Page 1

UDx2559LB

1

UDx2559B

Data Sheet

29317.14A

2559

PROTECTED

QUAD POWER DRIVER

Providing improved output current limiting, the UDK, UDN, and

UDQ2559B, EB, and LB quad power drivers combine AND logic

gates and high-current bipolar outputs with complete output protection.

16

Each of the four outputs will sink 700 mA in the on state. The outputs

have a minimum breakdown voltage (load dump) of 60 V and a

sustaining voltage of 40 V. The inputs are compatible with TTL and

5 V CMOS logic systems.

OUT

OUT

GROUND

GROUND

OUT

OUT

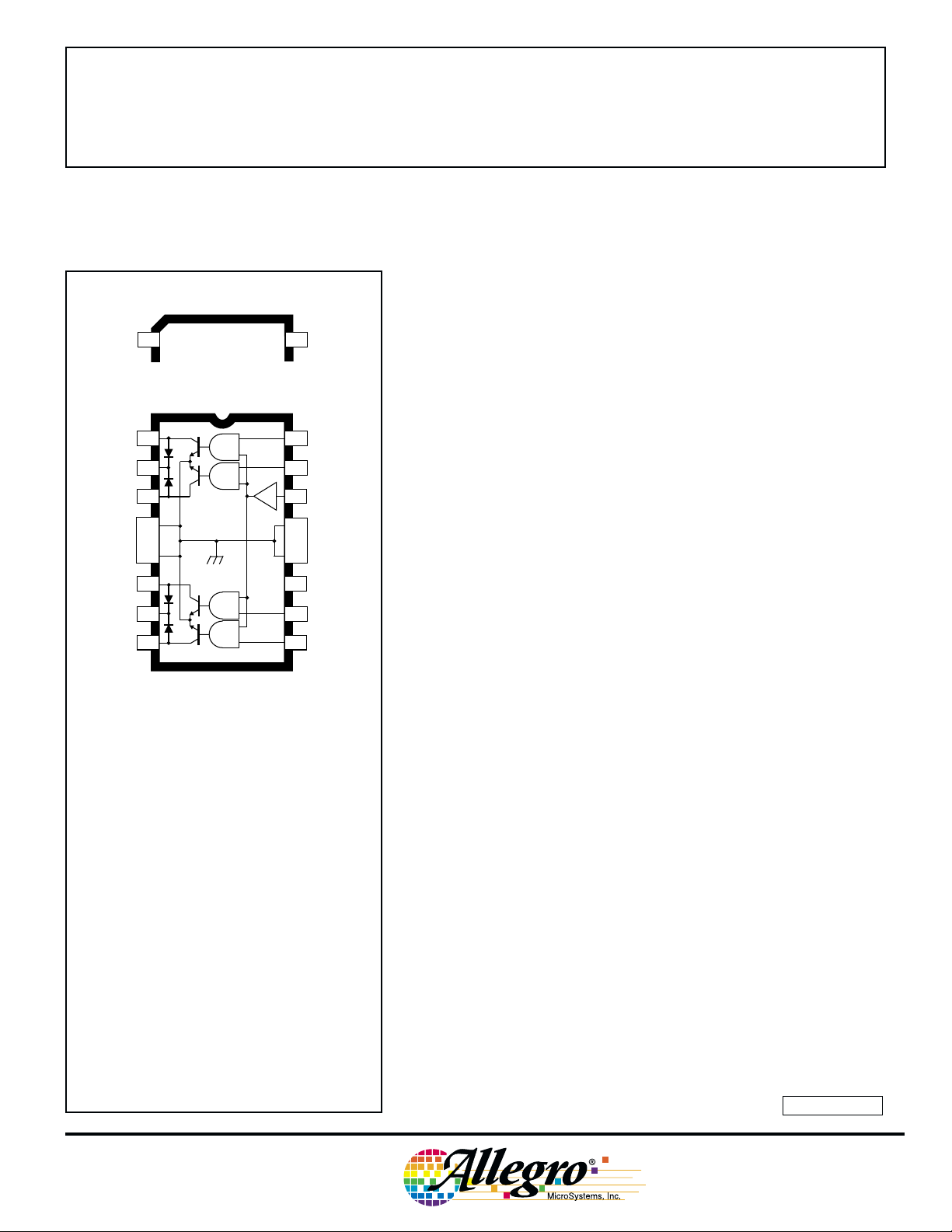

1

4

2

K

3

3

4

5

6

2

7

K

8

1

16

IN

15

IN

14

ENABLE

13

GROUND

12

GROUND

V

11

CC

10

IN

IN

9

Dwg. PP-017-1

4

3

2

1

ABSOLUTE MAXIMUM RATINGS

at TA = 25°C

Output Voltage, V

Over-Current Protected Output Voltage,

V

. . . . . . . . . . . . . . . . . . . 25 V

OUT

Output Current, I

Supply Voltage, VCC .. . . . . . . . . 7.0 V

Input Voltage, VIN or V

Package Power Dissipation,

PD . . . . . . . . . . . . . . . . See Graph

Operating Temperature Range, T

Prefix ‘UDK’ . . . . -40°C to +125°C

Prefix ‘UDN’ . . . . . -20°C to +85°C

Prefix ‘UDQ’ . . . . . -40°C to +85°C

Storage Temperature Range,

TS . . . . . . . . . . . . -55°C to +150°C

*Outputs are peak current limited at

approximately 1.0 A per driver. See

Circuit Description and Application for

further information.

. . . . . . . . . 60 V

OUT

. . . . . . . . . 1.0 A*

OUT

. . . . . . 7.0 V

EN

A

Over-current protection for each channel has been designed into

