Page 1

查询UC1875DWP供应商

Phase Shift Resonant Controller

FEATURES

Zero to 100% Duty Cycle Control

•

Programmable Output Turn-On Delay

•

Compatible with Voltage or Current

•

Mode Topologies

Practical Operation at Switching

•

Frequencies to 1MHz

Four 2A Totem Pole Outputs

•

10MHz Error Amplifier

•

Undervoltage Lockout

•

Low Startup Current –150µA

•

Outputs Active Low During UVLO

•

Soft-Start Control

•

• Latched Over-Current Comparator

With Full Cycle Restart

• Trimmed Reference

BLOCK DIAGRAM

DESCRIPTION

The UC1875 family of integrated circuits implements control of a bridge

power stage by phase-shifting the switching of one half-bridge with respect

to the other, allowing constant frequency pulse-width modulation in combi

nation with resonant, zero-voltage switching for high efficiency performance

at high frequencies. This family of circuits may be configured to provide

control in either voltage or current mode operation, with a separate

over-current shutdown for fast fault protection.

A programmable time delay is provided to insert a dead-time at the turn-on

of each output stage. This delay, providing time to allow the resonant

switching action, is independently controllable for each output pair (A-B,

C-D).

With the oscillator capable of operation at frequencies in excess of 2MHz,

overall switching frequencies to 1MHz are practical. In addition to the stan

dard free running mode, with the CLOCKSYNC pin, the user may configure

these devices to accept an external clock synchronization signal, or may

lock together up to 5 units with the operational frequency determined by the

fastest device.

Protective features include an undervoltage lockout which maintains all outputs in an active-low state until the supply reaches a 10.75V threshold.

1.5V hysteresis is built in for reliable, boot-strapped chip supply.

Over-current protection is provided, and will latch the outputs in the OFF

state within 70nsec of a fault. The current-fault circuitry implements

full-cycle restart operation.

application

INFO

available

UC1875/6/7/8

UC2875/6/7/8

UC3875/6/7/8

-

-

07/99

UDG-95073

Page 2

DESCRIPTION (cont.)

Additional features include an error amplifier with band

width in excess of 7MHz, a 5V reference, provisions for

soft-starting, and flexible ramp generation and slope com

pensation circuitry.

