Page 1

Ultrasonic sensor UC2000-L2-E6-V15

Technical data

General specifications

Sensing range 60 ... 2000 mm

Adjustment range 80 ... 2000 mm

Dead band 0 ... 60 mm

Standard target plate 100 mm x 100 mm

Transducer frequency approx. 175 kHz

Model Number

UC2000-L2-E6-V15

Single head system

Features

• Sensor head bidirectional and rotatable

• Function indicators visible from all

directions

• Quick mounting bracket

• Selectable sound lobe width

• Programmable

Diagrams

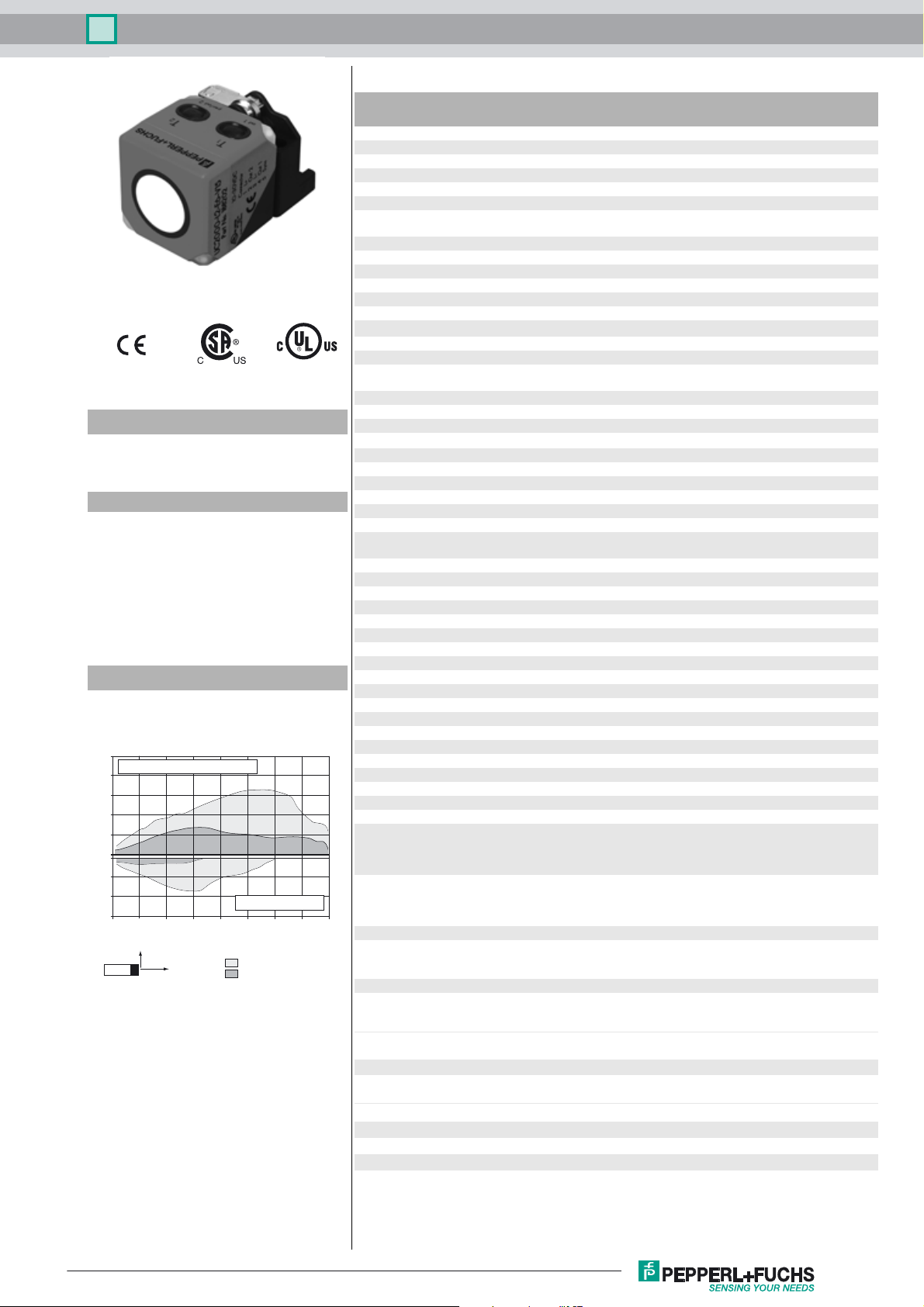

Characteristic response curve

Distance Y [mm]

