Page 1

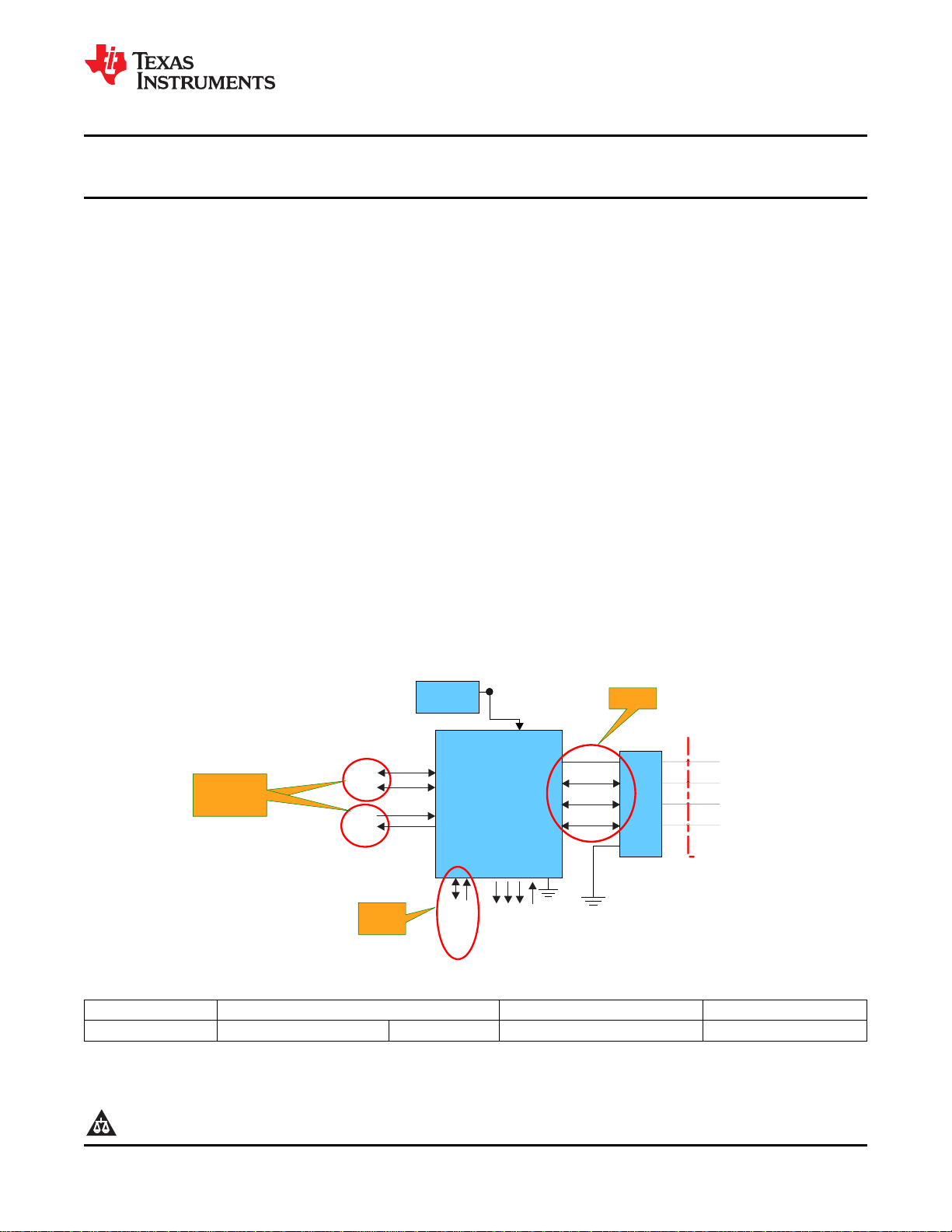

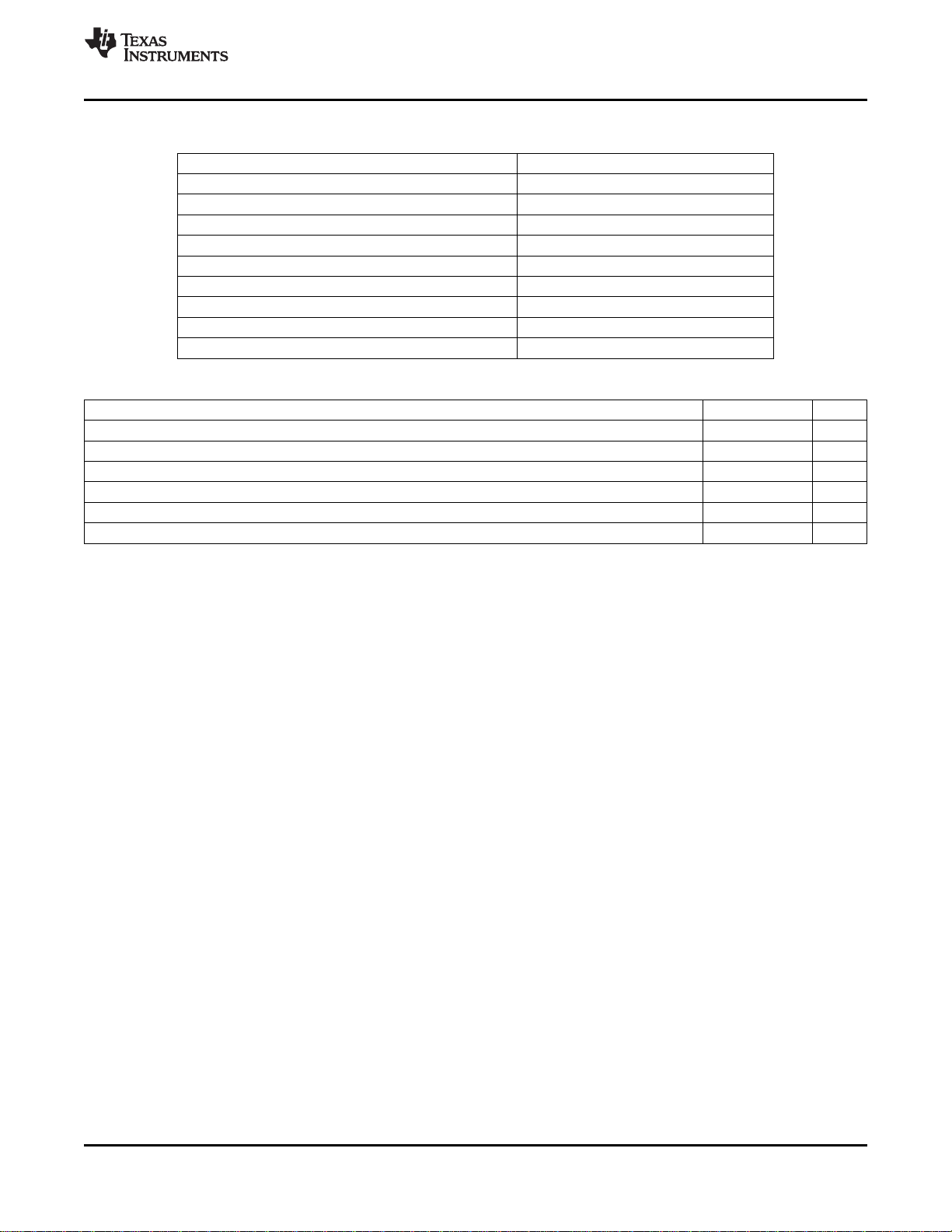

USB CONNECTOR

BATTERY

VBAT

RxD

TxD

DP_HT

DM_HT

MICMICMICMIC

ID_CON

DP_CON

VBUS

DM_CON

TSU6111

I2C_SDA

INTB

BOOT

JIG

I2C_SCL

VDDIO

USB

UART

inside

outside

VBUS

ID_CON

DP_CON

DM_CON

IEC ESD

I2C

Control

USB2.0 High

Speed

USB2.0 High

Speed

TSU6111A

www.ti.com

USB Port SP2T Switch Supports USB & UART

1

FEATURES

• Switch Matrix

– USB

– UART Supports USB 2.0 High Speed

• Charger Detection

– USB BCDv1.1 Compliant

– VBUS Detection

– Data Contact Detection

– Primary and Secondary Detection

• Compatible Accessories

– USB Chargers (DCP, CDP)

– Factory Cable

• Additional Features

– I2C Interface with Host Processor

– Switches Controlled by Automatic

Detection or Manual Control

– Interrupts Generated for Plug/Unplug

– Support Control Signals used In

Manufacturing (JIG, BOOT)

SCDS331A –FEBRUARY 2012–REVISED AUGUST 2012

Check for Samples: TSU6111A

• Max Voltage

– 28V VBUS rating

• ESD Performance Tested Per JESD 22

– 5000-V Human-Body Model

(A114-B, Class II)

– 1000-V Charged-Device Model (C101)

• IEC ESD Performance

– ±8kV Contact Discharge (IEC 61000-4-2) for

VBUS/DP_CON/DM_CON/ID_CON to GND

• Surge Protection on VBUS/DP_CON/DM_CON

– USB Connector Pins Without External

Component

APPLICATIONS

• Cell Phones and Smart Phones

• Tablet PCs

• Digital Cameras and Camcorders

• GPS Navigation Systems

• Micro USB interface with USB/UART

TYPICAL APPLICATION DIAGRAM

T

A

–40°C to 85°C uQFN 0.4-mm pitch – RSV Tape and Reel TSU6111ARSVR ZTN

(1) For the most current package and ordering information, see the Package Option Addendum at the end of this document, or see the TI

Web site at www.ti.com.

