Page 1

PLC Demo System User Guide

A

UG-181

One Technology Way • P. O . Box 9106 • Norwood, MA 02062-9106, U.S.A. • Tel : 781.329.4700 • Fax : 781.461.3113 • www.analog.com

PLC Demo System, Industrial Process Control Demo System

FEATURES

EMC performance tested

Inputs selectable: 0 mA to 20 mA, 4 mA to 20 mA, 0 V to 5 V,

0 V to 10 V, ±5 V, ± 10 V, R TD, TC

Outputs programmable: 0 mA to 20 mA, 0 mA to 24 mA,

4 mA to 20 mA, 0 V to 5 V, 0 V to 10 V, ±5 V, ±10 V

Four isolated 24-bit analog input channels

AD7793 24-bit sigma-delta (Σ-Δ) ADC, 40 nV noise

AD8220 instrumentation amplifier, >80 dB CMRR

ADuM5401 isoPower® integrated, isolated dc-to-dc

converter, 500 mW output power

ADR441 precision 2.5 V reference

4 isolated 16-bit analog output channels

AD5422 single-channel, 16-bit, serial input, current source

and voltage output DAC

0.01% typical total unadjusted error (TUE)

Single chip solution

Output fault detection and protection

Power/interface/control

Analog Devices, Inc., ARM7 ADuC7027

ADP1715 500 mA low-dropout CMOS linear regulator

ADM3251E isolated single-channel RS-232 line

driver/receiver

APPLICATIONS

Process control

Transmitters

Actuator control

PLC/DCS systems

GENERAL DESCRIPTION

The PLC demonstration system is aimed at demonstrating the

value Analog Devices parts can add to a PLC system. The demo

board contains four fully isolated ADC channels, a microprocessor with RS-232 interface and four fully isolated DAC

output channels.

Input ranges are hardware programmable and include 0 V to

5 V, 0 V to 10 V, ±5 V, ±10 V, 4 mA to 20 mA, 0 mA to 20 mA,

±20 mA, thermocouple and RTD. Output ranges are software

programmable and include 0 V to 5 V, 0 V to 10 V, ±5 V,

±10 V, 4 mA to 20 mA, 0 mA to 20 mA, and 0 mA to 24 mA.

The PLC demo system features the AD5422 (a single-chip

16-bit DAC solution with ±0.05% TUE) and AD7793 (low

noise, low power, 24-bit Σ-Δ ADC). Isolation is achieved using

the ADuM5401 (quad-channel isolator with integrated dc-todc converter), ADuM1401 (quad-channel isolator), or

ADM3251E (fully isolated RS-232 transceiver).

Input signal conditioning is performed by the AD8220 (>80 dB

CMRR, JFET in-amp). Voltage references include the ADR441,

ADR445 (ultralow noise, XFET® voltage reference), and

ADP1720 (50 mA, high voltage, micropower linear regulator).

Communications with the ADC and DAC channels take place

using the ADuC7027 microcontroller, which can be connected

to a PC via an isolated RS-232 interface.

