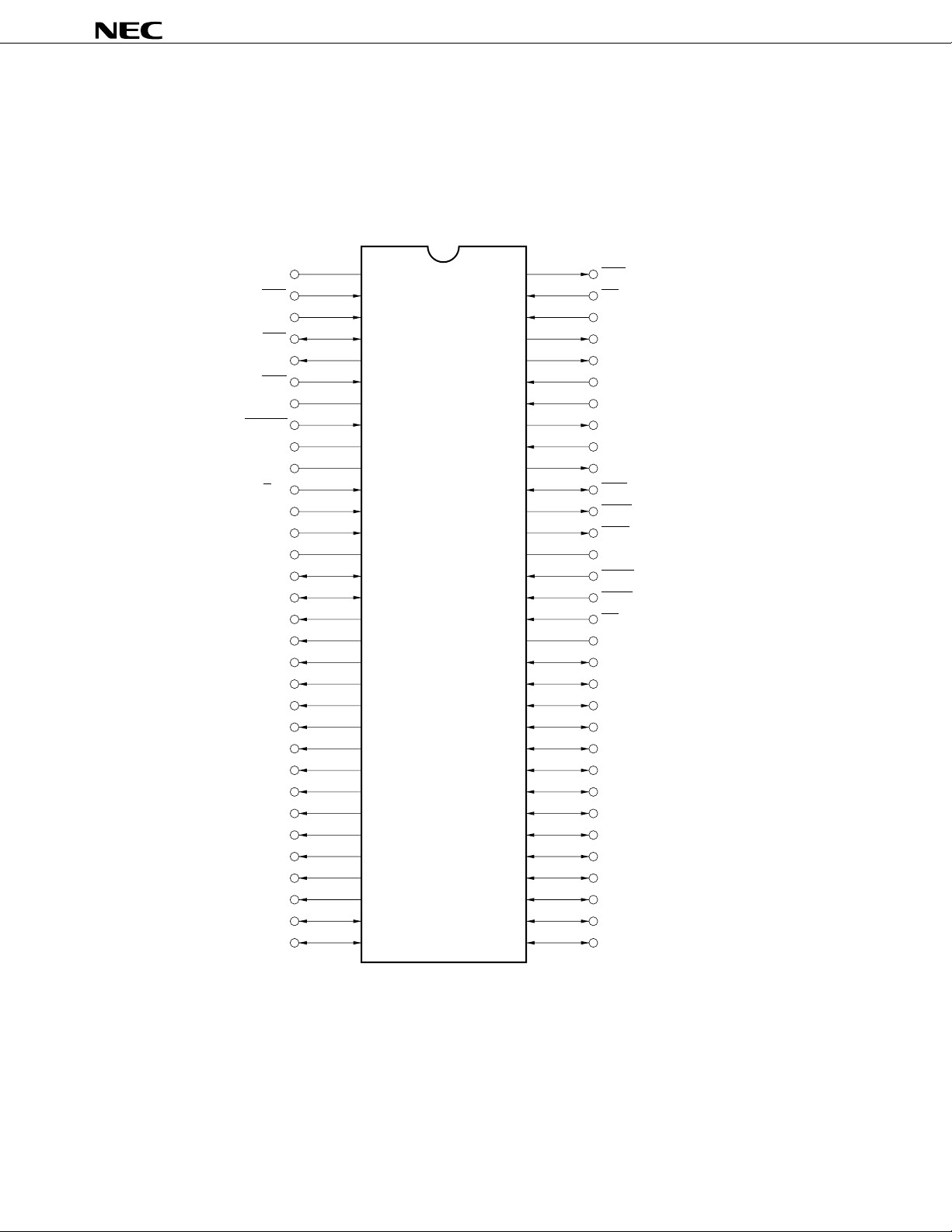

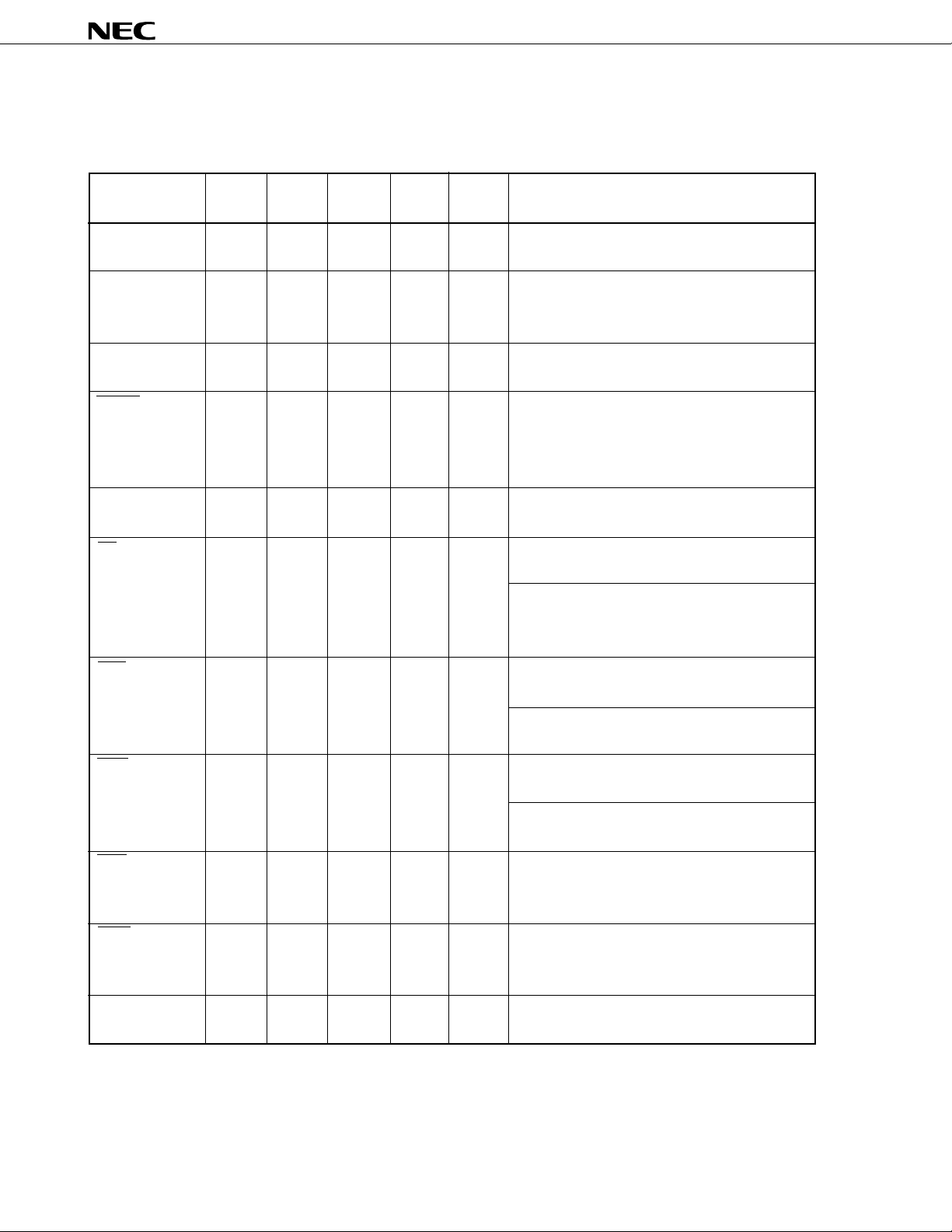

80-pin plastic QFP (14 × 14 mm)

