Page 1

1

FEATURES

DESCRIPTION

APPLICATIONS

UCC28230

UCC28231

www.ti.com

................................................................................................................................................... SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008

Advanced PWM Controller for Bus Converters

• Programmable, Load Depended Off Time

Control

The UCC28230, UCC28231 PWM bus controllers are

optimized for use in high efficiency, high power

• Frequency Controlled Start Up Allows Small

density, unregulated intermediate bus converters.

Output Inductor, Low Ripple and Constant

Topologies include push-pull, half-bridge and

Current Start with Large Output Capacitor

full-bridge. External drivers, such as the UCC27200

• Two 0.2-A Push-Pull Outputs Provide Matched

120-V high-side/low-side drivers, can be used with

Control Signals D to External Drivers

this controller.

• Two Additional 1- D Outputs for Optimal Use

Low cost, small size and highly efficient solutions are

of Self-Driven or Control Driven Synchronous

provided by innovations such as:

Rectifiers

• Start-up frequency control circuit allowing small

• Unregulated, Fixed Volt-Second or Fixed

output inductor and the ability to start with large

Frequency Modes set by User

intermediate bus capacitor.

• Two, 1.5% Overall Accuracy Reference Voltage

• Load depended off-time control set by user.

Options: 5-V for UCC28230 and 3.3-V for

Additional 1-D control outputs can be used for

UCC28231

primary winding clamping in self-driven output

• Resistor Programmable Switching Frequency

synchronous rectifier applications or as drive signals

up to 1 MHz

for the control-driven synchronous rectifier.

• Cycle-by-Cycle Current Limit Allows Parallel

Cycle-by-cycle current limit prevents overstresses of

Operation with Droop Based Current Sharing

converter. If the over current condition causes less

than 80% duty cycle at the output, then after a

• Single External Capacitor sets Soft-Start and

programmed time the controller proceeds into

Over Current Hiccup Mode Parameters with

periodical shutdown and restart hiccup mode.

Restart

The UCC28230 provides 5 V, and the UCC28231

• Severe Short Circuit Hiccup with Restart or

provides 3.3-V precision reference voltages with 1.5%

Latch Off Protection Option by External

overall accuracy and 10-mA output current. This

Resistor

reference voltage can be used to supply

• Input Under Voltage Lock Out

housekeeping circuit and/or microcontroller. The

• Thermal Shutdown

precision reference voltage can also be used for

accurate setting of system parameters.

• Thermally Enhanced 3 mm × 2 mm SON-12

and TSSOP-14 Package Options

Other features include under-voltage lockout, thermal

shut down, programmable soft start, over-current

hiccup mode and short circuit protection with internal

restart by default that can be set into latch-off mode

• Intermediate Bus Isolated Converters

by an external resistor.

• DC-to-DC Transformers

1

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PRODUCTION DATA information is current as of publication date.

Copyright © 2008, Texas Instruments Incorporated

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Page 2

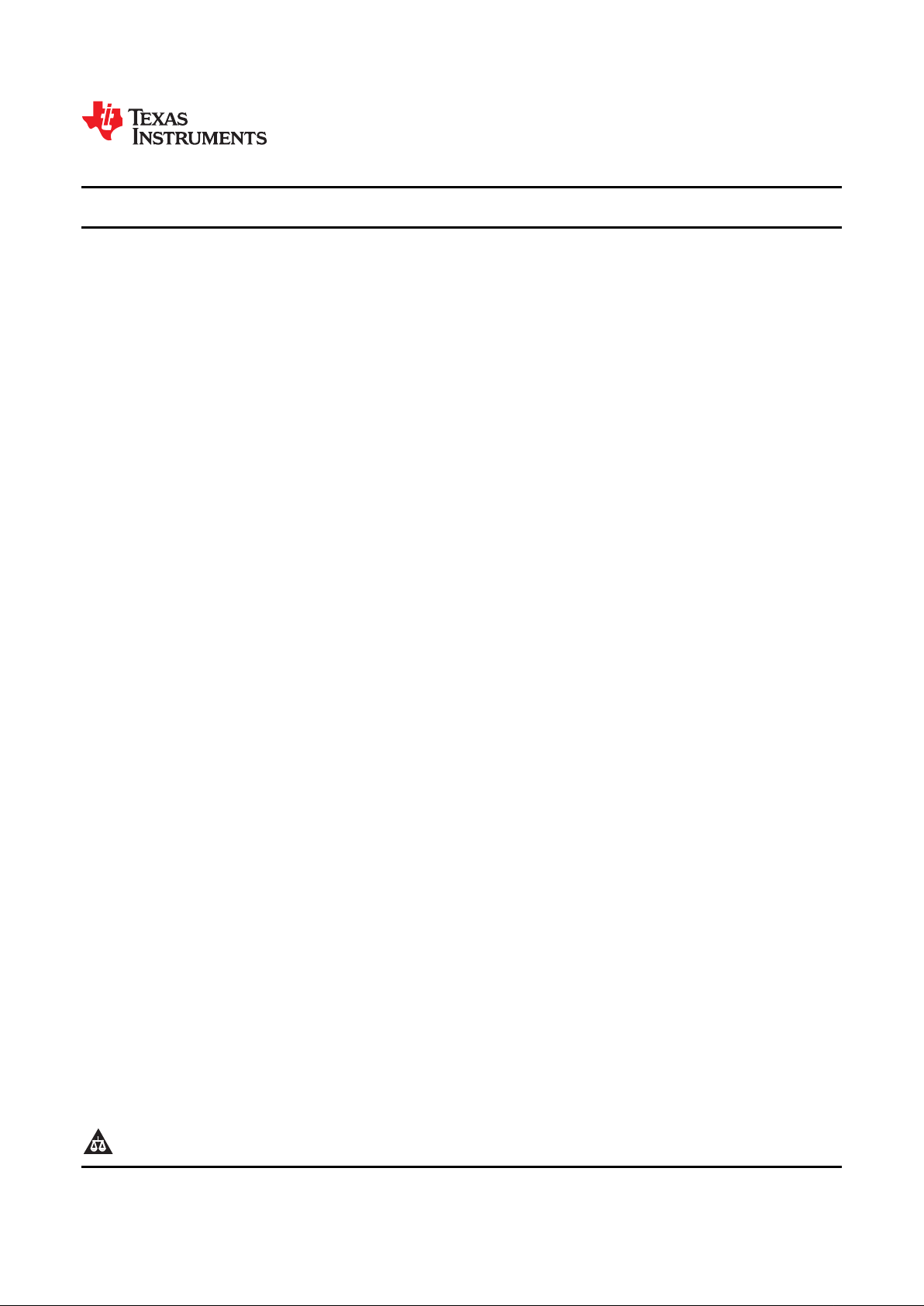

TYPICAL APPLICATION DIAGRAMS

Vin

36 Vto60V

+

_

CT

Vout

7 Vto12 V

400W

+

_

Vbias

Vbias

Vcc=5 Vor3.3V

Interface

with

System

HI

V

DD

V

SS

LI

HB

HO

HS

LO

HI

V

DD

V

SS

LI

HB

HO

HS

LO

UCC27200UCC27200

Bias

Power

Supply

Vbias

Housekeeping

Micro

Controller

GND

O1_D

VREF

V

DD

5V/3.3V

LDO

EN

UVLO

Comp.

6.3Vrise

5.7 Vfall

V

DD

V

DD

RT

CS

SS

Vin

OS

Thermal

Shutdown

Is

R1

R2

O2_DIN

O2_D

O1_DIN

8

10

11

9

7

1

2

6

4

12

SoftStart

&

HiccupCurrent

LimitCircuit

Logic

Block

V

DD

Reference

Generator

ShortCircuit

Shutdown

Oscillator

&

StartUp

Frequency

Control

Off Time

Control

Circuit

Cycle-by

-

CycleCurrent

Limit

CLK

3

OST

R3

5

Vin

36Vto60V

+

_

CT

Vout

7Vto12V

200W

+

_

Vbias

Houskeeping

Micro-

Controller

Vcc=5Vor3.3V

Interface

with

System

HI

V

DD

V

SS

LI

HB

HO

HS

LO

UCC27200

Bias

Power

Supply

Vbias

UCC28230/1

INA

2

4

7

5

6

3

V

DD

GND

INB

UCC27324

OUTA

OUTB

Vbias

GND

O1_D

VREF

V

DD

5V/3.3V

LDO

EN

UVLO

Comp.

6.3Vrise

5.7 Vfall

V

DD

V

DD

RT

CS

SS

Vin

OS

Thermal

Shutdown

Is

R1

R2

O2_DIN

O2_D

O1_DIN

8

10

11

9

7

1

2

6

4

12

SoftStart

&

HiccupCurrent

LimitCircuit

Logic

Block

V

DD

Reference

Generator

ShortCircuit

Shutdown

Oscillator

&

StartUp

Frequency

Control

Off Time

Control

Circuit

Cycle -by -

CycleCurrent

Limit

CLK

3

OST

R3

5

UCC28230

UCC28231

SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008 ...................................................................................................................................................

www.ti.com

Figure 1. Full-Bridge Bus Converter

Figure 2. Half-Bridge Bus Converter with Control-Driven Synchronous Rectifier

2 Submit Documentation Feedback Copyright © 2008, Texas Instruments Incorporated

Product Folder Link(s): UCC28230 UCC28231

Page 3

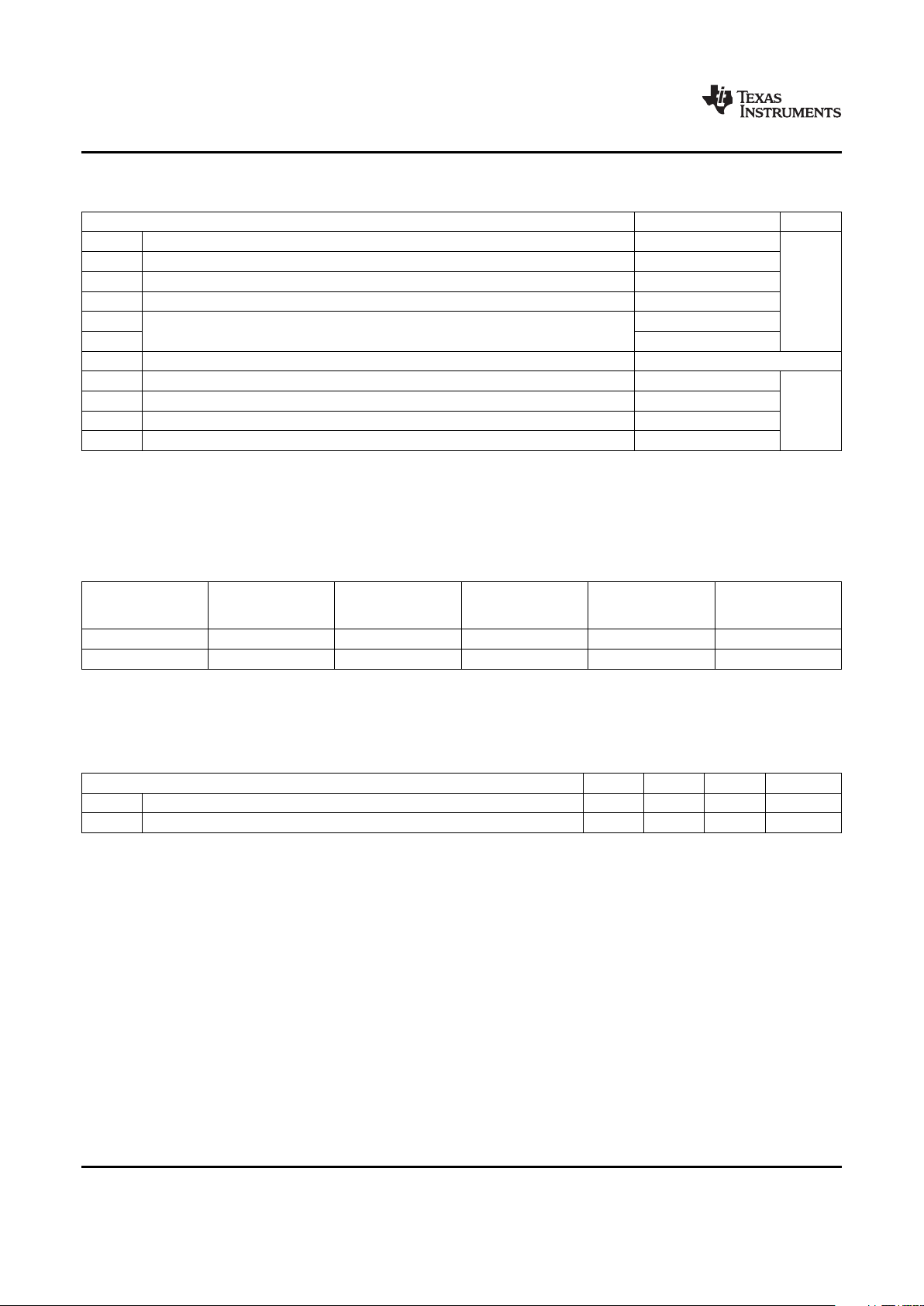

PINOUT CONFIGURATION

UCC28230

UCC28231

www.ti.com

................................................................................................................................................... SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008

ORDERING INFORMATION

(1) (2)

TEMPERATURE RANGE,

REFERENCE VOLTAGE PACKAGE TAPE and REEL QTY PART NUMBER

TA= T

J

5 V .250 UCC28230DRNT

5 V 3000 UCC28230DRNR

Plastic 12-pin SON (DRN)

3.3 V 250 UCC28231DRNT

3.3 V 3000 UCC28231DRNR

– 55 ° C to +125 ° C

5 V 250 UCC28230PW

5 V 2000 UCC28230PWR

Plastic 14-pin TSSOP (PW)

3.3 V 250 UCC28231PW

3.3 V 2000 UCC28231PWR

(1) The 12-pin SON (DRN) and 14-pin TSSOP packages use Pb-Free lead finish of Pd-Ni-Au which is compatible with MSL level 1 at

255-260 ° C peak reflow temperature to be compatible with either lead free or Sn/Pb soldering operations.

