Page 1

查询UCC1917供应商

Positive Floating Hot Swap Power Manager

FEATURES

Manages Hot Swap of 15V and

•

Above

Precision Fault Threshold

•

Programmable Average Power

•

Limiting

Programmable Linear Current

•

Control

Programmable Overcurrent Limit

•

Programmable Fault Time

•

Internal Charge Pump to Control

•

External NMOS Device

Fault Output and Catastrophic

•

Fault Indication

• Fault Mode Programmable to

Latch or Retry

• Shutdown Control

• Undervoltage Lockout

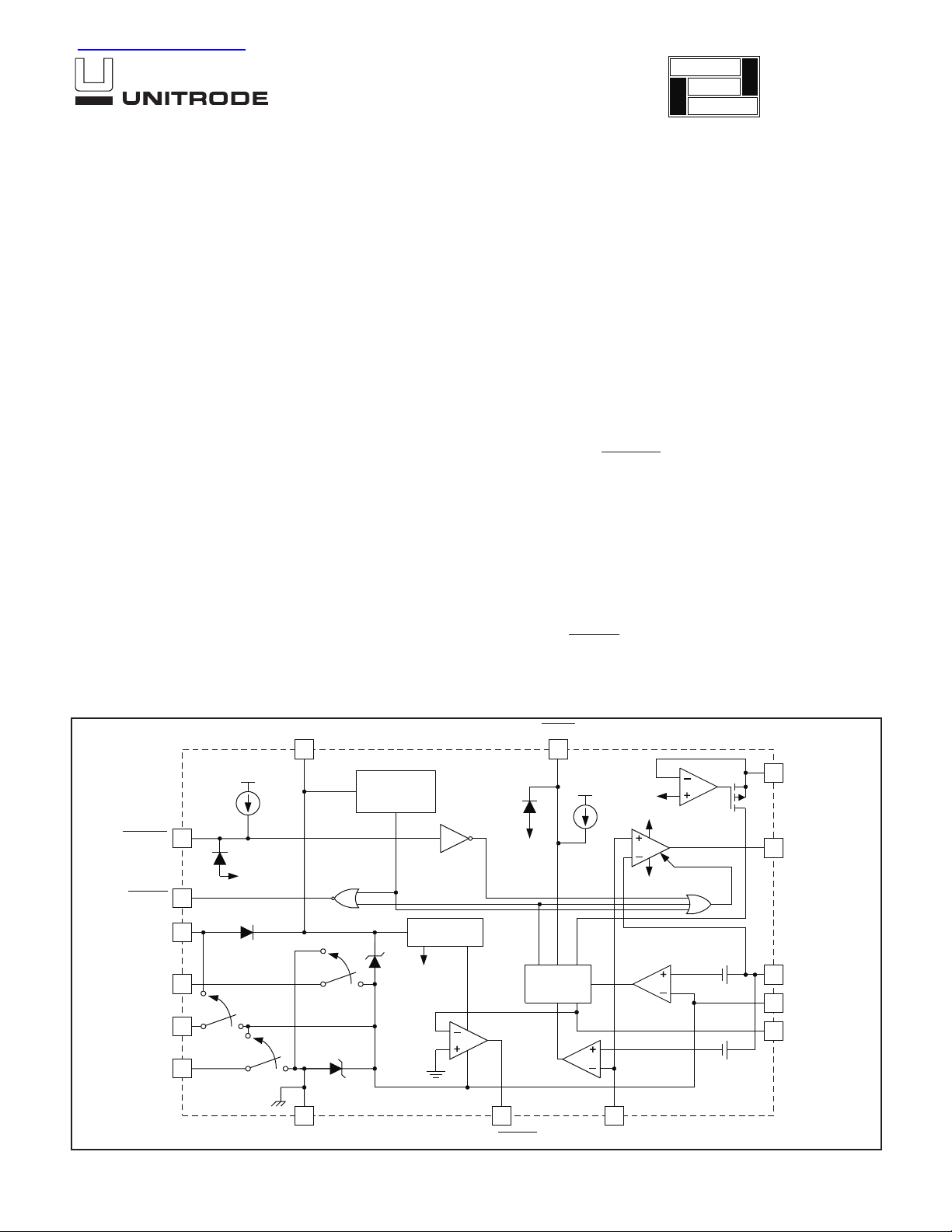

BLOCK DIAGRAM

V

DD

40µA

SHTDWN

12

DESCRIPTION

The UCC3917 family of positive floating hot swap managers provides complete

power management, hot swap, and fault handling capability. The voltage limita

tion of the application is only restricted by the external component voltage limi

tations. The IC provides its own supply voltage via a charge pump off of VOUT.

