Page 1

查询UCC1583J供应商

Switch Mode Secondary Side Post Regulator

UCC1583

UCC2583

UCC3583

FEATURES

• Precision Secondary Side Post

Regulation for Multiple Output Power

Supplies

• Useful for Both Single Ended and

Center Tapped Secondary Circuits

• Ideal Replacement for Complex

Magnetic Amplifier Regulated Circuits

• Leading Edge Modulation

• Does Not Require Gate Drive

Transformer

• High Frequency (>500kHz) Operation

• Applicable for Wide Range of Output

Voltages

• High Current Gate Driver (0.5A

Sink/1.5A Source)

• Average Current Limiting Loop

DESCRIPTION

The UCC3583 is a synchronizable secondary side post regulator for precision regulation of the auxiliary outputs of multiple output power supplies. It

contains a leading edge pulse width modulator, which generates the gate

drive signal for a FET power switch connected in series with the rectifying

diode. The turn-on of the power switch is delayed from the leading edge of

the secondary power pulse to regulate the output voltage. The UCC3583

contains a ramp generator slaved to the secondary power pulse, a voltage

error amplifier, a current error amplifier, a PWM comparator and associated logic, a gate driver, a precision reference, and protection circuitry.

The ramp discharge and termination of the gate drive signal are triggered

by the synchronization pulse, typically derived from the falling edge of the

transformer secondary voltage. The ramp starts charging again once its

low threshold is reached. The gate drive signal is turned on when the ramp

voltage exceeds the control voltage. This leading edge modulation technique prevents instability when the UCC3583 is used in peak current mode

primary controlled systems.

The controller operates from a floating power supply referenced to the output voltage being controlled. It features an undervoltage lockout (UVLO)

circuit, a soft start circuit, and an averaging current limit amplifier. The current limit can be programmed to be proportional to the output voltage, thus

achieving foldback operation to minimize the dissipation under short circuit

conditions.

TYPICAL APPLICATION AND BLOCK DIAGRAM

(continued)

