Page 1

UCC3830-4/-5/-6

02/99

FEATURES

• 5-Bit Digital-to-Analog Converter

(DAC)

• Supports 4-Bit and 5-Bit

Microprocessor VID Codes

• Combined DAC/Voltage Monitor

and PWM Functions

• 1% DAC/Reference

• Current Sharing

• 100kHz, 200kHz, 400kHz

Oscillator Frequency Options

• Foldback Current Limiting

• Overvoltage and Undervoltage

Fault Windows

• Undervoltage Lockout

• 4Ω Totem Pole Output

• Chip Disable Function

5-Bit Microprocessor Power Supply Controller

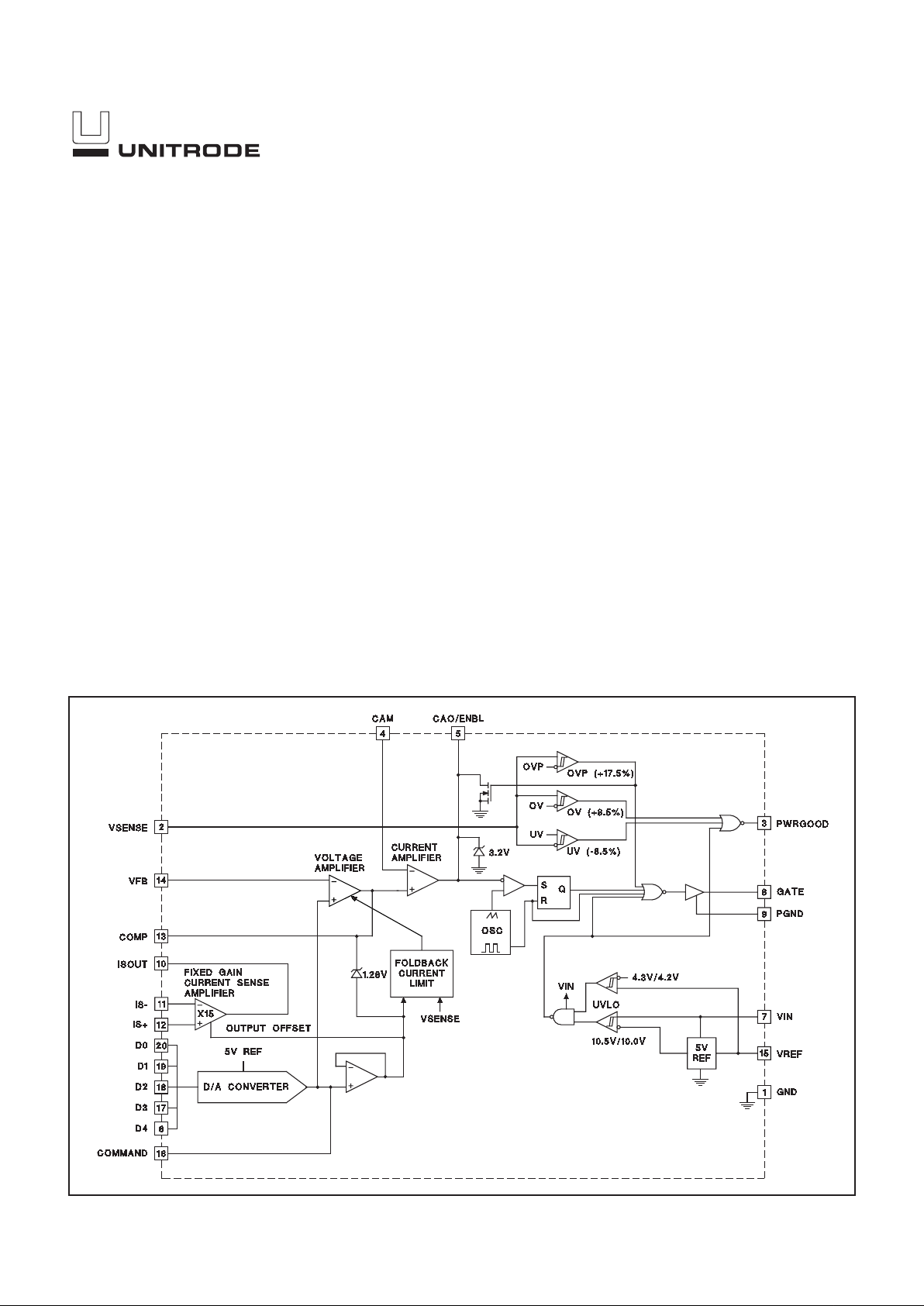

BLOCK DIAGRAM

UDG-96188-2

DESCRIPTION

The UCC3830-4/-5/-6 is a fully integrated single chip solution ideal for powering high performance microprocessors. The chip includes an average current