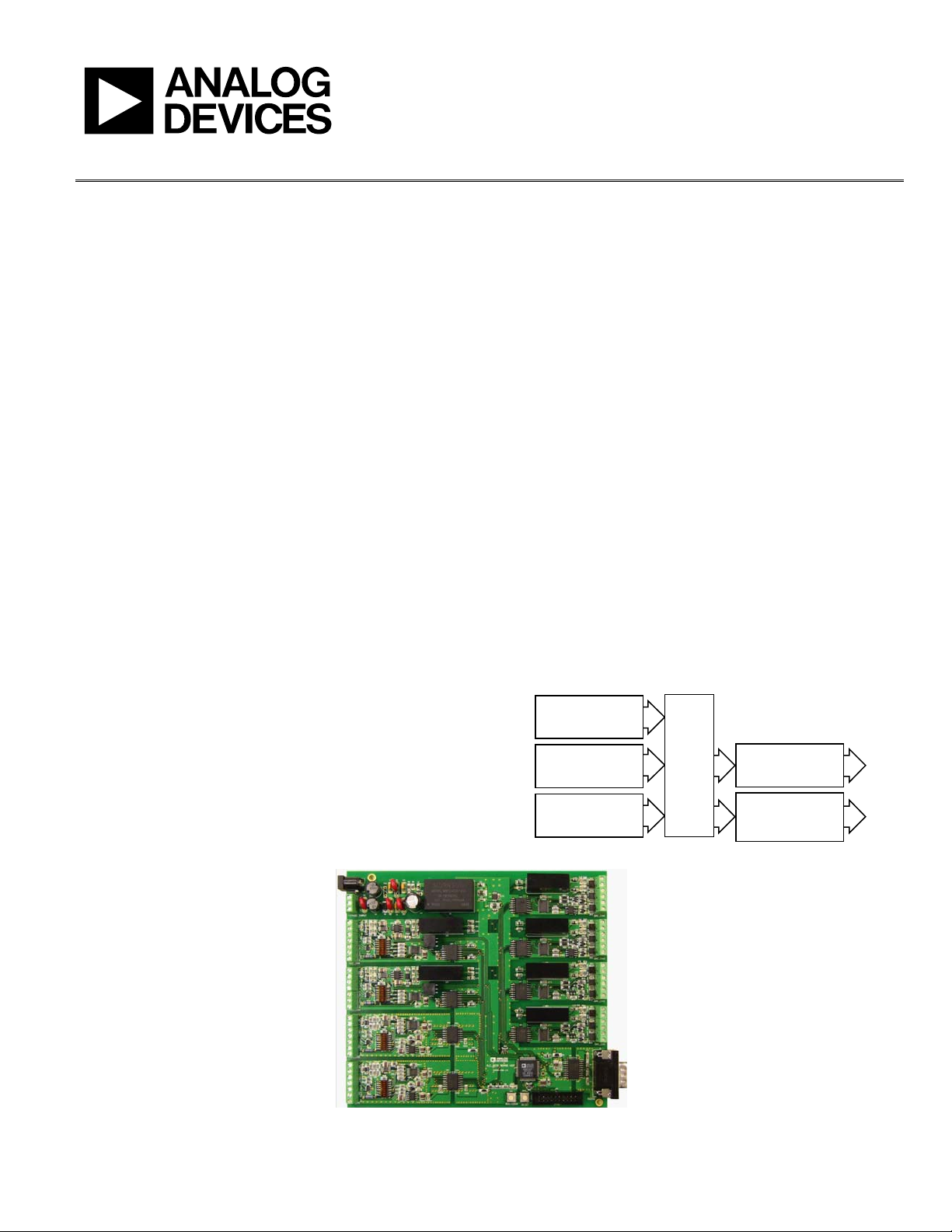

NALOG SIGNALS

SENSOR INPUTS

• RTD

• TC

• GAS

VOLTAGE INPUTS

(FLOW, PRESSURE)

• 0V TO 5V, 0V TO 10V

• ±5V, ±10V

CURRENT INPUTS

(COMMU NICATIONS)

• 0mA TO 20mA

• 4mA TO 20mA

Figure 1. PLC System Level Diagram

PLC

MODULE

BOARD

ANALOG OUTPUTS

VOLTAGE OUTPUTS

• 0V TO 5V, 0V TO 10V

• ±5V, ±10V

CURRENT OUTPUTS

• 0mA TO 20mA

• 0mA TO 24mA

• 4mA TO 20mA

09257-001

09257-002

Figure 2. PLC Demo Board

PLEASE SEE THE LAST PAGE FOR AN IMPORTANT

WARNING AND LEGAL TERMS AND CONDITIONS.

Rev. 0 | Page 1 of 16

Page 2

UG-181 PLC Demo System User Guide

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

General Description ......................................................................... 1

Revision History ............................................................................... 2

PLC Total Solution Diagram ........................................................... 3

Demo Systems Hardware ................................................................. 4

Inputs ............................................................................................. 4

Outputs .......................................................................................... 5

REVISION HISTORY

8/10—Revision 0: Initial Version

Power Supplies ...............................................................................6

RS-232 Communications .............................................................6

Demo System Software .....................................................................7

Software Installation .....................................................................7

Software Operation .......................................................................7

Firmware .........................................................................................9

EMC Test Results ............................................................................ 10