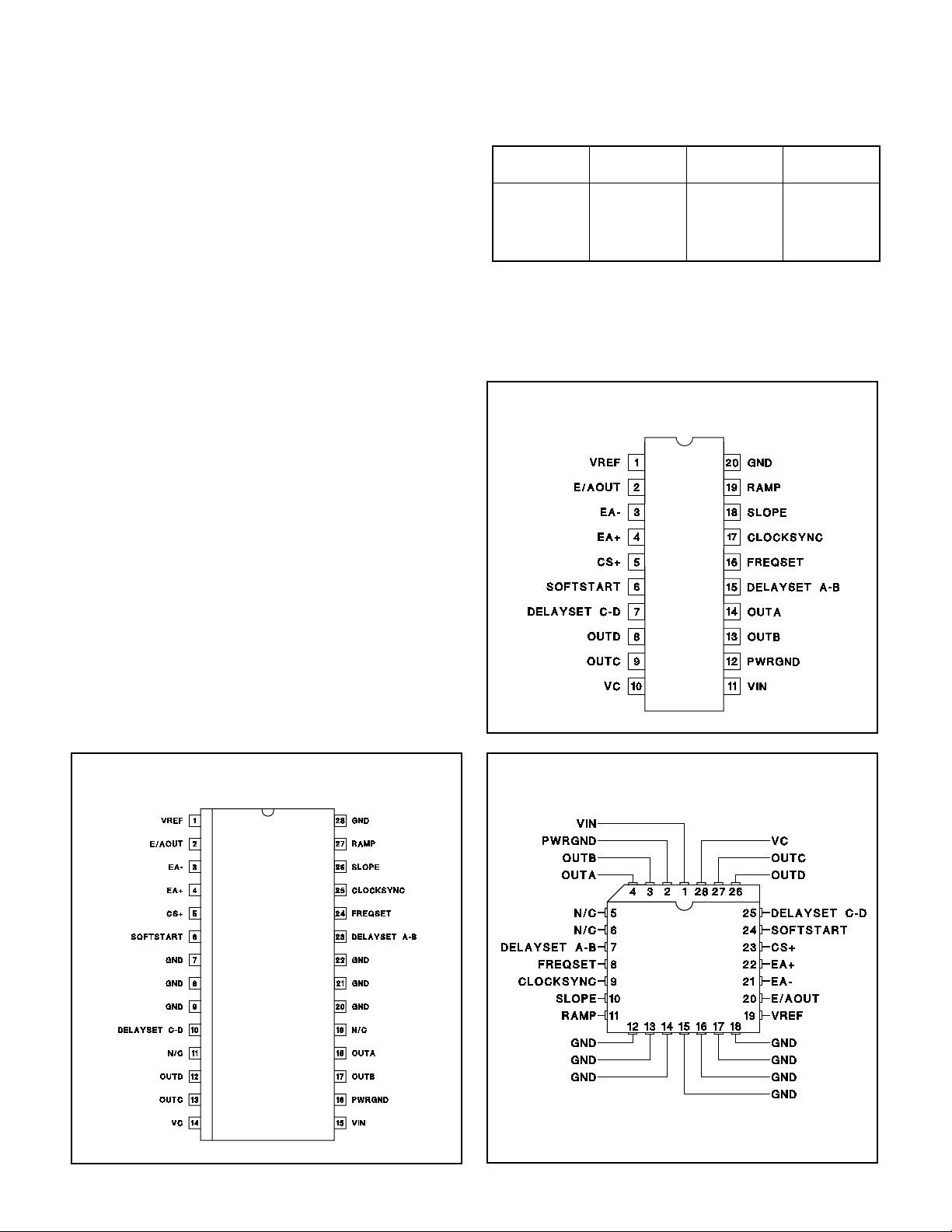

These devices are available in 20-pin DIP, 28-pin

“bat-wing” SOIC and 28 lead power PLCC plastic pack

ages for operation over both 0°C to 70°C and –25°C to

+85°C temperature ranges; and in hermetically sealed

cerdip, and surface mount packages for –55°C to +125°C

operation.

UC1875/6/7/8

UC2875/6/7/8

UC3875/6/7/8

-

-

-

Device UVLO

Turn-On

UC1875 10.75 9.25V Yes

UC1876 15.25V 9.25V Yes

UC1877 10.75V 9.25V No

UC1878 15.25V 9.25V No

UVLO

Turn-Off

Delay

Set

ABSOLUTE MAXIMUM RATINGS

Supply Voltage (VC, VIN) . . . . . . . . . . . . . . . . . . . . . . . . . . 20V

Output Current, Source or Sink

DC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.5A

Pulse (0.5µs). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3A

Analog I/0s

(Pins 1, 2, 3, 4, 5, 6, 7, 15, 16, 17, 18, 19) . . . . –0.3 to 5.3V

Storage Temperature Range . . . . . . . . . . . . . –65°C to +150°C

Junction Temperature. . . . . . . . . . . . . . . . . . . –55°C to +150°C

Lead Temperature (Soldering, 10 sec.) . . . . . . . . . . . . +300°C

Note: Pin references are to 20 pin packages.All voltages are

with respect to ground.Currents are positive into, negative out of, device terminals. Consult Unitrode

databook for information regarding thermal specifications and limitations of packages.