mode PWM controller, has a fully integrated 5-Bit DAC, and includes an

on-board precision reference and voltage monitor circuitry. The UCC3830-x

converts 5VDC to an adjustable output, ranging from 3.5VDC down to 1.8VDC

with 1% DC system accuracy (see Table 1). The UCC3830-x fully supports

Intel’s 4-bit Pentium® Pro and 5-bit Pentium® II VID codes.

The accuracy of the DAC/reference combination is 1%. The overvoltage and

undervoltage comparators monitor the system output voltage and indicate

when it rises above or falls below its programmed value by more than 8.5%. A

second overvoltage protection comparator pulls the current amplifier output

voltage low to force zero duty cycle when the system output voltage exceeds

its designed value by more than 17.5%. This comparator also terminates the

cycle. Undervoltage lockout circuitry assures the correct logic states at the

outputs during powerup and powerdown. The gate output can be disabled by

bringing the CAO/ENBL pin to below 0.8V.

(continued)

Page 2

2

UCC3830-4/-5/-6

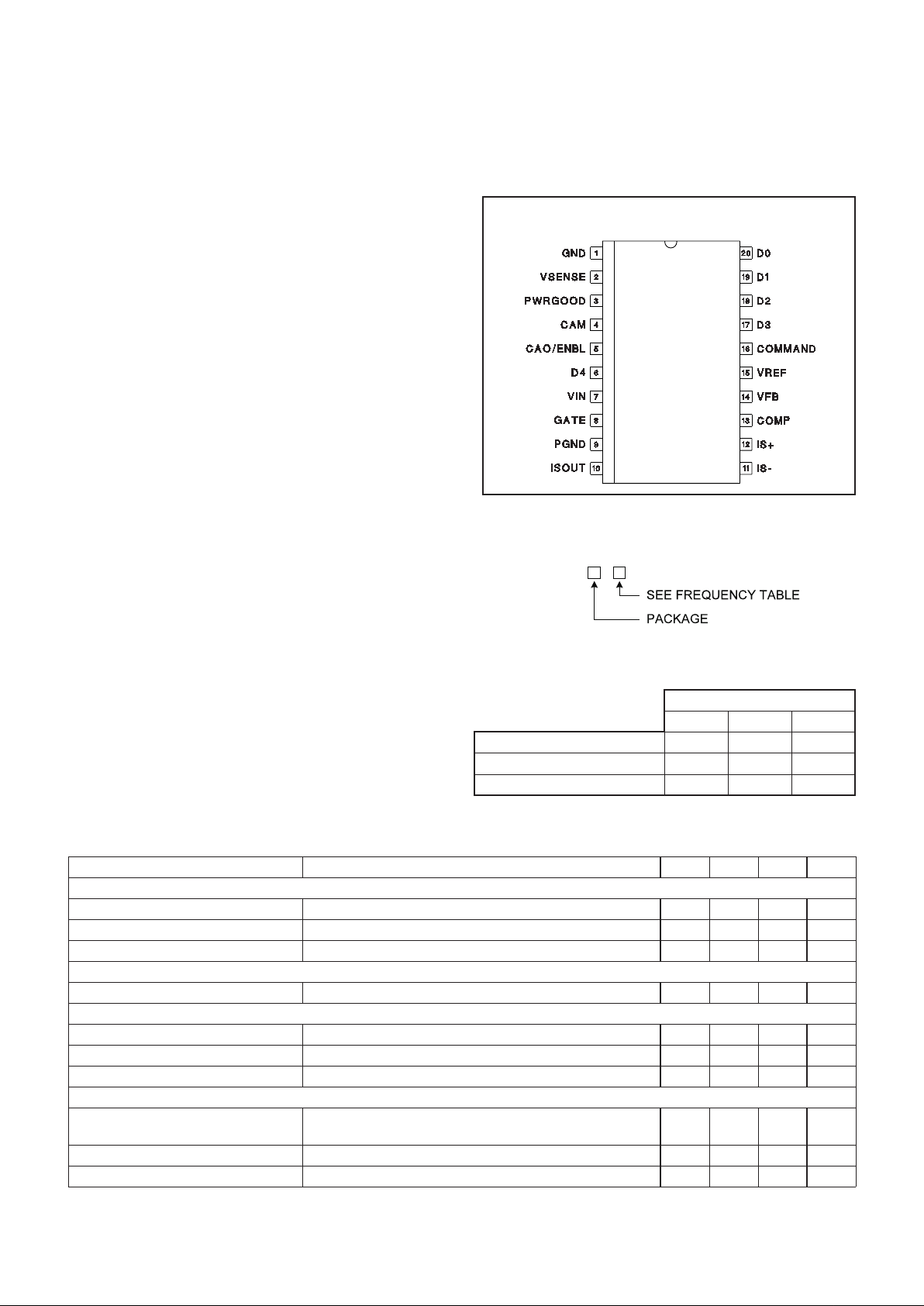

CONNECTION DIAGRAM

SOIC-20 (Top View)

DW Package

ELECTRICAL CHARACTERISTICS:

Unless otherwise specified, VIN = 12V, VSENSE = 3.5V, VD0 = VD1 = VD2 = VD3 =

VD4 = 0V, 0°C < TA < 70°C, TA= TJ.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Undervoltage Lockout

VIN UVLO Turn-on Threshold 10.5 10.8 V

VIN UVLO Turn-off Threshold 9.5 10 V

UVLO Threshold Hysteresis 200 500 700 mV

Supply Current

l

IN D0 through D4 = Open 7.5 13.5 mA

DAC/Reference

COMMAND Voltage Accuracy 10.8V < VIN < 13.2V, I

VREF

= 0mA, 0°C < TA < 70°C –1 1 %

D0-D4 Voltage High DX Pin Floating 4 5 5.2 V

D0-D4 Input Bias Current DX Pin Tied to GND –100 –70 –20 µA

OVP Comparator

Trip Point % Over COMMAND Voltage (Note 1), D0 = D1 = D2 = D4

= Open, D3 = GND

10 17.5 25 %

Hysteresis 20 30 mV

VSENSE Input Bias Current OV, OVP, UV Combined –0.5 –0.1 0.5 µA