(2) Package drawings, thermal data, and symbolization are available at www.ti.com/packaging.

1

PACKAGE

ORDERING INFORMATION

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

(2)

(1)

ORDERABLE PART NUMBER TOP-SIDE MARKING

Copyright © 2012, Texas Instruments Incorporated

Page 2

UART

USB

Micro

USB

DP_HT

TxD

RxD

TSU6111 SWITCH

MATRIX

DM_HT VBUS

DM_CON

DP_CON

ID_CON

Charger

Detection

Sources

And

Comp’s

Accessory

ID

Detection

ADC

I2C Interface

&

Hardware

Control

VBUS

DP

DM

ID

Buffers and/or

Comparators

JIG

INTB

SDA

SCL

VDDIO

BOOT

I2C

Interface

Switches

RxD

TxD

USB_DM

USB_DP

State Machine

Switch

Ctrl

TSU6111A

SCDS331A –FEBRUARY 2012–REVISED AUGUST 2012

www.ti.com

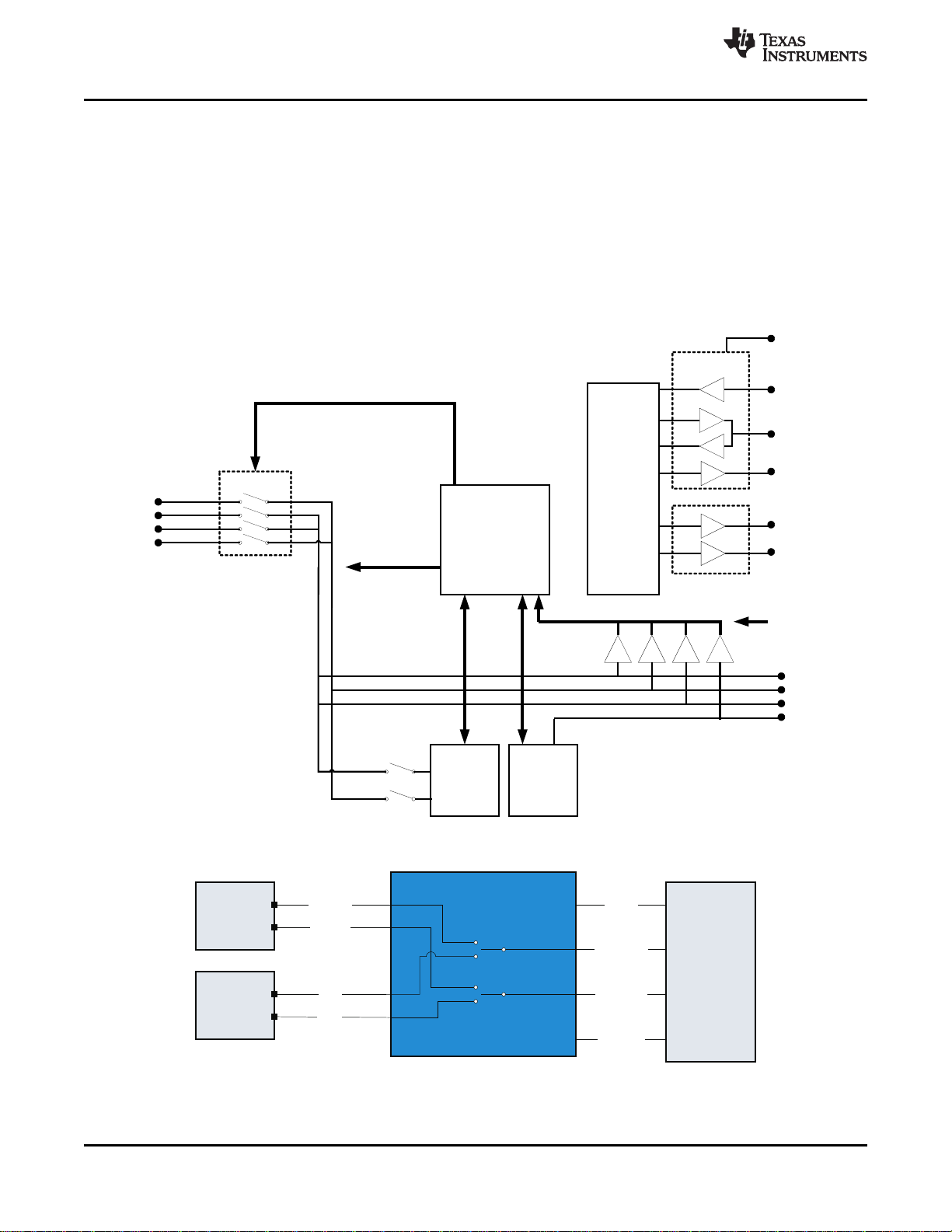

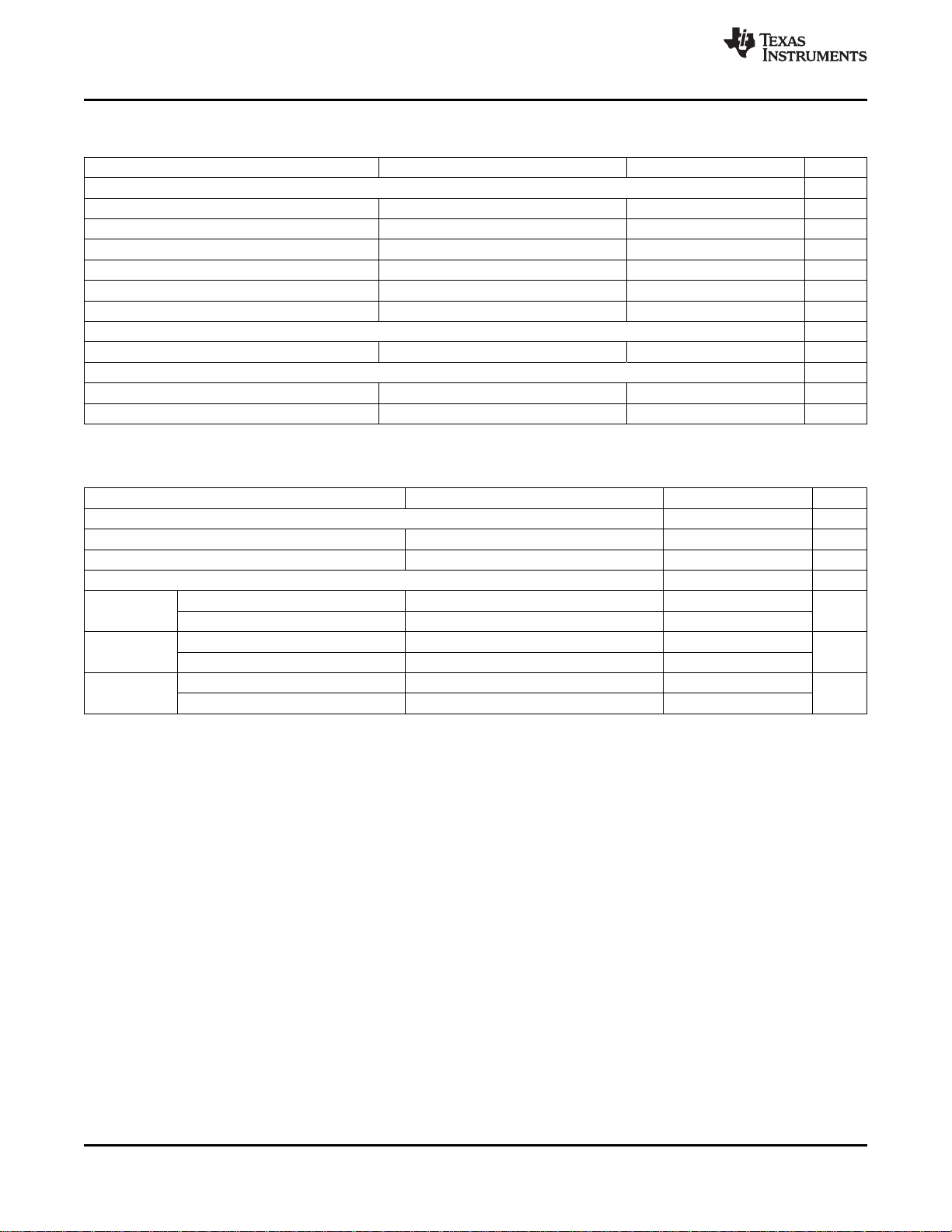

DESCRIPTION

The TSU6111A is a high performance differential autonomous SP2T switch with impedance detection. The

switch supports the detection of various accessories that are attached through DP, DM, and ID. The charger

detection satisfies USB charger specification v1.1 and V

external protection. Power for this device is supplied through VBAT of the system or through V

attached to a charger.