1000

flat surface 100 mm x 100 mm

800

600

400

200

0

-200

-400

-600

0 500 1000 1500 2000 2500 3000 3500 4000

Y

X

round bar, Ø 25 mm

Distance X [mm]

wide sound lobe

narrow sound lobe

Response delay minimum : 60 ms

Indicators/operating means

LED green Operating display

LED yellow 1 switching state switch output 1

LED yellow 2 switching state switch output 2

LED red error

Electrical specifications

Operating voltage U

No-load supply current I

Interface

B

0

Interface type Serial interface (programming adapter required)

Input/Output

Input/output type 1 synchronization connection, bidirectional

0 Level 0 ... 1 V

1 Level 4 V ... U

Input impedance > 12 kΩ

Output rated operating current < 12 mA

Pulse length 0.5 ... 300 ms (level 1)

Pulse interval ≥ 33 ms (level 0)

Synchronization frequency

Common mode operation ≤ 30 Hz

Multiplex operation ≤ 33 Hz / n , n = number of sensors , n ≤ 10

Output

Output type 2 switch outputs PNP, NO/NC, programmable

Rated operating current I

Voltage drop U

Repeat accuracy ≤ 0.1 % of full-scale value

d

e

Switching frequency f ≤ 5 Hz

Range hysteresis H programmable , preset to 1 mm

Temperature influence < 1.5 % of full-scale value

Ambient conditions

Ambient temperature -25 ... 70 °C (-13 ... 158 °F)

Storage temperature -40 ... 85 °C (-40 ... 185 °F)

Mechanical specifications

Connection type Connector M12 x 1 , 5-pin

Degree of protection IP67

Material

Housing PA-GF35

Transducer epoxy resin/hollow glass sphere mixture; polyurethane foam

Mass 115 g

Factory settings

Output 1 near switch point: 80 mm

Output 2 near switch point: 150 mm

Beam width wide

Evaluation procedure averaging (MxN)

General information

Supplementary information Switch settings of the external programming adapter:

Compliance with standards and

directives

Standard conformity

Standards EN 60947-5-2:2007 + A1:2012

Ex works settings: 120 ms

10 ... 30 V DC , ripple 10 %

SS

≤ 50 mA

9600 BPS, no parity, 8 data bits, 1 stop bit

B

(factory setting: n = 5 )

200 mA , short-circuit/overload protected

≤ 2 V

far switch point: 2000 mm

output function: Window mode

output behavior: NO contact

far switch point: 1000 mm

output function: Window mode

output behavior: NO contact

M = 5

N = 2

"output load": pull-down

"output logic": inv

IEC 60947-5-2:2007 + A1:2012

Release date: 2016-02-15 13:04 Date of issue: 2016-02-15 277765_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