The voltage and current amplifiers have a 3MHz gain

bandwidth product to satisfy high performance system

requirements. The internal current sense amplifier permits the use of a low value current sense resistor, minimizing power loss. The oscillator frequency is fixed

internally at 100kHz, 200kHz, or 400kHz, depending

upon the option selected. The foldback circuit reduces

the converter short circuit current limit to 50% of its nominal value when the converter is short circuited. The gate

driver is a 4Ω totem pole output stage capable of driving

an external MOSFET.

This device is available in 20-pin dual in-line and surface

mount packages. The UCC3830-x is specified for operation from 0°C to 70°C.

Pentium®Pro and Pentium®Pro II are registered trademarks of

Intel Corporation.

DESCRIPTION (cont.)

FREQUENCY TABLE

Frequency

100kHz 200kHz 400kHz

UCC3830-4 X

UCC3830-5 X

UCC3830-6 X

UCC3830 –

ORDERING INFORMATION

Note: Consult factory for temperature range or package op-

tions not shown.

ABSOLUTE MAXIMUM RATING

Input Supply Voltage VIN . . . . . . . . . . . . . . . . . . . . . . . . . . 15V

D0, D1, D2, D3, D4, VSENSE, VFB, IS+, IS–, CAM Inputs

Maximum Forced Voltage. . . . . . . . . . . . . . . . –0.3V to 5.3V

PWRGOOD Output Maximum Voltage. . . . . . . . . . . . . . . . 5.5V

COMMAND Ouput Maximum Current . . . . . . Internally Limited

Reference Output Current . . . . . . . . . . . . . . . Internally Limited

Storage Temperature . . . . . . . . . . . . . . . . . . . –65°C to +150°C

Junction Temperature. . . . . . . . . . . . . . . . . . . –55°C to +150°C

Lead Temperature (Soldering, 10 sec.). . . . . . . . . . . . . +300°C

Currents are positive into negative out of the specified terminal.

Pulse is defined as a less than 10% duty cycle with a maximum

duration of 500 s. Consult Packaging Section of Databook for

thermal limitations and considerations of packages.

