Page 1

REF 1

V

44

PWM 1

24

21

I

1

PHASE

43

θ

PWM 2

25

REF 2

V

ENABLE

424140

1

θ

26

PHASE

1

1

RC

1

EN

2

2

EN

27

2

2

ENABLE

1

1A

OUT

6

GND

7

8

9

10

11

12

13

14

15

16

GND

17 29

18

2A

OUT

1B

1

E

SENSE

4

5

1

2

19

20

2

2

E

SENSE

OUT

3

21

OUT

2B

11

10

I

I

2

1

BB

V

22

23

20

I

LOAD SUPPLY

ABSOLUTE MAXIMUM RATINGS

at TJ ≤ +150°C

LOGIC SUPPLY

CC

V

39

38

37

36

35

34

33

32

31

30

28

2

RC

Dwg. PP-021

Dwg. PP-021

GND

GND

29319.22†

2 9 1 7

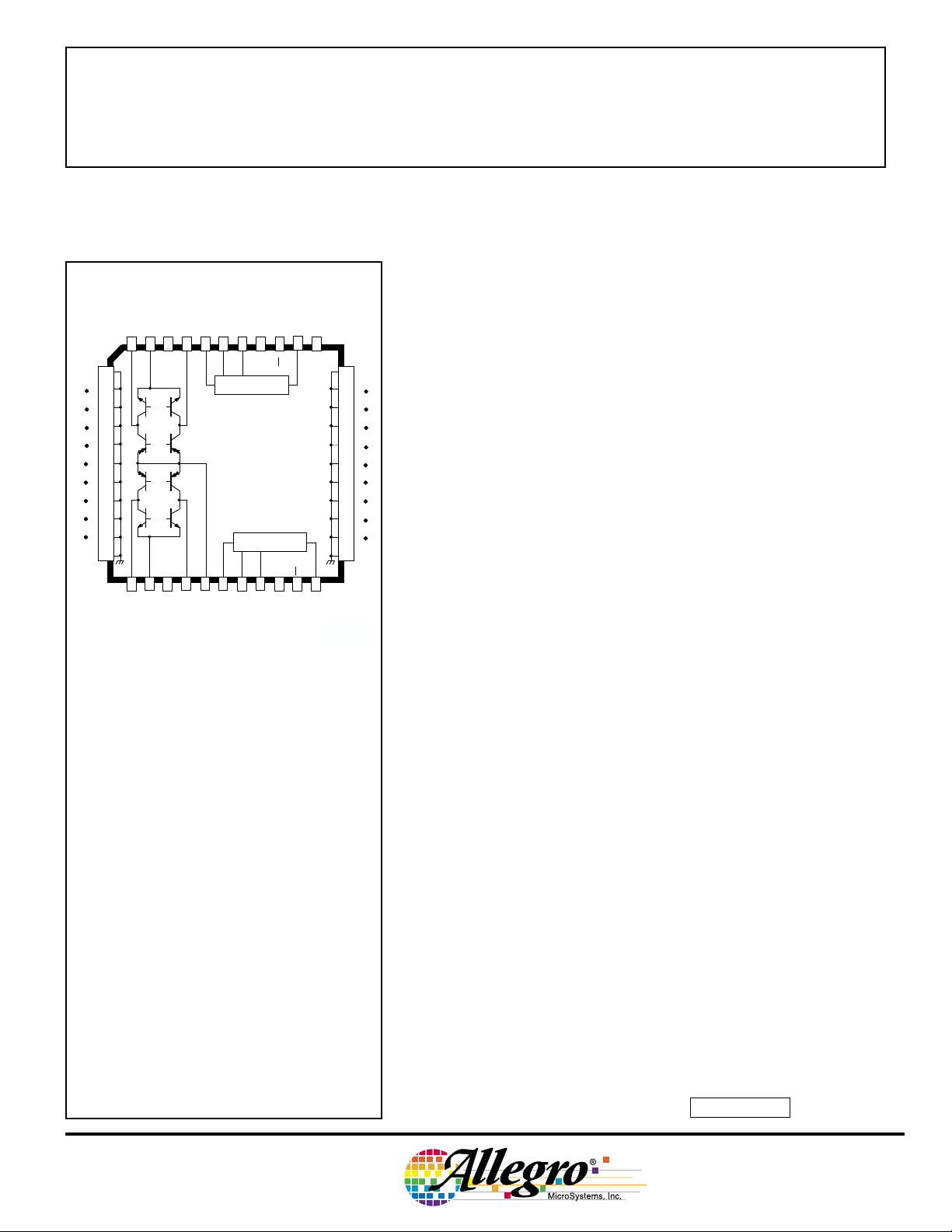

DUAL FULL-BRIDGE

PWM MOTOR DRIVER

The UDN2917EB motor driver is designed to drive both windings

of a bipolar stepper motor or bidirectionally control two dc motors. Both

bridges are capable of sustaining 45 V and include internal pulse-width modula-

tion (PWM) control of the output current to 1.5 A.

For PWM current control, the maximum output current is determined by the

user’s selection of a reference voltage and sensing resistor. Two logic-level

inputs select output current limits of 0, 33%, 67%, or 100% of the maximum

level. A PHASE input to each bridge determines load current direction. Active-

low ENABLE inputs control the four drivers in each bridge.

The bridges include both ground clamp and flyback diodes for protection

against inductive transients. Internally generated delays prevent cross-over

currents when switching current direction. Special power-up sequencing is not

required. Thermal protection circuitry disables the outputs if the chip tempera-