these devices and is activated at approximately 1 A. It protects each

output from short circuits with supply voltages up to 25 V. When an

output current trip point is reached, that output stage is driven linearly

resulting in a reduced output current level. If an over-current or shortcircuit condition continues, the thermal-limiting circuits will first sense

the rise in junction temperature and then the rise in chip temperature,

further decreasing the output current. Under worst-case conditions,

these devices will tolerate short circuits on all outputs, simultaneously.

These devices can be used to drive various loads including incandescent lamps (without warming or limiting resistors) or inductive

loads such as relays, solenoids, or dc stepping motors.

The suffix ‘B’ devices are 16-pin power DIPs, the suffix ‘EB’

devices are 28-lead power PLCCs and suffix ‘LB’ devices are 16-lead

power SOICs for surface-mount applications. All three packages are

of batwing construction to provide for maximum package power

dissipation.

FEATURES

■ 700 mA Output Current per Channel

■ Independent Over-Current Protection for Each Driver

■ Thermal Protection for Device and Each Driver

■ Low Output-Saturation Voltage

■ Integral Output Flyback Diodes

■ TTL and 5 V CMOS Compatible Inputs

■ Pin-Compatible With UDQ2543B/EB and UDK2549B/EB

Always order by complete part number: a prefix to

indicate operating temperature range + the basic four-digit

part number + a suffix to indicate package style, e.g., UDK2559LB .

