Page 1

查询UC3717A供应商

Stepper Motor Drive Circuit

FEATURES DESCRIPTION

• Full-Step, Half-Step and Micro-Step

Capability

• Bipolar Output Current up to 1A

• Wide Range of Motor Supply Voltage

10-46V

• Low Saturation Voltage with Integrated

Bootstrap

• Built-In Fast Recovery Commutating

Diodes

• Current Levels Selected in Steps or Varied

Continuously

• Thermal Protection with Soft Intervention

ABSOLUTE MAXIMUM RATINGS (Note 1)

Voltage

Logic Supply, VCC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7V

Output Supply, Vm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50V

Input Voltage

Logic Inputs (Pins 7, 8, 9) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6V

Analog Input (Pin 10). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V

Reference Input (Pin 11) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15V

Input Current

Logic Inputs (Pins 7, 8, 9) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -10mA

Analog Inputs (Pins 10, 11). . . . . . . . . . . . . . . . . . . . . . . . . . . . -10mA

Output Current (Pins 1, 15) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±1.2A

Junction Temperature, TJ. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +150°C

Storage Temperature Range, TS. . . . . . . . . . . . . . . . . . -55°C to +150°C

The UC3717A is an impro ved ver sion of the UC3717, us ed to switch

drive the current in one winding of a bipolar stepper motor. The

UC3717A has been modified to supply higher winding current, more

reliable thermal protection, and improved efficiency by providing integrated bootstrap circuitry to lower recirculation saturation voltages.