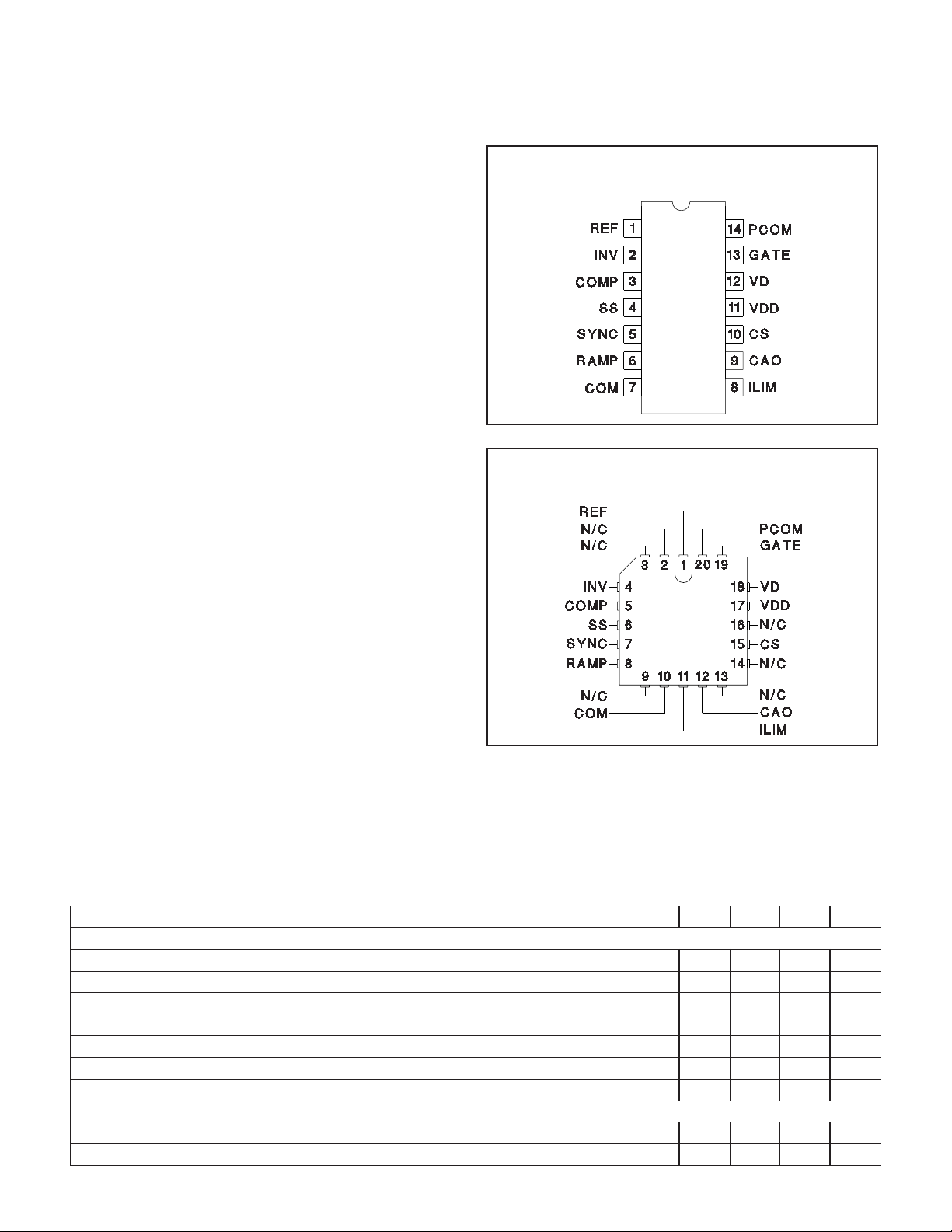

Note: Pin connections shown for 14-pin packages.

11/98

UDG-96201-2

Page 2

ABSOLUTE MAXIMUM RATINGS

VDD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15V

I

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15mA

VDD

RAMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3V to V

I

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5mA

RAMP

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I

REF

PCOM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.2V to 0.2V

I

(twp < 1µS and Duty Cycle < 10%) . . . . . . –0.8A to 1.8A

GATE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –5mA to 5mA

I

COMP

I

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –5mA to 5mA

CAO

. . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.6V to V

V

SYNC

I

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –05mA to 5mA

SYNC

INV, SS, ILIM, ISENSE. . . . . . . . . . . . . . –0.3V to VREF + 0.3V

Storage Temperature . . . . . . . . . . . . . . . . . . . –65°C to +150°C

Junction Temperature. . . . . . . . . . . . . . . . . . . –55°C to +150°C

Lead Temperature (Soldering, 10 sec.). . . . . . . . . . . . . +300°C

All voltages are with respect to the COM terminal unless otherwise stated. Currents are positive into, negative out of the

specified terminal. Consult Packaging Section of Databook for

thermal limitations and considerations of packages.

REF

+ 1V

DD

–30mA

+0.3V

UCC1583

UCC2583

UCC3583

CONNECTION DIAGRAMS

DIL-14, SOIC-14 (Top View)

J, N, or D Packages

PLCC-20 (Top View)

Q Package

ELECTRICAL CHARACTERISTICS: Unless otherwise stated, these specifications apply for T

= –55°C to 125°C for

A

UCC1583, –40°C to 85°C for UCC2583, and 0°C to 70°C for UCC3583; VDD = 12V, RT= 60k, CT= 200pF, TA= TJ.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Ramp Generation and Synchronization

Maximum Input Operating Frequency For input with 5% to 90% duty cycle (Note 1) 500 kHz

Ramp Frequency, Free Running 95 100 105 kHz

Ramp Discharge Current V

= 0.5V 2.0 3.6 mA

RAMP

Low Threshold Voltage No min, no max, 0=TYP 0 V

High Threshold Voltage 3.75 4 4.25 V

Synchronizing Threshold Voltage (On) (Note 1) 1 V

Synchronizing Comparator Hysteresis 1 V

Output Duty Cycle

Minimum Duty Cycle Output D/C = Output PW / Input PW 0 %

Maximum Duty Cycle Output D/C = Output PW / Input PW 100 %

2

Page 3

UCC1583

UCC2583

UCC3583

ELECTRICAL CHARACTERISTICS:

Unless otherwise stated, these specifications apply for TA= –55°C to 125°C for

UCC1583, –40°C to 85°C for UCC2583, and 0°C to 70°C for UCC3583; VDD = 12V, RT= 60k, CT= 200pF, TA= TJ.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Voltage Error Amplifier