Page 2

2559

PROTECTED

QUAD POWER DRIVER

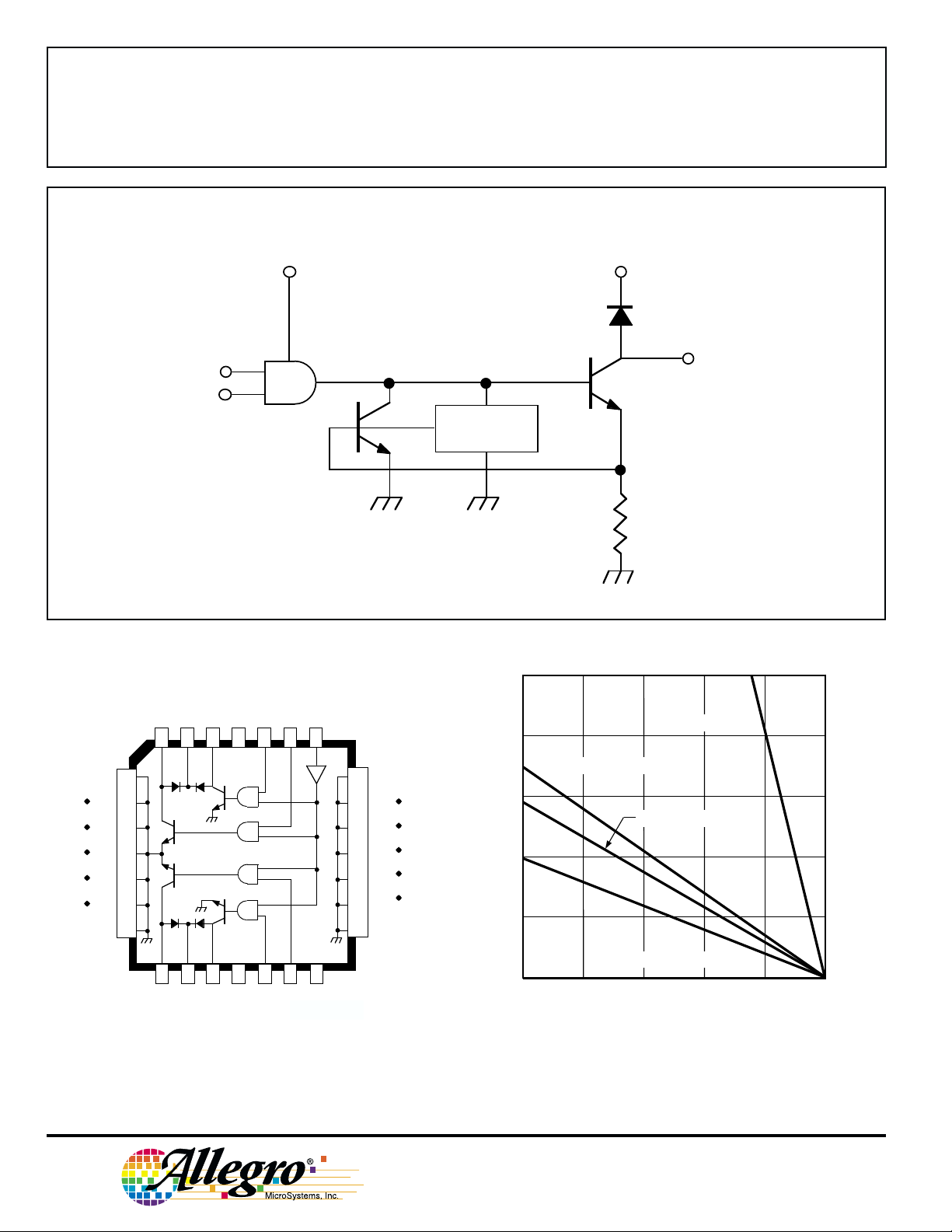

FUNCTIONAL BLOCK DIAGRAM

(1 of 4 Channels)

GROUND

GROUND

ENABLE

5

6

7

8

9

10

11

IN

N

UDx2559EB

2

OUT

4

12

3

OUT

1

OUT

NO

K

2

14

4

OUT

1

NC

NC

15

NO

3

13

K

1

IN

CONNECTION

28

16

4

IN

CONNECTION

V

CC

K

OUT

N

THERMAL

LIMIT

<<1 Ω

Dwg. FP-041

5

2

ENABLE

IN

26

27

GROUND

25

24

23

22

21

20

GROUND

19

V

CC

18

17

3

IN

SUPPLY

Dwg. PP-019-1

4

SUFFIX 'EB', R = 36°C/W

θJA

3

SUFFIX 'B', R = 43°C/W

2

1

SUFFIX 'LB', R = 63°C/W

0

25

ALLOWABLE PACKAGE POWER DISSIPATION IN WATTS

PD = (V

50 75 100 125 150

TEMPERATURE IN °C

OUT1

x I

x dc) + … + (V

OUT1

+ (VCC x ICC) = (TJ - TA)/R

R = 6°C/W

θJT

θJA

θJA

θJA

OUTn

x I

Dwg. GP-004-2A

x dc)

OUTn

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 1995, 2000 Allegro MicroSystems, Inc.