ture exceeds safe operating limits.

The UDN2917EB is supplied in a 44-lead power PLCC for surface-mount

applications. Its batwing construction provides for maximum package power

dissipation in the smallest possible construction. The UDN2917EB is available

for operation from -40°C to +85°C. To order, change the prefix from 'UDN' to

'UDQ'. This device is also available on special order for operation to +125°C.

Data Sheet

Motor Supply Voltage, VBB.................... 45 V

Output Current, I

(tw ≤ 20 µs) ..... ±1.75 A

OUT

(Continuous) ............................... ±1.5 A

Logic Supply Voltage, V

.................... 7.0 V

CC

Logic Input Voltage Range,

VIN................................ -0.3 V to +7.0 V

Output Emitter Voltage, V

................... 1.0 V

E

Package Power Dissipation,

PD......................................... See Graph

Operating Temperature Range,

T

.................................. -20°C to +85°C

A

Storage Temperature Range,

T

................................ -55°C to +150°C

S

Output current rating may be limited by duty cycle,

ambient temperature, and heat sinking. Under any

set of conditions, do not exceed the specified peak

current rating or a junction temperature of +150°C.

FEATURES

■ 1.5 A Continuous Output Current

■ 45 V Output Sustaining Voltage

■ Internal Clamp Diodes

■ Digital Control of Output Current

■ Internal Thermal Shutdown Circuitry

■ Similar to Dual PBL3770

Always order by complete part number: UDN2917EB .

