Datasheet UC3845D1, UC3843D1, UC3844D1, UC3845, UC3844 Datasheet (Fairchild Semiconductor)

...Page 1

www.fairchildsemi.com

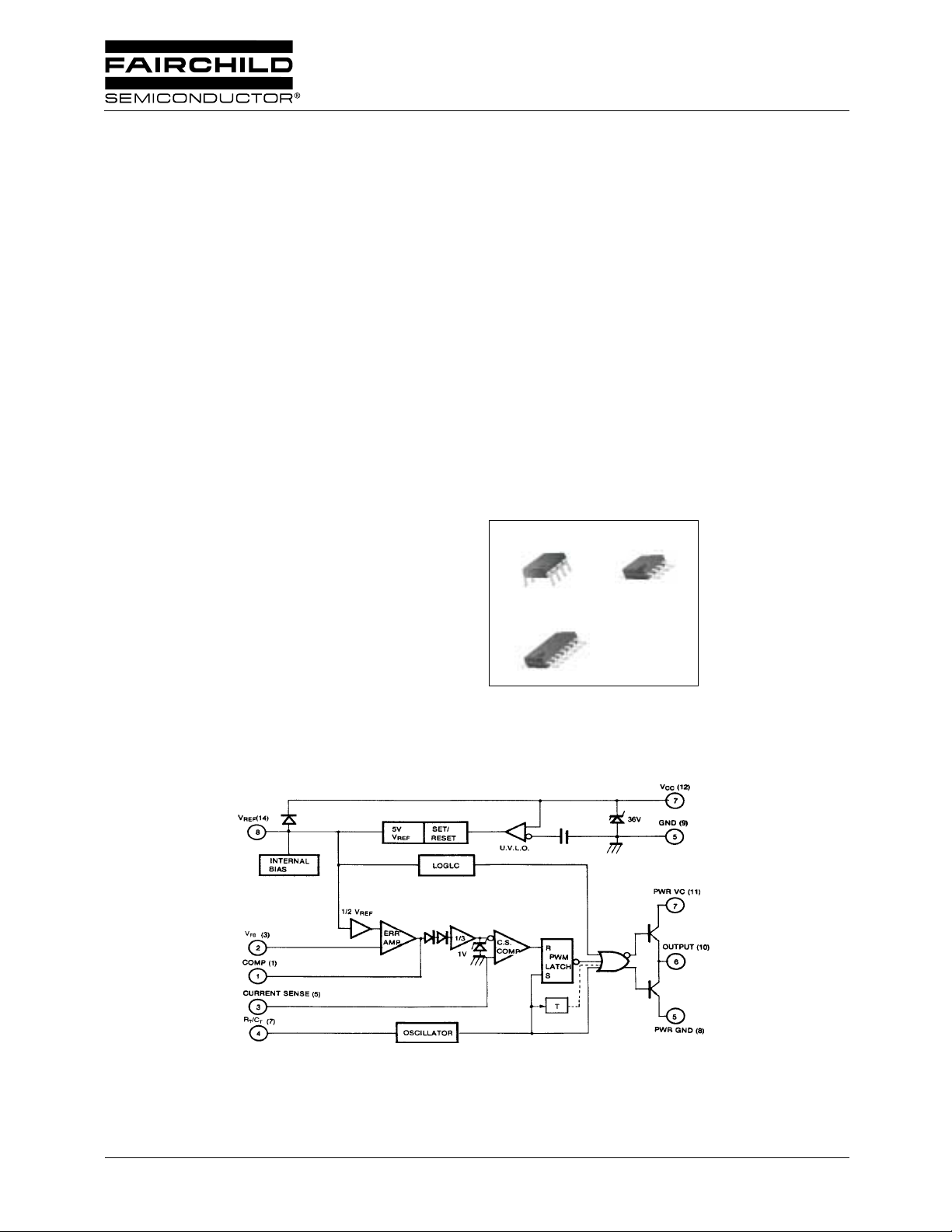

UC3842/UC3843/UC3844/UC3845

SMPS Controller

Features

• Low Start up Current

• Maximum Duty Clamp

• UVLO With Hysteresis

• Operating Fr equency up to 500KHz

Description

The UC3842/UC3843/UC3844/UC3845 are fixed

frequencycurrent-mode PWM controller. They are specially

designed for Off-Line and D C t o DC con ver t e r a pp l ic ati o ns

with minimum external components. These integrated

circuits feature a trimmed oscillator for precise duty cycle

control, a temperature compensated reference, high gain

error amplifier, current sensing comparator and a high

current totemp ole ou t pu t for dr ivi n g a Po we r M OSF E T. The

UC3842 and UC3844 have UVLO threshold s of 16V (on)

and 10V (off ). The UC3843 and UC3845 are 8.5V(on) and

7.9V (off). The UC3842 and UC3843 can operate within

