Page 1

TWR-MCF51MM

User Manual

Rev. 1.0

Freescale Semiconductor Inc.

Page 2

Contents

1 Overview ...................................................................................................................................................... 3

2 Reference Documents .............................................................................................................................. 4

3 Hardware Features ................................................................................................................................... 4

3.1 Clocking .................................................................................................................................................................................. 4

3.2 System Power ....................................................................................................................................................................... 4

3.3 Debug Interface ................................................................................................................................................................... 4

3.4 RS232 Interface ................................................................................................................................................................... 5

3.5 Infrared Port ......................................................................................................................................................................... 5

3.6 Medical Connector .............................................................................................................................................................. 5

3.7 Elevator Connections ........................................................................................................................................................ 6

3.8 Mechanical Form Factor .................................................................................................................................................. 8

4 Jumper Table .............................................................................................................................................. 8

5 Input/Output Connectors and Pin Usage Table........................................................................... 10

6 OSBDM ........................................................................................................................................................ 10

6.1 Bootloader Mode For MC9S08JM60......................................................................................................................... 10

7 Bootloader Mode For MCF51MM256 .............................................................................................. 11

8 BDM inteface (Optional) ...................................................................................................................... 12

TWR-MCF51MM User Manual Page 2 of 12

Page 3

1 Overview

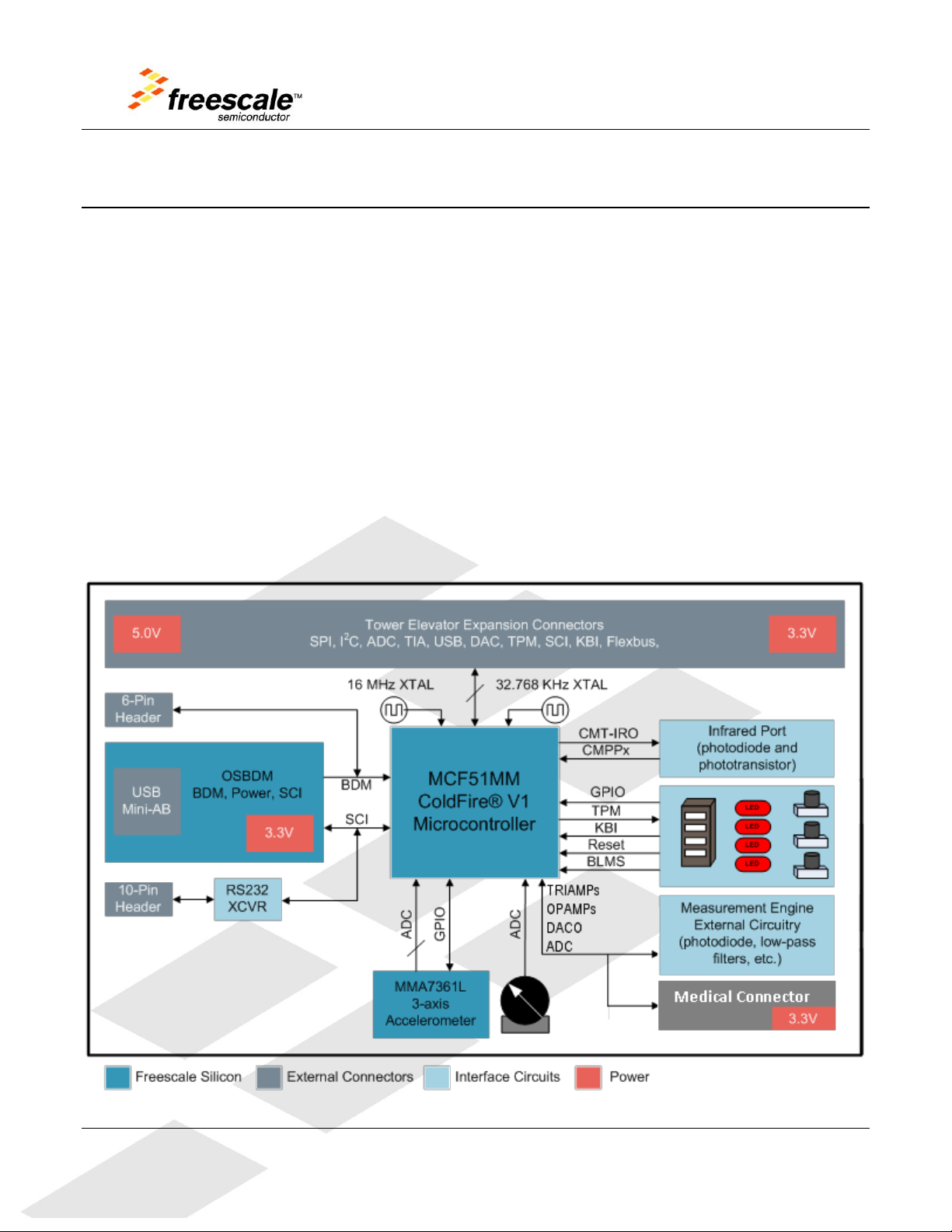