Page 2

2917

DUAL FULL-BRIDGE

PWM MOTOR DRIVER

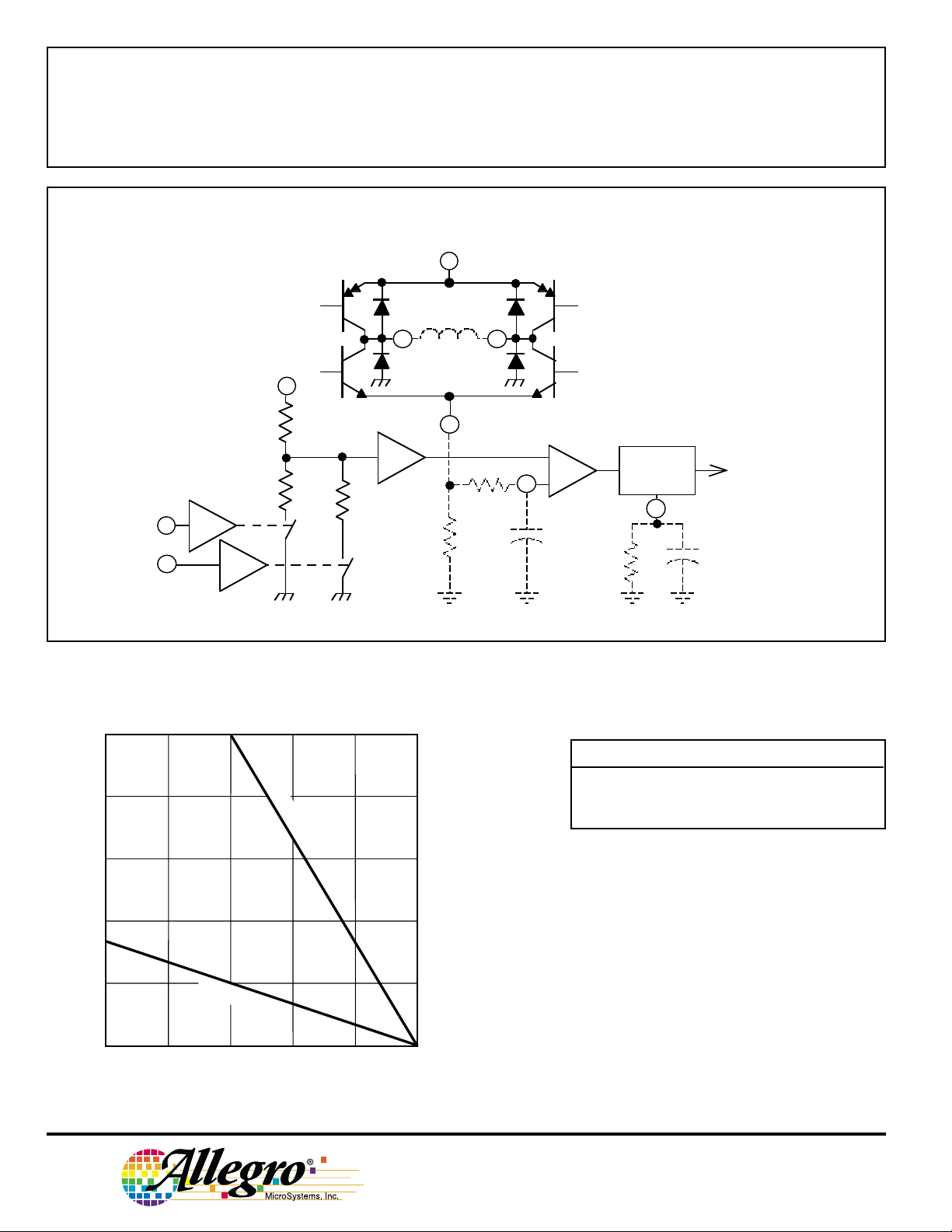

PWM CURRENT-CONTROL CIRCUITRY

CHANNEL 1

PIN NUMBERS

SHOWN.

V

44

REF

20 kΩ

OUT

V

BB

22

OUT

B

36

A

5

E

12.5

10

7.5

÷10

40 kΩ

10 kΩ

2

I

0

1

I

1

R

S

R

C

SENSE

–

4

+

C

C

ONE

SHOT

41

RC

R

T

SOURCE

DISABLE

C

T

Dwg. EP-007-2A

TRUTH TABLE

R

=

θJT

Enable Phase Out

6

°C

/W

LHHL

LLLH

A

HXZZ

X = Don’t care

Z = High impedance

Out

B

5.0

2.5

0

ALLOWABLE PACKAGE POWER DISSIPATION IN WATTS

25

R = 30

θ

J

A

°C/W

50 75 100 125 150

TEMPERATURE IN °C

Dwg. GP-020B

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 1991, 2000 Allegro MicroSystems, Inc.