(2) The pad underneath the center of the IC is a thermal substrate. The PCB “ thermal land ” design for this exposed die pad should include

thermal vias that drop down and connect to one or more buried copper plane(s). This combination of vias for vertical heat escape and

buried planes for heat spreading allows the DRN to achieve its full thermal potential. This pad is also internally connected to GND pin.

Copyright © 2008, Texas Instruments Incorporated Submit Documentation Feedback 3

Product Folder Link(s): UCC28230 UCC28231

Page 4

ABSOLUTE MAXIMUM RATINGS

DISSIPATION RATINGS

(1)

RECOMMENDED OPERATING CONDITIONS

UCC28230

UCC28231

SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008 ...................................................................................................................................................

www.ti.com

over operating free-air temperature range

(1) (2)

(unless otherwise noted)

PARAMETER VALUE UNIT

V

DD

(3)

Input supply voltage range – 0.3 to 20.0

O1_D, O2_D, O1_DIN, O2_DIN – 0.3 to V

DD

+0.3

Inputs voltages on OS, CS, SS, RT, OST – 0.3 to 6.3

V

Output voltage on VREF – 0.3 to 5.6

HBM 2k

ESD rating

CDM 500

Continuous total power dissipation See Dissipation Rating Table

T

J

Operating virtual junction temperature range – 55 to +150

T

A

Operating ambient temperature range – 55 to +125

° C

T

stg

Storage Temperature – 65 to +150

Lead Temperature (Soldering, 10 sec.) PW Package +300

(1) Stresses beyond those listed under absolute maximum ratings may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under recommended operating

conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2) These devices are sensitive to electrostatic discharge; follow proper device handling procedures.

(3) All voltages are with respect to GND unless otherwise noted. Currents are positive into, negative out of the specified terminal. See

Packaging Section of the datasheet for thermal limitations and considerations of packages.

θJC( ° C/W) θJA( ° C/W) θJB( ° C/W)

θJP( ° C/W)

BOARD PACKAGE JUNCTION TO JUNCTION TO JUNCTION TO

JUNCTION TO PAD

CASE AMBIENT BOARD

High-K

(2)

DRN 70.66 15 37.66

PW 2.71 97.65 2.07

(1) These thermal data are taken at standard JEDEC test conditions and are useful for the thermal performance comparison of different

packages. The cooling condition and thermal impedance R

θ JA

of practical design is specific.

(2) The JEDEC test board JESD51-5 with direct thermal pad attach, 3-inch × 3-inch, 4-layer with 1-oz internal power and ground planes and

2-oz top and bottom trace layers (preliminary data based on modeling)

MIN NOM MAX UNIT

V

DD

Supply voltage range 7 12 17 V

Operating junction temperature range – 55 125 ° C

4 Submit Documentation Feedback Copyright © 2008, Texas Instruments Incorporated

Product Folder Link(s): UCC28230 UCC28231

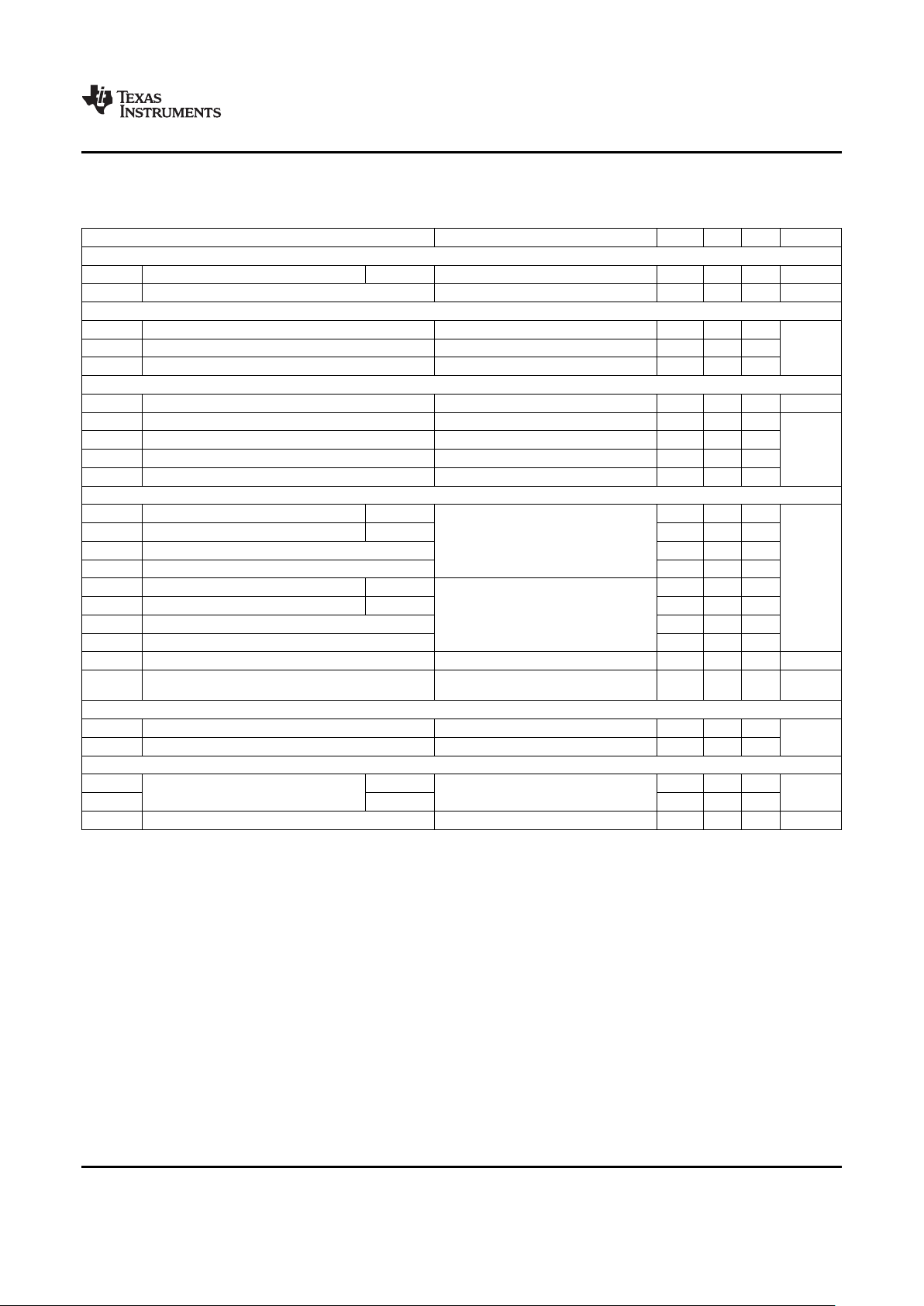

Page 5

ELECTRICAL CHARACTERISTICS

(1)

UCC28230

UCC28231

www.ti.com

................................................................................................................................................... SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008

V

DD

= 12V, 1- µ F capacitor from V

DD

and VREF to GND, TA= TJ= – 55 ° C to 125 ° C, RT = 49.9 k Ω connected to 4.4V supply to

set Fsw = 100 kHz (unless otherwise noted).

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Supply Currents

ID

DD(off)

Startup current VDD= 5.2 V 150 200 µ A

I

DD

Operating supply current 1.5 2.5 mA

Under Voltage Lockout

Start threshold 5.9 6.3 6.9

Minimum operating voltage after start 5.3 5.7 6.2 V

Hysteresis 0.55 0.6 0.75

Soft Start (SS PIN, Figure 41 , Figure 44 )

I

SS

Charge current VSS= 0 V – 30 – 25 – 20 µ A

V

SS_STD

Shutdown/restart/reset threshold 0.3 0.55 0.68

V

SS_FP

Soft-start first pulse threshold 0.68 0.85 1.1

V

V

SS_PU

Pull up threshold 3.3 3.5 3.8

V

SS_CL

Clamp voltage 4.3 4.5 4.8

Off-Time Programming (Figure 33 )

T

OFF5

Off time between O1_D and O2_D UCC28230 32 40 50

T

OFF3

Off time between O1_D and O2_D UCC28231 30 40 53

OS = 8.45 k Ω , CS = 0.3 V, OST = 1 V

T

DT

Dead time between O1_D, O1_DIN and O2_D, O2_DIN 10 16

Δ T

OFF

Off time matching 2

ns

T

OFFR5

Off time between O1_D and O2_D UCC28230 32 40 50

T

OFFR3

Off time between O1_D and O2_D UCC28231 30 40 53

OS = 8.45 k Ω , CS = 0 V, OST = VREF

T

DTREF

Dead time between O1_D, O1_DIN and O2_D, O2_DIN 10 16

Δ T

OFFR

Off time matching 2

I

HYST

Hysteresis current source 10 µ A

OS = 8.45 k Ω , OST = 1 V, CS = CS

TH

– 0.03

T

OFFMAX

Maximum off time at low CS 165 235 ns

V

Switching Frequency at O1_D and O2_D Outputs

F

SWNOM

Nominal frequency VSS= 4 V 92 100 108

kHz

F

SWMAX

Maximum frequency VSS= 1.8 V 425 550 675

VREF Output Voltage

V

REF5

UCC28230 4.925 5 5.075

0 ≤ IR ≤ 10 mA; VDD= from 7 V to 17 V,

VREF total output range V

– 55 ° C ≤ TJ≤ 125 ° C

V

REF3

UCC28231 3.25 3.3 3.35

I

SCC

Short circuit current VREF = 0 V – 35 – 25 – 12 mA

(1) Typical values for TA= 25 ° C

Copyright © 2008, Texas Instruments Incorporated Submit Documentation Feedback 5

Product Folder Link(s): UCC28230 UCC28231

Page 6

UCC28230

UCC28231

SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008 ...................................................................................................................................................

www.ti.com

ELECTRICAL CHARACTERISTICS (continued)

V

DD

= 12V, 1- µ F capacitor from V

DD

and VREF to GND, TA= TJ= – 55 ° C to 125 ° C, RT = 49.9 k Ω connected to 4.4V supply to

set Fsw = 100 kHz (unless otherwise noted).

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Current Sense, Cycle-by-Cycle Current Limit With Hiccup, Short Circuit Protection With Latch Off

V

CS_LIM

CS pin cycle-by-cycle threshold 0.48 0.5 0.515 V

Input pulse at CS from 0.3 V to 0.6 V with

T

CS

CS to O1_D and O2_D propagation delay 100

0.03 V/ns slew rate

ns

Input pulse at CS from 0.3 V to 0.6 V with

T

BL

Leading edge blanking time by internal filter 50

0.03 V/ns slew rate

Discharge current to set cycle-by-cycle current limit duration

I

DS

CS = 0.6 V, VSS= 4 V 15 20 25 µ A

(Figure 41 )

Hiccup OFF time threshold 3.1 3.4 3.7 V

Discharge current to set Hiccup Mode OFF Time

I

HCC

1.9 2.5 3.1 µ A

(Figure 41 , Figure 44 )

V

CS_SC

CS pin short circuit protection threshold (Figure 44 ) 0.65 0.7 0.75 V

Outputs O1_D, O2_D, O1_DIN, O2_DIN

Sink/Source peak current

(2)

0.2 A

Rise time C

LOAD

= 100 pF 12 25

ns

Fall time C

LOAD

= 100 pF 10 25

RSRC Output source resistance I

OUT

= 20 mA 10 20 35

Ω

RSINK Output sink resistance I

OUT

= 20 mA 5 15 30

Pins 7 and 9 pulses matching at FSW= 100

Duty cycle matching 35 ns

kHz

Thermal Shutdown

Rising threshold

(3)

150 160 170

Falling threshold

(3)

130 140 150 ° C

Hysteresis 20

(2) Output sink/source peak current value, defined by equation IP= 100 pF × dV/dt where dV/dt is taken from the output rise and fall

switching waveforms. It is not tested in production. Characterization is available upon request.