Page 3

2559

PROTECTED

QUAD POWER DRIVER

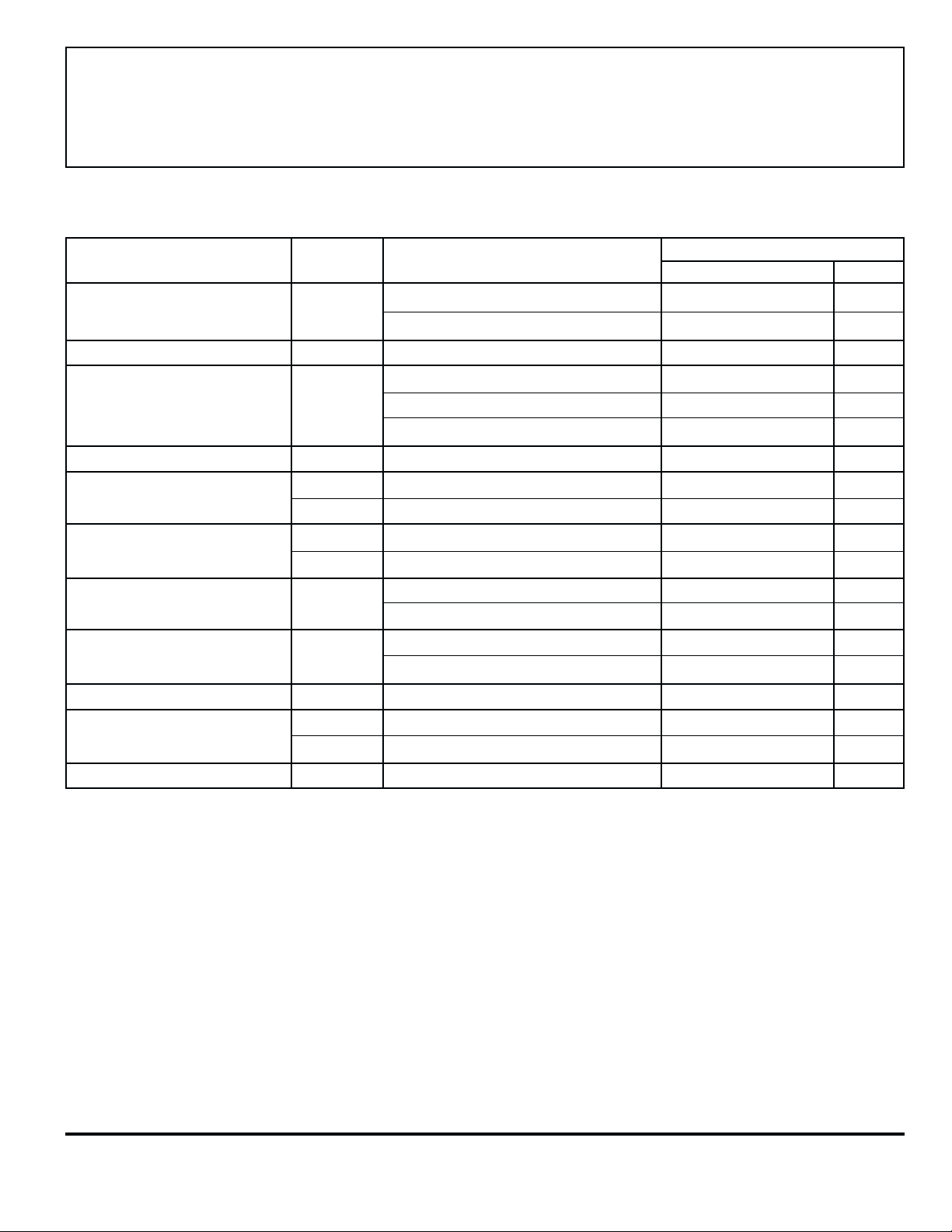

ELECTRICAL CHARACTERISTICS at TA = +25°C (prefix ‘UDN’) or over operating

temperature range (prefix ‘UDK’ or ‘UDQ’), VCC = 4.75 V to 5.25 V

Limits

Characteristic Symbol Test Conditions Min. Typ. Max. Units

Output Leakage Current I

Output Sustaining Voltage V

Output Saturation Voltage V

Over-Current Trip I

CEX

OUT(SUS)

OUT(SAT)