The SP2T switch is controlled by the automatic detection logic or through manual configuration of the I2C. JIG

and BOOT pins are used when a USB or UART JIG cable is used to test the device in the development and

manufacturing. TSU6111A has open-drain JIG output (active low).

BLOCK DIAGRAM

has a 28V tolerance to eliminate the need for

BUS_IN

BUS_IN

when

SWITCH MATRIX

2 Submit Documentation Feedback Copyright © 2012, Texas Instruments Incorporated

Product Folder Link(s): TSU6111A

Page 3

ID_CON

DP_CON

DM_CON

V

BUS_IN

16 15 14 13

DM_HOST 1 12 GND

DP_HOST 2 11 SDA

TxD 3 10 SCL

RxD 4 9 INTB

5 6 7 8

V

BAT

BOOT

JIG

V

DDIO

TSU6111A

www.ti.com

SCDS331A –FEBRUARY 2012–REVISED AUGUST 2012

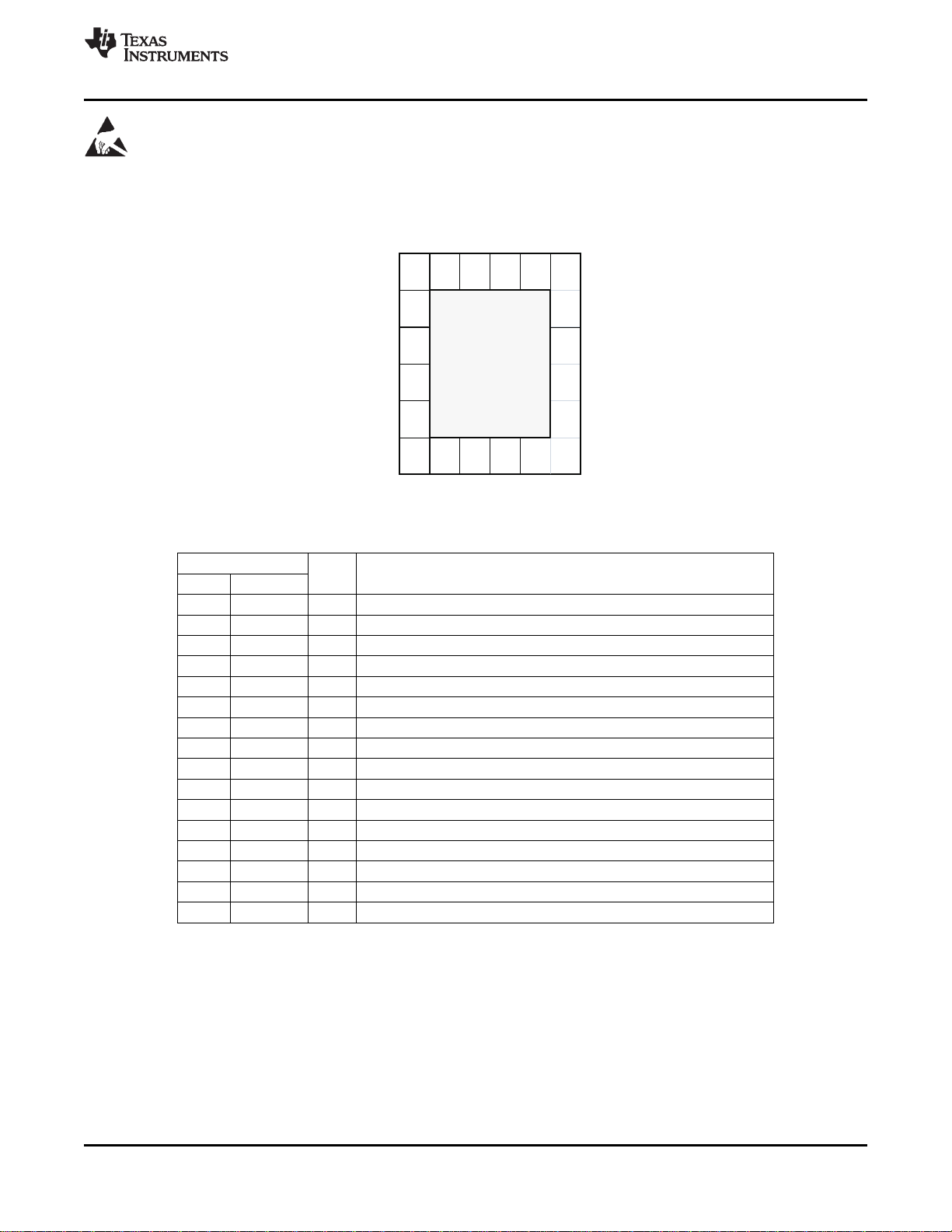

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

PINOUT DIAGRAM (TOP VIEW)

