Page 1

Evaluation Board User Guide

p

UG-364

One Technology Way • P. O . Box 9106 • Norwood, MA 02062-9106, U.S.A. • Tel : 781.329.4700 • Fax : 781.461.3113 • www.analog.com

Evaluating the AD5933 1 MSPS, 12-Bit Impedance Converter Network Analyzer

FEATURES

Full-featured evaluation board for the AD5933

Graphic user interface software with frequency sweep

capability for board control and data analysis

Various power supply linking options

Standalone capability with serial I

2

C loading from on-board

microcontroller

Selectable system clock options including internal RC

oscillator or on-board 16 MHz crystal

APPLICATIONS

Electrochemical analysis

Impedance spectroscopy

Complex impedance measurement

Corrosion monitoring and protection equipment

Biomedical and automotive sensors

Proximity sensing

GENERAL DESCRIPTION

This user guide describes the EVAL-AD5933EBZ evaluation board,

and the application software developed to interface with the device.

The AD5933 is a high precision impedance converter system that

combines an on-board frequency generator with a 12-bit, 1 MSPS

analog-to-digital converter (ADC). The frequency generator

allows an external complex impedance to be excited with a

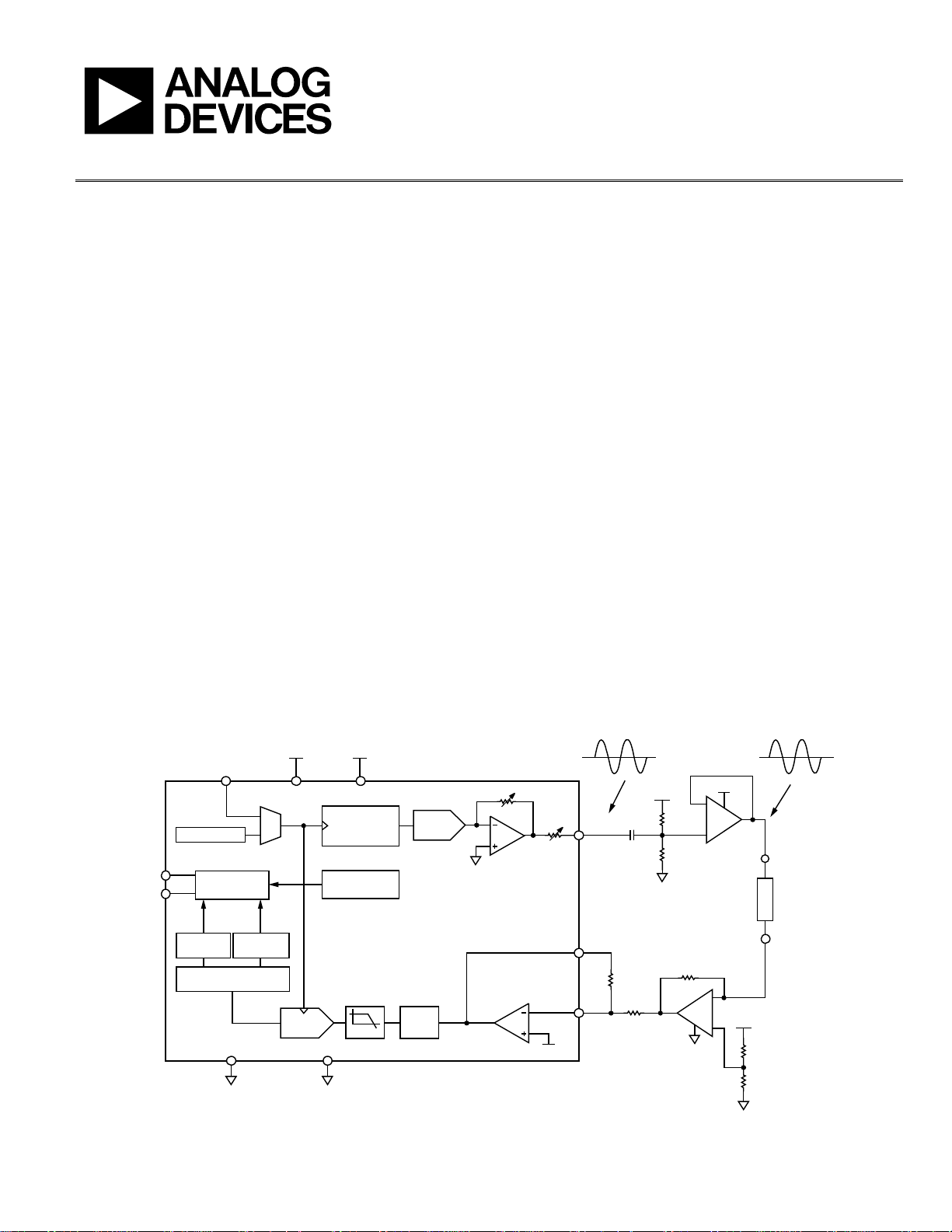

EVALUATION BOARD BLOCK DIAGRAM

V

DD

MCLK

OSCILLATOR

SCL

SDA

PLEASE SEE THE LAST PAGE FOR AN IMPORTANT

WARNING AND LEGAL TERMS AND CONDITIONS.

I2C

INTERFACE

IMAGINARY

REAL

REGISTER

REGISTER

1024-POINT DFT

AGND DGND

ADC

(12 BITS)

Rev. 0 | Page 1 of 28

V

DD

DVDDAVD D

DDS

CORE

(27 BITS)

TEMPERATURE

SENSOR

AD5933

LPF

DAC

GAIN

OUTPUT AMPLIFIER

Figure 1.

known frequency. The on-board ADC samples the response

signal from the impedance, and an on-board DSP engine at each

excitation frequency processes the DFT. The AD5933 also contains

an internal temperature sensor with 13-bit resolution. The part

operates from a 2.7 V to 5.5 V supply. Other on-board components

include a ADR423 3.0 V reference to act as a stable supply voltage

for the separate analog and digital sections of the device and a

ADP3303 ultrahigh precision regulator to act as a supply to the

on-board universal serial bus controller that interfaces to the

AD5933. The user has the option to power the entire circuitry

from the USB port of a computer.

The evaluation board also has a high performance trimmed

16 MHz surface-mount crystal to act as a system clock to the

AD5933, if required. The various link options located around the

evaluation board are listed in Table 1 . Interfacing to the AD5933

is through a USB microcontroller that generates the I

necessary to communicate with the AD5933. Interfacing to the

USB microcontroller is done through a Visual Basic® graphic user

interface located on and run from the PC. Complete specifications

for the AD5933 are available in the AD5933 data sheet available

from Analog Devices, Inc., and should be consulted in conjunction

with this user guide when using the evaluation board.

TRANSMIT SI DE

I-V

R

VDD/2

1.48V

OUT

1.98V p-p

VOUT

RFB

VIN

47nF

20kΩ

20kΩ

V

DD

50kΩ

50kΩ

A1, A2 ARE

½

AD8606

V

DD

−

A1

+

R

FB

−

A2

+

VDD/2

V

DD

50kΩ

50kΩ

1.98V p-

Z

UNKNOWN

2

C signals

10441-001

Page 2

UG-364 Evaluation Board User Guide

TABLE OF CONTENTS

Features.............................................................................................. 1

Applications....................................................................................... 1

General Description ......................................................................... 1

Evaluation Board Block Diagram................................................... 1

Revision History ............................................................................... 2

Evaluation Board Hardware............................................................ 3

Terminal Block Functions ........................................................... 3

Getting Started.................................................................................. 4

Setup Sequence Summary........................................................... 4

Installing the Software ................................................................. 4

Connecting the USB Cable.......................................................... 5

Verifying the Links and Power Up the Evaluation Board ....... 6

REVISION HISTORY

2/12—Revision 0: Initial Version

Performing a Frequency Sweep ...................................................6

Two Installation Frequently Asked Questions ....................... 10

Source Code for Impedance Sweep.............................................. 12

Evaluation Board Source Code Extract................................... 13

Gain Factor Calculation ............................................................ 17

Temperature Measurement ....................................................... 17

Impedance Measurement Tips ................................................. 18

Evaluation Board Schematics and Artwork................................ 23

Ordering Information.................................................................... 26

Bill of Materials........................................................................... 26

Related Links............................................................................... 27

Rev. 0 | Page 2 of 28

Page 3

Evaluation Board User Guide UG-364

EVALUATION BOARD HARDWARE

TERMINAL BLOCK FUNCTIONS

Table 1. Link Functions

Link No. Default Location Function

LK1 Out Option to remove external conditioning

LK2 Out Option to remove external conditioning

LK3 In On-board, 16 MHz crystal connection, connects to Y2

LK4 Out SMB connected external clock

LK5 In Connects 5 V from USB to ADP3303

LK6 A AVDD and DVDD power supply connector

Rev. 0 | Page 3 of 28

Page 4

UG-364 Evaluation Board User Guide

GETTING STARTED

SETUP SEQUENCE SUMMARY

The evaluation board installation instructions are for the

Windows XP® operating system with English (United States) set

for its language. The regional and language settings of a PC can

be changed in the Regional and Language directory within the

Control Panel (Start/Control Panel/Regional and Language/

Formats). The installation consists of the following steps that

are described in detail in the sections that follow.

1. Install the AD5933 graphical user interface software on the

CD that accompanies the evaluation board. Do not connect

the USB cable from the AD5933 evaluation board to the

computer USB hub until the evaluation software is properly

installed. See the Installing the Software section for

additional information.

2. Connect the computer USB port to the evaluation board

using the USB cable provided in the evaluation kit and run

the USB hardware installation wizard after the evaluation

software is correctly installed (the hardware installation

may happen automatically depending on the settings of the

current operating system). See the Connecting the USB

Cable section for additional information.

3. Ensure that the appropriate links are made throughout

the evaluation board. Prior to opening and running the

evaluation software program, power up the evaluation

board appropriately. See the Verifying the Links and Power

Up section for additional information.

4. Configure the front panel of the evaluation board software to

run the required sweep function. See the Performing a

Frequency Sweep section for additional information.

3. Install the evaluation board software in the default destination

folder path, C:\Program Files\Analog Devices\AD5933\

AD5933 Evaluation Software Rev 1.0 Setup (see Figure 4).

Figure 3. Installation Wizard

10441-004

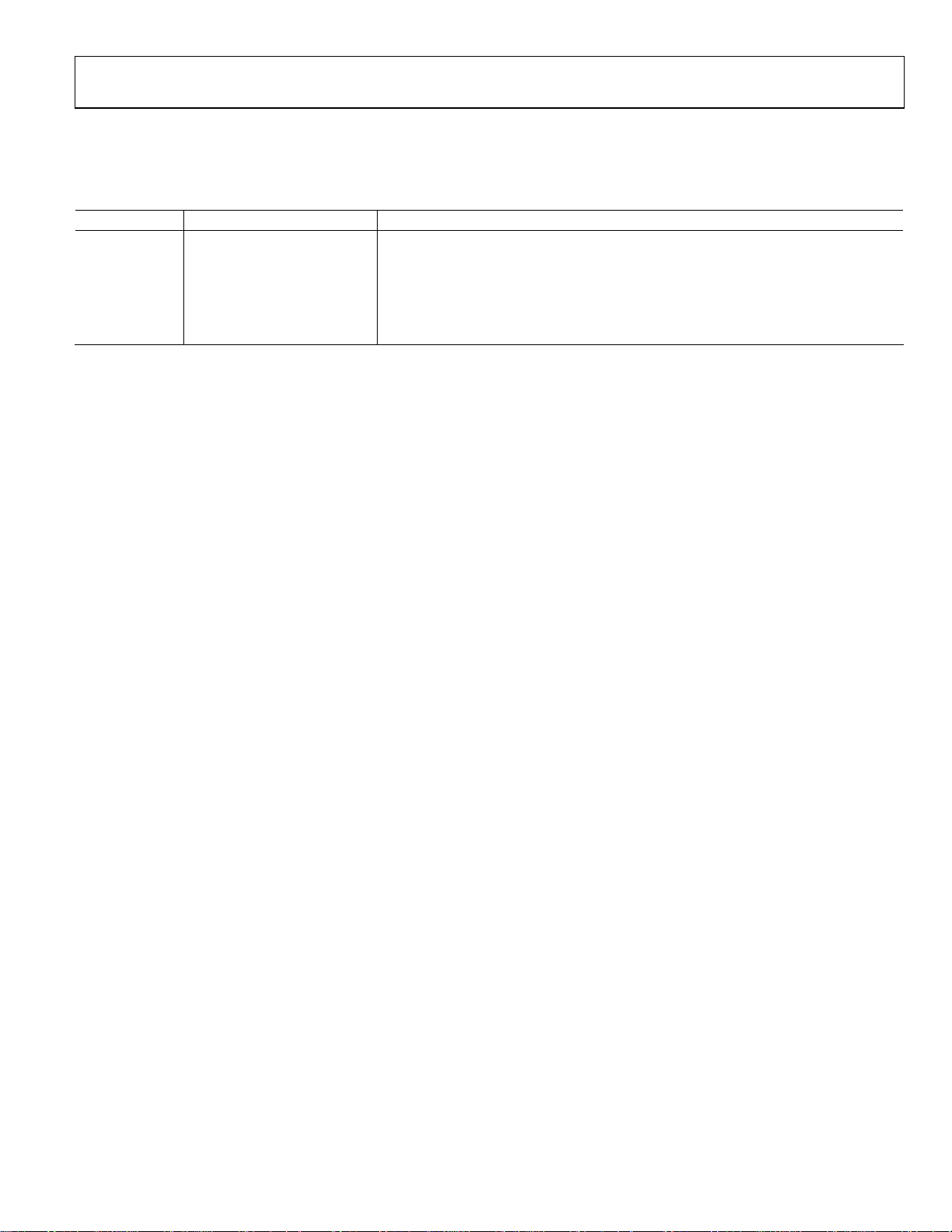

INSTALLING THE SOFTWARE

To install the evaluation board software, use the following steps:

1. Put the evaluation board CD into the CD drive of the PC

and click Start/My Computer.