Approvals and certificates

UL approval cULus Listed, General Purpose

CSA approval cCSAus Listed, General Purpose

CCC approval CCC approval / marking not required for products rated

≤36 V

1

Page 2

Ultrasonic sensor UC2000-L2-E6-V15

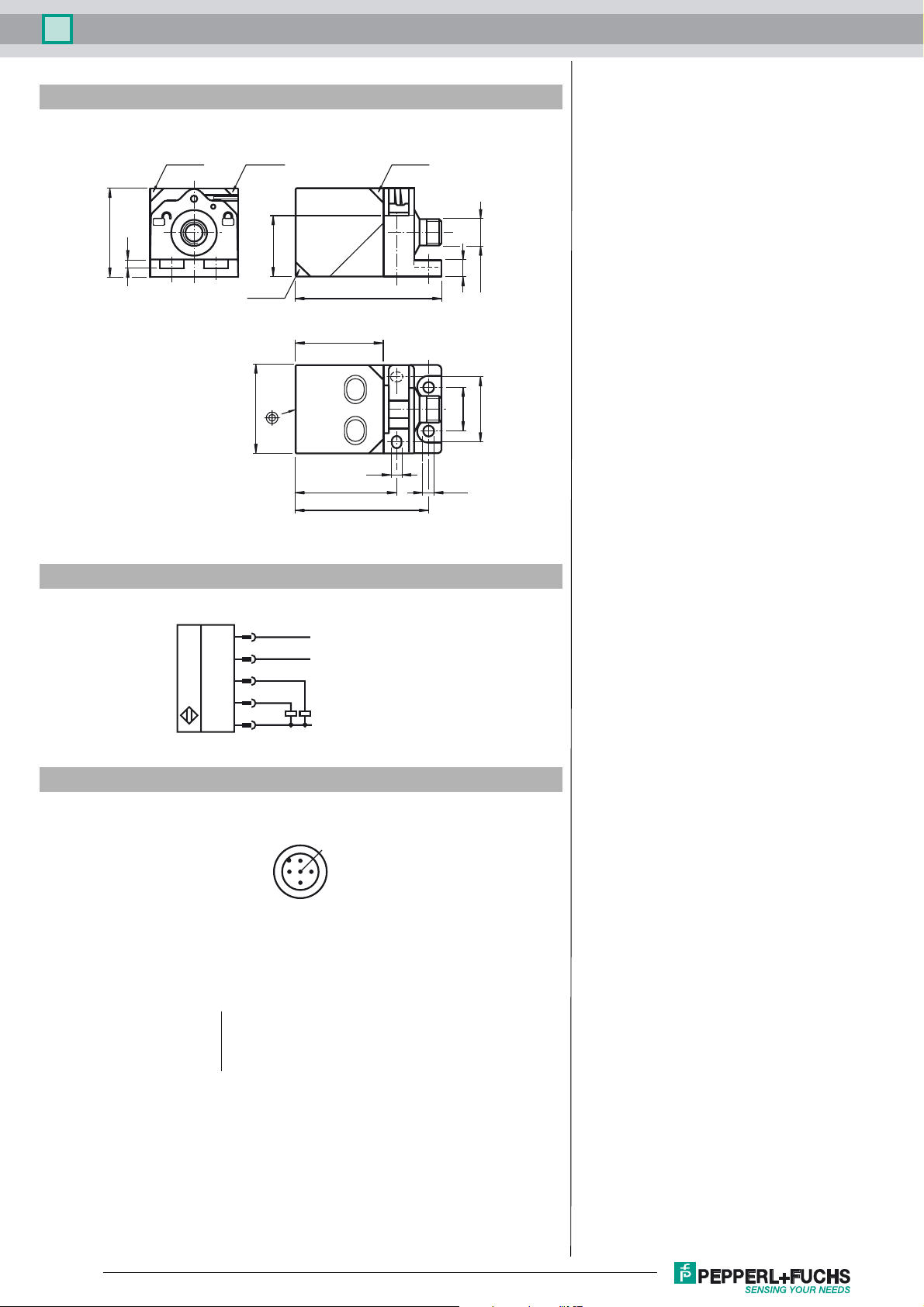

Dimensions

LED yeLED gnLED ye

40

3

LED gn

28

7

67

40

M12 x 1

Electrical Connection

Pinout

40

T1 T2

out 1 pwr/out 2

5.5

60

1

5

4

2

3

2

L+

Synchronization

Switch output 1

Switch output 2

L-

1

5

4

20

30

ø 5.546

3

Wire colors in accordance with EN 60947-5-2

1 BN

2 WH

3 BU

4 BK

5 GY

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

(brown)