Simplified Input/Output circuit Diagrams ................................. 11

Rev. 0 | Page 2 of 16

Page 3

PLC Demo System User Guide UG-181

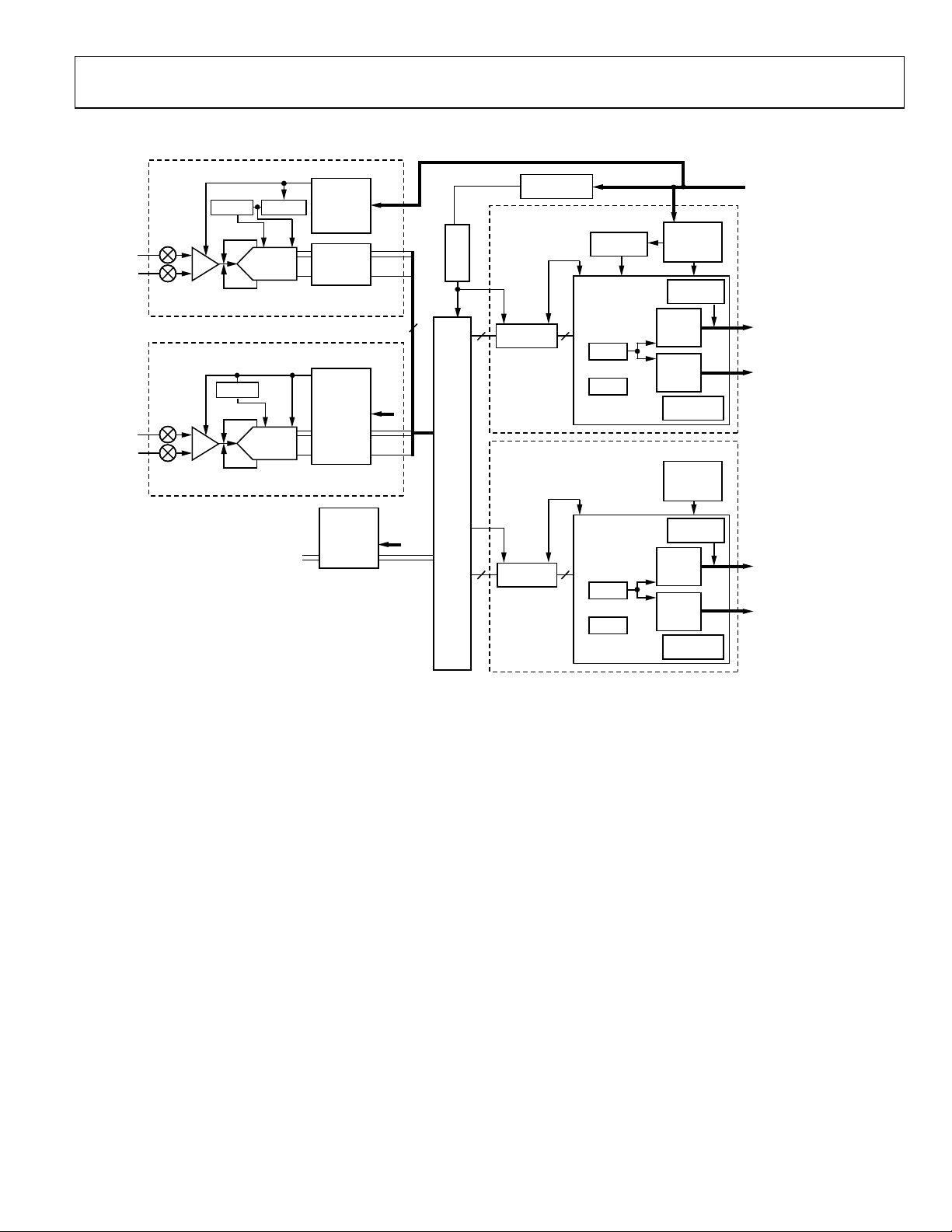

PLC TOTAL SOLUTION DIAGRAM

V/I INPUT S, BIPOLAR SUPPLY, HIGH PERF ORMANCE

±15V

ADR441

AD8220

V/I INPUTS, SINGLE SUPPLY, LO WER COST

IOUT1

IOUT2

ADR441

IOUT1

ADP1720

2.5V 5V

AD7793

2.5V 5V

±15V

ISOLATED

DC-TO-DC

ADuM1401

ISOLATED

ADuM5401

24V

5V

SPI

ADP1715

3.3V

5V

ISO DC-TO-DC

ADuM1401

ISOLATED

ADR445

AD5422

DAC

SPI

24V

(>30mA)

±15V

ISOLATED

DC-TO-DC

OPEN

DETECT

I

OUT

RANGE

SCALE

V

OUT

RANGE

SCALE

OVERTEMP

DETECT

4mA TO 20mA,

0mA TO 24mA

0V TO 5V,

0V TO 10V,

±5V, ±10V

AD8220

IOUT2

AD7793

TX/RX

ISOLATED

ADM3251E

ISOLATED

RS-232

5V

3.3V

ADuC7027

AD5422

ADuM1401

DAC

SPI

ISOLATED

(>30mA)

±15V

ISOLATED

DC-TO-DC

OPEN

DETECT

I

OUT

RANGE

SCALE

V

OUT

RANGE

SCALE

OVERTEMP

DETECT

4mA TO 20mA,

0mA TO 24mA

0V TO 5V,

0V TO 10V,

±5V, ±10V

09257-003

Figure 3. PLC Block Diagram

Rev. 0 | Page 3 of 16

Page 4

UG-181 PLC Demo System User Guide

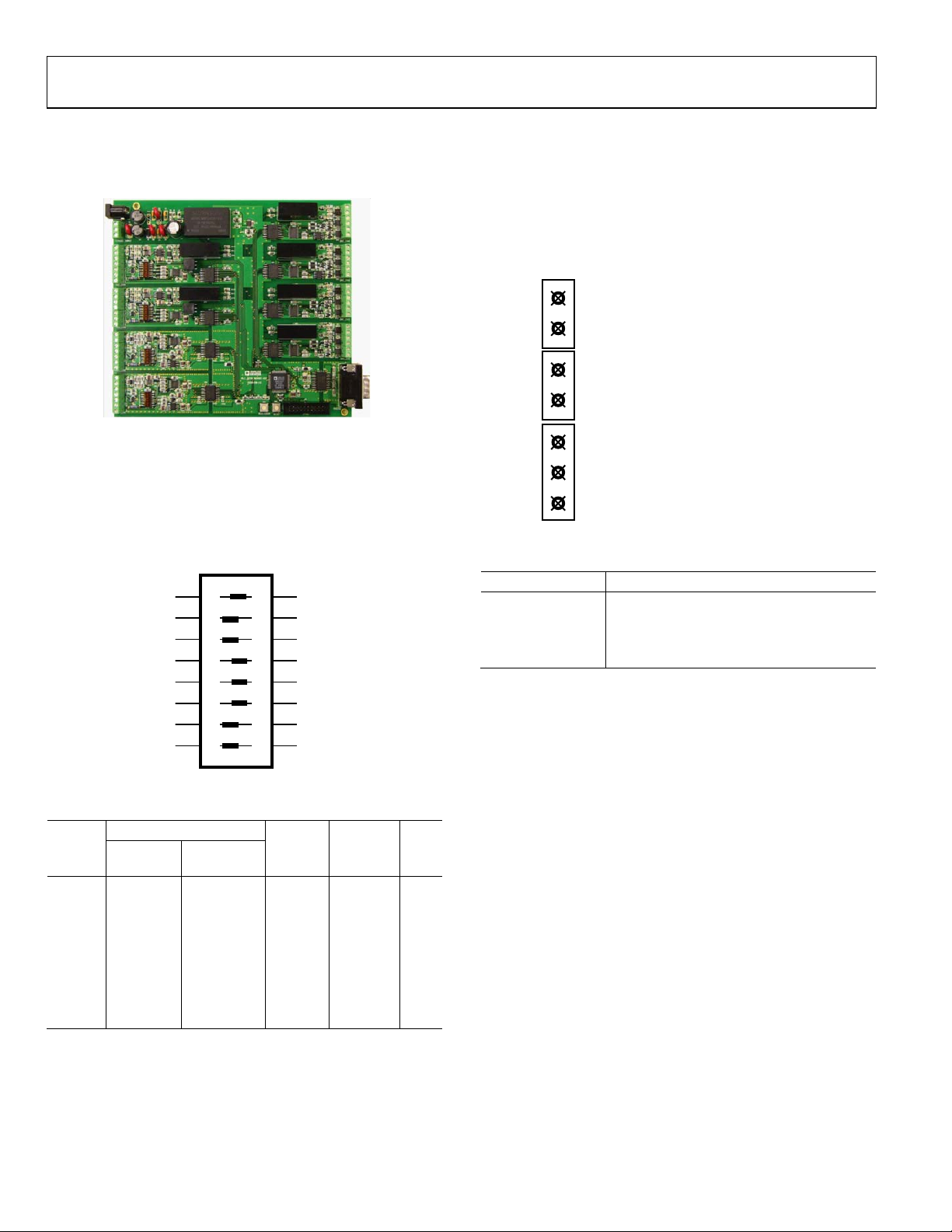

DEMO SYSTEMS HARDWARE

Figure 4 shows the locations of the various functional blocks of

the PLC demo system.