2. The CD software installation may happen automatically

after the CD is inserted into the CD drive; however, this may

depend on the settings of the current operating system. If the

software installation does not automatically start, go to

AD5933 Installation/Setup.exe and double-click Setup.exe

to install the software on the PC through the installation

wizard (see Figure 2 and Figure 3).

10441-003

Figure 2. Evaluation Software CD Contents

Rev. 0 | Page 4 of 28

10441-005

Figure 4. Default Destination Folder

Page 5

Evaluation Board User Guide UG-364

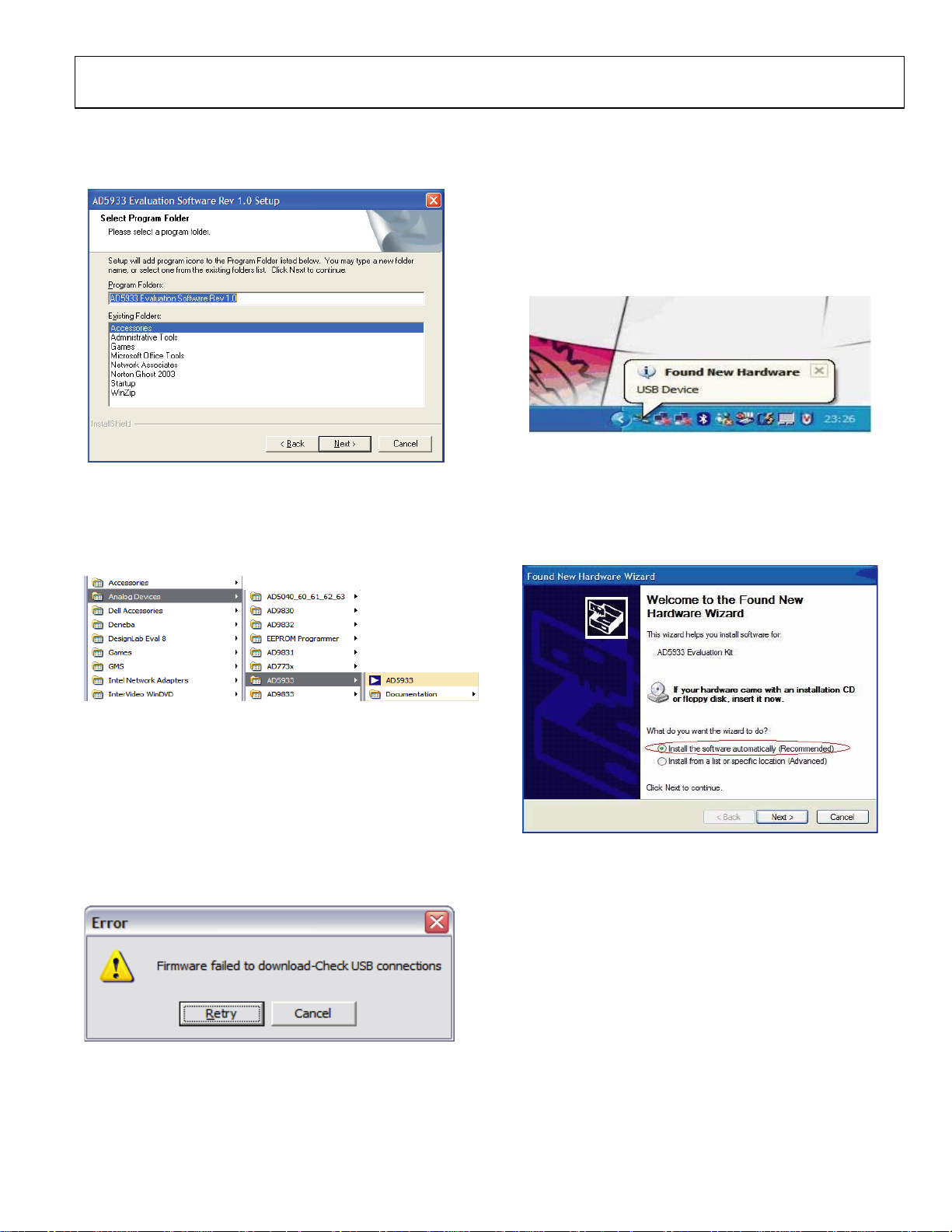

4. Choose the Analog Devices directory (see Figure 5). If the

Analog Devices folder does not yet exist, create an Analog

Devices folder and add the program icon to this new folder.

Figure 5. Select Analog Devices Directory

5. After installing the software, remove the CD from the CD

drive. You may be asked to reboot the computer at this stage.

6. Go to Start/All Programs/Analog Devices/AD5933/

AD5933 (see Figure 6).

10441-006

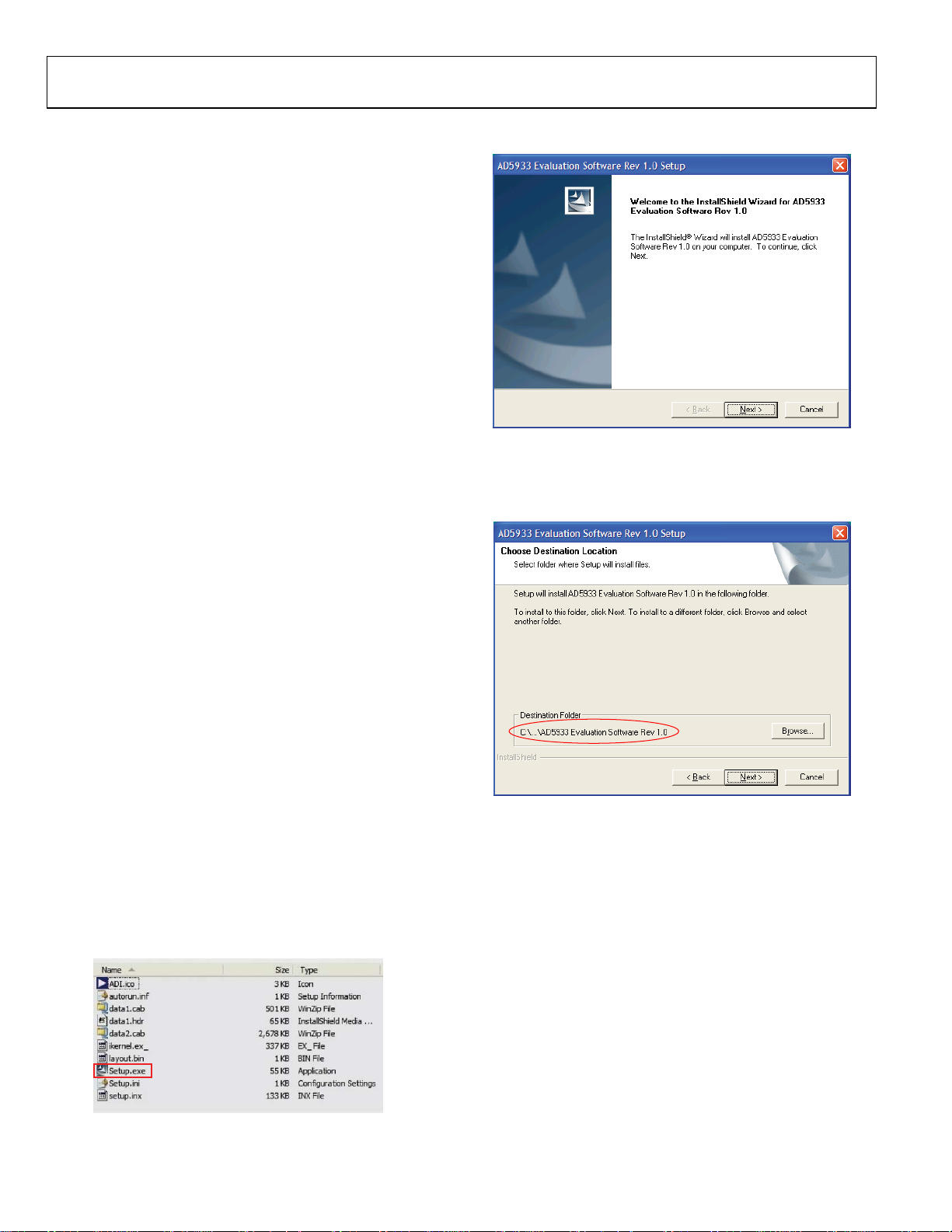

CONNECTING THE USB CABLE

To connect the USB cable, use the following steps:

1. Plug the USB cable into the USB hub of the PC and connect

the other end of the USB cable into the AD5933 evaluation

board USB socket (see J1 in Figure 32). A message may

appear that a USB device has been detected on the host

computer and that new hardware has been found (see

Figure 8).

10441-009

Figure 8. USB Device Detected by Host Computer

2. The Found New Hardware Wizard then appears (see

Figure 9). This wizard locates and installs the appropriate

driver files for the AD5933 evaluation kit in the operating

system registry. Select Install the software automatically

(Recommended) and click Next > to continue (see Figure 9).

Figure 6. Opening the Evaluation Software

The following message appears (see Figure 7) because the

firmware code that the evaluation software operates from,

and that needs to be downloaded to the evaluation board USB

microcontroller memory each time the interface software

program is opened, cannot be successfully downloaded to

the evaluation board. The error message is presented because

there is currently no USB connection between the computer

and the AD5933 evaluation board at this stage; therefore,

this error message is to be expected. Click Cancel.

