Page 1

CONTACT FACTORY

for availability

and latest information

ABSOLUTE MAXIMUM RATINGS

3625

AND

3626

POWERHALL® SENSOR/DRIVERS

FOR BRUSHLESS DC MOTORS

Requiring a minimum of external components, the UDN3625M

and UDN3626M are monolithic ICs that provide single-chip control

and direct drive solutions for many small, single-phase, unipolar

brushless dc motor applications. Integrated into the ICs are a highsensitivity Hall-effect sensor, control and commutating logic, a stable

voltage regulator, extensive self and system protective functions, and

two high-current saturated npn outputs. Both ICs include thermal

shutdown, output over-current limiting, and output transient protection/

flyback diodes. The UDN3625M is nominally for 12 V motor applications while the UDN3626M is better suited to 24 V motors.

Output over-current limiting (relating to startup surge or a locked

rotor condition) and short-circuit protection are provided by an internal

current-sense resistor. The maximum (default) output load current is

typically 1.3 A for the UDN3625M or 600 mA for the UDN3626M,

but may be decreased by user selection of an external low-wattage

resistor.

A separate low-level output provides tachometer capability for

motor speed control or sensing a locked rotor condition. With appropriate external logic, pulse-width modulated (PWM) speed control can

be accomplished at the output current adjust pin.

Data Sheet

27690A

Supply Voltage, VCC. . . . . . . . . . See Table

Output Current, I

PWM Current Control Voltage,

V

. . . . . . . . . . . . . See Applications

ADJ

Magnetic Flux Density, B . . . . . . Unlimited

Package Power Dissipation,

. . . . . . . . . . . . . . . . . . . . See Graph

P

D

Operating Temperature Range,

. . . . . . . . . . . . . . . . . -20°C to +85°C

T

A

Storage Temperature Range,

TS. . . . . . . . . . . . . . . . -65°C to +150°C

V

CC(MAX)

I

O(CONT)

I

O(PEAK)

Output current rating will be limited by

ambient temperature, supply voltage, and

duty cycle. Under any set of conditions, do

not exceed a junction temperature of

+150°C.

. . . . . . . . . . . . See Table

O

UDN3625M UDN3626M

14 V 26 V

1.0 A 0.45 A

1.6 A 0.75 A

These sensor/drivers are supplied in an 8-pin mini-DlP plastic

package with a copper leadframe for increased package power

handling capability.

FEATURES

■ 900 mA/12 V or 400 mA/24 V Operation

■ Speed-Control (PWM) Capability

■ Locked-Rotor Indication

■ Minimum External Components

■ Over-Current Protected

■ Thermal Protection

■ Enhanced Reliability

■ Reduced Cost

Always order by complete part number, e.g., UDN3625M .

See Maximum Ratings at left.