Page 3

3

UCC3830-4/-5/-6

ELECTRICAL CHARACTERISTICS: Unless otherwise specified, VIN = 12V, VSENSE = 3.5V, VD0 = VD1 = VD2 = VD3 =

VD4 = 0V, 0°C < TA < 70°C, TA= TJ.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

OV Comparator

Trip Point % Over COMMAND Voltage (Note 1), D0 = D1 = D2 = D4

= Open, D3 = GND

5 8.5 12 %

Hysteresis 20 30 mV

PWRGOOD Equivalent Resistance VSENSE = 2.0V 470 Ω

UV Comparator

Trip Point % Over COMMAND Voltage (Note 1), D0 = D1 = D2 = D4

= Open, D3 = GND

–12 –8.5 –5 %

Hysteresis 20 30 mV

Voltage Error Amplifier

Input Bias Current V

CM = 3.0V –0.5 –0.02 0.5 µA

Open Loop Gain 1.5V < V

COMP

< 2.5V, D4 = D3 = D2 = D1 = GND, D0 =

Open

80 dB

Power Supply Rejection Ratio 10.8V < VIN < 15V 85 dB

Output Sourcing Current V

VFB = 2V, VCOMMAND = VCOMP = 2.5V –0.5 –0.3 mA

Output Sinking Current V

VFB = 3V, VCOMMAND = VCOMP = 2.5V 0.5 1 mA

Current Sense Amplifier

Gain 14.25 15.25 V/V

Input Resistance 3kΩ

Common Mode Rejection Ratio 0V < V

CM < 4.5V 60 dB

Power Supply Rejection Ratio 10.8V < VIN < 15V 80 dB

Output Sourcing Current V

IS– = 2V, VISOUT = VIS+ = 2.5V –0.5 –0.3 mA

Output Sinking Current V

IS– = 3V, VISOUT = VIS+ = 2.5V 5 8 mA

Current Amplifier

Input Offset Voltage V

CM = 3.0V –12 12 mV

Input Bias Current V

CM = 3.0V –0.1 µA

Open Loop Gain 1V < V

CAO/ENBL < 2.5V 80 dB

Output Voltage High V

COMP = 3V, VCAM = 2.5V 3.2 V

Power Supply Rejection Ratio 10.8V < VIN < 15V 80 dB

Output Sourcing Current V

CAM = 2V, VCAO/ENBL = VCOMP = 2.5V –1 –0.5 mA

Output Sinking Current V

CAM = 3V, VCAO/ENBL = VCOMP = 2.5V 3 5 mA

Oscillator

Frequency (-4) 85 100 115 kHz

Frequency (-5) 170 200 230 kHz

Frequency (-6) 340 400 460 kHz

Frequency Change With Voltage 10.8V < VIN < 15V 1 %

Output Section

Maximum Duty Cycle 90 95 99 %

Output Low Voltage I

GATE = –100mA 0.2 V

Output High Voltage I

GATE = 100mA 11.8 V

Rise Time C

GATE = 3.3nF 20 70 ns

Fall Time C

GATE = 3.3nF 15 70 ns

Foldback Current Limit

Clamp Level Measured at Voltage EA Output;

V

SENSE = VCOMMAND = 3V

4.28 V

V

COMMAND = 3V, VSENSE = 0 3.64 V

Note 1: This percentage is measured with respect to the ideal COMMAND voltage programmed by the D0 - D4 pins.

Page 4

4

UCC3830-4/-5/-6

CAM (Current Amplifier Inverting Input): The average

load current feedback from ISOUT is applied through a

resistor to this pin. The current loop compensation

network is also connected to this pin (see CAO/ENBL

below).

CAO/ENBL (Current Amplifier Output/Chip Enable):

The current loop compensation network is connected

between this pin and CAM. The voltage on this pin is the

input to the PWM comparator and regulates the output

voltage of the system. The GATE output is disabled

(held low) unless the voltage on this pin exceeds 1V,

allowing the PWM to force zero duty cycle when

necessary. The PWM forces maximum duty cycle when

the voltage on CAO/ENBL exceeds the oscillator peak

voltage (3V). A 3.2V clamp circuit prevents the

CAO/ENBL voltage from rising excessively past the

oscillator peak voltage for excellent transient response.

The user can force this pin below 0.8V externally with an

open collector, disabling the GATE drive.

