Page 1

DATA SHEET

BIPOLAR DIGITAL INTEGRATED CIRCUIT

µµµµ

PB1508GV

3 GHz INPUT DIVIDE BY 2 PRESCALER IC

FOR DBS TUNERS

PB1508GV is a 3.0 GHz input divide by 2 prescaler IC for DBS tuner applications. µPB1508GV can make

µ

VHF/UHF band PLL frequency synthesizer apply to DBS/ECS tuners. µPB1508GV is a shrink package version of

PB584G so that this small package contributes to reduce the mounting space.

µ

PB1508GV is manufactured using NEC’s high fT NESAT™ IV silicon bipolar process. This process uses silicon

µ

nitride passivation film and gold electrodes. These materials can protect chip surface from external pollution and

prevent corrosion/migration. Thus, this IC has excellent performance, uniformity and reliability.

FEATURES

• High toggle frequency : fin = 0.5 GHz to 3.0 GHz

• High-density surface mounting : 8 pin plastic SSOP (175 mil)

• Low current consumption : 5 V, 12 mA

• Fixed division :÷2

APPLICATION

• Prescaler between local oscillator and PLL frequency synthesizer included modulus prescaler

• DBS tuners with kit use of VHF/UHF band PLL frequency synthesizer

ORDERING INFORMATION

PART NUMBER PACKAGE MARKING SUPPLYING FORM

µ

PB1508GV-E1 8 pin plastic SSOP

(175 mil)

Remarks

To order evaluation samples, please contact your local NEC sales office.

(Part number for sample order:

µ

1508 Embossed tape 8 mm wide. Pin 1 is in tape pull-out

direction. 1 000 p/reel.

PB1508GV)

Document No. P10768EJ2V0DS00 (2nd edition)