OUTPUT 4

INPUT 4

OUTPUT 3

Input Connectors

Each input channel contains three sets of connectors; Jx1

connectors for voltage and current inputs, Jx2 connectors for

thermocouple inputs, and Jx3 for RTD inputs (see Figure 6).

Although all the channels allow for all three input types, the

PLC demo software limits the inputs as described in Table 2.

INPUT 3

INPUT 2

INPUT 1

Figure 4. Channel Locations

OUTPUT 2

OUTPUT 1

09257-004

INPUTS

DIP switches on the PLC demo board must be set to configure

each input channel to the required input range. These switches

are found to the left of each input channel’s circuitry. Figure 5

shows a diagram of these switches, and Tab le 1 lists the required

switch configurations for each input range.

1

2

3

4

5

6

7

8

Figure 5. Input Channel Switches

Table 1. Input Channel Switch Settings

Range

Switch

No.

0 V to 5 V,

±5 V

0 V to 10 V,

±10 V

1 On Off On Off Off

2 Off Off Off Off Off

3 Off Off On Off Off

4 On On On Off Off

5 On On On Off Off

6 On On On Off Off

7 Off Off Off On Off

8 Off Off Off On Off

ON

Current

9257-005

Thermocouple RTD

–

VOLTAGE AND CURRENT INPUTS

0V TO 5V, 0V TO 10V, ±5V, ±10V

Jx1

0mA TO 20mA, 4mA TO 20mA, ±20mA

+

–

THERMOCOUPL E INPUT

Jx2Jx3

+

I

OUT2

I

3-WIRE RTD I NPUT

OUT1

REF

Figure 6. Input Connectors

09257-006

Table 2. Ranges Allowed in PLC Demo Software

Input Channel Input Type

1 JA1—voltage and current (unipolar)

2 JB2—thermocouple

3 JC1—voltage and current (bipolar)

4 JD3—RTD

Voltage and Current

The JA1 and JC1 connectors allow for various signaling inputs

(see Figure 6). JA1 (Channel 1) allows for single-ended unipolar

inputs: 0 V to 5 V, 0 V to 10 V, 4 mA to 20 mA, and 0 mA to

20 mA. Figure 20 shows a circuit diagram of this input. JC1

(Channel 3) allows for differential inputs: 0 V to 5 V, 0 V to

10 V, ±5 V, ±10 V, 4 mA to 20 mA, 0 mA to 20 mA, and

±20 mA. Figure 21 shows a circuit diagram of this input. To

set the input range switches, see Tabl e 1.

The 250 Ω current sensing resistor on the input channels has a

25 ppm/°C drift specification. The user can observe the drift

from this resistor and can chose to replace this with a lower

drift resistor if greater performance is desired.

Rev. 0 | Page 4 of 16

Page 5

PLC Demo System User Guide UG-181

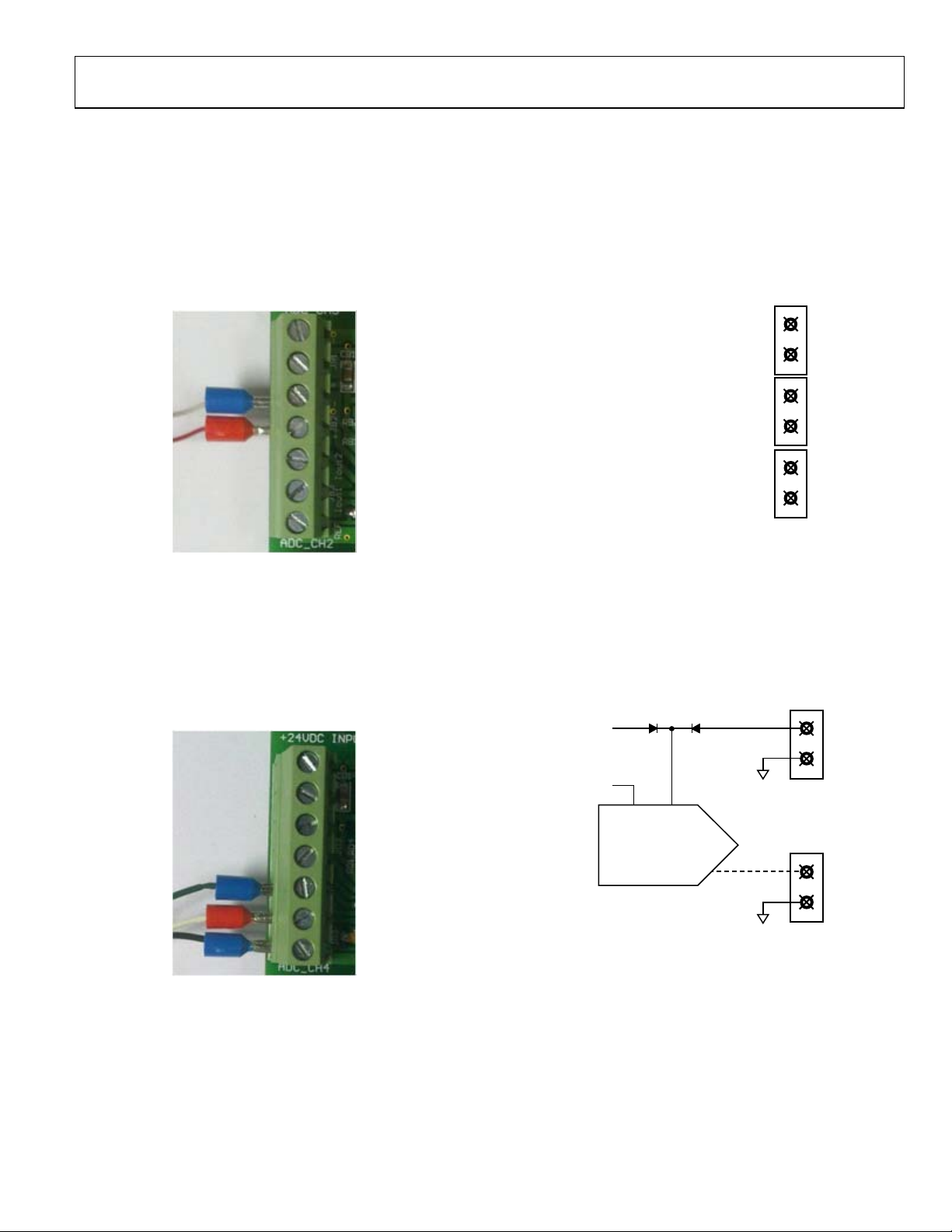

Thermocouple

JB2 (Channel 2) is for thermocouple inputs (see Figure 6).

