Page 1

2943

A

HIGH-CURRENT HALF-BRIDGE MOTOR DRIVER

2943

HIGH-CURRENT

HALF-BRIDGE MOTOR DRIVER

Designed for use as a general-purpose motor driver, the

UDN2943Z half-bridge driver combines high-current sink and source

drivers with logic stages, level shifting, diode transient protection, and

a voltage regulator for single-supply operation. Capable of operating

in extremely harsh environments, this device can withstand high

ambient temperatures, output overloads, and repeated power supply

transient voltages without damage. The driver can be used in pairs for

full-bridge operation, or as triplets in three-phase brushless dc motordrive applications.

The input circuitry is compatible with TTL, low-voltage CMOS,

and NMOS logic. Logic lockout prevents both source and sink drivers

from turning ON simultaneously. Each driver is turned ON by an activelow input, making the UDN2943Z especially desirable in many microprocessor applications. An accidental input open circuit will turn OFF

the corresponding output. The device also provides an internallygenerated dead time to prevent crossover currents during output

switching. Monolithic, space-saving construction offers reliability

unobtainable with discrete components.

Data Sheet

29318.4B

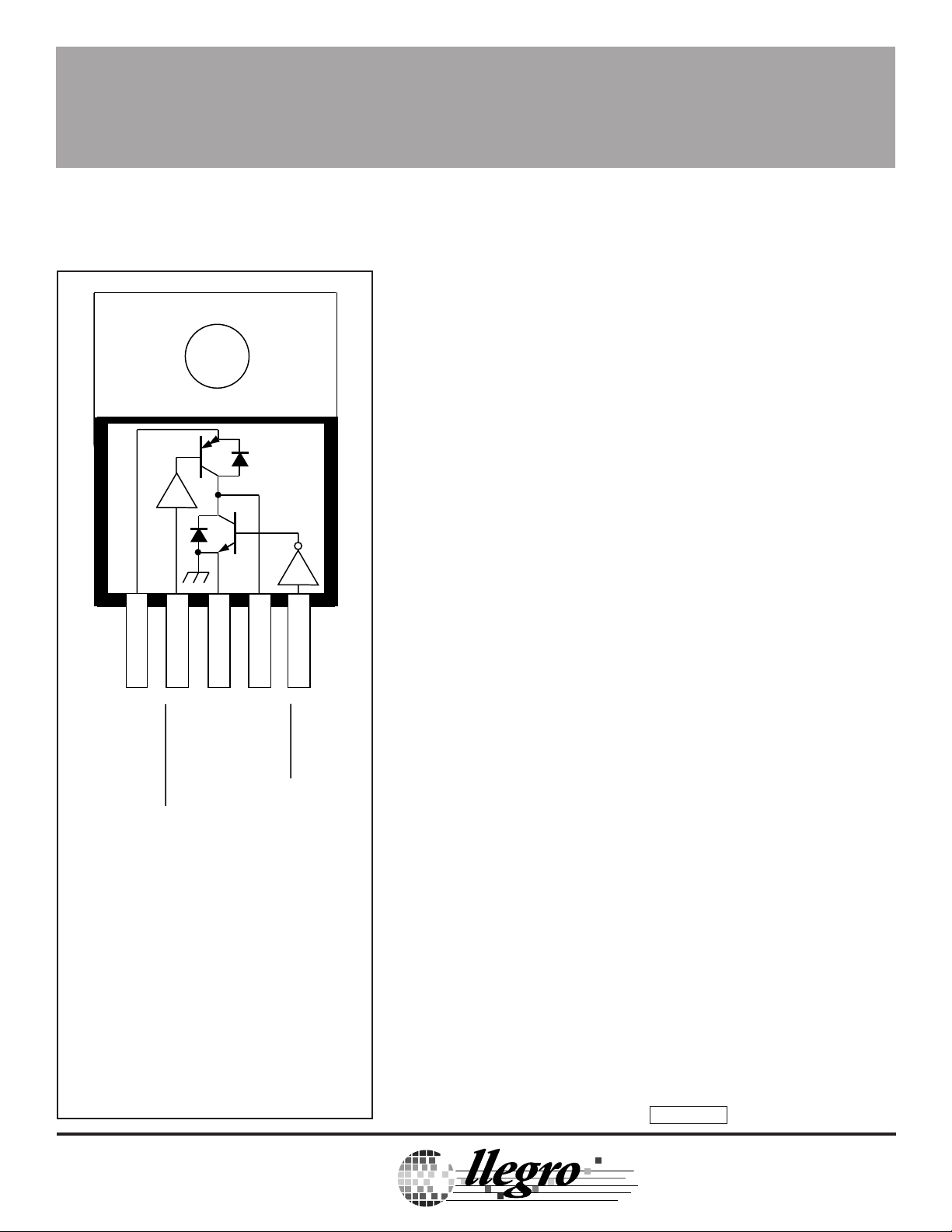

12345

S

+V

OUTPUT

GROUND

SINK INPUT

SOURCE INPUT

DISCONTINUED

ABSOLUTE MAXIMUM RATINGS

Supply Voltage, Range VS.... 8.5 V to 35 V*

Output Voltage, V

Input Voltage Range, V

Continuous Output Current, I

Package Power Dissipation,

P

....................................... See Graph

D