100% duty cycle. The UC3844 and UC3845 can operate

with 50% duty cycle.

8-DIP

14-SOP

8-SOP

1

1

1

Internal Block Diagram

* NORMALLY 8DIP/8SOP PIN NO.

* ( ) IS 14SOP PINNO.

* TOGGLE FLIP FLOP USED ONLY IN UC3844, UC3845

©2002 Fairchild Semiconductor Corporation

Rev. 1.0.1

Page 2

UC3842/UC3843/UC3844/UC3845

Absolute Maximum Ratings

Parameter Symbol Value Unit

Supply Voltage V

Output Current I

Analog Inputs (Pin 2.3) V

Error Amp Output Sink Current I

Power Dissipation at T

Power Dissipation at T

Power Dissipation at T

≤25°C (8DIP) P

A

≤25°C (8SOP) P

A

≤25°C (14SOP) P

A

Storage Temperature Range T

Lead Temperature (Soldering, 10sec) T

CC

O

(ANA)

SINK (E.A)

(Note1,2) 1200 mW

D

(Note1,2) 460 mW

D

(Note1,2) 680 mW

D

STG

LEAD

Note:

1. Board Thickness 1.6mm, Board Dimension 76.2mm ×114.3mm, (Reference EIA / JS ED51-3, 51-7)

2. Do not exceeed P

and SOA (Safe Operation Area)