SOIC-28, (Top View)

DWP Package

CONNECTION DIAGRAMS

Dil-20 (Top View)

J or N Package

PLCC-28 (Top View)

QP Package

2

Page 3

UC1875/6/7/8

UC2875/6/7/8

UC3875/6/7/8

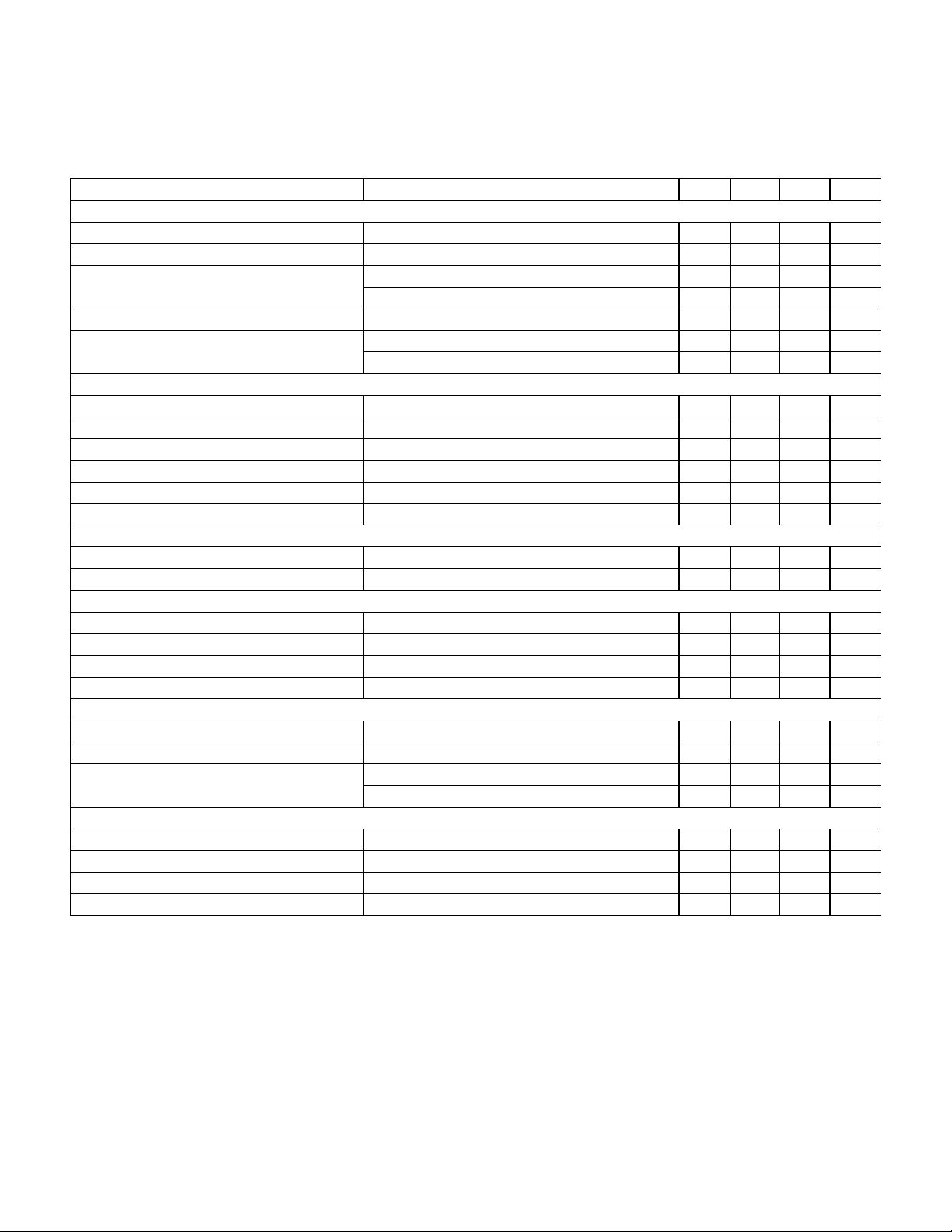

ELECTRICAL CHARACTERISTICS:

85°C for the UC2875/6/7/8 and 0°C < T

R

SLOPE

= 12kΩ, C

RAMP

= 200pF, C

DELAYSET A-B=CDELAYSET C-D

Unless otherwise stated, –55°C < TA< 125°C for the UC1875/6/7/8, –25°C < TA<

< 70°C for the UC3875/6/7/8, VC = VIN = 12V, R

A

= 0.01µF, I

DELAYSET A-B=IDELAYSET C-D

FREQSET

= 12kΩ,C

FREQSET

= –500µA, TA=TJ.