Operating Temperature Range,

T

................................. -20°C to +85°C

A

Storage Temperature Range,

T

............................... -55°C to +150°C

S

*Internal high-voltage shutdown above 24 V.

.......................24 V

CE(sus)

.... -0.3 V to +18 V

IN

— FOR REFERENCE

PRODUCT

Dwg. PP-022-1

...... ±1.0 A

OUT

Saturated output drivers provide for low saturation voltage at the

maximum rated current. Internal short-circuit protection, activated at

load currents above 1 A, protects the source driver from accidental

short-circuits between the output and ground.

The UDN2943Z driver is rated for continuous operation with

inductive loads at supply voltages of up to 24 V. With supply voltage

transients (to 35 V maximum), a high-voltage protection circuit

becomes operative, shutting OFF both output drivers. The internal

thermal shutdown is triggered by a nominal junction temperature

of 160°C.

Single-chip construction and a 5-lead power-tab TS-001 plastic

package provide cost-effective and reliable systems designs.

It also features excellent power dissipation ratings, minimum size, and

ease of installation. The heat-sink tab is at ground potential and does

not require insulation.

ONLY

FEATURES

■ ±1 A Output Current ■ 8.5 V to 24 V Operating Range

■ Saturated Output Drivers ■ Crossover-Current Protected

■ Logic-Compatible Inputs ■ Withstands 35 V Supply Transients

■ Output-Transient Protection ■ Internal Over-Voltage Protection

■ Tri-State Output ■ Internal Short-Circuit Protection

Always order by complete part number: UDQ2943Z .

TM

TM

A

MicroSystems, Inc.