TWR-MCF51MM is a low-cost evaluation, demonstration and development board that features a 32-bit

MCF51MM256 microcontroller. The TWR-MCF51MM can operate stand-alone or as the main control

board in a Tower System with peripheral modules.

The following list summarizes the features of the MCF51MM Tower MCU boards:

Tower compatible processor board

Open Source BDM (OSBDM) circuit

Analog measurement circuitry

4 LEDs

DIP Switches and push buttons for user input

Potentiometer

MMA7361L three-axis accelerometer

RS232 transceiver and 2x5 pin header

Figure 1. TWR-MCF51MM Block Diagram

TWR-MCF51MM User Manual Page 3 of 12

Page 4

2 Reference Documents

The documents listed below are available online. Refer to http://www.freescale.com/tower for the

latest revision of all Tower System documentation.

TWR-MCF51MM Schematics

TWR-MCF51MM Quick Start Guide

TWR-MCF51MM-KIT Lab Tutorial

MCF51MM256 Reference Manual

MCF51MM256 Data Sheet

AN3561, USB Bootloader for the MC9S08JM60

3 Hardware Features

This section provides more details about the features and functionality of the TWR-MCF51MM.

3.1 Clocking

Two crystals are provided on the board for clocking the MCF51MM256 device:

1. A 16 MHz crystal connected to XTAL2 and EXTAL2 for system clocking

2. A 32.768kHz crystal connected to XTAL1 and EXTAL1 for TOD usage

3.2 System Power

The TWR-MCF51MM can be powered by the Open Source BDM (OSBDM) circuit via the Mini-B USB

connector when stand-alone. When assembled with the Tower System and the TWR-SER is configured

to run USB device mode (J16 pin 3 and 4 connected), the Mini-B USB connector is no longer used as a

power source and only used for OSBDM debugging purposes. In this case, the power will be supplied

from the Mini-B USB from the TWR-SER. Please plug in the Mini-B USB connector from TWE-SER before

plugging in the Mini-B USB connector from TWR-MCF51MM.

A standard USB A male to Mini-B male cable (provided) can be used to supply power from a USB host

or powered USB hub. Optionally, an AC to DC adapter with a USB A female receptacle (not provided)

can be used as the power source.

A jumper, J11, can be used to isolate the 3.3V supply from the microcontroller. This connection can be

used to measure the power usage of the MCF51MM256 microcontroller.

3.3 Debug Interface

An on-board, MC9S08JM60 based OSBDM circuit provides a debug interface to the MCF51MM256. A

standard USB A male to Mini-B male cable (provided) can be used for debugging via the USB connector,

J17. Refer to Section 6 for information on other modes of operation of the OSBDM.

TWR-MCF51MM User Manual Page 4 of 12

Page 5

MCF51MM256

Signal

Pin

MCF51MM256

Signal

Not Connected

1 2 Not Connected

TX2

3 4 Not Connected

RX2

5 6 Not Connected

Not Connected

7 8 Not Connected

GND

9

10

3.3V

3.4 RS232 Interface

An RS232 transceiver on the TWR-MCF51MM connects to a standard 2x5 pin header (refer to Figure 2).

Selection jumpers J15 and J16 allow MCF51MM256 SCI2 signals to be routed to either the RS232

transceiver or the OSBDM circuit. Refer to Figure 5 for more details.

