Page 1

查询UCC19411供应商

Low Power Synchronous Boost Converter

FEATURES

1V Input Voltage Operation Start-up

•

Guaranteed under FULL Load on

Main Output, and Operation Down to

0.5V

200mW Output Power at Battery

•

Voltages as low as 0.8V

Secondary 7V Supply from a Single

•

Inductor

Output Fully Disconnected in

•

Shutdown

Adaptive Current Mode Control for

•

Optimum Efficiency

High Efficiency over Wide Operating

•

Range

• 6µA Shutdown Supply Current

• Output Reset Function with

Programmable Reset Period

DESCRIPTION

The UCC39411 family of low input voltage, single inductor boost

converters is optimized to operate from a single or dual alkaline cell, and

steps up to a 3.3V, 5V, or adjustable output at 200mW. The UCC39411

family also provides an auxiliary 7V output, primarily for the gate drive

supply, which can be used for applications requiring an auxiliary output,

such as 5V, by linear regulating. The primary output will start up under full

load at input voltages typically as low as 0.8V with a guaranteed max of

1V, and will operate down to 0.5V once the converter is operating,

maximizing battery utilization.

The UCC39411 family is designed to accommodate demanding

applications such as pagers and cell phones that require high efficiency

over a wide operating range of several milli-watts to a couple of hundred

milli-watts. High efficiency at low output current is achieved by optimizing

switching and conduction losses with a low total quiescent current (50µA).

At higher output current the 0.5Ω switch, and 1.2Ω synchronous rectifier

along with continuous mode conduction provide high power efficiency. The

wide input voltage range of the UCC39411 family can accommodate other

power sources such as NiCd and NimH.

The 39411 family also provides shutdown control. Packages available are

the 8 pin SOIC (D), 8 pin DIP (N or J), and 8 pin TSSOP (PW) to optimize

board space.