Figure 7. Expected Error Message

10441-007

10441-008

Rev. 0 | Page 5 of 28

Figure 9. Hardware Installation Wizard

10441-010

Page 6

UG-364 Evaluation Board User Guide

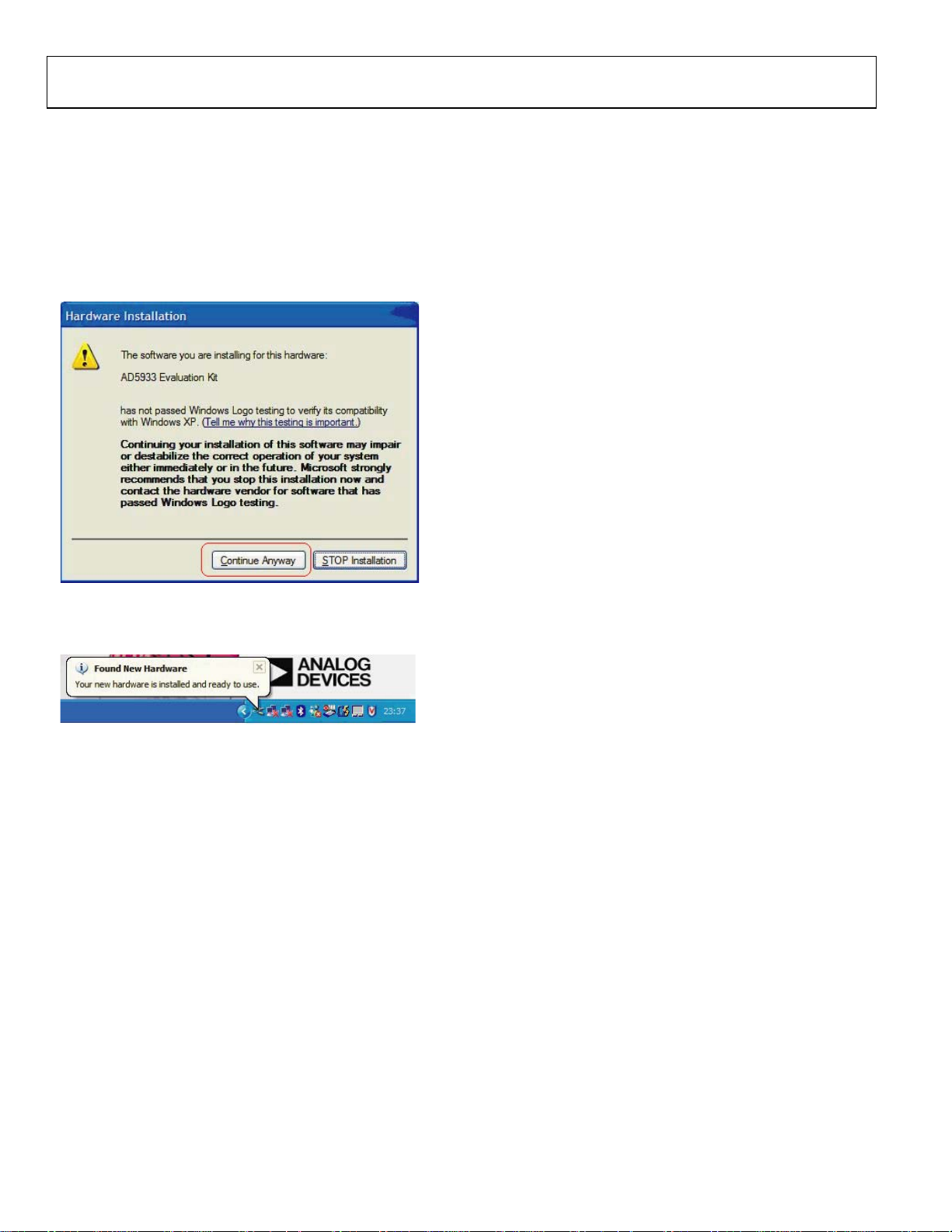

3. A standard windows operating system warning message

then appears, as shown in Figure 10. It indicates that the

new hardware currently being installing on the Windows®

operating system (AD5933 evaluation kit) has not passed the

Windows logo testing to verify compatibility with Windows

XP. This warning appears because the installation is an

evaluation setup installation and is not intended to be used

in a production environment. Click Continue Anyway and

then click Finish.

Figure 10. Expected Warning Message

The message shown in Figure 11 appears once the hardware has

been successfully installed.

Figure 11. Successful Hardware Installation

VERIFYING THE LINKS AND POWER UP THE EVALUATION BOARD

Ensure that the relevant links are in place on the evaluation board

(see Tabl e 1) and that the proper power connections and supply

values have been made to the terminal blocks before applying

power to the evaluation board. The power supply terminal blocks

are outlined in evaluation board schematic (see Figure 32). Note

that the USB connector only supplies power to the Cypress USB

controller chip that interfaces to the AD5933. If required, a

dedicated external voltage supply to each terminal block can

be provided. Ensure that all relevant power supply connections

and links are made before running the evaluation software. For

optimum performance, supply the three supply signals (A

A

VDD2

, and D

) from a stable external reference supply via the

VDD

power supply terminal blocks on the board.

,

VDD1

Rev. 0 | Page 6 of 28

10441-011

10441-012

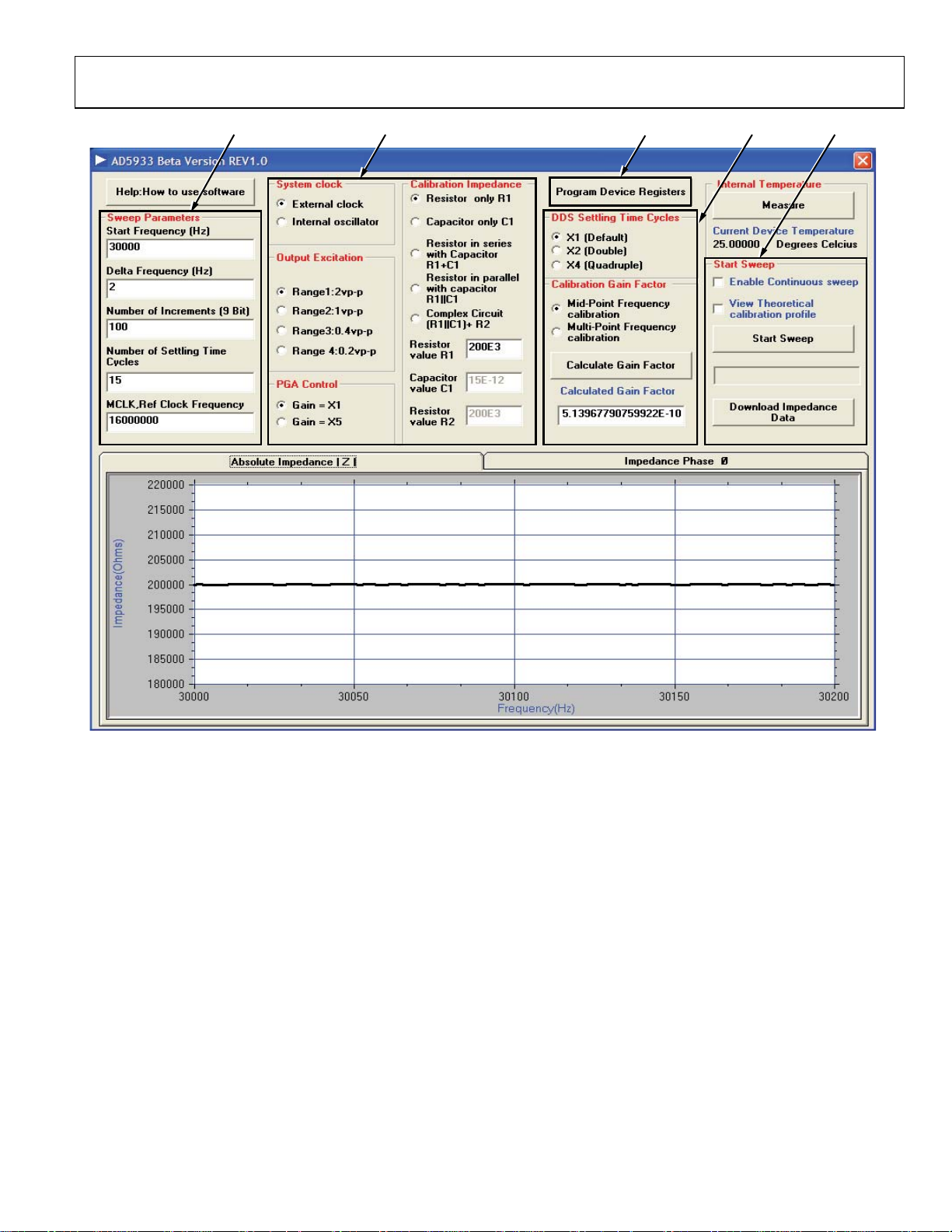

PERFORMING A FREQUENCY SWEEP

The sequence for performing a linear frequency sweep across a

200 k resistive impedance connected across the VOUT and

VIN pins within the frequency range of 30 kHz to 30.2 kHz is

outlined in this section. The default software settings for the

evaluation board are shown in Figure 12. (Note that a 200 k

resistor must be connected across the VIN and VOUT pins of

the AD5933). The default link positions are outlined in Tabl e 1,

see this before continuing.

To open the software, go to Start > Programs > Analog Devices >

AD5933 and click AD5933 Evaluation Software.

Figure 12 shows the graphic user interface program open and

running successfully. It also shows the interface panel along with

a frequency sweep impedance profile for a 200 k resistive

impedance (note R

To setup a typical sweep across a 200 k impedance (R

use the following steps:

• Set Start Frequency (Hz) to 30000 (Hz) within the Sweep

Parameters section (see 1 in Figure 12). The start frequency

is 24-bit accurate.

• Set Delta Frequency (Hz) to 2 (Hz) within the Sweep

Parameters section (see 1 in Figure 12). The frequency step

size is also 24-bit accurate.

• Set Number Increments (9 Bit) within the Sweep Parameters

section to 200 (see 1 in Figure 12) to set the number of

increments along the sweep to 200. The maximum number

of increments that the device can sweep across is 511, and

the value is stored in a register as a 9-bit value.

• Set Number of Settling Time Cycles to 15 (see 1 in Figure 12).

Note that when sweeping across a high-Q structure, such

as resonant impedance, users must ensure that the contents

of the settling time cycles register is sufficient to ensure

that the impedance under test settles before incrementing

between each successive frequency in the programmed

sweep. This is achieved by increasing the Number of

Settling Time Cycles value.

The delay between the time a frequency increment takes place

on the output of the internal direct digital synthesizer (DDS)

core and the time the ADC samples the response signal at

this new frequency is determined by the contents of the

number of settling time cycles registers (Register 0x8A and

Register 0x8B), see the AD5933 data sheet for further details.

For example, if a value of 15 is programmed into the Number

of Settling Time Cycles box, and if the next output frequency

is 32 kHz, the delay between the time the DDS core starts

to output the 32 kHz signal and the time the ADC samples the

response signal is 15 × (1/32 kHz) ≈ 468.7 µs. The maximum

number of settling time cycle delays that can be programmed

to the board is 511 cycles. The value is stored in a register as

a 9-bit value, and this value can be further multiplied by a

factor of 2 or by a factor of 4.

= 200 k).

FB

= 200 k),

FB

Page 7

Evaluation Board User Guide UG-364

432 51

Figure 12. AD5933 Evaluation Software Front Panel (Impedance Profile of 200 kΩ Resistor Displayed)

• Choose the external clock as the system clock. Select

External clock in the System Clock section (see 2 in

Figure 12).

• Set Output Excitation voltage range of the AD5933 at

Pin 6 (VOUT) to Range1:2v p-p (see 2 in Figure 12). The

four possible output ranges available are 2 V p-p, 1 V p-p,

0.4 V p-p, or 0.2 V p-p, typically.

• Set the PGA gain of the ADC on the receive stage (either

×1 or ×5) in the PGA Control section to ×1 (see 2 in

Figure 12).

• Refer to the Calibration Impedance panel (see 2 in Figure 12).

Prior to making any measurements, calibrate the AD5933

with a known (that is, accurately measured) calibration

impedance connected between the VIN and VOUT pins of

the AD5933. The choice of calibration impedance topology

(for example, R1 in series with C1, R1 in parallel with C1)

depends on the application in question. However, ensure

that each component of the measured calibration impedance

is entered correctly into each chosen topology component

text box (see 2 in Figure 12). For this example, Resistor

Rev. 0 | Page 7 of 28

only R1 was chosen in the Calibration Impedance

section, that is, to measure the impedance of a 200 k

resistive impedance across frequency. Also for this example,

set Resistor value R1 to 200E3 (Ω).

• Click Program Device Registers (see 3 in Figure 12) to

program the sweep parameters as previously chosen into

the appropriate on-board registers of the AD5933 through

2

the I

C interface.

• The value programmed into the settling time cycles can be

further multiplied by a factor of 2 or a factor of 4 for a sweep.

Select ×1 (Default) in the DDS Settling Time Cycles section.

• Now that the frequency sweep parameters and gain settings

are programmed, the next step is to calibrate the AD5933

system by calculating the gain factor.

The explanation of the system calibration gain factor, a term

calculated once at system calibration, is provided in detail

in the AD5933 data sheet. The AD5933 gain factor must be

calibrated correctly for a particular impedance range before

any subsequent valid impedance measurement (refer to the

AD5933 data sheet for further details).