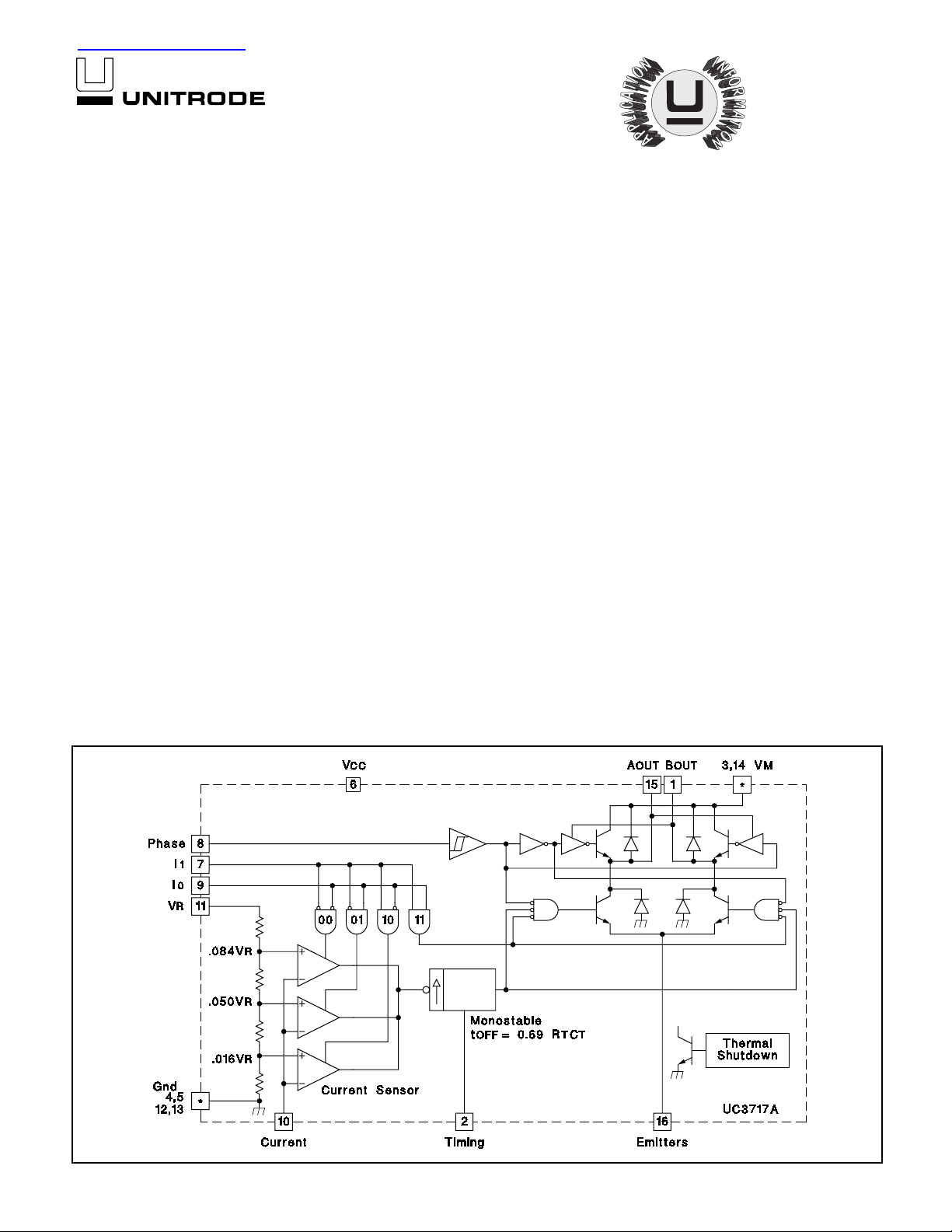

The diagram shown below presents the building blocks of the

UC3717A. Includ ed are an LS-TTL compatible l ogic input, a current

sensor, a monostable, a ther mal shutd ow n netw ork, and an H-bri dge

output stage. The output stage features built-in fast recovery commutating diodes and integrated bootstrap pull up. Two UC3717As

and a few external components form a complete control and drive

unit for LS-TTL or micro-processor controlled stepper motor systems.

The UC3717A is characterized for operation over the temperature

range of 0°C to +70°C.

CC

UC3717A

Note 1: All voltages are with respect to ground, Pins 4,

5, 12, 13. Currents are positive into, negative out of the

specified terminal. Pin numbers refer to DIL-16 package.

Consult Packaging Section of Databook for thermal limitations and considerations of package.