Page 2

3625

POWERHALL

AND

3626

®

SENSOR/DRIVERS FOR

BRUSHLESS DC MOTORS

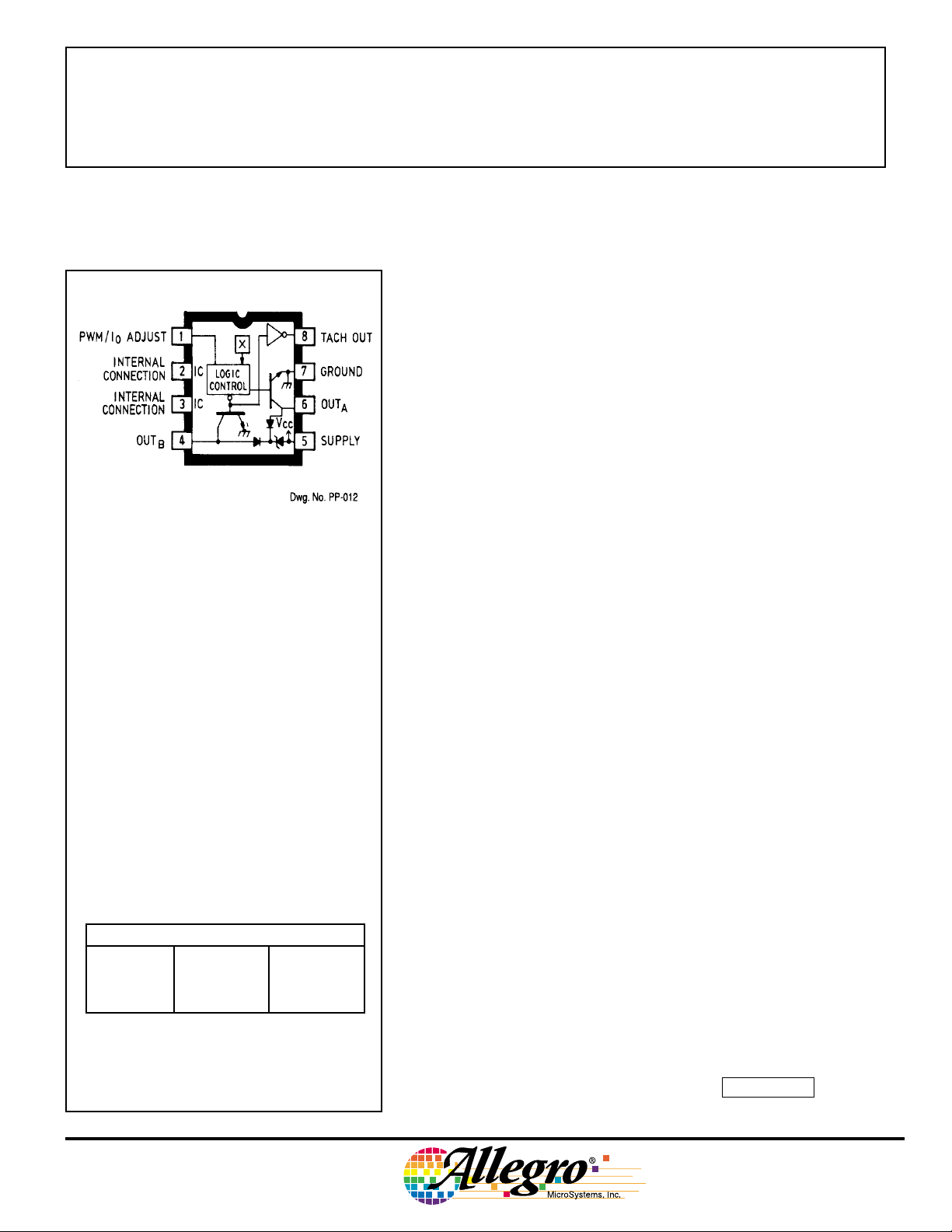

REG.