The onboard 10V shunt regulator protects the IC from excess voltage. The IC

also has catastrophic fault indication to alert the user that the ability to shut off

the output NMOS has been bypassed. All control and housekeeping functions

are integrated and externally programmable. These include the fault current

level, maximum output sourcing current, maximum fault time, soft start time,

and average NMOS power limiting.

The fault level across the current sense amplifier is fixed at 50mV to minimize

total drop out. Once 50mV is exceeded across the current sense resistor, the

fault timer will start. The maximum allowable sourcing current is programmed

with a voltage divider from the VREF/CATFLT

on the MAXI pin. The current level at which the output appears as a current

source is equal to V

trolled current startup can be programmed with a capacitor on MAXI.

When the output current is below the fault level, the output device is switched

on with full gate drive. When the output current exceeds the fault level, but is

less than maximum allowable sourcing level programmed by MAXI, the output

remains switched on, and the fault timer starts charging CT. Once CT charges

to 2.5V, the output device is turned off and attempts either a retry sometime

later or waits for the state on the LATCH

the output current reaches the maximum sourcing current level, the output device appears as a current source.

13 16

UVLO

>10V=ENABLE

< 6V=DISABLE

MAXI divided by the current sense resistor. If desired, a con

LATCHVDD

V

DD

VOUT

application

INFO

available

UCC1917

UCC2917

UCC3917

pin to generate a fixed voltage

pin to change if in latch mode. When

1

PLIM

5V

VDD

40µA

DISABLE

3

OUTPUT

-

-

-

VOUT

FLTOUT

C1P

C1N

C2P

C2N

11

8

7

6

5

SLUS203A - AUGUST 1999

5V

REFERENCE

LOGIC

SUPPLY

4V

9 15 14

VSS VREF/CATFLT MAXI

ON-TIME

DELAY

VOUT

OVER

CURRENT

COMPARATOR

OUTPUT

LOW

200mV

50mV

+

+

10

2

4

SENSE

VOUT

CT

UDG-99055

Page 2

ABSOLUTE MAXIMUM RATINGS

IDD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20mA

SHTDWN

LATCH

VREF Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –500µA

PLIM Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10mA

MAXI Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . VDD + 0.3V

Storage Temperature . . . . . . . . . . . . . . . . . . . –65°C to +150°C

Junction Temperature. . . . . . . . . . . . . . . . . . . –55°C to +150°C

Lead Temperature (Soldering, 10 sec.) . . . . . . . . . . . . . +300°C

Currents are positive into, negative out of the specified

terminal. Consult Packaging Section of Databook for thermal

limitations and considerations of package.

Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –500µA

Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –500µA

UCC1917

UCC2917

UCC3917

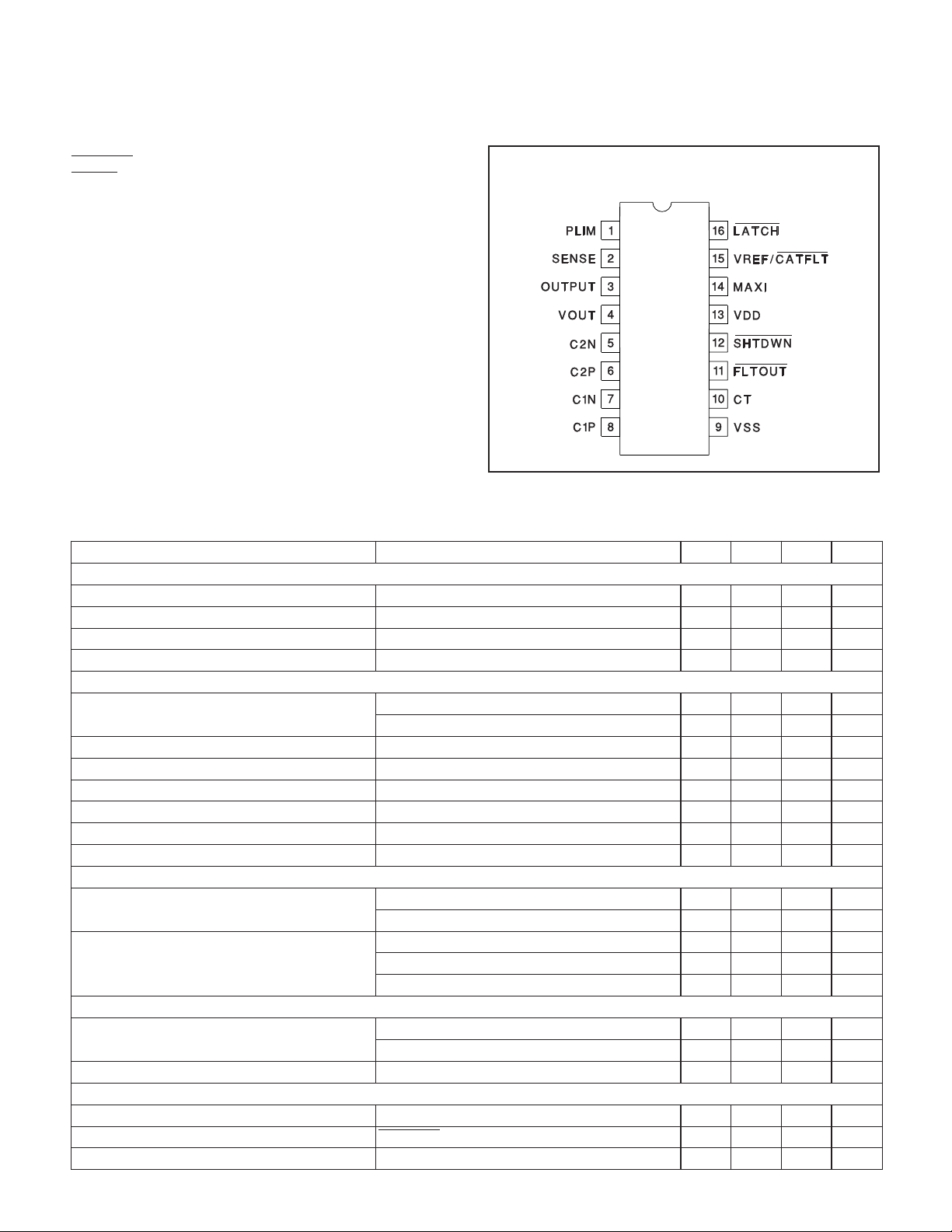

CONNECTION DIAGRAM

DIL-16, SOIC-16 (Top View)

J or N Package, D Package

ELECTRICAL CHARACTERISTICS:

UCC2917 and –55°C to 125°C for the UCC1917, C

Unless otherwise specified, TA= 0°C to 70°C for the UCC3917, –40°C to 85° for the

= 4.7nF. TA=TJ. All voltages are with respect to VOUT. Current is positive

T

into and negative out of the specified terminal.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