BLOCK DIAGRAM

4/97

1

Page 2

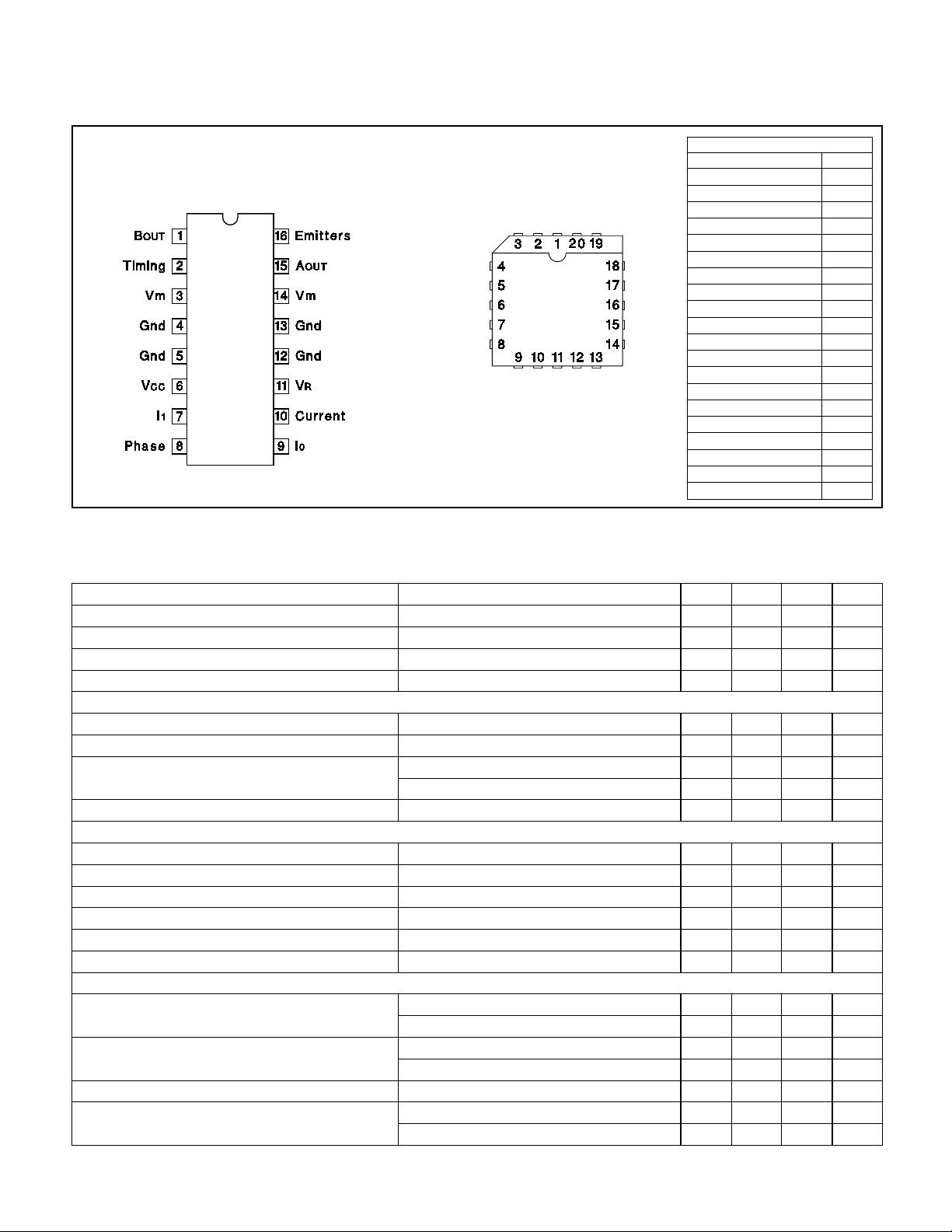

CONNECTION DIAGRAMS

UC3717A

DIL-16 (TOP VIEW)

J or N Package

ELECTRICAL CHARACTERISTICS

PLCC-20 (TOP VIEW)

Q Package

(Refer to the te st c irc ui t, F ig ure 6 . Vm = 36V, VCC = 5V, VR = 5V, TA = 0°C to 70°C,

PACKAGE PIN FUNCTION

FUNCTION PIN

N/C

B

OUT

Timing

m

V

Gnd

N/C

Gnd

V

CC

I

1

Phase

N/C

I

0

Current

V

R

Gnd

N/C

Gnd

m

V

A

OUT

Emitters

unless otherwis e stat ed , TA = TJ.)

PARAMETERS TEST CONDITIONS MIN TYP MAX UNITS

Supply Voltage, Vm (Pins 3, 14) 10 46 V

Logic Supply Voltage, V

Logic Supply Current, I

(Pin 6) 4.75 5.25 V

CC

(Pin 6) IO = I1 = 0 7 15 mA

CC

Thermal Shutdown Temperature +160 +180 °C

Logic Inputs

Input Low Voltage, (Pins 7, 8, 9) 0.8 V

Input High Voltage, (Pins 7, 8, 9) 2 V

Low Voltage Input Current, (Pins 7, 8, 9) V

High Voltage Input Current, (Pins 7, 8, 9) V

= 0.4V, Pin 8 -100

I

V

= 0.4V, Pins 7 and 9 -400 mA

I

= 2.4V 10

I

CC

Comparators

Comparator Low, Thres ho ld Volt ag e (Pin 10) V

Comparator Medium, Threshold Voltage (Pin 10) V

Comparator High, Thre sh ol d Vol tage (Pin 10) V

Comparator Input, Current (Pin 10)