Page 3

2917

DUAL FULL-BRIDGE

PWM MOTOR DRIVER

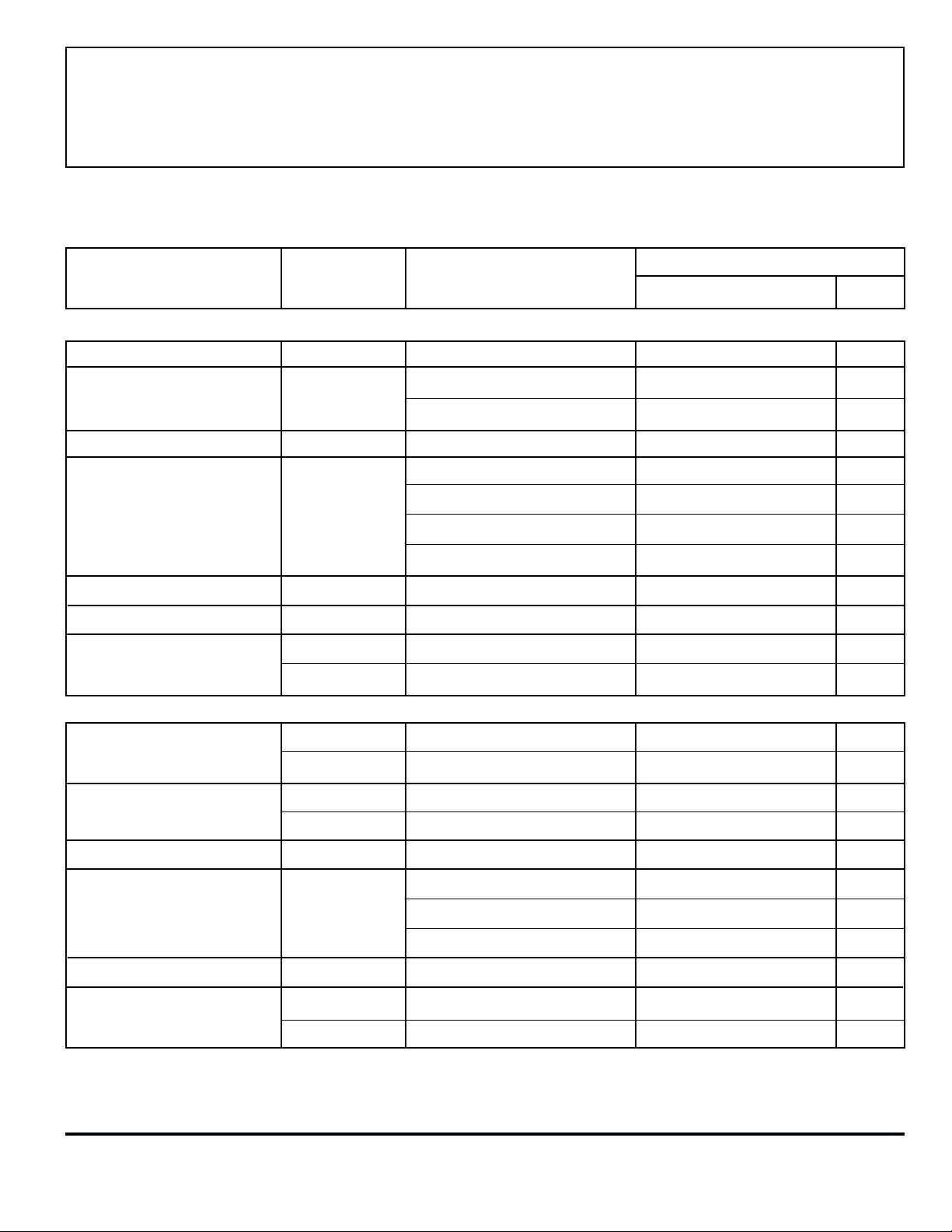

ELECTRICAL CHARACTERISTICS at T

= +25°C, VBB = 45 V, VCC = 5.0 V, V

A

= 5.0 V (unless

REF

otherwise noted).