10441-013

Page 8

UG-364 Evaluation Board User Guide

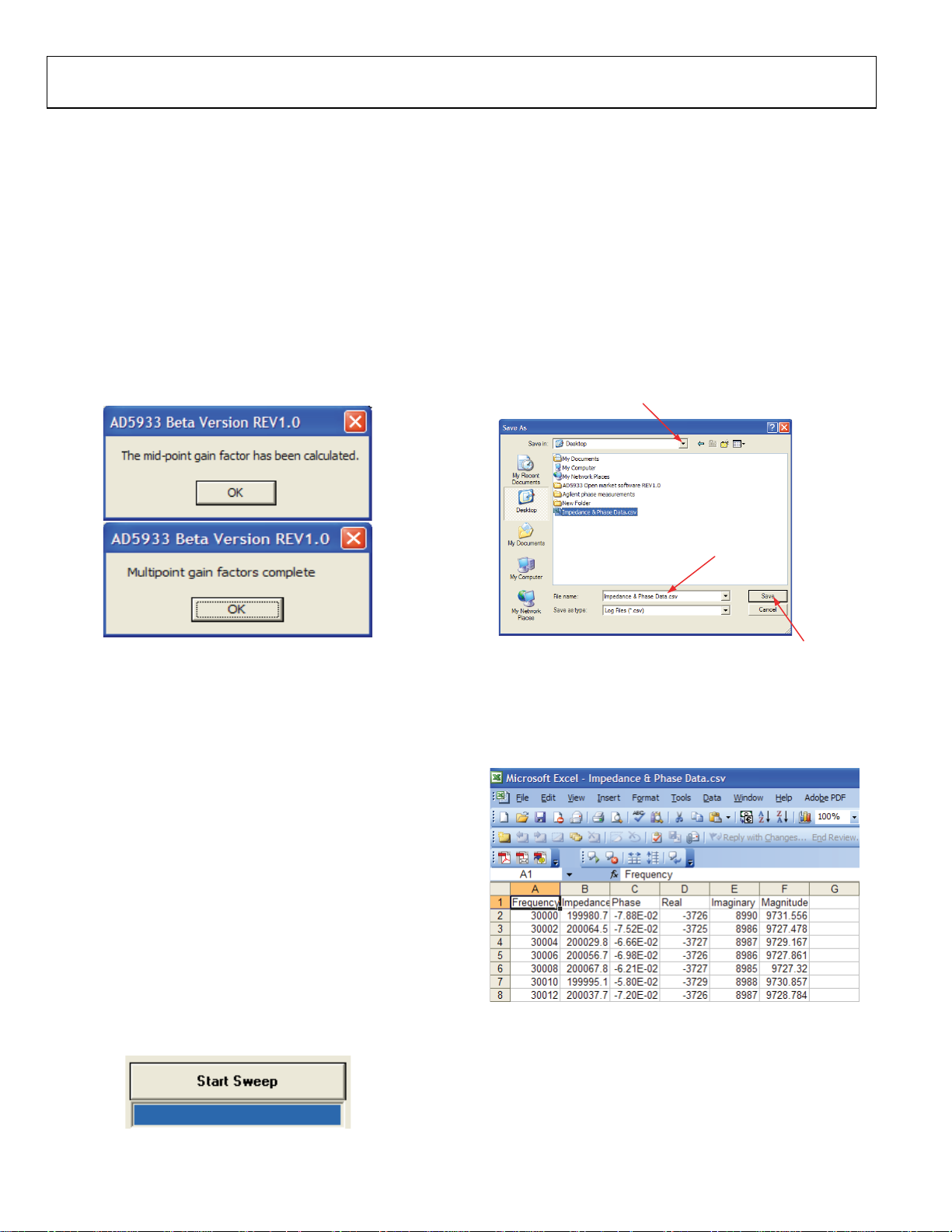

• To automatically calculate the gain factor(s) for the

subsequent sweep, click Calculate Gain Factor. The

evaluation software evaluates either a single midpoint

frequency gain factor or multipoint frequency gain factors,

that is, a gain factor for each point in the programmed sweep

(see 4 in Figure 12). The midpoint gain factor is determined

at the midpoint of the programmed sweep, and the multipoint

gain factors are determined at each point in the programmed

frequency sweep.

When either the midpoint gain factor or the multipoint gain

factors are calculated, a message appears on the evaluation

board software front panel, as shown in Figure 13. The gain

factor(s) returned to the evaluation software are subsequently

used for the sweep across the impedance under test.

• Click Measure in the Internal Temperature section of the

evaluation board software front panel to take a reading

from the on-board temperature sensor. This returns the

13-bit temperature of the device. See AD5933 data sheet

for more information on the temperature sensor.

• Click Download Impedance Data to download the frequency

sweep data (that is, frequency, impedance phase, real,

imaginary, and magnitude data) from the DFT of the sweep

(see 5 in Figure 12). The common dialog front panel is

presented as shown in Figure 15. Choose a file name in a

directory of choice and click Save (see Figure 15). This

saves the sweep data to a comma separated variable file

(.CSV) located in the chosen directory.

1. CHOOSE

DIRECTORY

2. CHOOSE

FILE NAME

10441-014

Figure 13. Confirmation of a Midpoint Calculation or

a Multipoint Gain Factors Calculation

After the system interface software calculates the gain factor(s)

for the programmed sweep parameters, the results are shown

in the Calculated Gain Factor box.

Note that should any of the system gain settings (for example,

change in output excitation range or PGA gain) change after

the system is calibrated (that is, gain factor(s) are calculated),

it is necessary to recalculate the gain factor(s) to subsequently

measure accurate impedance results. The gain factor(s)

calculated in the software are not programmed into the

AD5933 RAM and are only valid when the evaluation

software program is open and running. The gain factor(s)

are not retained in the evaluation software when the software

program is closed.

• Click Start Sweep (see 5 in Figure 12) to begin the sweep.

Once the evaluation software completes the sweep, it

automatically returns both a plot of the impedance vs.

frequency and phase vs. frequency for the impedance

under test (see Figure 12).The progress of the sweep is

outlined with a progress bar, as shown in Figure 14.

10441-015

Figure 14. Sweep Progress Bar (Blue)

3. SAVE THE FILE

Figure 15. Saving the Sweep Data

The contents of this file can be accessed by using Notepad

or Microsoft Excel to plot the data. Each file contains a single

column of data. The format of the downloaded data is shown

in Figure 16.

Figure 16. Opening the Sweep Data in Excel

10441-016

10441-017

Rev. 0 | Page 8 of 28

Page 9

Evaluation Board User Guide UG-364

Each data entry corresponds to a single measurement

(frequency) point; therefore, if the value for the number of

increments is programmed as 511 point, the array contains

a single column of data with 512 data points, starting at the

start frequency and ending at stop frequency value, which

is determined by

Start Frequency + (Number of Increments × Delta

Frequency)

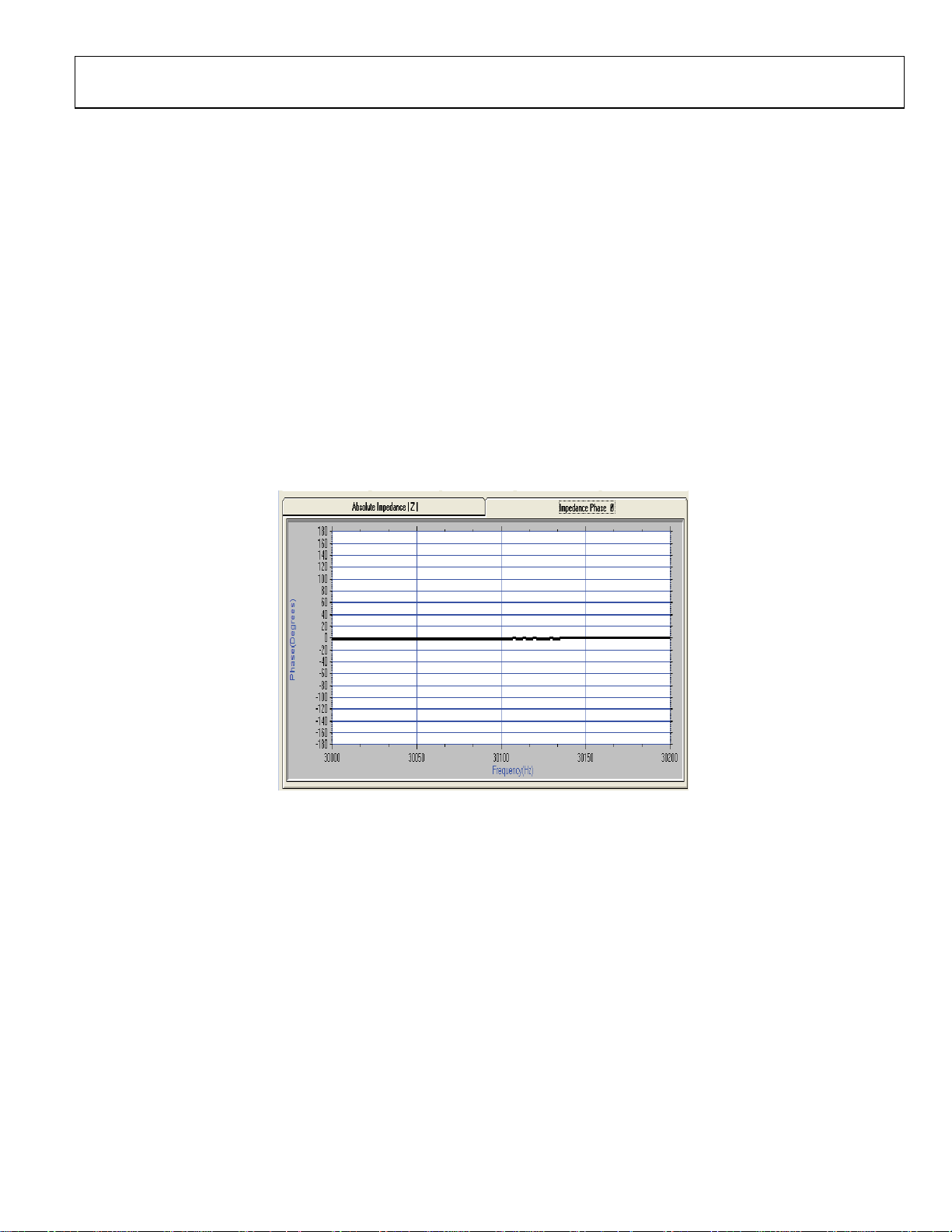

The impedance profile and phase profile vs. frequency appears

in the evaluation software front panel after the sweep has

completed. Click the individual tabs to switch between

Absolute Impedance |Z| and Impedance Phase Ø. Click

Absolute Impedance |Z| to show how the impedance under

analysis (Z

) varies across the programmed frequency

UNKNOWN

range. To view how the phase across the network under

analysis varies, click Impedance Phase Ø, as shown

in Figure 17.

Note that the phase measured by the AD5933 takes into

account the phase introduced through the entire signal path,

that is, the phase introduced through the output amplifiers,

receive current-to-voltage (I-V) amplifier, and the low-pass

filter, along with the phase through the impedance (Z

analysis connected between VOUT and VIN (Pin 6 and Pin 5

of the AD5933). Calibrate out the phase of the system using

a resistor before any subsequent impedance (Z

) phase

Ø

measurement is calculated. Calibrate with a resistor in the

evaluation software to calibrate the system phase correctly

(refer to the Impedance Measurement Tips section for

further details).

) under

Ø

10441-018

Figure 17. The Phase Tab on the A D5933 Evaluation Software Front Panel, Phase of 200 kΩ Resistor (0°) Displayed

Rev. 0 | Page 9 of 28

Page 10

UG-364 Evaluation Board User Guide

TWO INSTALLATION FREQUENTLY ASKED QUESTIONS

Q: How can I confirm that the hardware was correctly installed

on the PC?

A: To confirm the hardware was correctly installed on the PC,

use the following steps:

1. Right-click My Computer and left-click Properties.

2. Go to the Hardware tab, and click Device Manager (see

Figure 18).

3. Scroll to Universal Serial Bus controllers and expand the

root directory (see Figure 19). When the AD5933 hardware is

correctly installed, each time the USB cable connecting the

evaluation board to the computer is plugged in, the items

within the Universal Serial Bus controllers are refreshed.