COMMAND (Digital-to-Analog Converter Output

Voltage): This pin is the output of the 5-bit

digital-to-analog converter (DAC) and the noninverting

input of the voltage amplifier. The voltage on this pin sets

the switching regulator output voltage. This voltage

ranges from 1.8V to 3.5V as programmed by the 5-bit

DAC according to Table 1. The GATE output is disabled

when all 1s or illegal codes are presented at the 5 Bit

DAC. The COMMAND source impedance is typically

1.2kΩ and must therefore drive only high impedance

inputs if accuracy is to be maintained. Bypass

COMMAND with a 0.01µF, low ESR, low ESL capacitor

for best circuit noise immunity.

COMP (Voltage Amplifier Output): The system voltage

compensation network is applied between COMP and

VFB.

D0 - D4 (DAC Digital Input Control Codes): These are

the DAC digital input control codes, with D0 representing

the least significant bit (LSB) and D4, the most significant

bit (MSB) as shown in Table 1. A bit is set low by being

connected to GND. A bit is set high by floating it, or

connecting it to a 5V source. Each control pin is pulled

up to approximately 5V by an internal 70µA current

source.

GATE (PWM Output, MOSFET Driver): This output

provides a 4Ω totem pole driver. Use a series resistor

between this pin and the gate of the external MOSFET to

prevent excessive overshoot.

GND (Signal Ground): All voltages are measured with

respect to GND. Bypass capacitors on the VCC and

VREF pins should be connected directly to the ground

plane near the GND pin.

IS– (Current Sense Amplifier Inverting Input): This pin

is the inverting input to the current sense amplifier and is

connected to the low side of the average current sense

resistor.

IS+ (Current Sense Amplifier Noninverting Input):

This pin is the noninverting input to the current sense

amplifier and is connected to the high side of the

average current sense resistor.

ISOUT (Current Sense Amplifier Output): This pin is

the output of the current sense amplifier. The voltage on

this pin is (COMMAND + G

CSA •I•RSENSE), where

COMMAND is the voltage on the COMMAND pin, G

CSA

is the fixed gain of the current sense amplifier, equal to

15, I is the current through the sense resistor, and

R

SENSE is the value of the average current sensing

resistor.

PGND (Power Ground): This pin provides a dedicated

ground for the output gate driver. The GND and PGND

pins should be connected externally using a short printed

circuit board trace close to the IC. Decouple VIN to

PGND with a low ESR capacitor 0.10µF.

PWRGOOD (Undervoltage/Lower Overvoltage

Output): This pin is an open drain output which is driven

low to reset the microprocessor when VSENSE rises

above or falls below its nominal value by 8.5%. The on

resistance of the open drain switch will be no higher than

470Ω. The OV and UV comparators’ hysteresis is fixed

at 20mV independent of the COMMAND voltage.

VIN (Positive Supply Voltage): This pin supplies power

to the chip. Connect VIN to a stable voltage source of at

least 10.8V. The GATE and PWRGOOD outputs will be

held low until VCC exceeds the upper undervoltage

lockout threshold. This pin should be bypassed directly

to the GND pin.

VFB (Voltage Amplifier Inverting Input): This input is

connected to COMP through a feedback network and to

the power supply output through a resistor or a divider

network.

VREF (Voltage Reference Output): This pin provides

an accurate 5V reference and is internally short circuit

current limited. VREF powers the D/A converter and also

provides a threshold voltage for the UVLO comparator.

For best reference stability, bypass VREF directly to

GND with a low ESR, low ESL capacitor of at least

0.01µF.

PIN DESCRIPTIONS

Page 5

5

UCC3830-4/-5/-6

The curves shown in Figures 1 and 2 depict the typical

high gain-bandwidth products for the UCC3830-x Voltage

Amplifier, Current Amplifier and Current Sense Ampli-

fiers. These high gain-bandwidth devices help achieve

an excellent transient response to load and line changes.

TYPICAL PERFORMANCE CURVES

Figure 1. Open loop gain for UCC3830 voltage and

current amplifier.

Figure 2. Current sense amplifier gain vs frequency.

Short Circuit Current Limit

The short circuit current limit, ISC, is set according to:

ISC =

1.28V

RSENSE • GCSA

where R

SENSE is the average current sense resistor and

GCSA is the current sense amplifier gain. GCSA equals

15.

Example: Choose RSENSE to set the short circuit limit at

17A using the UCC3830-5

RSENSE =

1.28V

17A •15

=0.005Ω

.

A lower resistance value may be needed if the AC ripple

current in the inductor is more than 20% of the load current.

