Page 1

查询UC2577T-ADJ供应商

Simple Step-Up Voltage Regulator

FEATURES DESCRIPTION

•

Requires Few External Components

•

NPN Output Switches 3.0A, 65V(max)

•

Extended Input Voltage Range: 3.0V to 40V

•

Current Mode Operation for Improved

Transient Response, Line Regulation, and

Current Limiting

•

Soft Start Function Provides Controlled

Startup

•

52kHz Internal Oscillator

•

Output Switch Protected by Current Limit,

Undervoltage Lockout and Thermal

Shutdown

•

Improved Replacement for LM2577-ADJ

Series

The UC2577-ADJ device provides all the active functions necessary to implement step-up (boost), flyback, and forward converter

switching regulat ors. R equirin g only a few c omponen ts, these simple regula tors efficiently provide up to 60V as a step-up regulator,

and even high er volta ges as a flyback or forwa rd converter regulator.

The UC2577-ADJ features a wide input voltage range of 3.0V to

40V and an adjustable output voltage. An on-chip 3.0A NPN switch

is included with undervoltage lockout, thermal protection circuitry,

and current limiting , as well as soft star t mode operation to reduce

current during startup. Other features include a 52kHz fixed frequency on-chip oscillator with no external components and current

mode control for better line and load regulation.

A standard series of inductors and capacitors are available from

several manufacturers optimized for use with these regulators and

are listed in this data sheet.

UC2577-ADJ

TYPICAL APPLICATIONS

•

Simple Boost and Flyback Converters

•

SEPIC Topology Permits Input Voltage to

be Higher or Lower than Output Voltage

•

Transformer Coupled Forward Regulators

•

Multiple Output Designs

BLOCK DIAGRAM

CONNECTION DIAGRAM

5-Pin TO-220 (Top View)

T Package

Also available in TO-263 Package (TD).

3/97

UDG-94034

Page 2

UC2577-ADJ

ABSOLUTE MAXIMUM RATINGS

(Note 1)