VDD Section

I

DD From VOUT (Note 1) 3.0 5 11 mA

UVLO Turn On Threshold 7.9 8.8 9.7 V

UVLO Off Voltage 5.5 6.5 7.5 V

VSS Regulator Voltage –6 –5 –4 V

Fault Timing Section

Overcurrent Threshold T

A = 25°C 47.5 50 53 mV

Over Operating Temperature 46 50 54 mV

Overcurrent Input Bias 50 500 nA

CT Charge Current V

CT = 1V –78 –50 –28 µA

CT Catastrophic Fault Threshold 3.4 4.5 V

CT Fault Threshold 2.25 2.5 2.75 V

CT Reset Threshold 0.32 0.5 0.62 V

Output Duty Cycle Fault Condition 1.7 2.7 3.7 %

Output Section

Output High Voltage I

Output Low Voltage I

OUT = 0 6 8 10 V

OUT = –500µA 579V

I

OUT = 0 0 0.05 V

OUT = 500µA 0.1 0.5 V

I

OUT = 1mA 0.5 0.9 V

I

Linear Current Section

Sense Control Votlage MAXI = 100mV 85 100 115 mV

MAXI = 400mV 370 400 430 mV

Input Bias MAXI = 200mV 50 500 nA

SHUTDOWN Section

Shutdown Threshold 2.0 2.4 2.8 V

Input Current SHTDWN

= 0V 24 40 60 µA

Shutdown Delay 100 500 ns

2

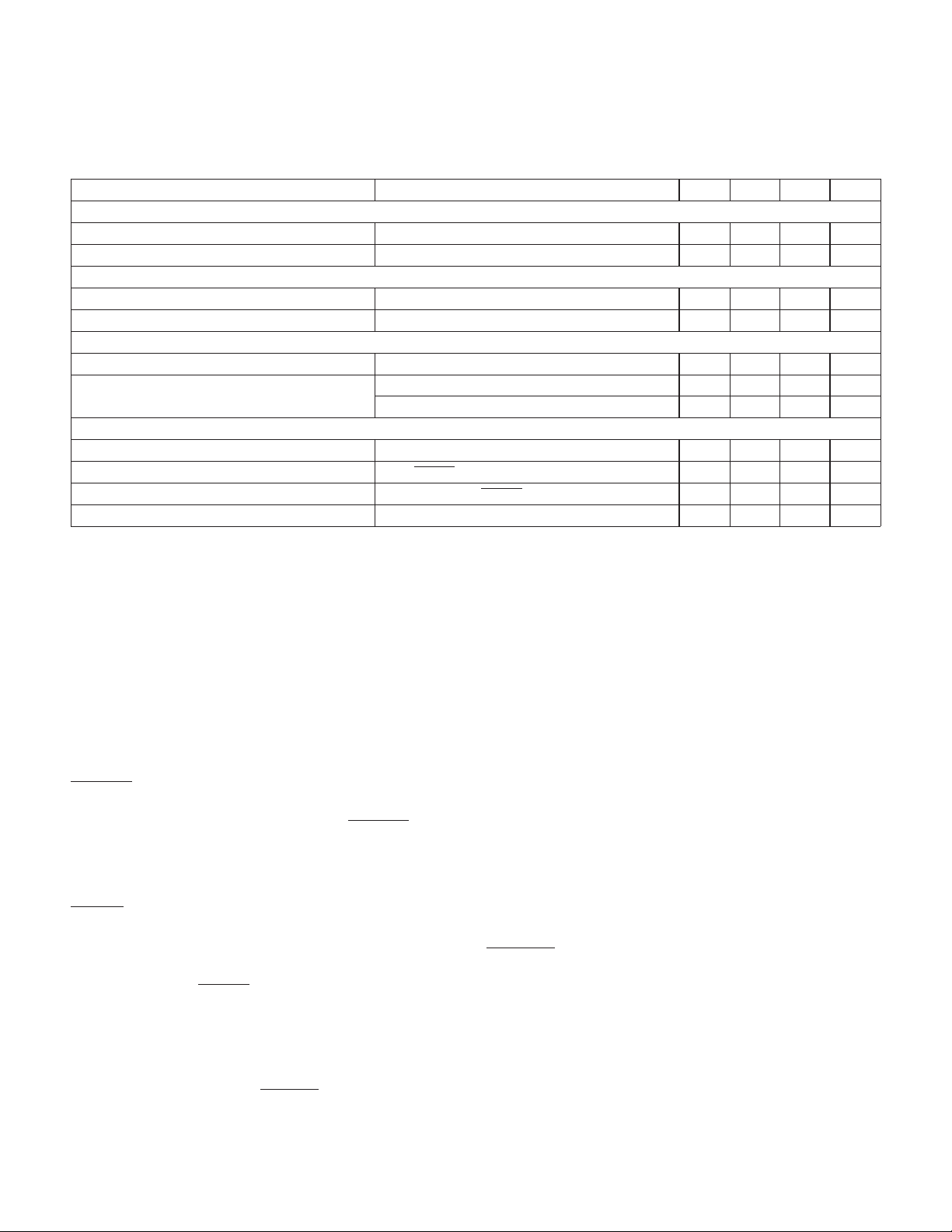

Page 3

UCC1917

UCC2917

UCC3917

ELECTRICAL CHARACTERISTICS:

the UCC2917 and –55°C to 125°C for the UCC1917, C

positive into and negative out of the specified terminal.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

LATCH Section

Latch Threshold 1.7 2 2.3 V

Input Current LATCH = 0V 24 40 60 µA

Fault Out Section

Fault Output High 6 8 10 V

Fault Output Low 0.01 0.05 V

Power Limiting Section

SENSE Regulator Voltage I

V

Duty Cycle Control I

VREF/CATFLT Section

V

REF Regulator Voltage 4.5 5 5.5 V

Fault Output Low I

Output Sink Current V

Overload Comparator Threshold Relative to MAXI 110 200 290 mV

Note 1: Set by user with RSS.