(3) Thermal shutdown is not tested in production. Characterization is available upon request

6 Submit Documentation Feedback Copyright © 2008, Texas Instruments Incorporated

Product Folder Link(s): UCC28230 UCC28231

Page 7

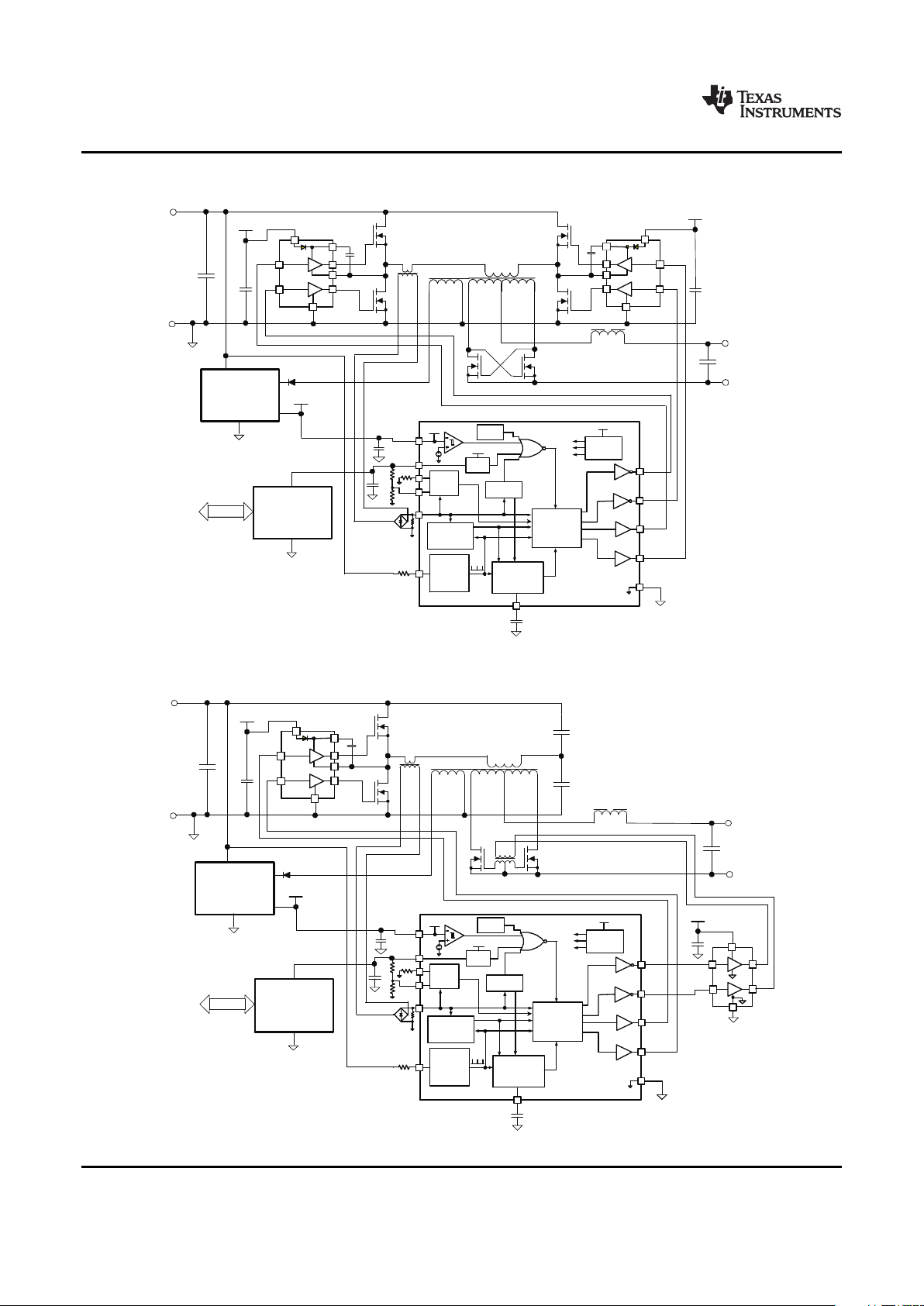

FUNCTIONAL BLOCK DIAGRAMS

GND

O1_D

VREF

V

DD

5V/3.3V

LDO

EN

UVLO

Comp.

6.3V rise

5.7V fall

V

DD

V

DD

RT

CS

SS

Vin

CT

OS

Thermal

Shutdown

Is

R1

R2

O2_DIN

O2_D

O1_DIN

8

10

11

9

7

5

1

2

6

4

12

Soft Start &

Hiccup Current

Limit Circuit

Logic

Block

V

DD

Reference

Generator

Short Circuit

Shutdown

Oscillator &

Start Up

Frequency

Control

Off Time

Control

Circuit

Cycle-by-

Cycle Current

Limit

CLK

3

OST

R3

GND

O1_D

VREF

V

DD

5V/3.3V

LDO

EN

UVLO

Comp.

6.3V rise

5.7V fall

V

DD

V

DD

RT

CS

SS

Vin

CT

OS

Thermal

Shutdown

Is

R1

R2

O2_DIN

O2_D

O1_DIN

10

12

13

11

9

6

1

2

7

5

14

Soft Start &

Hiccup Current

Limit Circuit

Logic

Block

V

DD

Reference

Generator

Short Circuit

Shutdown

Oscillator &

Start Up

Frequency

Control

Off Time

Control

Circuit

Cycle-by-

Cycle Current

Limit

CLK

3

OST

R3

AGND

8

NC

4

UCC28230

UCC28231

www.ti.com

................................................................................................................................................... SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008

Figure 3. SON-12 Package

Figure 4. TSSOP-14 Package

Copyright © 2008, Texas Instruments Incorporated Submit Documentation Feedback 7

Product Folder Link(s): UCC28230 UCC28231

Page 8

UCC28230

UCC28231

SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008 ...................................................................................................................................................

www.ti.com

TERMINAL FUNCTIONS

TERMINAL

I/O FUNCTION

DFN-12 TSSOP-14

NAME

PIN# PIN#

± 1.5% accurate 5 V for UCC28230 and 3.3 V for UCC28231, 10-mA output reference voltage with

short circuit protection that can be used for fixed switching frequency setting and/or for

1 1 VREF O

housekeeping microcontroller. Place decoupling capacitor in 1 µ F to 2.2 µ F range from this pin to

GND.

Off time control threshold pin uses a resistor divider to set current level as percentage of current

2 2 OST I

limit threshold.

Nominal off time T

OFF

and dead time TDTset pin. An external resistor connected between this pin

3 3 OS I

and GND sets the dead time and nominal off time.

4 NC Not connected pin, TSSOP-14 only.

Oscillator timing input pin. The external resistor which is connected between this pin and VINsets

4 5 RT I the oscillator frequency which varies with VIN. Tying the external resistor to VREF sets fixed

frequency operation independent of VIN.

Input to adjustable soft-start,and hiccup mode circuit. Place soft-start capacitor from this pin to

5 6 SS I/O GND. The internal charge/discharge current ISSand an external capacitor value set the soft-start

timing, duration of cycle-by-cycle current limit and controller turn-off time for hiccup mode operation.

6 7 CS I Current sensing pin used for cycle-by-cycle current limit, short circuit protection and off time control.

8 AGND Analog ground, TSSOP-14 only.

7 9 GND Ground pin connected to thermal pad. All signals are referenced to this node.

8 10 O2_DIN O 0.2-A sink/source switching output pin to an external driver providing 1-D pulse.

9 11 O2_D O 0.2-A sink/source switching output pin to an external driver providing D pulse.

10 12 O1_DIN O 0.2-A sink/source switching output pin to an external driver providing 1-D pulse.

11 13 O1_D O 0.2-A sink/source switching output pin to an external driver providing D pulse.

Connect this pin to a 7-V to 17-V bias supply. Place a high quality at least 1- µ F ceramic bypass

12 14 VDD I

capacitor from this pin to GND.

8 Submit Documentation Feedback Copyright © 2008, Texas Instruments Incorporated

Product Folder Link(s): UCC28230 UCC28231

Page 9

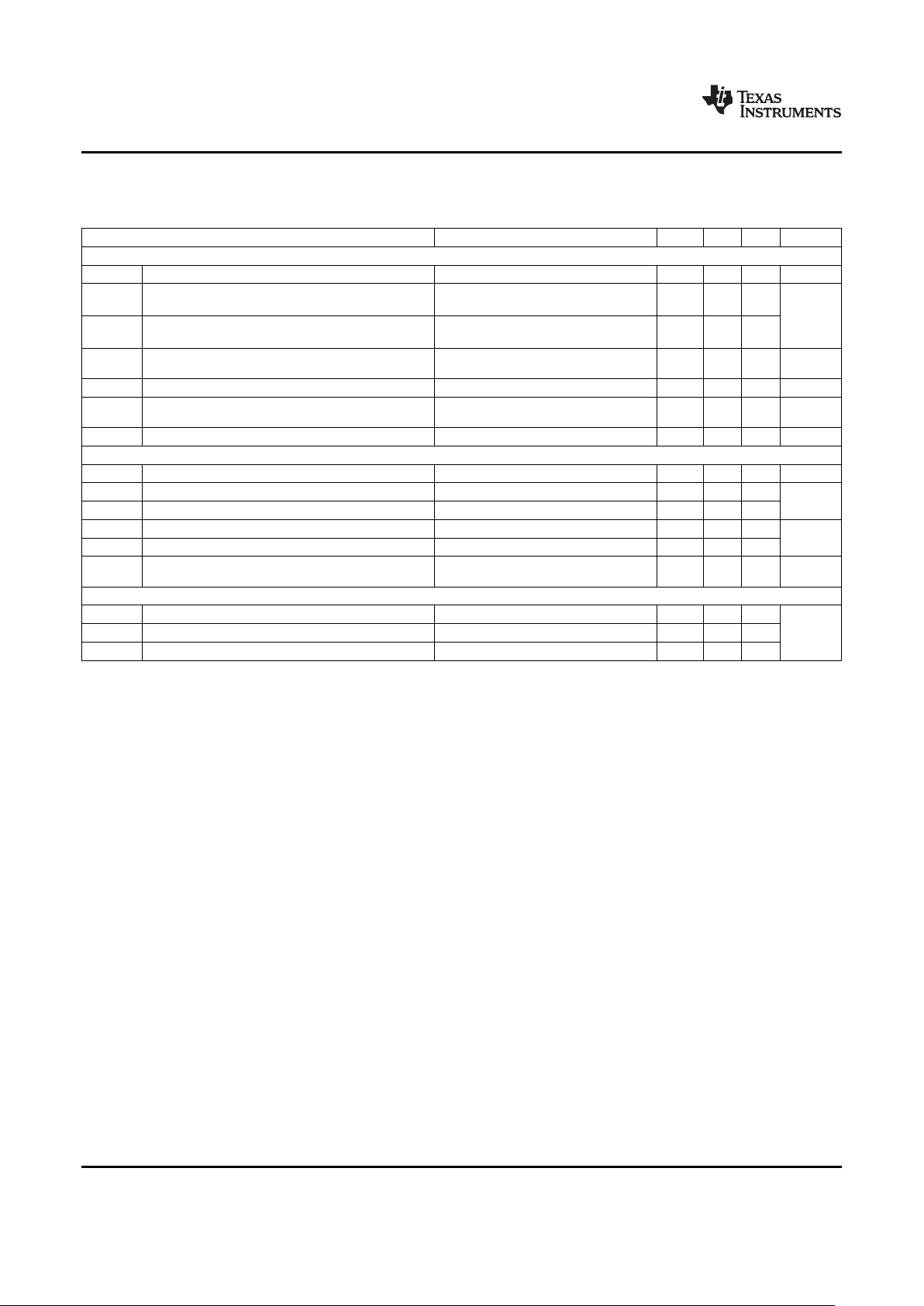

TYPICAL CHARACTERISTICS

Operating Supply Current I

DD

over Temperature at FSW=100kHz

1.40

1.45

1.50

1.55

1.60

-55 -35 -15 5 25 45 65 85 105 125

TJ-tempe rature, °C

I

DD,

mA

Start-up Current I

DDoff

over Temperature at VDD=5.2V

135

140

145

150

155

160

165

-55 -35 -15 5 25 45 65 85 105 125

TJ-tempera ture, °C

I

DDo ff,,

µA

Under Voltage Lockout Thresholds

over Temperature

5.3

5.5

5.7

5.9

6.1

6.3

6.5

6.7

-55 -35 -15 5 25 45 65 85 105 125

TJ-temperature, °C

UVLO Thresholds, V

Rising threshold

Falling threshold

Under Voltage Lockout Hysteresis

over Temperature

0.62

0.64

0.66

0.68

0.70

-55 -35 -15 5 25 45 65 85 105 125

TJ-temperature, °C

UVLO Hysteresis, V

Soft Start Shutdown V

SS_STD

and First Pulse V

SS_FP

Thresholds over Temperature

0.30

0.40

0.50

0.60

0.70

0.80

0.90

1.00

-55 -35 -15 5 25 45 65 85 105 125

TJ-te mperature, ° C

V

SS_STD

, V

SS_FP

, V

Soft Start Shutdown

First Puls e Threshold

Soft Start Pull-up V

SS_PU

and Clamp Voltage V

SS_CL

Thresholds over Temperature

3.00

3.50

4.00

4.50

5.00

-55 -35 -15 5 25 45 65 85 105 125

TJ-te mperature, ° C

V

SS_PU

, V

SS_CL

, V

Pull-up Threshold

Clamp Voltage

UCC28230

UCC28231

www.ti.com

................................................................................................................................................... SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008

Figure 5. Figure 6.