D

30 V

±1A

-0.3 to 6.3 V

10 mA

-65 ~ +150 °C

+300 °C

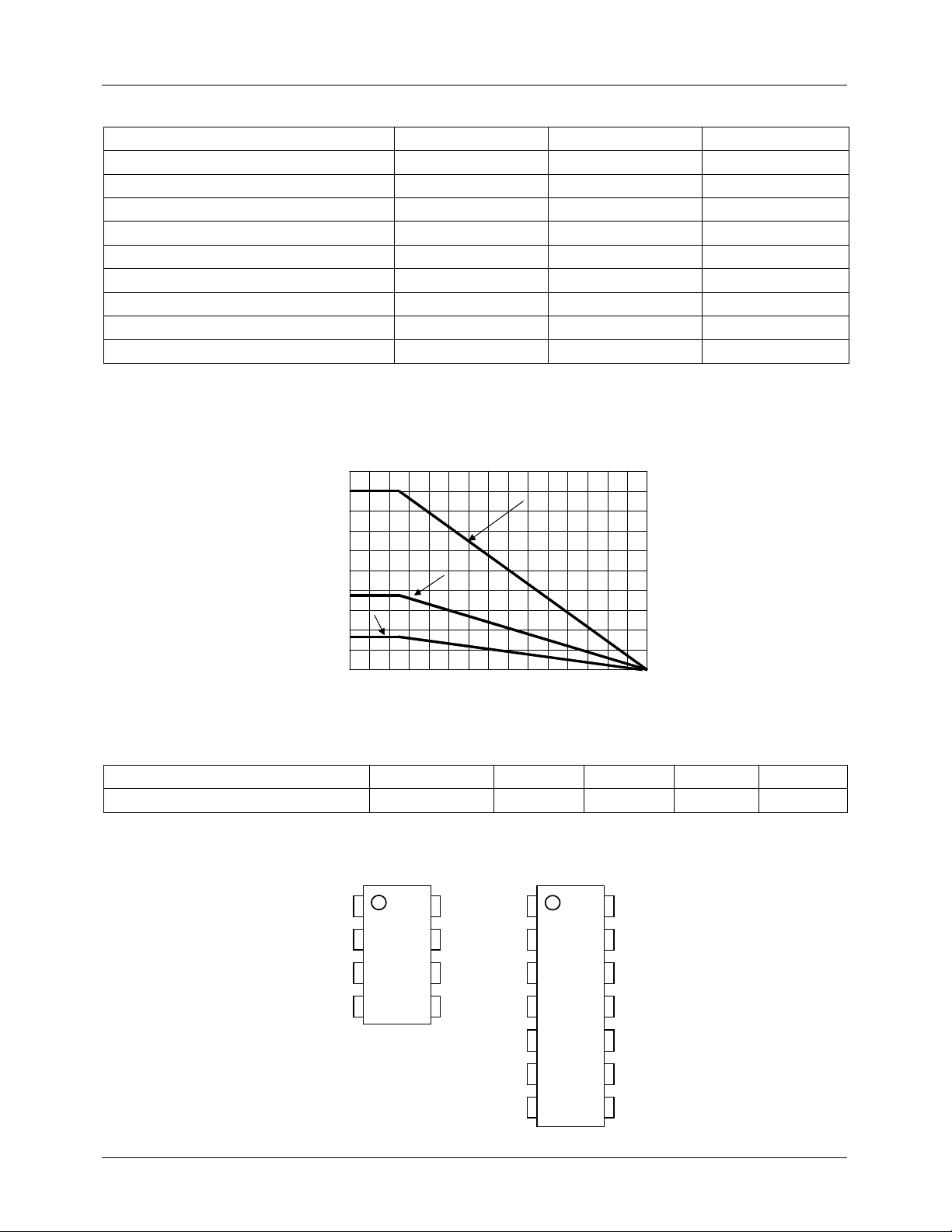

Power Dissipation Curve

1200

1200

1100

1100

1000

1000

900

900

14SOP

800

800

700

700

8SOP

8SOP

600

600

500

500

POWER DISSIPATION (mW)

POWER DISSIPATION (mW)

400

400

300

300

0 102030405060708090100110120130140150

0 102030405030 40 50 60 70 8060 70 80 90 100 11090 100 110 120 130 140120 130 140 150

14SOP

AMBIENT TEMPERATURE (℃)

AMBIENT TEMPERATURE (℃)

8DIP

8DIP

Thermal Data

Characteristic Symbol 8-DIP 8-SOP 14-SOP Unit

Thermal Resistance Junction-ambient R

thj-amb(MAX)