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45V

Output Switch Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65V

Output Switch Current (Note 2) . . . . . . . . . . . . . . . . . . . . . 6.0A

Power Dissipation. . . . . . . . . . . . . . . . . . . . . . Internally Limited

RECOMMENDED OPERATING RANGE

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . 3.0V ≤ VIN ≤ 40V

Output Switch Voltage . . . . . . . . . . . . . . . 0V ≤ V

Output Switch Current . . . . . . . . . . . . . . . . . . . . I

Junction Temperature Range. . . . . . . . . . −40°C ≤ TJ ≤ +125°C

SWITCH

SWITCH

Storage Temperature Range . . . . . . . . . . . . . −65°C to +150°C

Lead Temperature (Soldering, 10 sec.) . . . . . . . . . . . . . . 260°C

Maximum Junction Temperature . . . . . . . . . . . . . . . . . . . 150°C

Minimum ESD Rating (C = 100pF, R = 15kΩ) . . . . . . . . . . . 2kV

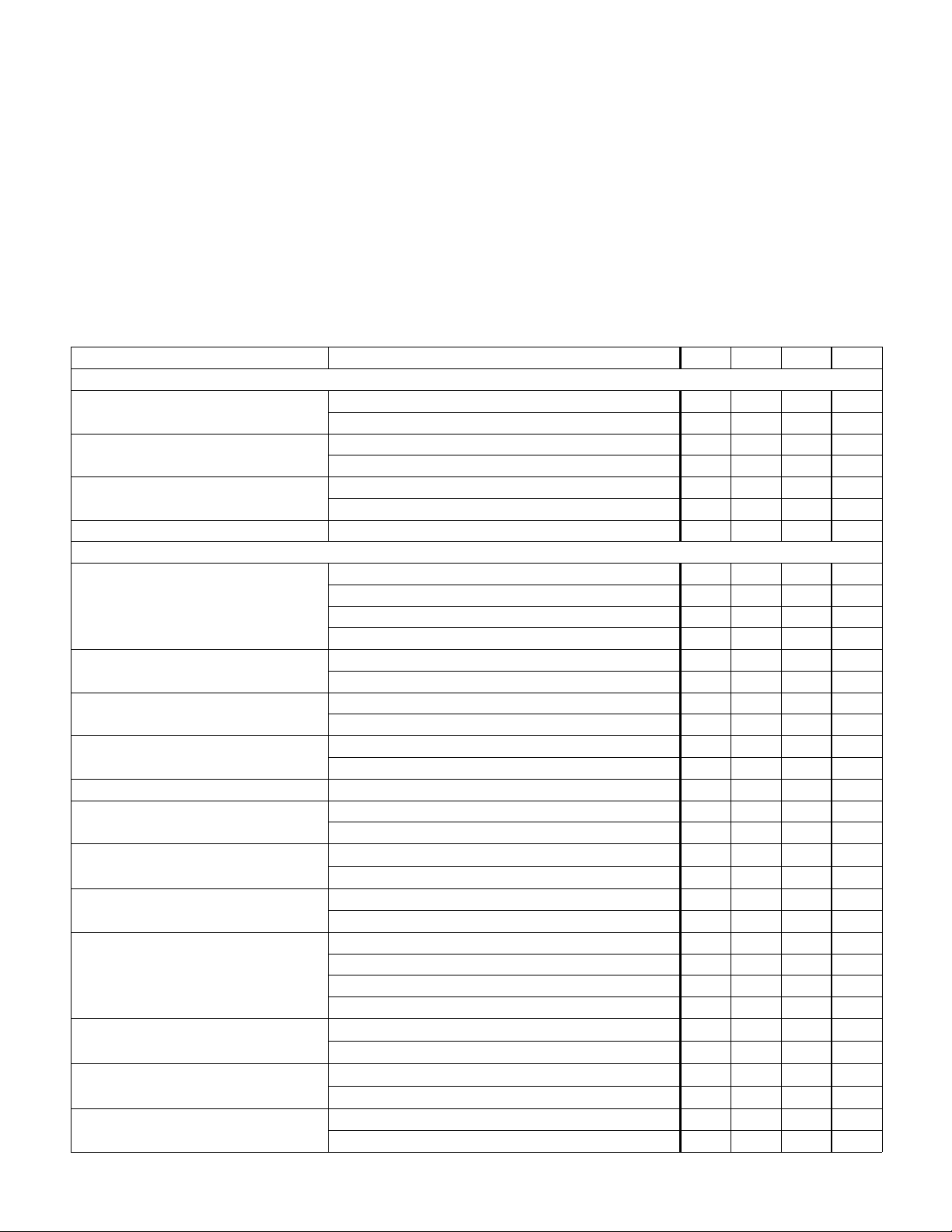

ELECTRICAL CHARACTERISTICS

Unless otherwise stated, these specifications apply for T

5V, VFB = V

REF

, I

SWITCH

= 0, and TA =TJ.

= −40°C to +125°C, VIN =

A

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

System Parameters

Output Voltage VIN = 5V to 10V, I

Line Regulation VIN = 3.0V to 10V, I

Load Regulation VIN = 5V, I

Efficiency VIN = 5V, I

Circuit Figure 1

(Note 3)