Figure 7. Figure 8.

Figure 9. Figure 10.

Copyright © 2008, Texas Instruments Incorporated Submit Documentation Feedback 9

Product Folder Link(s): UCC28230 UCC28231

Page 10

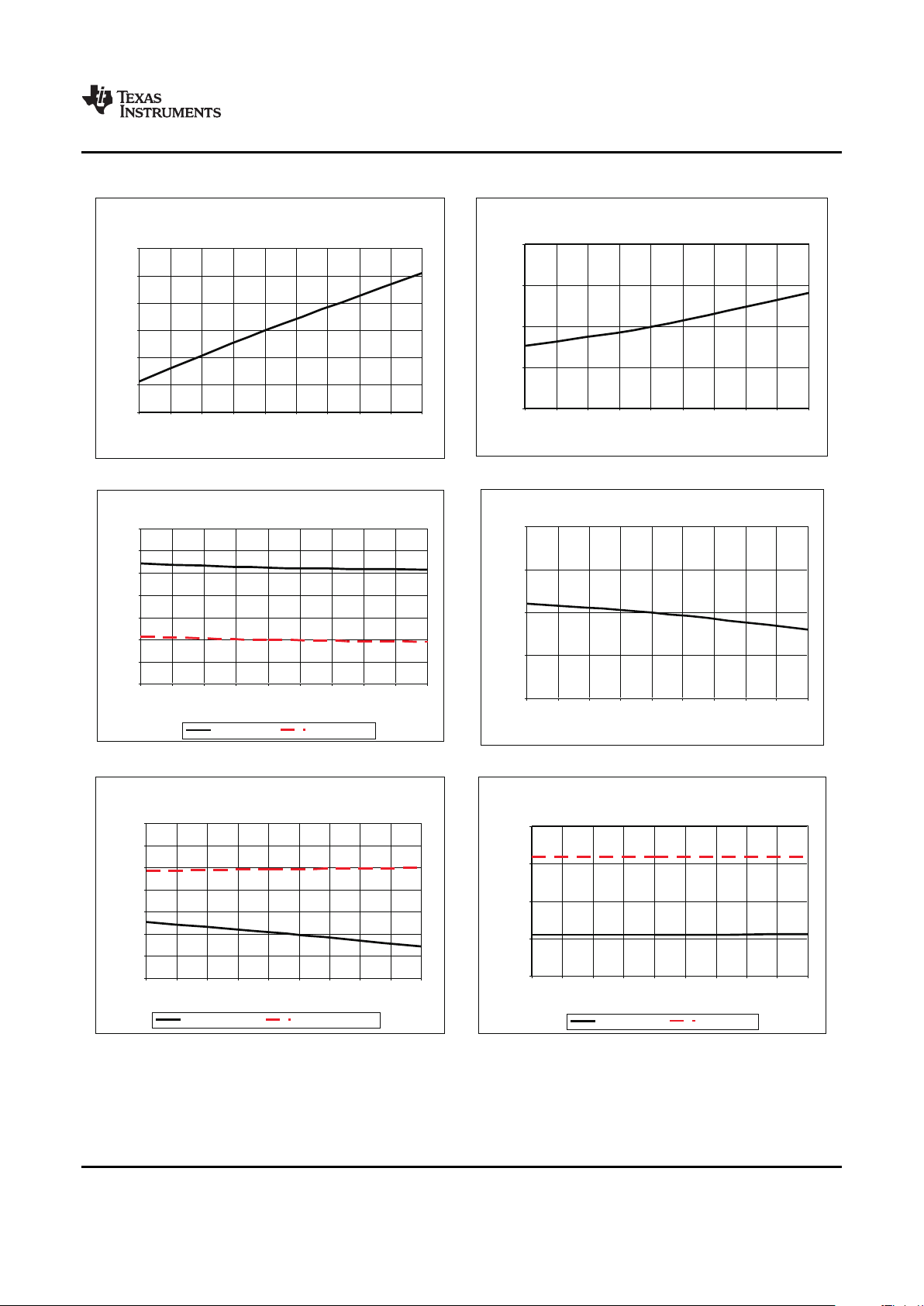

Soft-Start Charge Current I

SS

over Temperature

24.80

24.85

24.90

24.95

25.00

25.05

25.10

25.15

25.20

-55 -35 -15 5 25 45 65 85 105 125

TJ-temperature, °C

Iss, µA

OffTimeMatching ∆T

OFF

overTemperature

1.00

1.50

2.00

2.50

3.00

3.50

4.00

-55 -35 -15 5 25 45 65 85 105 125

TJ-temperature,°C

∆T

OFF

,ns

UCC28230 Off Time T

OFF

and Dead Time T

DT

over Temperature

10

20

30

40

50

-55 -35 -15 5 25 45 65 85 105 125

TJ- te mperature, °C

T

OFF

, T

DT

, ns

Off Time

Dead Time

UCC28231 Off Time T

OFF

and Dead Time T

DT

over T emperature

10

20

30

40

50

-55 -35 -15 5 25 45 65 85 105 125

TJ- tempe rature, °C

T

OFF

, T

DT

, ns

Off Time

Dead Time

Maximum Off Time T

OFFMAX

at Low V

CS

over Temperature

170.00

180.00

190.00

200.00

210.00

220.00

-55 -35 -15 5 25 45 65 85 105 125

TJ- te mperatu re, °C

T

OFFM AX

, ns

Nominal Switching Frequency F

SWNOM

over Temperature

99.00

99.50

100.00

100.50

101.00

-55 -35 - 15 5 25 45 65 85 105 125

TJ- te mperature, ° C

F

SWNOM

, kHz

UCC28230

UCC28231

SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008 ...................................................................................................................................................

www.ti.com

TYPICAL CHARACTERISTICS (continued)

Figure 11. Figure 12.

Figure 13. Figure 14.

Figure 15. Figure 16.

10 Submit Documentation Feedback Copyright © 2008, Texas Instruments Incorporated

Product Folder Link(s): UCC28230 UCC28231

Page 11

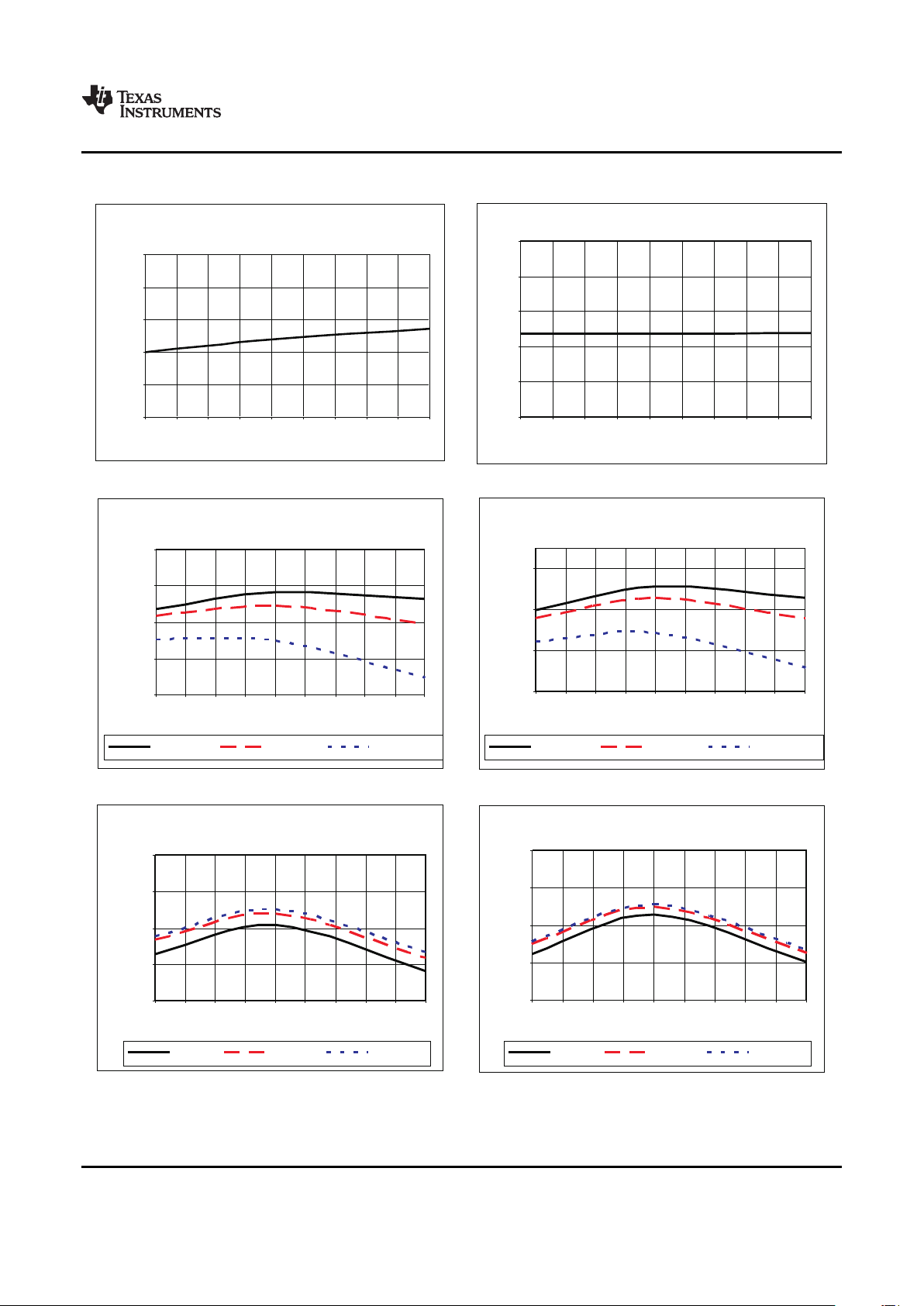

Maximum Switching Frequency F

SWMAX

over Temperature

500.00

510.00

520.00

530.00

540.00

550.00

-55 -35 - 15 5 25 45 65 85 105 125

TJ- temperature , °C

FSWMAX , kHz

Cycle-by-Cycle Current Limit Threshold

over Temperature

0.45

0.47

0.49

0.51

0.53

0.55

-55 -35 -15 5 25 45 65 85 105 125

TJ-tempera ture, °C

V

CS_LIM

, V

UCC28230 Refer ence Voltage at VDD=12V

over Te mperature and Load Curr ent

4.9 75

4.9 85

4.9 95

5.0 05

5.0 15

-55 -3 5 - 15 5 2 5 45 65 8 5 105 125

TJ- te mper ature, °C

V

REF

, V

Iload=10uA

Iload=1mA Iload=10mA

UCC28231 Refer ence Voltage at VDD=12V

over Te mperature and Load Curr ent

3.2 75

3.2 85

3.2 95

3.3 05

-55 -35 - 15 5 2 5 45 65 85 105 1 25

T

J

- te mper ature, °C

V

REF

, V

Iload=10uA

Iload=1mA Iload=10mA

UCC28230 Refer ence Voltage at I

LOAD

=1mA

over Te mper ature and Supply Voltage V

DD

4.990

4.994

4.998

5.002

5.006

-55 - 35 -15 5 25 45 65 85 105 125

TJ- te mper ature, °C

V

REF

, V

Vdd=7V

Vdd=12V Vdd=17V

UCC28231 Refer ence Voltage at I

LOAD

=1mA

over Te mperature and Supply Voltage V

DD

3.2 90

3.2 94

3.2 98

3.3 02

3.3 06

-55 -35 -1 5 5 25 45 65 8 5 105 1 25

TJ- te mper ature, °C

V

REF

, V

Vdd=7V

Vdd=12V Vdd=17V

UCC28230

UCC28231

www.ti.com

................................................................................................................................................... SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008

TYPICAL CHARACTERISTICS (continued)

Figure 17. Figure 18.

Figure 19. Figure 20.

Figure 21. Figure 22.