Unless otherwise specified, TA= 0°C to 70°C for the UCC3917, –40°C to 85° for

= 4.7nF. TA=TJ. All voltages are with respect to VOUT. Current is

T

= 64µA 4.5 5 5.5 V

PLIMIT

= 64µA 0.6 1.2 1.7 %

PLIMIT

= 1mA 0.045 0.1 0.2 %

I

PLIMIT

VREF/CATFLT

=

CT

= 5mA 0.22 0.50 V

5V, V

VREF/CATFLT

= 5V 15 40 70 mA

PIN DESCRIPTIONS

C1N: Negative side of the upper charge pump capacitor.

C1P: Positive side of the upper charge pump capacitor.

C2N: Negative side of the lower charge pump capacitor.

C2P: Positive side of lower charge pump capacitor.

CT: A capacitor is connected to this pin to set the fault

time. The fault time must be more than the time to

charge the external load capacitance (see Application In

formation).

FLTOUT

: This pin provides fault output indication. Inter

face to this pin is usually performed through level shift

transistors. Under a non-fault condition, FLTOUT

will pull

to a high state. When a fault is detected by the fault timer

or the under voltage lockout, this pin will drive to a low

state, indicating the output NMOS is in the off state.

LATCH

: Pulling this pin low causes a fault to latch until

this pin is brought high or a power on reset is attempted.

However, pulling this pin high before the reset time is

reached will not clear the fault until the reset time is

reached. Keeping LATCH

high will result in normal oper

ation of the fault timer. Users should note there will be an

RC delay dependent upon the external capacitor at this

pin.

MAXI: This pin programs the maximum allowable sour

cing current. Since VREF/CATFLT

is a regulated volt

age, a voltage divider can be derived to generate the

program level for MAXI. The current level at which the

output appears as a current source is equal to the volt

age on MAXI divided by the current sense resistor. If desired, a controlled current start up can be programmed

with a capacitor on MAXI (to VOUT), and a programmed

start delay can be achieved by driving the shutdown with

an open collector/drain device into an RC network.

OUTPUT: Gate drive to the NMOS pass element.

PLIM: This feature ensures that the average external

-

NMOS power dissipation is controlled. A resistor is con

nected from this pin to the drain of the external NMOS

pass element. When the voltage across the NMOS ex

ceeds 5V, current will flow into PLIM which adds to the

fault timer charge current, reducing the duty cycle from

the 3% level.

SENSE: Input voltage from the current sense resistor.

When there is greater than 50mV across this pin with re

spect to VOUT, a fault is sensed, and CT starts to

charge.

SHTDWN

: This pin provides shutdown control. Interface

to this pin is usually performed through level shift transis

-

tors. When shutdown is driven low, the output disables

the NMOS pass device.

VDD: Power to the I.C. Is supplied by an external current

limiting resistor on initial power-up or if the load is

-

shorted. As the load voltages rises (VOUT), a small

-

amount of power is drawn from VOUT by an internal

charge pump. The charge pump’s input voltage is regu

lated by an on-chip 5V zener. Power to VDD is supplied

-

-

-

-

-

-

3

Page 4

PIN DESCRIPTIONS (cont.)

by the charge pump under normal operation (i.e., exter

nal FET is on).

VOUT: Ground reference for the IC.

VREF/CATFLT

erence for the programming of MAXI. Secondarily, it pro

vides catastrophic fault indication. In a catastrophic fault,

when the IC unsuccessfully attempts to shutdown the

: This pin primarily provides an output ref

UCC1917

UCC2917

UCC3917

NMOS pass device, this pin pulls to a low state when C

charges about the catastrophic fault thershold. A

possible application for this pin is to trigger the shutdown

of an auxilliaty FET in series with the main FET for

-

redundency.

VSS: Negative reference out of the chip. Normally cur

rent fed via a resistor to ground.

T

-

Figure 1. Fault timing circuitry for the UCC3917, including power limit and overload.

APPLICATION INFORMATION

Fault Timing

Fig. 1 shows the detailed circuitry for the fault timing func

tion of the UCC3917. For simplicity, we first consider a

typical fault mode where the overload comparator and the

current source I3 do not come into play. A typical fault oc

curs once the voltage across the current sense resistor,

S, exceeds 50mV. This causes the over current com

R

parator to trip and the timing capacitor to charge with cur

rent source I1 plus the current from the power limiting

amplifier, or PLIM amplifier. The PLIM amplifier is de

signed to only source current into the CT pin once the

voltage across the output FET exceeds 5V. The current

PL is related to the voltage across the FET with the fol

I

lowing expression:

(V –VOUT)–5V

I=

PL

IN

R

PL

Note that under normal fault conditions where the output

current is just above the fault level, VOUT ≅ V

and the C

charging current is just I1.