PIN FUNCTIONS

PIN

NO. NAME

1 DM_HOST I/O USB DM connected to host

2 DP_HOST I/O USB DP connected to host

3 TxD I/O UART Tx

4 RxD I/O UART Rx

5 VBAT I Connected to battery

6 BOOT O BOOT mode out (push-pull). Used for factory test modes.

7 JIG O JIG detection JIG detection (Open-drain). Used for factory test modes

8 VDDIO O I/O voltage reference

9 INTB O Interrupt to host (push-pull)

10 SCL I I2C clock

11 SDA I/O I2C data

12 GND Ground

13 VBUS_IN I VBUS connected to USB receptacle

14 DM_CON I/O USB DM connected to USB receptacle

15 DP_CON I/O USB DP connected to USB receptacle

16 ID_CON I/O USB ID connected to USB receptacle

I/O DESCRIPTION

Copyright © 2012, Texas Instruments Incorporated Submit Documentation Feedback 3

Product Folder Link(s): TSU6111A

Page 4

TSU6111A

SCDS331A –FEBRUARY 2012–REVISED AUGUST 2012

ABSOLUTE MAXIMUM RATINGS

(1)(2)

www.ti.com

over operating free-air temperature range (unless otherwise noted)

MIN MAX UNIT

V

BUS

V

BAT

V

DDIO

V

ID_CON

V

USBIO

V

UARTIO

V

JIG

V

LOGIC_O

I

K

I

SW-DC

I

SW

I

IK

I

LOGIC_O

I

GND

T

stg

(1) Stresses above these ratings may cause permanent damage. Exposure to absolute maximum conditions for extended periods may

degrade device reliability. These are stress ratings only, and functional operation of the device at these or any other conditions beyond

those specified is not implied.

(2) The algebraic convention, whereby the most negative value is a minimum and the most positive value is a maximum.

Supply voltage from USB connector –0.5 28

Supply voltage from battery –0.5 6.0

Logic supply voltage –0.5 4.6 V

ID Connector voltage –0.5 V

Switch I/O voltage range USB Switch –0.5 V

Switch I/O voltage range UART Switch –0.5 V

JIG voltage –0.5 V

+0.5 V

BAT

+0.5 V

BAT

+0.5 V

BAT

+0.5 V

BAT

Voltage applied to logic output (SCL, SDA, INTB, BOOT) –0.5 4.6 V

Analog port diode current –50 50 mA

ON-state continuous switch current –60 60 mA

ON-state peak switch current PEAK –150 150 mA

Digital logic input clamp current V

< 0 –50 mA

DDIO

Continuous current through logic output (SCL, SDA, INTB, BOOT) –50 50 mA

Continuous current through GND 100 mA

Storage temperature range –65 150 °C

V

THERMAL IMPEDANCE RATINGS

θJA Package thermal impedance RSV package 184 °C/W

UNIT

4 Submit Documentation Feedback Copyright © 2012, Texas Instruments Incorporated

Product Folder Link(s): TSU6111A

Page 5

TSU6111A

www.ti.com

SCDS331A –FEBRUARY 2012–REVISED AUGUST 2012

SUMMARY OF TYPICAL CHARACTERISTICS

AMBIENT TEMPERATURE = 25°C USB/UART PATH

Number of channels 2

ON-state resistance (ron) 8 Ω

ON-state resistance match (Δron) 0.5 Ω

ON-state resistance flatness (r

Turn-on/turn-off time (tON/t

OFF

) 0.5 Ω

on(flat)

) 95 µs/ 3.5 µs

Bandwidth (BW) 920 MHz

OFF isolation (O

Crosstalk (X

Leakage current (I

) –26 dB at 250 MHz

ISO

) –32 dB at 250 MHz

TALK

) 50 nA

IO(ON)

RECOMMENDED OPERATING CONDITIONS

MIN MAX UNIT

V

BUS_IN

V

BAT

V

DDIO

ID_CON_Cap ID_CON capacitance 1 nF

USB_I/O USB path signal range 0 3.6 V

Temperature Operating Temperature –40 85 °C

VBUS voltage 4.0 6.5 V

VBAT voltage 3.0 4.4 V

VDDIO voltage 1.65 3.6 V

Copyright © 2012, Texas Instruments Incorporated Submit Documentation Feedback 5

Product Folder Link(s): TSU6111A

Page 6

TSU6111A

SCDS331A –FEBRUARY 2012–REVISED AUGUST 2012

www.ti.com

ELECTRICAL SPECIFICATION

over operating free-air temperature range (unless otherwise noted)