V

V

INV

I

INV

Low V

V

COMP

V

High V

COMP

= VINV, 0°C to 70°C (UCC3583) 2.462 2.5 2.538 V

COMP

V

= VINV, All Other Temperature Ranges 2.45 2.5 2.55 V

COMP

V

= VINV 300 500 nA

COMP

= 2.6V, ICOMP = 100µA 450 700 mV

INV

= 2.4V, ICOMP = –100µA 5.0 5.5 6.0 V

INV

AVOL No Load 70 90 dB

GBW Product At f = 100kHz, T

A = 25°C (Note 1) 3 5 MHz

Current Error Amplifier

Input Offset Voltage 10 mV

Input CM Low Common Mode for CS and ILIM (Note 1) 0 V

Input CM High Common Mode for CS and ILIM (Note 1) 2 V

Low V

V

CAO

V

High V

CAO

+IN

+IN

= 0V, V

= 0V, V

= 0.1V, ICAO = 100µA 250 500 mV

–IN

= 0.1V, ICAO = –100µA 5.0 5.5 6.0 V

–IN

Input Current (ILIM and CS Pins) –50 0 50 nA

AVOL No Load 70 90 dB

GBW Product At f = 100kHz, T

= 25°C 2 4 MHz

A

Soft Start Current 10 25 µA

UVLO

VDD On Threshold Voltage 8.5 9.0 9.5 V

VDD Off Threshold Voltage 7.9 8.4 8.9 V

UVLO Hysteresis 0.3 0.6 0.9 V

Bias Supply

Supply Clamp Voltage 13 14 15 V

Supply Current (VDD) f = 100kHz With No Gate Output Load 3 5 mA

Output Driver

SAT High I

V

= –150mA 0.6 1.0 V

GATE

VSAT Low IGATE = 50mA 0.4 0.75 V

Rise Time C

GATE = 1nF 50 75 ns

Fall Time CGATE = 330pF 20 40 ns

Reference

VREF IREF = 0, 0°C to 70°C (UCC3583) 4.925 5 5.075 V

REF = 0, All Other Temperature Ranges 4.900 5 5.100 V

I

Line Regulation VDD = 10V to 14V 2 30 mV

Load Regulation IREF = 0mA to 2mA 1 20 mV

Note 1: Guaranteed by design. Not 100% tested in production.

3

Page 4

PIN DESCRIPTIONS

CAO: Output of the current error amplifier. Averaging of

the sensed current signal is provided by connecting an

integrating capacitor between ILIM and CAO. CAO feeds

into the PWM comparator input and controls the loop

when its voltage is higher than the voltage at COMP

(output of the voltage error amplifier).

COM: Signal ground for the chip. It is connected to the

positive terminal of the output voltage being regulated by

the IC.

COMP: Output of the voltage error amplifier fed into the

PWM comparator. Loop compensation components are

connected between COMP and INV.

CS: Non-inverting input of the current error amplifier. The

sensed current signal from the current sense resistor is

connected to this pin. By making the signal at CS

proportional to the output voltage, effective current

foldback limiting can be provided.

GATE: Gate drive output for the power switch FET. The

drive pin has a 0.5A sink/1.5A source capability and very

low output off-state impedance.

ILIM: Inverting input of the current error amplifier. It sets

the DC limit for the output current.

INV: Inverting input of the voltage error amplifier. The

feedback signal is connected to this pin using a resistive

divider between REF and –V

PCOM: Power ground for the chip. It is connected to the

source terminal of the MOSFET being regulated by the

IC.

RAMP: This pin is the input to the PWM comparator and

provides a ramp signal for generation of the PWM signal.

A capacitor to COM and a resistor to REF set the

charging rate for the ramp. An internal current source of

O.

UCC1583

UCC2583

UCC3583

1mA discharges RAMP when synchronization signal

appears or when RAMP crosses a 4V threshold. In the

intended mode of operation, the switching frequency is

determined by the secondary power pulse. The RC

components at RAMP should be selected to give an

appropriately sized ramp signal. In the absence of a

synchronizing pulse, these RC components determine

the free running frequency of the controller.

REF: Precision 5V reference pin. REF stays off until

VDD exceeds 9V and turns off again when VDD drops

below 8.4V. Bypass REF to COM.

SS: This pin provides a soft start function. A capacitor to

REF programs the soft start time. During soft start, the

PWM comparator is controlled by the soft start voltage

resulting in a slow increase in output duty cycle. Once

the soft start capacitor is discharged, output control is

dictated by the larger of the output at CAO or COMP.

SYNC: Synchronization input pin. It is connected to a

signal representative of the secondary power pulse. One

possible implementation is to use a resistive divider

between terminal S2 of the secondary winding shown in

Figure 1 and REF for generating the input to the SYNC

pin. The synchronizing comparator is referenced to 0.5V

and has ±500mV of hysteresis. The trip levels are

approximate 1.0V and 0.0V. The designer should prevent

the SYNC pin from exceeding 0.3V below ground as this

will turn on the ESD diode.