Figure 19 shows what to expect when the AD5933 evaluation

board is correctly installed and when the evaluation board and

USB cable are connected correctly to the computer. The root

directory is subsequently refreshed when the USB cable is

unplugged from evaluation board, and the AD5933 evaluation

kit icon is removed from the main root.

Figure 18. System Properties

EXPAND ROOT

DIRECTORY

10441-019

Rev. 0 | Page 10 of 28

Figure 19. Correctly Installed Hardware

10441-020

Page 11

Evaluation Board User Guide UG-364

Q: During installation, when the board is plugged in for the first

time, the message shown in Figure 20 appears. When I click

Finish, the message shown in Figure 21 appears. What do I do

next?

10441-021

Figure 20. Error During the Hardware Installation

Figure 21. Found New Hardware Issue

A: If the evaluation software is installed correctly (install the

software correctly prior to plugging in the board for the first

time), this message simply indicates that the AD5933 device

drivers have not been installed to the correct registry and,

therefore, could not be correctly located by the install wizard.

To reinstall the device drivers, use the following steps:

1. Right-click My Computer, and left-click Properties.

2. Go to the Hardware tab, select Device Manager, and

expand Other devices (see Figure 22). The computer has

not recognized the USB device, that is, the AD5933

evaluation board.

3. Right-click USB Device and select Uninstall Driver.

4. Unplug the evaluation board and wait approximately

30 seconds before plugging it in again.

5. Proceed through the installation wizard a second time. The

expanded root directory shown in Figure 19 is a correct

installation. If the same error message is encountered the

second time, uninstall the device driver, uninstall the

software, and contact Analog Devices applications support

at www.analog.com for further instructions regarding valid

driver files.

1. EXPAND TH IS

DIRECTORY

Figure 22. USB Device Not Recognized

10441-022

Figure 23. Correctly Installed Hardware

2. RIGHT CLICK

ON THIS DE VICE

CORRECTLY INSTALLED

HARDWARE

10441-023

10441-024

Rev. 0 | Page 11 of 28

Page 12

UG-364 Evaluation Board User Guide

SOURCE CODE FOR IMPEDANCE SWEEP

PROGRAM F REQUENCY SWEEP PARAMETERS

INTO RELEVANT REGI STERS

(1) START FREQUENCY REG ISTER

(2) NUMBER OF INCREMENTS REG ISTER

(3) FREQUENCY INCREMENT REGISTER

PLACE THE AD5933 IN TO STANDBY MODE.

RESET: BY ISSUING A RESET COMMAND TO

THE CONTROL REGISTER, THE DEVICE IS

PLACED IN S TANDBY MODE.

PROGRAM THE INITIALIZE WITH START

FREQUENC Y COMMAND TO THE CO NTROL

AFTER A SUFFICI ENT AMOUNT OF SETTLING

TIME HAS ELAPSED, PROGRAM THE START

FREQUENC Y SWEEP COMMAND IN T HE

POLL THE STATUS REGISTER TO CHECK IF

THE DFT CONVERSION IS COMPLETE.

REGISTER.

CONTROL REG ISTER.

N

Y

READ VALUES FROM THE REAL AND

IMAGINARY DATA REGISTER.

POLL THE STATUS REGISTER TO CHECK IF

FREQUENC Y SWEEP IS COMPL ETE.

PROGRAM T HE AD5933

INTO POWER-DOWN MODE.

Figure 24. Sweep Flow Outline

This section outlines the evaluation board code structure required

to set up the AD5933 frequency sweep. The sweep flow outline is

shown in Figure 24. Each section of the flow diagram is explained

with the help of the visual basic code extracts. The firmware

code (c code), which is downloaded to the USB microcontroller

connected to the AD5933, implements the low level I

2

C signal

control (that is, read and write vendor request).

The code extract, which is shown in the Evaluation Board

Source Code Extract section, shows how to program a single

frequency sweep starting at 30 kHz, with a frequency step of

10 Hz and with 150 points in the sweep. The code assumes

that a 16 MHz clock signal is connected to Pin 8 (MCLK) of

PROGRAM T HE INCREMENT FREQUE NCY OR

THE REPEAT FREQUENCY COMMAND TO THE

Y

N

Y

CONTROL REG ISTER.

the AD5933. The impedance range under test is from 90 kΩ

to 110 kΩ. The gain factor is calculated at the midpoint of the

frequency sweep, that is, 30.750 kHz. The calibration is carried

out with a 100 kΩ resistor connected between VOUT and VIN.

The feedback resistor = 100 kΩ.

The first step in Figure 24 is to program the three sweep

parameters necessary to define the frequency sweep (that is,

the start frequency, number of increments, and frequency

increments). Refer to the AD5933 data sheet for more details.

10441-025

Rev. 0 | Page 12 of 28

Page 13

Evaluation Board User Guide UG-364

EVALUATION BOARD SOURCE CODE EXTRACT

‘------------------------------------------------------------------------------------------------------‘Code developed using visual basic® 6.

‘Datatype range

‘Byte 0-255

‘Double -1.797e308 to – 4.94e-324 and 4.94e-324 to 1.7976e308

‘Integer -32,768 to 32767

‘Long -2,147,483,648 to 2,147,483,647

‘Variant‘...when storing numbers same range as double. When storing strings same range as string.

‘-------------------------------------- Variable Declarations ----------------------------------------Dim ReadbackStatusRegister As Long 'stores the contents of the status register.

Dim RealData As Double 'used to store the 16 bit 2s complement real data.

Dim RealDataUpper As Long 'used to store the upper byte of the real data.

Dim RealDataLower As Long 'used to store the lower byte of the real data.

Dim ImagineryData As Double 'used to store the 16 bit 2s complement real data.

Dim ImagineryDataLower As Long 'used to store the upper byte of the imaginary data.

Dim ImagineryDataUpper As Long 'used to store the lower byte of the imaginary data.

Dim Magnitude As Double 'used to store the sqrt (real^2+imaginary^2).

Dim Impedance As Double 'used to store the calculated impedance.

Dim MaxMagnitude As Double 'used to store the max impedance for the y axis plot.

Dim MinMagnitude As Double 'used to store the min impedance for the y axis plot.

Dim sweep_phase As Double 'used to temporarily store the phase of each sweep point.

Dim Frequency As Double 'used to temporarily store the current sweep frequency.

Dim Increment As Long 'used as a temporary counter

Dim i As Integer 'used as a temporary counter in (max/min) mag,phase loop

Dim xy As Variant 'used in the stripx profile

Dim varray As Variant

Dim Gainfactor as double ‘either a single mid point calibration or an array of calibration points

Dim TempStartFrequency As Double

Dim StartFrequencybyte0 As Long

Dim StartFrequencybyte2 As Long

Dim StartFrequencybyte1A As Long

Dim StartFrequencybyte1B As Long

Dim DDSRefClockFrequency As Double

Dim NumberIncrementsbyte0 As Long

Dim NumberIncrementsbyte1 As Long

Dim FrequencyIncrementbyt0 As Long

Dim FrequencyIncrementbyt1 As Long

Dim FrequencyIncrementbyt2 As Long

Dim SettlingTimebyte0 As Long

Dim SettlingTimebyte1 As Long

‘-------------------------------------- I^2C read/write definitions----------------------------------------‘used in the main sweep routine to read and write to AD5933.This is the vendor request routines in the

firmware

Private Sub WritetToPart(RegisterAddress As Long, RegisterData As Long)

PortWrite &HD, RegisterAddress, RegisterData

‘parameters = device address register address register data

End Sub

Public Function PortWrite(DeviceAddress As Long, AddrPtr As Long, DataOut As Long) As Integer

PortWrite = VendorRequest(VRSMBus, DeviceAddress, CLng(256 * DataOut + AddrPtr), VRWRITE, 0, 0)

End Function

Public Function PortRead(DeviceAddress As Long, AddrPtr As Long) As Integer

PortRead = VendorRequest(VRSMBus, DeviceAddress, AddrPtr, VRREAD, 1, DataBuffer(0))

PortRead = DataBuffer(0)

End Function

‘------------------------------------- PHASE CONVERSION FUNCTION DEFINITION -------------------------------‘This function accepts the real and imaginary data(R, I) at each measurement sweep point and converts it to

a degree

‘-----------------------------------------------------------------------------------------------------------

Public Function phase_sweep (ByVal img As Double, ByVal real As Double) As Double

Dim theta As Double

Dim pi As Double

pi = 3.141592654

If ((real > 0) And (img > 0)) Then

theta = Atn(img / real) ' theta = arctan (imaginary part/real part)

phase2 = (theta * 180) / pi 'convert from radians to degrees

Rev. 0 | Page 13 of 28

Page 14

UG-364 Evaluation Board User Guide

ElseIf ((real > 0) And (img < 0)) Then

theta = Atn(img / real) '4th quadrant theta = minus angle

phase2 = ((theta * 180) / pi ) +360

ElseIf ((real < 0) And (img < 0)) Then

theta = -pi + Atn(img / real) '3rd quadrant theta img/real is positive

phase2 = (theta * 180) / pi

ElseIf ((real < 0) And (img > 0)) Then

theta = pi + Atn(img / real) '2nd quadrant img/real is neg

phase2 = (theta * 180) / pi

End If

End Function

‘-----------------------------------------------------------------------------------------------------------

Private Sub Sweep ()

’ the main sweep routine

‘This routine coordinates a frequency sweep using a mid point gain factor (see datasheet).

'The gain factor at the mid-point is determined from the real and imaginary contents returned at this mid

‘point frequency and the calibration impedance.

'The bits of the status register are polled to determine when valid data is available and when the sweep is

‘complete.

'----------------------------------------------------------------------------------------------------------IndexArray = 0 'initialize counter variable.

Increment = NumberIncrements + 1 'number of increments in the sweep.

Frequency = StartFrequency 'the sweep starts from here.

‘------------------------- PROGRAM 30K Hz to the START FREQUENCY register ---------------------------------

DDSRefClockFrequency = 16E6 ‘Assuming a 16M Hz clock connected to MCLK

StartFrequency = 30E3 ‘frequency sweep starts at 30K Hz

TempStartFrequency = (StartFrequency / (DDSRefClockFrequency / 4)) * 2^27 ‘dial up code for the DDS

TempStartFrequency = Int(TempStartFrequency) ‘30K Hz = 0F5C28 hex

StartFrequencybyte0 = 40 ‘40 DECIMAL = 28 HEX

StartFrequencybyte1 = 92 ‘92 DECIMAL = 5C HEX

StartFrequencybyte2 = 15 ’15 DECIMAL = 0F HEX

'Write in data to Start frequency register

WritetToPart &H84, StartFrequencybyte0 '84 hex lsb

WritetToPart &H83, StartFrequencybyte1 '83 hex

WritetToPart &H82, StartFrequencybyte2 '82 hex

‘--------------------------------- PROGRAM the NUMBER OF INCREMENTS register -----------------------------‘The sweep is going to have 150 points 150 DECIMAL = 96 hex

'Write in data to Number Increments register

WritetToPart &H89, 96 ‘lsb

WritetToPart &H88, 00 ‘msb

‘--------------------------------- PROGRAM the FREQUENCY INCREMENT register -----------------------------‘The sweep is going to have a frequency increment of 10Hz between successive points in the sweep

DDSRefClockFrequency = 16E6 ‘Assuming a 16M Hz clock connected to MCLK

FrequencyIncrements = 10 ‘frequency increment of 10Hz

TempStartFrequency = (FrequencyIncrements / (DDSRefClockFrequency / 4)) * 2^27 ‘dial up code for the DDS

TempStartFrequency = Int(TempStartFrequency) ’10 Hz = 335 decimal = 00014F hex

FrequencyIncrementbyt0 = 4F ‘335 decimal = 14f hex

FrequencyIncrementbyt1 = 01

FrequencyIncrementbyt2 = 00

'Write in data to frequency increment register

WritetToPart &H87, FrequencyIncrementbyt0 '87 hex lsb

WritetToPart &H86, FrequencyIncrementbyt1 '86 hex

WritetToPart &H85, FrequencyIncrementbyt2 '85 hex msb

‘--------------------------------- PROGRAM the SETTLING TIME CYCLES register -----------------------------‘The DDS is going to output 15 cycles of the output excitation voltage before the ADC will start sampling

