Page 1

5140

PROTECTED POWERHALL

®

SENSOR:

LAMP/SOLENOID DRIVER

5140

Data Sheet

27695*

X

V

CC

1

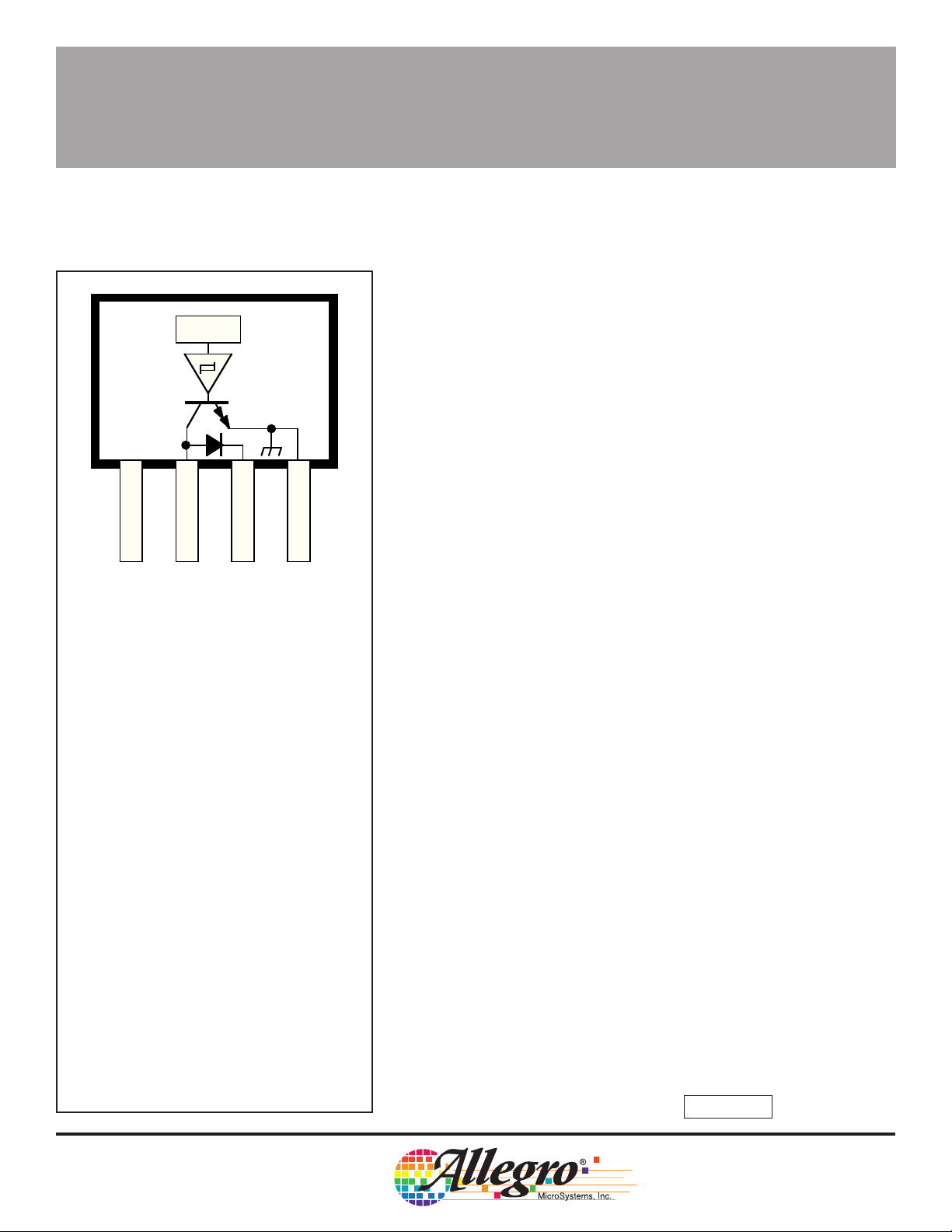

Pinning is shown viewed from branded side.