PARAMETERS TEST CONDITIONS MIN MAX UNIT

DIGITAL SIGNALS – I2C INTERFACE (SCL and SDA)

V

DDIO

V

IH

V

IL

V

OH

V

OL

f

SCL

JIG OUTPUT (TSU6111A – OPEN-DRAIN OUTPUT, ACTIVE LOW)

V

OL

INTB AND BOOT (PUSH-PULL OUTPUT)

V

OH

V

OL

ELECTRICAL SPECIFICATIONS

over operating free-air temperature range (unless otherwise noted)

TOTAL SWITCH CURRENT CONSUMPTION

I

BAT(Standby)

I

DD(Operating)

VOLTAGE PROTECTION

V

VBUS_UVLO

V

VBAT_UVLO

V

VDDIO_UVLO

(1) VOis equal to the asserted voltage on DP_CON and DM_CON pins. VIis equal to the asserted voltage on DP_HT and DM_HT pins. I

is equal to the current on the DP_CON and DM_CON pins. IIis equal to the current on the DP_HT and DM_HT pins.

Logic and I/O supply voltage 1.65 3.6 V

High-level input voltage V

Low-level input voltage 0 V

High-level output voltage IOH= –3 mA V

× 0.7 V

DDIO

× 0.3 V

DDIO

× 0.7 V

DDIO

DDIO

V

Low-level output voltage IOL= 3 mA 0.4 V

SCL frequency 400 kHz

Low-level output voltage IOL= 10 mA, V

High-level output voltage IOH= –4 mA , V

Low-level output voltage IOL= 4 mA , V

(1)