(white)

(blue)

(black)

(gray)

Release date: 2016-02-15 13:04 Date of issue: 2016-02-15 277765_eng.xml

2

Page 3

Ultrasonic sensor UC2000-L2-E6-V15

Accessories

UC-PROG1-USB

Programming adapter

PACTware 4.X

FDT Framework

Ultraschall-Sensoren DTM

DTM devices for communication with cube style and UMC... sensors

V15-G-2M-PVC

Female cordset, M12, 5-pin, PVC cable

Microsoft .NET

Description of Sensor Functions

Programming procedure

The sensor features two outputs with two programmable switch points, each (for a total of 4). Programming the switch points and the operating mode can be done in two

different ways:

- via the sensor’s programming buttons

- via the serial interface, which requires an external interface adapter

The procedure for programming via the sensor's programming buttons is described below. For programming using the serial interface, please refer to the software manual.

Switch points and operating modes of each output can be programmed independently without influencing each other.

Note:

- Programming is enabled for 5 minutes after power-on. After 5 minutes without programming activity the programming feature will be locked.

- During any programming step it is possible to leave the programming routine without changing the sensor settings by pressing the currently used programming button

for 10 s.

Programming the Switch Points

Notes:

- The description below leads you through programming output 1’s switch points. The procedure for output 2 is exactly the same with the only difference, being to use the

Programming Button T2.

- If the red LED flashes during the programming procedure, it indicates uncertain target detection. In this case, please correct the target alignment until the yellow LED

flashes. The new settings will only be stored in the sensor’s memory if the yellow LED flashes.

Programming the Near Switch Point

1. Place the target at the desired near switch point position

2. Press Programming Button T1 for 2 s (corresponding yellow LED flashes)

3. Press Programming Button T1 briefly (green LED flashes three times for confirmation). The sensor returns to normal operation.

Programming of the Far Switch Point

1. Place the target at the desired far switch point position

2. Press Programming Button T1 for 2 s (corresponding yellow LED flashes)

3. Press Programming Button T1 for 2 s (green LED flashes three times for confirmation). The sensor returns to normal operation.

Programming Modes of Operation

Note:

The description below leads you through programming of the modes of operation for output 1. The procedure for output 2 is exactly the same with the only difference,being to

use Programming Button T2.

The sensor provides a three step routine to program the modes of operation. In this routine you can program:

1. Output function

2. Output behavior

3. Beam width

Programming the modes is carried out sequentially. To toggle from one mode to the next, press the Programming button for 2 s.

Press Programming Button T1 for 5 s to enter the operating modes programming routine.

Programming the output function

1. The green LED flashes. The number of flashes indicates the current output function:

single flash: Switch point output function

double flash: Window output function

triple flash: Hysteresis output function.

2. Press Programming Button T1 briefly to toggle sequentially through these output functions and select the desired mode.

3. Press Programming Button T1 for 2 s to save and enter the programming routine for output behavior

Programming the output behavior

1. The yellow LED flashes. The number of flashes indicates the current output behavior:

single flash: Normally Open (NO)

double flash: Normally Closed (NC).

2. Press Programming Button T1 briefly to toggle sequentially through these output behaviors and select the desired mode.

3. Press Programming Button T1 for 2 s to save and enter the programming routine for beam width.

Programming the beam width

1. The red LED flashes. The number of flashes indicates the current beam width setting:

single flash: narrow

double flash: medium

triple flash: wide.

Release date: 2016-02-15 13:04 Date of issue: 2016-02-15 277765_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

3

Page 4

Ultrasonic sensor UC2000-L2-E6-V15

2. Press Programming Button T1 briefly to toggle sequentially through these beam shapes.

3. Press Programming Button T1 for 2 s to save and exit the operating modes programming routine.

Note:

Independently programming the beam width for each individual output is not possible. The last programmed beam width is valid for both outputs. It doesn’t matter which Programming Button is used.