= 100mA to 800mA 11.40 12.0 12.60 V

LOAD

= 25°C 11.60 12.40 V

T

J

= 300mA 20 100 mV

LOAD

T

= 25°C50mV

J

= 100mA to 800mA 20 100 mV

LOAD

= 25°C50mV

T

J

= 800mA 80 %

LOAD

Device Parameters

Input Supply Current VFB = 1.5V (Switch Off) 7.5 14 mA

= 25°C10mA

T

J

= 2.0A, V

I

SWITCH

T

= 25°C70mA

J

Input Supply UVLO I

= 100mA 2.70 2.95 V

SWITCH

= 25°C2.85V

T

J

Oscillator Frequency Measured at SWITCH Pin, I

T

= 25°C4856kHz

J

Reference Voltage Measured at FB Pin, VIN = 3.0V to 40V, V

= 25°C 1.214 1.246 V

T

J

= 2.0V (Max Duty Cycle) 45 85 mA

COMP

= 100mA 42 52 62 kHz

SWITCH

= 1.0V 1.206 1.230 1.254 V

COMP

Reference Voltage Line Regulation VIN = 3.0V to 40V 0.5 mV

Error Amp Input Bias Current V

Error Amp Transconductance

Error Amp Voltage Gain V

Error Amplifier Output Swing Upper Limit V

Error Amp Output Current

Soft Start Current

Maximum Dut y C yc le V

= 1.0V 100 800 nA

COMP

= 25°C 300 nA

T

J

= −30µA to +30µA, V

I

COMP

T

= 25°C 2400 4800

J

= 0.8V to 1.6V, R

COMP

= 25°C 500 V/V

T

J

= 1.0V 2.0 2.4 V

FB

= 25°C2.2V

T

J

Lower Limit V

= 25°C0.40V

T

J

= 1.0V to 1.5V, V

V

FB

T

= 25°C

J

V

= 1.0V, V

FB

T

= 25°C2.57.5

J

= 1.5V, I

COMP

= 25°C93%

T

J

= 1.5V 0.3 0.55 V

FB

COMP

SWITCH

COMP

COMP

= 0.5V 1.5 5.0 9.5

= 100mA 90 95 %

= 1.0V 1600 3700 5800

COMP

= 1.0MW (Note 4) 250 800 V/V

±

= 1.0V

±

90

130

±

200±400 µA

±

300 µA

≤ 60V

≤ 3.0A

µ

mho

µmho

µA

µA

2

Page 3

UC2577-ADJ

ELECTRICAL CHARACTERISTICS

Unless otherwise stated, these specifications apply for T

5V, VFB = V

REF

, I

SWITCH

= 0, and TA =TJ.

= −40°C to +125°C, VIN =

A

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Device Parameters (cont.)

Switch Transconductance 12.5 A/V

Switch Leakage Current

Switch Saturation Voltage I

NPN Switch Current Limit V

Thermal Resistance

V

T

SWITCH

T

= 65V, VFB = 1.5V (Switch Off) 10 600

SWITCH

= 25°C300

J

= 2.0A, V

J

= 25°C0.7V

= 2.0V 3.0 4.3 6.0 A

COMP

= 2.0V (Max Duty Cycle) 0.5 0.9 V

COMP

Junction to Ambient 65

Junction to Case 2

COMP Pin Current

V

= 0 25 50

COMP

TJ = 25°C40

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating ratings

indicate cond it io ns during which the devi ce is in te nd ed to be functional, but device parameter sp ec if ic at ions may not be

guaranteed under these conditions. For guaranteed specifications and test conditions, see the Electrical Characteristics.

Note 2: Output current cannot be internally limited when the UC2577 is used as a step- up regulator. To prevent damage to

the switch, its current must be externally limited to 6.0A. However, output current is in ternally limited when the UC2577 is

used as a flyback or forward converter regulator.

Note 3. External components such as the diode, inductor, input and output capacitors can affect switching regulator

performance. Wh en the UC2 577 is used as shown in the Test Circuit, sys te m pe rfo rmance will be as specif ie d by t he

system parameters.

Ω

Note 4: A 1.0M

measuring A

resistor is connected to the compensation pin (which is the error amplifier’s output) to ensure accuracy in

In actual applications, this pin’s load resistance should be ≥ 10MΩ, resulting in A

VOL.

that is typically twice

VOL

the guaranteed minimum limit.