application

INFO

available

UCC19411/2/3

UCC29411/2/3

UCC39411/2/3

PRELIMINARY

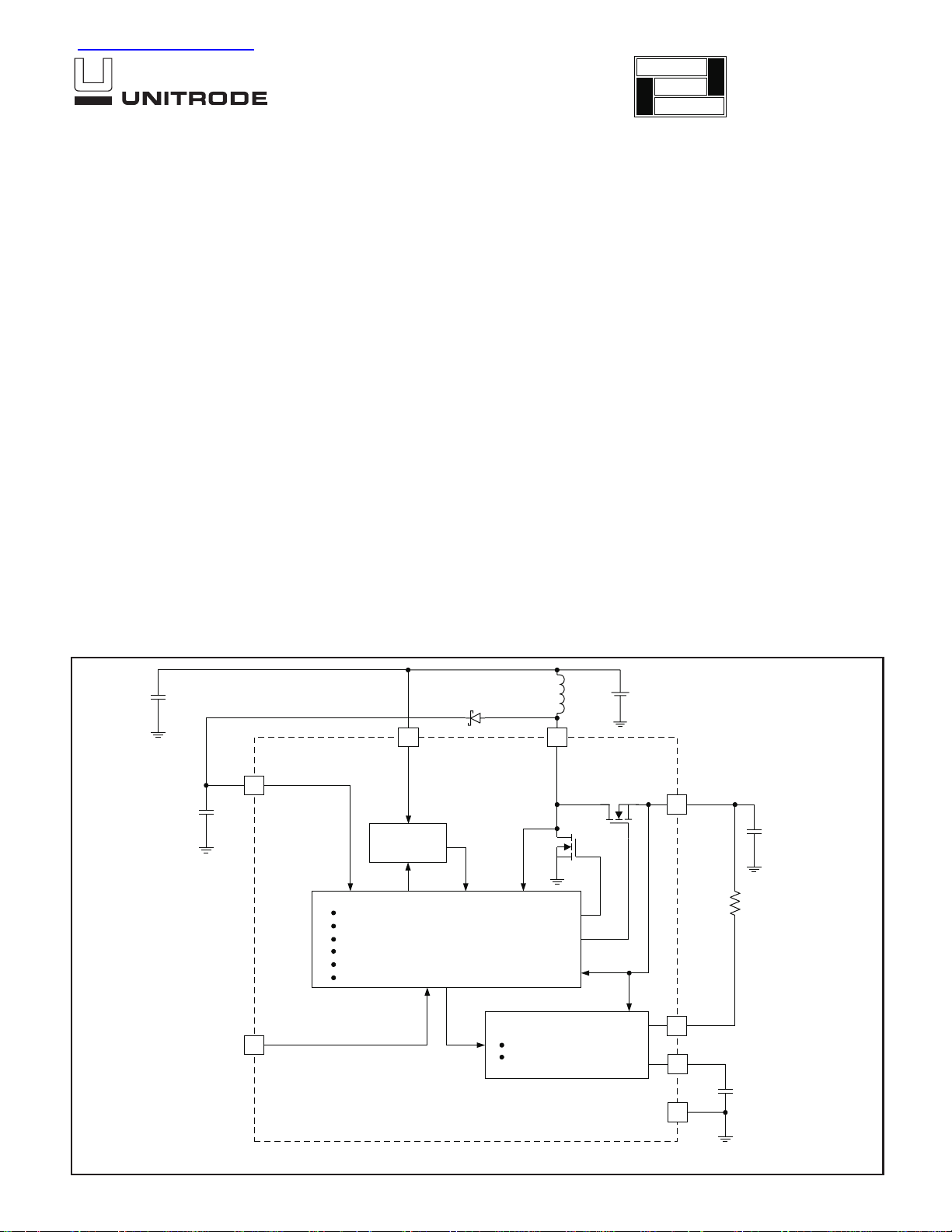

SIMPIFIED BLOCK DIAGRAM AND APPLICATION CIRCUIT (UCC39412)

100µF

VGD

100µF

22µH

1

VIN

8

START-UP

CIRCUITRY

MODULATOR CONTROL CIRCUIT

SYNCHRONOUS RECTIFICATION CIRCUITRY

ANTI-CROSS CONDUCTION

START-UP

MULTIPLEXING LOGIC

MAX INPUT POWER CONTROL

ADAPTIVE CURRENT CONTROL

RESET CONTROL CIRCUIT

2SD/FB

GLITCH SUPRESSION

PROGRAMMABLE TIMING

SW

6

+

1.2Ω

0.5Ω

1V TO 3.5V

VOUT

7

3

4

5

3.3V 200mW

RESB

CT

C

GND

100µF

R

RES

T

Note: Pinout shown is for the TSSOP Package. Consult Package Descriptions for DIP and SOIC configurations.

SLUS245A - MARCH 1999

UDG-98067

Page 2

ABSOLUTE MAXIMUM RATINGS

VIN Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3V to 10V

SD Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3V to V

VGD Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3V to 14V

SW Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3V to 15V

Currents are positive into, negative out of the specific terminal.

Consult Packaging Section of the Databook for thermal limita

tions and considerations of packages.