Reset Sensor to Factory Settings

The sensor has a feature to reset to factory settings

1. Disconnect the sensor from power supply

2. Press and hold one of the Programming Buttons T1 or T2

3. Connect Sensor to power supply (red and yellow LED flash simultaneously for 5 s then green and yellow LED flash simultaneously)

4. Release Programming Button

The sensor now operates with default factory settings.

Factory settings

See technical data.

Display

The sensor is provided with LEDs to indicate various conditions.

#

During Normal operation

Proper operation

Interference (e.g. compressed air)

During Switch Point Programming

Object detected

No object detected

Confirmation after Programming

Programming failed warning

During Sensor Mode Programming

Programming the output function

Programming the output behaviour

Programming the beam width

*)

off if yellow LED out2 is on

Green LED Yellow LED out1 / out2 Red LED

*)

On

Off

Off

Off

Triple flashing

Off

Flashing

Off

Off

Switching state

output 1 / output 2

remains in previous state

Flashing

Off

Off

Off

Off

Flashing

Off

Off

On

Off

Flashing

Off

Triple flashing

Off

Off

Flashing

Synchronization

This sensor features a synchronization input for suppressing ultrasonic mutual interference ("cross talk"). If this input is not connected, the sensor will operate freewheeling

using internally generated clock pulses. It can be synchronized by applying an external square wave or by means of appropriate programming via the serial interface. Each

falling edge of the synchronization pulse triggers transmission of a single ultrasonic pulse. If the synchronization signal remains low for ≥ 1 second, the sensor will revert to

normal operating mode. Normal operating mode can also be activated by opening the signal connection to the synchronization input.(See note below)

If the synchronization input goes to a high level for > 1 second, the sensor will switch to standby mode, indicated by the green LED. In this mode, the output(s) will remain in

the last valid output state. When using the external synchronization feature, please refer to the software description.

Note:

If the option for synchronization is not used, the synchronization input has to be connected to ground (0V) or the sensor has to be operated via a V1 cordset (4-pin).

The synchronization function cannot be activated during programming mode and vice versa.

The following synchronization modes are possible:

1. Several sensors (max. number see technical data) can be synchronized together by interconnecting their respective synchronization inputs. In this case, each sensor

alternately transmits ultrasonic pulses in a self multiplexing mode. No two sensors will transmit pulses at the same time. (See note below)

2. Several sensors (max. number see technical data) can be synchronized together by interconnecting their respective synchronization inputs. Due to programming via the

sensors interface one sensor acts as a master device, all the others as slave devices. (see description of the interface) In this master / slave mode the sensors are triggered

in parallel and are synchronized by a common synchronization pulse, provided by the master device.

3. Multiple sensors can be controlled by the same external synchronization signal. In this mode the sensors are triggered in parallel and are synchronized by a common

external synchronization pulse. All sensors must be parameterized for external synchronization by means of the sensor interface. See software description.

4. A separate synchronization pulse can be sent to each individual sensor. In this mode the sensors operate in external multiplex mode. (See note below). All sensors must

be parameterized for external synchronization by means of the sensor interface. See software description.

5. A high level (+U

Note:

Sensor response times will increase proportionally to the number of sensors that are in the synchronization string. This is a result of the multiplexing of the ultrasonic transmit

and receive signal and the resulting increase in the measurement cycle time.

Note:

The sensors syncronization input delivers an output current in case of low level and burdens with its input impedance in case of high level. Please pay attention that the synchronizing device needs to have that driver capability:

driver current against +U

driver current against 0V ≥ n * output current (n = number of sensors to be synchronized).

) or a low level (-UB)on the synchronization input switches the sensor to standby mode if it is parameterized for external synchronization.

B

≥ n * high-level/input impedance (n = number of sensors to be synchronized)

B

Release date: 2016-02-15 13:04 Date of issue: 2016-02-15 277765_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

4

Loading...

Loading...