Date Published September 1997 N

Printed in Japan

Caution: Electro-static sensitive devices

1996©

Page 2

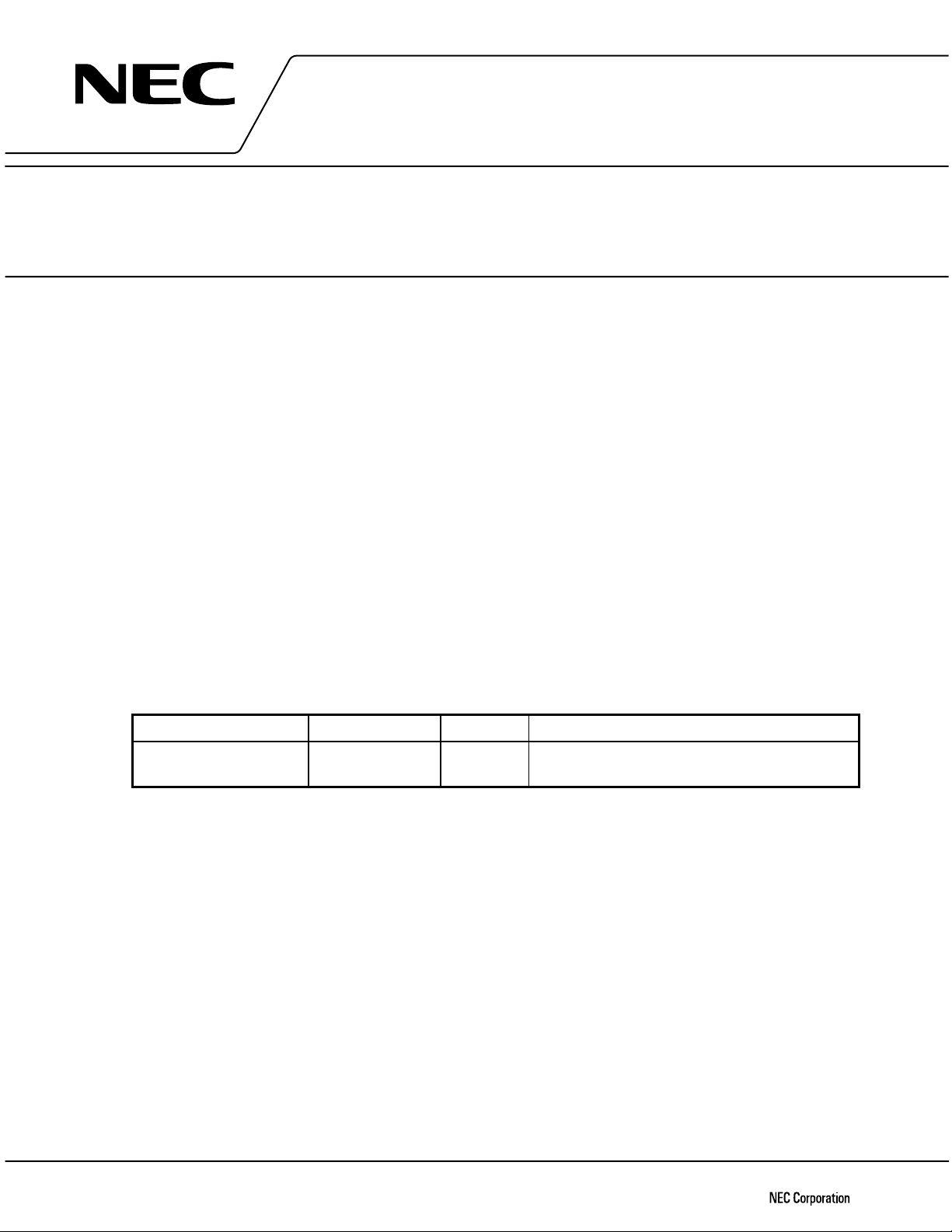

PIN CONNECTION (Top View)

1

2

3

4

PRODUCT LINE-UP

Product No. ICC (mA) fin (GHz) VCC (V) Package Pin Connection

PB581A 30 0.5 to 2.8 4.5 to 5.5 8 pins CAN –

µ

PB581C 30 0.5 to 2.2 4.5 to 5.5 8 pins DIP (300 mil) NEC Original

µ

PB584G 18 0.5 to 2.5 4.5 to 5.5 8 pins SOP (225 mil) NEC Original

µ

PB1508GV 12 0.5 to 3.0 4.5 to 5.5 8 pins SSOP (175 mil)

µ

8

7

6

5

µµµµ

PB1508GV

Pin No. Pin name

1V

2IN

3IN

4 GND

5 GND

6NC

7 OUT

8NC

CC

Remarks

This table shows the TYP values of main parameters. Please refer to ELECTRICAL

CHARACTERISTICS.

PB581A, µPB581C and µPB584G are discontinued.

µ

INTERNAL BLOCK DIAGRAM

IN

IN

SYSTEM APPLICATION EXAMPLE

RF unit block of DBS tuners

1stIF input

from DBS converter

BPF

D

CLK

CLK

OSC

MIX

Q

Q

AMP

SAW AGC amp. FM demo.

PB1508GV

µ

÷ 2

Prescaler

OUT

Baseband output

PLLsynth.