Figure 22 shows a circuit diagram of this input. The PLC

software allows the user to connect many different thermocouple types including J-, K-, and T-types. To set the input

range switches for thermocouple inputs, see Tab l e 1.

The PLC demo system hardware comes with a T-type

thermocouple. Figure 7 shows how to connect this

thermocouple to the PLC demo board.

OUTPUTS

Each output channel contains both a current and a voltage

output connector. The relevant connectors are +VOUT/GND

and IOUT/GND (Figure 9). The available output ranges are 0 V

to 5 V, 0 V to 10 V, ±5 V, ±10 V, 4 mA to 20 mA, 0 mA to 20 mA,

and 0 mA to 24 mA. On each channel, either the voltage or

the current output can be enabled. The output that is not in

use is tristated. If neither channel is enabled both are tristated.

Figure 24 shows a circuit diagram of the output channels.

09257-007

Figure 7. Thermocouple Connector

RTD

JD3 (Channel 4) is for 3-wire RTD inputs (see Figure 6).

Figure 23 shows a circuit diagram for these inputs. To set

the input range switches for 3-wire RTD inputs, see Ta ble 1 .

The PLC demo system hardware comes with a PT1000 RTD

temperature sensor. Figure 8 shows how to connect this RTD

to the PLC demo board.

OPTIONAL 32V INPUT

TO INCREASE THE VOLTAGE

COMPLIANCE LIMIT ON THE

CURRENT OUTPUT

VOLTAGE OUTPUT

0V TO 5V,

0V TO 10V,

±5V, ±10V

CURRENT OUTPUT

0mA TO 20mA,

4mA TO 20mA,

0mA TO 24mA

+32VDC

GND

+VOUT

GND

IOUT

GND

09257-009

Figure 9. Output Connectors

Increasing the Output Compliance

The voltage compliance limit on the current output is 12.5 V.

A connector is available to externally provide 32 V dc, which

increases the output compliance to 29.5 V. The relevant

connectors are labeled +32VDC and GND (see Figure 9).

Figure 10 shows how +32VDC is connected to the channel

supply of the AD5422. There is a 20 V TVS on the I

, which

OUT

may need to be changed/removed if an external supply is used.

+15V

ISO

+32VDC

GND

Figure 8. RTD Connection

–15V

ISO

V

V

DD

SS

V

I

OUT

OUT

I

OUT

GND

09257-010

AD5422

Figure 10. +32VDC Connection on the Output Channels

09257-008

Rev. 0 | Page 5 of 16

Page 6

UG-181 PLC Demo System User Guide

POWER SUPPLIES RS-232 COMMUNICATIONS

The PLC demo system uses an RS-232 straight through DB-9

connector. This connector is supplied with the PLC demo

system board. The RS-232 signal can be connected straight to

the RS-232 port of the PC. If the PC being used does not have

an RS-232 port, a RS-232-to-USB converter can be used.

COM

+24VDC

09257-011

Figure 11. Power Connections

The demo board should be powered by a 24 V dc, ±10%,

500 mA supply. This should be connected via the +24VDC

INPUT (JP2) socket. All other supplies on the PLC demo

board are derived from this 24 V dc supply.

The RS-232 connection between the PLC demo board and PC

is fully isolated using the ADM3251E isolated single-channel

RS-232 line driver/receiver.

Rev. 0 | Page 6 of 16

Page 7

PLC Demo System User Guide UG-181

DEMO SYSTEM SOFTWARE

SOFTWARE INSTALLATION

The demonstration kit includes self-installing software. The

software is compatible with Windows® 2000 and Windows XP.

Run the setup.exe file to begin the installation.

After the installation has completed, connect the demo board

to the computer serial port using a serial cable and power the

board using a 24 V dc supply as described in the Power Supplies

section.

SOFTWARE OPERATION

1. To run the software, click Start > All Programs > Analog

Devices > PLC Demo System > PLC EVALUATION SW

V3.x. The window in Figure 12 should appear.

09257-013

Figure 13. Menu Bar

The following tabs are available in the software:

• Operate tab

• Thermocouple tab

• PT1000 RTD tab

• ADC Stats tab

• ADC Configure tab

• DAC Configure tab

Figure 12. Main Window

2. The menu bar on the left of the main window (see

Figure 13) allows the user to select the ADC/DAC

channel and range. It also allows the user to set the

RS-232 communication port of the PC.

To set up an input channel, see the Demo Systems

Hardware section. Ensure the ADC range switches

are set correctly for the selected channel.

Then, use the correct connector for the specified

channel

and range.

Operate Tab

09257-012

The Operate tab can be used with Input Channel 1 and Input

Channel 3 as well as all the output channels. In the Operate tab

of the software window, you can

• Perform an ADC conversion(s).

• Write to an output channel. To do this, enter a value in

the DAC Output Value box and click Write. The hex

value written to the DAC is displayed to the right of

these controls.

09257-014

Figure 14. Operate Tab

Rev. 0 | Page 7 of 16

Page 8

UG-181 PLC Demo System User Guide

Thermocouple Tab

The Thermocouple tab allows for thermocouple measurement

on Output Channel 2. See the Demo Systems Hardware section

for setting up a thermocouple channel. Click Run to start the

measurement (see Figure 15).