µ

PD72107GC-3B9

NC

CLRINT

INT

80 79 78 77 76 75 74 73 72 71 70 69 68 67 66 65 64 63 62 61

UBE

MWR

MRD

GND

IOWR

IORDCSVCCNCVCCD7D6D5D4D3D2

NC

µ

PD72107

NC

HLDRQ

HLDAK

READY

ASTB

AEN

NC

CRQ

CD

RTS

NC

IC

RxC

RxD

NC

TxC

TxD

CTS

IC

NC

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

NC

IC

RESET

B/W

PU

CLK

GND

A0A1A2A3A4A5A6A7A8

NC

GND

A9

NC

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

D1

D0

A23D15

A22D14

A21D13

NC

A20D12

A19D11

A18D10

NC

NC

A17D9

A16D8

A15

A14

A13

A12

A11

A10

NC

4

Page 5

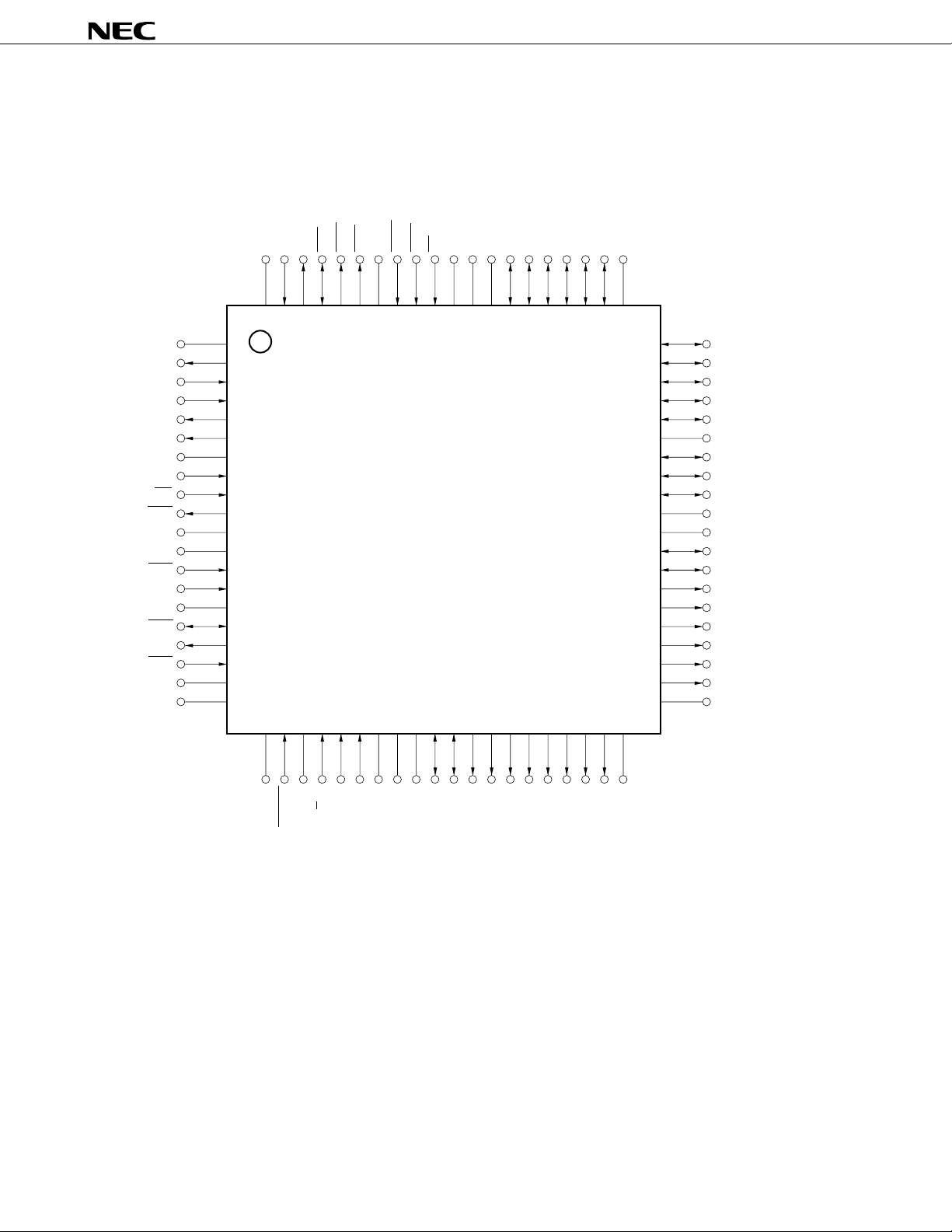

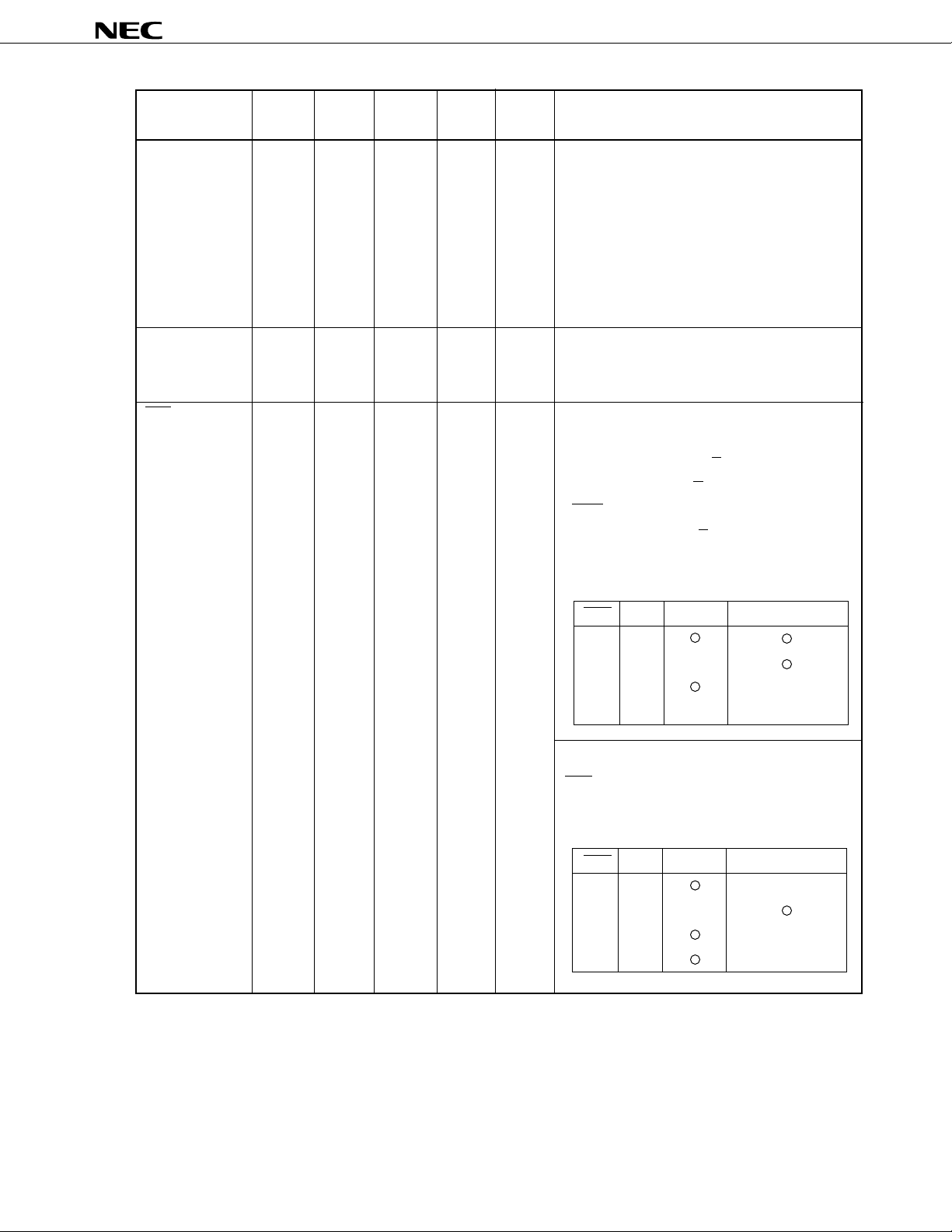

68-pin plastic QFJ (950 × 950 mils)