for VHF/UHF

band

LPF

2

Page 3

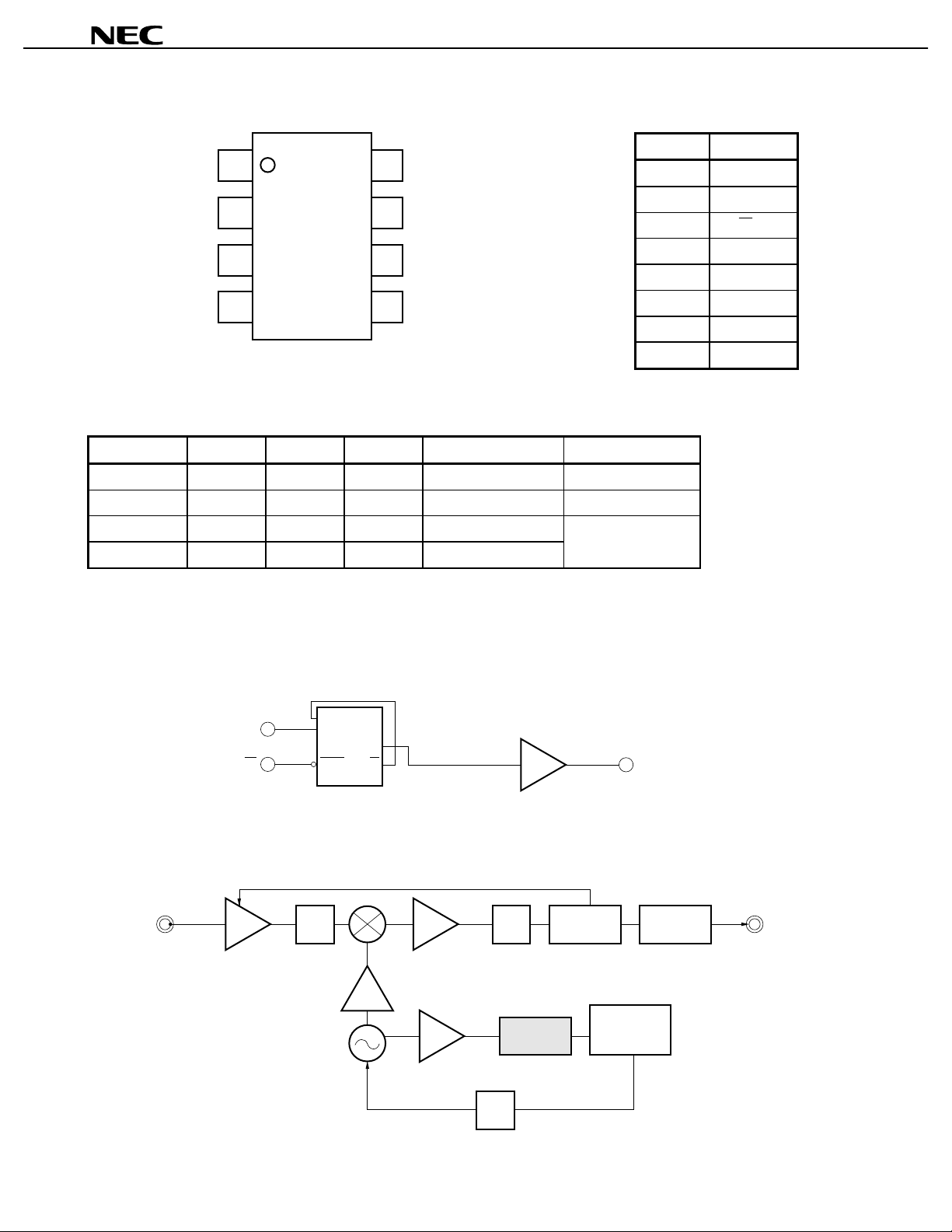

PIN EXPLANATION

Pin No. Symbol Applied voltage PIN voltage Functions and explanation

µµµµ

PB1508GV

1VCC4.5 to 5.5

2IN

3IN

4, 5 GND 0

6, 8 NC

7 OUT

1.7 to 4.95 Signal input pin. This pin should be coupled to signal

1.7 to 4.95 Signal input bypass pin. This pin must be equipped with

1.0 to 4.7 Divided frequency output pin. This pin is designed as

Power supply pin. This pin must be equipped with bypass

capacitor (eg 1 000 pF) to minimize ground impedance.

source with capacitor (eg 1 000 pF) for DC cut.

bypass capacitor (eg 1 000 pF) to minimize ground

impedance.

Ground pin. Ground pattern on the board should be

formed as wide as possible to minimize ground

impedance.

Non connection pins. These pins should be opened.

emitter follower output. This pin can be connected to

input of prescaler within PLL synthesizer through DC cut

capacitor.

3

Page 4

ABSOLUTE MAXIMUM RATINGS

PARAMETER SYMBOL CONDITION RATINGS UNIT

µµµµ

PB1508GV

Supply voltage V

Input voltage V

Total power dissipation P

CC

in

D

TA = +25 °C 6.0 V

TA = +25 °C 6.0 V

Mounted on double sided copper clad

50 × 50 × 1.6 mm epoxy glass PWB (T

Operating ambient temperature T

Storage temperature T

A

stg

RECOMMENDED OPERATING CONDITIONS

PARAMETER SYMBOL MIN. TYP. MAX. UNIT REMARKS

Supply voltage V

Operating ambient temperature T

ELECTRICAL CHARACTERISTICS (TA =

PARAMETER SYMBOL TEST CONDITION MIN. TYP. MAX. UNIT

Circuit current I

Upper limit operating frequency 1 f

Upper limit operating frequency 2 f

Lower limit operating frequency f

Input power 1 P

Input power 2 P

Output power P

CC

A

CC

in(U)1

in(U)2

in(L)