IN

-

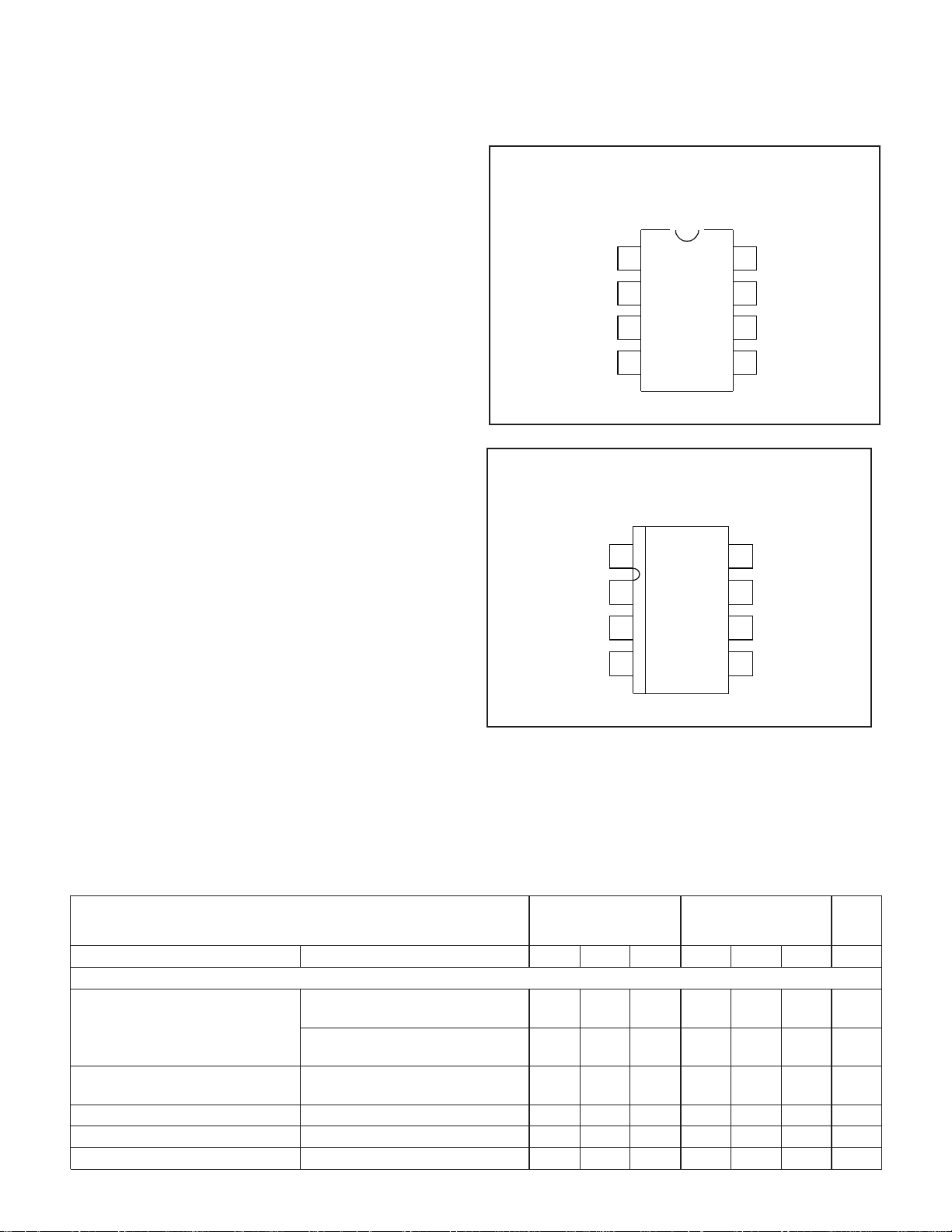

CONNECTION DIAGRAMS

DIL-8, SOIC-8 (TOP VIEW)

N or J Package, D Package

VOUT

VGD

1

2

UCC19411/2/3

UCC29411/2/3

UCC39411/2/3

8

SW

7

GND

VIN

3

SD/FB

4

TSSOP-8 (TOP VIEW)