µA

µA

°C/W

°

C/W

µ

A

µA

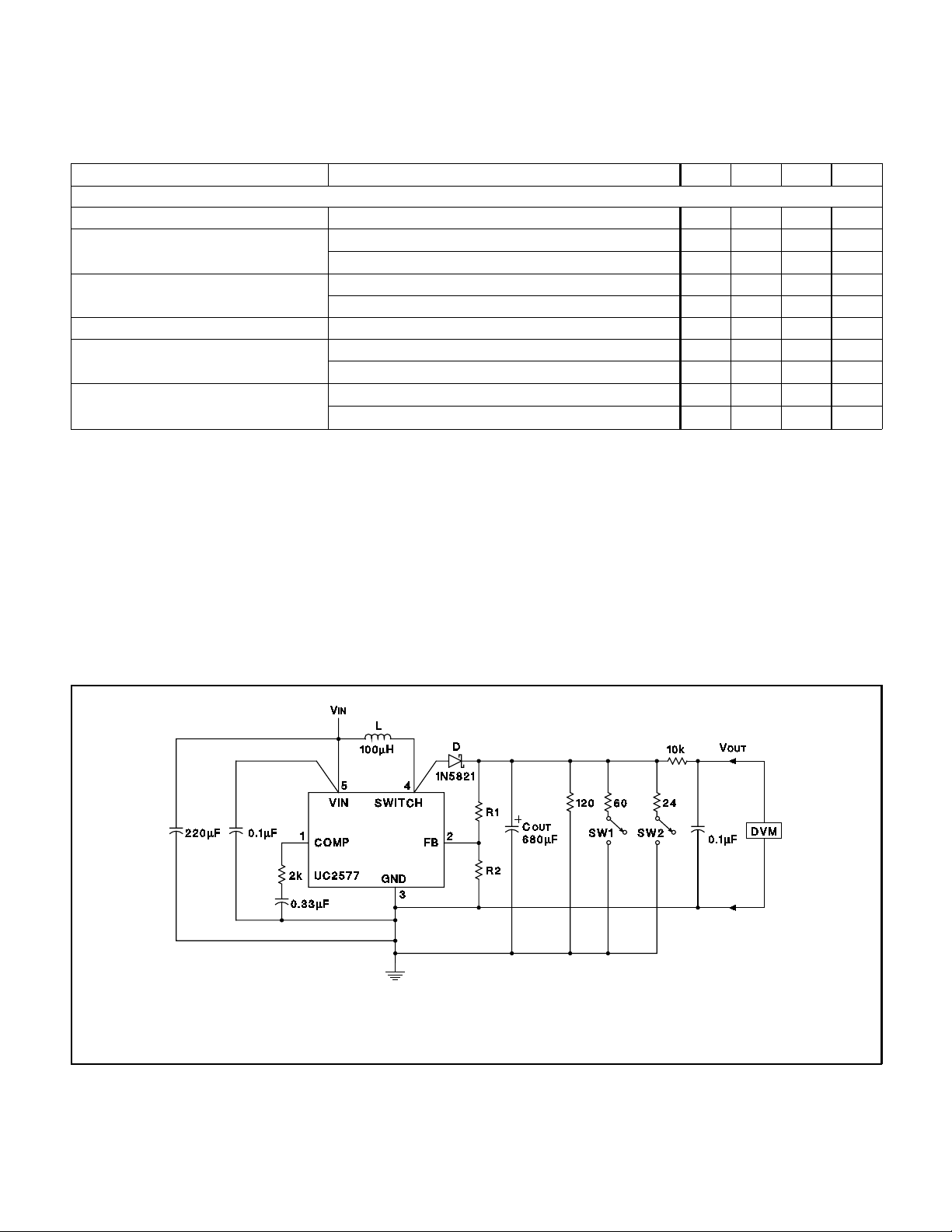

L = 415-0930 (AIE)

D = any manufacturer

C

= Sprague Type 673D

OUT

Electrolytic 680µF, 20V

R1 = 48.7k in series with 511Ω (1%)

R2 = 5.62k (1%)

Figure 1. Circuit Used to Specify System Parameters

3

UDG-94035

Page 4

APPLICATIONS INFORMATION

Step-up (Boost) Regulator

The Block Di agram shows a step-up switc hing regulator

utilizing the UC2577. The regulator produces an output

voltage highe r than the inpu t volta ge. The UC 2577 turns

its switc h on and off at a fixed frequency of 52kHz, thus

storing en ergy in the in ductor ( L). When the NPN switch

is on, the inductor c urrent is charged at a r ate of VIN/L.

When the switch is off, the voltage at the SWITCH terminal of the inductor rises above VIN, discharging the

stored current through the output diode (D) into the output capacitor (C

) at a rate of (V

OUT

- VIN)/L. The en-

OUT

ergy stored in the inductor is thus transferred to the

output.

The output vol tage is controlled by the amount of energy

transferred, which is controlled by modulating the peak

inductor current. This modulation is accomplished by

feeding a po rtion of the out put voltage to an error amplifier which am plifies th e difference between the feedback

voltage and an internal 1.23V precision reference voltage. The output of the error amplifier is then compared to

a voltage proportional to the switch current, or the inductor current, during the switch on time. A comparator terminates the switch on time when the two voltages are

equal and thus c ontrols the peak switch current to maintain a constant output voltage. Figure 2 shows voltage

and current waveforms for the circuit. Formulas for calculation are shown in Figure 3.