234

SUPPLY

OUTPUT

DIODE

GROUND

Dwg. PH-001

ABSOLUTE MAXIMUM RATINGS

at T

= +25°C

A

PROTECTED POWERHALL

®

SENSOR

— LAMP/SOLENOID DRIVER

The UGQ5140K unipolar Hall effect switch is a monolithic

integrated circuit designed for magnetic actuation of low-power

incandescent lamps or inductive loads such as relays or solenoids.

Included on chip is a Darlington power output that is capable of continuously sinking in excess of 300 mA. Internal protection circuitry

limits surge (lamp turn-ON) or fault currents to approximately 900 mA.

A sensitive magnetic threshold allows the device to be used in conjunction with inexpensive magnets or in applications that require

relatively large operating distances.

Each sensor/driver includes a magnetic sensing Hall voltage

generator, operational amplifier, Schmitt trigger, voltage regulator, and

an open-collector, high-gain Darlington power output stage. The

regulator allows use of the device with supply voltages of 4.5 V to

28 V. On-chip compensation circuitry stabilizes switch-point performance over temperature. The magnetic operation of this device is

similar to that of the A3141E— Hall-effect switch.

The sensitive magnetic switch point coupled with the power output,

current limiting, and thermal limiting circuitry allow the UGQ5140K to

magnetically actuate various loads without requiring any external

components.

The UGQ5140K is rated for operation over an extended temperature range of -40°C to +85°C. It is supplied in a four-pin mini-SIP

plastic package, 0.200" (5.08 mm) wide, 0.130" (3.30 mm) high, and

0.060" (1.54 mm) thick.

Supply Voltage, VCC . . . . . . . . . . . . . . 28 V

Reverse Battery Voltage, V

Output OFF Voltage, V

Over-Current Protected Output Voltage,

V

. . . . . . . . . . . . . . . . . . . . . . . . 25 V

OUT

Output ON Current, I

Magnetic Flux Density, B . . . . . . Unlimited

Package Power Dissipation,

P

.. . . . . . . . . . . . . . . . . . . See Graph

D

Operating Temperature Range,

T

. . . . . . . . . . . . . . . . . -40°C to +85°C

A

Storage Temperature Range,

T

. . . . . . . . . . . . . . . . -65°C to +150°C

S

* Output is current limited at approximately 900

mA and junction temperature limited if current in

excess of 900 mA is attempted. See Circuit

Description and Applications for further

information.

OUT

OUT

. . . . . -45 V

RCC

. . . . . . . . . . 45 V

. . . . . . . 900 mA*

FEATURES

■ Magnetically Actuated Power Switch

■ Temperature-Compensated Switch Points

■ High Current-Sink Capability

300 mA Continuous

900 mA Peak Current Limit

■ Output Short-Circuit Protection

■ Low Quiescent Standby Current

■ Linear Thermal Limiting

■ Automotive Temperature Range

-40°C to +85°C, Operating

■ Internal Inductive Flyback/Clamp Diode Protection

■ Reverse Battery Protection

■ Low-Profile 4-Pin Mini-SIP

Always order by complete part number: UGQ5140K .