Q

µ

PD72107L

IC

CTS

TxD

9876543216867666564636261

RESET

IC

B/W

PU

CLK

GND

GND

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43

TxCNCRxD

RxCICNC

RTSCDCRQ

AEN

ASTB

READY

HLDAK

HLDR

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

µ

PD72107

CLRINT

INT

UBE

MWR

MRD

GND

IOWR

IORD

CS

V

CC

VCC

D7

D6

D5

D4

D3

D2

A10

A11

A12

A13

A14

A15

A16D8

A17D9

NC

A18D10

A19D11

A20D12

A21D13

A22D14

A23D15

D0

D1

5

Page 6

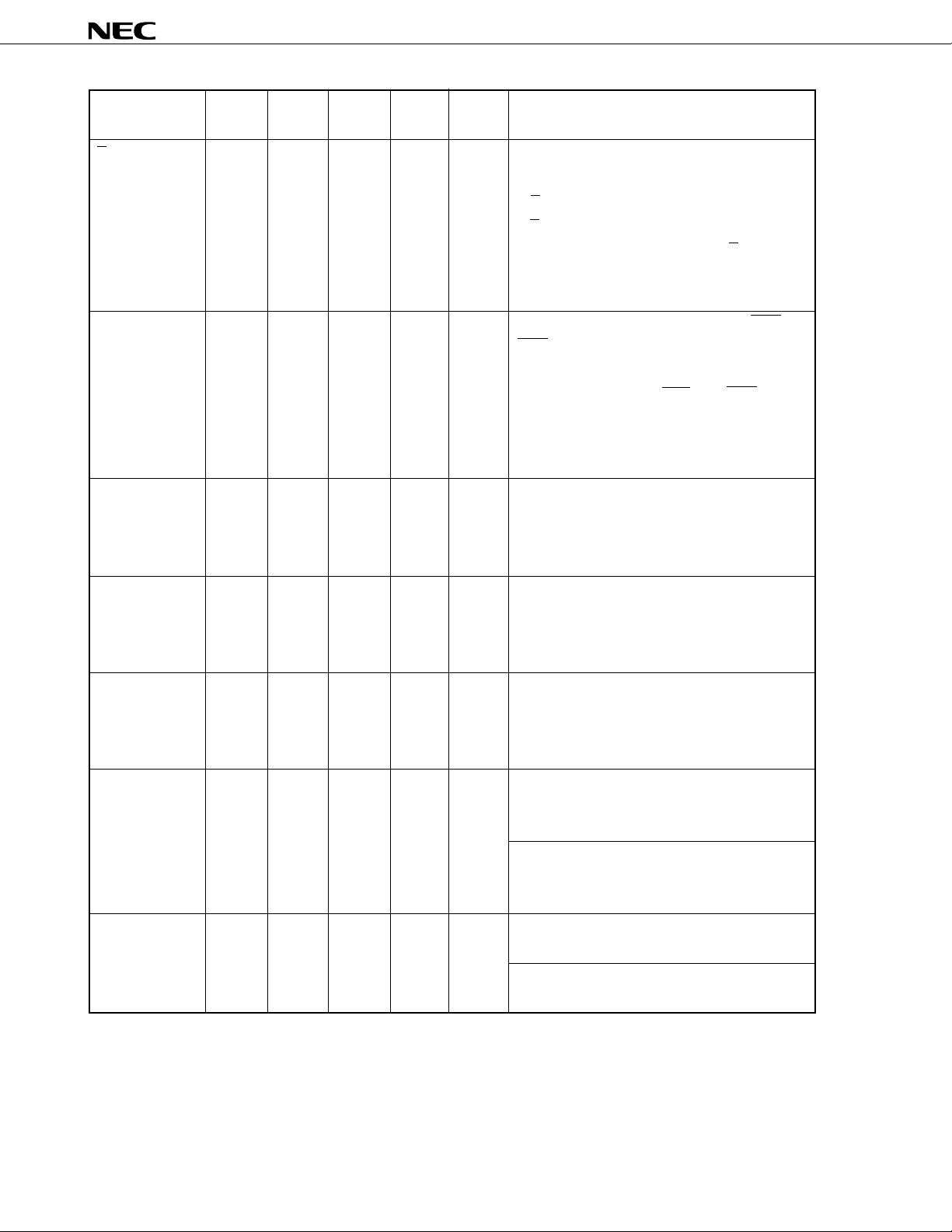

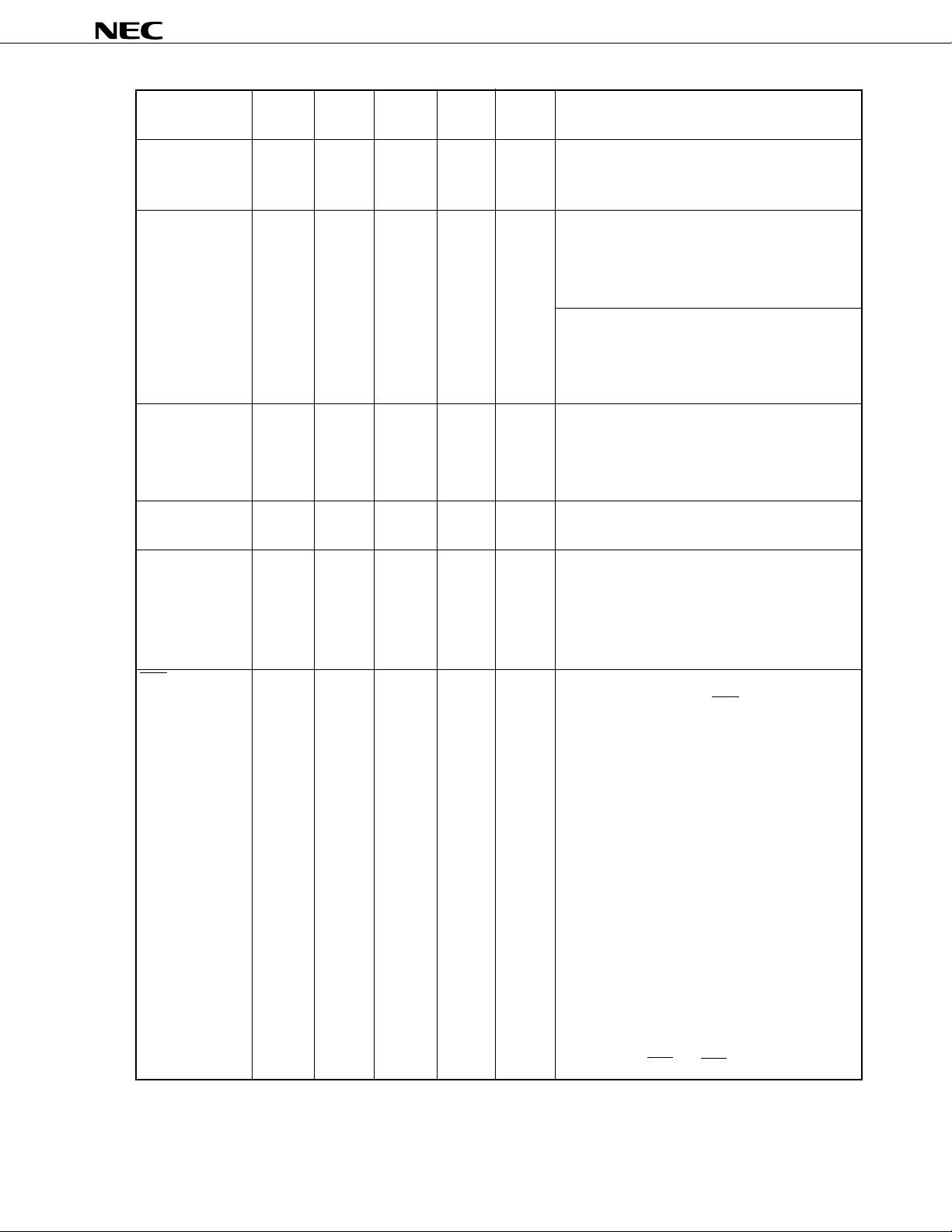

1. PINS

1.1 Pin Functions

µ

PD72107

SDIP QFP QFJ Active

Pin No. Pin No. Pin No. Level

V

CC 47 68 50 – – +5 V power supply

70 51

GND 14 27 15 – – Ground (0 V)

51 28 16 Note that there is more than one ground pin.

74 55

CLK 13 26 14 I – System clock input

(Clock) Input clock of 1 MHz to 8.2 MHz.

RESET 8 22 10 I L Initializes the internal

(Reset) more than 7 CLK clock cycles is required (clock

PU 12 25 13 I – Pull up to high level when using in normal operation.

(Pull Up)

CS 48 71 52 I L When bus master

(Chip Select) Set to disable.

MRD 52 75 56 O L When bus master

(Memory Read) 3-state Reads the data of the external memory at low level.

MWR 53 76 57 O L When bus master

(Memory Write) 3-state Writes the data to the external memory at low level.

IORD 49 72 53 I L This pin is used when the external host processor

(I/O Read) reads the contents of the internal registers of the

IOWR 50 73 54 I L This pin is used when the external host processor