STEP-UP REGULATOR DESIGN PROCEDURE

Refer to the Block Diagram

Given:

V

= Minimum input supply voltage

INmin

V

= Regulated output voltage

OUT

V

+ VF − V

Duty Cycle D

Avg. Inductor

Current

Inductor

Current Ripple

Peak Inductor

Current

Peak Switch

Current

Switch Voltage

when Off

Diode Reverse

Voltage

Avg. Diode

Current

Peak Diode

Current

Power

Dissipation

I

IND(AVG)

∆I

I

IND(PK)

I

SW(PK)

V

SW(OFF)

V

I

D(AVG)

I

D(PK)

P

IND

R

D

OUT

V

OUT

0.25Ω

+ V

VIN − V

I

VF = Forward Biased Diode Voltage, I

Figure 3. Step-up Regulator Formulas

F

I

I

I

LOAD

1−D

LOAD

1−D

LOAD

− V

L

LOAD

1−D

LOAD

1−D

V

OUT

V

OUT

2

UC2577-ADJ

IN

V

OUT

≈

V

D

52,000

I

IND

2

IND

2

F

SAT

IND

.

2

I

LOAD

50

OUT

• D • V

(1−D)

SAT

I

LOAD

D

1 −

SAT

•

∆

+

∆I

+

+ V

- V

I

LOAD

∆I

+

D +

= Output Load

− V

IN

IN

Figure 2. Step-up Regulator Waveforms

First, determi ne if the UC 2577 can provide these values

of V

value of V

OUT

and I

LOADmax

. The upper l imit s for V

IN

when operatin g with the mi nimum

OUT

and I

LOADmax

given by the following equations.

V

≤ 60V and

OUT

V

≤ 10 • V

OUT

LOADmax

I

2.1A • V

≤

INmin

OUT

V

INmin

These limits must be gr eater t han or equa l to the values

specified in this application.

1. Output Voltage Section

Resistors R1 and R2 are u sed to select the desired output voltage. These resistors for m a voltage divider and

present a portion of the output voltage to the error amplifier which co mpares it to an internal 1.23V reference. Select R1 and R2 such that:

=

OUT

V

1.23V

− 1

R1

R2

4

are

Page 5

APPLICATIONS INFORMATION (cont.)

2. Inductor Selection (L)

A. Preliminary Calculations

To select the inductor, the calculation of the following

three parameters is necessary:

UC2577-ADJ

If L

is smaller than the inductor values found in step

min

B1, go on to step C. Otherwise, the inductor v alue found

in step B1 is too low; an appropriate inductor code

should be obtained from the graph as follows:

Dmax, the maximum switch duty cycle (0 ≤ D ≤ 0.9):

OUT

V

max

D

=

+ VF − V

OUT

V

+ VF − 0.6V

INmin

where typicall y VF = 0.5V for Schottky diodes and VF =

0.8V for fast recovery diodes.

E • T, the product of volts • time that charges the inductor:

6

(V• µs

)

E • T =

I

IND, DC

I

max

D

• (V

INmin

− 0.6V)10

52,000Hz

, the average inductor current under full load:

IND, DC

1.05 • I

=

1 − D

LOADmax

max

B. Identify Inductor Value:

1. From Figure 4, identify the inductor code for the region

indicated b y the intersection of E • T and I

IND, DC

. This

code gives the inductor value in microhenries. The L or H

prefix sig nifies whethe r the inductor is rated for a maximum E • T of 90Vµs (L) or 250Vµs (H).

2. If D < 0.85, go to step C. If D ≥ 0.85, calculate the

minimum inductance needed to ensure the switching

regulator’s stability:

1. Find the lowest value inductor that is greater than

L

.

min

2. Find where E • T intersects this inductor value to

determine if it has an L or H prefix. If E • T intersects

both the L and H regions, select the inductor with an

H prefix.

C.

Inductor Selection

Select an ind uctor fr om the table of Figure 5 which cross

references the in duc tor code s t o th e par t numbers of the

three differe nt m anuf act ure rs. The i ndu ctors l isted in thi s

table have the following characteristics:

AIE

(ferrite, po t-core inductors): Benefits of this type

are low etectromagnetic interference (EMI), small

physical size, and very low power dissipation (core

loss).

Pulse

(powdered iro n, toroid core inductors): Benefits are low EMI and ability to withstand E • T and

peak current above rated value better than ferrite

cores.