PW Package

VIN

1

CT

2

3

4

SD/FB

RESB

6

CT

5

RESB

8

VGD

7

VOUT

6

SW

5

GND

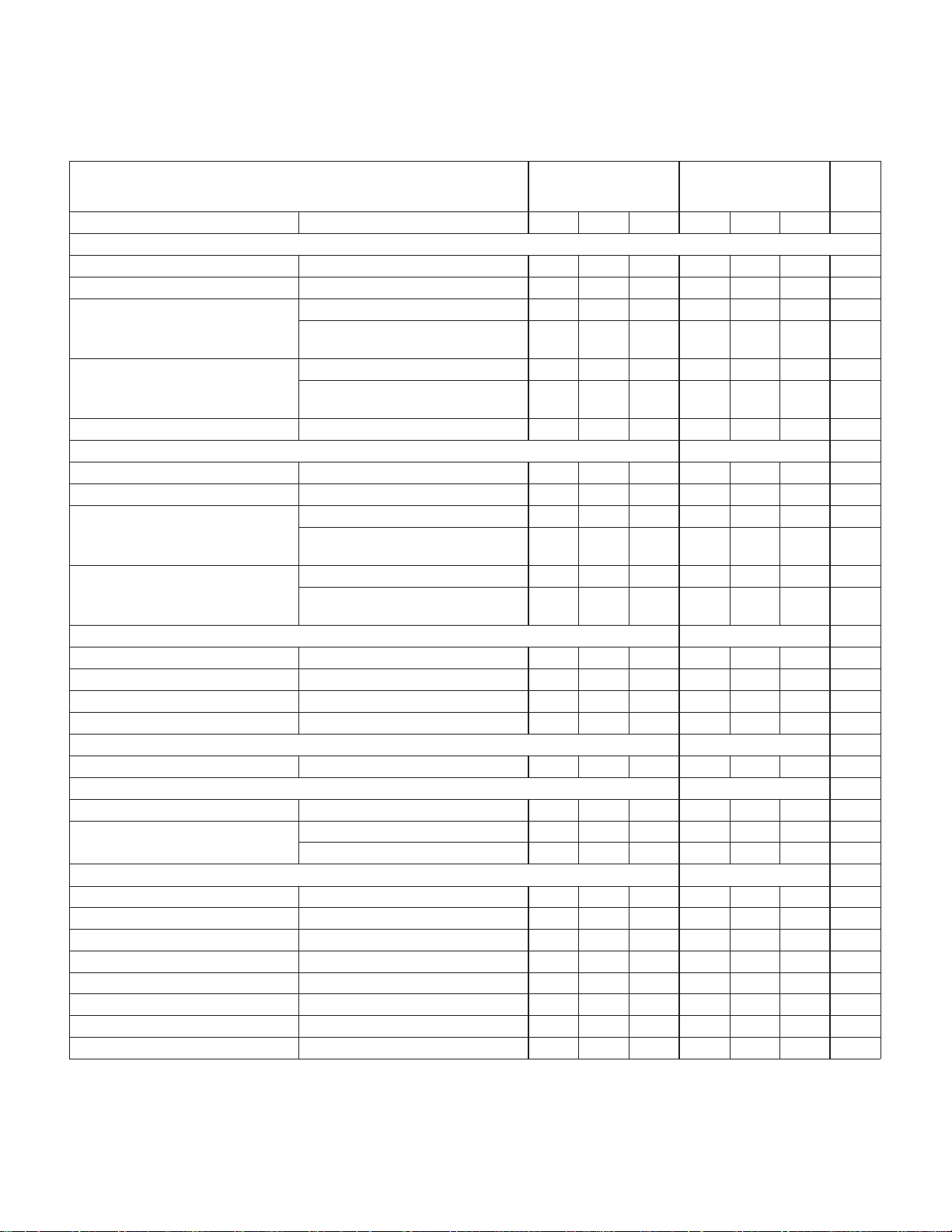

ELECTRICAL CHARACTERISTICS:

UCC29411/2/3, T

= –55C to +125°C for the UCC19411/2/3, VIN= 1.25V for UCC39411/2, VIN= 2.5V for the UCC39413, TA=TJ.

