Page 1

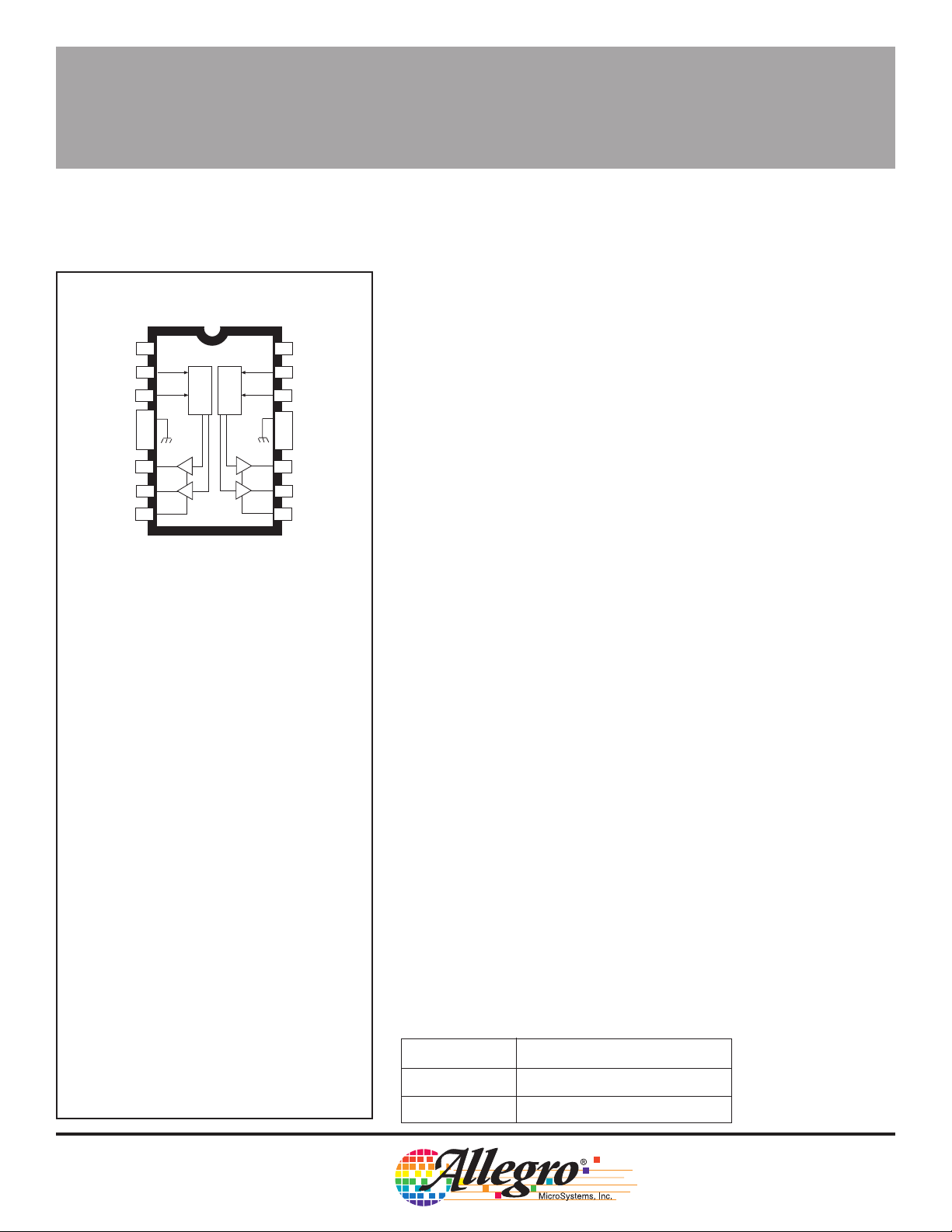

2993

DUAL H-BRIDGE

MOTOR DRIVERS

UDN2993B

LOAD SUPPLY

ENABLE

PHASE

GROUND

GROUND

OUT

OUT

V

V

BB

1

2

A

3

A

4

5

6

1A

7

2A

8

EA

LOGIC

V

LOGIC

DD

16

15

14

13

12

11

10

9

Dwg. No. A-12,455

LOGIC SUPPLY

ENABLE

B

PHASE

B

GROUND

GROUND

OUT

1B

OUT

2B

V

EB

2993

DUAL H-BRIDGE MOTOR DRIVERS

Cost-effective monolithic drive electronics for bipolar stepper and

dc (brush) servo motors to 30 V and 500 mA is very practical with the

UDN2993B and UDN2993LB. These dual full-bridge motion control

ICs integrate separate inputs, level shifting for upper power outputs,

control logic, integral inductive transient protection, and source (upper)

and sink (lower) drivers in an H-bridge configuration. The single-chip

power IC provides improved space utilization and reliability unmatched

by discrete component circuitry.