Copyright © 2008, Texas Instruments Incorporated Submit Documentation Feedback 11

Product Folder Link(s): UCC28230 UCC28231

Page 12

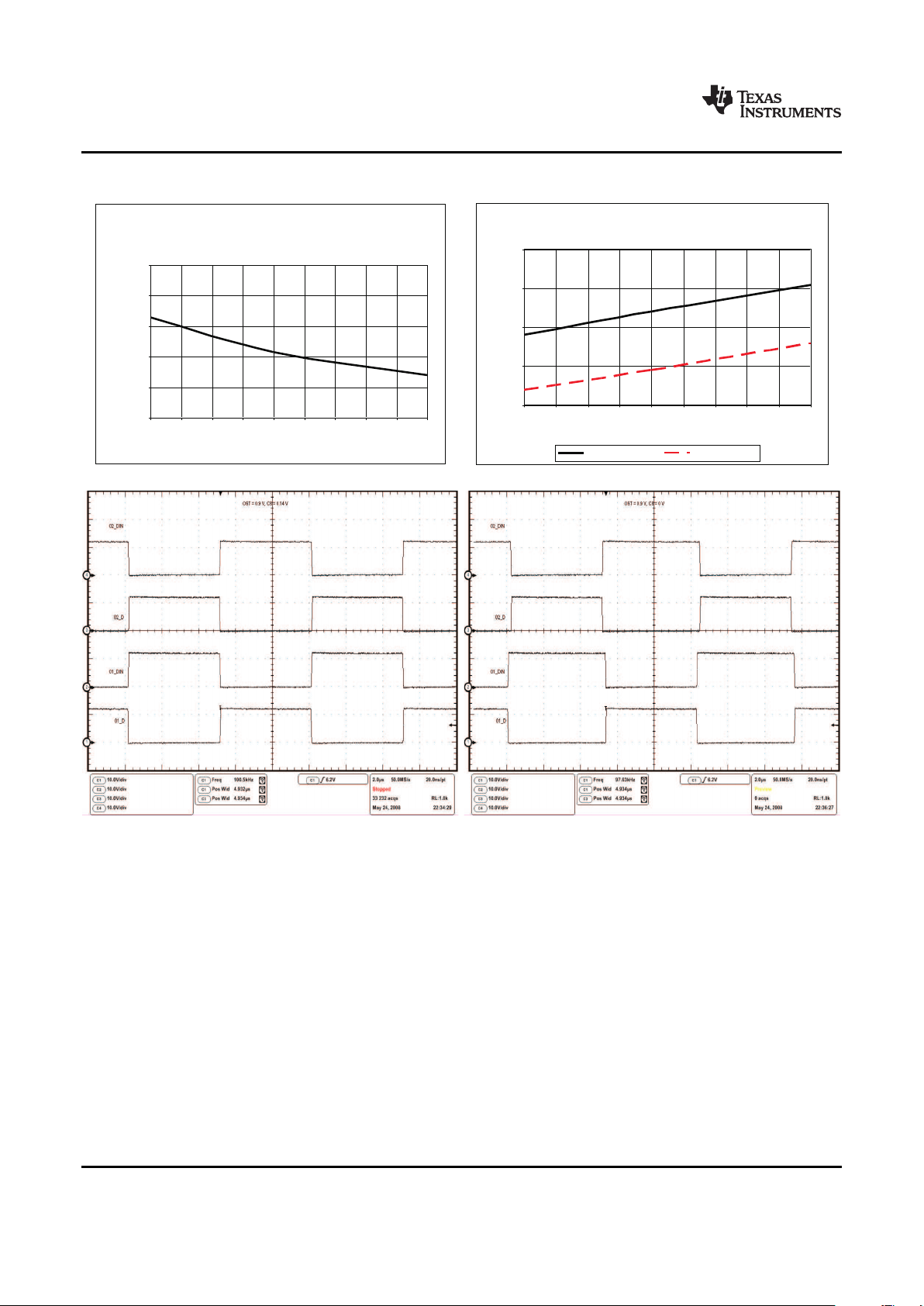

Current Sense Propogation Delay T

CS

over Temperature

90.00

95.00

100.00

105.00

110.00

115.00

-55 -35 - 15 5 25 45 65 85 105 125

TJ- te mperatu re, °C

T

CS

, ns

Output Source Resistance R

SRC

and Sink Resistance

R

SINK

over Temperature

10.0

15.0

20.0

25.0

30.0

-55 -35 -15 5 25 45 65 85 105 125

TJ- te mperatur e, °C

R

SCR

, R

SINK

, O

Source Resistance

Sink Resist ance

UCC28230

UCC28231

SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008 ...................................................................................................................................................

www.ti.com

TYPICAL CHARACTERISTICS (continued)

Figure 23. Figure 24.

Figure 25. O1_D and O2_D Duty Cycle Matching at V

CS

= Figure 26. O1_D and O2_D Duty cycle Matching at V

CS

=

0.14 V and V

OST

= 1 V 0.0 V and V

OST

= 1 V

12 Submit Documentation Feedback Copyright © 2008, Texas Instruments Incorporated

Product Folder Link(s): UCC28230 UCC28231

Page 13

UCC28230

UCC28231

www.ti.com

................................................................................................................................................... SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008

TYPICAL CHARACTERISTICS (continued)

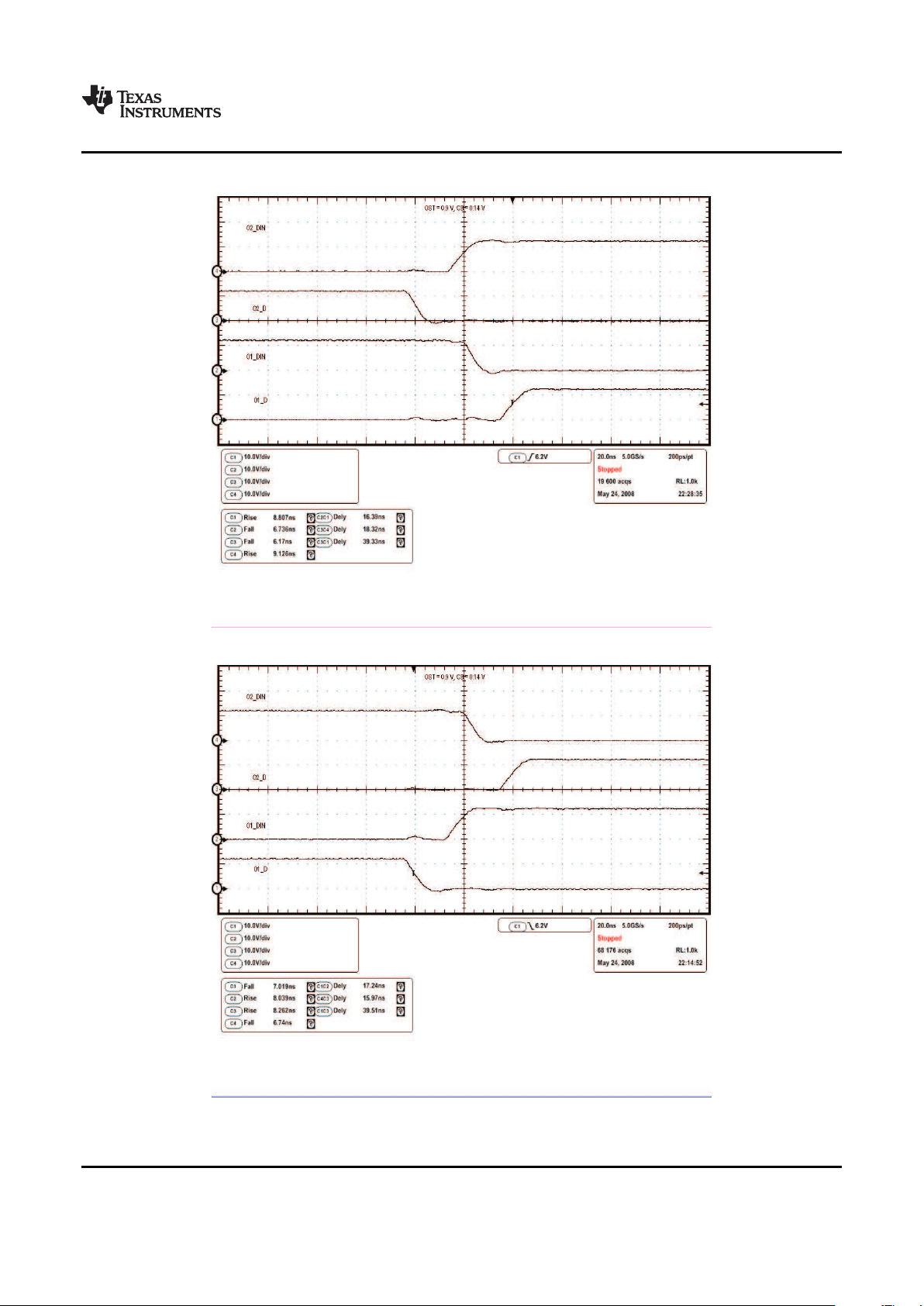

Figure 27. Output Waveforms During First Half Switching Cycle at V

CS

= 0.14 V and V

OST

= 1 V

Figure 28. Output Waveforms During Second Half Switching Cycle at V

CS

= 0.14 V and V

OST

= 1 V

Copyright © 2008, Texas Instruments Incorporated Submit Documentation Feedback 13

Product Folder Link(s): UCC28230 UCC28231

Page 14

UCC28230

UCC28231

SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008 ...................................................................................................................................................

www.ti.com

TYPICAL CHARACTERISTICS (continued)

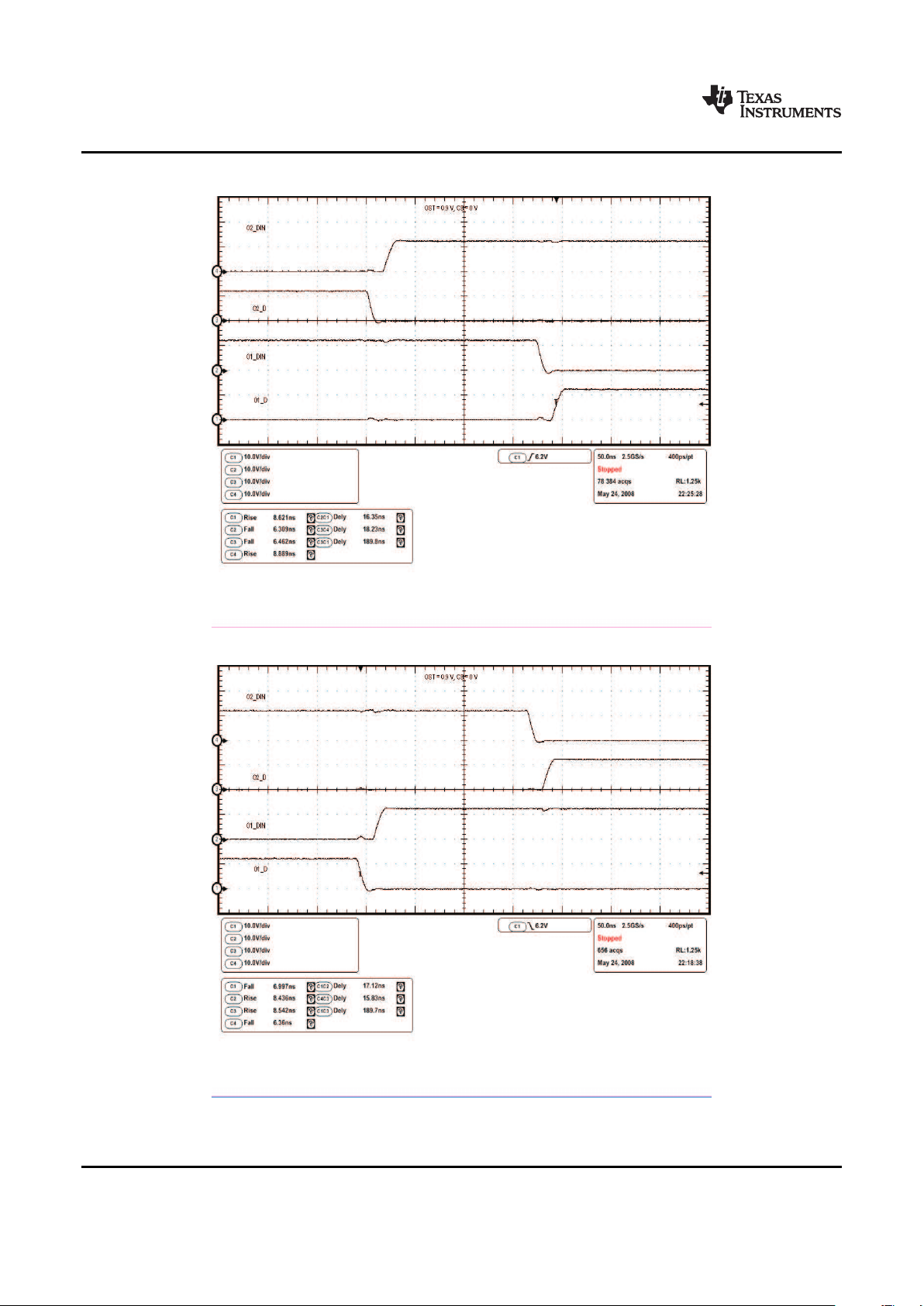

Figure 29. Output Waveforms During First Half Switching Cycle at V

CS

= 0 V and V

OST

= 1 V

Figure 30. Output Waveforms During Second Half Switching Cycle at V

CS

= 0 V and V

OST

= 1 V

14 Submit Documentation Feedback Copyright © 2008, Texas Instruments Incorporated

Product Folder Link(s): UCC28230 UCC28231

Page 15

DETAILED DESCRIPTION

Start-Up Protection Logic

Internal Oscillator and Converter Switching Frequency

1

1 2

2500 2 4

=

+ ´

´ -

SW (nom)

OFF

IN

F

RT

. T

(V . )

(1)

UCC28230

UCC28231

www.ti.com

................................................................................................................................................... SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008

Before the controller allows the start up, the following conditions must be met:

• VDD voltage exceeds rising UVLO threshold 6.3 V typical

• The reference voltage 5 V for UCC28230 or 3.3 V for UCC28231 is available

• Junction temperature is below the thermal shutdown threshold 130 ° C min

• The voltage at soft-start capacitor is not below 0.55 V typical

If all those conditions are met, an internal enable signal EN is generated that initiates the soft start process. The

duty cycle during the soft start is defined by the voltage at the SS pin or by cycle-by-cycle current limit circuit

depending on load conditions.