(I/O Write) writes the data to the internal registers of the

ASTB 60 5 64 O H This pin is used to latch the address output from

(Address Strobe) the

I/OPin Name Function

µ

PD72107. Active width of

input is required).

After reset, this pin becomes a bus slave.

When bus slave

Read/write operation from the host processor at low

level is enabled.

When bus slave

High impedance

When bus slave

High impedance

µ

PD72107.

µ

PD72107.

µ

PD72107 externally.

6

Page 7

µ

PD72107

SDIP QFP QFJ Active

Pin No. Pin No. Pin No. Level

NC 9 1, 7, 1 – – Use this pin open.

(No Connection) 11, 15, 5

20, 21, 35

29, 40,

41, 50,

51, 55,

61, 69,

80

IC 1 12 2 – – Do not connect anything to this pin.

(Internally 7 19 9

Connected) 10 23 11

UBE 54 77 58 I/O L/H When bus master (output)

(Upper Byte 3-state The signal output from this pin changes according

Enable) to the input value of the B/W pin.

I/OPin Name Function

• Byte transfer mode (B/W = 0)

UBE is always high impedance.

• Word transfer mode (B/W = 1)

Indicates that valid data is either in pins D0 to D7

or pins A16D8 to A23D15 (or both).

UBE A0 D0 to D7 A16D8 to A23D15

00

01 ×

10 ×

11 ××

When bus slave (input)

UBE pin becomes input, and indicates that valid

data is either in pins D0 to D7 or pins A16D8 to

A23D15.

UBE A0 D0 to D7 A16D8 to A23D15

00 ×

01 ×

10 ×

11 ×

7

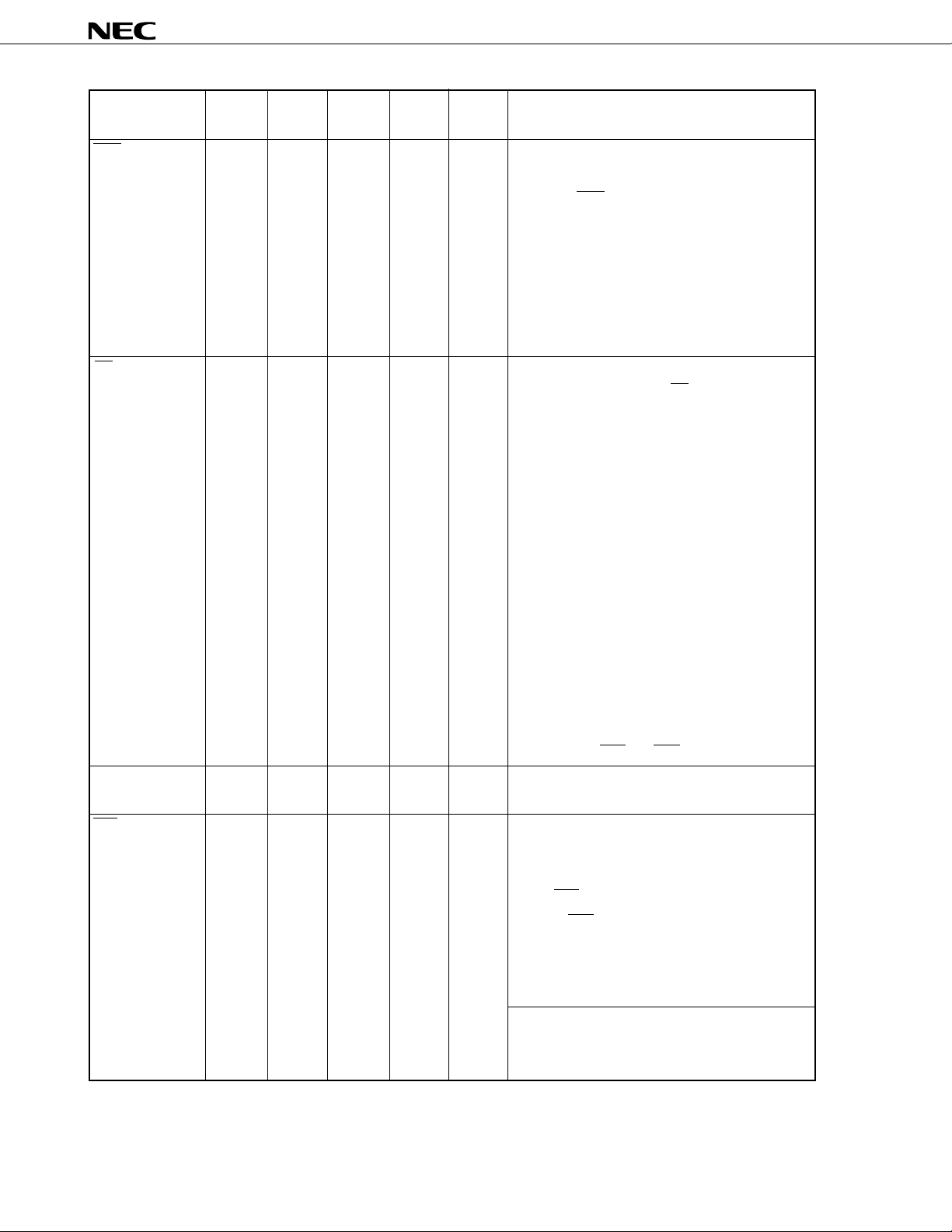

Page 8

µ

PD72107

SDIP QFP QFJ Active

Pin No. Pin No. Pin No. Level

B/W 11 24 12 I L/H Specifies the data bus that accesses the external

(Byte/Word) memory when bus master.