100 265 180 °C/W

Pin Array

8DIP,8SOP

8DIP,8SOP

REF

REF

REF

V

V

V

8

8

COMP

COMP

COMP

CURRENT SENSE

CURRENT SENSE

CURRENT SENSE

RT/C

RT/C

RT/C

1

1

1

FB

FB

FB

V

V

V

2

2

2

3

3

3

T

T

T

4

4

4

8

7

7

7

6

6

6

5

5

5

CC

CC

CC

V

V

V

OUTPUT

OUTPUT

OUTPUT

GND

GND

GND

COMP

COMP

COMP

CURRENT SENSE 5

CURRENT SENSE 5

CURRENT SENSE 5

2

N/C 2

N/C 2

N/C 2

N/C

N/C

N/C

N/C

N/C

N/C

T/CT

T/CT

T/CT

R

R

R

14SOP

14SOP

14

14

14

REF

REF

13

13

13

12

12

12

11

11

11

10

10

10

9

9

9

8

8

8

REF

V

V

V

N/C

N/C

N/C

CC

CC

CC

V

V

V

PWR V

PWR V

PWR V

OUTPUT

OUTPUT

OUTPUT

GND

GND

GND

PWR GND

PWR GND

PWR GND

C

C

C

1

1

1

FB

FB

FB

V

V

V

3

3

3

4

4

4

6

6

6

7

7

7

Page 3

UC3842/UC3843/UC3844/UC3845

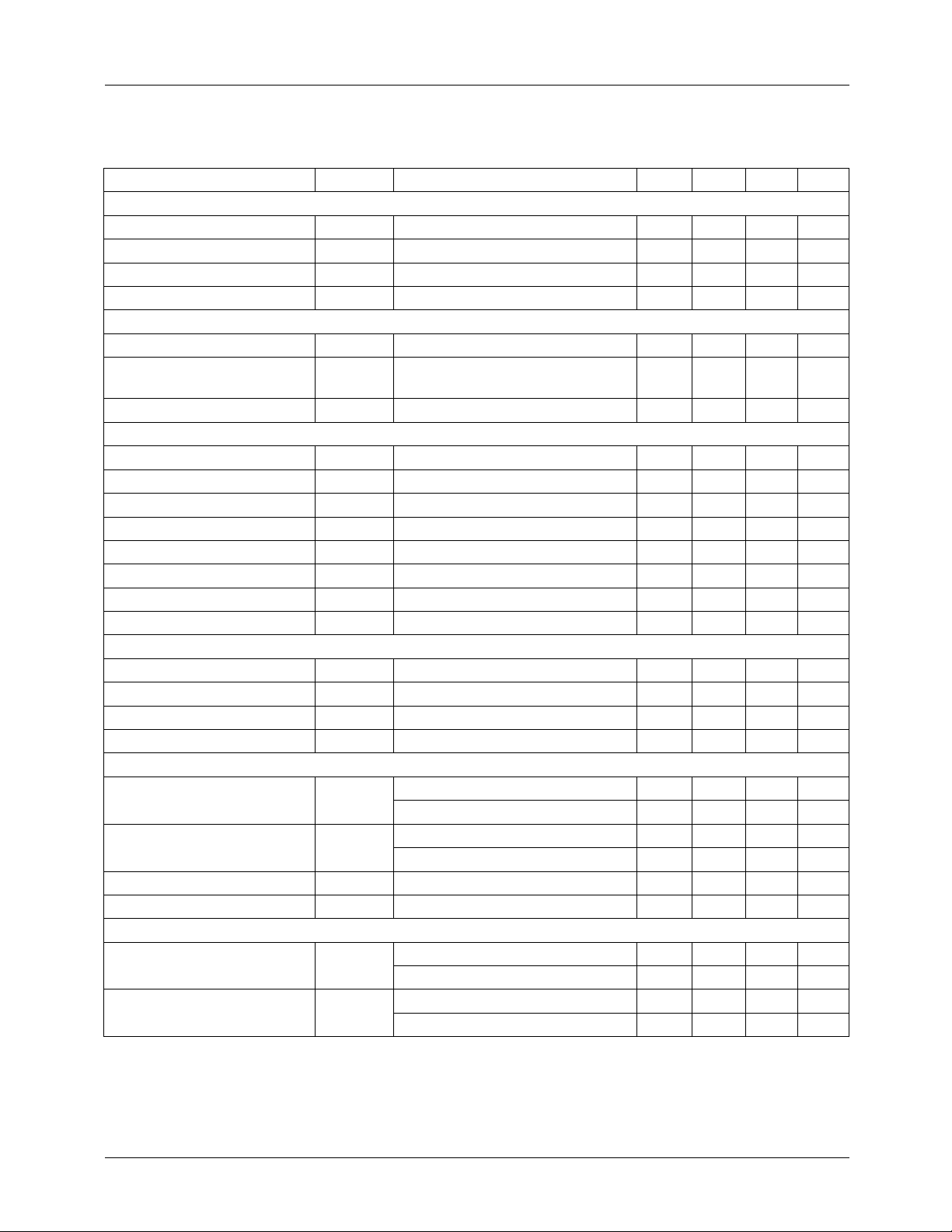

Electrical Characteristics

(VCC=15V, RT=10kΩ, CT=3.3nF, TA= 0°C to +70°C, unless otherwise specified)