The oscillator frequency is set by an external resistor at RT pin (see Figure 3 and Figure 4 ). The oscillator

frequency F

OSC

is twice that of converter switching frequency F

SW

. The oscillator performs the following main

functions:

• Generates clock signal CLK to synchronize internal functional blocks

• By changing the switching frequency during the start up and cycle-by-cycle current limit, the oscillator limits

the current ripple at the output inductor allowing the use of small output inductor and start with large output

capacitor

Oscillator can operate in the following modes:

• Fixed volt-second mode of operation when the resistor RT is connected between V

IN

and RT pin. In this mode

the switching frequency increases in accordance to an input voltage rise

• Fixed switching frequency mode when the resistor RT is connected between VREF and RT pins.

The switching frequency of converter is defined as F

SW(nom)

= 1/T

SW(nom)

(see Figure 33 ). Equation 1 is used to

calculate the nominal switching frequency of the converter and its transformer.

Where RT is in k Ω , V

IN

is in volts, T

OFF

is in ms and F

SW(nom)

is in kHz.

Copyright © 2008, Texas Instruments Incorporated Submit Documentation Feedback 15

Product Folder Link(s): UCC28230 UCC28231

Page 16

2 4

2500

-

= ´

IN

SW (nom)

(V . )

F

RT

(2)

0

100

200

300

400

500

600

700

800

900

1,000

100 300 500 700 900 1100

RT Res istance ( kO)

Switching F requency (k Hz)

Vin=36V

Vin=48V

Vin=60V

0

100

200

300

400

500

600

700

800

36 40 44 48 52 56 60

Vin V oltage (V)

Switching F requency (kHz )

RT=200kohm

RT=400kohm RT=1,100kohm

2 4

2500

SW (nom)

(VREF . )

F

RT

-

= ´

(3)

UCC28230

UCC28231

SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008 ...................................................................................................................................................

www.ti.com

In most applications, T

OFF

is set at about 40~50 ns, which can be neglected compared to the total oscillator

period. Therefore Equation 1 can be simplified as:

In this equation RT is in k Ω , V

IN

is in volts and F

SW(nom)

is in kHz.

Figure 31 shows how the nominal switching frequency of converter depends on value of resistor RT, and

Figure 32 shows how the switching frequency changes over the input voltage range in case of fixed volt-second

mode of operation. The T

OFF

is set to 40 ns for both figures.

Figure 31. Nominal Switching Frequency of Converter vs Figure 32. Switching Frequency Variation Over the Input

Resistor RT Voltage for Fixed Volt-Second Mode of Operation

Fixed frequency mode of operation can be achieved by connecting the resistor RT between VREF and RT pins.

In such case the switching frequency is defined by the following Equation 3 , where the impact of T

OFF

is

neglected as well.

In this equation the RT is in k Ω , VREF is in volts and F

SW(nom)

is in kHz.

16 Submit Documentation Feedback Copyright © 2008, Texas Instruments Incorporated

Product Folder Link(s): UCC28230 UCC28231

Page 17

Output Signals

O1_D

O2_D

O2_DIN

O1_DIN

T

DT

T

DT

T

DT

T

DT

T

OFF

T

OFF

T

OFF

T

OFF

T

CLAMP

T

CLAMP

T

CLAMP

T

CLAMP

T

SWNOM

T

OUT_D

UCC28230

UCC28231

www.ti.com

................................................................................................................................................... SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008

The UCC28230/1 has two push-pull outputs O1_D and O2_D that provide D pulse signals to external drivers.

The additional two outputs O1_DIN and O2_DIN provide 1-D output pulses with dead time between D and 1-D

pulses to avoid shoot-through currents. Such combination of outputs allows use of UCC28230/1 either with

self-driven synchronous rectifier, or with the control-driven synchronous rectifier in push-pull, half-bridge or

full-bridge configuration.

For the full-bridge self-driven rectifier configuration, outputs O1_D and O2_D control high-side MOSFETs while

outputs O1_DIN and O2_DIN control low-side MOSFETs thus shorting the primary winding during (1-D)

switching cycle. This avoids number of issues related to self-driven rectification such as start up disabling,

reverse current during parallel operation, tendency to oscillate during low duty cycles. The applications circuit for

this configuration is shown on Figure 1 and the output signal timing diagrams are shown in Figure 33 .

Figure 33. D and (1-D) Output Pulses Providing Dead Time T

DT

in Each Leg and the Off Time T

OFF

Between Upper FETs That Includes Some Overlapping Time T

CLAMP

.

In the steady state condition an unregulated bus converter operates at maximum duty cycle thus having

minimum overlapping T

CLAMP

of (1-D) outputs. During start up or cycle-by-cycle current limit, the duty cycle can

be very low, so (1-D) output pulses occupy most of the switching cycle time. This provides zero voltage clamping

of the transformer ’ s primary winding. The UCC28230/1 also includes an off-time control feature. This feature

allows user to increase off time T

OFF

when the converter output current is below a programmable current

threshold. This feature reduces switching losses of the synchronous rectifier at light load and it is described in

detail in Offtime Control Circuit section.

For the control driven half-bridge topology, the outputs O1_D and O2_D provide control pulses for the high-side

and low-side MOSFETs, while the outputs O1_DIN and O2_DIN can be used to drive the pulse transformers

providing control signals to the secondary-side MOSFET rectifiers as shown in Figure 2 .

In case of full-bridge topology with the control-driven rectifier, the outputs O1_DIN and O2_DIN are used to

control primary low-side MOSFETs as well as the secondary-side rectifier MOSFETs.

Copyright © 2008, Texas Instruments Incorporated Submit Documentation Feedback 17

Product Folder Link(s): UCC28230 UCC28231

Page 18

Start-Up Frequency Control Circuit

=

+

OUT

OUT OFF

T _ D

D

T _ D T

(4)

Fsw vs DutyCycle, RT=1M tied to Vin,

Vost=1V, R3(OS)=15k, Toff=53ns, Vcs=0.4V

0

100

200

300

400

500

600

700

800

900

0 10 20 30 40 50 60 70 80 90 100

Duty Cycle, %

Fsw, kHz

Vin=48V

Vin=36V Vin=72V Vin=48V, RT=287K

FswvsDutyCycle,RT=1MtiedtoVin,

Vost=1V,R3(OS)=15k,Toff=196ns,Vcs=0V

0

100

200

300

400

500

600

700

800

900

0 10 20 30 40 50 60 70 80 90 100

DutyCycle,%

Fsw

,

Vin=48V Vin=36V Vin=72V Vin=48V,RT=287K

UCC28230

UCC28231

SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008 ...................................................................................................................................................

www.ti.com

The start-up frequency control circuit addresses the need for bus converter to start at heavy load with a large

output capacitance. In the steady state condition bus converters operate with the minimum off time and as the

result, the output inductor current ripple is low. Therefore the output inductor value is able to be selected very low

to save the size and cost. During over current or soft start condition the duty cycle is controlled by the

cycle-by-cycle current limit circuit or by the voltage at soft-start capacitor. In this condition, the duty cycle D for

the output inductor can be anywhere between 0 and 1 causing significant output inductor current ripple that

reaches its maximum at duty cycle D = 0.5. The current limit circuit on primary side limits the peak current, not

the average current. The limiting of peak current with a large ripple causes the fold back characteristic of

converter output, which prevents the converter from ever reaching its nominal steady state output voltage.

The output inductor duty cycle is a ratio of output pulses T

OUT

_D at pins O1_D and O2_D to the half of switching

cycle T

SW(nom)

, i.e. T

OUT

_D +T

OFF

(see Figure 33 ):

The start-up frequency control circuit changes the switching frequency during the start up or during the

cycle-by-cycle current limit to maintain the output inductor current ripple almost constant at any duty cycle D. This

allows an additional cost and size saving because the output inductor can be selected based on steady state

condition rather than the transient condition, which dictates significantly larger inductance value and size.

Examples of switching frequency changes over duty cycle variation for the selected nominal frequencies 100 kHz

and 450 kHz are shown in Figure 34 . The plots are given for the nominal off time at 53 ns and 77 ns (right

column) and for no load off time at 196 ns, 209 ns accordingly. It is shown that the impact of nominal off time on

switching frequency is minimal. However the no load off time causes visible frequency reduction especially at

maximum frequency when the duty cycle D is around 0.5.

Switching Frequency Plots vs Duty Cycle for F

SW(nom)

Set at 100 kHz and 450 kHz at Different No Load and

Nominal T

OFF

Time Sets.

Figure 34. Figure 35.

18 Submit Documentation Feedback Copyright © 2008, Texas Instruments Incorporated

Product Folder Link(s): UCC28230 UCC28231

Page 19

Fsw vs DutyCycle at Lout, RT=1M tie d to Vin,

Vost=1V, R3(OS)=30k, Toff=209ns, Vcs=0V

0

100

200

300

400

500

600

700

800

900

0 10 20 30 40 50 60 70 80 90 100

Duty Cycle, %

Fsw, kHz

Vin=48V

Vin=36V Vin=72V Vin= 48V, RT=287K

Fsw vs Duty Cycle, RT=1M tied to Vin,

Vost=1V, R3(OS)=30k, Toff=77ns, Vcs=0.4V

0

100

200

300

400

500

600

700

800

900

0 10 20 30 40 50 60 70 80 90 100

Duty Cycle, %

Fsw, kHz

Vin=48V

Vin=36V Vin=72V Vin=48V, RT=287K

375@ +

SW (m ax) SW (nom)

F F kHz

(5)

0 1 0 9

0 4 0 6

1 0 1 0 4 0 6 0 9

ì

< >

ï

» £ £

í

ï

´ ´ - £ < < £

î

SW (nom)

SW SW (max)

SW (max)

F D . or D .

F F . D .

F D ( D ) . D . or . D .

(6)

1

4 1

´ ´ -

=

´ ´ ´ - ´

IN

O

TR SW (max) O

V D ( D)

L

N F ( KL ) I

(7)

2

L (ma x) L ( ch )

I I£ ´

(8)

UCC28230

UCC28231

www.ti.com

................................................................................................................................................... SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008

Figure 36. Figure 37.

To avoid jittering during the fast duty cycle change and reduce sensitivity to noise, the transfer function of

switching frequency of the converter to the duty cycle has 20-kHz bandwidth well below the switching frequency.

The maximum switching frequency F

SW(max)

of converter is given by:

Where T

OFF

affect is neglected as well and the frequency is in kHz. T

OFF

has more affect on switching frequency

F

SW

at very high frequency. One can see how T

OFF

affects FSW(max) in Figure 34 .

The relation between switching frequency F

SW

and duty cycle D in Figure 34 can be best described by:

Knowing the maximum switching frequency F

SW(max)

at D = 0.5 and the ratio of peak output inductor current to

the nominal load current KL = I

L(max)

/IO, allows calculate the output inductor value by using the following

Equation 7 .

In this equation N

TR

is transformer turns ratio from primary winding to the secondary. The selection of KL

depends on the average output inductor current I

L(ch)

that needs to be provided during the start up to charge the

output capacitor and supply the load. To ensure that the converter starts the following condition needs to be met.

How I

L(ch)

needs to be defined is described in the following section.