Cutoff Time, t

Turn Off Dela y, t

OFF

D

= 5V; IO = L; I1 = H 668090mV

R

= 5V; IO = H; I1 = L 236 250 266 mV

R

= 5V; IO = L; I1 = L 396 420 436 mV

R

20

±

RT = 56kΩ, CT = 820pF 25 35

(See Figure 5) 2

Source Diode-Transistor Pair

Saturation Voltage, V

(See Figure 5) I

Saturation Voltage, V

(See Figure 5) I

Leakage Current V

Diode Forward Voltage, V

(Pins 1, 15) Im = -0.5A, Conduction Period 1.7 2.1 V

SAT

= -0.5A, Recirculation Period 1.1 1.35 V

m

(Pins 1, 15) Im = -1A, Conduction Period 2.1 2.8 V

SAT

= -1A, Recirculation Period 1.7 2.5 V

m

= 40V 300

m

F

Im = -0.5A 1 1.25 V

I

= -1A 1.3 1.7 V

m

10

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

9

V

A

µ

A

µ

A

µ

s

µ

s

µ

A

µ

2

Page 3

UC3717A

ELECTRICAL

CHARACTERISTICS (cont.)

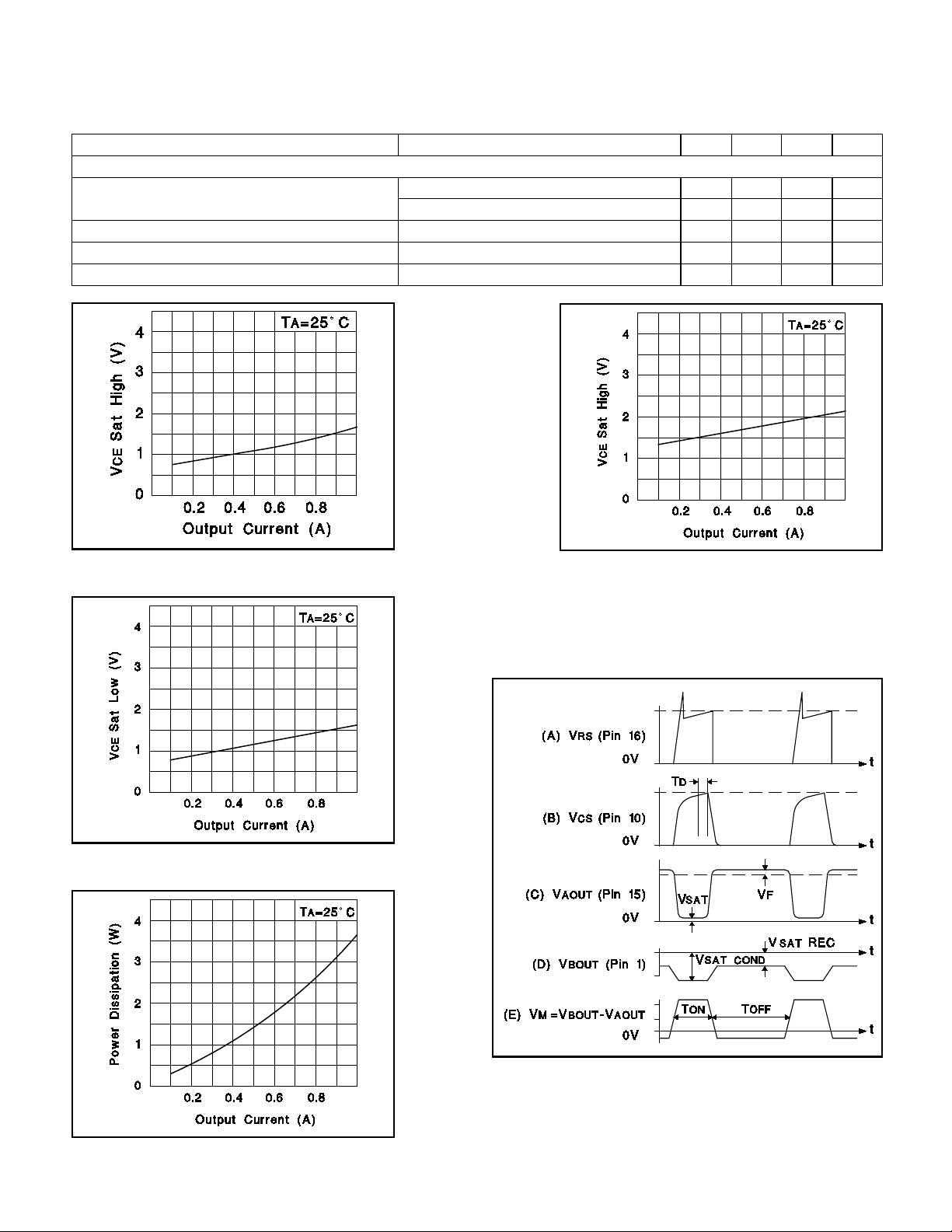

PARAMETERS TEST CONDITIONS MIN TYP MAX UNITS

Sink Diode-Transistor Pair

Saturation Voltage, V

Leakage Current V

Diode Forward Voltage, V

(Pins 1, 15) Im = 0.5A 0.8 1.1 1.35 V

SAT

F

(Refer to the te st c irc ui t, F ig ure 6 . VM = 36V, VCC = 5V, VR = 5V, TA = 0°C to 70°C, unless

otherwise stated, TA = TJ.)

I

= 1A 1.6 2.3 V

m

= 40V 300

m

Im = 0.5A 1.1 1.5 V

= 1A 1.4 2 V

I

m

µ

A

Figure 1. Typical Source Saturation Voltage

vs Output Current (Recirculation Period)

Figure 3. Typical Sink Saturation

Voltage vs Output Current

Figure 2. Typical Source Saturation Voltage

vs Output Current (Conduction Period)

Figure 4. Typical Power Dissipation

vs Output Current

Figure 5. Typical Waveforms with MA Regulating

(phase = 0)

3

Page 4

UC3717A

Figure 6. UC3717A Test Circuit

FUNCTIONAL DESCRIPTION

The UC3717A’s drive circuit shown in the block diagram

includes the following components.

(1) H-bridge output stage

(2) Phase polarity logic

(3) Voltage divider coupled with current sensing compa rators

(4) Two-bit D/A current level select

(5) Monostable generating fixed off-time

(6) Thermal protection

OUTPUT STAGE