Renco

(ferrite, bobbin-core inductors): Benefits are

low cost and best abil ity to withstand E • T and peak

current above rated value. Be aware that these inductors generate more EMI than the other types, and

this may interfere with signals sensitive to noise.

200

H2200

E·T (V·µs)

150

100

90

80

70

60

50

45

40

35

30

25

20

0.3 0.4

0.35

H1000 H680 H470 H330 H220

H1500

L680

L470

0.6

0.45

0.5

0.7 0.8 0.9 1.0 1.5 2.0 2.5 3.0

I

IND, DC

(A)

H150

L100L150L220L330

L68

L47

Note: This chart assumes that the inductor ripple current inductor is approximately 20% to 30% of the average inductor current

(when the regulator is under full load). Greater ripple current causes higher peak switch currents and greater output ripple voltage. Lower ripple current is achieved with larger value inductors. The factor of 20% to 30% is chosen as a convenient balance

between the two extremes.

Figure 4. Inductor Selection Graph

5

Page 6

APPLICATIONS INFORMATION (cont.)

Inductor

Code

L47 415 - 0932 PE - 53112 RL2442

L68 415 - 0931 PE - 92114 RL2443

L100 415 - 0930 PE - 92108 RL2444

L150 415 - 0953 PE - 53113 RL1954

L220 415 - 0922 PE - 52626 RL1953

L330 415 - 0926 PE - 52627 RL1952

L470 415 - 0927 PE - 53114 RL1951

L680 415 - 0928 PE - 52629 RL1950

H150 415 - 0936 PE - 53115 RL2445

H220 430 - 0636 PE - 53116 RL2446

H330 430 - 0635 PE - 53117 RL2447

H470 430 - 0634 PE - 53118 RL1961

H680 415 - 0935 PE - 53119 RL1960

H1000 415 - 0934 PE - 53120 RL1959

H1500 415 - 0933 PE - 53121 RL1958

H2200 415 - 0945 PE - 53122 RL2448

AIE Magnetics, Div. Vernitron Corp.,

2801 72nd Street North, St. Pet ers bu rg, FL 33710

Pulse Engineerin g,

12220 World Trade Drive, San Diego, CA 92128

Renco Electronics, Inc. ,

60 Jeffryn Blvd. East, Deer Park, NY 11729

Figure 5. Tabl e of Standardized Indu cto rs and

Manufacturer’s Part Numbers

3. Compensation Network (RC, CC) and Output

Capacitor (C

OUT

The compensation network consists of resistor R

capacitor C

which for m a simple pole-zero network and

C

stabilize the regulator. The values of R

upon the volt age gain of the regulator, I

ductor L, and output capacitance C

calculate and select the values for R

which ensures stability is described below. It should be

noted, however, that this may not result in optimum compensation. To guarantee optimum compensation a standard procedure for testing loop stabili ty is recommended,

such as measu ring V

I

.

LOAD

A. Calculate the maximum value for RC.

750 • I

RC ≤

Select a r esistor less tha n or equal to this value, not to

exceed 3kΩ.

B. Calculate the minimum value for C

lowing two equations.

0.19

OUT

C

≥

Manufacturer’s Part Number

AIE Pulse Renco

(813)347-2181

(619)674-8100

(516)586-5566

) Selection

and CC depend

C

LOADmax

. A procedure to

OUT

, CC, and C

C

transient responses to pulsing

OUT

LOADmax

INmin

V

•

L • R

INmin

V

• V

2

C

• V

OUT

•

I

OUT

2

LOADmax

and

using the fol-

OUT

and

C

, the in-

OUT

UC2577-ADJ

(

• RC

•

INmin

V

OUT

C

≥

487,800 • V

The larger of these two values is the minimum value that

ensures stability.

C. Calculate the minimum value of CC.

CC ≥

58.5

• V

C

R

2

• V

OUT

• C

INmin

2

The compensation capacitor is also used in the soft start

function of the regulator. When the input voltage is applied to the pa rt, the switch duty cy cle is increased slowl y

at a rate def ined by the compensation capacitor and the

soft start current, thus eliminating high input currents.

Without the soft start circuitry, the switch duty cycle would

instantly rise to a bout 90% and draw large currents from

the input s up pl y. For proper soft starti ng, the val ue for C

should be equal or greater than 0.22µF.