Limits

Characteristic Symbol Test Conditions Min. Typ. Max. Units

Output Drivers (OUT

Motor Supply Range V

Output Leakage Current I

Output Sustaining Voltage V

Output Saturation Voltage V

Clamp Diode Leakage Current I

Clamp Diode Forward Voltage V

Driver Supply Current I

Control Logic

or OUTB)

A

BB

CEX

CE(sus)

CE(SAT

R

F

BB(ON)

I

BB(OFF)

10 — 45 V

V

= V

OUT

BB

= 0 — <-1.0 -50 µA

V

OUT

I

= ±1.5 A, L = 3.5 mH 45 —— V

OUT

)

Sink Driver, I

Sink Driver, I

Source Driver, I

Source Driver, I

= +1.0 A* — 0.5 0.7 V

OUT

= +1.5 A* — 0.8 1.0 V

OUT

= -1.0 A* — 1.8 1.9 V

OUT

= -1.5 A* — 1.9 2.1 V

OUT

— <1.0 50 µA

VR = 45 V — <1.0 50 µA

IF = 1.5 A — 1.6 2.0 V

Both Bridges On, No Load — 9.0 12 mA

Both Bridges Off — 4.0 6.0 mA

Input Voltage V

Input Current I

Reference Voltage Range V

Current Limit Threshold V

(at trip point)

Thermal Shutdown Temp. T

Total Logic Supply Current I

IN(1)

V

IN(0)

IN(1)

I

IN(0)

REF

REF/VSENSE

J

CC(ON)

I

CC(OFF)

All Inputs 2.4 —— V

All Inputs ——0.8 V

V

= 2.4 V — <1.0 20 µA

IN

VIN = 0.8 V — -3.0 -200 µA

Operating 1.5 — 7.5 V

I0 = I1 = 0.8 V 9.5 10 10.5 —

= 2.4 V, I1= 0.8 V 13.5 15 16.5 —

I

0

= 0.8 V, I1 = 2.4 V 25.5 30 34.5 —

I

0

I0 = I1 = VEN = 0.8 V, No Load — 90 105 mA

I0 = I1 = 2.4 V, No Load — 10 12 mA

Negative current is defined as coming out of (sourcing) the specified device pin.

Typical Data is for design information only.

* Pulse test (<10 ms).

www.allegromicro.com

— 170 — °C

Page 4

2917

DUAL FULL-BRIDGE

PWM MOTOR DRIVER

APPLICATIONS INFORMATION

PWM CURRENT CONTROL

The UDN2917EB dual bridge is designed

to drive both windings of a bipolar stepper

motor. Output current is sensed and controlled independently in each bridge by an

external sense resistor (R

parator, and monostable multivibrator.

), internal com-

S

PWM OUTPUT CURRENT WAVEFORM

V

PHASE

When the bridge is turned on, current

increases in the motor winding and it is

sensed by the external sense resistor until the

sense voltage (V

) reaches the level set

SENSE

at the comparator’s input:

I

TRIP

= V

REF

/10 R

S

The comparator then triggers the monostable which turns off the source driver of

the bridge. The actual load current peak will

be slightly higher than the trip point (especially for low-inductance loads) because of

the internal logic and switching delays. This

delay (td) is typically 2 µs. After turn-off, the

motor current will normally decay, circulating

through the ground clamp diode and sink

transistor. The source driver’s off time (and

therefore the magnitude of the current decrease) is determined by the monostable’s

external RC timing components, where t

=

off

RTCT within the range of 20 kΩ to 100 kΩ and

200 pF to 500 pF.

When the source driver is re-enabled, the

winding current (the sense voltage) is again

allowed to rise to the comparator’s threshold.

This cycle repeats itself, maintaining the

average motor winding current at the desired

level.

+

I

0

OUT

–

I

TRIP

t

d

t

off

Dwg. WM-003-1A

LOAD CURRENT PATHS

V

BB

Special circuitry has been included to

prevent runaway current control when the

fixed off time (t

) is set too short. This

off

circuitry prevents the source driver from being

re-enabled until the load current has decayed

to below the I

TRIP

level.