4.5 5.0 5.5 V

−

40 to +85

−−−−

in1

in2

out

250 mW

A

= +85 °C)

40 to +85

−

55 to +150

−

40 +25 +85

C, VCC = 4.5 to 5.5 V, ZS = ZL = 50

°°°°

C

°

)

ΩΩΩΩ

No signals 7.6 12 14.5 mA

Pin = −10 to +6 dBm 3.0

Pin = −15 to +6 dBm 2.7

Pin = −15 to +6 dBm

fin = 2.7 to 3.0 GHz

fin = 0.5 to 2.7 GHz

Pin = 0 dBm, fin = 2 GHz

10

−

15

−

12

−

0.5 GHz

−

7

+6 dBm

+6 dBm

GHz

GHz

dBm

C

°

C

°

4

Page 5

TYPICAL CHARACTERISTICS (unless otherwise specified TA = +25°C)

CIRCUIT CURRENT vs. SUPPLY VOLTAGE

15

No signals

TA = +85 ˚C

10

µµµµ

PB1508GV

TA = +25 ˚C

5

- Circuit Current - mA

CC

I

0

0123

V

CC

- Supply Voltage - V

INPUT POWER vs. INPUT FREQUENCY

+20

TA = +25 ˚C

+10

VCC = 4.5 to 5.5 V

0

–10

–20

- Input Power - dBm

–30

in

P

VCC = 4.5 to 5.5 V

–40

–50

TA = –40 ˚C

456

Guaranteed

Operating

Window

INPUT POWER vs. INPUT FREQUENCY

+20

VCC = 4.5 to 5.5 V

+10

TA = –40 ˚C

TA = +85 ˚C

0

–10

TA = +85 ˚C

–20

- Input Power - dBm

–30

in

P

–40

–50

TA = +25 ˚C

Guaranteed

Operating

Window

TA = +25 ˚C

TA = –40 ˚C

–60

100 1000 4000

in

- Input Frequency - MHz

f

–60

100 1000 4000

in

-Input Frequency - MHz

f

OUTPUT POWER vs. INPUT FREQUENCY OUTPUT POWER vs. INPUT FREQUENCY

0

VCC = 5.0 V

P

–2

Z

–4

–6

–8

in

= 0 dBm

L

= 50 Ω

TA = +85 ˚C

TA = +25 ˚C

TA = –40 ˚C

TA = –40 ˚C

0

TA = +25 ˚C

P

–2

Z

–4

–6

–8

in

= 0 dBm

L

= 50 Ω

VCC = 5.5 V

VCC = 5.0 V

VCC = 4.5 V

TA = +85 ˚C

–10

- Output Power - dBm

out

–12

P

TA = +25 ˚C

–14

–16

100 1000 4000

f

in

- Input Frequency - MHz fin -Input Frequency - MHz

–10

- Output Power - dBm

out