Excepting the power supply connections, the two H-bridges are

independent. An ENABLE input is provided for each bridge and

permits pulse-width modulation (PWM) through the use of external

circuitry. PWM drive techniques provide the benefits of reduced power

dissipation, improved motor performance (especially torque), and

positively affect system efficiency. Separate PHASE inputs for each

bridge determine the direction of current flow in the load. Additionally,

each pair of (sink) emitters are terminated to package connections.

This allows the use of current-sensing circuitry. Both devices

incorporate an intrinsic “dead time” to preclude high crossover

(or cross-conduction) currents during changes in direction (phase).

Data Sheet

29319.5A

These devices are packaged in plastic DIPs (suffix B) or surface-

ABSOLUTE MAXIMUM RATINGS

at T

≤ +150°C

J

mountable wide-body SOICs (suffix LB) with copper lead frames for

optimum power dissipation without heat sinks. The lead configurations

allow automatic insertion, fit standard IC sockets or printed wiring

Load Supply Voltage, VBB.................... 30 V

Logic Supply Voltage, VDD................... 7.0 V

Logic Input Voltage Range, V

V

Output Current, I

............... -0.3 V to VDD + 0.3 V

ENABLE

..................... ±600 mA

OUT

PHASE

or

Sink Driver Emitter Voltage,

.................................................. 1.5 V

V

E

Package Power Dissipation,

........................................ See Graph

P

D

Operating Temperature Range,

................................. -20°C to +85°C

T

A

DISCONTINUED PRODUCT

Storage Temperature Range,

............................... -55°C to +150°C

T

S

IMPORTANT: Load supply voltage must never be

applied without logic supply voltage present.

NOTE: Output current rating may be limited by

chopping frequency, ambient temperature,

airflow, and heat sinking. Under any set of

conditions, do not exceed the specified maximum

current and a junction temperature of +150°C.

— FOR REFERENCE ONLY

board layouts, and enable easy attachment of a heat sink for maximum

power-handling capability. The heat-sink tabs are at ground potential

and require no insulation.

Dual full-bridge drivers with peak current ratings of ±3 A are

supplied as the UDN2998W.

FEATURES

■ ±600 mA Output Current

■ Output Voltage to 30 V

■ Crossover Current Protection

■ TTL/NMOS/CMOS Compatible Inputs

■ Low Input Current

■ Internal Clamp Diodes

■ Automotive Capable

Always order by complete part number:

Part Number Package

UDN2993B 16-Pin DIP

UDN2993LB 20-Lead Wide-Body SOIC

Page 2

2993

DUAL H-BRIDGE

MOTOR DRIVERS

UDN2993LB

LOAD

SUPPLY

ENABLE

PHASE

GROUND

GROUND

GROUND

GROUND

OUT

OUT

V

V

1

BB

2

A

3

A

4

5

6

7

8

1A

9

2A

10

EA

LOGIC

LOGIC

V

DD

20

19

18

17

16

15

14

13

12

11

LOGIC

SUPPLY

ENABLE

PHASE

GROUND

GROUND

GROUND

GROUND

OUT

1B

OUT

2B

V

EB

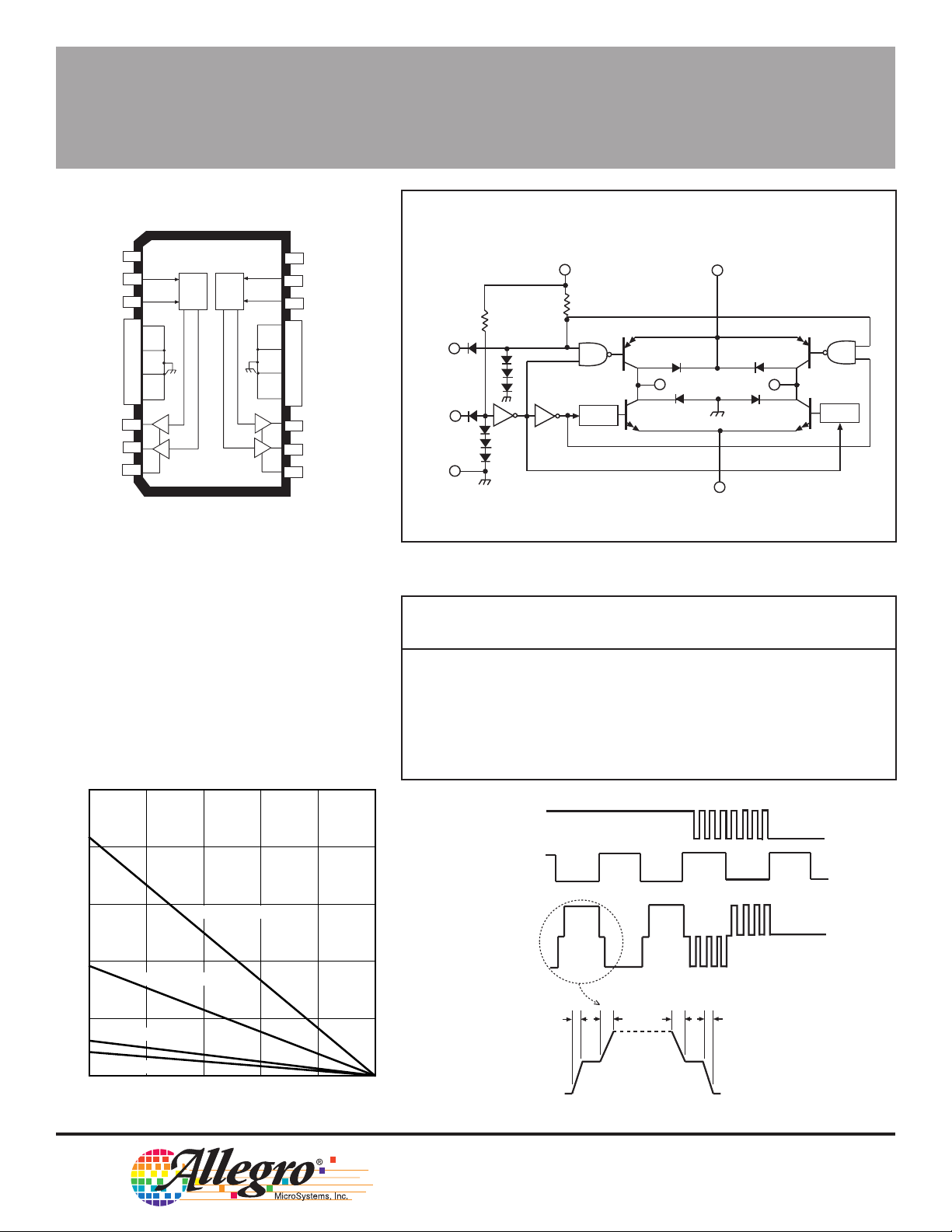

FUNCTIONAL BLOCK DIAGRAM

(One of Two Drivers)

V

B

B

ENABLE

PHASE

GROUND

DD

TURN-ON

DELAY

OUT

V

BB

OUT

1

2

TURN-ON

DELAY

V

E

Dwg. No. A-14,340

Dwg. No. A-12,447

TRUTH TABLE

Enable Phase

Input Input Output 1 Output 2

High High Low High

High Low High Low

Low High Low Open

Low Low Open Low

25

V

ENABLE

20

V

PHASE

15

10

SUFFIX 'B', R = 13°C/W

SUFFIX 'LB', R = 6.0°C/W

θJT

θJT

I

+

OUT

_

5

SUFFIX 'B', R = 40°C/W

ALLOWABLE PACKAGE POWER DISSIPATION IN WATTS

SUFFIX 'LB', R = 61°C/W

0

25

θJA

θJA

50 75 100 125 150

TEMPERATURE IN °C

Dwg. GP-021A

t

t

t

f

r

d

t

t

f

d

115 Northeast Cutoff, Box 15036

W

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 1985, 1993, Allegro MicroSystems, Inc.

t

r

Dwg. No. A-12,448

Page 3

2993

DUAL H-BRIDGE

MOTOR DRIVERS

ELECTRICAL CHARACTERISTICS at T

= +25°C, V

A

= 30 V, VDD = 5 V, VE = 0 V, T

BB

≤ +150°C

J

Figure 1 (unless otherwise noted).