R

S

BRIDGE ON

SOURCE OFF

ALL OFF

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Dwg. EP-006-1

Page 5

2917

DUAL FULL-BRIDGE

PWM MOTOR DRIVER

CURRENT-CONTROL

TRUTH TABLE

I

0

LLV

HLV

LHV

HH 0

I

1

Output Current

/10 RS = I

REF

/15 RS = 2/3 I

REF

/30 RS = 1/3 I

REF

TRIP

TRIP

TRIP

Loads with high distributed capacitances may result in high turn-on

current peaks. This peak (appearing across RS) will attempt to trip the

comparator, resulting in erroneous current control or high-frequency

oscillations. An external RCCC low-pass filter may be needed to delay

the action of the comparator.

LOGIC CONTROL OF OUTPUT CURRENT

Two logic level inputs (I0 and I1) allow digital selection of the motor

winding current at 100%, 67%, 33%, or 0% of the maximum level per

the table. The 0% output current condition turns off all drivers in the

bridge and can be used as an output enable function. These logic level

inputs greatly enhance the implementation of µP-controlled drive

formats.

During half-step operations, the I0 and I1 inputs allow the µP to

control the motor at a constant torque between all positions in an eightstep sequence. This is accomplished by digitally selecting 100% drive

current when only one phase is on and 67% drive current when two

phases are on.

The logic control inputs can also be used to select a reduced

current level (and reduced power dissipation) for ‘hold’ conditions

and/or increased current (and available torque) for start-up conditions.

GENERAL

To avoid excessive voltage spikes on the LOAD SUPPLY pin

(VBB), a large-value capacitor (≥47 µF) should be connected from V

BB

to ground as close as possible to the device. Under no circumstances

should the voltage at LOAD SUPPLY exceed 45 V.

The PHASE input to each bridge determines the direction motor

winding current flows. An internally generated deadtime (approximately 3 µs) prevents crossover currents that can occur when switching the PHASE input.

All four drivers in the bridge output can be turned off (VEN ≥ 2.4 V

or I0 = I1 ≥ 2.4 V), resulting in a fast current decay through the internal

output clamp and flyback diodes. The fast current decay is desirable

in half-step and high-speed applications. All logic inputs float high; the

ENABLE input must be tied low if it is not used.

Varying the reference voltage (V

) provides continuous control

REF

of the peak load current for micro-stepping applications, within the

specified limits for V

REF

.

Thermal protection circuitry turns off all drivers when the junction

temperature reaches +170°C. It is only intended to protect the device

from failures due to excessive junction temperature and should not

imply that output short circuits are permitted. The output drivers are

re-enabled when the junction temperature cools to +145°C.

www.allegromicro.com

Page 6

2917

DUAL FULL-BRIDGE

PWM MOTOR DRIVER

UDN2917EB

Dimensions in Inches

(controlling dimensions)

28

18

0.319

0.291

0.319

0.291

8.10

7.39

8.10

7.39

0.021

0.013

0.050

BSC

0.533

0.331

1.27

BSC

0.020

MIN

0.180

0.165

29

0.032

0.026

0.695

0.685

0.656

0.650

39

40

Dimensions in Millimeters

(for reference only)

28

29

0.812

0.661

17.65

17.40

16.662

16.510

39

0.656

0.650

144

0.695

0.685

INDEX AREA

2

INDEX AREA

17

7

6

Dwg. MA-005-44A in

18

17

7

0.51

MIN

4.57

4.20

NOTES: 1. MO-047AC except for terminal shoulder height.

2. Webbed lead frame. Leads 7-17 and 29-39 are internally one piece.

3. Lead spacing tolerance is non-cumulative.

4. Exact body and lead configuration at vendor’s option within limits shown.

5. Supplied in standard sticks/tubes of 27 devices or add “TR” to part number for tape and reel.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

144

17.65

17.40

2

6

Dwg. MA-005-44A mm

40

16.662

16.510

Page 7

2917

DUAL FULL-BRIDGE

PWM MOTOR DRIVER

www.allegromicro.com

The products described here are manufactured under one or more

U.S. patents or U.S. patents pending.