‘the response signal. The settling time cycle multiplier is set to x1

Rev. 0 | Page 14 of 28

Page 15

Evaluation Board User Guide UG-364

SettlingTimebyte0 = 0F ‘15 cycles (decimal) = 0F hex

SettlingTimebyte1 = 00 ’00 = X1

WritetToPart &H8B, SettlingTimebyte0

WritetToPart &H8A, SettlingTimebyte1

‘-------------------------------------- PLACE AD5933 IN STANDBYMODE ----------------------------------------

‘Standby mode command = B0 hex

WritetToPart &H80, &HB0

'------------------------- Program the system clock and output excitation range and PGA setting----------‘Enable external Oscillator

WritetToControlRegister2 &H81, &H8

‘Set the output excitation range to be 2vp-p and the PGA setting to = x1

WritetToControlRegister2 &H80, &H1

‘----------------------------------------------------------------------------------------------------------‘------------- ------------ Initialize impedance under test with start frequency --------------------------'Initialize Sensor with Start Frequency

WritetToControlRegister &H80, &H10

msDelay 2 'this is a user determined delay dependent upon the network under analysis (2ms delay)

‘-------------------------------------- Start the frequency sweep -----------------------------------------'Start Frequency Sweep

WritetToControlRegister &H80, &H20

'Enter Frequency Sweep Loop

ReadbackStatusRegister = PortRead(&HD, &H8F)

ReadbackStatusRegister = ReadbackStatusRegister And &H4 ' mask off bit D2 (i.e. is the sweep complete)

Do While ((ReadbackStatusRegister <> 4) And (Increment <> 0))

'check to see if current sweep point complete

ReadbackStatusRegister = PortRead(&HD, &H8F)

ReadbackStatusRegister = ReadbackStatusRegister And &H2

'mask off bit D1 (valid real and imaginary data available)

‘------------------------------------------------------------------------ If (ReadbackStatusRegister = 2) Then

' this sweep point has returned valid data so we can proceed with sweep

Else

Do

‘if valid data has not been returned then we need to pole stat reg until such time as valid data

'has been returned

‘i.e. if point is not complete then Repeat sweep point and pole status reg until valid data

returned

WritetToControlRegister &H80, &H40 'repeat sweep point

Do

ReadbackStatusRegister = PortRead(&HD, &H8F)

ReadbackStatusRegister = ReadbackStatusRegister And &H2

' mask off bit D1- Wait until dft complete

Loop While (ReadbackStatusRegister <> 2)

Loop Until (ReadbackStatusRegister = 2)

End If

'-------------------------------------------------------------------------

RealDataUpper = PortRead(&HD, &H94)

RealDataLower = PortRead(&HD, &H95)

RealData = RealDataLower + (RealDataUpper * 256)

'The Real data is stored in a 16 bit 2's complement format.

'In order to use this data it must be converted from 2's complement to decimal format

If RealData <= &H7FFF Then ' h7fff 32767

' Positive

Else

' Negative

' RealData = RealData And &H7FFF

RealData = RealData - 65536

End If

ImagineryDataUpper = PortRead(&HD, &H96)

Rev. 0 | Page 15 of 28

Page 16

UG-364 Evaluation Board User Guide

ImagineryDataLower = PortRead(&HD, &H97)

ImagineryData = ImagineryDataLower + (ImagineryDataUpper * 256)

'The imaginary data is stored in a 16 bit 2's complement format.

'In order to use this data it must be converted from 2's complement to decimal format

If ImagineryData <= &H7FFF Then

' Positive Data.

Else

' Negative

' ImagineryData = ImagineryData And &H7FFF

ImagineryData = ImagineryData - 65536

End If

‘-----------------Calculate the Impedance and Phase of the data at this frequency sweep point ---------- Magnitude = ((RealData ^ 2) + (ImagineryData ^ 2)) ^ 0.5

'the next section calculates the phase of the dft real and imaginary components

‘phase_sweep calculates the phase of the sweep data.

sweep_phase = (phase_sweep(ImagineryData, RealData) - calibration_phase_mid_point)

GainFactor = xx ‘this is determined at calibration. See gain factor section and Datasheet.

Impedance = 1 / (Magnitude * GainFactor)

' Write Data to each global array.

MagnitudeArray(IndexArray) = Impedance

PhaseArray(IndexArray) = sweep_phase

ImagineryDataArray(IndexArray) = ImagineryData

code(IndexArray) = Magnitude

RealDataArray(IndexArray) = RealData

Increment = Increment - 1 ' increment was set to number of increments of sweep at the start

FrequencyPoints(IndexArray) = Frequency

Frequency = Frequency + FrequencyIncrements ' holds the current value of the sweep freq

IndexArray = IndexArray + 1

------------- Check to see if sweep complete ---------------------ReadbackStatusRegister = PortRead (&HD, &H8F)

ReadbackStatusRegister = ReadbackStatusRegister And &H4 ' mask off bit D2

'Increment to next frequency point Frequency

WritetToControlRegister &H80, &H30

Loop

‘--------------------- END OF SWEEP: Place device into POWERDOWN mode-----------------------------------'Enter Powerdown Mode,Set Bits D15,D13 in Control Register.

WritetToPart &H80, &HA0

END SUB

‘--------------------------------------------------------------------------------------------------------

‘The programmed sweep is now complete and the impedance and phase data is available to read in the two

‘arrays MagnitudeArray() = Impedance and PhaseArray() = phase.

sweepErrorMsg:

MsgBox "Error completing sweep check values"

End Sub

‘The programmed sweep is now complete and the impedance and phase data is available to read in the two

‘arrays MagnitudeArray() = Impedance and PhaseArray() = phase.

Rev. 0 | Page 16 of 28

Page 17

Evaluation Board User Guide UG-364

GAIN FACTOR CALCULATION

The code shown in the Evaluation Board Source Code Extract

section for the impedance sweep is based on a single point gain

factor calculation. This calculation is carried out once system

calibration is at the midpoint sweep frequency and with a

known impedance connected between VOUT and VIN. The

gain factor is calculated by exciting the calibration impedance with

a 2 V p-p sinusoid with a frequency of 30.750 kHz. The PGA

setting is ×1. The calibration is carried out with a 100 kΩ

resistor connected between VOUT and VIN. The feedback

resistor is 100 kΩ. The magnitude of the real and imaginary

component at the calibration frequency is given by the formula

22

IRMagnitude +=

where:

R is the real component.

I is the imaginary component of the calibration code.

Example Code for Temperature Measurement

Private Sub MeasureTemperature()

' The Digital temperature Result is stored over two registers as a 14 bit twos complement number.

' 92H <D15-D8> and 93H<D7 to D0>.

Dim TemperatureUpper As Long.

Dim TemperatureLower As Long

'Write xH90 to the control register to take t empera ture readi ng.

WritetToPart &H80, &H90

msDelay 5 'nominal delay

ReadbackStatusRegister = PortRead(&HD, &H8F)

ReadbackStatusRegister = ReadbackSta tusRegiste r And &H1

'if a valid temperature conversion i s complete , igno re this.

If ReadbackStatusRegister <> 1 Then

'loop to wait for temperatur e measurem ent to complete.

Do

ReadbackStatusRegister = PortRead (&HD, &H8F )

ReadbackStatusRegister = Readback StatusRegi ster A nd &H1

Loop Until (ReadbackStatusRegist er = 1)

Form1.Label10.Caption = "Cur rent Devic e Temp erature"

MsgBox "Device Temperature M easurement Compl ete"

End If

' The Digital temperature Result is stored over two registers as a 14 bit twos complement number.

' 92H <D15-D8> and 93H<D7 to D0>.

TemperatureUpper = PortRead(&HD, &H92)

TemperatureLower = PortRead(&HD, &H93)

Temperature = TemperatureLower + (Te mperatureU pper * 256)

If Temperature <= &H1FFF Then ' msb =0.

' Positive Temperature.

Label8.Caption = (Temperature / 32#)

Else

' Negative Temperature.

Rev. 0 | Page 17 of 28

The gain factor is then given by

⎞

1

⎟

⎟

⎠

=

MagnitudeMagnitude

⎟

⎜

⎟

⎜

k100

⎠

⎝

GainFactor

Admittance

⎛

=

⎜

⎝

Code

⎞

=

⎟

⎠

⎛

⎜

⎜

Impedance

⎝

⎞

⎛

1

Refer to the AD5933 data sheet for more details.

TEMPERATURE MEASUREMENT

Refer to the AD5933 data sheet for details on the temperature

sensor. The temperature sensor data is stored in a 14-bit twos

complement format. The conversion formula is given in the

AD5933 data sheet.

Page 18

UG-364 Evaluation Board User Guide

r

g

V

Label8.Caption = (Temperature - 16384) / 32#

End If

're-assign variables used.

TemperatureUpper = 0

TemperatureLower = 0

Temperature = 0

End Sub

IMPEDANCE MEASUREMENT TIPS

This section outlines some of the workarounds for using the

AD5933 to measure the impedance profiles under certain

conditions.

Calibrating the AD5933

When calculating the calibration term (that is, gain factor, see

the AD5933 data sheet for further details), it is important that

the receive stage operates in its linear region. This requires careful

selection of the system gain settings. The system gain settings

include the following:

• Output excitation voltage range

• Current-to-voltage gain setting resistor

• PGA gain

The gain through the system shown in Figure 25 is given by

Resisto

Settin

Output Excitation Voltage Range ×

PGA Gain

CURRENT-TO-VOLTAGE

GAIN SETTING RESISTOR

RFB

Z

OUT

UNKNOWN

VIN

VDD

Figure 25. AD5933 System Voltage Gain

For example, assume the following system calibration settings:

• VDD = 3.3 V

• Gain setting resistor = 200 kΩ

• Z

UNKNOWN

= 200 kΩ

• PGA setting = ×1

• Range 1 = 2 V p-p

The peak-to-peak voltage presented to the ADC input is 2 V p-p.

However, if a programmable gain amplifier setting gain of ×5 is

chosen, the voltage saturates the ADC, and the calculated

calibration term (that is, the gain factor) is inaccurate due to the

saturation of the ADC.

Gain

PGA

(×1 OR ×5)

Z

UNKNOWN

LPF

×

ADC

Rev. 0 | Page 18 of 28

10441-026

Calculate the gain factor when the largest response signal is

presented to the ADC while ensuring that the signal is always

maintained within the linear range of the ADC over the impedance

range of interest (the reference range of the ADC is the AVDD

supply).

Configure the system gain settings (see Figure 25), that is, the

output excitation voltage range (Range 1, Range 2, Range 3, or

Range 4), the I-V amplifier gain setting resistor based on the

unknown impedance range of interest, and the programmable

gain amplifier setting (either ×1 or ×5) that proceeds the ADC.

Choose a calibration impedance that is midvalue between the limits

of the unknown impedance; therefore, the user must know the

impedance limits to correctly calibrate the system. Then choose an

equal value I-V gain setting resistor to the calibration impedance.

This results in a unity gain condition about the receive side of

the I-V amplifier.

For example, assume the following:

• Unknown test impedance limits are 180 kΩ ≤ Z

UNKNOWN

≤

220 kΩ

• Frequency range of interest is 30 kHz to 32 kHz

The following are the system calibration gain settings:

• VDD = 3.3 V

• Gain setting resistor (R

• Z

CALIBRATION

= 200 kΩ

) = 200 kΩ

FB

• PGA setting = ×1

• Calibration frequency = 31 kHz (midpoint frequency)

The gain factor calculated at the midpoint frequency of 31 kHz

can be used to calculate any impedance in the 180 k to 220

region. Impedance results degrade if the unknown impedance span

is large or if the frequency sweep is large. If any of the calibration

system gain settings change, recalibrate the AD5933 and recalculate

the gain factor (see AD5933 data sheet for further details).

Page 19

Evaluation Board User Guide UG-364

Measuring Lower Excitation Frequencies

The AD5933 has a flexible internal DDS core and a digital-toanalog converter (DAC) that together generate the excitation

signal used to measure the impedance (Z

UNKNOWN

). The DDS core

has a 27-bit phase accumulator that allows subhertz (0.1 Hz)

frequency resolution. The output of the phase accumulator is

connected to the input of a read-only memory (ROM).The digital

output of the phase accumulator is used to address individual

memory locations in the ROM. The digital contents of the ROM

represent amplitude samples of a single cycle of a sinusoidal

excitation waveform. The contents of each address within the

ROM look-up table are in turn passed to the input of a DAC that

produces the analog excitation waveform made available at the

VOUT pin. The DDS core (that is, the phase accumulator and the

ROM look-up) and the DAC are all referenced from a single system

clock. The function of the phase accumulator is simply to act as

a system clock divider.