The UC3717A’s output stage consists of four Darlington

power trans i s to rs an d a s s oci a te d r e c i rc ul a ti n g power diodes in a full H-bridge configuration as shown in Figure

7. Also presented, is the new added feature of inte-

grated bootstrap pull up, which improves device performance during switched mode operation. While in

switched mode, with a low level phase polarity input, Q2

is on and Q3 is being switched. At the moment Q3 turns

off, winding current begins to decay through the commutating di ode pu lling the collector of Q3 above the supply

voltage. Meanwhile, Q6 turns on pulling the base of Q2

higher than its previ ous val ue. The net effect lowers the

saturation voltage of source transistor Q2 during recirculation, thus improving efficiency by reducing power dissipation.

Note: Dashed lines indicate current decay paths.

Figure 7. Simplified Schematic of Output Stage

4

Page 5

FUNCTIONAL DESCRIPTION (cont.)

PHASE POLARITY INPUT

The UC3717A phase polarity input controls current direction in the motor winding. Built-in hysteresis insures immunity to noise, something frequently present in

switched drive environments. A low level phase polarity

input enables Q 2 and Q3 as shown in Figure 7. During

phase revers al, the act ive transis tors are both turned off

while winding current delays through the commutating diodes shown. As winding current decays to zero, the inactive transistors Q1 and Q4 turn on and charge the

winding with current of the reverse direction. This delay

insures n oise immunity a nd freedom from power supply

current spikes caused by overlapping drive signals.

PHASE INPUT Q1, Q4 Q2, Q3

LOW OFF ON

HIGH ON OFF

CURRENT CONTROL

The voltage div ider, comparators, monostable, and twobit D/A provide a me ans to sen se winding pe ak current,

select win di n g peak current, and disabl e the windi ng si nk

transistors.

The UC3717A switched driver accomplishes current control using an algorithm referred to as "fixed off-time."