Limits

Characteristic Symbol Test Conditions Min. Typ. Max. Units

Output Drivers

Operating Voltage Range V

Output Leakage Current I

Output Saturation Voltage V

Output Sustaining Voltage V

Motor Supply Current I

CE(sus)

BB(ON)

I

BB(OFF)

Source Driver Rise Time t

Source Driver Fall Time t

Clamp Diode Forward Voltage V

Control Logic (PHASE or ENABLE)

Logic Input Current I

I

Logic Input Voltage V

V

Logic Supply Current I

Turn-On Delay Time t

Turn-Off Delay Time t

BB

CEX

CE(SAT)

r

f

F

IN(1)

IN(0)

IN(1)

IN(0)

DD

pd0

pd1

V

V

V

V

I

V

V

I

I

= 0.8 V, V

ENABLE

= 0.8 V, V

ENABLE

= 2.4 V, I

ENABLE

= 2.4 V, I

ENABLE

= ±500 mA, Figure 2, Note 2 30 — — V

OUT

= 2.4 V, Outputs Open, Note 2 — 1.0 3.0 mA

ENABLE

= 0.8 V, Outputs Open, Note 2 — 250 300 µA

ENABLE

= -500 mA — 75 — ns

OUT

= -500 mA — 280 — ns

OUT

= VBB, Note 2 — < 1.0 50 µA

OUT

= 0 V, Note 2 — < -1.0 -50 µA

OUT

= 500 mA — 1.6 1.8 V

OUT

= -500 mA — 1.6 2.0 V

OUT

IF = 500 mA — 1.6 1.8 V

V

PHASE

V

PHASE

or V

or V

= 2.4 V — < 1.0 10 µA

ENABLE

= 0.8 V — -200 -300 µA

ENABLE

ENABLE Input to Source Drivers — 250 — ns

ENABLE lnput to Source Drivers — 500 — ns

10 — 30 V

2.4 — — V

— — 0.8 V

—1420mA

NOTES: 1. Each driver is tested separately.

2. Test is performed with V

3. Negative current is defined as coming out of (sourcing) the specified device pin.

PHASE

= 0.8 V and then repeated for V

PHASE

= 2.4 V.

Page 4

2993

INPUT

INPUT

A

B

0

0

+5V

+5V

DUAL H-BRIDGE

MOTOR DRIVERS

TEST FIGURES

FIGURE 1

= 5V

V

DD

ENABLE

OUT

1

PHASE

GROUND

2.4V

0.8V

TURN-ON

DELAY

FIGURE 2

= 5V

V

DD

= 40V

V

BB

I

OUT

mA

V

E

OUT

2

TURN-ON

DELAY

Dwg. No. A-12,449

TYPICAL APPLICATION

2-PHASE BIPOLAR STEPPER MOTOR DRIVE

= 40V

V

BB

(Chopper Mode)

ENABLE

PHASE

GROUND

TURN-ON

DELAY

+5V

10K

0.1

10K

Dwg. No. A-12,453

5.6K

_

+

470K

10K

0.1

10K

IN

+36V

A

+ 5V

1Ω

LOGIC

LOGIC

V

DD

16

15

IN

B

14

13

12

11

10

9

V

BB

1

2

3

4

5

6

7

8

1Ω

0.1

1K

56Ω

mH

2

TURN-ON

DELAY

V

E

Dwg. No. A-12,450

+5V

5.6K

_

+

470 K

Dwg. No. A-12,454

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Page 5

2993

DUAL H-BRIDGE

MOTOR DRIVERS

16

0.280

0.240

UDN2993B

Dimensions in Inches

NOTE 4

0.020

9

0.008

0.300

BSC

0.430

MAX

0.210

MAX

7.11

6.10

0.015

MIN

1

0.070

0.045

16

1

1.77

1.15

0.022

0.014

8

0.150

0.115

0.775

0.735

0.100

BSC

Dimensions in Millimeters

(Based on 1” = 25.4 mm)

NOTE 4

19.68

18.67

2.54

BSC

9

8

0.005

MIN

0.13

MIN

0.508

0.204

Dwg. MA-001-17A in

10.92

MAX

7.62

BSC

5.33

MAX

0.39

MIN

0.558

0.356

NOTES: 1. Exact body and lead configuration at vendor’s option within limits shown.