Allegro MicroSystems, Inc. reserves the right to make, from time to

time, such departures from the detail specifications as may be required

to permit improvements in the performance, reliability, or

manufacturability of its products. Before placing an order, the user is

cautioned to verify that the information being relied upon is current.

Allegro products are not authorized for use as critical components

in life-support devices or systems without express written approval.

The information included herein is believed to be accurate and

reliable. However, Allegro MicroSystems, Inc. assumes no responsibility for its use; nor for any infringement of patents or other rights of

third parties which may result from its use.

Page 8

2917

DUAL FULL-BRIDGE

PWM MOTOR DRIVER

MOTOR DRIVERS

Function Output Ratings* Part Number

INTEGRATED CIRCUITS FOR BRUSHLESS DC MOTORS

3-Phase Power MOSFET Controller — 28 V 3933

3-Phase Power MOSFET Controller — 50 V 3932

3-Phase Power MOSFET Controller — 50 V 7600

2-Phase Hall-Effect Sensor/Driver 400 mA 26 V 3626

Bidirectional 3-Phase Back-EMF Controller/Driver ±600 mA 14 V 8906

2-Phase Hall-Effect Sensor/Driver 900 mA 14 V 3625

3-Phase Back-EMF Controller/Driver ±900 mA 14 V 8902–A

3-Phase Controller/Drivers ±2.0 A 45 V 2936 & 2936-120

INTEGRATED BRIDGE DRIVERS FOR DC AND BIPOLAR STEPPER MOTORS

Dual Full Bridge with Protection & Diagnostics ±500 mA 30 V 3976

PWM Current-Controlled Dual Full Bridge ±650 mA 30 V 3966

PWM Current-Controlled Dual Full Bridge ±650 mA 30 V 3968

PWM Current-Controlled Dual Full Bridge ±750 mA 45 V 2916

PWM Current-Controlled Dual Full Bridge ±750 mA 45 V 2919

PWM Current-Controlled Dual Full Bridge ±750 mA 45 V 6219

PWM Current-Controlled Dual Full Bridge ±800 mA 33 V 3964

PWM Current-Controlled Full Bridge ±1.3 A 50 V 3953

PWM Current-Controlled Dual Full Bridge ±1.5 A 45 V 2917

PWM Current-Controlled Microstepping Full Bridge ±1.5 A 50 V 3955

PWM Current-Controlled Microstepping Full Bridge ±1.5 A 50 V 3957

PWM Current-Controlled Dual DMOS Full Bridge ±1.5 A 50 V 3972

Dual Full-Bridge Driver ±2.0 A 50 V 2998

PWM Current-Controlled Full Bridge ±2.0 A 50 V 3952

DMOS Full Bridge PWM Driver ±2.0 A 50 V 3958

Dual DMOS Full Bridge ±2.5 A 50 V 3971

UNIPOLAR STEPPER MOTOR & OTHER DRIVERS

Voice-Coil Motor Driver ±500 mA 6 V 8932–A

Voice-Coil Motor Driver ±800 mA 16 V 8958

Unipolar Stepper-Motor Quad Drivers 1 A 46 V 7024 & 7029

Unipolar Microstepper-Motor Quad Driver 1.2 A 46 V 7042

Unipolar Stepper-Motor Translator/Driver 1.25 A 50 V 5804

Unipolar Stepper-Motor Quad Driver 1.8 A 50 V 2540

Unipolar Stepper-Motor Quad Driver 1.8 A 50 V 2544

Unipolar Stepper-Motor Quad Driver 3 A 46 V 7026

Unipolar Microstepper-Motor Quad Driver 3 A 46 V 7044

* Current is maximum specified test condition, voltage is maximum rating. See specification for sustaining voltage limits or

over-current protection voltage limits. Negative current is defined as coming out of (sourcing) the output.

† Complete part number includes additional characters to indicate operating temperature range and package style.

Also, see 3175, 3177, 3235, and 3275 Hall-effect sensors for use with brushless dc motors.

†

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Loading...

Loading...