The measurement is performed by executing a thermocouple

voltage reading (the bias voltage generator for the AD7793 is

used for this) followed by a cold-junction reading from the

on-board thermistor (using the excitation current sources

of the AD7793).

See the AN-880 Application Note, ADC Requirements for

Temperature Measurement Systems, for information on

thermocouple measurements using the AD7793.

ADC Stats Tab

The ADC Stats tab can be used to perform statistical analysis

on channel input. To carry out this analysis, complete the

following steps:

1. Connect the input channel to the desired source.

2. Select the number of samples to be taken from the No.

of Samples box.

3. Click Measure.

4. The sampling can be stopped at any stage by clicking

STOP.

Once the sampling is complete, the histogram is updated

as well as the statistical information (mean, RMS value,

p-p noise, standard deviation, and p-p resolution)

09257-015

Figure 15. Thermocouple Tab

PT1000 RTD Tab

The PT1000 RTD tab allows for RTD measurement on ADC

Channel 4. See the Demo Systems Hardware section for setting

up an RTD channel. Click Run to start the measurement (see

Figure 16).

See the AN-880 Application Note, ADC Requirements for

Temperature Measurement Systems, and the AD7793 data

sheet, for information on RTD measurements using the

AD7793.

09257-025

Figure 16. PT1000 RTD Tab

Figure 17. ADC Stats Tab

9257-016

Rev. 0 | Page 8 of 16

Page 9

PLC Demo System User Guide UG-181

ADC Configure Tab DAC Configure Tab

Use the ADC Configure tab to alter ADC register settings.

Some of these setting are automatically altered when using

the Thermocouple or PT1000 RTD tab (see Figure 18).

The ADC Configure tab also displays the current calibration

values. The ADC can be recalibrated using the following

procedure:

1. Connect a (precision) dc source to the system voltage

input (Jx3 connector).

2. Ensure that the correct input range is set in both the

hardware and the software.

3. Click New Calibration and follow the on-screen

instructions.

Use the DAC Configure tab to alter the control register of a

DAC (see Figure 19).

To revert to the default calibration values, click Load Original

Values. These default calibration values were created using the

DAC outputs. To generate more accurate calibration values,

use a precision dc source as previously outlined in this section.

09257-017

Figure 18. ADC Configure Tab

09257-019

Figure 19. DAC Configure Tab

FIRMWARE

The firmware on the ADuC7027 is designed to perform basic

communications between the on-board data converters and a

PC. This basic firmware is available on the PLC website. The

firmware that comes on the PLC demo board also has functions

to store calibration data for the PLC demo software.

Rev. 0 | Page 9 of 16

Page 10

UG-181 PLC Demo System User Guide

EMC TEST RESULTS

A sample was tested during initial release and met the following test compliances. These results should be viewed as typical data taken at

25°C. For these tests, the DAC outputs were connected to the DAC inputs, that is, DAC2 to ADC2, DAC3 to ADC3, and DAC4 to ADC4.

The DAC outputs were set to 5 V, 6 V, and 10 mA, respectively.

Table 3.

Test Item Description Result

EN55022

EN and IEC 61000-4-2

EN and IEC 61000-4-3

EN and IEC 61000-4-4

EN and IEC 61000-4-5 Power line surge, ±2 kV

EN and IEC 61000-4-6

Radiated emission Class A,

3-meter anechoic chamber

Electrostatic discharge (ESD)

±8 kV VCD

Electrostatic discharge (ESD)

±8 kV HCD

Radiated immunity 80 MHz to

1 GHz 18 V/m, vertical antenna

polarization

Radiated immunity 80 MHz to

1 GHz 18 V/m, horizontal antenna

polarization

Electrically fast transient (EFT)

±4 kV power port

Electrically fast transient (EFT)

±2 kV analog I/O ports

Conducted immunity test on

power cord, 10 V/m for 30 minutes

Conducted immunity test on I/O

cable 10 V/m for 30 minutes

Passed and met −6 dB margin.

Maximum deviations in Input Channel 2, Input Channel 3, and Input Channel 4

are respectively −8 ppm, 10 ppm, 13 ppm when there is interference.

Maximum deviations in Input Channel 2, Input Channel 3, and Input Channel 4

are respectively −8 ppm, 10 ppm, 13 ppm when there is interference.

Maximum deviations in Input Channel 2, Input Channel 3, and Input Channel 4

are 0.05%, 0.004%, −0.13%. Performance automatically resorted to ≤0.05%

after interference. Class B.

Maximum deviations in Input Channel 2, Input Channel 3, and Input Channel 4

are −0.09%, 0.003%, −0.02%. Performance automatically resorted to ≤0.05%

after interference. Class B.

Passed Class B.

Passed Class B

No board or part damage occurred, no performance degrade, passed with

Class A.

Maximum deviations in Input Channel 2, Input Channel 3, and Input Channel 4

are respectively 9.3%, 11%, 3.4%. Passed Class B.

Maximum deviations in Input Channel 2, Input Channel 3, and Input Channel 4

are respectively 4.5%, 4.7%, 1.4%. Performance automatically resorted to

≤0.05% when interference stopped.

Rev. 0 | Page 10 of 16

Page 11

PLC Demo System User Guide UG-181

V

SIMPLIFIED INPUT/OUTPUT CIRCUIT DIAGRAMS

Figure 20 shows a simplified circuit diagram for Input Channel 1

(Input Channel 2 follows the same format). On the input side,

the precision current setting resistor can be switched in and out

selecting either current or voltage mode. Resistors R

and RB

A

divide down the input signal into the range of the AD7793.

The AD8226 output is biased with a common-mode signal

connected to the REF pin so that the signal meets the input

requirements of the AD7793.

For more information on this circuit, see Circuit Note CN-0067.