When a vol tage is applied across the motor winding, the

current through the winding increases exponentially. The

current can be sensed across an external resistor as an

analog voltage proportional to instantaneous current.

This voltage is normally filtered with a simple R

low-

C

pass network to remove high frequency transients, and

then compared to one of the three selectable threshol ds.

The two bit D/ A input signal de termi nes wh ich on e of the

three thres holds is selected, c orresponding to a desired

winding peak current level. At the moment the sense voltage rises above the selected threshold, the UC3717A’s

monostable is triggered and disables both output sink

drivers fo r a fixed o ff-time. The w inding current then circulates th rough t he sourc e transistor and appropriate diode. The re ference termin al of the UC3717A provides a

means of conti nuously adj usting th e current threshold to

allow microstepping. Table 1 presents the relationship

between the t wo-bit D/A input signa l and selectable current level.

UC3717A

ture to a maximum of 180C by reducing the windi ng current.

PERFORMANCE CONSIDERATIONS

In order to achieve optimum performance from the

UC3717A careful atten tion s houl d be given to the following items.

External Components:

mal number of ex ternal compone nts to form a complete

control and switch drive unit. However, proper selection

of external components is necessary for optimum performance. The timing pin, (pin 2) is normally connected

to an RC network which sets the off-time for the sink

power trans istor during switc hed mode. As shown in Figure 8, prior to switched mode, the winding current increases exponentially to a peak value. Once peak

current is attained the monostable is triggered which

turns off the lo wer sink drivers for a fixed off-time. During

off-time windi ng current decays through the appropriate

diode and sou rce transistor. The moment off-time times

out, the motor current agai n rises exponentially producing the ripple waveform shown. The mag nitude of winding ripple is a direct function of off-time. For a given

off-time T

, the values of RT and CT can be calculated

OFF

from the expression:

T

with the r estrict ion that RT should be in the ra nge of 10100k. As s h ow n i n Fi gu r e 5, t he s witc h frequency F

function of T

and TON. Since TON is a function of the

OFF

reference voltage, sense resistor, motor supply, and

winding e lectrical c haracteristics, it generally v aries during different modes of operation. Thus, F

proximated nominally as:

Normally, Switch Frequency Is Selected Greater than

The UC3717A requires a mini-

0.69

=

OFF

F

1

⁄

=

S

1.5

RTC

(

T

OFF

T

may be ap-

S

).

is a

S

TABLE 1

O

I

0 0 100%

10 60%

01 19%

1 1 Current Inhibit

1

I

CURRENT LEVEL

OVERLOAD PROTECTION

The UC3717A is equipped with a new, more reliable thermal shutdown circuit which limits the junction tempera-

Figure 8. A typical winding current waveform. Winding current rises exponentially to a selected peak

value. The peak value is limited by switched mode

operation producing a ripple in winding current. A

phase polarity reversal comma nd is given and winding current decays to zero, then increases exponentially.

5

Page 6

FUNCTIONAL DESCRIPTION (cont.)

Low-pass filter components RC CC should be selected so

that all switching transients from the power transistors

and commutating diodes are well smoothed, but the primary signal, which can be in the range of 1/T

OFF

or

higher must be passed. Figure 5A shows the waveform

which must be smoothed, Figure 5B presents the desired

waveform that just smoothes out overshoot without radical distortion.

The sense resistor should be chosen as small as practical to allo w as much of the winding supply voltage to be

used as overd rive to the motor winding. V

, the voltage

RS

across the sense resistor, should not exceed 1.5V.