J

TJ= 0°C to +70°C for the UCC39411/2/3, TJ= –40°C to +85°C for the

UCC39411

UCC39412

UCC39413

UCC19411/2/3

UCC29411/2/3

PARAMETER TEST CONDITIONS MIN TYP MAX MIN TYP MAX UNITS

VIN Section

Minimum Start-up Voltage No External VGD Load, T

I

=60mA (Note 1)

OUT

No External VGD Load, I

=25°C,

J

OUT

=60mA

0.8 1 .08 1 V

0.9 1.1 1.2 1.4 V

(Note 1)

Minimum Dropout Voltage No External VGD Load, I

OUT

=10mA

0.5 0.7 V

(Note 1)

Input Voltage Range 1.1 3.2 1.3 3.2 V

Quiescent Supply Current (Note 2) 6 12 8 16

Supply Current at Shutdown SD = GND 6 12 8 16

2

µA

µA

Page 3

UCC19411/2/3

UCC29411/2/3

UCC39411/2/3

ELECTRICAL CHARACTERISTICS:

UCC29411/2/3, T

= –55C to +125°C for the UCC19411/2/3, VIN= 1.25V for UCC39411/2, VIN= 2.5V for the UCC39413, TA=TJ.

J

TJ= 0°C to +70°C for the UCC39411/2/3, TJ= –40°C to +85°C for the

UCC39411

UCC39412

UCC39413

UCC19411/2/3

UCC29411/2/3

PARAMETER TEST CONDITIONS MIN TYP MAX MIN TYP MAX UNITS

Output Section

Quiescent Supply Current (Note 2) 15 28 20 37

Supply Current at Shutdown SD = GND 3 6 5 10

Regulation Voltage (UCC39412) 1V < V

1V < V

< 3V 3.2 3.3 3.39 3.15 3.3 3.45 V

IN

< 3V, 0mA<I

IN

OUT

<60mA

3.17 3.3 3.43 3.11 3.3 3.5 V

(Note 1)

Regulation Voltage (UCC39413) 1V < V

1V < V

< 5V 4.85 5 5.15 4.78 5 5.23 V

IN

< 5V, 0mA<I

IN

OUT

<60mA

4.8 5 5.2 4.71 5 5.3 V

(Note 1)

ADJ Voltage (UCC39411) 1V < V

< 3V 1.212 1.25 1.288 1.194 1.25 1.306 V

IN

VGD Output Section

Quiescent Supply Current (Note 2) 20 40 27 55

Supply Current at Shutdown SD = GND 20 40 27 55

Regulation Voltage

(UCC39411/2)

1V < V

1V < V

< 3V 6.3 7 7.7 6.3 7 7.7 V

IN

< 3V, 0mA<I

IN

OUT

<10mA

6.3 7 7.7 6.3 7 7.7 V

(Note 1)

Regulation Voltage (UCC39413) 1V < V

1V < V

< 5V 7.7 8.5 9.3 7.7 8.5 9.3 V

IN

< 5V, 0mA<I

IN

OUT

<10mA

7.7 8.5 9.3 7.7 8.5 9.3 V

(Note 1)

Inductor Charging Section (L=22

µH)

Peak Discontinuous Current Operating Range, L=22.1µH 180 250 300 180 250 300 mA

Peak Continuous Current 385 550 715 385 550 715 mA

Charge Switch RDS

ON

D Package 0.5 0.75 0.6 0.85 Ω

Current Limit Delay (Note 1) 50 50 ns

Synchronous Rectifier Section

Rectifier RDS

ON

D Package 1.2 1.8 1.4 2.16 Ω

Shutdown Section

Threshold 0.4 0.6 0.8 0.2 0.6 0.9 V

Input Bias Current SD = GND 2 5 15 2 5 15

SD = 1.25V 5 20 20 100 nA

Reset Section

Threshold (UCC39411) 1.08 1.125 1.17 1.07 1.125 1.18 V

Threshold (UCC39412) 2.85 2.97 3.09 2.83 2.97 3.11 V

Threshold (UCC39413) 4.32 4.5 4.68 4.3 4.5 4.7 V

Reset Period C

to Reset Delay V

V

OUT

= 0.15µF 113 188 263 94 188 282 ms

T

Falling at –1mV/µs (Note 1) 60 60 µs

OUT

Sink Current 1 20 1 20 mA

Output Low Voltage I

= 500µA 0.1 0.1 V

OUT

Output Leakage 0.5 0.5

Note 1 : Guaranteed by design and alternate test methods. Not 100% tested in production.