Alternatively, when assembled as a Tower System, the MCF51MM256 SCI1 TX and RX are routed to the

SER-TWR. If the SER-TWR jumpers are configured to run in RS-232 mode, the SCI1 TX and the RX signal

can be communicated via the RS232 connector from the TWR-SER. Please refer to the TWE-SER user

manual (TWRSERUM) from www.freescale.com/tower for more detail.

Figure 2. RS232 2x5 Pin Header Connections

3.5 Infrared Port

The TWR-MCF51MM implements an infrared transmit and receive port. The transmit circuit is

implemented with an infrared diode and the user can choose to drive the diode either with IRO or SCI

TX. The receiver is implemented by an infrared transistor and the user can choose to input this signal

to the SCI RX or the ACMP input. Jumpers J9, J25 and J26 are used for routing the connections, refer to

Section 4 to set the jumpers. Please refer to application note AN4116, searchable from

www.freescale.com

3.6 Medical Connector

The TWR-MCF51MM features a 2x10 expansion connector J27 (refer to Figure 3) to MED-EKG for

routing the medical engine signals to external medical board so it can use the OPAMP, TRIAMP, ADC

and DAC on MCF51MM to implement the requirement signal conditioning for medical applications.

When the DSC MC56F8006 from the MED-EKG is enabled, MCF51MM256 can choose to read the

conditioned EKG results output from the DSC via I2C transmission (pin 3 and pin 4). To enable I2C

communication, you must assemble the MEG-EKG with the Tower System because the TWR-SER has

the pulled up resistors circuit required for I2C transmission.

In Figure 3, the bold text highlights the functions that are used to implement the MED-EKG

demonstration. For detail about the MED-EKG, please refer to the MED-EKG user manual, MED-EKG lab

and schematic included in the TWR-MCF51MM-KIT or TWR-S08MM128-KIT. All these are also available

on Freescale.com/tower

TWR-MCF51MM User Manual Page 5 of 12

Page 6

MCF51MM256 Signal

Pin

MCF51MM256 Signal

MOSFET Q6 (pin 3)-Power (3.3V)

1 2 Ground(GND)

PTD4/SDA/RGPIOP10/TPM1CH2

3 4 PTD5/SCL/RGPIOP11/TPM1CH3

DADP0

5 6 DADM0

PTC4/KBI1P7/CMPP0/ADP8

7 8 DACO_E

OUT1

9

10

OUT2

INP1-

11

12

INP2-

PTA4/INP1+

13

14

PTA7/INP2+

VINP1

15

16

VINP2

VINN1/DADM2

17

18

VINN2/DADM3

TRIOUT1/DADP2

19

20

TRIOUT2/DADP3

TWR-MCF51MM Primary Connector

Pin

Name

Usage

Used

Jmp

Pin

Name

Usage

Used

Jmp

B1

5V

5V Power

X A1

5V

5V Power

X

B2

GND

Ground

X A2

GND

Ground

X

B3

3.3V

3.3V Power

X A3

3.3V

3.3V Power

X

B4

ELE_PS_SENSE

Elevator power sense

X A4

3.3V

3.3V Power

X

B5

GND

Ground

X A5

GND

Ground

X B6

GND

Ground

X A6

GND

Ground

X

B7

SPI1_CLK

SPI1 clock

X A7

SCL0

IIC clock

X

B8

SPI1_CS1

A8

SDA0

IIC data

X

B9

SPI1_CS0

SPI1 chip select

X

A9

GPIO9 / OPEN

GPIO PTE4

X

B10

SPI1_MOSI

SPI1 MOSI

X A10

GPIO8 / OPEN

GPIO PTC7

X

B11

SPI1_MISO

SPI1 MISO

X A11

GPIO7 / OPEN

GPIO PTC6

X

B12

ETH_COL

A12

ETH_CRS

B13

ETH_RXER

A13

ETH_MDC

B14

ETH_TXCLK

A14

ETH_MDIO

Figure 3. Medical Connector 2x10 Pin Header Connections

3.7 Elevator Connections

The TWR-MCF51MM features two expansion card-edge connectors that interface to elevator boards in

a Tower System: the Primary and Secondary Elevator connectors. The Primary Elevator connector,

comprised of sides A and B, is utilized by the TWR-MCF51MM, while the Secondary Elevator connector

only makes connections to ground (GND). Figure 4 provides the pinout for the Primary Elevator

connector. An “X” in the “Used” column indicates that there is a connection from the TWR-MCF51MM

to that pin on the elevator connector. An “X” in the “Jmp” column indicates that a jumper is available

that can configure or isolate the connection from the elevator connector.