Parameter Symbol Conditions Min. Typ. Max. Unit

REFERENCE SECTION

Reference Output Voltage V

Line Regulation ∆V

Load Regulation ∆V

Short Circuit Output Current I

REF

REF

REF

SC

OSCILLATOR SECTION

Oscillation Frequency f T

Frequency Change with

Voltage

Oscillator Amplitude V

∆f/∆V

OSC

ERROR AMPLIFIER SECTION

Input Bias Current I

Input Voltage V

Open Loop Voltage Gain G

BIAS

I(E>A)

VO

Power Supply Rejection Ratio PSRR 12V ≤ V

Output Sink Current I

Output Source Current I

High Output Voltage V

Low Output Voltage V

SINK

SOURCE

OH

OL

CURRENT SENSE SECTION

Gain G

Maximum Input Signal V

I(MAX)

Power Supply Rejection Ratio PSRR 12V ≤ V

Input Bias Current I

BIAS

OUTPUT SECTION

V

Low Output Voltage

High Output Voltage

Rise Time t

Fall Time t

OL

V

OH

R

F

UNDER-VOLTAGE LOCKOUT SECTION

Start Threshold

Min. Operating Voltage

(After Turn On)

V

TH(ST)

V

OPR(MIN)

TJ = 25°C, I

12V ≤ V

1mA ≤ I

CC

REF

= 1mA 4.90 5.00 5.10 V

REF

≤ 25V - 6 20 mV

≤ 20mA - 6 25 mV

TA = 25°C - -100 -180 mA

= 25°C475257kHz

J

CC

12V ≤ V

≤ 25V - 0.05 1 %

CC

- -1.6-V

- --0.1-2µA

V

= 2.5V 2.42 2.50 2.58 V

pin1

2V ≤ V

V

pin2

V

pin2

V

pin2

V

pin2

(Note 1 & 2) 2.85 3 3.15 V/V

V

V

pin1

≤ 4V (Note3) 65 90 - dB

O

≤ 25V (Note3) 60 70 - dB

CC

= 2.7V, V

= 2.3V, V

= 1.1V 2 7 - mA

pin1

= 5V -0.6 -1.0 - mA

pin1

= 2.3V, RL = 15kΩ to GND 5 6 - V

= 2.7V, RL = 15kΩ to Pin 8 - 0.8 1.1 V

= 5V(Note 1) 0.9 1 1.1 V

≤ 25V (Note 1,3) - 70 - dB

CC

- --3-10µA

I

= 20mA - 0.08 0.4 V

SINK

= 200mA - 1.4 2.2 V

I

SINK

I

SOURCE

I

SOURCE

= 20mA 13 13.5 - V

= 200mA 12 13.0 - V

TJ = 25°C, CL= 1nF (Note 3) - 45 150 ns

TJ = 25°C, CL= 1nF (Note 3) - 35 150 ns

UC3842/UC3844 14.5 16.0 17.5 V

UC3843/UC3845 7.8 8.4 9.0 V

UC3842/UC3844 8.5 10.0 11.5 V

UC3843/UC3844 7.0 7.6 8.2 V

P-P

3

Page 4

UC3842/UC3843/UC3844/UC3845

Electrical Characteristics

(Continued)

(VCC=15V, RT=10kΩ, CT=3.3nF, TA= 0°C to +70°C, unless otherwise specified)