Page 2

2943

A

HIGH-CURRENT HALF-BRIDGE MOTOR DRIVER

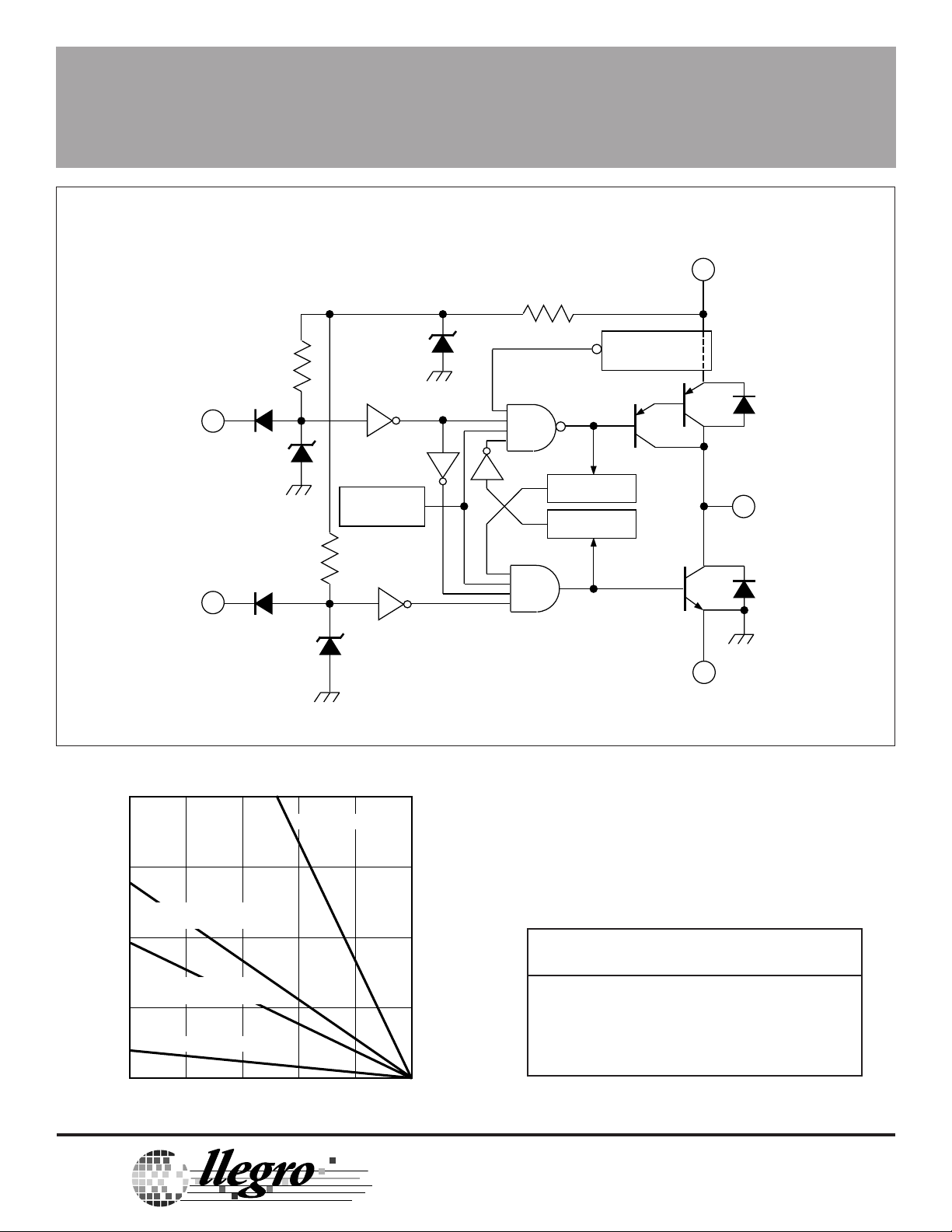

FUNCTIONAL BLOCK DIAGRAM

V

S

1

SOURCE

INPUT

SINK

INPUT

6.35 V

2

2.1 V

OVER-VOLT.

& TSD

5

2.1 V

L-TO-H DELAY

H-TO-L DELAY

HIGH-CURRENT

SENSE

GROUND

OUTPUT

4

3

Dwg. FP-038

20

R = 3.0°C/W

JT

θ

15

AAVID 5071B + 5072B HEAT SINKS,

R = 9.0°C/W

JA

θ

10

STAVER V1-5 HEAT SINK,

R = 13°C/W

JA

θ

5

FREE AIR, R = 65°C/W

0

25

ALLOWABLE PACKAGE POWER DISSIPATION IN WATTS

JA

θ

50 75 100 125 150

TEMPERATURE IN °C

TM

TM

A

MicroSystems, Inc.