TRIP

Input Voltage Logic 1 V

Logic 0 V

Input Current Logic 1 V

Logic 0 V

Total Supply Current I

CC

V

= 50 V, VIN = 0.8 V, VEN = 2.0 V — <1.0 100 µA

OUT

V

= 50 V, VIN = 2.0 V, VEN = 0.8 V — <1.0 100 µA

OUT

I

= 100 mA, VIN = VEN = 0.8 V 40 —— V

OUT

All Devices, I

All Devices, I

‘B’ & ‘EB’ Packages Only, I

= 100 mA ——300 mV

OUT

= 400 mA ——500 mV

OUT

= 600 mA ——700 mV

OUT

— 1.0 — A

IN(1)

IN(0)

IN(1)

IN(0)

or V

or V

or V

or V

EN(1)

EN(0)

= 2.0 V ——40 µA

EN(1)

= 0.8 V ——-10 µA

EN(0)

2.0 —— V

——0.8 V

All Outputs ON, VIN* = VEN = 2.0 V ——80 mA

All Outputs OFF ——5.0 mA

Clamp Diode Forward Voltage V

Clamp Diode Leakage Current I

Turn-On Delay t

t

Thermal Limit T

F

R

PHL

PLH

J

IF = 1.0 A ——1.7 V

I

= 1.5 A ——2.1 V

F

VR = 50 V, D1 + D2 or D3 + D

I

= 500 mA ——20 µs

OUT

I

= 500 mA ——20 µs

OUT

4

——50 µA

— 165 — °C

Typical Data is for design information only.

Negative current is defined as coming out of (sourcing) the specified terminal.

As used here, -100 is defined as greater than +10 (absolute magnitude convention) and the minimum is implicitly zero.

* All inputs simultaneously, all other tests are performed with each input tested separately.

www.allegromicro.com

Page 4

2559

E

PROTECTED

QUAD POWER DRIVER

TYPICAL OUTPUT

CHARACTERISTIC

THERMAL

GRADIENT

SENSING

NOT TO SCALE

OUT

OUT

T = 165°C

J

JUNCTION

OUTPUT VOLTAGE, V

TEMP. LIMIT

T < 150°C

J

V

OUT(SAT)

OUTPUT CURRENT, I

TYPICAL OUTPUT BEHAVIOR

NORMAL LAMP IN-RUSH CURRENT

I

TRIP

Dwg. GP-013

CIRCUIT DESCRIPTION AND APPLICATION

INCANDESCENT LAMP DRIVER

High incandescent lamp turn-ON/in-rush currents can contribute to

poor lamp reliability and destroy semiconductor lamp drivers. Warming or current-limiting resistors protect both driver and lamp but use

significant power either when the lamp is OFF or when the lamp is

ON, respectively. Lamps with steady-state current ratings up to 700

mA can be driven by these devices without the need for warming

(parallel) or current-limiting (series) resistors.

When an incandescent lamp is initially turned ON, the cold filament is at minimum resistance and would normally allow a 10x to 12x

in-rush current. With these drivers, during turn-ON, the high in-rush

current is sensed by the internal low-value sense resistor. Drive current

to the output stage is then diverted by the shunting transistor, and the

load current is momentarily limited to approximately 1.0 A. During

this short transition period, the output current is reduced to a value

dependent on supply voltage and filament resistance. During lamp

warmup, the filament resistance increases to its maximum value, the

output stage goes into saturation and applies maximum rated voltage to

the lamp.

INDUCTIVE LOAD DRIVER

Bifilar (unipolar) stepper motors, relays, or solenoids can be driven

directly. The internal flyback diodes prevent damage to the output transistors

by suppressing the high-voltage spikes that occur when turning OFF an

inductive load.

LAMP CURRENT

0

For rapid current decay (fast turn-OFF speeds), the use of Zener diodes

NOT TO SCALE

will raise the flyback voltage and inprove performance. However, the peak

voltage must not exceed the specified minimum sustaining voltage (V

VZ + VF ≤ V

OUT(SUS)

).

SUPPLY

+

FAULT CONDITIONS

In the event of a shorted load, the load current will attempt to

increase. As described above, the drive current to the affected output

stage is reduced, causing the output stage to go linear, limiting the peak

output current to approximately 1 A. As the power dissipation of that

THERMAL GRADIENT SENSING

I

TRIP

CURRENT LIMIT

output stage increases, a thermal gradient sensing circuit will become

operational, further decreasing the drive current to the affected output

stage and reducing the output current to a value dependent on supply

voltage and load resistance.