READY 59 4 63 I H An input signal that is used to extend the MRD and

(Ready) MWR signal widths output by the µPD72107 to

HLDRQ 57 2 61 O H A hold request signal to the external host processor.

(Hold Request) When a DMA operation is performed in the µPD72107,

HLDAK 58 3 62 I H A hold acknowledge signal from the external host

(Hold Acknowledge)

AEN 61 6 65 O H When bus master, this signal enables the latched

(Address Enable) higher addresses and outputs them to system ad-

A0, A1 15, 16 30, 31 17, 18 I/O – Bidirectional 3-state address lines.

A2 to A15 17 to 30 32 to 47 19 to 32 O – When bus master

(except 3-state Output bit 2 to bit 15 of memory access addresses.

40, 41) When bus slave

I/OPin Name Function

B/W = 0 Byte units (8 bits)

B/W = 1 Word units (16 bits)

After power-on, fix the status of the B/W pin.

In the case of word access, the lower data bus is the

contents data of even addresses.

adapt to low-speed memory. When the READY

signal is low level, the MRD and MWR signals

maintain active low. Do not change the READY

signal at any time other than the specified setup/

hold time.

this signal is activated to switch from bus slave to

bus master.

processor. When the µPD72107 detects that this

signal is active, the bus slave switches to bus

master, and a DMA operation is started.

dress bus. This signal is also used for disabling

other system bus drivers.

3-state When bus master (output)

Indicate the lower 2-bit addresses of memory access.

When bus slave (input)

Input addresses when the external host processor

I/O accesses the µPD72107.

Become high impedance.

8

Page 9

µ

PD72107

SDIP QFP QFJ Active

Pin No. Pin No. Pin No. Level

A16D8 to A23D15 31 to 38 48 to 58 33 to 41 I/O – Bidirectional 3-state address/data buses. Multiplex

(except 50, (except 35)

51, 55) and the higher 8 bits to 15 bits of data.

D0 to D7 39 to 46 59 to 67 42 to 49 I/O – Bidirectional 3-state data buses.

(except 61)

CRQ 62 8 66 I H A signal requesting command execution to the

(Command

Request)

INT 55 78 59 O H An interrupt signal from the µPD72107 to the

(Interrupt) external host processor.

CLRINT 56 79 60 I H A signal inactivating the INT signal being output by

(Clear Interrupt) the µPD72107. The µPD72107 generates the CLRINT

CTS 6 18 8 I – A general-purpose input pin.

(Clear To Send) The µPD72107 reports the “CTS pin change detection

I/OPin Name Function

3-state pins of the higher 16 bits to 23 bits of addresses

3-state When bus master

When writing to external memory, these pins become

input if reading at output.

When bus slave

Usually, these pins become high impedance. When

the external host processor reads I/O of the µPD72107,

the internal register data is output.

µ

PD72107 by the external host processor. The

µ

PD72107 starts fetching commands from on the

external memory at the rising edge of this signal.

signal in the LSI internal circuit at the rising edge of

this signal, and forcibly makes the INT output signal

low.

status” to the external host processor when the

input level of this pin is changed in the generalpurpose input/output pin support (setting RSSL to

1 by the “system initialization command”). The

change of input level is recognized only when the

same level is sampled twice in succession after

sampling in 8-ms cycles and detecting the change.

Moreover, when the external host processor issues

a “general-purpose input/output pin read command”

to the µPD72107, the µPD72107 reports the pin

information of this pin to the external host processor

by a “general-purpose input/output pin read response

status”.

The change can be detected even in the clock input

stop status of TxC and RxC.

9

Page 10

µ

PD72107

SDIP QFP QFJ Active

Pin No. Pin No. Pin No. Level

RTS 64 10 68 O – A general-purpose output pin.

(Request To Send)

CD 63 9 67 I – A general-purpose input pin.

(Carrier Detect) The µPD72107 reports the “CD pin change detection

TxD 5 17 7 O – A serial transmit data output pin.

(Transmit Data)

TxC 4 16 6 I/O – When CLK is set to 01 or 10 by “operation mode

(Transmit Clock) 3-state setting LCW” (output)

I/OPin Name Function

The output value of this pin can be changed by

issuing an “RTS pin write command” from the external

host processor to the µPD72107. Moreover, when

the external host processor issues a “general-purpose

input/output pin read command” to the µPD72107,

the µPD72107 reports the pin information of this pin

to the external host processor by a “general-purpose

input/output pin read response status”.

status” to the external host processor when the

input level of this pin is changed in the generalpurpose input/output pin support (setting RSSL to

1 by the “system initialization command”). The

change of input level is recognized only when the

same level is sampled twice in succession after

sampling in 8-ms cycles and detecting the change.

Moreover, when the external host processor issues

a “general-purpose input/output pin read command”

to the µPD72107, the µPD72107 reports the pin

information of this pin to the external host processor

by a “general-purpose input/output pin read response

status”.

The change can be detected even in the clock input

stop status of TxC and RxC.

Outputs a clock that divides by 16 the input signal

of the RxC pin or CLK pin made by the µPD72107.

Caution TxC becomes input because CLK = 00

is the default after reset. It becomes

output after setting CLK to 01 or 10 by

“operation mode setting LCW”.

When CLK is set to 00 by “operation mode setting

LCW” (input)

Inputs transmit clock externally.

Remark LCW: abbreviation for Link Command Word

10

Page 11

µ

PD72107

SDIP QFP QFJ Active

Pin No. Pin No. Pin No. Level

RxD 3 14 4 I – A serial receive data input pin.

(Receive Data)

RxC 2 13 3 I – When CLK is set to 01 or 10 by “operation mode

(Receive Clock) setting LCW”

I/OPin Name Function

Sixteen times the clock input of the transmit/receive

clock for the on-chip DPLL of the

When CLK is set to 00 by “operation mode setting

LCW”

One time the clock input of the receive clock

µ

PD72107

Remark LCW: abbreviation for Link Command Word

1.2 Pin Status after Reset of µPD72107

The status of the output pins and input/output pins after reset in the µPD72107 is as shown in Table 1-1.

Table 1-1. Pin Status after Reset

Pin Number

64-pin SDIP 80-pin QFP 68-pin QFJ

4 16 6 TxC I/O

5 17 7 TxD O H

15, 16 30, 31 17, 18 A0, A1 I/O

17 to 30 32 to 47 19 to 32 A2 to A15 O

(except 40, 41)

31 to 38 48 to 58 33 to 41 A16D8 to A23D15 I/O

(except 50, 51, 55) (except 35)

39 to 46 59 to 67 42 to 49 D0 to D7 I/O

(except 61)

52 75 56 MRD O

53 76 57 MWR O

54 77 58 UBE I/O

55 78 59 INT O L

57 2 61 HLDRQ O L

60 5 64 ASTB O L

61 6 65 AEN O L

64 10 68 RTS O H

Pin Name

I/O

Note

Note

Note

Note

Note

Note

Note

Note

During Reset

High impedance

High impedance

High impedance

High impedance

High impedance

High impedance

High impedance

High impedance

Note 3-state

Remarks 1. The status after reset is released is the same as the status during reset.