APPLICATION INFORMATION

Figure 3. Short circuit foldback reduces stress on

circuit components by reducing short circuit current.

VSENSE (Output Voltage Sensing Input): This pin is

connected to the system output voltage through a low

pass filter. When the voltage on VSENSE rises above or

falls below the COMMAND voltage by 8.5%, the

PWRGOOD output is driven low to reset the

microprocessor. When the voltage on VSENSE rises

above the COMMAND voltage by 17.5%, the OVP

comparator pulls the current amplifier output voltage

below the oscillator valley voltage to force zero duty

cycle at the GATE output. This pin is also used by the

foldback current limiting circuitry.

PIN DESCRIPTIONS (cont.)

Page 6

6

UCC3830-4/-5/-6

The UCC3830-x incorporates short circuit current

foldback, as shown in Figure 3. When the output of the

power supply is short circuited, the output voltage falls.

When the output voltage reaches 1/2 of its nominal voltage (COMMAND/2) then the output current is reduced.

This feature reduces the amount of current in the

MOSFET, diode and capacitors, and insures high reliability.

Enabling/Disabling the UCC3830-x Gate Drive

The CAO/ENBL pin can be used to disable the UCC3830

gate drive by forcing this pin below 0.8V, as shown in

Figure 4. Bringing the voltage below the valley of the

PWM oscillator ramp will insure a 0% duty cycle, effectively disabling the gate drive. A low noise open collector

signal should be used as an Enable/Disable command.

Setting the Output Voltage Using the DAC

The 5-bit Digital-to-Analog Converter (DAC) is programmed according to Table 1. The COMMAND voltage

is always active as long as the UCC3830 VIN pin is

above the undervoltage lockout voltage. The output gate

drive, GATE, is disabled at certain DAC codes, as shown

in Table 1. Disabling the gate drive disables the power

supply.

Operating the 5-Bit Controller with Intel’s 4-Bit

Pentium Pro

The UCC3830-x 5-Bit Controller is completely backward

compatible. When the fifth bit, D4 is left open (4-Bit Processor in circuit), the UCC3830-x acts as a 4-Bit controller with the COMMAND voltage fully compatible with

Intel’s 4-Bit Pentium

®

Pro family.

APPLICATION INFORMATION (cont.)

Digital Command Command GATEHI/GATELO Digital Command Command GATEHI/GATELO

D4 D3 D2 D1 D0

Voltage Status

D4 D3 D2 D1 D0

Voltage Status

01111 1.300 Note 1 11111 2.000 Note 1

01110 1.350 Note 1 11110 2.100 Enabled

01101 1.400 Note 1 11101 2.200 Enabled

01100 1.450 Note 1 11100 2.300 Enabled

01011 1.500 Note 1 11011 2.400 Enabled

01010 1.550 Note 1 11010 2.500 Enabled

01001 1.600 Note 1 11001 2.600 Enabled

01000 1.650 Note 1 11000 2.700 Enabled

00111 1.700 Note 1 10111 2.800 Enabled

00110 1.750 Note 1 10110 2.900 Enabled

00101 1.800 Enabled 10101 3.000 Enabled

00100 1.850 Enabled 10100 3.100 Enabled

00011 1.900 Enabled 10011 3.200 Enabled

00010 1.950 Enabled 10010 3.300 Enabled

00001 2.000 Enabled 10001 3.400 Enabled

00000 2.050 Enabled 10000 3.500 Enabled

Table 1. Programming the command voltage for the UCC3830-x.

Figure 4. Disabling the UCC3830-x.

Figure 5. Input capacitors current waveform.

UDG-96189

Page 7

7

UCC3830-4/-5/-6

Figure 7. Efficiency of UCC3830-5 200kHz demo kit at

2.8V ouput.

Figure 8. UCC3830 configured for 4-bit or 5-bit operation.

UDG-96190-1

Figure 6. Load current vs RMS current for input

capacitors.

APPLICATION INFORMATION (cont.)

Page 8

8

UCC3830-4/-5/-6

Choosing the Input Capacitor

The input capacitors are chosen primarily based on their

switching frequency RMS current handling capability and

their voltage rating. The input capacitors must handle

virtually all of the RMS current at the switching frequency, even if the circuit does not have an input inductor. The switching current in the input capacitors

appears as shown in Figure 5.