The system clock for the AD5933 DDS engine can be provided

in one of two ways.

• The user can provide a highly accurate and stable clock

(crystal oscillator) at the external clock pin, MCLK (Pin 8).

• Alternatively, the AD5933 provides an internal clock oscillator

with a typical frequency of 16.776 MHz.

The user can select the preferred system clock by programming

Bit D3 in the control register (Address 0x81, see the AD5933

data sheet).

The internal ADC also uses the system clock to digitize the

response signal. The ADC requires 16 clock periods to perform

a single conversion. Therefore, with a maximum system clock

frequency of 16.776 MHz, the ADC can sample the response

signal with a frequency of 1.0485 MHz, that is, a throughput

rate of ≈ 1.04 MSPS. The ADC converts 1024 samples and passes

the digital results to the MAC core for processing. The AD5933

MAC core performs a 1024 point DFT to determine the peak

of the response signal at the ADC input. The DFT offers many

advantages over conventional peak detection mechanisms,

including excellent dc rejection, an averaging of errors, and

phase information.

The throughput rate of the AD5933 ADC scales with the system

clock, that is, lower ADC throughput rates, and therefore sampling

frequencies can be achieved by lowering the system clock.

The conventional DFT assumes a sequence of periodic input

data samples to determine the spectral content of the original

continuous signal. In the AD5933, these samples obviously come

from the 12-bit ADC for a user-defined range of signal frequencies.

The conventional DFT correlates the input signal against a series

of test phasor frequencies to determine the fundamental signal

frequency and its harmonics. The frequency of the test phasor is

at integer multiples of a fundamental frequency given by the

following formula:

Test Phasor Frequency = (f

/N)

S

where:

f

is the sampling frequency of the ADC.

S

N is the number of samples taken equals 1024.

The correlation is performed for each frequency integer

fundamental. If the resulting correlation of the test phasor

with the input sample set is nonzero, there is signal energy at

this frequency. If no energy is found in a bin, there can be no

energy at that test frequency.

The DFT implemented by the AD5933 is called a single point

DFT; this means that the analysis or correlation frequency in

the MAC core is always at the same frequency as the current

output excitation frequency. Therefore, when the system clock

for the AD5933 is 16.776 MHz, the sample rate of the ADC is

1.04 MHz. The DSP core requires 1024 samples to perform

the single point DFT. Therefore, the resolution of the DFT is

1.04 MHz/1024 points ≈ 1 kHz. This calculation is based on

a system clock frequency of 16 MHz being applied at MCLK. If

the AD5933 tries to examine excitation frequencies below ≈ 1 kHz,

the errors introduced by the spectral leakage become significant

and result in erroneous impedance readings.

If the input signal does not have an exact integer number of cycles

over the 1024-point sample interval, as shown in Figure 26, there

will not be a smooth transition from the end of one period to

the next, as shown in Figure 27. The leakage is a result of the

discontinuities introduced by the DFT assuming a periodic

input signal like that shown in Figure 27.

SAMPLES SPAN ENTIRE EXCITATION PERIOD

SAMPLE

WINDOW

Figure 26. Sample Set Spanning the Entire Excitation Period

SAMPLES DO NOT SPAN ENTIRE EXCITATION PERIOD

DFT ASSUMES A PERIODIC

SAMPLE SET

10441-027

Rev. 0 | Page 19 of 28

DFT ASSUMES A PERIODIC

SAMPLE SET

Figure 27. Sample Set Not Spanning the Entire Excitation Period

10441-028

Page 20

UG-364 Evaluation Board User Guide

For the AD5933 to analyze the impedance (Z

UNKNOWN

) at

frequencies lower than ≈ 1 kHz, it is necessary to scale the system

clock such that the sample rate of the ADC is lowered and cause

the 1024 samples required for the single point DFT to cover an

integer number of periods of the current excitation frequency.

To analyze frequencies between the 1 kHz to 10 kHz range using

the AD5933 and a 16 MHz crystal, scale the system clock by

using an external clock divider. This reduces the sampling

frequency of the ADC to a value less than 1 MHz (f

SAMPLING

=

MCLK/16); however, the 1024 sample set now covers the

response signal under analysis. When scaling the system clock,

the maximum bandwidth of the sweep must be reduced.

To help analyze lower clock frequencies, scale the system clock

connected to the AD5933. This scaling establishes a lower

impedance limit (see Tabl e 2 ); however, the upper excitation

frequency is now limited.

Table 2. Experimental Lower Frequency Limits vs. MCLK

AD5933 Lower Frequency1

Clock Frequency Applied

to MCLK Pin

2

100 kHz to 5 kHz 16 MHz

5 kHz to 1 kHz 4 MHz

5 kHz to 300 Hz 2 MHz

300 Hz to 200 Hz 1 MHz

200 Hz to 100 Hz 250 kHz

100 Hz to 30 Hz 100 kHz

30 Hz to 20 Hz 50 kHz

20 Hz to 10 Hz 25 kHz

1

Lower frequency sweep limit established by applying the divided clock

signal to the MCLK pin of the AD5933 and by calibrating and remeasuring a

nominal impedance Z

linear sweep from the programmed start frequency (I-V gain resistor setting =

Z

, for example, 200 kΩ, PGA = X1. ΔFrequency = 5 Hz, and number

CALIBRATION

of points = 100). The lower frequency limit is established as the frequency at

which the DFT and, therefore, the impedance vs. the frequency results begin

to degrade and deviate from the expected value of the measured impedance

, for example, 200 kΩ.

Z

CALIBRATION

2

TTL clock levels applied to MCLK pin, VIH = 2 V, and VIL = 0.8 V.

, for example, a 200 kΩ resistor over a 500 Hz

CALIBRATION

As an example, if a scaled clock frequency of 4 MHz must be

applied to the external clock pin of the AD5933 to correctly

analyze a 3 kHz signal that has already been established. The

applied system clock (external or internal oscillator) is divided

by a factor of 4 before being routed as the reference clock to the

DDS. The system clock is directly connected to the ADC without

any divide so that the ADC sampling clock is running at 4 times

the speed of the DDS core. Therefore, with a system clock of 4

MHz, the DDS reference clock is now 1/4 × 4 MHz = 1 MHz,

and the ADC clock is 4 MHz. The AD5933 DDS has a 27-bit

phase accumulator; however, the top three most significant bits

(MSBs) are internally connected to logic zero. Therefore, with

the top three MSBs set to zero, the maximum DDS output

frequency is now reduced by a further factor of ⅛th. Therefore, the

maximum output frequency is now 1/32 × 1 MHz = 31.25 kHz.

Rev. 0 | Page 20 of 28

It is possible to accurately measure the 3 kHz signal using a lower

system clock of 4 MHz; however, the two main trade-offs are

that it takes the AD5933 longer to return the impedance results

due to the slower ADC conversion clock speed and that the

upper excitation limit is now restricted to 31.25 kHz.

Measuring Higher Excitation Frequencies

The AD5933 is specified to a typical system accuracy of 0.5%

(assuming the AD5933 system is calibrated correctly for the

impedance range under test) within the frequency range of 1 kHz

to 100 kHz. The lower frequency limit is determined by the value

of the system clock frequency connected to the external clock pin

(MCLK) of the AD5933. The lower limit can be reduced by scaling

the system clock (see the Measuring Lower Excitation Frequencies

section). The upper frequency limit of the system is due to the

finite bandwidth of the internal amplifiers coupled with the

effects of the low-pass filter pole locations (for example, 200 kHz

and 300 kHz), which are used to roll-off any noise signals from

corrupting the DFT output on the receive side of the AD5933.

Therefore, the AD5933 has a finite frequency response similar

to that shown in Figure 28.

20

0

–20

SYSTEM GAIN (dB)

–40

–60

100 1k 10k 100k 1M

Figure 28. Typical AD5933 System Bandwidth

SYSTEM BANDWIDTH (Hz)

10441-031

Using the AD5933 to analyze frequencies past 100 kHz introduces

errors in impedance profile if the sweep span is large, due to the

effect of the increased roll-off in the finite frequency response

of the system past 100 kHz. However, if the user is sweeping in

frequency above 100 kHz, it is important to ensure that the sweep

range is as small as possible, for example, 120 kHz to 122 kHz. The

impedance error from the calibration frequency is approximately

linear over a small frequency range. The user can remove the linear

error introduced by carrying out an endpoint/multipoint

calibration (see the Two Point Calibration section of the AD5933

data sheet for additional details on endpoint calibration).

Page 21

Evaluation Board User Guide UG-364

∇

∇

Measuring the Phase Across an Impedance

The AD5933 returns a complex output code made up of a separate

real and imaginary component. The real component is stored at

Register 0x94 and Register 0x95, and an imaginary component

is stored at Register 0x96 and Register 0x97 after each sweep

measurement. These correspond to the real and imaginary

components of the DFT and not the resistive and reactive

components of the impedance under test.

For example, it is a common misconception that when analyzing a

series RC circuit that the real value stored in Register 0x94 and

Register 0x95 and the imaginary value stored at Register 0x96

and Register 0x97 corresponds to the resistance and capacitive

reactance, respectfully. However, this is incorrect; the magnitude of

the impedance (|Z|) can be calculated by calculating the magnitude

of the real and imaginary components of the DFT given by

22

IRMagnitude +=

After each measurement, multiply it by the calibration term

(see gain factor calculation in AD5933 data sheet) and invert

the product. The magnitude of the impedance is therefore given by

Impedance×=

1

Magnitude FactorGain

where the Gain Factor is given by

⎛

⎜

⎜

Admittance

FactorGain

⎛

=

⎜

Code

⎝

⎞

=

⎟

⎠

Impedance

⎝

Magnitude

⎞

1

⎟

⎟

⎠

Before any valid measurement can take place, the AD5933 system

must be calibrated for a know impedance range to determine

the gain factor. Therefore, the impedance limits of the complex

impedance (Z

) for the sweep frequency range of interest

UNKNOWN

must be known. Place known impedance between the input/output

of the AD5933 and measure the resulting magnitude of the code

to determine what the gain factor is. The AD5933 system gain

settings must be chosen to place the excitation signal in the

linear region of the on-board ADC (refer to the AD5933 data

sheet for further details).

Because the AD5933 returns a complex output code made up of a

real and an imaginary component, the phase of the response

signal through the AD5933 signal path can be calculated. The

−1

phase is given by Phase (rads) = Tan

(I/R).

The phase measured by the previous formula accounts for the

phase shift introduced to the DDS output signal as it passes

through the internal amplifiers on the transmit and receive side

of the AD5933 along with the low-pass filter and the impedance

connected between the VOUT and VIN pins of the AD5933.

The AD5933 parameters of interest are the magnitude of the

impedance (|Z

|) and the impedance phase (ZØ). The

UNKNOWN

measurement of ZØ is a two-step process. The first step

involves calculating the AD5933 system phase. The AD5933

system phase can be calculated by placing a resistor across the

VOUT and VIN pins of the AD5933 and calculating the phase

(using the previous formula) after each measurement point in

the sweep. By placing a resistor across the VOUT and VIN pins,

there is no additional phase lead or lag introduced to the AD5933

signal path, and the resulting phase is due entirely to the internal

poles of the AD5933, that is, the system phase.

Once the system phase has been calibrated using a resistor, the

phase of any unknown impedance can be calculated by inserting

the unknown impedance between the VIN and VOUT terminals

of the AD5933 and by recalculating the new phase (including the

phase due to the impedance) using the previous formula. The

phase of the unknown impedance (ZØ) is given by

ZØ = (Φunknown − ) system∇

where:

system

is the phase of the system with a calibration resistor

connected between VIN and VOUT.

unknown is the phase of the system with the unknown

Φ

impedance connected between VIN and VOUT.

ZØ is the phase due to the impedance, that is, the impedance

phase.

Note that it is possible both to calculate the gain factor and to

calibrate the system phase using the same real and imaginary

component values when a resistor is connected between the

VOUT and VIN pins of the AD5933.

For example, measuring the impedance phase (ZØ) of a

capacitor.

The excitation signal current leads the excitation signal voltage

across a capacitor by −90°; therefore, before any measurement

is taken, expect to see an approximate −90° phase difference

between the system phase responses measured with a resistor

and the system phase responses measured with capacitive

impedance.