–12

P

–14

–16

100 1000 4000

5

Page 6

µµµµ

PB1508GV

OUTPUT POWER vs. INPUT FREQUENCY

0

TA = –40 ˚C

P

in

= 0 dBm

–2

Z

L

= 50 Ω

–4

–6

–8

–10

- Output Power - dBm

out

P

–12

–14

–16

100 1000 4000

in

- Input Frequency - MHz

f

S11 vs. INPUT FREQUENCY

VCC = 5.0 V

S

11

REF 1.0 Units

200.0 mUnits/

4

34.604 Ω –26.496 Ω

hp

C

MARKER 4

3.0 GHz

D

Z

START 0.500000000 GHz

STOP 3.000000000 GHz

VCC = 5.0 V

4

3

VCC = 5.5 V

VCC = 4.5 V

2

OUTPUT POWER vs. INPUT FREQUENCY

0

TA = +85 ˚C

P

in

= 0 dBm

–2

Z

L

= 50 Ω

–4

–6

VCC = 5.0 V

VCC = 5.5 V

–8

VCC = 4.5 V

–10

- Output Power - dBm

out

P

–12

–14

–16

100 1000 4000

f

in

- Input Frequency - MHz

FREQUENCY S

11

MHz MAG ANG

500.0000 .850 –30.2

600.0000 .796 –37.8

700.0000 .790 –39.2

800.0000 .754 –45.2

900.0000 .766 –53.7

1000.0000 .701 –57.6

1100.0000 .660 –62.3

: 500 MHz

1

: 1000 MHz

2

: 2000 MHz

3

: 3000 MHz

4

1

1200.0000 .606 –67.2

1300.0000 .571 –70.3

1400.0000 .521 –70.6

1500.0000 .495 –68.3

1600.0000 .441 –60.6

1700.0000 .479 –45.1

1800.0000 .602 –62.3

1900.0000 .595 –74.2

2000.0000 .608 –82.9

2100.0000 .603 –89.8

2200.0000 .599 –97.3

2300.0000 .588 –107.7

2400.0000 .532 –122.0

2500.0000 .396 –132.0

2600.0000 .325 –127.1

2700.0000 .270 –123.6

2800.0000 .232 –122.7

2900.0000 .258 –105.8

3000.0000 .351 –103.7

6

Page 7

S22 vs. OUTPUT FREQUENCY

VCC = 5.0 V, fin = 498 MHz

S22 Z

REF 1.0 Units

200.0 mUnits/

4

87.789 Ω –13.633 Ω

hp

C

MARKER 4

1.5 GHz

D

1

2

START 0.250000000 GHz

STOP 1.500000000 GHz

µµµµ

PB1508GV

FREQUENCY S

22

MHz MAG ANG

250.0000 .526 118.9

300.0000 .463 131.2