= 330pF,

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Undervoltage Lockout

Start Threshold UC1875/UC1877 10.75 11.75 V

UC1876/UC1878 15.25 V

UVLO Hysteresis UC1875/UC1877 0.5 1.25 2.0 V

UC1876/UC1878 6.0 V

Supply Current

I

Startup VIN = 8V, VC = 20V, R

IN

Startup VIN = 8V, VC = 20V, R

I

C

I

IN

I

C

SLOPE

SLOPE

open, I

open, I

= 0 150 600 µA

DELAY

= 0 10 100 µA

DELAY

30 40 mA

15 30 mA

Voltage Reference

Output Voltage T

= +25°C 4.92 5 5.08 V

J

Line Regulation 11 < VIN < 20V 1 10 mV

Load Regulation I

= –10mA 5 20 mV

VREF

Total Variation Line, Load, Temperature 4.9 5.1 V

Noise Voltage 10Hz to 10kHz 50 µVrms

Long Term Stability T

Short Circuit Current VREF = 0V, T

= 125°C, 1000 hours 2.5 mV

J

= 25°C 60 mA

J

Error Amplifier

Offset Voltage 515mV

Input Bias Current 0.6 3 µA

AVOL 1V < V

CMRR 1.5V < V

< 4V 60 90 dB

E/AOUT

< 5.5V 75 95 dB

CM

PSRR 11V < VIN < 20V 85 100 dB

Output Sink Current V

Output Source Current V

Output Voltage High I

Output Voltage Low I

E/AOUT

E/AOUT

= 1V 1 2.5 mA

E/AOUT

= 4V –1.3 –0.5 mA

E/AOUT

= –0.5mA 4 4.7 5 V

= 1mA 0 0.5 1 V

Unity Gain BW 7 11 MHz

Slew Rate 611 V/µsec

3

Page 4

UC1875/6/7/8

UC2875/6/7/8

UC3875/6/7/8

ELECTRICAL CHARACTERISTICS:

85°C for the UC2875/6/7/8 and 0°C < T

R

SLOPE

= 12kΩ, C

RAMP

= 200pF, C

DELAYSET A-B=CDELAYSET C-D

Unless otherwise stated, –55°C < TA< 125°C for the UC1875/6/7/8, –25°C < TA<

< 70°C for the UC3875/6/7/8, VC = VIN = 12V, R

A

= 0.01µF, I

DELAYSET A-B=IDELAYSET C-D

FREQSET

= 12kΩ,C

FREQSET

= –500µA, TA=TJ.

= 330pF,

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

PWM Comparator

Ramp Offset Voltage T

= 25°C (Note 3) 1.3 V

J

Zero Phase Shift Voltage (Note 4) 0.55 0.9 V

PWM Phase Shift (Note1) V

V

Output Skew (Note 1) V

> (Ramp Peak + Ramp Offset) 98 99.5 102 %

E/AOUT

< Zero Phase Shift Voltage 0 0.5 2 %

E/AOUT

< 1V 5 ±20 nsec

E/AOUT

Ramp to Output Delay UC3875/6/7/8 (Note 6) 65 100 nsec

UC1875/6/7/8, UC2875/6/7/8 (Note 6) 65 125 nsec

Oscillator

Initial Accuracy T

= 25°C 0.85 1 1.15 MHz

J

Voltage Stability 11V < VIN < 20V 0.2 2 %

Total Variation Line, Temperature 0.80 1.20 MHz

Sync Pin Threshold T

Clock Out Peak T

Clock Out Low T

= 25°C 3.8 V

J

= 25°C 4.3 V

J

= 25°C 3.3 V

J

Oscillator (cont.)