Page 2

5140

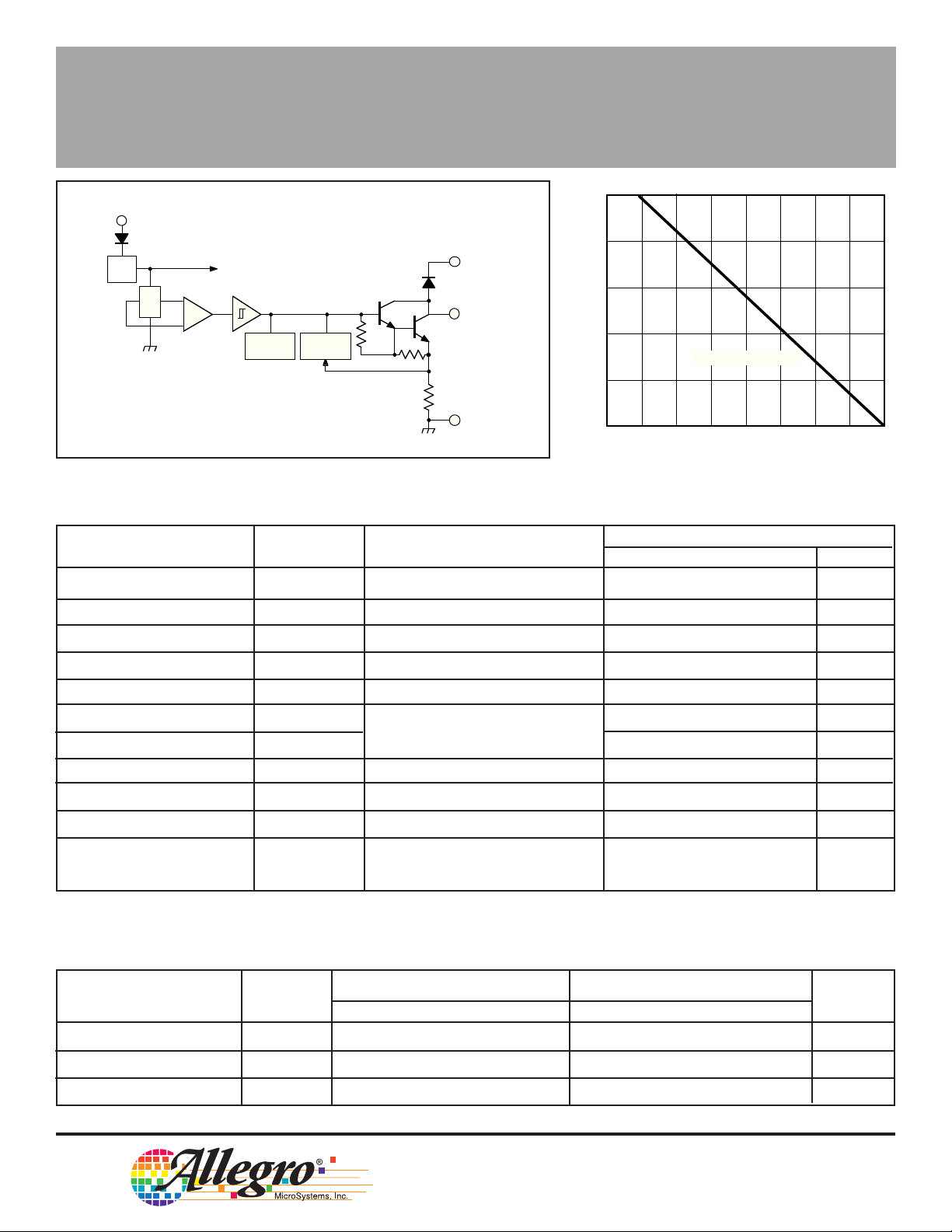

ALLOWABLE PACKAGE POWER DISSIPATION IN WATTS

1

3

2

4

PROTECTED POWERHALL

®

SENSOR:

LAMP/SOLENOID DRIVER

FUNCTIONAL BLOCK DIAGRAM

V

CC

REV. BATTERY

PROTECTION

REG.

X

THERMAL

LIMIT

CURRENT

LIMIT

ELECTRICAL CHARACTERISTICS at T

DIODE

OUTPUT

<<1Ω

GROUND

Dwg. FH-001

= -40°C to +85°C, V

A

1.0

0.8

0.6

0.4

0.2

0

-50

= 4.5 V to 24 V

CC

FREE AIR, R = 177°C/W

θJA

25

0-25

AMBIENT TEMPERATURE IN °C

50 75 100 125 150

(unless otherwise noted).