Copyright © 2008, Texas Instruments Incorporated Submit Documentation Feedback 19

Product Folder Link(s): UCC28230 UCC28231

Page 20

Soft Start

25

2 85 0 85

m´

=

-

SS

SS

T A

C

( . V . V )

(9)

0 85

25 m

´

=

SS

DEL

C . V

T

A

(10)

UCC28230

UCC28231

SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008 ...................................................................................................................................................

www.ti.com

The soft-start pin SS is multi-function pin used for the following operations:

• Soft start with the duty cycle graduate increase from zero to its maximum value of almost 100%

• Setting cycle-by-cycle over current hiccup mode conditions

• On/off control for the converter

• Indicator of severe short circuit condition

The soft-start duration is defined by an external capacitor connected between SS pin and ground and the internal

charge current that has typical value of 25 µ A. During soft start, the duty cycle of controller is determined by the

voltage at SS pin. Below the 0.85-V threshold, there are no switching pulses at the outputs. Pulling the soft-start

pin externally below or above 0.55-V typical threshold can be used for the on/off control. When the soft-start

voltage is rising from 0.85 V up to 2.85 V and there is no current limit condition, the duty cycle applied to the

output inductor is increasing accordingly from 0 to 1. The external capacitor C

SS

value can be defined by the

Equation 9 :

For example, if the soft-start time T

SS

is selected 10 ms, then the soft-start capacitor C

SS

is equal to 125 nF and

the closest available standard value100 nF can be selected. Notice, that the output pulses do not appear until the

voltage at soft start capacitor reaches 0.85 V. An additional typical soft start delay caused by this can be

calculated by the Equation 10 :

For the C

SS

= 100 nF the calculated delay is 3.4 ms.

20 Submit Documentation Feedback Copyright © 2008, Texas Instruments Incorporated

Product Folder Link(s): UCC28230 UCC28231

Page 21

1

4 4

TR IN IN

OUT O(lim)

m SW TR O SW

N V D V D ( D)

I I

L F N L F

´ ´ ´ ´ -

= - -

´ ´ ´ ´ ´

(11)

- ´ ´

= - ´

IN OUT PR TR

O OUT SEC

TR

(V I R / N ) D

V I R

N

(12)

0.1 1 10

0.01

0.1

1

10

100

1.10

3

Cout=100uF

Cout=1000uF

Cout=10000uF

Soft start time, ms

Required primary current, A

UCC28230

UCC28231

www.ti.com

................................................................................................................................................... SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008

The Equation 9 and Equation 10 use typical values for calculations. If the output capacitor of the bus converter is

large and the soft-start time is selected relatively short, then the converter should deliver large charge current to

the output capacitor to provide the required soft start time. This current might hit the current limit threshold and

the soft-start time can be longer than expected. Figure 38 provides an estimation of the required average charge

current from the converter to charge the output capacitor within predetermined soft-start time. To avoid tripping of

the current limit comparator, the current limit threshold should be set above the required average charge current

with the additional current required by the load, half of the output inductor current ripple and the magnetizing

current of the transformer. The average output inductor charge current I

OUT

during the cycle-by-cycle current limit

can be described by the following equation:

Here I

O(lim)

is the output current limit and L

m

is magnetizing inductance. The I

O(lim)

is always less or equal to I

L(max)

to avoid saturation of the output inductor. The output voltage V

O

over output current I

OUT

is as follows

Where R

PR

is the equivalent resistance on primary side and R

SEC

is the equivalent resistance on secondary side.

Figure 38. Estimated Average Primary-Side Charge Current From the Converter Required to Charge the

Output Capacitor of Specified Value Within Required Soft-Start Time

Copyright © 2008, Texas Instruments Incorporated Submit Documentation Feedback 21

Product Folder Link(s): UCC28230 UCC28231

Page 22

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80

0

2

4

6

8

10

12

100kHz

200kHz

400kHz

Vout Steady State (top)

Cycle-by-cycle current limit

Iout, A

Vout, V

UCC28230

UCC28231

SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008 ...................................................................................................................................................

www.ti.com

Figure 39 shows the output voltage as function of the average load current limited by the cycle-by-cycle current

limit threshold after substituting (9) into (10). These plots are generated for the following conditions: V

IN

= 48 V,

N

TR

= 5, LO= 0.1 µ H, L

m

= 75 µ H, I

O(lim)

= 73 A, R

pr

= 25 m Ω and R

SEC

= 4 m Ω at F

SW

= 100 kHz, 200 kHz and

400 kHz. This fold back type of behavior limits the start-up capability of unregulated IBC. One can see that at

100-kHz switching frequency and 0.5 duty cycle (i.e., V

O

≈ 5 V), only about 11.5 A average current is available to

charge the output capacitor while at 400 kHz, the charge current can be as high as 60 A. The plots in Figure 39

show the required average charge current reflected to the primary side of the converter with N

TR

= 5:1 for

different output capacitor values depending on the selected soft-start time, which do not count extra current

drawn by the load itself. Therefore the significant output inductor current ripple not only can trip the peak current

mode control current limit circuit to reduce the average output inductor current available to charge the output

capacitor, but also can cause the hiccup or latch off of the converter to prevent it from starting at all. Increasing

the current limit threshold to allow the normal start up of the converter can cause potential overstress if for some

reason the load exceeds its nominal current during the steady state operation.

Without frequency control circuit, the module operates only at 100 kHz. At 100 kHz the secondary charge current

available is only 11.5 A, which is only 2.3 A if reflected to the primary side (N

TR

= 5). The 2.3-A current is able to

charge the 10000- µ F output capacitor within 10 ms provided that there is no additional load current applied.

Figure 39. Output Voltage at Cycle-by-Cycle Current Limit

22 Submit Documentation Feedback Copyright © 2008, Texas Instruments Incorporated

Product Folder Link(s): UCC28230 UCC28231

Page 23

Current Sensing

UCC28230

UCC28231

www.ti.com

................................................................................................................................................... SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008

With the frequency control circuit, the start up switching frequency is 400 kHz. At 400-kHz, 60-A charge current is

available, which is 12 A if reflected to the primary side. Assuming as in previous case 2.3 A portion of this current

is used to charge the 10000- µ F output capacitor within 10 ms, the remaining 9.7 A on primary side allows extra

48.5-A current to supply the load itself on the secondary side. Figure 40 shows a design example using the

startup frequency control of UCC28230 to start up with 30-A constant load current and 10900- µ F output

capacitor.

Using SS pin and soft-start capacitor to set cycle-by-cycle over-current hiccup mode is described further in

Cycle-by-Cycle Current Limit section and Short Circuit Protection section.

Figure 40. Start up at 30-A Constant Current Load With C

O

= 10900 µ F

The current sensing pin CS is used for the following functional blocks:

• Cycle-by-cycle current limit

• Adjustable off-time control

• Short circuit protection

Copyright © 2008, Texas Instruments Incorporated Submit Documentation Feedback 23

Product Folder Link(s): UCC28230 UCC28231

Page 24

Cycle-by-Cycle Current Limit and Short Circuit Protection

( )

( )

25 1 5 m= - ´ - +

DS

I D A

(13)

Soft-Start

Normal

Operation

Cycle-by-

CycleIlim.

Off Timebeforerestart Soft-

Restart

0

SSpin,

Volts

Ids=(-25x(1-D)+5)μA

Ihcc=-2.5μA

OutputPulses, D

25μA

FastPullUp

by

1kΩ Switch

SSClampVoltage 4.5

Outp. Enbl. Thresh. 0.85

SSShDn. Thresh. 0.55

PullUp Thresh. 3.5

Dmax Thresh. 2.85

(forreference)

Iss=25μA

t

( )

4 5 3 5

20 m

´ -

=

SS

CL( on)

C . V . V

T

A

(14)

( )

3 5 0 55

2 5 m

´ -

=

SS

CL( off )

C . V . V

T

. A

(15)

UCC28230

UCC28231

SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008 ...................................................................................................................................................

www.ti.com

The cycle-by-cycle current limit provides peak current limit on primary side when the load current exceeds its

predetermined threshold. For peak current mode control, certain leading edge blanking time is needed to prevent

the controller from false tripping due to switching noise. In order to save external RC filter for the blanking time,

an internal 50-ns filter at CS input is provided. With the 50-ns delay from the input of the current sense

comparator to the outputs, the total propagation delay T

CS

from CS pin to outputs is about 100 ns. An external

RC filter is still needed if the power stage requires more blanking time. The 0.5-V ± 3% cycle-by-cycle current limit

threshold is optimized for efficient current transformer based sensing. The duration when a converter operates at

cycle-by-cycle current limit depends on the value of soft-start capacitor and how severe is the over current

condition. The soft-start capacitor value also determines the so called hiccup mode off-time duration. These are

achieved by the internal discharge current IDS(Equation 13 ) and I

HCC

(see Figure 41 ) at SS pin.

When the output inductor duty cycle D at cycle-by-cycle current limit is above 80%, the converter operates as the

current source and does not enter into hiccup mode at all. This allows parallel operation of converters using

droop current sharing technique. At more severe over current condition, the duty cycle D becomes lower and Ids

becomes large enough to initiate hiccup mode with periodical restart. The behaviour of the converter at different

modes and related soft-start capacitor charge/discharge currents are shown in Figure 41 .

Figure 41. Timing Diagram of Soft-Start Voltage V

SS

at Different Modes of Operation Defined by Voltage

Thresholds and Related Soft-Start Capacitor Charge/Discharge Currents

The largest discharge current is at the duty cycle close to zero as 20 µ A. This current sets the shortest operation

time during the cycle-by-cycle current limit which is defined as:

Thus, if the soft-start capacitor CSS = 100 nF is selected, then the T

CL(on)

time will be 5 ms.

To calculate the hiccup off time T

CL(off)

before the restart, Equation 15 needs to be used:

24 Submit Documentation Feedback Copyright © 2008, Texas Instruments Incorporated

Product Folder Link(s): UCC28230 UCC28231

Page 25

UCC28230

UCC28231

www.ti.com

................................................................................................................................................... SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008

With the same soft-start capacitor value 100 nF, the off time before the restart is going to be 118 ms. Notice, that

if the over current condition happens before the soft-start capacitor voltage reaches the 3.5-V threshold during

start up, the controller limits the current but the soft-start capacitor continues to be charged. As soon as the 3.5-V

threshold is reached, the soft-start voltage is quickly pulled up to the 4.5-V threshold by an internal 1-k Ω R

DS(on)

switch and the cycle-by-cycle current limit duration timing starts by discharging the soft-start capacitor.

Depending on specific design requirements, the user can override default parameters by applying external

charge or discharge currents to the soft-start capacitor. Figure 42 shows the operation of a full-bridge system at

cycle-by-cycle current limit. The waveforms include drain-source voltages of synchronous rectifiers and voltage at

CS pin. The whole cycle-by-cycle current limit and hiccup operation is shown in Figure 43 . In this example the

cycle-by-cycle current limit lasts about 25 ms followed by 150 ms of off time.

Figure 42. Cycle-by-Cycle Current Limit

Figure 43. Hiccup Mode with Cycle-by-Cycle Current Limit at I

OUT

= 60 A

Copyright © 2008, Texas Instruments Incorporated Submit Documentation Feedback 25

Product Folder Link(s): UCC28230 UCC28231

Page 26

SoftStart

Thesecondcurrentlimitthreshold0.7V

ishitatCSpinindicatingshortcircuit

Off Timebeforerestart

Soft-

Restart

0

SSpin,

Volts

4.5

Iss=25µA

Ihcc= -2.5µA

SSClampVoltage

OutputPulses, D

FastPullUpby

1kΩ Switch

Outp. Enbl. Thresh. 0.85

SSShDn. Thresh. 0.55

( )

4 5 0 55

2 5 m

´ -

=

SS

CL( off )

C . V . V

T

. A

(16)

UCC28230

UCC28231

SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008 ...................................................................................................................................................

www.ti.com

In the event of a severe short circuit condition, the current sense voltage will exceed the short circuit threshold

set at 0.7 V min. At this point the controller shuts down the converter with propagation time 100 ns and pulls the

soft start pin up to the 4.5-V threshold. (see Figure 44 ).

Figure 44. Timing Diagram for the Soft-Start Capacitor Voltage V

SS

During Short Circuit Protection

At this condition the soft-start voltage is forcibly pulled up even if the soft-start charge is not completed. After

that, the soft-start capacitor is discharged by 2.5- µ A current until its voltage reaches the 0.55 V in order to

resume the soft-start cycle again. The duration of off time before the restart is defined by Equation 16 :

With the same soft-start capacitor value 100 nF, the off time before the restart is going to be about 158 ms.

Similar to the over current condition, the hiccup mode with the restart can be override by user if a pull-up resistor

is connected between the SS and VREF pins. If the pull-up current provided by the resistor exceeds 2.5 µ A, then

the controller remains in the latch-off mode. In this case, an external soft-start capacitor value should be

calculated with the additional pull-up current taken into account. The latch-off mode can be reset externally if the

soft-start capacitor forcibly discharged below 0.55 V or the V

DD

voltage is lowered below the UVLO threshold.