350.0000 .466 124.7

400.0000 .460 117.1

450.0000 .441 110.2

500.0000 .456 103.0

550.0000 .353 94.8

: 250 MHz

3

4

1

: 500 MHz

2

: 1000 MHz

3

: 1500 MHz

4

600.0000 .438 91.1

650.0000 .444 83.9

700.0000 .436 78.3

750.0000 .435 71.8

800.0000 .431 65.9

850.0000 .431 60.3

900.0000 .431 53.7

950.0000 .408 49.2

1000.0000 .445 44.9

1050.0000 .428 41.0

1100.0000 .429 33.7

1150.0000 .355 42.7

1200.0000 .418 20.0

1250.0000 .403 17.1

1300.0000 .392 9.6

1350.0000 .368 3.3

1400.0000 .343 –3.4

1450.0000 .319 –9.2

1500.0000 .289 –14.1

S22 vs. OUTPUT FREQUENCY

VCC = 5.0 V, fin = 3002 MHz

S22 Z

REF 1.0 Units

200.0 mUnits/

4

91.109 Ω 2.6523 Ω

hp

C

MARKER 4

1.5 GHz

D

2

1

START 0.250000000 GHz

STOP 1.500000000 GHz

FREQUENCY S

22

MHz MAG ANG

250.0000 .555 146.6

300.0000 .545 139.9

350.0000 .571 136.1

400.0000 .529 127.9

450.0000 .521 122.4

500.0000 .515 116.9

550.0000 .510 104.5

3

4

: 250 MHz

1

: 500 MHz

2

: 1000 MHz

3

: 1500 MHz

4

600.0000 .492 106.6

650.0000 .487 100.9

700.0000 .482 95.3

750.0000 .473 89.9

800.0000 .461 83.8

850.0000 .454 78.4

900.0000 .449 72.3

950.0000 .430 69.6

1000.0000 .443 64.3

1050.0000 .444 58.8

1100.0000 .440 52.3

1150.0000 .438 46.0

1200.0000 .501 37.5

1250.0000 .408 32.9

1300.0000 .388 25.1

1350.0000 .359 16.3

1400.0000 .335 9.7

1450.0000 .304 3.1

1500.0000 .285 4.6

7

Page 8

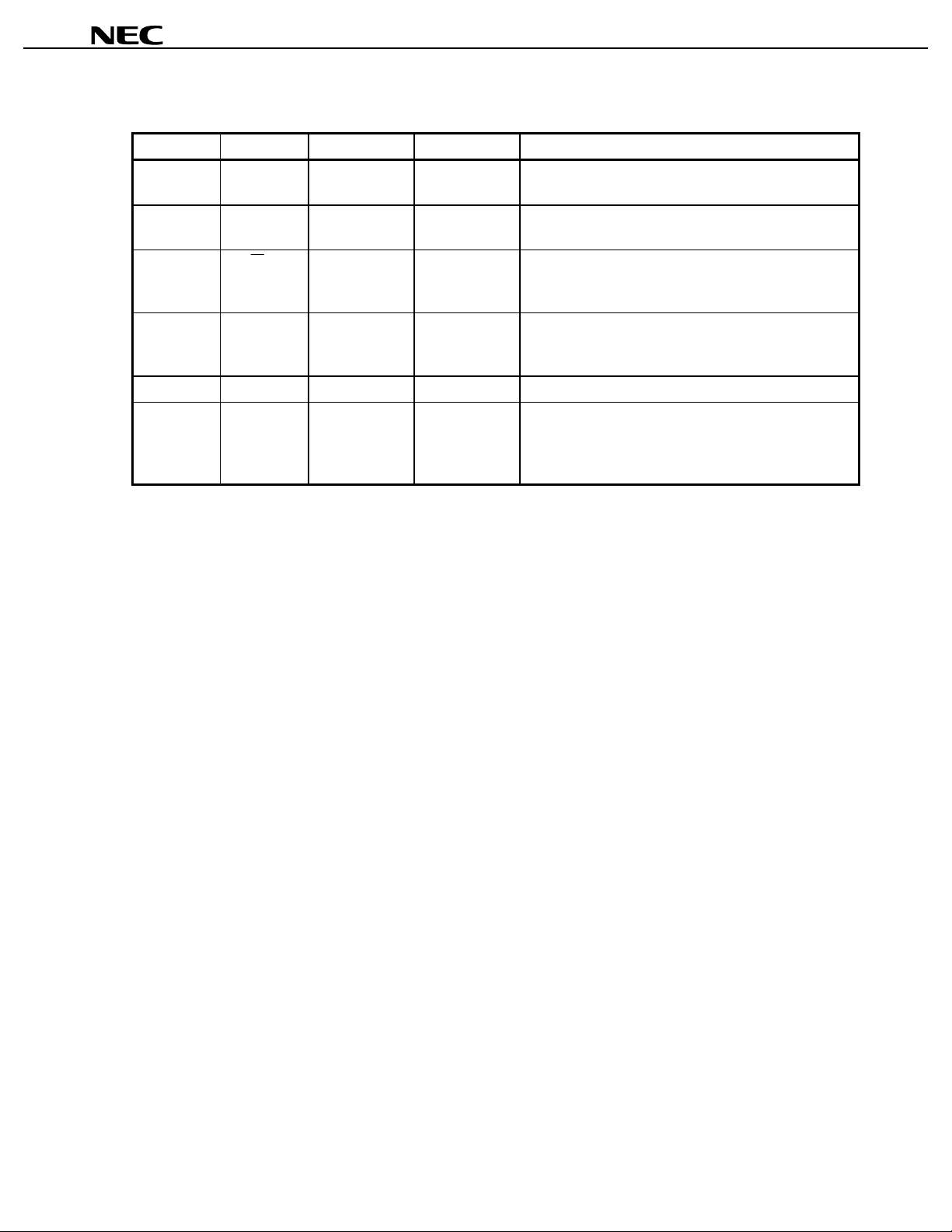

TEST CIRCUIT

Power Supply

µµµµ

PB1508GV

Signal Generator

50 Ω

HP8665A

1000 pF

1000 pF

C1

1000 pF

1000 pF

C2

C3

5 V±0.5 V

1

2

3

4

8

OPEN

1000 pF

7

C4

OPEN

6

5

Counter HP5350B

(Spectrum Analyzer)