The amount of RMS current in an Aluminum Electrolytic

capacitor has a strong impact on the reliability and lifetime of the capacitor. Other factors which affect the life

of an input capacitor are internal heat rise, external airflow, the amount of time that the circuit operates at maximum current and the operating voltage. The curves in

Figure 6 show the RMS current handled by the total input

capacitance in typical VRM circuits delivering 1.8V to

2.8V and powered from 5V.

Related Publications

U-156 and U-157 are Unitrode Application Notes describing the operation of the UC3886 and the UC3886/

UC3910 together in a Pentium® Pro application.

Typical Application

The UCC3830-x is ideal for converting the 5.0V system

bus into the required Pentium® Pro bus voltage. The

3.3V system bus can also be converted using the

UCC3830-x when the Pentium® Pro requires lower bus

voltages.

APPLICATION INFORMATION (cont.)

Table I. Parts list.

REFERENCE

DESIGNATOR

DESCRIPTION PACKAGE

U1 Unitrode UCC3830DWP-5 DAC/PWM SOIC-20 Wide

C1 Sanyo 6MV1500GX, 1500µF, 6.3V, Aluminum Electrolytic 10x20mm Radial Can

C2 Sanyo 6MV1500GX, 1500µF, 6.3V, Aluminum Electrolytic 10x20mm Radial Can

C3 Sanyo 6MV1500GX, 1500µF, 6.3V, Aluminum Electrolytic 10x20mm Radial Can

C4 Sanyo 6MV1500GX, 1500µF, 6.3V, Aluminum Electrolytic 10x20mm Radial Can

C5 Sprague/Vishay 595D475X0016A2B, 4.7µF 16V Tantalum SPRAGUE Size A

C6 Sanyo 6MV1500GX, 1500µF, 6.3V, Aluminum Electrolytic 10x20mm Radial Can

C7 Sanyo 6MV1500GX, 1500µF, 6.3V, Aluminum Electrolytic 10x20mm Radial Can

C8 Sanyo 6MV1500GX, 1500µF, 6.3V, Aluminum Electrolytic 10x20mm Radial Can

C9 Sanyo 6MV1500GX, 1500µF, 6.3V, Aluminum Electrolytic 10x20mm Radial Can

C10 Sanyo 6MV1500GX, 1500µF, 6.3V, Aluminum Electrolytic 10x20mm Radial Can

C11 Sprague 593D107X9010D2, 100µF, 6.3V Tantalum EIA Size D SMD

C12 0.10µF Ceramic 1206 SMD

C13 0.01µF Ceramic 0603 SMD

C14 0.01µF Ceramic 0603 SMD

C15 0.01µF Ceramic 0603 SMD

C16 1000pF Ceramic 0603 SMD

C17 0.10µF Ceramic 1206 SMD

C18 33pF NPO Ceramic 0603 SMD

C19 1500pF Ceramic 0603 SMD

C20 82pF NPO Ceramic 0603 SMD

C21 0.10µF Ceramic 1206 SMD

C22 0.10µF Ceramic 1206 SMD

CR1 International Rectifier 32CTQ030 30V, 30A Schottky Diode TO-220AB

L1 Micrometals T50-52B, 10 Turns #16AWG, 4.5µH Toroid

Page 9

9

UCC3830-4/-5/-6

UNITRODE CORPORATION

7 CONTINENTALBLVD. • MERRIMACK, NH 03054

TEL. (603) 424-2410 • FAX (603) 424-3460

REFERENCE

DESIGNATOR

DESCRIPTION PACKAGE

Q1 International Rectifier IRL3103, 30V, 56A TO-220AB

R1 Dale/Vishay WSR-2 0.005Ω 1% SMD Power Package

R2 10Ω, 5%, 1/16 Watt 0603 SMD

R3 8.2kΩ, 5%, 1/16 Watt 0603 SMD

R4 6.81kΩ, 1%, 1/16 Watt 0603 SMD

R5 3.92kΩ, 1%, 1/16 Watt 0603 SMD

R6 261kΩ, 1%, 1/16 Watt 0603 SMD

R7 100kΩ, 1%, 1/16 Watt 0603 SMD

R8 3.92kΩ, 1%, 1/16 Watt 0603 SMD

R9 10.5kΩ, 1%, 1/16 Watt 0603 SMD

Q1-HS AAVID 576802 TO-220 Heat Sink TO-220AB

CR1-HS AAVID 577002 TO-220 Heat Sink TO-220AB

Table I. Parts list. (cont.)

Page 10

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. T esting and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERSTOOD T O

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...