Clock Out Pulse Width R

Maximum Frequency R

CLOCKSYNC

FREQSET

= 3.9kΩ 30 100 nsec

= 5kΩ 2 MHz

Ramp Generator/Slope Compensation

Ramp Current, Minimum I

Ramp Current, Maximum I

SLOPE

SLOPE

= 10µA, V

= 1mA, V

FREQSET

FREQSET

= VREF –11 –14 µA

= VREF –0.8 –0.95 mA

Ramp Valley 0V

Ramp Peak - Clamping Level R

FREQSET

= 100kΩ 3.8 4.1 V

Current Limit

Input Bias V

+ = 3V 2 5 µA

CS

Threshold Voltage 2.4 2.5 2.6 V

Delay to Output UC3875/6/7/8 85 125 nsec

UC1875/6/7/8, UC2875/6/7/8 85 150 nsec

Soft-Start/Reset Delay

Charge Current V

Discharge Current V

SOFTSTART

SOFTSTART

= 0.5V –20 –9 –3 µA

= 1V 120 230 µA

Restart Threshold 4.3 4.7 V

Discharge Level 300 mV

4

Page 5

UC1875/6/7/8

UC2875/6/7/8

UC3875/6/7/8

ELECTRICAL CHARACTERISTICS:

85°C for the UC2875/6/7/8 and 0°C < T

R

SLOPE

= 12kΩ, C

RAMP

= 200pF, C

DELAYSET A-B=CDELAYSET C-D

Unless otherwise stated, –55°C < TA< 125°C for the UC1875/6/7/8, –25°C < TA<

< 70°C for the UC3875/6/7/8, VC = VIN = 12V, R

A

= 0.01µF, I

DELAYSET A-B=IDELAYSET C-D

FREQSET

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Output Drivers

Output Low Level I

Output High Level I

= 50mA 0.2 0.4 V

OUT

= 500mA 1.2 2.6 V

I

OUT

= –50mA 1.5 2.5 V

OUT

= –500mA 1.7 2.6 V

I

OUT

Delay Set (UC1875 and UC1876 only)

Delay Set Voltage I

Delay Time I

= –500µA 2.3 2.4 2.6 V

DELAY

= –250µA (Note 5) (UC3875/6/7/8,

DELAY

UC2875/6/7/8)

= –250µA (Note 5) (UC1875/6/7/8) 150 250 600 nsec

I

DELAY

Note 1: Phase shift percentage (0% = 0°, 100% = 180°) is defined as

fined in Figure 1. At 0% phase shift,

is the output skew.

θ=

200

T

, where is the phase shift, and and T are de

Φ%

Note 2: Delay time is defined as delay = T (1/2–(duty cycle)), where T is defined in Fig. 1.

Note 3: Ramp offset voltage has a temperature coefficient of about –4mV/°C.

Note 4: Zero phase shift voltage has a temperature coefficient of about –2mV/°C.

Note 5: Delay time can be programmed via resistors from the delay set pins to ground.Delay time

I

DELAY

=

R

DELAY

The recommended range for I

DELAY

is 25 A I

DELAY

1mA

Delay set voltage

Note 6: Ramp delay to output time is defined in Fig.2.

= 12kΩ,C

FREQSET

= 330pF,

= –500µA, TA=TJ.

150 250 400 nsec

12.–

•62 5 10

≅

I

DELAY

sec. Where

-

Duty Cycle = t/T

Period = T

T

(A to C) = T

DHL

(B to D) = Φ

DHL

Phase Shift, Output Skew & Delay Time Definitions

Figure 1

UDG-95074

UDG-95075

Figure 2

5

Page 6

PIN FUNCTIONAL DESCRIPTIONS

CLOCKSYNC (bi-directional clock and synchroniza

tion pin): Used as an output, this pin provides a clock

signal. As an input, this pin provides a synchronization

point. In its simplest usage, multiple devices, each with

their own local oscillator frequency, may be connected to

gether by the CLOCKSYNC pin and will synchronize on

the fastest oscillator. This pin may also be used to syn

chronize the device to an external clock, provided the ex

ternal signal is of higher frequency than the local

oscillator. A resistor load may be needed on this pin to

minimize the clock pulse width.