2. Input low level to the RESET pin for more than 7 clocks of the system clock.

11

Page 12

µ

PD72107

2. ELECTRICAL SPECIFICATIONS

Absolute Maximum Ratings (TA = +25°C)

Parameter Symbol Conditions Ratings Unit

Power supply voltage VDD –0.5 to +7.0 V

Input voltage VI –0.5 to VDD + 0.3 V

Output voltage VO –0.5 to VDD + 0.3 V

Operating ambient temperature TA –40 to +85 °C

Storage temperature Tstg –40 to +125 °C

Caution Product quality may suffer if the absolute maximum rating is exceeded even momentarily for

any parameter. That is, the absolute maximum ratings are rated values at which the product

is on the verge of suffering physical damage, and therefore the product must be used under

conditions that ensure that the absolute maximum ratings are not exceeded.

DC Characteristics (T

Parameter Symbol Conditions MIN. TYP. MAX. Unit

Input voltage, low VILC CLK pin –0.5 +0.8 V

Input voltage, high VIHC CLK and PU pins +3.3 VDD + 0.3 V

Output voltage, low VOL IOL = 2.5 mA 0.4 V

Output voltage, high VOH IOH = –400 µA 0.7 × VDD V

Power supply current IDD At operation 20 50 mA

Input leakage current ILI 0 V ≤ VIN ≤ VDD ±10

Output leakage current ILO 0 V ≤ VOUT ≤ VDD ±10

A = –40 to +85°C, VDD = 5 V ±10%)

VIL Other pins –0.5 +0.8 V

VIH Other pins +2.2 VDD + 0.3 V

µ

A

µ

A

Capacitance (TA = +25°C, VDD = 0 V)

Parameter Symbol Conditions MIN. TYP. MAX. Unit

Input capacitance CI fC = 1 MHz – 8 15 pF

Output capacitance CO Unmeasured pins returned to 0 V – 8 15 pF

I/O capacitance CIO –820pF

12

Page 13

µ

PD72107

AC Characteristics (TA = –40 to +85°C, VDD = 5 V ±10%)

When bus master (1)

Parameter Symbol Conditions MIN. MAX. Unit

CLK cycle time tCYK 121 1000 ns

CLK low-level time tKKL 50 ns

CLK high-level time tKKH 50 ns

CLK rise time tKR 1.5 – 3.0 V 10 ns

CLK fall time tKF 3.0 – 1.5 V 10 ns

Load condition

DUT

C

L = 50 pF

CL includes jig capacitance.

Caution If the load capacitance exceeds 50 pF due to the configuration of the circuit, keep the load

capacitance of this device to within 50 pF by inserting a buffer or by some other means.

Remark DUT: device under test

AC test input/output waveform (except clock)

2.4 V

2.2 V

Test points

0.8 V

0.4 V

2.2 V

0.8 V

System clock

CLK

tKF tKR

tKKL

1.5 V

tCYK

3.0 V

tKKH

13

Page 14

µ

PD72107

When bus master (2)

Parameter Symbol Conditions MIN. MAX. Unit

HLDRQ ↑ delay time (vs. CLK ↓)tDHQH 100 ns

HLDRQ ↓ delay time (vs. CLK ↑)tDHQL 100 ns

HLDAK setup time (vs. CLK ↑)tSHA 35 ns

HLDAK hold time (vs. CLK ↑)tHHA 20 ns

AEN ↑ delay time (vs. CLK ↓)tDAEH 100 ns

AEN ↓ delay time (vs. CLK ↑)tDAEL 100 ns

ASTB ↑ delay time (vs. CLK ↑)tDSTH 70 ns

ASTB high-level width tSTSTH tKKH–15 ns

ASTB ↓ delay time (vs. CLK ↓)tDSTL 100 ns

ADR/UBE/MRD/MWR delay time tDA 100 ns

(vs. CLK ↑)

ADR/UBE/MRD/MWR float time tFA 70 ns

(vs. CLK ↑)

ADR setup time (vs. ASTB ↓)tSAST tKKH–35 ns

ADR hold time (vs. ASTB ↓)tHSTA tKKL–20 ns

MRD ↓ delay time (vs. ADR float) tDAR 0ns

MRD ↓ delay time (vs. CLK ↑)tDRL 70 ns

MRD low-level width tRRL2 2t CYK–50 ns

MRD ↑ delay time (vs. CLK ↑)tDRH 70 ns

Data setup time (vs. MRD ↑)tSDR 100 ns

Data hold time (vs. MRD ↑)tHRD 0ns

MWR ↓ delay time (vs. CLK ↑)tDWL 70 ns

MWR low-level width tWWL2 2tCYK–50 ns

MWR ↑ delay time (vs. CLK ↑)tDWH 70 ns

READY setup time (vs. CLK ↑)tSRY 35 ns

READY hold time (vs. CLK ↑)tHRY 20 ns

14

Page 15

tDHQH

tSHA

tHHA

tDAEH

tDSTH

tDSTL

tDA

tSTSTH

tSAST tHSTA

tDWL

tFA

tSRY tSRY

tDA

tDAR

tDRL

tRRL2

tDRH

tSDR

tHRD

tFA

tHRY tDWHtHRY

tWWL2

tDAEL

tDHQL

Hi-Z

Hi-Z

Hi-Z

Hi-Z

Hi-ZHi-Z

Hi-Z

Hi-Z

Hi-Z

Hi-Z

Address

Input data

Output data

Address

CLK

HLDRQ

HLDAK

AEN

ASTB

A16D8-A23D15

A0, A1/A2-A15

UBE

MWR

READY

A16D8-A23D15

MRD

Address

tHHA

When bus master

15

µ

PD72107

Page 16

µ

PD72107

When bus slave (1)

Parameter Symbol Conditions MIN. MAX. Unit

IOWR low-level width tWWL 100 ns

CS low-level hold time tHWCS 0ns

(vs. IOWR ↑)

ADR/UBE/CS low-level setup time tSAW 0ns

(vs. IOWR ↓)

ADR/UBE hold time (vs. IOWR ↑)tHWA 0ns

Data setup time (vs. IOWR ↑)tSDW 100 ns

Data hold time (vs. IOWR ↑)tHWD 0ns

IORD low-level width tRRL 150 ns

ADR/CS low-level setup time tSAR 35 ns

(vs. IORD ↓)

ADR/CS low-level hold time tHRA 0ns

(vs. IORD ↑)

Data delay time (vs. IORD ↓)tDRD 120 ns

Data float time (vs. IORD ↑)tFRD 10 100 ns

RESET low-level width tRSTL 7tCYK ns

VDD setup time (vs. RESET ↑)tSVDD 1000 ns

RESET ↑ –1st • IOWR/IORD tSYWR 2tCYK ns

IOWR/IORD recovery time tRVWR 200 ns

16

Page 17

When bus slave

A0-A23

CS

IOWR

t

SAW

t

WWL

t

HWA

t

HWCS

µ

PD72107

UBE

D0-D15

CS

A0-A23

IORD

D0-D15

t

t

SDW

t

SAR

t

DRD

t

RRL

HWD

t

HRA

t

FRD

Hi-Z Hi-Z

V

RESET

IORD/IOWR

IORD

IOWR

DD

t

RVWR

t

RVWR

t

SVDD

t

RSTL

t

RVWR

t

SYWR

t

RVWR

17

Page 18

µ

PD72107

When bus slave (2)

Parameter Symbol Conditions MIN. MAX. Unit

IOWR/IORD high-level setup time tSWR –20 ns

(vs. HLDAK ↑)