T

During a fault, CT will charge at a rate determined by

-

the internal charging current and the external timing ca

pacitor, CT. Once CT charges to 2.5V, the fault com

-

parator switches and sets the fault latch. Setting the

-

fault latch causes both the output to switch off and the

charging switch to open. CT must now discharge with

-

current source I2 until 0.5V is reached. Once the voltage

at CT reaches 0.5V, the fault latch resets (assuming

LATCH

-

until the LATCH

is high, otherwise the fault latch will not reset

pin is brought high or a power-on reset

occurs) which re-enables the output and allows the fault

circuitry to regain control of the charging switch. If a fault

is still present, the overcurrent comparator will close the

charging switch causing the cycle to repeat. Under a

constant fault the duty cycle is given by:

4

UDG-96265-1

IN,IPL

=0,

-

-

Page 5

APPLICATION INFORMATION (cont.)

15

I

Duty Cycle =

where I

is 0µA under normal operations (see Fig. 2).

PL

2

IIAIA

1

PL PL

However, under large transients, average power dissipa

tion can be limited using the PLIM pin. A proof follows,

average dissipation in the pass element is given by:

I

OUT

I

MAX

I

FAULT

. µ

≅

50+

+

µ

-

P =(V – VOUT)•I •Duty Cycle

FET AVG IN MAX

µ

=(V – VOUT)•I •

IN MAX

Where (V

IN – VOUT) >> 5V,

V–VOUT

PL

IN

≅

R

I

PL

1.5 A

I+50A

PL

µ

UCC1917

UCC2917

UCC3917

I

O(nom)

V

CT

2.5V

0.5V

0V

V

OUT

V

IN

0V

t

t1t

0

t

2

3

t

4

t0: Safe condition - output current is nominal, output

voltage is at the positive rail, V

.

IN

t1: Fault control reached - output current rises above

the programmed fault value, CT begins to charge with ≅

50µA.

t2: Maximum current reached - output current reaches

the programmed maximum level and becomes a con

stant current with value I

MAX

.

t3: Fault occurs - CT has charged to 2.5V, fault output

goes low, the FET turns off allowing no output current to

flow, VOUT discharges to ground.

t4: Retry - CT has discharged to 0.5V, but fault current

is still exceeded, CT begins charging again, FET is on,

VOUT rises to V

.

IN

OUTPUT

CURRENT

t

CTVOLTAGE

(WITH RESPECT TO V

t

OUTPUT VOLTAGE

(WITH RESPECT TO GND)

t

t

5

t6t7t

t9t

8

10

OUT

)

t5 = t3: Illustrates 3% duty cycle.

t6 = t4:

t7: Output short circuit - if VOUT is short circuited to

ground, CT charges at a higher rate depending upon

the values for V

and RPL.

IN

t8: Fault occurs - output is still short circuited, but the

occurrence of a fault turns the FET off so no current is

conducted.

t9 = t4: Output short circuit released, still in fault

mode.

t10 = t0: Fault released, safe condition - return to nor

mal operation of the circuit breaker.

Note that t6 – t5 ≅ 36 • (t5 – t4).

UDG-99147

-

Figure 2. Nominal timing diagram.

5

Page 6

APPLICATION INFORMATION (cont.)

and where IPL>> 50µA, the duty cycle can be approxi

mated as:

1.5 A • R

µ

PL

VVOUT

−

IN

Therefore the average power dissipation in the MOSFET

can be approximated by:

P=(V-VOUT)•I•

FET AVG IN MAX

Notice that since (V

dissipation is limited in the NMOS pass element (see Fig.

3). Also, a value for R

this approximation.

R=

PL

.