VD: Power supply for the output driver. VD should be

tied to VDD in the application.

VDD: Power supply for the chip. VDD should be

bypassed to COM. VDD has to be 9V for the IC to start

and 8.4V for it to remain operational. A shunt clamp from

VDD to COM limits the supply voltage to 14V.

APPLICATION INFORMATION

Power Stage Circuit Configuration

The UCC3583 is designed for use in a post regulator application for tightly regulating auxiliary outputs in a multiple output converter. The post regulation is applied to the

secondary side power pulse of a power transformer

where the power pulse is controlled by the feedback signal from the main output. In order to simplify the application of the UCC3583, it is required that the IC be

referenced to the positive output terminal and the output

filter inductor be placed in the return path. The placement of the inductor in the return path facilitates better

EMI performance, in addition to making magnetic de-

signs and terminations easier to implement. Typical setup and circuit waveforms of the UCC3583 system application are shown in Figure 1. Figure 2 shows waveforms

for a single ended output rectifier application of the

UCC3583 shown on page 1. The UCC3583 can also be

used in half bridge rectifier applications as shown by the

circuit and waveforms depicted in Figures 3 and 4. Referencing the IC to the positive output terminal creates a requirement for a floating bias voltage for the IC which can

be referenced to the same positive voltage terminal. Possible implementations of deriving the floating bias voltage

are shown in Figure 5.

4

Page 5

APPLICATION INFORMATION (cont.)

For the circuit shown in Figure 5a, CC1 is charged when

the transformer voltage is positive and the synchronous

switch is on. During the off period of Q-SYNC, the charge

is transferred to CC2 through diode DC2. Diode DC3

charges CC2 during the blocking interval of Q-SYNC.

This method is preferable when the transformer positive

voltage is high enough to generate the required bias voltage. For the circuit shown in Figure 5b, CC1 is charged

during the period when reverse (reset) voltage appears

across the secondary. The charge on CC1 is transferred

to CC2 through DC2 when Q-SYNC turns on. This

method is preferable when the reverse voltage is high

enough to generate the required bias voltage. The series

resistor should be chosen to handle the required voltage

drop at full IC operating current when the zener clamp

across VDD and COM is activated.

The following is a description of the major functional

blocks of the UCC3583. Refer to Figure 6 (Typical Application Circuit) for component designations.

UVLO and Start Up

The UCC3583 has an internal undervoltage lockout circuit which keeps the internal circuitry inactive until VDD

exceeds the upper threshold (9V). Once the chip is activated, VDD has to be above the lower UVLO threshold

(8.4V) for it to remain functional. The IC requires a low

startup current of only 100µA when VDD is under the

UVLO threshold. VDD has an internal clamp of 14V

which can sink up to 10mA. Measures must be taken not

to exceed this current. The internal reference (REF) is

brought up when the UVLO on threshold is exceeded.

The soft start pin provides an effective means to start the

IC in a controlled manner. An internal current of 10µA

starts discharging a capacitor connected to SS when the

UVLO conditions have been removed. The voltage on

SS controls the duty cycle of the output during the discharge period.

Synchronizing Circuit and Oscillator

UCC3583 is primarily intended for synchronizable operation where its switching frequency is determined by the

secondary pulse of the power transformer. However, it

has an internal oscillator which allows it to operate in

free-running mode when an external synchronization

pulse is not available. The switching frequency is determined by resistor R

RAMP and capacitor CT connected from RAMP to GND.

The frequency is given by:

=

+

CH DIS

and

T connected between REF and

=••

CH T T

UCC1583

UCC2583

UCC3583

•

T

=

DIS

RAMP dis

The values of RT and CT are also dictated by the fact

that the ramp is discharged through an internal impedance of 2k. The value of R

ensure that the internal discharge current is the current

through R

T during the entire discharge period. This re-

sults in making the value of CT relatively small for a desired frequency of operation.

When the synchronizing signal is available, the oscillator

frequency should be programmed to be lower than the

synchronizing frequency to ensure proper operation. A

large difference in self-running and synchronizing frequencies leads to smaller ramp amplitude and higher

noise sensitivity. The ramp capacitor is discharged when

the synchronization signal arrives and begins charging

when the low threshold is crossed.