X

7

GROUND

TSD

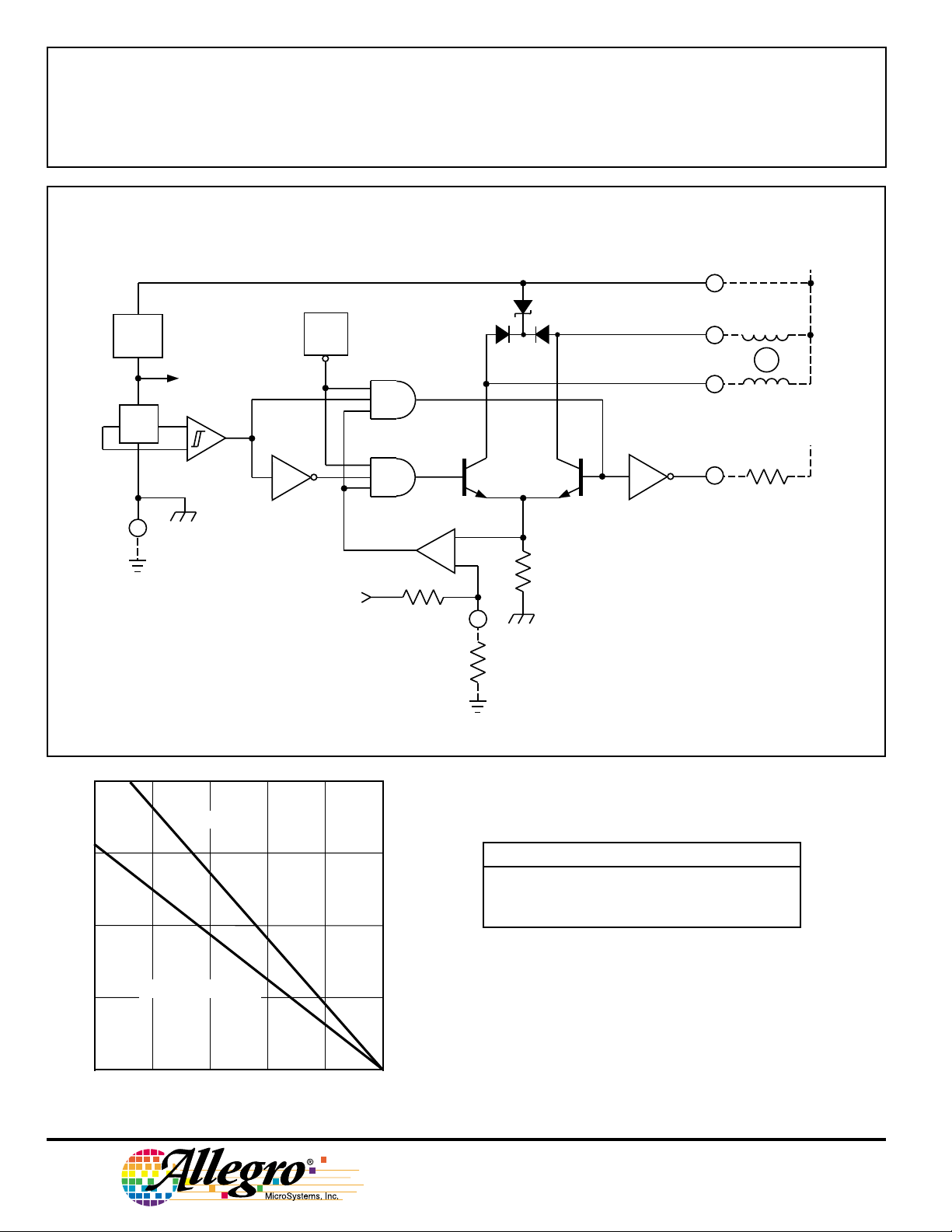

FUNCTIONAL BLOCK DIAGRAM

SUPPLY

5

OUT

4

6

OUT

A

8

TACH

OUT

V

S

B

+V

2.0

R = 55°C/W

θJC

1.5

1.0

0.5

0

25

ALLOWABLE PACKAGE POWER DISSIPATION IN WATTS

FREE AIR, R = 80°C/W

50 75 100 125 150

θJA

TEMPERATURE IN °C

Dwg. GP-009-1B

PWM/I

ADJUST

1

O

R

ADJ

TRUTH TABLE

Mag. Field PWM/IOADJ OUTAOUT

> +B

OP

> -B

OP

Any <0.3 V High High

Open Low High

Open High Low

Dwg. FP-005-1

B

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 1988, 1995, Allegro MicroSystems, Inc.