Parameter Symbol Conditions Min. Typ. Max. Unit

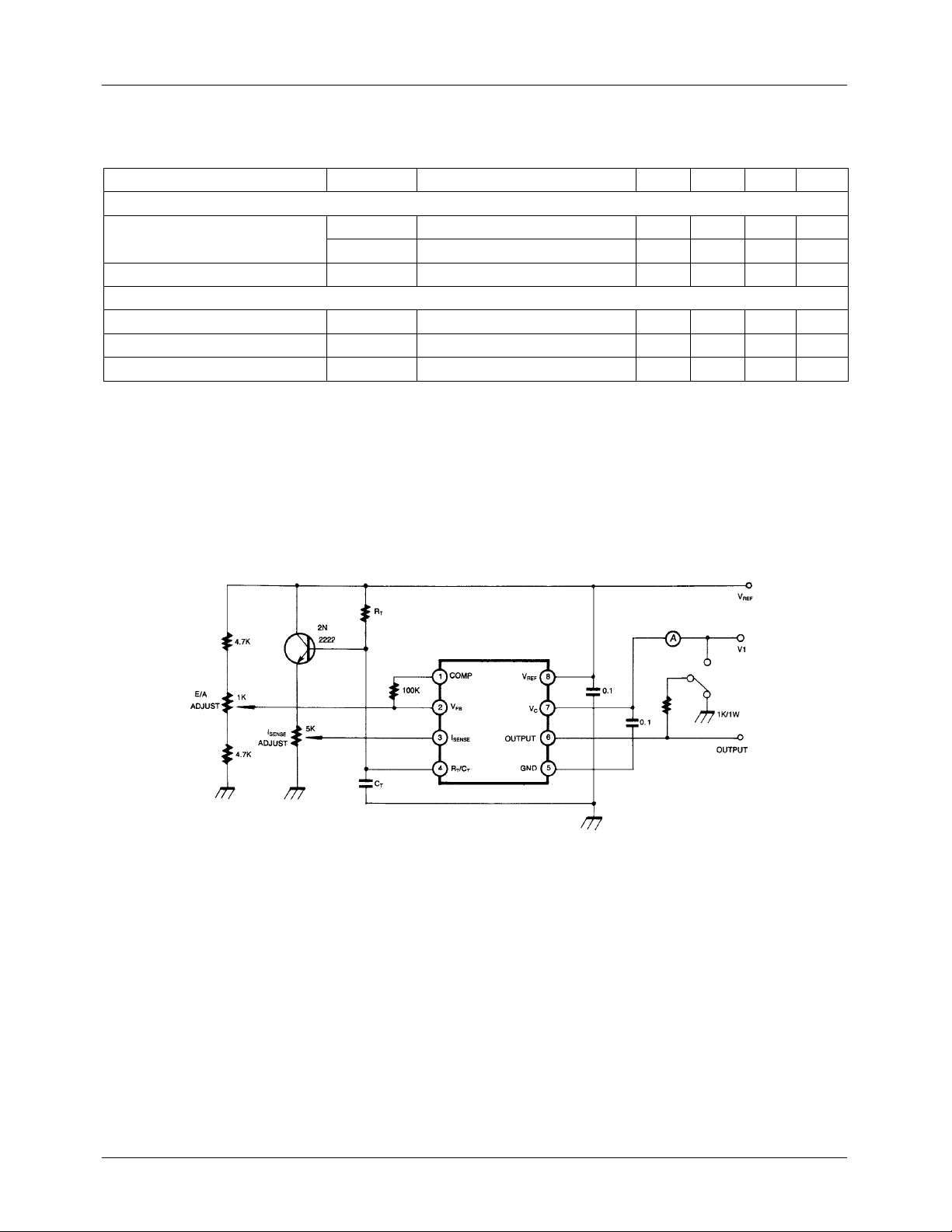

PWM SECTION

Max. Duty Cycle

Min. Duty Cycle D

D

D

(Max)

(Max)

(MIN)