2. Lead spacing tolerance is non-cumulative

3. Lead thickness is measured at seating plane or below.

4. Webbed lead frame. Leads 4, 5, 12, and 13 are internally one piece.

3.81

2.93

Dwg. MA-001-17A mm

Page 6

2993

D

DUAL H-BRIDGE

MOTOR DRIVERS

UDN2993LB

Dimensions in Inches

(Based on 1 mm = 0.03937”)

0.2992

0.2914

0.020

0.013

0.0926

0.1043

20 11

1 2

0.0040

MIN.

3

0.5118

0.4961

Dimensions in Millimeters

20

11

0.050

BSC

NOTE 1

NOTE 3

0.419

0.394

0° TO 8°

0.0125

0.0091

0.050

0.016

wg. MA-008-21A in

0.32

0.23

7.60

7.40

0.51

0.33

2.65

2.35

1

0.10

2

MIN.

3

13.00

12.60

1.27

BSC

NOTE 1

NOTE 3

10.65

10.00

0° TO 8°

Dwg. MA-008-21A mm

1.27

0.40

NOTES: 1. Webbed lead frame. Leads 5, 6, 15, and 16 are internally one piece.

2. Lead spacing tolerance is non-cumulative.

3. Exact body and lead configuration at vendor’s option within limits shown.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Page 7