Limits

Characteristic Symbol Test Conditions Min. Typ. Max. Units

Supply Voltage Range V

Output Leakage Current I

Output Sustaining Voltage V

Output Saturation Voltage V

OUT(SUS)

OUT(SAT)

Over-Current Limit I

Output Rise Time t

Output Fall Time t

Supply Current I

Diode Forward Voltage V

Diode Leakage Current I

Thermal Limit T

CC

OUT

LIMIT

r

f

CC

F

R

LIMIT

Operating 4.5 12 24 V

V

= 24 V — <1.0 10 µA

OUT

I

= 100 mA 35 — — V

OUT

I

= 300 mA, VCC = 24 V — 0.84 1.2 V

OUT

VCC = V

= 12 V, B ≥ 500 G — 900 — mA

OUT

VCC = 12 V, VBB = 18 V, — 0.04 2.0 µs

RL = 1.1 kΩ, CL = 20 pF — 0.04 2.0 µs

Output OFF — 5.5 10 mA

IF = 300 mA — 1.1 1.5 V

VR = 35 V — <1.0 50 µA

VCC = V

I

OUT

= 12 V, B ≥ 500 G,

OUT

= 10 mA — 165 — °C

Dwg. GH-001

Typical Data is at TA = +25°C and is for design information only.

MAGNETIC CHARACTERISTICS at VCC = 4.5 V to 24 V.

Characteristic Symbol Min. Typ. Max. Min. Typ. Max. Units

Magnetic Operate Point B

Magnetic Release point B

Hysteresis B

OP

RP

hys

TA = +25°CT

= -40°C to +85°C

A

70 155 200 45 — 240 G

50 100 180 25 — 220 G

20 55 — 20 — — G

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

W

Copyright © 1991, 1995 Allegro MicroSystems, Inc.

Page 3

5140

PROTECTED POWERHALL

®

SENSOR:

LAMP/SOLENOID DRIVER

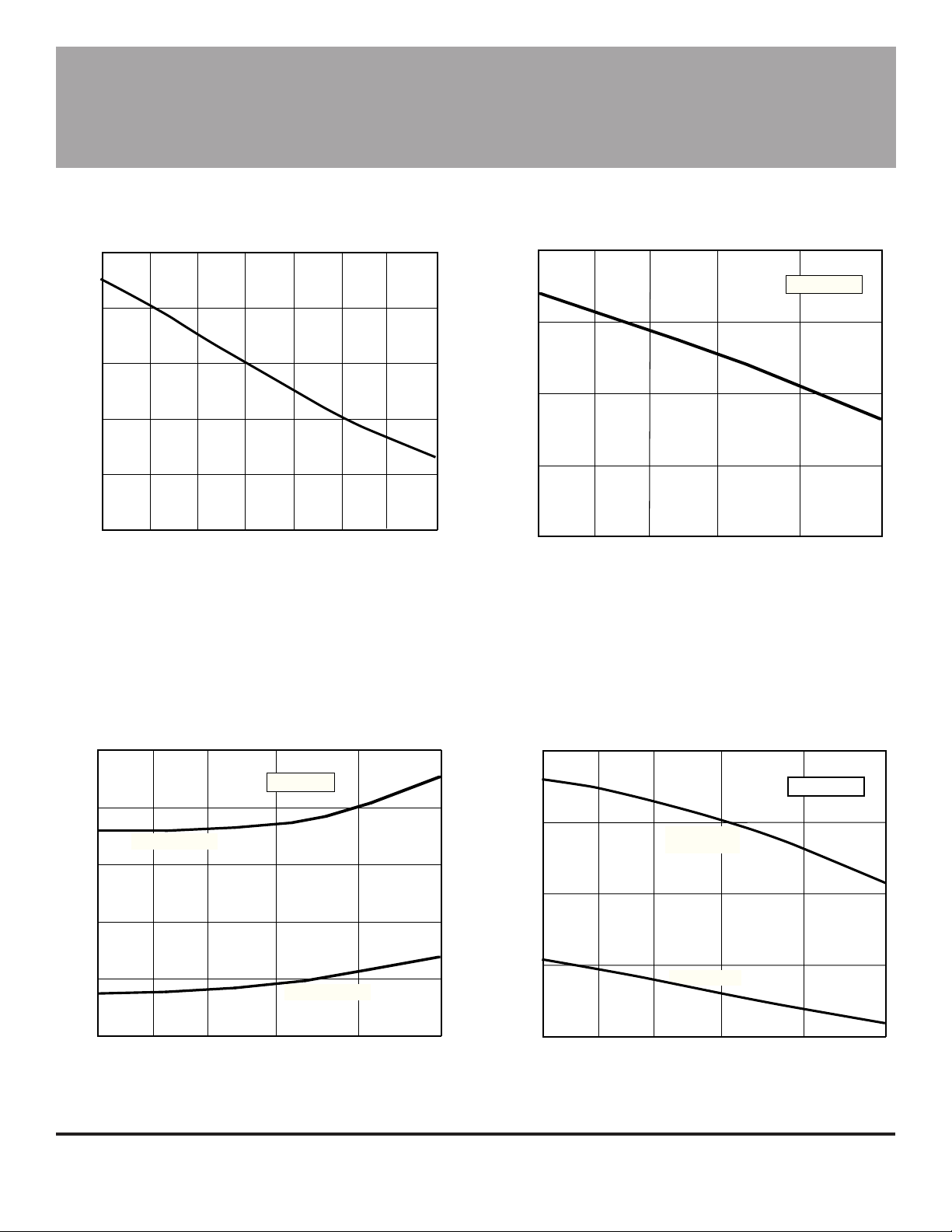

TYPICAL OPERATING CHARACTERISTICS

1000

950

900

850

PEAK CURRENT LIMIT IN mA

800

750

-20-40

0

AMBIENT TEMPERATURE IN °C

25 85 105 125

55

Dwg. GH-004

1.0

0.9

0.8

0.7

SATURATION VOLTAGE IN VOLTS

0.6

-40

-20 0 25 55

AMBIENT TEMPERATURE IN °C

I = 300 mA

OUT

Dwg. GH-002A

85

180

160

OPERATE POINT

140

120

SWITCH POINT IN GAUSS

100

80

-40

-20 0 25 55

AMBIENT TEMPERATURE IN °C

I = 10 mA

OUT

RELEASE POINT

85

Dwg. GH-006A

9.0

8.0

7.0

6.0

SUPPLY CURRENT IN mA

5.0

-40

-20 0 25 55

AMBIENT TEMPERATURE IN °C

OUTPUT ON

I = 10 mA

OUT

OUTPUT OFF

V = 12 V

CC

85

Dwg. GH-003A

Page 4

5140

PROTECTED POWERHALL

®

SENSOR:

LAMP/SOLENOID DRIVER

TYPICAL TRANSFER CHARACTERISTICS

at T

= +25°C

A

15

12

9.0

6.0

3.0

OUTPUT VOLTAGE IN VOLTS

V

B B

I = 300 mA

OUT

B

RP

V

0

MAGNETIC FLUX DENSITY IN GAUSS

75

50250

OUT(SAT)

100 125 150 175 200

B

OP

Dwg. GH-007

CIRCUIT DESCRIPTION AND OP-

ERATION

The UGQ5140K merges state-of-the-art

Hall effect sensing and power driving technologies to allow precision non-contact

actuation of incandescent lamps or inductive

loads. It is rated for operation over an

extended temperature range as typically

required in automotive applications.

MAGNETIC OPERATION

As shown in the Transfer Characteristics

graph, the output of the device (pin 2)

switches low when the magnetic field at the

Hall sensor exceeds the operate point

threshold (BOP). At this point, the output

voltage is V

OUT(SAT)

is reduced to below the release point threshold (BRP), the device output goes high. The

difference in the magnetic operate and

release points is called the hysteresis (BH) of

the part. This built-in hysteresis allows clean

switching of the output even in the presence

of external mechanical vibration and electrical noise.

. When the magnetic field

CURRENT AND THERMAL

LIMITING

Output short circuits may be caused by

faulty connectors, crimped wiring harnesses,

or blown loads. In such cases, current and

thermal limit circuitry will protect the output

transistor against destruction.