Dwg. GP-014A

LOGIC TRUTH TABLE

Source Driver Sink Driver Output

Pin 2 Pin 5 Pin 4

Low Low High

Low High High

High Low Low

High High High Z

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 1986, 1994, Allegro MicroSystems, Inc.

Page 3

2943

T

T

HIGH-CURRENT HALF-BRIDGE MOTOR DRIVER

ELECTRICAL CHARACTERISTICS at T

= +25°C, V

A

= +24 V (unless otherwise noted).

S

Source Driver Sink Driver Output Limits

Characteristic Symbol Input, Pin 2 Input, Pin 5 Pin 4 Other Min. Typ. Max. Units

Output Leakage Current I

(V

= +35 V) 2.4 V 2.4 V 35 V — — 10 100 µA

S

Output Sustaining Voltage V

CEX

CE(sus)

2.4 V 2.4 V 0 V — — -10 -100 µA

2.4 V 0.8 to 2.4 V 1.0 A Fig. 1A 24 — — V

0.8 to 2.4 V 2.4 V -1.0 A Fig. 1B 24 — — V

Output Saturation Voltage V

CE(SAT)

0.8 V 2.4 V -1.0 A — — 1.2 1.8 V

2.4 V 0.8 V 1.0 A — — 0.6 1.0 V

Short-Circuit Source Current I

Logic Input Voltage V

V

Input Current I

I

Clamp Diode Forward Voltage V

Logic Supply Current I

SC

IN(1)

IN(0)

IN(1)

IN(0)

F

S

0.8 V 2.4 V 0 V — 1.0 — 1.8 A

— — ——2.0——V

— — ————0.8V

2.4 V 2.4 V NC — — 10 100 µA

0.8 V 0.8 V NC — — -50 -200 µA

NC NC 1.0 A Fig. 2 — 1.5 2.0 V

2.4 V 2.4 V NC — — 15 30 mA

2.4 V 0.8 V NC — — 55 75 mA

0.8 V 2.4 V NC — — 30 40 mA

Thermal Shutdown Temperature T

Over-Voltage Shutdown V

Propagation Delay t

J

S

PD

— — ———160—°C

————24—35V

2.4 V 2.4 V to 0.8 V 0.4 A Fig. 3 — 0.6 — µs

0.8 to 2.4 V 2.4 V -0.4 A Fig. 4 — 1.0 — µs

2.4 V 0.8 to 2.4 V 0.4 A Fig. 3 — 1.1 — µs

2.4 to 0.8 V 2.4 V -0.4 A Fig. 4 — 0.6 — µs

Notes: Negative current is defined as coming out of (sourcing) the specified device pin.

Typical Data is for design information only.

SOURCE INPUT

VOLTAGE

SINK INPUT

VOLTAGE

+

OUTPUT

0

CURRENT

–

SINKING CURREN

OPEN CIRCUIT

SOURCING CURREN

Dwg. WP-024

Dwg. WP-024

Page 4

2943

A

HIGH-CURRENT HALF-BRIDGE MOTOR DRIVER

V

S

12 345

2.4 V ∆V

28 mH

I

OUT

Dwg. EP-053

IN

V

S

12 345

I

OUT

2.4 V∆V

28 mH

Dwg. EP-054

IN

Figure 1B

12 345

NC

NC

NC

Dwg. EP-055

Figure 2Figure 1A

V

S

I

F

V

S

A

12 345

2.4 V ∆V

I

OUT

IN

Dwg. EP-056

S

12 345

IN

V

Figure 3 Figure 4

TM

TM

MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

I

OUT

2.4 V∆V

Dwg. EP-057

Page 5

2943

HIGH-CURRENT HALF-BRIDGE MOTOR DRIVER

1.045

0.945

0.539

0.465

0.040

0.020

Dimensions in Inches

0.415

0.390

1 5

0.156

0.139

0.625

0.570

0.067

BSC

O

0.370

0.330

0.025

0.012

0.190

0.165

0.055

0.035

0.115

0.085

26.54

24.00

13.69

11.81

1.01

0.51

Dimensions in Millimeters

(Based on 1" = 25.40 mm)