Figure 6 lists several types of aluminum electrolytic capacitors which could be used for the output filter. Use the

following parameters to select the capacitor.

Working Voltage (WVDC):

working voltage at least 20% higher than the regulator

output voltage.

Ripple Current:

This is the maximum RMS value of current that char ges t he ca paci tor during each switchi ng cycle. For step-up and flyback regulators, the formula for

ripple current is:

RIPPLErms

I

=

LOADmax

I

•

D

−

max

D

1

Choose a c apacitor that is rated at l east 50% higher than

this value at 52kHz.

Equivalent S eries Resistance (ESR):

cause of ou tput rippl e vol tage, and it also affects the val ues of R

and CC needed to stabilize the regulator. As a

C

result, th e preceding calculations for C

valid if the ESR does not exceed the maximum value

specified by the following equations.

ESR ≤

RIPPLE(P−P

I

0.01 • 15V

RIPPLE

I

)

=

and ≤

)

(

P−P

1.15 • I

−

1

LOADmax

max

D

Select a capacitor with an ESR, at 52kHz, that is less

than or eq ual to th e lower value cal culated. Most electrolytic capacitors specify ESR at 120kHz which is 15% to

30% higher than at 52kHz. Also, note that ESR increases

by a factor of 2 when operating at −20°C.

In general, low values of ESR are achieved by using

large value capacitors (C ≥ 470µF), and capacitors with

high WVDC, or by paralleling smaller value capacitors.

V

OUT

INmin

+

(3.74

OUT

• 105 • L

3

))

Choose a capacitor with a

max

This is the primary

and RC are only

C

−

3

8.7 • 10

LOADmax

I

• V

IN

where

C

6

Page 7

APPLICATIONS INFORMATION (cont.)

4. Input Capacitor Selection (CIN)

To reduce noise on the supply voltage caused by the

switching action of a step-up regulator (ripple current

noise), V IN sh ould be by passed to gr ound. A good quality 0.1µF capacitor with low ESR should provide sufficient decoupling. If the UC2577 is located far from the

supply source filter capacitors, an additional electrolytic

(47µF, for example) is required.

Nichicon -

United Chemi-CON -

Figure 6. Aluminum Electrolytic Capacitors Recommended

5. Output Diode Selection (D)

In the step-up regulator, the switching diode must withstand a reverse voltage and be able to conduct the peak

output curre nt of th e UC2577. Therefor e a su i ta bl e diode

must have a minimum reverse breakdown voltage

greater than the circuit output voltage, and should also

be rated for average and peak current greater than

I

LOADmax

drop (and thus higher regulator efficiencies), Schottky

barrier dio de s are often used in switchi ng regulators. Refer to Figure 7 for recommended part numbers and voltage ratings of 1A and 3A diodes.

Types PF, PX, or PZ

927 East StateP arkway, Schaumburg, IL 60173

(708)843-7500

Types LX, SXF, or SXJ

9801 West Higgens, Rosemont, IL 60018

(708)696-2000

for Switching Regulators

and I

. Because of their low forward voltage

Dpk

UC2577-ADJ

OUTmax

V

20V

30V

40V

50V

100V

MBRxxx and MURxxx ar e ma nu fa ctured by Motorola.

1DDxxx, 11Cxx and 31Dxx are manu factured by

International Rectifier

Schottky Fast Recovery

1A 3A 1A 3A

1N5817 1N5820

MBR120P MBR320P

1N5818 1N5821

MBR130P MBR330P

11DQ03 31DQ03

1N5819 1N5822

MBR140P MBR340P

11DQ04 31DQ04

MBR150 MBR350 1N4933

11DQ05 31DQ05 MUR105

1N4934 MR851

MUR110 30DL1

10DL1 MR831

Figure 7. Diode Selection Chart

ORDERING INFORMATION

Unitrode Type Number

UC2577T-ADJ 5 Pin TO-220 Plastic Package

UC2577TD-ADJ 5 Pin TO-263 Plastic Package

UNITRODE CORPORATI ON

7 CONTINENTAL BLVD. • MERRIMACK, NH 03054

TEL. (603) 424- 24 10 • FAX (603) 424-3460

7

Page 8

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...