E/AOUT (error amplifier output): This is is the gain

stage for overall feedback control. Error amplifier output

voltage levels below 1 volt will force 0° phase shift. Since

the error amplifier has a relatively low current drive capa

bility, the output may be overridden by driving with a suffi

ciently low impedance source.

CS+ (current sense): The non-inverting input to the cur

rent-fault comparator whose reference is set internally to

a fixed 2.5V (separate from VREF). When the voltage at

this pin exceeds 2.5V the current-fault latch is set, the

outputs are forced OFF and a SOFT-START cycle is initiated. If a constant voltage above 2.5V is applied to this

pin the outputs are disabled from switching and held in a

low state until the CS+ pin is brought below 2.5V. The

outputs may begin switching at 0 degrees phase shift before the SOFTSTART pin begins to rise -- this condition

will not prematurely deliver power to the load.

FREQSET (oscillator frequency set pin): A resistor

and a capacitor from FREQSET to GND will set the oscil

lator frequency.

DELAYSET A-B, DELAYSET C-D (output delay con

trol): The user programmed current flowing from these

pins to GND set the turn-on delay for the corresponding

output pair. This delay is introduced between turn-off of

one switch and turn-on of another in the same leg of the

bridge to provide a dead time in which the resonant

switching of the external power switches takes place.

Separate delays are provided for the two half-bridges to

accommodate differences in the resonant capacitor

charging currents.

EA– (error amplifier inverting input): This is normally

connected to the voltage divider resistors which sense

the power supply output voltage level.

EA+ (error amplifier non-inverting input): This is nor

mally connected to a reference voltage used for compari

son with the sensed power supply output voltage level at

the EA+ pin.

GND (signal ground): All voltages are measured with

respect to GND. The timing capacitor, on the FREQSET

UC1875/6/7/8

UC2875/6/7/8

UC3875/6/7/8

pin, any bypass capacitor on the VREF pin, bypass ca

-

pacitors on VIN and the ramp capacitor, on the RAMP

pin, should be connected directly to the ground plane

near the signal ground pin.

-

OUTA-OUTD (outputs A-D): The outputs are 2A to

tem-pole drivers optimized for both MOSFET gates and

-

level-shifting transformers. The outputs operate as pairs

-

with a nominal 50% duty-cycle. The A-B pair is intended

to drive one half-bridge in the external power stage and

is syncronized with the clock waveform. The C-D pair will

drive the other half-bridge with switching phase shifted

with respect to the A-B outputs.

PWRGND (power ground): VC should be bypassed with

a ceramic capacitor from the VC pin to the section of the

-

ground plane that is connected to PWRGND. Any re

-

quired bulk reservoir capacitor should parallel this one.

Power ground and signal ground may be joined at a sin

gle point to optimize noise rejection and minimize DC

drops.

RAMP (voltage ramp): This pin is the input to the PWM

comparator. Connect a capacitor from here to GND. A

voltage ramp is developed at this pin with a slope:

SenseVoltage

dV

=

dT

RC

SLOPE RAMP

Current mode control may be achieved with a minimum

amount of external circuitry, in which case this pin provides slope compensation.

Because of the 1.3V offset between the ramp input and

-

the PWM comparator, the error amplifier output voltage

can not exceed the effective ramp peak voltage and duty

cycle clamping is easily achievable with appropriate val

-

ues of R

SLOPE

SLOPE (set ramp slope/slope compensation): A resis

tor from this pin to VCC will set the current used to gen

erate the ramp. Connecting this resistor to the DC input

line voltage will provide voltage feed-forward.

SOFTSTART (soft start): SOFTSTART will remain at

GND as long as VIN is below the UVLO threshold.