Current through the output transistor is

sensed with a low-value on-chip aluminum

resistor. The voltage drop across this

resistor is fed back to control the base drive

of the output stage. This feedback prevents

the output transistor from exceeding its

maximum current density rating by limiting

the output current to approximately 900 mA.

It may also cause the output voltage to

increase (V

mode, the device will dissipate an increased

amount of power (PD = V

output transistor will be thermally stressed.

= VBB - [I

OUT

x RL]). In this

LIMIT

x I

OUT

LIMIT

) and the

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Page 5

5140

PROTECTED POWERHALL

®

SENSOR:

LAMP/SOLENOID DRIVER

This stress, unless protected against (as in the

UGQ5140K), will cause the device junction temperature to rise until it fails catastrophically.

Thermal stress protection is provided in two

manners; delta temperature protection, and junction

temperature protection. Under worst-case conditions

(see Figures 1 and 2), if the output is shorted to

supply, the output transistor will heat up much faster

than the rest of the integrated circuit. This condition

could cause localized failure in the output transistor.

To prevent damage, a delta temperature limiting

scheme is used. If a large thermal gradient is sensed

across the device, the output transistor base drive is

reduced to lower the output current. This reduces the

power (heat) generated by the output transistor.

When thermal stresses cause the junction temperature to reach approximately +165°C, a linear

thermal limiting circuit is activated. This circuit linearly

reduces the base drive of the output transistor to

maintain a constant junction temperature of 165°C. In

this mode, the output current will be a function of the

heat dissipating characteristics of the package and its

environment. Linear thermal limiting eliminates the

low-frequency thermal oscillation problems experienced by thermal shutdown (ON-OFF) schemes.

FIGURE 1

OUTPUT CURRENT UNDER SHORT-CIRCUIT

CONDITIONS

NOT TO SCALE

PEAK CURRENT LIMIT

DELTA TEMP.

LIMIT

OUTPUT CURRENT

TIME

JUNCTION

TEMP. LIMIT

FIGURE 2

OUTPUT VOLTAGE vs OUTPUT CURRENT

Dwg. WH-002

The output characteristics are shown in Figures 1

and 2. Note the three distinct operating regions: peak

limit, delta limit, and thermal limit. In practice the

output voltage and current may exhibit some oscillations during peak current limiting due to output load

characteristics. These oscillations are of very-short

duration (typically 50 ms) and may be damped with an

external capacitor between pins 2 and 4.

When the fault condition that caused the output

overload is corrected, the device returns to normal

operating mode.

OUT

T = 165°C

J

JUNCTION

OUTPUT VOLTAGE, V

TEMP. LIMIT

T < 150°C

J

V

OUT(SAT)

OUTPUT CURRENT, I

DELTA

TEMP. LIMIT

NOT TO SCALE

CURRENT LIMIT

OUT

Dwg. GP-013-1

Page 6

5140

PROTECTED POWERHALL

®

SENSOR:

LAMP/SOLENOID DRIVER

FIGURE 3

TYPICAL LAMP DRIVER APPLICATION

X

V

+12 V

CC

1

OPTIONAL LAMP TEST

(SEE TEXT)

432

Dwg. EH-001

FIGURE 4

LAMP CURRENT vs TIME

NORMAL LAMP IN-RUSH CURRENT

TYPICAL APPLICATIONS

INCANDESCENT LAMP DRIVER

High incandescent lamp turn-ON currents (commonly called in-rush currents) can contribute to poor lamp

reliability and destroy semiconductor lamp drivers. Warming resistors protect both driver and lamp but use significant power when the lamp is OFF while current-limiting

resistors waste power when the lamp is ON. Lamps with

steady-state current ratings to 300 mA can be driven by

the UGQ5140K (Figure 3) without the need for warming or

current limiting resistors. In applications using several

sensor/drivers to control multiple lamps, the internal clamp

diodes may be connected together to an appropriate

current-limiting resistor and simple “lamp test” switch.