Page 3

3625

AND

3626

POWERHALL

®

SENSOR/DRIVERS FOR

BRUSHLESS DC MOTORS

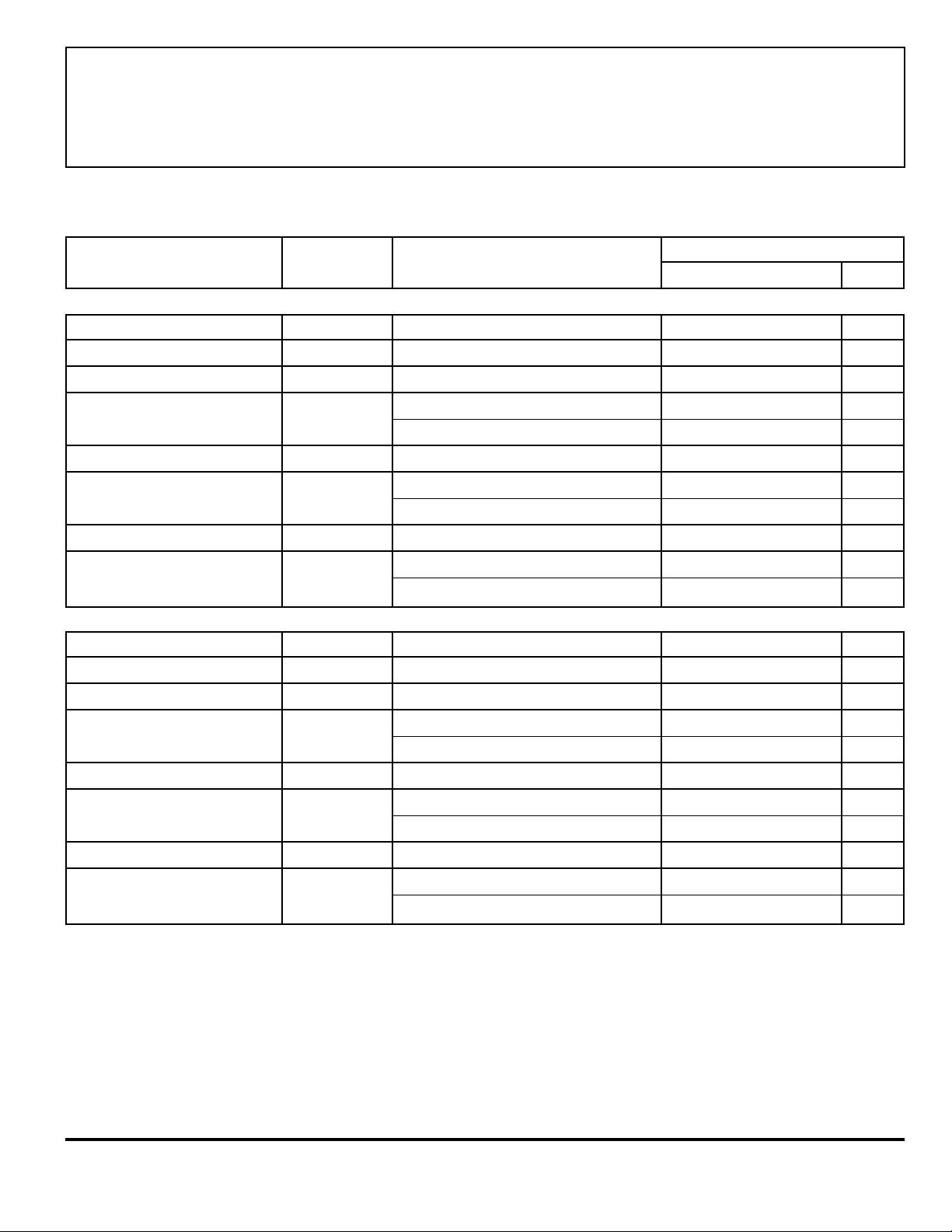

ELECTRICAL CHARACTERISTICS at T

= +25°C, R

A

= ∞, Over Operating Voltage Range

ADJ

(unless otherwise noted).

Limits

Characteristic Symbol Test Conditions Min. Typ. Max. Units

UDN3625M

Operating Voltage Range V

Output Leakage Current I

Output Breakdown Voltage V

Output Saturation Voltage V

S

O

(BR)CEX

O(SAT)

Output Current Limit IO MAX R

Output Clamp Voltage

V

CL

(Test Fig. 1)

Output Switching Time t

Supply Current

PLH

l

CC

(Test Fig. 2)

UDN3626M

VCC = VO = 24 V — — 100 µA

VCC = 24 V, lO = 10 mA* 34 — — V

IO = 450 mA, VS = 6.5 V — 0.25 0.4 V

IO = 900 mA, VS = 12 V — 0.5 0.8 V

= ∞, VO = 2 V 1.0 1.3 1.6 A

ADJ

ICL = 10 mA, VCC = 0 11 12 13 V

ICL = 450 mA=, VCC = 0 13 14 15 V

50% V

R

ADJ

R

ADJ

to VO = 3.0 V, lO = 450 mA — — 5.0 µs

ADJ

= ∞, VS = 14 V, One Output ON — 30 38 mA

= 0 Ω, VS = 14 V, Outputs OFF — 8.0 10 mA

6.5 12 14 V

Operating Voltage Range V

Output Leakage Current l

Output Breakdown Voltage V

Output Saturation Voltage V

S

O

(BR)CEX

O(SAT)