FERRITE BEAD

250Ω

LOW DRIFT

TVS

RESIST OR

20V

INPUT

S3

ISO

R

A

51kΩ

R

B

S1

REF

AD8226

R

G

R

G

ISO

S4

S5

AIN1(+)

AIN1(–)

Figure 21 shows a simplified circuit diagram for Input Channel 3

(Input Channel 4 follows the same format). On the input side,

the precision current setting resistor can be switched in and out

selecting either current or voltage mode. Resistors R

divide down the pseudodifferential input signal into the range

of the AD7793. The AD8226 output is biased with a commonmode signal connected to the REF pin so that the signal meets

the input requirements of the AD7793. This circuit has bipolar

supplies and, thus, allows bipolar inputs.

For more information on a similar circuit, see Circuit Note

CN-0067.

ADuM5401

AV

DD

AD7793

REFIN( +) REFI N(–)

ISO ISO

S6

CS

SCLK

DIN

DOUT

GND

ISO

ISO

V

ISO

GND

V

OA

V

OB

V

OC

V

ID

V

SEL

GND

ISO

ISO

V

GND1

RC

GND1

V

DD1

V

V

V

OD

OUT

5V

IA

IB

IC

CS

SCLK

D

D

OUT

GND

IN

and RB

A

EXTERNAL INPUTS

AD8601

0.5V

ISO

25kΩ

5.1kΩ

ISO

ADR441

V

OUTVIN

ISO

09257-020

Figure 20. Input Channel 1 and Input Channel 2—Voltage and Current Input

+15

ISO

ISOLATED

BIPOLAR

SUPPLY

+15V

ISO

ADR441

ISO

ISO

ADuM1401

V

DD2

GND

V

OA

V

OB

V

OC

V

ID

V

E2

GND

OUTVIN

+15V

REF

R

R

G

G

ISO

AD8226

+15V

ISO

ISO

AV

AIN1(+)

S4

AIN1(–)

S5

DD

AD7793

REFIN(+) REFIN(–)

ISO ISO

S6

CS

SCLK

DIN

DOUT

GND

FERRITE BEAD

250Ω

LOW DRIFT

TVS

RESISTO R

20V

INPUT

S3

FERRITE BEAD

ISO

R

A

51kΩ

R

B

R

B

S1

R

A

ADR441

V

OUTVIN

ISO

Figure 21. Input Channel 3 and Input Channel 4—Voltage and Current Input

ISO

–15V

ISO

V

DD1

GND

V

GND

1

V

IA

V

IB

V

IC

OD

V

E1

1

2

2

5V

CS

SCLK

D

D

OUT

GND

IN

EXTERNAL INPUTS

09257-021

Rev. 0 | Page 11 of 16

Page 12

UG-181 PLC Demo System User Guide

A

T

A

Figure 22 shows a simplified circuit diagram for the thermocouple inputs. The ADC includes an on-chip PGA and can,

therefore, accept small signal inputs from sensors directly. The

PGA gains can be set for 1, 2, 4, 8, 16, 32, 64, or 128. The PLC

demo board also includes an on-board thermistor for the coldjunction compensation measurement.

See the AN-880 Application Note, ADC Requirements for

Temperature Measurement Systems, and the AD7793 data

sheet for information on thermocouple measurements using

the AD7793.

IOUT2

HERMISTOR

5.1kΩ

LOW DRIFT

RESISTOR

THERMOCOUPL E

INPUT

S8

S7

ISO

AIN2(+)

AIN2(–)

AIN1(+)

AIN1(–)

IOUT1

V

BIAS

Figure 23 shows a simplified circuit diagram for the 3-wire RTD

inputs. The AD7793 contains two matched excitation current

sources for 3-wire RTD measurements. See the AN-880 Application Note, ADC Requirements for Temperature Measurement

Systems, and the AD7793 data sheet, for information on RTD

measurements using the AD7793.

DuM5401

AV

INAMP

REFIN(+)

DD

AD7793

Σ-Δ

ADC

REFIN(–)

ISO

SCLK

DOUT

ISO

CS

DIN

GND

ISO

ISO

V

ISO

GND

V

OA

V

OB

V

OC

V

ID

V

SEL

GND

ISO

ISO

V

GND1

RC

GND1

DD1

V

V

V

V

OUT

5V

IA

IB

IC

OD

CS

SCLK

D

D

OUT

GND

IN

EXTERNAL INPUTS

ISO

09257-022

Figure 22. Thermocouple Inputs

DuM5401

INPUT

3-WIRE RTD

5.1kΩ

LOW DRIFT

RESISTOR

ISO

ISO

AIN2(+)

AIN2(–)

AIN1(+)

AIN1(–)

IOUT2

IOUT1

AV

DD

AD7793

REFIN(+)

REFIN(–)

SCLK

DOUT

ISO

CS

DIN

GND

ISO

ISO

V

ISO

GND

V

OA

V

OB

V

OC

V

ID

V

SEL

GND

ISO

ISO

V

GND1

RC

GND1

V

DD1

V

V

V

OD

OUT

5V

IA

IB

IC

CS

SCLK

D

D

OUT

GND

IN

EXTERNAL INPUTS

09257-023

Figure 23. 3-Wire RTD Inputs

Rev. 0 | Page 12 of 16

Page 13

PLC Demo System User Guide UG-181

V

Figure 24 shows a simplified circuit diagram for Output

Channel 3 and Output Channel 4. Output Channel 1 and

Output Channel 2 are the same except they use the AD5422

internal 10 ppm/°C (maximum) reference. An internal boost

transistor is available on-chip though an external boost

+15

ISO

ADR445

VINV

+15V

ISO

OUT

–15V

ISO

ISOLATED

BI-POLAR

SUPPLY

+15V

–15V

ISO

ISO

ISO

ADuM1401

AV

AV

DD

ISO

SS

CLEAR

SELECT

LOW DRIF T

RESISTOR

EXTERNAL INPUTS

3.3V

SYNC

SCLK

DIN

0V

V

DD1

GND

V

IA

V

IB

V

IC

V

OD

V

E1

GND

V

DD2

GND

V

V

V

GND

2

OA

OB

OC

V

ID

V

E2

2

1

1

ISO

DV

CC

LATCH

SCLK

SDIN

SDO

FAU LT

CLEAR GND

Figure 24. Output Channel 3 and Output Channel 4—Voltage and Current Output

REFIN

AD5422

R

15kΩ

transistor has been used for those who may wish to operate

at the extremes of the supply voltage, load current, and

temperature range.