As shown in Figure 4, when an incandescent lamp is

initially turned ON, the cold filament is at minimum resistance and will normally allow a 10x to12x peak in-rush

current. As the lamp warms up, the filament resistance

increases to its rated value and the lamp current is

reduced to its steady-state rating. When switching a lamp

with the UGQ5140K, the internal current-limiting circuitry

limits the peak current to approximately 900 mA. The

device will stay in the current limit and delta temperature

limit modes until the lamp resistance increases to its rated

steady-state value (Figure 4). A side-effect of this currentlimiting feature is that lamp turn-on times will increase.

Typical lamp turn-on times are shown in Figure 5.

CURRENT LIMIT

DELTA TEMP.

LIMIT

TIME

NOT TO SCALE

INDUCTIVE LOAD DRIVER

Connecting the internal clamp diode (pin 3) to the

positive supply allows relays or other inductive loads to be

driven directly, as shown in Figure 6. The internal diode

prevents damage to the output transistor by clamping the

high-voltage spikes which occur when turning OFF an

inductive load. An optional external Zener diode can be

used to increase the flyback voltage, providing a much

faster inductive load turn-OFF current decay, resulting in

faster dropout (reduced relay contact arcing), and improved performance. The maximum Zener voltage, plus

the load supply voltage, plus the clamp diode forward

voltage should not exceed 35 volts.

-

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Page 7

5140

A

PROTECTED POWERHALL

®

SENSOR:

LAMP/SOLENOID DRIVER

FIGURE 5

LAMP TURN-ON TIME

150

125

#168 BULB

100

75

#194 BULB

14 V, 270 mA

50

APPROXIMATE LAMP TURN-ON TIME IN ms

25

-40

-20 0 25 55

AMBIENT TEMPERATURE IN °C

14 V, 350 mA

TYPICAL RELAY/SOLENOID DRIVER APPLICATION

V = 14 V

BB

85

Dwg. GH-005A

FIGURE 6

SENSOR LOCATION

ACTIVE AREA DEPTH

0.015"

0.38 mm

NOM

BRANDED

SURFACE

0.121"

3.07 mm

0.053"

1.34 mm

1 432

Dwg. MH-001B

+12 V

X

V

CC

1

OPTIONAL ZENER

432

Dwg. EH-002

V

OUTPUT

VOLTAGE

OUTPUT

CURRENT

BB

V

OUT(SAT)

V + V + V

BB Z F

ZENER CLAMP

V + V

BB F

DIODE CLAMP

Dwg. WP-001-1

Page 8

5140

PROTECTED POWERHALL

®

SENSOR:

LAMP/SOLENOID DRIVER

Dimensions in Inches

(controlling dimensions)

0.208

0.203

45°

0.138

0.133

0.085

1234

MAX

0.600

0.560

0.063

0.059

0.033

0.015

45°

Dimensions in Millimeters

(for reference only

5.28

5.16

45°

3.51

3.38

2.16

1234

MAX

15.24

14.23

1.60

1.50

45°

0.84

0.38

SEE NOTE

0.016

NOTES: 1. Tolerances on package height and width represent allowable mold offsets. Dimensions given are measured at the widest point (parting line).

2. Exact body and lead configuration at vendor’s option within limits shown.

3. Height does not include mold gate flash.

4. Recommended minimum PWB hole diameter to clear transition area is 0.035” (0.89 mm).

5. Where no tolerance is specified, dimension is nominal.

0.050

BSC

Dwg. MH-009C in

Allegro MicroSystems, Inc. reserves the right to make, from time to time, such departures from

the detail specifications as may be required to permit improvements in the design of its products.

The information included herein is believed to be accurate and reliable. However, Allegro

MicroSystems, Inc. assumes no responsibility for its use; nor for any infringements of patents or

other rights of third parties which may result from its use.

SEE NOTE

0.41

1.27

BSC

Dwg. MH-009C mm

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Loading...

Loading...