IOWR/IORD high-level hold time t HWR 100 ns

(vs. AEN ↓)

HLDAK

tSWR

IOWR/IORD

AEN

tHWR

IOWR/IORD

When bus slave (3)

Parameter Symbol Conditions MIN. MAX. Unit

CLRINT high-level width tCLCLH 100 ns

INT ↑ delay time (vs. CLK ↑)tDIH 100 ns

INT ↓ delay time (vs. CLRINT ↑)tDIL 100 ns

CRQ high-level width tCRCRH 100 ns

CLK

CLRINT

tCLCLH

18

INT

CRQ

tDIH

tDIL

tCRCRH

Page 19

µ

PD72107

Serial block (1)

Parameter Symbol Conditions MIN. MAX. Unit

TxC/RxC cycle time tCYS When on-chip DPLL is not used 250 DC ns

TxC/RxC low-level time tSSL 110 ns

TxC/RxC high-level time tSSH 110 ns

TxC/RxC rise time tSR 20 ns

TxC/RxC fall time tSF 12 ns

TxD delay time (vs. TxC ↓)tDTXD 100 ns

RxD setup time (vs. RxC ↑)tSRXD 50 ns

RxD hold time (vs. RxC ↑)tHRXD 70 ns

Serial clock (when on-chip DPLL is not used)

TxC/RxC

TxC (input)

TxD

RxC

RxD

tSF tSR

0.8 V

tSRXD tHRXD

tSSL

tCYS

tDTXD tDTXD

t

2.2 V

SSH

19

Page 20

µ

PD72107

Serial block (2)

Parameter Symbol Conditions MIN. MAX. Unit

RxC cycle time tCYR When on-chip DPLL is used (source clock = RxC) 30.3 ns

When on-chip DPLL is used (source clock = CLK) 125 1000

RxC low-level time tSSRL When on-chip DPLL is used (source clock = RxC) 10 ns

When on-chip DPLL is used (source clock = CLK) 50

RxC high-level time tSSRH When on-chip DPLL is used (source clock = RxC) 10 ns

When on-chip DPLL is used (source clock = CLK) 50

RxC rise time tSRR When on-chip DPLL is used (source clock = RxC) 5 ns

When on-chip DPLL is used (source clock = CLK) 10

RxC fall time tSRF When on-chip DPLL is used (source clock = RxC) 5 ns

When on-chip DPLL is used (source clock = CLK) 10

Transmit/receive data cycle tCYD When on-chip DPLL is used (source clock = RxC) 500 ns

When on-chip DPLL is used (source clock = CLK) 2000 16000

TxC low-level time tTCTCL When on-chip DPLL is used

TxC high-level time tTCTCH

TxD delay time (vs. TxC ↓)tDTCTD 50 ns

TxD hold time (vs. TxC ↑)tHTCTD

0.5tCYD–25

0.5tCYD–25

0.5tCYD–25

ns

ns

ns

Serial clock (when on-chip DPLL is used)

tCYR

tSSRL

tSRF

RxC

TxC

tTCTCL

tDTCTD

TxD

tSSRH

tSRR

tTCTCH

tHTCTD

tCYD

20

Page 21

µ

PD72107

Serial block (3)

Parameter Symbol Conditions MIN. MAX. Unit

RTS ↑ delay time (vs. CLK ↑)tDRTH 100 ns

RTS ↓ delay time (vs. CLK ↑)tDRTL 100 ns

CD setup time (vs. CLK ↑)tSCD 35 ns

CD hold time (vs. CLK ↑)tHCD 20 ns

CTS setup time (vs. CLK ↑)tSCT 35 ns

CTS hold time (vs. CLK ↑)tHCT 20 ns

CLK

RTS

tDRTL

tHCD

tDRTH

CD

CTS

tSCD

tHCT

tSCT

21

Page 22

3. APPLICATION CIRCUIT EXAMPLE

(1) Connection with SIFC (µPD98201)

µµ

PD72107 PD98201

TxD BINA

µ

PD72107

RxD

TxC

RxC

BOUT1

SIFCLAP-B

BCLK

22

Page 23

µ

PD72107 System Configuration Example (Local Memory Type)

Local memory 64 Kbytes

Host processor PD72107

RD WR CS UBE A0-A15 D0-D15

µ

4. SYSTEM CONFIGURATION EXAMPLES

MEMR

MEMW

IOR

IOW

AB0-AB7

AB8-AB15

AB16-AB19

BHE

DB0-DB15

INT

Local

bus request

WAIT

A B

µ

PD71086

OE

A B

µ

PD71086

OE

A B

µ

PD71086

OE

A B

µ

PD71086

OE

Access

contention

resolution

circuit

Decoder

A0-A15

D0-D15

MRD

MWR

IORD

IOWR

CS

A0-A15

D0-D7

A16D8-A23D15

UBE

AEN

INT

HLDRQ

HLDAK

µ

PD72107

23

Page 24

24

µ

PD72107 System Configuration Example (Main Memory Sharing Type)

Host processor PD72107

INTP

µ

PD70116

AD8-AD15

INT

INTAK

RD

WR

HLDRQ

HLDAK

ASTB

A16-A19

AD0-AD7

UBE

BUF R/W

BUFEN

INT

INTAK

PD71059

µ

RD WR D0-D7

STB OE

µ

PD71082×3

CS

A0

A16-A19

Decoder

A0-A15

D8-D15

OE STB

µ

PD71082

µ

INT

IORD

IOWR

CS

MRD

MWR

HLDRQ

HLDAK

AEN

ASTB

D0-D7

A16D8-A23D15

A0-A15

UBE

µ

PD71086×2

TOE

D0-D7

RD WR CS UBE

Memory

D0-D7 D8-D15

µ

PD72107

Page 25

I

J

G

H

F

D

N

M

CB

M

R

64 33

321

K

L

NOTES

1. Controlling dimension millimeter.

P64C-70-750A,C-3

ITEM MILLIMETERS INCHES

B

C

D

F

G

H

J

K

1.778 (T.P.)

3.2±0.3

0.51 MIN.

1.78 MAX.

L

M

0.17

0.25

19.05 (T.P.)

5.08 MAX.

17.0±0.2

N

0 to 15°

0.50±0.10

0.9 MIN.

R

0.070 MAX.

0.020

0.035 MIN.

0.126±0.012

0.020 MIN.

0.200 MAX.

0.750 (T.P.)

0.669

0.010

0.007

0 to 15°

+0.004

–0.003

0.070 (T.P.)

+0.10

–0.05

+0.004

–0.005

64 PIN PLASTIC SHRINK DIP (750 mil)

2. Each lead centerline is located within 0.17 mm (0.007 inch) of

its true position (T.P.) at maximum material condition.

3. Item "K" to center of leads when formed parallel.

A 58.0 2.283

+0.028

–0.008

+0.68

–0.20

I 4.05 0.159

+0.011

–0.008

+0.26

–0.20

A

+0.009

–0.008

5. PACKAGE DRAWINGS

µ

PD72107

25

Page 26

80 PIN PLASTIC QFP (14x14)

µ

PD72107

A

B

61

60

41

40

CD

80

1

20

21

F

G

M

H

I

P

J

K

N

L

NOTE

Each lead centerline is located within 0.13 mm (0.005 inch) of

its true position (T.P.) at maximum material condition.

detail of lead end

S

Q

R

M

ITEM MILLIMETERS INCHES

A 17.2±0.4 0.677±0.016

B 14.0±0.2 0.551

C 14.0±0.2 0.551

D 17.2±0.4 0.677±0.016

F 0.825 0.032

G 0.825 0.032

H 0.30±0.10 0.012

I 0.13 0.005

J 0.65 (T.P.) 0.026 (T.P.)