VCC = VO = 30 V — — 100 µA

VCC = 30 V, lO = 10 mA* 50 — — V

lO = 250 mA, VS = 6.5 V — 0.15 0.3 V

lO = 400 mA, VS = 24 V — 0.3 0.5 V

Output Current Limit lOMAX R

Output Clamp Voltage

V

CL

(Test Fig. 1)

Output Switching Time t

Supply Current l

PLH

CC

(Test Fig. 2)

= ∞, VO = 2 V 450 600 750 mA

ADJ

ICL = 10 mA, VCC = 0 17 18 20 V

ICL = 250 mA, VCC = 0 19 20 22 V

50% V

R

ADJ

R

ADJ

to VO = 3.0 V, lO = 250 mA — — 5.0 µs

ADJ

= ∞, VS = 26 V, One Output ON — — 24 mA

= 0 Ω, VS = 26 V, Outputs OFF — 8.0 10 mA

*lO is almost entirely Zener clamp current.

† Pulse test.

‡ Dependent on value of external series Zener diode (see Applications), 6.5 V without a Zener diode.

‡2426 V

Continued next page...

Page 4

3625

POWERHALL

AND

3626

®

SENSOR/DRIVERS FOR

BRUSHLESS DC MOTORS

ELECTRICAL CHARACTERISTICS continued

Limits

Characteristic Symbol Test Conditions Min. Typ. Max. Units

Both

Operate Point§ B

Hysteresis B

Output Current Limit Ratio lO/lO MAX R

PWM Control Current I

Tach Output Leak. Current I

Tach Output Sat. Voltage V

Thermal Shutdown T

Thermal Hysteresis ∆T

OP

H

ADJ

T

T(SAT)

J

J

= 39 kΩ — 0.75 — —

ADJ

R

= 17 kΩ — 0.50 — —

ADJ

R

= 10 kΩ — 0.25 — —

ADJ

V

= 0 — -350 -500 µA

ADJ

V

= 14 V — — 10 µA

T

IT = 750 µA — 0.2 0.4 V

— ±100 ±150 G

— 200 — G

–– 165 — °C

–– 10 — °C

§ Magnetic flux density is measured at most sensitive area of device, nominally located 0.055" (1.40 mm) below the top of the package.

OUTPUT CLAMP VOLTAGE TEST

SUPPLY CURRENT TEST

(ONE OUTPUT TESTED AT A TIME)

Dwg. No. EP-013

TEST FIG. 2 TEST FIG. 1

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Page 5

3625

AND

POWERHALL

SENSOR/DRIVERS FOR

BRUSHLESS DC MOTORS

SENSOR LOCATION APPLICATIONS INFORMATION

Power Dissipation. Care should be taken in evaluating the package power

dissipation of these devices. Total power dissipated by the device will consist

of power due to the internal regulator, logic and drive circuitry (ICC x VCC),

power due to the output drivers (IO x V

circuitry (ICL x VCL x duty cycle).

For example:

ICC x VCC = 38 mA (max) x 14 V = 532 mW (max)

), and power due to the clamp

O(SAT)

3626

®

IO x V

ICL x VCL x duty cycle = 450 mA x 15 V (max) x 1% = 67.5 mW (max)

Some of the power dissipated by the device (ICC x VCC) can be reduced

by inserting a Zener diode in the supply line (ZA in the figure). Note that the

voltage at the VCC pin under worst-case conditions must be greater than the

minimum operating voltage (6.5 V).

Transient Protection. A note of caution concerns negative (below ground)

excursions of the outputs. In application, the coupling of the two motor

windings can provide for just such a case. Reducing the coupling between

windings will help, but ground clamp diodes or diodes in series with the

motor windings might be required (DC or DS in the figure). Most small

brushless motors will not require these diodes.