=I •1.5 A •R

MAX PL

P

FET AVG

I • I.5 A

MAX

µ

– VOUT) cancels, average power

IN

PL

µ

µ

1.5 A • R

V-VOUT

IN

PL

can be roughly determined from

UCC1917

UCC2917

UCC3917

-

IImVR

OVERLOAD MAX S

Once the overcurrent comparator trips the UCC3917 will

enter programmed fault mode (hiccup or latched). It

should be noted that on subsequent retries during Hic

cup mode or if a short should occur when the UCC3917

is actively limiting the current, the output current will not

exceed I

not respond during a fault the UCC3917 will set the

VREF/CATFLT

Selecting the Minimum Timing Capacitance

To ensure that the IC will startup correctly the designer

must ensure that the fault time programmed by CT ex

ceeds the startup time of the load. The startup time

(T

) is a function of several components; load resis

START

tance and load capacitance, soft start components R1,

R2 and C

mined by R

For a parallel capacitor-constant current load: (1)

=+200 /

. In the event that the external FET does

MAX

pin low to indicate a catastrophic failure.

, the power limit current contribution deter

SS

, and CIN.

PL

-

-

-

-

RPL = INF

IMAX = 4A

RPL = 10M

PAVG

RPL = 5M

RPL = 2M

RPL = 1M

RPL = 200k

RPL =500k

Figure 3. Plot of average power vs. FET voltage

for increasing values of R

PL

.

Overload Comparator

The overload comparator provides protection against a

shorted load during normal operation when the external

N-channel FET is fully enhanced. Once the FET is fully

enhanced the linear current amplifier essentially saturates

and the system is in effect operating open loop. Once the

FET is fully enhanced the linear current amplifier requires

a finite amount of time to respond to a shorted output

possibly destroying the external FET. The overload com

parator is provided to quickly shutdown the external

MOSFET in the case of a shorted output (if the FET is

fully enhanced). During an output short CT is charged by

I3 at ~ 1mA. The current threshold for the overload com

parator is a function of I

and a fixed offset and is de

MAX

fined as:

T

START

CVIN

=

II

•

LOAD

–

MAX LOAD

For a parallel R-C load :

T

––

=

START

RC n

••

LOAD LOAD

l 1

V

IN

IR

•

MAX LOAD

If the power limit function is not be used then CT(min)

can be easily found:

IT

•

CT

(min) =

where dV

CH START

dV

CT

is the hysteresis on the fault detection cir

CT

cuitry. During operation in the latched fault mode config

uration dVCT = 2.5V. When the UCC3917 is configured

for the hiccup or retry mode of fault operation

=2.0V.

dV

CT

If the power limit function is used the CT charging cur

rent becomes a function of I

CH+IPL

. And CT(min) is

found from:

-

-

-

6

(2)

(3)

-

-

-

Page 7

APPLICATION INFORMATION (cont.)

CT

(min)

≅

–

VIN I R e

I

CH

––

+

••

MAX LOAD

1

R

PL

t

•

RC

LOAD LOAD

dt

•

dV

CT

IPL(PK)

I

VIN-V

PL

T

Figure 4. Relationship between IPL,V

Since I

is a function of the output voltage, V

PL

START

PL

and T

OUT

OUT

varies over time, equation 4 must be integrated to solve

for CT(min). However equation 4 can be easily approxi

mated if the output voltage slews. If the output voltage

slews linearly then the CT charge current contribution

from the power limit circuitry is shown to be at a peak

when V

is the power limit voltage threshold. IPLis shown in

V

PL

= 0V and at 0A when V

OUT

=VIN-VPL, where

OUT

Fig. 4 below.

Where I

I

is defined as:

PL

VIN V V

––

()

≡

PL

OUT PL

R

PL

V

OUT

START

, which

(4)

.

(5)

UCC1917

UCC2917

UCC3917

Please note that the actual on-time in hiccup mode

threshold current 60µA. For example, if the minimum

when operating into a short is defined by:

CT dV

•

CT

Ton

()=

IIpk

+

CH PL

where dV

Ipk

PL

~2.0V and

CT

=

()

VIN

R

PL

A

Selecting Other External Components

Other external components are necessary for correct

operation of the IC. Referring to the application diagram

at the back of the data sheet, resistors R

R1, R2 and R3 are required and follow certain equations

with a brief description following where applicable:

R=

SENSE

R=

SS

50mV

I

FAULT

V–5V

IN

5mA

GND)

R3 =

IN

5mA

(Used in series with a diode to

–

V10

connect VIN to VDD)

(R1+ R2) > 20kΩ

Lastly, the external capacitors used for the charge pump

are required and need to equal 0.1µF, i.e. C

C1 = C2 = 0.1µF.

LEVEL Shift Circuitry (Optional)

The UCC3917 can be used in many systems without

logic command or diagnostic feedback. If a system re

quires control from low-voltage logic or feedback to

low-voltage logic, then level shifting circuits are required.