K 1.6±0.2 0.063±0.008

L 0.8±0.2 0.031

M 0.15 0.006

N 0.10 0.004

P

Q 0.1±0.1 0.004±0.004

R5°±5° 5°±5°

S 3.0 MAX. 0.119 MAX.

+0.10

–0.05

2.7±0.1 0.106

+0.009

–0.008

+0.009

–0.008

+0.004

–0.005

+0.009

–0.008

+0.004

–0.003

+0.005

–0.004

S80GC-65-3B9-5

26

Page 27

68 PIN PLASTIC QFJ (950 x 950 mil)

A

B

68

1

CD

µ

PD72107

G

H

J

F

S

K

M

M

N

P

I

NOTES

1. Controlling dimension millimeter.

2. Each lead centerline is located within 0.12 mm of

its true position (T.P.) at maximum material condition.

E

Q

U

T

S

ITEM MILLIMETERS INCHES

A 25.2±0.2 0.992±0.008

B 24.20±0.1 0.953

C 24.20±0.1 0.953

D 25.2±0.2 0.992±0.008

E 1.94±0.15 0.076

F 0.6 0.024

G 4.4±0.2 0.173

H 2.8±0.2 0.110

I 0.9 MIN. 0.035 MIN.

J 3.4±0.1 0.134

K 1.27 (T.P.) 0.050 (T.P.)

M 0.42±0.08 0.017

N 0.12 0.005

P 23.12±0.2 0.910

Q 0.15 0.006

T R 0.8 R 0.031

U 0.22 0.009

+0.08

−0.07

+0.004

−0.005

+0.004

−0.005

+0.007

−0.006

+0.009

−0.008

+0.009

−0.008

+0.004

−0.005

+0.003

−0.004

+0.009

−0.008

+0.003

−0.004

P68L-50A1-3

27

Page 28

µ

PD72107

6. RECOMMENDED SOLDERING CONDITIONS

The µPD72107 should be soldered and mounted under the following recommended conditions.

For the details of the recommended soldering conditions, refer to the document Semiconductor Device

Mounting Technology Manual (C10535E).

For soldering methods and conditions other than those recommended below, contact your NEC sales representative.

Surface mounting type

µ

PD72107GC-3B9: 80-pin plastic QFP (14 × 14 mm)

•

Soldering Method Soldering Conditions Recommended Condition Symbol

Infrared reflow Package peak temperature: 235°C, Time: 30 sec. Max. IR35-00-3

(at 210°C or higher), Count: three times or less

VPS Package peak temperature: 215 °C, Time: 40 sec. Max. VP15-00-3

(at 200°C or higher), Count: three times or less

Wave soldering Solder bath temperature: 260°C, Time: 10 sec. Max., WS60-00-1

Count: one time, Preheating temperature: 120°C Max.

(package surface temperature)

Partial heating Pin temperature: 300°C Max., Duration: 3 sec. Max. (per pin row) –

Caution Do not use different soldering methods together (except for partial heating).

•

µ

PD72107L: 68-pin plastic QFJ (950 × 950 mils)

Soldering Method Soldering Conditions Recommended Condition Symbol

VPS Package peak temperature: 215 °C, Time: 40 sec. Max. VP15-00-1

(at 200°C or higher), Count: one time

Partial heating Pin temperature: 300°C Max., Duration: 3 sec. Max. (per pin row) –

Insertion type

•

µ

PD72107CW: 64-pin plastic shrink DIP (750 mils)

Soldering Method Soldering Conditions

Wave soldering (pin only) Solder bath temperature: 260°C Max., Time: 10 sec. Max.

Partial heating Pin temperature: 300°C Max., Duration: 3 sec. Max. (per a pin)

Caution Wave soldering must be applied only to pins. Be sure to avoid jet soldering the package body.

28

Page 29

[MEMO]

µ

PD72107

29

Page 30

[MEMO]

µ

PD72107

30

Page 31

µ

NOTES FOR CMOS DEVICES

1 PRECAUTION AGAINST ESD FOR SEMICONDUCTORS

Note: Strong electric field, when exposed to a MOS device, can cause destruction

of the gate oxide and ultimately degrade the device operation. Steps must

be taken to stop generation of static electricity as much as possible, and

quickly dissipate it once, when it has occurred. Environmental control must

be adequate. When it is dry, humidifier should be used. It is recommended

to avoid using insulators that easily build static electricity. Semiconductor

devices must be stored and transported in an anti-static container, static

shielding bag or conductive material. All test and measurement tools

including work bench and floor should be grounded. The operator should

be grounded using wrist strap. Semiconductor devices must not be touched

with bare hands. Similar precautions need to be taken for PW boards with

semiconductor devices on it.

PD72107

2 HANDLING OF UNUSED INPUT PINS FOR CMOS

Note: No connection for CMOS device inputs can be cause of malfunction. If no

connection is provided to the input pins, it is possible that an internal input

level may be generated due to noise, etc., hence causing malfunction. CMOS

device behave differently than Bipolar or NMOS devices. Input levels of

CMOS devices must be fixed high or low by using a pull-up or pull-down

circuitry. Each unused pin should be connected to VDD or GND with a

resistor, if it is considered to have a possibility of being an output pin. All

handling related to the unused pins must be judged device by device and

related specifications governing the devices.

3 STATUS BEFORE INITIALIZATION OF MOS DEVICES

Note: Power-on does not necessarily define initial status of MOS device. Produc-

tion process of MOS does not define the initial operation status of the device.

Immediately after the power source is turned ON, the devices with reset

function have not yet been initialized. Hence, power-on does not guarantee

out-pin levels, I/O settings or contents of registers. Device is not initialized

until the reset signal is received. Reset operation must be executed immediately after power-on for devices having reset function.

31

Page 32

µ

PD72107

The export of this product from Japan is prohibited without governmental license. To export or re-export this product from

a country other than Japan may also be prohibited without a license from that country. Please call an NEC sales

representative.

No part of this document may be copied or reproduced in any form or by any means without the prior written

consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which may appear in

this document.

NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual property

rights of third parties by or arising from use of a device described herein or any other liability arising from use

of such device. No license, either express, implied or otherwise, is granted under any patents, copyrights or other

intellectual property rights of NEC Corporation or others.

While NEC Corporation has been making continuous effort to enhance the reliability of its semiconductor devices,

the possibility of defects cannot be eliminated entirely. To minimize risks of damage or injury to persons or

property arising from a defect in an NEC semiconductor device, customers must incorporate sufficient safety

measures in its design, such as redundancy, fire-containment, and anti-failure features.

NEC devices are classified into the following three quality grades:

"Standard", "Special", and "Specific". The Specific quality grade applies only to devices developed based on a

customer designated "quality assurance program" for a specific application. The recommended applications of

a device depend on its quality grade, as indicated below. Customers must check the quality grade of each device

before using it in a particular application.

Standard: Computers, office equipment, communications equipment, test and measurement equipment,

audio and visual equipment, home electronic appliances, machine tools, personal electronic

equipment and industrial robots

Special: Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support)

Specific: Aircrafts, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems or medical equipment for life support, etc.

The quality grade of NEC devices is "Standard" unless otherwise specified in NEC's Data Sheets or Data Books.

If customers intend to use NEC devices for applications other than those specified for Standard quality grade,

they should contact an NEC sales representative in advance.

Anti-radioactive design is not implemented in this product.

M4 96.5

2

Loading...

Loading...