50 Ω

8

Page 9

ILLUSTRATION OF THE TEST CIRCUIT ASSEMBLED ON EVALUATION BOARD

,,,,

,,

,

1P

VCC

µµµµ

PB1508GV

IN OUT

COMPONENT LIST

SYMBOL VALUE

C1 to C4 1000 pF

IN

C2 C4

C1

C3

PB1506/08/09GV

µ

EVALUATION BOARD CHARACTERS

(1) 35

(2) Back side: GND pattern

(3) Solder plated patterns

(4)

(5)

(6)

m thick double-sided copper clad 50 × 50 × 0.4 mm

µ

polyimide board

: Through holes

°

of pin 3 : partern should be removed.

of pin 5 : short chip must be attached to be grounded.

OUT

The application circuits and their parameters are for reference only and are not intended for use in actual design-ins.

9

Page 10

PACKAGE DIMENSIONS

8 pin PLASTIC SSOP (175 mil) (unit : mm)

85

14

+7°

3°

4.94±0.2

µµµµ

PB1508GV

–3°

1.8 MAX.

0.1±0.1

1.5±0.1

0.575 MAX.

3.0 MAX.

0.65

0.3

+0.10

–0.05

+0.10

0.10

–0.05

0.15

0.5±0.2

M

3.2±0.1

0.87±0.2

0.15

10

Page 11

µµµµ

PB1508GV

NOTE CORRECT USE

(1) Observe precautions for handling because of electro-static sensitive devices.

(2) Form a ground pattern as wide as possible to minimize ground impedance (to prevent undesired operation).

(3) Keep the wiring length of the ground pins as short as possible.

(4) Connect a bypass capacitor (e.g. 1 000 pF) to the V

CC

pin.