Continuous or multiple overload conditions causing the chip

TIM

Dwg. WP-008

temperature to reach approximately 165°C will result in an additional

reduction in output current to maintain a safe level.

If the fault condition is corrected, the output stage will return to its

normal saturated condition.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Page 5

0.280

0.240

16

UDx2559B

Dimensions in Inches

(controlling dimensions)

NOTE 4

2559

PROTECTED

QUAD POWER DRIVER

0.020

9

0.008

0.300

BSC

0.430

MAX

0.210

MAX

7.11

6.10

0.015

MIN

1

0.070

0.045

16

1

1.77

1.15

0.022

0.014

0.100

0.775

0.735

BSC

Dimensions in Millimeters

(for reference only)

NOTE 4

2.54

19.68

18.67

BSC

8

0.005

MIN

0.150

0.115

Dwg. MA-001-17A in

0.508

9

8

0.13

MIN

0.204

7.62

BSC

10.92

MAX

5.33

MAX

0.39

MIN

0.558

0.356

3.81

2.93

NOTES: 1. Exact body and lead configuration at vendor’s option within limits shown.

2. Lead spacing tolerance is non-cumulative

3. Lead thickness is measured at seating plane or below.

4. Webbed lead frame. Leads 4, 5, 12, and 13 are internally one piece.

www.allegromicro.com

Dwg. MA-001-17A mm

Page 6

2559

PROTECTED

QUAD POWER DRIVER

UDx2559EB

Dimensions in Inches

(controlling dimensions)

18 12

0.219

0.191

0.219

0.191

0.013

0.021

0.050

BSC

0.331

0.533

0.020

MIN

0.165

0.180

19

0.026

0.032

0.456

0.450

0.495

0.485

25

26

Dimensions in Millimeters

(for reference only)

18 12

19

0.495

0.485

128

0.456

0.450

11

INDEX AREA

5

4

Dwg. MA-005-28A in

11

5.56

4.85

5.56

4.85

1.27

BSC

0.51

MIN

4.57

4.20

12.57

12.32

0.812

0.661

11.58

11.43

25

26

12.57

12.32

NOTES: 1. Exact body and lead configuration at vendor’s option within limits shown.

2. Lead spacing tolerance is non-cumulative

3. Webbed lead frame. Leads 5–11, and 19–25 are internally one piece.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

128

11.582

11.430

INDEX AREA

5

4

Dwg. MA-005-28A mm

Page 7

UDx2559LB

Dimensions in Inches

(for reference only)

2559

PROTECTED

QUAD POWER DRIVER

0.2992

0.2914

0.020

0.013

0.0926

0.1043

16 9

1 2

0.0040

MIN.

3

0.4133

0.3977

Dimensions in Millimeters

(controlling dimensions)

16

0.0125

0.0091

0.419

0.394

0.050

0.016

0.050

BSC

9

0° TO 8°

Dwg. MA-008-17A in

0.32

0.23

7.60

7.40

0.51

0.33

2.65

2.35

1

0.10

2

MIN.

3

10.50

10.10

1.27

BSC

NOTES: 1. Exact body and lead configuration at vendor’s option within limits shown.

2. Lead spacing tolerance is non-cumulative

3. Webbed lead frame. Leads 4, 5, 12, and 13 are internally one piece.

www.allegromicro.com

10.65

10.00

0° TO 8°

1.27

0.40

Dwg. MA-008-17A mm

Page 8

2559

PROTECTED

QUAD POWER DRIVER

The products described here are manufactured under one or more

U.S. patents or U.S. patents pending.

Allegro MicroSystems, Inc. reserves the right to make, from time to

time, such departures from the detail specifications as may be

required to permit improvements in the performance, reliability, or

manufacturability of its products. Before placing an order, the user is

cautioned to verify that the information being relied upon is current.

Allegro products are not authorized for use as critical components

in life-support devices or systems without express written approval.

The information included herein is believed to be accurate and

reliable. However, Allegro MicroSystems, Inc. assumes no responsibility for its use; nor for any infringement of patents or other rights of

third parties which may result from its use.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Loading...

Loading...