10.54

9.91

1 5

15.87

14.48

1.70

BSC

3.96

3.53

O

9.39

8.39

0.63

0.31

4.82

4.19

1.39

0.89

2.92

2.16

Dwg. MP-005 in

Dwg. MP-005 mm

Page 6

2943

A

HIGH-CURRENT HALF-BRIDGE MOTOR DRIVER

MOTOR DRIVERS SELECTION GUIDE

Function Output Ratings * Part Number †

INTEGRATED CIRCUITS FOR BRUSHLESS DC MOTORS

3-Phase Controller/Drivers ±2.0 A 45 V 2936 and 2936-120

Hall-Effect Latched Sensors 10 mA 24 V 3175 and 3177

2-Phase Hall-Effect Sensor/Controller 20 mA 25 V 3235

Hall-Effect Complementary Output Sensor 20 mA 25 V 3275

2-Phase Hall-Effect Sensor/Driver 900 mA 14 V 3625

2-Phase Hall-Effect Sensor/Driver 400 mA 26 V 3626

Hall-Effect Comp. Output Sensor/Driver 300 mA 60 V 5275

3-Phase Back-EMF Controller/Driver ±900 mA 14 V 8902–A

3-Phase Controller/DMOS Driver ±4.0 A 14 V 8925

3-Phase Back-EMF Controller/Driver ±1.0 A 7 V 8980 and 8983

INTEGRATED BRIDGE DRIVERS FOR DC AND BIPOLAR STEPPER MOTORS

PWM Current Controlled Dual Full Bridge ±750 mA 45 V 2916

PWM Current Controlled Dual Full Bridge ±1.5 A 45 V 2917

PWM Current Controlled Dual Full Bridge ±1.5 A 45 V 2918

PWM Current Controlled Dual Full Bridge ±750 mA 45 V 2919

Half-Bridge Driver ±1.0 A 24 V 2943

Dual Full Bridge Driver ±2.0 A 50 V 2998

PWM Current Controlled Full Bridge ±2.0 A 50 V 3952

PWM Current Controlled Full Bridge ±1.3 A 50 V 3953

PWM Current Controlled Dual Full Bridge ±800 mA 45 V 3961

PWM Current Controlled Dual Full Bridge ±800 mA 30 V 3962

OTHER INTEGRATED CIRCUIT MOTOR DRIVERS

Unipolar Stepper Motor Quad Driver 1.8 A 50 V 2544

Unipolar Stepper-Motor Translator/Driver 1.25 A 50 V 5804

Unipolar Stepper-Motor Quad Driver 1 A 46 V 7024 and 7029

Unipolar Microstepper-Motor Quad Driver 1.2 A 46 V 7042

Voice-Coil Motor Driver ±500 mA 6 V 8932-A

Voice-Coil Motor Driver ±800 mA 16 V 8958

Voice-Coil (and spindle) Motor Driver ±350 mA 7 V 8980 and 8983

* Current is maximum specified test condition, voltage is maximum rating. See specification for sustaining

voltage limits or over-current protection voltage limits.

Negative current is defined as coming out of (sourcing) the output.

† Complete part number includes additional characters to indicate operating temperature range and package style.

Allegro MicroSystems, Inc. reserves the right to make, from time to time, such departures

from the detail specifications as may be required to permit improvements in the design of its

products. Components made under military approvals will be in accordance with the approval

requirements.

The information included herein is believed to be accurate and reliable. However, Allegro

MicroSystems, Inc. assumes no responsibility for its use; nor for any infringements of patents

or other rights of third parties which may result from its use.

TM

A

TM

MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Loading...

Loading...