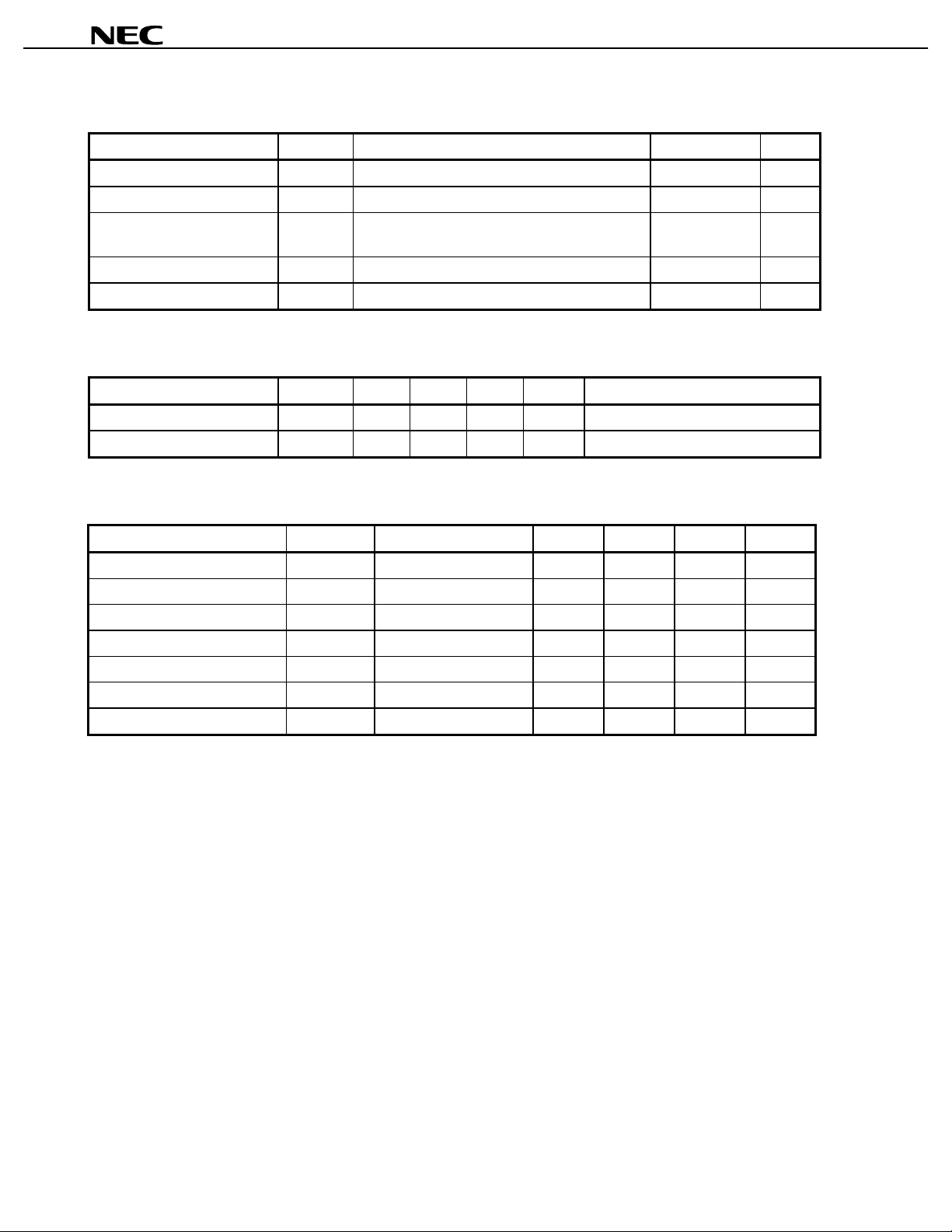

RECOMMENDED SOLDERING CONDITIONS

This product should be soldered in the following recommended conditions. Other soldering methods and

conditions than the recommended conditions are to be consulted with our sales representatives.

PB1508GV

µµµµ

Soldering method Soldering conditions Recommended condition symbol

Infrared ray reflow Package peak temperature: 235 °C,

Hour: within 30 s. (more than 210 °C),

Time: 3 times, Limited days: no.*

VPS Package peak temperature: 215 °C,

Hour: within 40 s. (more than 200 °C),

Time: 3 times, Limited days: no.*

Wave soldering Soldering tub temperature: less than 260 °C,

Hour: within 10 s.,

Time: 1 time, Limited days: no.

Pin part heating Pin area temperature: less than 300 °C,

Hour: within 3 s./pin,

Limited days: no.*

It is the storage days after opening a dry pack, the storage conditions are 25 °C, less than 65 % RH.

*

IR35-00-3

VP15-00-3

WS60-00-1

Caution The combined use of soldering method is to be avoided (However, except the pin area heating

method).

For details of recommended soldering conditions for surface mounting, refer to information document

SEMICONDUCTOR DEVICE MOUNTING TECHNOLOGY MANUAL (C10535E).

11

Page 12

µµµµ

PB1508GV

ATTENTION

OBSERVE PRECAUTIONS

FOR HANDLING

ELECTROSTATIC

SENSITIVE

DEVICES

No part of this document may be copied or reproduced in any form or by any means without the prior written

consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which may appear in this

document.

NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual

property rights of third parties by or arising from use of a device described herein or any other liability arising

from use of such device. No license, either express, implied or otherwise, is granted under any patents,

copyrights or other intellectual property rights of NEC Corporation or others.

While NEC Corporation has been making continuous effort to enhance the reliability of its semiconductor devices,

the possibility of defects cannot be eliminated entirely. To minimize risks of damage or injury to persons or

property arising from a defect in an NEC semiconductor device, customers must incorporate sufficient safety

measures in its design, such as redundancy, fire-containment, and anti-failure features.

NEC devices are classified into the following three quality grades:

"Standard", "Special", and "Specific". The Specific quality grade applies only to devices developed based on

a customer designated "quality assurance program" for a specific application. The recommended applications

of a device depend on its quality grade, as indicated below. Customers must check the quality grade of each

device before using it in a particular application.

Standard: Computers, office equipment, communications equipment, test and measurement equipment,

audio and visual equipment, home electronic appliances, machine tools, personal electronic

equipment and industrial robots

Special: Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support)

Specific: Aircrafts, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems or medical equipment for life support, etc.

The quality grade of NEC devices is "Standard" unless otherwise specified in NEC's Data Sheets or Data Books.

If customers intend to use NEC devices for applications other than those specified for Standard quality grade,

they should contact an NEC sales representative in advance.

Anti-radioactive design is not implemented in this product.

M4 96. 5

Loading...

Loading...