UC3842/UC3843 95 97 100 %

UC3844/UC3845 47 48 50 %

- --0%

TOTAL STANDBY CURRENT

Start-Up Current I

Operating Supply Current I

Zener Voltage V

Adjust V

Note:

1. Parameter measured at trip point of latch

2. Gain defined as:

A

3. These parameters, although guaranteed, are not 100 tested in production.

above the start threshould before setting at 15V

CC

∆V

pin1

----------------- -=

∆V

pin3

,0 ≤ V

pin3

≤ 0.8V

ST

CC(OPR)

Z

V

pin3=Vpin2

ICC = 25mA 30 38 - V

- -0.451mA

=ON - 14 17 mA

UC3842

Figure 1. Open Loop Test Circuit

High peak currents associated with capacitive loads necessitate careful grounding techniques Timing and bypass capacitors

should be c onnected close to pin 5 in a single point ground. The transistor and 5kΩ potentiometer are used to sample the

oscillator waveform and apply an adjustable ramp to pin 3.

4

Page 5

UC3842/UC3843/UC3844/UC3845

UC3842/44

UC3843/45

Figure 2. Under Voltage Lockout

During Under- Voltage Lock-Out, the o utp ut drive r is bia sed to a hig h impe dance sta te. P in 6 s hould be shunt ed to grou nd with

a bleeder resistor to prevent activating the power switch with output leakage current.

Figure 3. Error Amp Configuration

Figure 4. Current Sense Circuit

Peak current (IS) is determined by the formula:

ISMAX()

1.0V

------------=

R

S

A small RC filter may be required to suppress switch transients.

5

Page 6

UC3842/UC3843/UC3844/UC3845

Figure 5. Oscillator Waveforms and Maximum Duty Cycle

Oscillator timing capacitor, CT, is charged by V

discharge time, the internal clock signal blanks the output to the low state. Selection of R

through RT and discharged by an internal current source. During the

REF

and C

T

therefore determines both

T

oscillator frequency and maximum duty cycle. Charge and discharge times are determined by the formulas:

t

= 0.55 RT C

c

tDRTCTI

=

Frequency, then, is: f=(tc + td)

ForRT 5KΩ f

T

0.0063RT2.7–

--------------------------------------- -

n

0.0063R

Figure 6. Oscillator Dead Time & Frequency Figure 7. Timing Resistance vs Frequency

-------------- -=,>

R

1.8

TCT

4–

T

-1

(Deadtime vs CT RT > 5kΩ)

Figure 8. Shutdown Techniques

6

Page 7

UC3842/UC3843/UC3844/UC3845

Shutdown of the UC3842 can be accomplished by two methods; either raise pin 3 above 1V or pull pin 1 below a voltage two

diode drops above gro und. E ither m ethod cause s the ou tput o f the PWM compa rato r to be hig h (refe r to bl ock di agra m). The

PWM latch is reset dominant so that the output will remain low until the next clock cycle after the shutdown condition at pins

1 and/or 3 is r e mo ve d. In one example, an externa l ly latched shutdown may be a cco mplished by adding an SCR whic h will be

reset by cycling V

below the lower UVLO threshold. At this point the reference turns off, allowing the SCR to reset.

CC

UC3842/UC3843

Figure 9. Slope Compensation

A fraction of the oscillator ramp can be resistively summed with the current sense signal to provide slope compensation for

converters requiring duty cycles over 50%. Note that capacitor, C

, forms a filter with R2 to suppress the leading edge switch

T

spikes.