26 Submit Documentation Feedback Copyright © 2008, Texas Instruments Incorporated

Product Folder Link(s): UCC28230 UCC28231

Page 27

Off-Time Control Circuit

Off TimeControl Threshold

(SetbyresisterdividerR1/R2from

PinVREFtopinOST andtoGND)

0 Iout

T

OFF

T

CLAMP

T

DT

T

DT

T

CLAMP

Ensures

nocross

conductionat

lightload

Provides

minimumdiode

conductionover

widerangeof

loadconditions

T

DT

Hysteresis=I

HYST

xR1xR2/(R1+R2)

T

OFFMAX

atlightload=5x T

OFF

with Off TimeControl

Thresholdsetto20%ofI

MAX

T

OFF

≈2.5×TDTatheavyload

(setbyresisterR3from

pinOStoGND)

´ ´

= ´

´

CS CT ( pr ) PT (sec)

CS OUT

PT ( pr ) C T (sec)

R W W

V I

W W

(17)

UCC28230

UCC28231

www.ti.com

................................................................................................................................................... SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008

The off time control circuit provides optimal off time between O1_D and O2_D outputs depending on the load

current condition. The UCC28230/1 implements the off time control approach based on step function with

hysteresis (see Figure 45 ).

Off-time control is an important feature to address an optimal operation of self-driven synchronous rectifier over

the whole load current range. In self-driven rectifier applications, the turn-on and off time of the synchronous

FETs is defined by the current of output inductor and its polarity. Some additional energy is also provided from

the magnetizing inductance of a power transformer but it may not be sufficient for the fast switching. Therefore,

at light load the off-time should be longer than at full load to allow previously conducting rectifier MOSFET to be

completely turned off before the next switching half-cycle. This ensures the rectifier MOSFET having enough

time to turn off before the primary-side MOSFET forces it to turn off. The turn off of the rectifier MOSFET, while

still conducting, results in a current surge followed by a significant voltage spike which lowers the efficiency and

reliability of converter.

Figure 45. The Off Time Change as Function of Load Current

Usually there is no direct access to the load current of bus converters, so the primary current sensing is used to

replicate load current changes (see Figure 45 ). The largest part of the primary current is the load current on

secondary side of power transformer reflected into the primary side in accordance to transformer ’ s turn ratio. The

primary current includes not only the reflected load current, but also magnetizing current. However, for the most

practical applications the accuracy of solution with magnetizing current included is sufficient because in this

application the magnetizing current is only small percentage of overall current. With this assumption, the voltage

at pin CS can be defined as:

Copyright © 2008, Texas Instruments Incorporated Submit Documentation Feedback 27

Product Folder Link(s): UCC28230 UCC28231

Page 28

UCC28230 Off Time T

OFF

and Dead Time TDvs R

OS

0

10

20

30

40

50

60

70

80

90

100

0 5 10 15 20 25 30 35

R

OS

(kΩ)

T

OFF

and T

D

(ns)

Off Time

Dead Time

UCC28230 Off Time T

OFF

and Dead Time TDvs R

OS

0

50

100

150

200

250

300

350

0 15 30 45 60 75 90 105 120 135 150

ROS(kΩ)

T

OFF

and T

D

(ns)

Off Time

Dead Time

UCC28231 Off Time T

OFF

and Dead Time TDvs R

OS

0

50

100

150

200

250

300

0 20 40 6 0 8 0 100 12 0 140 160 180 200

R

OS

(kΩ)

T

OFF

and T

D

(ns)

Off Time

Dead Time

UCC28231 Off Time T

OFF

and Dead Time TDvs R

OS

0

10

20

30

40

50

60

70

80

90

100

0 5 10 1 5 20 25 30 35 4 0 45 50 55 60

ROS(kΩ)

T

OFF

and T

D

(ns)

Off Time

Dead Time

UCC28230

UCC28231

SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008 ...................................................................................................................................................

www.ti.com

Where I

OUT

is the output inductor current, R

CS

is the current sense resistor, W

PT(pr)

and W

PT(sec)

are the primary

and secondary number of turns of power transformer windings and the W

CT(pr)

and W

CT(sec)

are the primary and

secondary number of turns of current transformer windings.

UCC28230/1 uses OS pin and OST pin to program the nominal off time T

OFF

and the output current threshold

where the off time steps up to the new value T

OFF(max)

. The dead time Tdand nominal off time T

OFF

are set by

resistor R3 between OS pin and GND (Figure 3 , Figure 4 and Figure 50 ). Figure 46 shows how to choose R3

resistance to achieve the dead time Td and nominal off time T

OFF

for both UCC28230 and UCC28231. For

example, if a 40ns nominal T

OFF

is needed, the resistor value should be 8.45k Ω , and Td is about 17ns for

UCC28230 and 15ns for UCC28231. 15 k Ω R3 at OS pin sets T

OFF

to 50 ns and Tdto 23 ns for UCC28230, with

T

OFF

as 47 ns and Tdas 19 ns for UCC28231. Based on Figure 46 , one can tell that T

OFF

is about 2.2 to 2.64

times of Tdfor UCC28230, and 2.25 to 2.75 times of Tdfor UCC28231.

Figure 25 through Figure 30 from Typical Waveforms show the output switching waveforms including rise and fall

time and off time T

OFF1

, T

OFF2

for each half switching cycle and dead time Td1, Td2, T

d3

and T

d4

for each half

switching cycle.

Off time and dead time selection based on the resistor R3 value.

Figure 46. Figure 47.

Figure 48. Figure 49.

28 Submit Documentation Feedback Copyright © 2008, Texas Instruments Incorporated

Product Folder Link(s): UCC28230 UCC28231

Page 29

2

1 2

= ´

+

R

VOST VREF

R R

(18)

VREF

CS

CT

OS

Is

R 1

R 2

1

2

6

T

OFF

set

circuit

3

OST

R 3

5VforUCC28230,

3.3VforUCC28231

To Logic Block

Iprim

X

10

filtering

I

HYST

= 10 µA

RCS

Cycle-by-Cycle

CurrentLimit

1 2

1 2

´

= ´

+

hyst hyst

R R

V I

R R

(19)

UCC28230

UCC28231

www.ti.com

................................................................................................................................................... SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008

The next step is to set the output current threshold below that the off time changes to its maximum value. This

threshold is defined as:

The increase of off time at light load condition is provided by the increasing of overlapping time T

CLAMP

of

O1_DIN and O2_DIN outputs (see Figure 33 ). This ensures the faster turning off of the rectifier MOSFETs when

the primary winding is clamped. The dead time between the switching of primary MOSFETs in each leg remains

the same over the load current, which is still proportional to nominal off time as shown in Figure 46 .

Figure 50. The Off-Time Control Circuit Using Comparator With Hysteresis

Selecting optimal hysteresis is important to avoid oscillation. UCC28230/31 provides the flexibility of

programming the hysteresis with internal 10- µ A current I

HYST

and the values of external resistors R1 and R2 (see

Figure 50 ). Equation 19 shows how to choose the hysteresis.

In some cases, the disabling of off-time control circuit is needed, which can be done by simply connecting OST

pin to GND or to VREF. Connecting OST pin to the VREF is characterized in the electrical table and is the

preferable way to maintain fixed off time set by resistor R3.

The load dependent dead time will cause a slight change in output duty cycle at the programmed transition point

from light load to heavy load and vice-versa. This slight change in duty cycle corresponds to a slight change in

output voltage.

Copyright © 2008, Texas Instruments Incorporated Submit Documentation Feedback 29

Product Folder Link(s): UCC28230 UCC28231

Page 30

APPLICATION INFORMATION

DESIGN EXAMPLE

1

0

V

UCC28230

UCC28231

SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008 ...................................................................................................................................................

www.ti.com

Two design examples are provided to show how to design an intermediate bus converter with UCC28230/1.

Design Example 1 provides a concise step-by-step design. Its design specifications, schematics and test results

are illustrated on efficiency, power dissipation and output voltage regulation. Design Example 2 is to show an

industry standard quarter brick module design with 12-layer boards and embedded magnetic parts. Its design

specifications, schematics, and test results are provided.

Figure 51. Design Example of IBC Using UCC28230 Controller Device

30 Submit Documentation Feedback Copyright © 2008, Texas Instruments Incorporated

Product Folder Link(s): UCC28230 UCC28231

Page 31

Design Goals

UCC28230

UCC28231

www.ti.com

................................................................................................................................................... SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008

This example illustrates the design process and component selection for an intermediate bus converter using

UCC28230. The target design is a 300-W full bridge converter with narrowed input voltage range in a close to

quarter brick form factor with open-loop control for the telecom applications in intermediate bus architecture. Its

specifications are shown in Table 1 .

Table 1. 300W IBC Specifications

PARAMETER MIN TYP MAX UNIT

Input voltage V

IN

43 48 53 V

DC

Output voltage V

OUT

9.6

Output power P

OUT

300 W

Output load current I

OUT

30 A

Load capacitance C

OUT

10,000 µ F

Switching frequency F

SW

125 kHz

Over power limit P

LIMIT

150%

Efficiency at full load η (V

IN

= 48 V) 96%

Isolation 1500 V

Turns-ratio N

PRI

: N

SEC

5:1

Copyright © 2008, Texas Instruments Incorporated Submit Documentation Feedback 31

Product Folder Link(s): UCC28230 UCC28231

Page 32

Recommended PCB Device Layout

UCC28230

UCC28231

SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008 ...................................................................................................................................................

www.ti.com

The device programming components should be placed as close as possible to the device. The power ground

should be separated from the signal ground and connected only at one point at device pin 8 and 9 for TSSOP

package. For SON package there is only one ground pin available, pin 7. In this case, pin 7 is used to replace

the connection of pin 8 and pin 9 of TSSOP. The following takes TSSOP as the example. For SON, a similar

arrangement on the layout should be made. Capacitors for bias decoupling (C5), reference voltage decoupling

(C6), and soft start (C9), should be placed right across the signal ground and pins 14, 1 and 6, respectively. All

programming resistors, R2, R3, R5, and R7 should be placed next to the device pins they should be connected

to minimize their EMI noise reception. See Figure 52 for a recommended component layout and placement. PCB

design considerations of other circuit part are discussed later in the relevant part design.

Figure 52.

Figure 53.

32 Submit Documentation Feedback Copyright © 2008, Texas Instruments Incorporated

Product Folder Link(s): UCC28230 UCC28231

Page 33

Programming the UCC28230

2 5 2 4

7 1 2500 52 52 3

125

- -

= = ´ = ´ = W Þ W

SW

(VREF K ) ( . )

R RT K k . k

f

(20)

9

3

25 25

0 27 0 33

4 5 2 85 0 85

m

m m

´

´

= = = = Þ

- -

SS

SS

T K

A

C C . F . F

(K K ) ( . V . V )

(21)

5 13 15= W Þ WR k k

(22)

3

2

=

-

OST

OST

V

R

R (VREF V )

(23)

3 1

æ ö

= ´ +

ç ÷

-

è ø

hyst

OST

hyst OST

V

V

R

I VREF V

(24)

UCC28230

UCC28231

www.ti.com

................................................................................................................................................... SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008

Switching frequency: R7 Equation 3

Soft-start time: C9

Considering power on with maximum 10,000- µ F load capacitors, soft-start time may need be adjusted and if

soft-start time is determined as 25 ms, then based on Equation 9

Multilayer ceramic capacitor (X7R or X5R) should be used.

Dead time set-up resistor, R5

Assuming Td= 20 ns, based on Figure 46

Off-time adjustment threshold and hysteresis resistors: R2 and R3

T

OFF

is set up at 10% of rated load, V

OST

= 0.5V, with hysteresis V

HYST

= 100 mV. Based on Equation 18 and

Equation 19 , k Ω

Solution to the above two equations yields R2 = 99.9 k Ω , and R3 = 11.1 k Ω .

V

DD

decoupling capacitor: C5 High quality low ESR and low ESL such as multilayer ceramic capacitor (X7R or

X5R) with a value between 0.1 to 1.0 µ F should be used.

VREF decoupling and stability capacitor: C6

High quality low ESR and low ESL such as multilayer ceramic capacitor (X7R or X5R) with a value between 1.0

to 2.2 µ F should be used .

Copyright © 2008, Texas Instruments Incorporated Submit Documentation Feedback 33

Product Folder Link(s): UCC28230 UCC28231

Page 34

Current Sensing

450

10 5 20 12 6

43

= = = Þ

LIMIT

P ( rms )

IN (min)

P

I . (with % m arg in ) . A

V

(25)

UCC28230

UCC28231

SLUS814A – FEBRUARY 2008 – REVISED JUNE 2008 ...................................................................................................................................................

www.ti.com

Power stage design shows primary DC current maximum value is determined

If pick up a current transformer with turns ratio of 100:1, R4 is determined as 5.11 Ω with current sense threshold

at 150% of rated power.

Current sensing plays a critical role to achieve several features of UCC28230 including over current protection

and off time adjustment. Usually the sensing element cannot be placed next to the device. In such a case, it is

strongly recommended to route the PCB with Kelvin connection from the current sensing output device (R4) to

the IC (Pin 7) as shown in Figure 54 . A small RC filter (R8 and C10) is required to attenuate possible high

frequency noise. A small capacitor, C8, can also be added to get further filtering effect while usually it is not

needed.

Figure 54.

34 Submit Documentation Feedback Copyright © 2008, Texas Instruments Incorporated

Product Folder Link(s): UCC28230 UCC28231

Page 35