Note 2: For the UCC39411 FB=1.306V, VGD=7.7V, For the UCC39412 V

V

=5.3V, VGD=9.3V.

OUT

=3.5V and VGD=7.7V, For the UCC39413

OUT

µA

µA

µA

µA

µA

µA

3

Page 4

PIN DESCRIPTIONS

VIN: Input Voltage to supply the IC during start-up. After

the output is running the IC draws power from VOUT or

VGD.

SW: An inductor is connected between this node and

VIN. The VGD (Gate Drive Supply) flyback diode is also

connected to this pin. When servicing the main output

supply this pin will pull low charging the inductor, then

shut off dumping the energy through the synchronous

rectifier to the output. When servicing the VGD supply

the internal synchronous rectifier stays off and the en

ergy is diverted to VGD through the flyback diode. During

discontinuous portions of the inductor current, a MOS

FET resistively connects VIN to SW damping excess cir

culating energy to eliminate undesired high frequency

ringing.

VGD: The VGD pin which is coarsely regulated around

7V (8.5V for the UCC39413) is primarily used for the

gate drive supply for the power switches in the IC. This

pin can be loaded with up to 10mA as long as it does not

present a load at voltages below 2V (this ensures proper

start-up of the IC). The VGD supply can go as low as

UCC19411/2/3

UCC29411/2/3

UCC39411/2/3

6.3V without interfering with the servicing of the main

output. Below 6.3V, VGD will have the highest priority.

VOUT: Main output voltage (3.3V, 5V, or adjustable)

which has highest priority in the multiplexing scheme, as

long as VGD is above the critical level of 6.3V. Startup at

full load is achievable at input voltages down to 1V.

CT: This pin provides the timer for determining the reset

period. The period is controlled by placing a capacitor to

ground of value C = (0.81e

reset period.

RESB: This pin provides an active low signal to alert the

user when the main output voltage falls below 10% of its

targeted value. The open drain output can be used to re

set a microcontroller which may be powered off of the

main output voltage.

SD/FB: For the UCC39411, this pin is used to adjust the

output voltage via a resistive divider from VOUT. It also

serves as the shutdown pin for all three versions. Pulling

this pin low provides a shutdown signal to the IC.

GND: Ground of the IC.

-6

)•T where T is the desired

-

APPLICATION INFORMATION

Operation

A detailed block diagram of the UCC39411 is shown in

Figure 1. Unique control circuitry provides high efficiency

power conversion for both light and heavy loads by tran

sitioning between discontinuous and continuous conduc

tion based on load conditions. Figure 2 depicts

converter waveforms for the application circuit shown in

Figure 3. A single 22µH inductor provides the energy

pulses required for a highly efficient 3.3V converter at up

to 200mW output power

At time t1 the 3.3V output voltage has dropped below its

lower threshold, and the inductor is charged with an on

time determined by: T

anda22µH inductor, the resulting peak current is ap

proximately 250mA. At time t2, the inductor begins to

discharge with a minimum off time of approximately 1µs.

Under lightly loaded conditions, the amount of energy

delivered in this single pulse would satisfy the voltage

control loop, and the converter would not command any

more energy pulses until the output again drops below

the lower voltage threshold

At time t3 the VGD supply drops below its lower thresh

old, but the output voltage is still above its threshold

point. This results in an energy pulse to the gate drive

supply at t4. In some cases, a single pulse supplied to

= 5.5µs/VIN. For a 1.25V input

ON

VGD is insufficient to raise the VGD voltage level enough

to satisfy the voltage loop. Under this condition, multiple

pulses will be supplied to VGD. Note: when the

UCC39411/2/3 is servicing VGD only, the IC will maintain

a discontinuous mode of operation. After time t4, the

-

3.3V output drops below its threshold and requests to be

serviced once the VGD cycle has completed, which oc

curs at time t5.