Figure 4. TWR-MCF51MM Primary Elevator Connector Pinout

TWR-MCF51MM User Manual Page 6 of 12

Page 7

TWR-MCF51MM Primary Connector

Pin

Name

Usage

Used

Jmp

Pin

Name

Usage

Used

Jmp

B15

ETH_TXEN

A15

ETH_RXCLK

B16

ETH_TXER

A16

ETH_RXDV

B17

ETH_TXD3

A17

ETH_RXD3

B18

ETH_TXD2

A18

ETH_RXD2

B19

ETH_TXD1

A19

ETH_RXD1

B20

ETH_TXD0

A20

ETH_RXD0

B21

GPIO1 / OPEN

GPIO PTA2

X

A21

SSI_MCLK

B22

GPIO2 / OPEN

GPIO PTA6

X

A22

SSI_BCLK

TRIAMP1 negative input

X

B23

GPIO3 / OPEN

GPIO PTB1

X

A23

SSI_FS

TRIAMP2 output

X

B24

CLKIN0

A24

SSI_RXD

TRIAMP1 output

X

B25

CLKOUT1

A25

SSI_TXD

OPAMP1 output

X

B26

GND

Ground

X A26

GND

Ground

X B27

AN7

ADC channel 9

X A27

AN3

ADC differential minus

X

B28

AN6

ADC channel 8

X A28

AN2

ADC differential plus

X

B29

AN5

ADC channel 7

X A29

AN1

TRIAMP2 positive input

X

B30

AN4

ADC channel 6

X A30

AN0

TRIAMP2 negative input

X

B31

GND

Ground

X A31

GND

Ground

X

B32

DAC1

VREF output

X A32

DAC0

DAC output

X

X

B33

TMR3

TPM1 channel 3

X A33

TMR1

TPM1 channel 1

X B34

TMR2

TPM1 channel 2

X A34

TMR0

TPM1 channel 0

X

B35

GPIO4

GPIO PTF0

X A35

GPIO6

GPIO PTF1

X

B36

3.3V

3.3V Power

X A36

3.3V

3.3V Power

X

B37

PWM7

TPM1 channel 3

X A37

PWM3

TPM2 channel 3

X

B38

PWM6

TPM1 channel 2

X A38

PWM2

TPM2 channel 2

X B39

PWM5

TPM1 channel 1

X A39

PWM1

TPM2 channel 1

X

B40

PWM4

TPM1 channel 0

X A40

PWM0

TPM2 channel 0

X

B41

CANRX0

A41

RXD0

B42

CANTX0

A42

TXD0

B43

CAN

A43

RXD1

SCI1 receive

X

B44

SPI0_MISO

SPI0 MISO

X A44

TXD1

SCI1 transmit

X

B45

SPI0_MOSI

SPI0 MOSI

X A45

BKGD

B46

SPI0_CS0

SPI0 Chip Select

X

A46

ALLPST

B47

SPI0_CS1

SPI1 Chip Select

X

A47

JTAG_EN

B48

SPI0_CLK

SPI0 clock

X

A48

TRST_b / DSCLK

B49

GND

Ground

X

A49

GND

Ground

X

B50

SCL1

A50

TCLK / DSCLK

B51

SDA1

A51

TDI / DSI

B52

GPIO5 / OPEN

GPIO PTA3

X

A52

TDO / DSO

B53

USB0_DP_PDOWN

A53

TMS / BKPT_b

B54

USB0_DM_PDOWN

A54

USB_DM

USB data minus

X

B55

IRQ_H

KBI2P1

X

A55

USB_DP

USB data plus

X

B56

IRQ_G

KBI2P2

X A56

USB_ID

B57

IRQ_F

KBI2P1

X A57

USB_VBUS

USB VBUS input

X

B58

IRQ_E

KBI2P2

X A58

TMR7

OPAMP2 output

X

TWR-MCF51MM User Manual Page 7 of 12

Page 8

TWR-MCF51MM Primary Connector

Pin

Name

Usage

Used

Jmp

Pin

Name

Usage

Used

Jmp

B59

IRQ_D

IRQ pin

X A59

TMR6

OPAMP1 negative input

X

B60

IRQ_C

IRQ pin

X A60

TMR5

OPAMP2 negative input

X

B61

IRQ_B

KBI1P2

X A61

TMR4

OPAMP1 positive input

X

B62

IRQ_A

KBI1P1

X

A62

RSTIN_b

B63

EBI_ALE / EBI_CS1_b

Minibus chip select 1

X

A63

RSTOUT_b

B64

EBI_CS0_b

Minibus chip select 0

X

A64

CLKOUT0

Clock output on PTC7

X

B65

GND

Ground

X A65

GND

Ground

X

B66

EBI_AD15

Minibus address bus

X A66

EBI_AD14

Minibus address bus

X