As previously outlined, to determine the phase angle of capacitive

system

impedance (ZØ), the system phase response (

) must be

determined and subtracted from the phase calculated with the

capacitor connected between VOUT and VIN (Φ

unknown).

Rev. 0 | Page 21 of 28

Page 22

UG-364 Evaluation Board User Guide

–

Figure 29 shows the AD5933 system phase response calculated

using a 220 k calibration resistor (R

= 220 k, PGA = ×1)

FB

and the repeated phase measurement with a 10 pF capacitive

impedance.

200

180

160

140

120

100

80

PHASE (Degrees)

60

40

20

0

0 15k 30k 45k 60k 75k 90k 105k 120k

220kΩ RESISTOR

10pF CAPACIT OR

FREQUENCY (Hz)

10441-032

Figure 29. System Phase Response vs. Capacitive Phase

The phase difference (that is, ZØ) between the phase response

of a capacitor and the system phase response using a resistor is

the impedance phase of the capacitor (ZØ) and is shown in

Figure 30.

100

–90

–80

–70

–60

–50

–40

PHASE (Degrees)

–30

–20

–10

0

0 15k 30k 45k 60k 75k 90k 105k 120k

FREQUENCY (Hz)

10441-033

Figure 30. Phase Response of a Capacitor

Note that the phase formula used to plot Figure 29 uses the

arctangent function that returns a phase angle in radians and,

therefore, it is necessary to convert from radians to degrees.

In addition, take care when using the arctangent formula when

using the real and imaginary values to interpret the phase at

each measurement point. The arctangent function returns the

correct standard phase angle only when the sign of the real and

imaginary values are positive, that is, when the coordinates lie in

the first quadrant. The standard angle is taken counter clockwise

from the positive real x-axis. If the sign of the real component is

positive and the sign of the imaginary component is negative, that

is, the data lies in the second quadrant, the arctangent formula

returns a negative angle, and it is necessary to add a further 180°

to calculate the correct standard angle. Likewise, when the real

and imaginary components are both negative, that is, when the

coordinates lie in the third quadrant, the arctangent formula

returns a positive angle, and it is necessary to add 180° to the

angle to return the correct standard phase. Finally, when the

real component is positive and the imaginary component is

negative, that is, the data lies in the fourth quadrant, the arctangent

formula returns a negative angle, and it is necessary to add 360° to

the angle to calculate the correct phase angle.

Therefore, the correct standard phase angle is dependent on the

sign of the real and imaginary component and is summarized in

Tabl e 3 .

Table 3. Phase Angle

Real Imaginary Quadrant Phase Angle (Degrees)

Positive Positive First

Positive Negative Second

Negative Negative Third

Positive Negative Fourth

180

−

1

⎛

⎜

⎝

⎛

⎜

⎝

⎛

⎜

⎝

×

)/(Tan

RI

π

180

−

1

−

1

−

1

⎞

)/(Tan180

RI

×+

⎟

π

⎠

180

⎞

)/(Tan180

RI

×+

⎟

π

⎠

180

⎞

)/(Tan360

RI

×+

⎟

π

⎠

Once the magnitude of the impedance (|Z|) and the impedance

phase angle (ZØ, in radians) are correctly calculated, it is possible

to determine the magnitude of the real (resistive) and imaginary

(reactive) components of the impedance (Z

UNKNOWN

) by the vector

projection of the impedance magnitude onto the real and

imaginary impedance axis using the following formulas:

The real component is given by

Z

| = |Z| × cos(ZØ)

|

REAL

The imaginary component is given by

Z

| = |Z| × sin(ZØ)

|

IMAG

Rev. 0 | Page 22 of 28

Page 23

Evaluation Board User Guide UG-364

EVALUATION BOARD SCHEMATICS AND ARTWORK

10441-034

Figure 31. EVAL-AD5933EBZ USB Schematic

Rev. 0 | Page 23 of 28

Page 24

UG-364 Evaluation Board User Guide

10441-035

Figure 32. EVAL-AD5933EBZ Schematic

Rev. 0 | Page 24 of 28

Page 25

Evaluation Board User Guide UG-364

10441-036

Figure 33. Linear Regulator on the EVAL-AD5933EB Evaluation Board

Rev. 0 | Page 25 of 28

Page 26

UG-364 Evaluation Board User Guide

ORDERING INFORMATION

BILL OF MATERIALS

Table 4.

Name Part Description Manufacturer Part Number

C1 to C31 Capacitor, MR04, place holder Not applicable Not applicable

Z1

C5 10 μF tantalum capacitor, 10 V AVX Corporation TAJB106K016R

C7 47 nF capacitor, 50 V, through hole, 10%, R1/8 W Multicomp MCRR50473X7RK0050

C9, C11, C22, C25, C31, C32, C25 10 μF ceramic capacitor, X5R, 0805 Yageo Corporation CC0805KKX5R6BB106

C14 2.2 μF ceramic capacitor, 6.3 V, X5R, 0603, SMD Yageo Corporation CC0603KRX5R5BB225

C6, C8, C10, C12, C13, C15 to C21,

C23, C24, C26, C27, C30, C33,

C34, C36

C28, C29 22 pF ceramic capacitor, 50 V, 5%, 0603, NPO, SMD Yageo Corporation CC0603JRNPO9BN220

CLK1 SMB socket

D4 Green LED, 0805 Avago Technologies HSMG-C170

GL1 Copper short ground link Not applicable Not applicable

J1 USB Mini-B connector Molex 56579-0576

J2 2-pin terminal block (5 mm pitch), CON\POWER Camden Electronics CTB5000/2

LK1 to LK6 Jumper block, 2 pins, 0.1" spacing, SIP-2P Harwin M20-9990246

R1, R2, R7 to R8 49.9 kΩ, SMD resistor, 1%, 0603 Multicomp MC 0.063W 0603 1% 49K9

CAL1 Place holder, insert 2-wire wrap pins, R1/8 W Analog Devices issue 73017015

R4 20 kΩ, SMD resistor (0.1%), 0603 Panasonic ERA3AEB203V

R5 20 kΩ, SMD resistor (0.1%), 0603 Multicomp MC 0.063W 0603 1% 20K

R61 Through hole resistor, 1/8 W Not applicable Not applicable

R10 1 kΩ, 0805, SMD resistor Multicomp MC 0.1W 0805 1% 1K

R11, R12 100 kΩ, 1%, 0603, SMD resistor Multicomp MC 0.063W 0603 1% 100K

R13 0 Ω, 1%, 0603, SMD resistor Multicomp MC 0.063W 0603 0R

R14 10 kΩ, 1%, 0603, SMD resistor Multicomp MC 0.063W 0603 1% 10K

R15, R16 2.2 kΩ, 1%, 0603 SMD resistor Multicomp MC 0.063W 0603 1% 2K2

T1 to T8 Black test point Vero Technologies 20-2137

U1

U2

U3 USB microcontroller, LFCSP-56 Cypress Semiconductor CY7C68013-56LFC

U4 I2C serial EEPROM, 64k, 2.5 V, 8-SOIC Microchip Technologies 24LC64-I/SN

U5, U6

Y1 24 MHz SMD crystal, XTAL-CM309S AEL Crystals X24M000000S244

Y2 3.3 V, 16 MHz clock oscillator AEL Crystals AEL4303

1

Do not install.

Capacitor, MR04, place holder, insert 2-wire

wrap pins

0.1 μF ceramic capacitor, 50 V, X7R, 10%, 0603, SMD AVX Corporation 06035C104KAT2A

Precision, low noise, CMOS, rail-to-rail, input/output

operational amplifiers

1 MSPS, 12-bit impedance converter network

analyzer

High accuracy anyCAP® 200 mA low dropout

linear regulator

Analog Devices issue 73017015

Tyco Electronics

Corporation

Analog Devices AD8606ARZ

Analog Devices AD5933BRSZ

Analog Devices ADP3303ARZ-3.3

1-1337482-0

Rev. 0 | Page 26 of 28

Page 27

Evaluation Board User Guide UG-364

RELATED LINKS

Resource Description

AD5933 1 MSPS, 12-bit impedance converter network analyzer

AD9834 20 mW power, 2.3 V to 5.5 V, 75 MHz complete DDS

ADF4001 200 MHz clock generator PLL

ADuC7020 Precision analog microcontroller, 12-bit analog I/O, ARM7TDMI® MCU

ADCMP601 Rail-to-rail, very fast, 2.5 V to 5.5 V, single-supply TTL/CMOS comparator in a 6-lead SC70 package

ADP3303 High accuracy anyCAP® 200 mA low dropout linear regulator

AD8606 Precision, low noise, CMOS, rail-to-rail, input/output operational amplifiers

Rev. 0 | Page 27 of 28

Page 28

UG-364 Evaluation Board User Guide

NOTES

ESD Caution

ESD (electrostatic discharge) sensitive device. Charged devices and circuit boards can discharge without detection. Although this product features patented or proprietary protection

circuitry, damage may occur on devices subjected to high energy ESD. Therefore, proper ESD precautions should be taken to avoid performance degradation or loss of functionality.

Legal Terms and Conditions

By using the evaluation board discussed herein (together with any tools, components documentation or support materials, the “Evaluation Board”), you are agreeing to be bound by the terms and conditions

set forth below (“Agreement”) unless you have purchased the Evaluation Board, in which case the Analog Devices Standard Terms and Conditions of Sale shall govern. Do not use the Evaluation Board until you

have read and agreed to the Agreement. Your use of the Evaluation Board shall signify your acceptance of the Agreement. This Agreement is made by and between you (“Customer”) and Analog Devices, Inc.

(“ADI”), with its principal place of business at One Technology Way, Norwood, MA 02062, USA. Subject to the terms and conditions of the Agreement, ADI hereby grants to Customer a free, limited, personal,

temporary, non-exclusive, non-sublicensable, non-transferable license to use the Evaluation Board FOR EVALUATION PURPOSES ONLY. Customer understands and agrees that the Evaluation Board is provided

for the sole and exclusive purpose referenced above, and agrees not to use the Evaluation Board for any other purpose. Furthermore, the license granted is expressly made subject to the following additional

limitations: Customer shall not (i) rent, lease, display, sell, transfer, assign, sublicense, or distribute the Evaluation Board; and (ii) permit any Third Party to access the Evaluation Board. As used herein, the term

“Third Party” includes any entity other than ADI, Customer, their employees, affiliates and in-house consultants. The Evaluation Board is NOT sold to Customer; all rights not expressly granted herein, including

ownership of the Evaluation Board, are reserved by ADI. CONFIDENTIALITY. This Agreement and the Evaluation Board shall all be considered the confidential and proprietary information of ADI. Customer may

not disclose or transfer any portion of the Evaluation Board to any other party for any reason. Upon discontinuation of use of the Evaluation Board or termination of this Agreement, Customer agrees to

promptly return the Evaluation Board to ADI. ADDITIONAL RESTRICTIONS. Customer may not disassemble, decompile or reverse engineer chips on the Evaluation Board. Customer shall inform ADI of any

occurred damages or any modifications or alterations it makes to the Evaluation Board, including but not limited to soldering or any other activity that affects the material content of the Evaluation Board.

Modifications to the Evaluation Board must comply with applicable law, including but not limited to the RoHS Directive. TERMINATION. ADI may terminate this Agreement at any time upon giving written notice

to Customer. Customer agrees to return to ADI the Evaluation Board at that time. LIMITATION OF LIABILITY. THE EVALUATION BOARD PROVIDED HEREUNDER IS PROVIDED “AS IS” AND ADI MAKES NO

WARRANTIES OR REPRESENTATIONS OF ANY KIND WITH RESPECT TO IT. ADI SPECIFICALLY DISCLAIMS ANY REPRESENTATIONS, ENDORSEMENTS, GUARANTEES, OR WARRANTIES, EXPRESS OR IMPLIED, RELATED

TO THE EVALUATION BOARD INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTY OF MERCHANTABILITY, TITLE, FITNESS FOR A PARTICULAR PURPOSE OR NONINFRINGEMENT OF INTELLECTUAL

PROPERTY RIGHTS. IN NO EVENT WILL ADI AND ITS LICENSORS BE LIABLE FOR ANY INCIDENTAL, SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES RESULTING FROM CUSTOMER’S POSSESSION OR USE OF