System requirements usually utilize a diode type of reverse-polarity

protection. If series diode protection is used with an inductive load (the usual

fan application), a Zener clamp between VS and ground (ZB in the figure) is

required. The Zener voltage must be greater than the supply voltage but less

than the rated maximum allowable supply voltage.

With diode reverse-polarity protection, a high-impedance supply, or a

switched supply line, high-voltage spikes will be generated (especially with

high-current or high-inductance loads) during normal operation, coasting, or

immediately after turn-off. In these situations, a Zener clamp (ZB) from VS to

ground will be required.

= 450 mA x 0.4 V (max) = 180 mW (max)

O(SAT)

Total package power dissipation = 779.5 mW (max)

Over-Current Adjust Pin. The over-current limit may be reduced from the

default value (IO MAX) by selection of an external resistor (R

PWM/IO ADJ pin.

ADJ

) at the

Page 6

3625

POWERHALL

AND

3626

®

SENSOR/DRIVERS FOR

BRUSHLESS DC MOTORS

TYPICAL FAN APPLICATION

The external overcurrent adjust and the thermal shutdown are commoned

at the PWM/lO ADJ pin and tieing it to VCC will disable the thermal shutdown. PWM current/speed control can be performed at the PWM/lO ADJ pin

from a standard totem-pole logic output with a series Schottky diode

(1N5818,1N5819, or equivalent) or by pulling it low through an opencollector transistor (no pull-up resistor). PWM/lO ADJ input voltages greater

than 0.3 V are not recommended and may create an unstable operating

condition.

OUT ON/LOW

MAGNETIC FIELD

A

DEFINITIONS

+B

S

+B

N

Dwg. AP-001-1

-B

OUT ON/LOW

B

-B

O P

B = 0 G

By accepted magnetic convention, lines of flux emanate from the north pole of a magnet and enter the south pole.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

O P

Dwg. GP-008

+B

Page 7

0.280

0.240

Dimensions in Inches

(controlling dimensions)

58

3625

AND

3626

POWERHALL

®

SENSOR/DRIVERS FOR

BRUSHLESS DC MOTORS

0.014

0.008

0.430

MAX

0.300

BSC

0.100

BSC

4

1

0.070

0.045

0.210

MAX

0.015

MIN

0.022

0.014

NOTES: 1. Leads 1, 4, 5, and 8 may be half leads at vendor’s option.

2. Lead thickness is measured at seating plane or below.

3. Lead spacing tolerance is non-cumulative.

4. Exact body and lead configuration at vendor’s option

within limits shown.

0.400

0.355

0.005

MIN

0.150

0.115

Dwg. MA-001-8A in

Page 8

3625

POWERHALL

AND

3626

®

SENSOR/DRIVERS FOR

BRUSHLESS DC MOTORS

8

7.11

6.10

Dimensions in Millimeters

(for reference only)

5

0.355

0.204

7.62

BSC

10.92

MAX

1

4

1.77

1.15

10.16

9.02

5.33

MAX

0.39

MIN

0.558

0.356

NOTES: 1. Leads 1, 4, 5, and 8 may be half leads at vendor’s option.

2. Lead thickness is measured at seating plane or below.

3. Lead spacing tolerance is non-cumulative.

4. Exact body and lead configuration at vendor’s option

within limits shown.

2.54

BSC

0.13

MIN

3.81

2.93

Dwg. MA-001-8A mm

The products described herein are manufactured under one or

more of the following U.S. patents: 5,045,920; 5,264,783; 5,442,283;

5,389,889; 5,581,179; 5,517,112; 5,619,137; 5,621,319; 5,650,719;

5,686,894; 5,694,038; 5,729,130; 5,917,320; and other patents

pending.

Allegro MicroSystems, Inc. reserves the right to make, from time to

time, such departures from the detail specifications as may be

required to permit improvements in the performance, reliability, or

manufacturability of its products. Before placing an order, the user is

cautioned to verify that the information being relied upon is current.

Allegro products are not authorized for use as critical components

in life-support appliances, devices, or systems without express written

approval.

The information included herein is believed to be accurate and

reliable. However, Allegro MicroSystems, Inc. assumes no responsibility for its use; nor for any infringements of patents or other rights of

third parties that may result from its use.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Loading...

Loading...