SOFTSTART will be pulled up to about 4.8V by an inter

nal 9µA current source when VIN becomes valid (assum

ing a non-fault condition). In the event of a current-fault

(CS+ voltage exceeding 2.5V), SOFTSTART will be

pulled to GND and them ramp to 4.8V. If a fault occurs

during the SOFTSTART cycle, the outputs will be imme

diately disabled and SOFTSTART must charge fully prior

to resetting the fault latch.

For paralleled controllers, the SOFTSTART pins may be

paralled to a single capacitor, but the charge currents will

be additive.

6

•

and C

RAMP

.

-

-

-

-

-

-

-

-

-

-

Page 7

PIN FUNCTIONAL DESCRIPTIONS (cont.)

VC (output switch supply voltage): This pin supplies

power to the output drivers and their associated bias cir

cuitry. Connect VC to a stable source above 3V for nor

mal operation, above 12V for best performance. This

supply should be bypassed directly to the PWRGND pin

with low ESR, low ESL capacitors.

VIN (primary chip supply voltage): This pin supplies

power to the logic and analog circuitry on the integrated

circuit that is not directly associated with driving the out

put stages. Connect VIN to a stable source above 12V

for normal operation. To ensure proper chip functionality,

these devices will be inactive until VIN exceeds the upper

undervoltage lockout threshold. This pin should by by

passed directly to the GND pin with low ESR, low ESL

capacitors.

APPLICATIONS INFORMATION

UNDERVOLTAGE LOCKOUT SECTION

UC1875/6/7/8

UC2875/6/7/8

UC3875/6/7/8

NOTE: When VIN exceeds the UVLO threshold the sup

-

ply current (I

-

in excess of 20µA. If the UC1875 is not connected to a

well bypassed supply, it may immediately enter UVLO

again.

VREF: This pin is an accurate 5V voltage reference. This

output is capable of delivering about 60mA to peripheral

circuitry and is internally short circuit current limited.

-

VREF is disabled while VIN is low enough to force the

chip into UVLO. The circuit is also in UVLO until VREF

reaches approximately 4.75V. For best results bypass

VREF with a 0.1µF, low ESR, low ESL, capacitor to the

-

GND pin.

) will jump from about 100µA to a current

IN

-

When power is applied to the circuit and VIN is below

the upper UVLO threshold, I

will be below 600µA, the

IN

reference generator will be off, the fault latch is reset,

the soft-start pin is discharged, and the outputs are actively

OSCILLATOR

The high frequency oscillator may be either

free-running or externally synchronized. For

Simplified Oscillator Schematic

held low. When VIN exceeds the upper UVLO thresh

old, the reference generator turns on. All else remains

in the shut-down mode until the output of the reference,

VREF, exceeds 4.75V.

UDG-95076

free-running operation, the frequency is set via an ex

ternal resistor and capacitor to ground from the

FREQSET pin.

-

-

UDG-95077

UDG-95079

UDG-95078

7

Page 8

UC1875/6/7/8

UC2875/6/7/8

UC3875/6/7/8

APPLICATIONS INFORMATION (cont.)

SYNCHRONIZING THE OSCILLATOR

The CLOCKSYNC pin of the oscillator may be used to synchronize multiple UC1875 devices simply by connecting

the CLOCKSYNC of each UC1875 to the others:

1875/6/7/8s only

UDG-95080

All ICs will sync to chip with the fastest local oscillator.

R1 & RN

R1 & RN

may

be needed to keep sync pulse narrow due to capacitance on line.

may

also be needed to properly terminate R

SYNC

line.

Syncing to external TTL/CMOS

ICs will sync to fastest chip or TTL clock if it is higher frequency.

may

R & RN

Although each UC1875/6/7/8 has a local oscillator fre

quency, the group of devices will synchronize to the

fastest oscillator driving the CLOCKSYNC pin. This ar

rangement allows the synchronizing connection be

tween ICs to be broken without any local loss of

functionality.