For more information on this circuit, see Circuit Note CN-0065.

SET

BOOST

ISO

–V

C

SENSE

COMP

4nF

ISO

+15V

C

B

E

1kΩ 10Ω

22nF

ISO

ISO

FERRITE

ISO

+15V

I

OUT

+V

SENSE

V

OUT

BEAD

TVS

20V

ISO

–15V

ISO

–15V

ISO

TVS

20V

ISO

CURRENT

OUTPUT

RL

VOLTAGE

OUTPUT

09257-024

Rev. 0 | Page 13 of 16

Page 14

UG-181 PLC Demo System User Guide

NOTES

Rev. 0 | Page 14 of 16

Page 15

PLC Demo System User Guide UG-181

NOTES

Rev. 0 | Page 15 of 16

Page 16

UG-181 PLC Demo System User Guide

NOTES

ESD Caution

ESD (electrostatic discharge) sensitive device. Charged devices and circuit boards can discharge without detection. Although this product features patented or proprietary protection

circuitry, damage may occur on devices subjected to high energy ESD. Therefore, proper ESD precautions should be taken to avoid performance degradation or loss of functionality.

Legal Terms and Conditions

By using the evaluation board discussed herein (together with any tools, components documentation or support materials, the “Evaluation Board”), you are agreeing to be bound by the terms and conditions

set forth below (“Agreement”) unless you have purchased the Evaluation Board, in which case the Analog Devices Standard Terms and Conditions of Sale shall govern. Do not use the Evaluation Board until you

have read and agreed to the Agreement. Your use of the Evaluation Board shall signify your acceptance of the Agreement. This Agreement is made by and between you (“Customer”) and Analog Devices, Inc.

(“ADI”), with its principal place of business at One Technology Way, Norwood, MA 02062, USA. Subject to the terms and conditions of the Agreement, ADI hereby grants to Customer a free, limited, personal,

temporary, non-exclusive, non-sublicensable, non-transferable license to use the Evaluation Board FOR EVALUATION PURPOSES ONLY. Customer understands and agrees that the Evaluation Board is provided

for the sole and exclusive purpose referenced above, and agrees not to use the Evaluation Board for any other purpose. Furthermore, the license granted is expressly made subject to the following additional

limitations: Customer shall not (i) rent, lease, display, sell, transfer, assign, sublicense, or distribute the Evaluation Board; and (ii) permit any Third Party to access the Evaluation Board. As used herein, the term

“Third Party” includes any entity other than ADI, Customer, their employees, affiliates and in-house consultants. The Evaluation Board is NOT sold to Customer; all rights not expressly granted herein, including

ownership of the Evaluation Board, are reserved by ADI. CONFIDENTIALITY. This Agreement and the Evaluation Board shall all be considered the confidential and proprietary information of ADI. Customer may

not disclose or transfer any portion of the Evaluation Board to any other party for any reason. Upon discontinuation of use of the Evaluation Board or termination of this Agreement, Customer agrees to

promptly return the Evaluation Board to ADI. ADDITIONAL RESTRICTIONS. Customer may not disassemble, decompile or reverse engineer chips on the Evaluation Board. Customer shall inform ADI of any

occurred damages or any modifications or alterations it makes to the Evaluation Board, including but not limited to soldering or any other activity that affects the material content of the Evaluation Board.

Modifications to the Evaluation Board must comply with applicable law, including but not limited to the RoHS Directive. TERMINATION. ADI may terminate this Agreement at any time upon giving written notice

to Customer. Customer agrees to return to ADI the Evaluation Board at that time. LIMITATION OF LIABILITY. THE EVALUATION BOARD PROVIDED HEREUNDER IS PROVIDED “AS IS” AND ADI MAKES NO

WARRANTIES OR REPRESENTATIONS OF ANY KIND WITH RESPECT TO IT. ADI SPECIFICALLY DISCLAIMS ANY REPRESENTATIONS, ENDORSEMENTS, GUARANTEES, OR WARRANTIES, EXPRESS OR IMPLIED, RELATED

TO THE EVALUATION BOARD INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTY OF MERCHANTABILITY, TITLE, FITNESS FOR A PARTICULAR PURPOSE OR NONINFRINGEMENT OF INTELLECTUAL

PROPERTY RIGHTS. IN NO EVENT WILL ADI AND ITS LICENSORS BE LIABLE FOR ANY INCIDENTAL, SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES RESULTING FROM CUSTOMER’S POSSESSION OR USE OF

THE EVALUATION BOARD, INCLUDING BUT NOT LIMITED TO LOST PROFITS, DELAY COSTS, LABOR COSTS OR LOSS OF GOODWILL. ADI’S TOTAL LIABILITY FROM ANY AND ALL CAUSES SHALL BE LIMITED TO THE

AMOUNT OF ONE HUNDRED US DOLLARS ($100.00). EXPORT. Customer agrees that it will not directly or indirectly export the Evaluation Board to another country, and that it will comply with all applicable

United States federal laws and regulations relating to exports. GOVERNING LAW. This Agreement shall be governed by and construed in accordance with the substantive laws of the Commonwealth of

Massachusetts (excluding conflict of law rules). Any legal action regarding this Agreement will be heard in the state or federal courts having jurisdiction in Suffolk County, Massachusetts, and Customer hereby

submits to the pers onal jurisdiction and venu e of such courts. The United Nations Conventi on on Contracts for the Internation al Sale of Goods shall not apply to this Agreement and is expressly disclaimed.

©2010 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

UG09257-0-8/10(0)

Rev. 0 | Page 16 of 16

Loading...

Loading...