2993

DUAL H-BRIDGE

MOTOR DRIVERS

This page intentionally left blank

Page 8

2993

DUAL H-BRIDGE

MOTOR DRIVERS

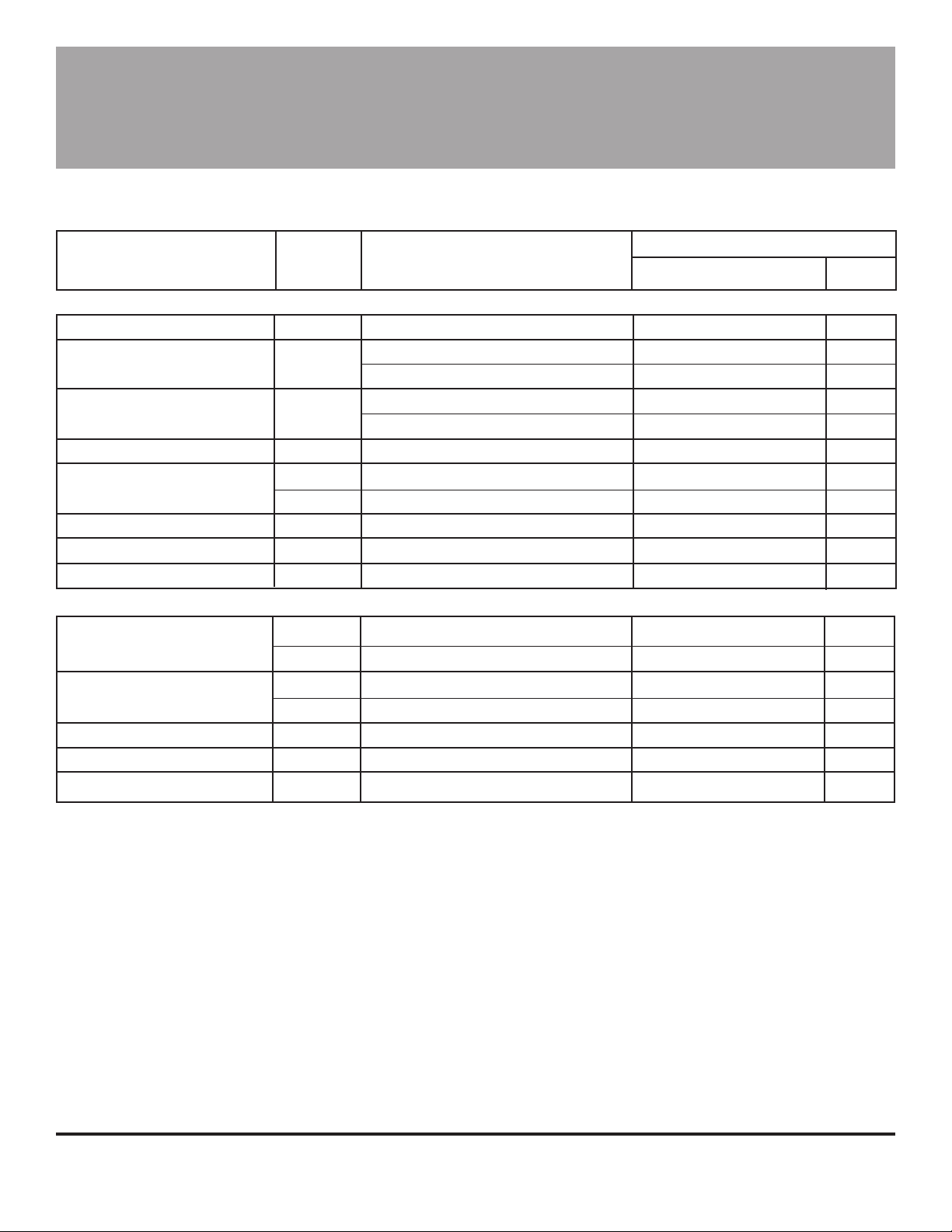

MOTOR DRIVERS SELECTION GUIDE

Function Output Ratings * Part Number †

INTEGRATED CIRCUITS FOR BRUSHLESS DC MOTORS

3-Phase Controller/Drivers ±2.0 A 45 V 2936 and 2936-120

Hall-Effect Latched Sensors 10 mA 24 V 3175 and 3177

2-Phase Hall-Effect Sensor/Controller 20 mA 25 V 3235

Hall-Effect Complementary Output Sensor 20 mA 25 V 3275

2-Phase Hall-Effect Sensor/Driver 900 mA 14 V 3625

2-Phase Hall-Effect Sensor/Driver 400 mA 26 V 3626

Hall-Effect Comp. Output Sensor/Driver 300 mA 60 V 5275

3-Phase Back-EMF Controller/Driver ±900 mA 14 V 8902–A

3-Phase Controller/DMOS Driver ±4.0 A 14 V 8925

3-Phase Back-EMF Controller/Driver ±1.0 A 7 V 8984

INTEGRATED BRIDGE DRIVERS FOR DC AND BIPOLAR STEPPER MOTORS

PWM Current Controlled Dual Full Bridge ±750 mA 45 V 2916

PWM Current Controlled Dual Full Bridge ±1.5 A 45 V 2917

PWM Current Controlled Dual Full Bridge ±1.5 A 45 V 2918

PWM Current Controlled Dual Full Bridge ±750 mA 45 V 2919

Dual Full Bridge Driver ±2.0 A 50 V 2998

PWM Current Controlled Full Bridge ±2.0 A 50 V 3952

PWM Current Controlled Full Bridge ±1.3 A 50 V 3953

PWM Current Controlled Dual Full Bridge ±800 mA 45 V 3961

PWM Current Controlled Dual Full Bridge ±800 mA 30 V 3962

OTHER INTEGRATED CIRCUIT & PMCM MOTOR DRIVERS

Unipolar Stepper Motor Quad Driver 1.8 A 50 V 2544

Unipolar Stepper-Motor Translator/Driver 1.25 A 50 V 5804

Unipolar Stepper-Motor Quad Driver 1 A 46 V 7024 and 7029

Unipolar Microstepper-Motor Quad Driver 1.2 A 46 V 7042

Voice-Coil Motor Driver ±500 mA 6 V 8932-A

Voice-Coil Motor Driver ±800 mA 16 V 8958

Voice-Coil (and spindle) Motor Driver ±350 mA 7 V 8984

* Current is maximum specified test condition, voltage is maximum rating. See specification for sustaining

voltage limits or over-current protection voltage limits.

Negative current is defined as coming out of (sourcing) the output.

† Complete part number includes additional characters to indicate operating temperature range and package style.

Allegro MicroSystems, Inc. reserves the right to make, from time to time, such departures from the

detail specifications as may be required to permit improvements in the design of its products.

Components made under military approvals will be in accordance with the approval requirements.

The information included herein is believed to be accurate and reliable. However, Allegro

MicroSystems, Inc. assumes no responsibility for its use; nor for any infringements of patents or other

rights of third parties which may result from its use.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Loading...

Loading...