The level shift circuits in Fig. 5A and Fig. 5B show ways

to interface to LATCH

circuits in Fig. 6 show ways of interfacing from FLTOUT

to low-voltage logic.

seconds

()

SENSE,RSS

(Sense Resistor)

(Connected between VSS and

(Current limit out of VREF)

IN

and SHTDWN and the level shift

(8)

(9)

,

=CH=

-

The average I

current for the interval (0, T

PL

Fig. 4 is defined as:

2

PL

I AVG

()

PL

VIN V

–

()

≡

RVIN

2

••

PL

Equation 4 can now be simplified to:

I I AVG

+

CT

()

min ≅

CH PL

()

dV

CT

T

•

START

START

) from

(6)

(7)

In Fig. 5A, resistor R limits the level shift current. Select

R so that the current in the level shift circuit never ex

ceeds the absolute maximum current in the logic com

mand inputs, 500µA. For example, if the maximum

supply voltage for the system is 75V, select

V

75

R

>=

500

A

150µΩ

.

k

R must also be chosen so that the minimum current in

the level shift circuit exceeds the worst case logic

7

-

-

Page 8

T

APPLICATION INFORMATION (cont.)

UCC1917

UCC2917

UCC3917

R

SHTDWN

OR

LATCH

(A)

SHTDWN

OR

LATCH

R

(B)

C

VOUT

C

VOUT

Figure 5. Potential level shift circuitry

to interface to LATCH

V

13

and SHTDWN on the

DD

TO

UCC3917

TO

UCC3917

UDG-99148

supply voltage for the system is 25V, choose

V

25

R

>=

60

A

416µΩ

.

k

The capacitor C shown on the output of this circuit is

useful to filter the level shift output and prevent false

triggering from noise. The minimum recommended ca

pacitor value is 100pF. Larger capacitors will result in

better noise immunity and longer delay to logic com

mand.

The circuit in Fig. 5B accomplished the same function as

the circuit in Fig. 5A, using different components. In this

circuit, select resistor R so that the transistor draws

enough current to exceed the 60µA logic threshold but

doesn’t exceed the 500µA maximum logic input current.

For example, if the input circuit is 5V logic, then

V

DD

13

V

DD

13

-

-

R1

LOCAL

FAULT

LOCAL

VDD

R2

LOCAL

FLTOUT11

LOCAL

FAULT

(A) (B) (C)

VDD

R1

R2

FLTOUT

11 11

LOCAL

FAULT

Figure 6. Potential level shift circuitry to interface to FLTOUT on the UCC3917.

LOCAL

VDD

FLTOU

R1

R2

8

Page 9

APPLICATION INFORMATION (cont.)

D1

UCC1917

UCC2917

UCC3917

V

IN

R3

SHTDWN

FLTOUT

C1P

C1

C1N

C2P

C2

C2N

VOUT

15

LATCH

V

DD

ON-TIME

DELAY

R1 R2

5V

VDD

40µA

VOUT

CURRENT

COMPARATOR

DISABLE

OUTPUT

OVER

LOW

50mV

200mV

R

PLIM

1

OUTPUT

3

+

+

10

2

4

SENSE

VOUT

CT

PL

C

IN

R

SENSE

C

T

C

H

C

SS

VDD

13 16

V

DD

40µA

12

VOUT

11

8

7

6

5

9 14

VSS MAXI

R

SS

UVLO

>10V=ENABLE

< 6V=DISABLE

10V SHUNT

REGULATOR

5V

REFERENCE

LOGIC

SUPPLY

4V

VREF/CATFLT

Figure 7. Positive floating hot swap power manager UCC1917, UCC2917 and UCC3917.

SAFETY RECOMMENDATIONS

Although the UCC3917 is designed to provide system

protection for all fault conditions, all integrated circuits can

ultimately fail short. For this reason, if the UCC3917 is in

tended for use in safety critical applications where UL or

some other safety rating is required, a redundant safety

UNITRODE CORPORATION

7 CONTINENTAL BLVD. • MERRIMACK, NH 03054

TEL. (603) 424-2410 FAX (603) 424-3460

device such as a fuse should be placed in series with

the power device. The UCC3917 will prevent the fuse

-

from blowing for virtually all fault conditions, increasing

system reliability and reducing maintenance cost, in ad

dition to providing the hot swap benefits of the device.

9

OUTPUT

UDG-99056

-

Loading...

Loading...