Time t6 represents a transition between light load and

heavy load. A single energy pulse is not sufficient to

force the output voltage above its upper threshold before

the minimum off time has expired and a second charge

cycle is commanded. Since the inductor current does

not reach zero in this case, the peak current is greater

than 250mA at the end of the next charge on time. The

result is a ratcheting of inductor current until either the

output voltage is satisfied, or the converter reaches its

set current limit. At time t7, the gate drive voltage has

dropped below its 7V threshold but the converter contin

ues to service the output because it has higher priority

unless VGD drops below ≈ 6.3V

Between time t7 and t8, the converter reaches its peak

current limit.

Once the peak current is reached, the converter oper

ates in continuous mode with approximately 60mA of in

-

-

-

-

4

Page 5

APPLICATION INFORMATION (continued)

UCC19411/2/3

UCC29411/2/3

UCC39411/2/3

SW

VOUT

1

SD

1.2Ω

Q

VGD

FROM SD

VON

VBAT

8

VGD

VBAT VGD

TIMER

OFF

1µS RISING

T

EDGE DELAY

VREF GOOD

PUMP

C

CLK

50nS

R.E.D.

D

R

50nS

SD/FB

4

0.5V

VGD

1.25V (UCC39411)

3.3V (UCC39412)

5.0V (UCC39413)

PRIORITY

ENCODER

R

Q

D

S

VON

-6

VBAT

R.E.D.

T

RISING EDGE

=5.5E

DELAY

VDD

ON

7.5V (UCC39411/2)

D

S

Q

1µS

R.E.D.

VGD

8.5V (UCC39413)

6V (UCC39411/2)

7.5V (UCC39413)

BIAS

INTERNAL

7

VLOW

FROM SD

3

VIN

200kHZ

START-UP

VREF

AND

OSCILLATOR

GOOD

CONTROL

2

VGD

GS

5V

6

CT

0.66A

MAX

CT

TIMER

RESET

5

RESET

Figure 1. Low power synchronous boost.

Notes: Switches are shown in the low state.

Pinout as shown is for the 8 pin D, N or J. See Package Descriptions for 8 pin SOIC.

5

1.25

REFERENCE

VGD

VOUT

2.5V

UDG-98068

Page 6

APPLICATION INFORMATION (continued)

VGD

RIPPLE

50mV/DIV

7V

OUTPUT

RIPPLE

20mV/DIV

3.3V

80mV P–P

TYPICAL

20mV P–P

TYPICAL

UCC19411/2/3

UCC29411/2/3

UCC39411/2/3

CURRENT

LIMIT

INDUCTOR

CURRENT

t1 t2 t3 t4 t5 t6 t7 t8 t9

Figure 2. Inductor current and output ripple waveforms.

10µF

3

VIN SW

80nF

2VGD

10µF

6SD/FB

CT

V

OUT

100kΩ

8

VOUT

L=10µHTO

100µH

1

4

HIGH LOAD CURRENTLIGHT LOAD CURRENT

1-2 CELL ALKALINE

1.0V TO 3.2V

100µF

R1

R2

UDG-98070

5

RESET

GND

7

Note: Shown pinout is for the TSSOP package. See Package Descriptions for DIP and SOIC pinouts.

Figure 3. Low power synchronous boost converter ADJ version –200mW.