B67

EBI_AD16

Minibus address bus

X A67

EBI_AD13

Minibus address bus

X

B68

EBI_AD17

Minibus address bus

X A68

EBI_AD12

Minibus address bus

X

B69

EBI_AD18

Minibus address bus

X A69

EBI_AD11

Minibus address bus

X

B70

EBI_AD19

Minibus address bus

X A70

EBI_AD10

Minibus address bus

X B71

EBI_R/W_b

Minibus read/write strobe

X X A71

EBI_AD9

Minibus address bus

X

B72

EBI_OE_b

Minibus output enable

X A72

EBI_AD8

Minibus address bus

X

B73

EBI_D7

Minibus data bus

X A73

EBI_AD7

Minibus address bus

X

B74

EBI_D6

Minibus data bus

X A74

EBI_AD6

Minibus address bus

X

B75

EBI_D5

Minibus data bus

X A75

EBI_AD5

Minibus address bus

X

B76

EBI_D4

Minibus data bus

X A76

EBI_AD4

Minibus address bus

X

B77

EBI_D3

Minibus data bus

X A77

EBI_AD3

Minibus address bus

X B78

EBI_D2

Minibus data bus

X A78

EBI_AD2

Minibus address bus

X

B79

EBI_D1

Minibus data bus

X A79

EBI_AD1

Minibus address bus

X

B80

EBI_D0

Minibus data bus

X A80

EBI_AD0

Minibus address bus

X

B81

GND

Ground

X A81

GND

Ground

X

B82

3.3V

3.3V Power

X A82

3.3V

3.3V Power

X

Jumper

Option

Setting

Description of MCF51MM256 signal routing

J1

DADP0 routing selection

1-2

Connect DADP0 to medical connector J27 pin 5

J2

DADM0 routing selection

1-2

Connect DADM0 to medical connector J27 pin 6

J3

VINP1 routing selection

1-2

VINP1 connect to GND

2-3

VINP1 optionally connected to DACO

J4

Potentiometer connection

1-2

Connection of ADP4 to potentiometer

3.8 Mechanical Form Factor

The TWR-MCF51MM is designed for the Freescale Tower System and complies with the electrical and

mechanical specification as described in Freescale Tower Electromechanical Specification.

4 Jumper Table

There are several jumpers provided for isolation, configuration, and feature selection. Refer to the

following table for details. The default installed jumper settings are shown in bold.

Figure 5. TWR-MCF51MM Jumper Table

TWR-MCF51MM User Manual Page 8 of 12

Page 9

J5

DACO routing selection

1-2

Connect DACO to VINP1 if pin 2-3 of J3 is connected

2-3

Connect DACO to a RC low pass filter

J6

DACO routing selection

1-2

Connect DACO to medical connector J27 pin 8

J7

TRIAMP routing selection

1-2

Connect TRIOUT1 to TRIOUT_SEL2

2-3

Connect TRIOUT2 to TRIOUT_SEL2

J8

TRIAMP routing selection

1-2

Connect TRIOUT1 to TRIOUT_SEL1

2-3

Connect TRIOUT2 to TRIOUT_SEL1

J9

Infrared receive routing

1-2

Connect Infrared transistor output to CMPP1

J10

USB3.3V connection

1-2

USB3.3V connects to external 3.3V power supply

2-3

USB3.3V connects to on-chip USB 3.3V regulator output

J11

MCU IDD measure

1-2

For measuring MCF51MM256 current

J12

OSBDM Bootloader mode or

debugger mode selection

1-2

OSBDM IC in bootloader mode(For OSBDM firmware

reprogramming)

Open

OSBDM IC in debugger mode .