Voltage Overdrive:

In many applications, maximum

speed or step rate is a desirable performance characteristic. Maximum step rate is a direct function of the time

necessary to reverse w inding current with each step. In

response to a constant motor supply voltage, the winding

current chan ges exponentially with time, whos e shape is

determined b y the windi ng time constant and expressed

as:

m

I

=

m

R [1−EXP

V

(

T

−

R

⁄

]

)

L

as present ed in Figure 9 . Wit h rated v oltage applied, the

time required to reach rated current is excessive when

compared with the time required with over-voltage applied, even though the time constant L/R remains constant. With over-voltage however, the final value of

UC3717A

current is excessive and must be prevented. This is accomplishe d w ith swi tch driv e by repetitivel y switc hing the

sink drivers on and off, so as to maintain an average

value of cur rent equal to the rated value. This results in a

small amount of r ipple in the controlled current, but the

increase in s tep rate and pe rformance may be considerable.

Interference:

action can cause interference problems, particularly in

the vicini ty of magnetic storage media. With this in mind,

printed ci rcuit layouts, wire runs and dec oupling must be

considered. 0.01 to 0.1µF ceramic capacitors for h igh fr equency bypass located near the drive package across

V+ and ground might be very helpful. The connection

and ground leads of the current sensing components

should be kept as short as possible.

Half-Stepping:

the motor alternates between one or two phases being

energized. In a two phase motor the electrical phase shift

between the windings is 90°. The torque developed is the

vector sum of the two windings energized. Therefore

when only one winding is energized the torque of the motor is reduced by approximately 30%. This causes a

torque ripple and if it is necessary to compensate for this,

the V

input can be used to boost the current of the sin-

R

gle energized winding.

Electrical noise gener ated by the chopping

In half step seq uence the power input to

Figure 9. With rated vol tage applied, winding current does not exceed rated value, but takes L/R seconds to

reach 63% of its final value - probably too long. Increased performance requires an increase in applied voltage, of overdrive, and therefore a m eans to limit current. The UC3717A motor driver performs this task efficiently.

6

Page 7

MOUNTING INSTRUCTIONS

The θJA of the UC3717AN plastic package can be reduced by soldering the GND pins to a suitable copper

area of the printed circuit board or to an external heat

sink. Due to different lead frame design, θ

of the ce-

JA

ramic J package cannot be similarly reduced.

The diagram of Figure 11 shows the maximum package

power P

and the θJA as a function of the side " l " of

TOT

two equal square copper areas having a thickness of 35µ

(see Figure 10).

UC3717A

12. The input can be controlled by a microprocessor,

TTL, LS, or CMOS logic.

The timing di agram in Fig ure 13 sho ws the required signal input for a two phase, full step stepping sequence.

Figure 14 shows the required input signal for a one

phase-two phase stepping sequence called half-stepping.

The circuit of Figure 15 prov ides the signal shown i n Figure 13, and in conjunction with the circuit shown in Figure 12 will implement a pulse-to-step two phase, full

step, bi-directional motor drive.

Figure 10. Example of P.C. Board Copper

Area which is used as Heatsink.

During soldering the pins’ temperature must not exceed

260°C and t he s o l de r i ng t i me must not be l onger than 12

seconds.

The printed circuit copper area must be connected to

electrical ground.

Figure 11. Maximum Package Power and Junction

to Ambient Thermal Resistance vs Side "

l

".

APPLICATIONS

A typical chopper drive for a two phase bipolar permanent magnet or hybrid stepping motor is shown in Figure

Figure 12. Typical Chopper Drive for a Two

Phase Permanent Magnet Motor.

The schemati c of Figure 16 shows a pulse to half step

circuit generating the signal shown in Figure 14. Care

has been taken to change the phase signal the same

time the cur rent inhi bit is a pplied . This will allow the cur rent to decay faster and therefore enhance the motor

performance at high step rates.

7

Page 8

Figure 13. Phase Input Signal for Two Phase Full Step Drive (4 Step Sequence)

UC3717A

Figure 14. Phase and Current-Inhibit Signal for Half-Stepping (8 Step Sequence)

Figure 15. Full Step, Bi-directional Two Phase Drive Logic

UNITRODE CORPORATI ON

7 CONTINENTAL BLVD. • MERRIMACK, NH 03054

TEL. (603) 424- 24 10 • FAX (603) 424-3460

Figure 16. Half-Step, Bi-directional Drive Logic

8

Page 9

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...