Temperature (°C)

Figure 10. Tempera ture Drift (V ref)

Temperature (°C)

Figure 12. Temperature Drift (Icc)

Temperature (°C)

Figure 11. Temperature Drift (Ist)

7

Page 8

UC3842/UC3843/UC3844/UC3845

Mechanical Dimensions

Package

6.40

±0.20

0.252

±0.008

8-DIP

0.79

0.031

()

±0.10

±0.004

±0.10

±0.004

#1

#8

#4 #5

7.62

0.300

MAX

9.60

0.378

5.08

0.200

3.40

0.134

±0.20

9.20

MAX

±0.20

±0.008

±0.008

0.362

0.33

0.013

MIN

0.46

3.30

0.130

2.54

±0.30

±0.012

0.018

0.100

1.524

0.060

+0.10

0.25

–0.05

+0.004

0.010

–0.002

0~15°

8

Page 9

UC3842/UC3843/UC3844/UC3845

Mechanical Dimensions

Package

#1

#4

6.00 ±0.30

0.006

0.15

0.236 ±0.012

(Continued)

8-SOP

1.55 ±0.20

0.061 ±0.008

#8

#5

0.071

MAX

5.13

1.80

0.202

4.92 ±0.20

MAX

0.194 ±0.008

MIN

0.004~0.001

1.27

0.1~0.25

0.56

0.022

()

0.41 ±0.10

0.050

0.016 ±0.004

+

-0.002

-0.05

0.004

0.50 ±0.20

0.020 ±0.008

+

0.10

3.95 ±0.20

0.156 ±0.008

5.72

0.225

0~8°

MAX0.10

MAX0.004

9

Page 10

UC3842/UC3843/UC3844/UC3845

Mechanical Dimensions

Package

#1

(Continued)

14-SOP

#14

1.55

0.061

MAX

8.70

0.343

±0.10

±0.004

±0.20

8.56

±0.008

0.337

MIN

0.05

0.002

0.47

()

0.10

0.004

-0.05

+

+

0.406

0.016

0.019

-0.002

0.10

+

-0.05

0.20

0.60

0.024

0.004

+

-0.002

0.008

±0.20

±0.008

#7

6.00

0.236

3.95

0.156

5.72

0.225

±0.30

±0.012

±0.20

±0.008

#8

0~8°

1.80

0.071

MAX

MAX0.10

MAX0.004

1.27

0.050

10

Page 11

Ordering Information

Product Number Package Operating Temperature

UC3842N

UC3843N

UC3844N

UC3845N

UC3842D1

UC3843D1

UC3844D1

UC3845D1

UC3842D

UC3843D

UC3844D

UC3845D

8-DIP

8-SOP

14-SOP

UC3842/UC3843/UC3844/UC3845

0 ~ + 70°C

11

Page 12

UC3842/UC3843/UC3844/UC3845

DISCLAIMER

FAIRCHILD SEMICONDUCTOR RESERVES THE RIGHT TO MAKE CHANGES WITHOUT FURT HER NOTICE TO ANY

PRODUCTS HEREI N TO IMPROVE RELIABILITY, FUNCTIO N OR DESIGN. FAIRCH IL D DOES NOT ASSUME ANY

LIABILITY ARISING OUT OF THE APPLICATION OR USE OF ANY PRODUCT OR CIRCUIT DESCRIBED HEREIN; NEITHER

DOES IT CONVEY ANY LICENSE UNDER IT S PATENT RIGHTS, NOR THE RIGHTS OF OTHE RS.

LIFE SUPPORT POL I CY

FAIRCHILD’S PR ODUCTS ARE NOT AUTH ORIZED FOR USE AS C RITICAL COMPONENT S IN LIFE SUPPORT DE VICES

OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF FAIRCHILD SEMICONDUCTOR

CORPORATION. As used herein :

1. Life support devices or systems are devices or systems

which, (a) are intended for surgical implant into the body,

or (b) support or sustain life, and (c) whose failure to

perform when properly used in accordance with

2. A critical component in any component of a life support

device or sy stem whose fai lure to perform can be

reasonably expec ted to cause the failur e of the life support

device or system, or to affect its safety or effec t iv ene ss .

instructions for use provided in the labeling, can be

reasonably expected to result in a significant injury of the

user.

www.fairchildsemi.com

2/19/02 0.0m 001

2002 Fairchild Semiconductor Corporation

Stock#DSxxxxxxxx

Loading...

Loading...