6

UDG-98069

Page 7

APPLICATION INFORMATION (continued)

ductor current ripple. At time t8, the 3.3V output is

satisfied and the converter can service the gate drive

voltage, VGD, which occurs at time t9

Shutdown Control

Shutdown of the UCC39411/2/3 is controlled via inter

face with the SD/FB pin. Pulling the SD/FB pin low, for

all versions, causes the IC to go into shutdown. In the

UCC39412/3, the SD/FB pin is used solely as a shut

down function. Therefore, the SD/FB pin for the

UCC39412 and UCC39413 can be directly controlled us

ing conventional CMOS or TTL technology. For the

UCC39411, interface into the SD/FB is slightly more

complicated due to the added feedback function. When

feeding back the output voltage to the SD/FB pin on the

UCC39411, the IC requires a thevenin impedance of at

least 200kΩ (500kΩ for industrial/military applications) to

ground. Then, to accomplish shutdown of the IC, an

open drain device may be used.

Component Selection Inductor Selection

An inductor value of 22µH will work well in most applications, but values between 10µHto100µH are also ac-

ceptable. Lower value inductors typically offer lower ESR

and smaller physical size. Due to the nature of the

“bang-bang” controllers, larger inductor values will typically result in larger overall voltage ripple, because once

the output voltage level is satisfied the converter goes

discontinuous, resulting in the residual energy of the inductor causing overshoot.

It is recommended to keep the ESR of the inductor below

0.15Ω for 200mW applications. A Coilcraft DT3316P-223

surface mount inductor is one choice since it has a cur

rent rating of 1.5A and an ESR of 84mΩ.

Other choices for surface mount inductors are shown in

Table 1.

MANUFACTURER PART NUMBERS

Coilcraft DT Series

Cary, Illinois

Tel: 708-639-2361

Fax: 708-639-1469

Coiltronics CTX Series

Boca Raton, Florida

Tel: 407-241-7876

Table 1. Inductor Suppliers

UCC19411/2/3

UCC29411/2/3

UCC39411/2/3

Output Capacitor Selection

Once the inductor value is selected the capacitor value

will determine the ripple of the converter. The worst case

peak to peak ripple of a cycle is determined by two com

ponents, one is due to the charge storage characteristic,

and the other is the ESR of the capacitor. The worst

case ripple occurs when the inductor is operating at max

current and is expressed as follows:

-

∆

V

-

•

•

•

•

•

=

CV V

2

I

= the peak inductor current = 550mA

CL

∆V= Output ripple

= Output Voltage

V

O

V

= Input Voltage

I

= ESR of the output capacitor.

C

ESR

A Sanyo OS-CON series surface mount capacitor

(10SN100M) is one recommendation. This part has an

ESR rating of 90mΩ at 100µF .

Other potential capacitor sources are shown in Table 2.

MANUFACTURER PART NUMBER

Sanyo Video

Components

San Diego, California

Tel: 619-661-6322

Fax: 619-661-1055

-

AVX TPS Series

Sanford, Maine

Tel: 207-282-5111

Fax: 207-283-1941

Sprague 695D Series

Concord, New Hampshire

Tel: 603-224-1961

Table 2. Capacitor Suppliers

Input Capacitor Selection

Since the UCC39411 family does not require a large de

coupling capacitor on the input voltage to operate prop

erly, a 10µF cap is sufficient for most applications.

Optimum efficiency will occur when the capacitor value is

large enough to decouple the source impedance, this

usually occurs for capacitor values in excess of 100µF.

2

IL

()

CL

−

()

OI

IC

+

CL ESR

OS-CON Series

-

-

-

7

Page 8

TYPICAL CHARACTERISTICS

UCC19411/2/3

UCC29411/2/3

UCC39411/2/3

Figure 4. Percent Efficiency at VIN= 1.0, V

Figure 5. Percent Efficiency at VIN= 1.25, V

= 3.3V Figure 6. Percent Efficiency at VIN= 2.5, V

OUT

= 3.3V Figure 7. Percent Efficiency at VIN= 3.3, V

OUT

OUT

OUT

= 3.3V

= 3.3V

UNITRODE CORPORATION

7 CONTINENTAL BLVD. • MERRIMACK, NH 03054

TEL. (603) 424-2410 • FAX (603) 424-3460

8

Loading...

Loading...