There are two methods to synchronize to the secondary

pulse. One method is to use the rising edge of the secondary pulse, which reduces the maximum duty cycle

available. Subsequently, the post regulator switch cannot

be turned on during the C

method is to use the falling edge of the secondary pulse

for synchronization. This method is preferable because it

allows a slower discharge of the ramp capacitor without

affecting the maximum available duty cycle of the post

regulator. The UCC3583 SYNC input needs to reach a

fixed threshold (1.0V typical) for synchronization to take

effect. Hence the IC is usable with either method of synchronization. However, the UCC3583 oscillator configuration is better suited for synchronization to the falling

edge. A recommended method to implement the synchronization is shown in Figure 6. By connecting SYNC

to a resistive divider between REF and the secondary

terminal S2, the synchronization is achieved whenever

the voltage on S2 goes from a negative value to zero. R

and RBshould be selected so that the voltage on the

SYNC pin varies from 0V to 1V. Placement of a Schottky

diode from SYNC to COM prevents the voltage at SYNC

from going negative. The internal hysteretic SYNC comparator has an inverting input set to 0.5V with about

±0.5V hysteresis.

PWM Comparator

The UCC3583 uses a leading edge PWM scheme. In a

leading edge PWM, the output pulse (gate signal) is

turned on when the error amplifier crosses the PWM

ramp and turned off by the clock/oscillator. Leading edge

modulation is naturally provided by magamp type post

regulators and is an essential feature for post regulators.

Without the leading edge modulation in a multiple output

()

RAMP p p

()

ť

T needs to be at least 50k to

T discharge time. The other

T

A

5

Page 6

APPLICATION INFORMATION (cont.)

converter with post regulation on one or more outputs,

the primary current shape does not remain monotonic

and can lead to instability when the primary current is

used for current mode control or current limiting. When

compared to conventional trailing edge PWMs, the leading edge modulation leads to a phase inversion that

needs to be accounted for in the feedback loop. For the

UCC3583, this inversion is automatically provided since

the sensed voltage at the power supply output negative

terminal has a negative polarity with respect to the chip

common. Thus, UCC3583 does not require inverting

buffers which would otherwise be needed.

Error Signal Generation and Current Limiting

The PWM comparator in the UCC3583 is controlled by

three parallel loops with only one of them in effect at a

time. During normal operation, the voltage error amplifier

output is fed to the PWM comparator. The voltage error

amplifier can be compensated using commonly used

feedback techniques to achieve the desired dynamic performance. The ouput drive capability of the voltage amplifier is limited to 100µA, so appropriately high

impedances should be used to utilize the full output

swing of the amplifier. During startup, the soft start ca-

UCC1583

UCC2583

UCC3583

pacitor controls the pulse width. The third control loop is

provided by the average current amplifier. By sensing the

instantaneous inductor current and filtering/averaging it

with the current error amplifier, accurate current limiting

is achieved. This loop is in effect only during the overcurrent mode and provides a more accurate and noise free

control of the maximum output current compared to conventional peak current limiting circuits. The current limit is

set by programming the voltage at ILIM based on the

current sense resistor chosen. In addition, the current

limit can be made proportional to the output voltage in order to limit the power dissipation under short circuit conditions. This is implemented by inserting a bias voltage

on CS which is proportional to the output voltage.

Gate Drive Circuit

The gate drive circuit of the UCC3583 provides high current drive capability and is very easy to implement as a

result of tying the chip common to the source of the

switching device. Turn on current is higher (1.5A) as fast

turn on is essential for low losses and effective operation.

During the turn off, the drain voltage disappears, so turn

off time can be slower without increasing switching

losses.

Figure 1. UCC3583 SSPR system application and typical waveforms.

6

UDG-98195

Page 7

APPLICATION INFORMATION (cont.)

UCC1583

UCC2583

UCC3583

Note: All waveforms are referenced to chip common.

Figure 2. Single ended post regulator waveforms.

Figure 3. Half-bridge synchronous post regulator application.

UDG-96141-1

UDG-96142-1

7

Page 8

APPLICATION INFORMATION (cont.)

UCC1583

UCC2583

UCC3583

Figure 4. Half-bridge synchronous post regulator to waveforms.

UDG-96143-1

8

Page 9

APPLICATION INFORMATION (cont.)

UCC1583

UCC2583

UCC3583

Figure 5. Possible implementation for floating bias voltage generation.

R

A

R

B

UDG-96175-1

Figure 6. Typical application circuit.

UNITRODE CORPORATION

7 CONTINENTALBLVD. • MERRIMACK, NH 03054

TEL. (603) 424-2410 • FAX (603) 424-3460

UDG-96072-2

9

Page 10

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...