J13

BDM connector for

MCF51MM256

Open

BDM connector for MCF51MM256

J14

BDM connector for JM60

Open

BDM connector for MC9S08JM60

J15

SCI2 TXD Routing Selection

1-2

Connect TX2 to the RS232 transceiver

2-3

Connect TX2 to the OSBDM debugger interface circuit

J16

SCI2 RXD Routing Selection

1-2

Connect RX2 to the RS232 transceiver

2-3

Connect RX2 to the OSBDM debugger interface circuit

J18

LED & Accelerometer

connections

1-2

Connects LED4 to pin PTE7/USB_VBUSVLD/TPM2CH3

3-4

Connects LED3 to pin PTF0/USB_ID/TPM2CH2

5-6

Connects LED2 to pin PTF1/RX2/USB_DP_DOWN/TPM2CH1

7-8

Connects LED1 to pin PTF2/TX2/USB_DM_DOWN/TPM2CH0

9-10

Connects ADP8 to ACCZ

11-12

Connects ADP7 to ACCY

13-14

Connects ADP6 to ACCX

J19

Accelerometer mode control

1-2

Connects PTA3 to SELF TEST pin of accelerometer

3-4

Connects PTA6 to SLEEP pin of accelerometer

5-6

Connects PTA5 to G-SELECT pin of accelerometer

J20

Accelerometer control

1-2

Connects PTB0 to 0G-DETECT pin of accelerometer

J21

RS232 connector

Open

2x5 RS232 connector

J24

Infrared filter connection

1-2

Choose whether to filter Infrared output

J25

Infrared transmit routing

1-2

Connects Infrared transistor output to ADP10

3-4

Connects Infrared transistor output to RX1

5-6

Connects either IRO or TX1 to Infrared diode base on J26

J26

Infrared transmit routing

1-2

TX1 pin drives Infrared transmit

2-3

IRO pin drives Infrared transmit

J27

Medical board connector

Open

Connects to MED-EKG board

TWR-MCF51MM User Manual Page 9 of 12

Page 10

TWR-MCF51MM

MCF51MM256

I/O Component

I/O Label

Default Alt 1

Alt 2

Alt 3

Dip Switch

SW3-1&4

PTA5 - -

-

SW3-2&3

PTB1

/BLMS

-

-

Push Button

SW1

PTD1

CMPP2

/RESET

-

SW2

PTC6

KBI2P1

PRACMPO

ADP10

SW4

PTE4

CMPP3

TPMCLK

IRQ

LED

LED1 (D9)

PTF2

TX2

USB_DM_DOWN

TPM2CH0

LED2(D10)

PTF1

RX2

USB_DP_DOWN

TPM2CH1

LED3(D11)

PTF0

USB_ID

TPM2CH2

-

LED4(D12)

PTE7

USB_VBUSVLD

TPM2CH3

-

Accelerometer

MMA7361L

X_OUT

PTC2

KBI1P5

SPSCK2

ADP6

Y_OUT

PTC3

KBI1P6

/SS2

ADP7

Z_OUT

PTC4

KBI1P7

CMPP0

ADP8

Potentiometer

POT

PTA2

KBI1P1

RX1

ADP4

RS232

ICL3232

232_RXD

PTE6

FB_RW

USB_SESSEND

RX2

232_TXD

PTE5

FB_D7

USB_SESSVLD

TX2

NOTE: For more detail, please refer to TWR-MCF51MM schematics available in the

TWR-MCF51MM-KIT or on Freescale.com/tower.

5 Input/Output Connectors and Pin Usage Table

The following tables provide details on which MCF51MM256 pins are communicating with the TWRMCF51MM sensors, LEDs, switches and other I/O interfaces.

Figure 6. I/O Connectors and Pin Usage Table

6 OSBDM

An on-board, MC9S08JM60 based OSBDM circuit provides a debug interface to the MCF51MM256.

The MC9S08JM60 is a USB-enabled microcontroller with an 8-bit HC9S08 core. The OSBDM circuit

provides a USB-to-debug interface that allows run-control and debugging of the MCF51MM256 target

device. The USB drivers required to communicate with the OSBDM are provided in development tools

such as Freescale CodeWarrior. When TWR-MCF51MM is used stand-alone, this single USB connection

can also be used for power.