Synchronizing the device to an external clock signal

may be accomplished with a minimum of external cir

cuitry, as shown in the previous figure.

be needed for same reasons as above

-

Capacitive loading on the CLOCKSYNC pin will in

crease the clock pulse width, and may adversely effect

-

system performance. Therefore, a resistor to ground

-

from the CLOCKSYNC pin is optional, but may be re

quired to offset capacitive loading on this pin. These re

sistors are shown in the oscillator schematics as R1,

RN.

-

UDG-95081

-

-

-

8

Page 9

APPLICATIONS INFORMATION (cont.)

DELAY BLOCKS AND OUTPUT STAGES

UC1875/6/7/8

UC2875/6/7/8

UC3875/6/7/8

In each of the output stages, transistors Q3 through Q6

form a high-speed totem-pole driver which will source

or sink more than one amp peak with a total delay of

approximately 30 nanoseconds. To ensure a low output

level prior to turn-on, transistors Q7 through Q9 form a

self-biased driver to hold Q6 on prior to the supply

reaching its turn-on threshold. This circuit is operable

when the chip supply is zero. Q6 is also turned on and

held low with a signal from the fault logic portion of the

chip.

The delay providing the dead-time is accomplished with

C1 which must discharge to V

before the output can

TH

go high. The time is defined by the current sources, I1,

which is programmed by an external resistor, R

TD

. The

2.5V and the range of dead time control is

from 50 to 200 nanoseconds. NOTE: There is no way

to disable the delay circuitry, and the delay time must

be programmed.

voltage on the Delay Set pins is internally regulated to

OUTPUT SWITCH ORIENTATION

The four outputs of the UC1875/6/7/8 interface to the full bridge converter switches as shown below:

UDG-95082

3 Winding Bifilar, AWG 30 Kynar Insulation

9

UDG-95083

Page 10

APPLICATIONS INFORMATION (cont.)

FAULT/SOFT-START

UC1875/6/7/8

UC2875/6/7/8

UC3875/6/7/8

The fault control circuitry provides two forms of power

shutdown:

• Complete turn-off of all four output power stages.

• Clamping the phase shift command to zero.

Complete turn-off is ordered for an over-current fault or

a low supply voltage. When the SOFTSTART pin

reaches its low threshold, switching is allowed to pro

ceed while the phase-shift is advanced from zero to its

nominal value with the time constant of the

SOFT-START capacitor.

The fault logic insures that a continuous fault will insti

tute a low frequency “hiccup” retry cycle by forcing the

SOFT-START capacitor to charge through its full cycle

between each restart attempt.

-

-

UDG-95084

UDG-95085

10

Page 11

APPLICATIONS INFORMATION (cont.)

SLOPE/RAMP PINS

UC1875/6/7/8

UC2875/6/7/8

UC3875/6/7/8

The ramp generator may be configured for the following

control methods:

• Voltage Mode

• Voltage Feedforward

• Current Mode

• Current Mode with Slope Compensation

Voltage Mode Operation

The figure below shows a voltage-mode configuration.

With R

SLOPE

form on C

conventional voltage-mode control. If R

tied to a stable voltage source, the wave

will be a constant-slope ramp, providing

RAMP

SLOPE

is con

nected to the power supply input voltage, a vari

able-slope ramp will provide voltage feedforward.

1. Simple voltage mode operation

achieved by placing R

SLOPE

between VIN

and SLOPE.

2. Voltage Feedforward achieved by placing R

SLOPE

between supply voltage and

SLOPE pin of UC1875.

RAMP

dV

≈

dTVRC

Rslope

•

SLOPE RAMP

-

-

-

UDG-95086

For current-mode control the ramp generator may be disabled by grounding the slope pin and using the ramp pin

as a direct current sense input to the PWM comparator.

UNITRODE CORPORATION

7 CONTINENTAL BLVD.• MERRIMACK, NH 03054

TEL. (603) 424-2410 • FAX (603) 424-3460

11

Page 12

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERTAIN APPLICA TIONS USING SEMICONDUCT OR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...