6.1 Bootloader Mode For MC9S08JM60

The MC9S08JM60 device used in the OSBDM circuit is preprogrammed with OSBDM debugger

firmware and a USB Bootloader. The bootloader mode can be used to update the OSBDM debugger

firmware if an update becomes available. Jumper J12 determines which application will run following a

power-on reset. If the Bootloader Mode is chosen (jumper shunt on J12), the bootloader will be

TWR-MCF51MM User Manual Page 10 of 12

NOTE: LED1 to LED4 are labelled as D9 to D12 on the TWR-MCF51MM silkscreen.

Page 11

executed, allowing in-circuit reprogramming of the JM60 flash memory via USB. Refer to Application

Note AN3561 on the Freescale website (http://www.freescale.com) for details on the USB Bootloader.

The USB Bootloader communicates with a GUI application running on a host PC. The GUI application

can be found on the Freescale website; search keyword “JM60 GUI.” Refer to section 2.5 and 3.3 of

AN3561 for details on installing and running the application.

Note:

The JM60 GUI Installer should be run before connecting the OSBDM in Bootloader

Mode to a host USB port. Otherwise, the JM60 USB device will not be recognized and

the proper drivers will not be loaded.

7 Bootloader Mode For MCF51MM256

Unlike MC9S08JM60, MCF51MM256 has an on-chip ROM based USB bootloader that allows the

MCF51MM256 for mass erase and programming via its USB interface. This on-chip bootloader does not

consume user flash space. To enable USB bootloader mode for MCF51MM256, on the TWR-MCF51MM

module, set SW3 DIP switch 2 and 3 to position 3, as indicated in Figure 7. NOTE: Under normal

development you will need to set SW3 DIP switch 2 and 3 to position 2.

Figure 7. Setting SW3 for MCF51MM256 USB bootloader mode

TWR-MCF51MM User Manual Page 11 of 12

Page 12

Freescale™ and the Freescale logo are trademarks of

Freescale Semiconductor, Inc. All other product or service names

are the property of their respective owners.

© Freescale Semiconductor, Inc. 2009. All rights reserved.

8 BDM inteface (Optional)

Both MCF51MM256 and MC9S08JM60 have an on-chip background debug module. The user can

choose to bypass the USB OSBDM interface and use the BDM interface for debugging and

programming the corresponding chip instead. The BDM interface for MCF51MM256 is at J13 header

and MC9S08JM60 is at J14 from the TWR-MCF51MM module. The user needs a P&E USB BDM

MULTILINK in order to use this interface. This is a repeat function of the OSBDM and is not required.

Information in this document is provided solely to enable system and software implementers to use Freescale Semiconductor products. There are no

express or implied copyright licenses granted hereunder to design or fabricate any integrated circuits or integrated circuits based on the information in this

document.

Freescale Semiconductor reserves the right to make changes without further notice to any products herein. Freescale Semiconductor makes no warranty,

representation, or guarantee regarding the suitability of its products for any particular purpose, nor does Freescale Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any liability, including without limitation consequential or incidental

damages. “Typical” parameters that may be provided in Freescale Semiconductor data sheets and/or specifications can and do vary in different

applications and actual performance may vary over time. All operating parameters, including “Typicals,” must be validated for each customer application

by customer’s technical experts. Freescale Semiconductor does not convey any license under its patent rights nor the rights of others.

Freescale Semiconductor products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body,

or other applications intended to support or sustain life, or for any other application in which failure of the Freescale Semiconductor product could create

a situation where personal injury or death may occur. Should Buyer purchase or use Freescale Semiconductor products for any such unintended or

unauthorized application, Buyer shall indemnify Freescale Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless

against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claims alleges that Freescale Semiconductor was negligent regarding the design or

manufacture of the part.

RoHS-compliant and/or Pb-free versions of Freescale products have the functionality and electrical characteristics as their non-RoHS-complaint and/or

non-Pb-free counterparts.

For further information, visit freescale.com or contact your Freescale sales representative.

For information on Freescale’s Environmental Products program, visit freescale.com/epp.

TWR-MCF51MM User Manual Page 12 of 12

Loading...

Loading...