= 3.0 V 0.5 V

BAT

= 1.65 V 1.16 V

DDIO

= 1.65 V 0 0.33 V

DDIO

DDIO

V

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

Standby current consumption V

BAT

V

Operating current consumption V

BAT

V

under voltage + Voltage is rising 2.85

BUS

V

under voltage– Voltage is falling 2.55

BUS

V

under voltage + Voltage is rising 2.65

BUS

V

under voltage– Voltage is falling 2.45

BUS

V

under voltage + Voltage is rising 1.30

BUS

V

under voltage– Voltage is falling 1.05

BUS

= 0 V, Idle state 25 30 µA

BUS

= 0 V, USB switches ON 45 75 µA

BUS_IN

V

V

V

O

6 Submit Documentation Feedback Copyright © 2012, Texas Instruments Incorporated

Product Folder Link(s): TSU6111A

Page 7

TSU6111A

www.ti.com

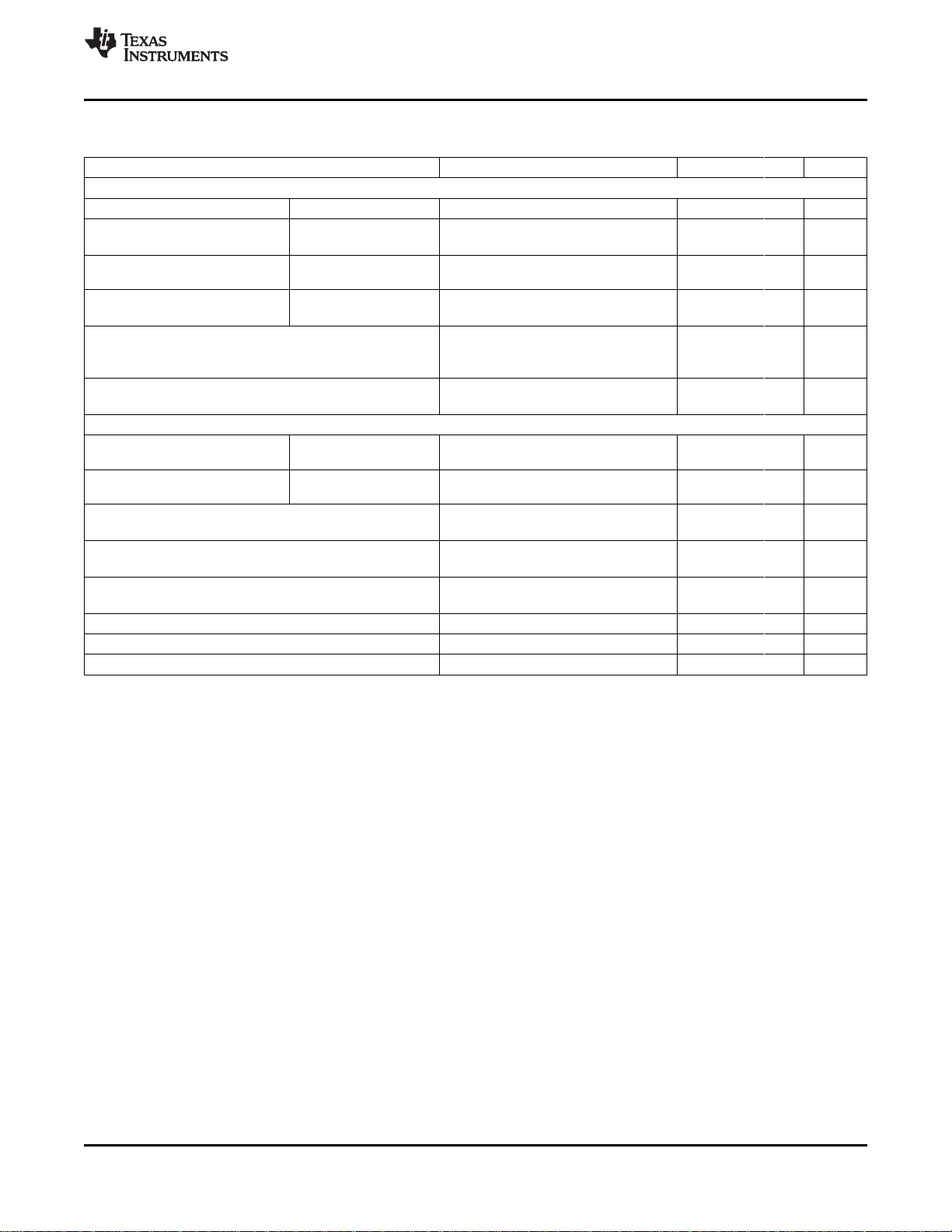

USB AND UART SWITCH ELECTRICAL CHARACTERISTICS

SCDS331A –FEBRUARY 2012–REVISED AUGUST 2012

(1)

over operating free-air temperature range (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

ANALOG SWITCH

V

r

ON

Δr

r

ON(flat)

I

IO(OFF)VI

I

IO(ON)VO

DYNAMIC

t

ON

t

OFF

C

C

C

C

BW Bandwidth RL= 50 Ω, Switch ON 920 MHz

O

X

Analog signal range 0 V

USBIO

ON-state resistance 8 15 Ω

ON-state resistance DM_HT, DP_HT,

ON

match between channels DM_CON, DP_CON

ON-state resistance

flatness

DM_HT, DP_HT, VI= 0 V to 3.6 V, IO= –2 mA,

DM_CON, DP_CON V

= 3.0 V

BAT

VI= 0.4 V, IO= –2 mA, V

BAT

DM_HT, DP_HT, VI= 0 V to 3.6 V, IO= –2 mA,

DM_CON, DP_CON V

BAT

= 3.0 V

= 3.0 V 0.5 2 Ω

VI= 0.3 V, VO= 2.7 V or

or VOOFF leakage current VI= 2.7 V, VO= 0.3 V, 45 200 nA

V

= 4.4 V, Switch OFF

BAT

ON leakage current 50 200 nA

Turn-ON time VIor VO= V

Turn-OFF time VIor VO= V

I(OFF)VI

O(OFF)VO

I(ON)

O(ON)

ISO

TALK

OFF capacitance 4 pF

OFF capacitance 7 pF

, DC bias = 0 V or 3.6 V, f = 10 MHz,

VI, VOON capacitance 9 pF

OFF Isolation f = 240 MHz, RL= 50 Ω, Switch OFF –26 dB

Crosstalk f = 240 MHz, RL= 50 Ω –32 dB

From receipt of I2C ACK

bit

From receipt of I2C ACK

bit

VI= OPEN, VO= 0.3 V or 2.7 V,

V

= 4.4 V, Switch ON

BAT

, RL= 50 Ω, CL= 35 pF 95 µs

BAT

, RL= 50 Ω, CL= 35 pF 3.5 µs

BAT

DC bias = 0 V or 3.6 V, f = 10 MHz,

Switch OFF

DC bias = 0 V or 3.6 V, f = 10 MHz,

Switch OFF

Switch ON

BAT

0.5 2 Ω

V

(1) VOis equal to the asserted voltage on DP_CON and DM_CON pins. VIis equal to the asserted voltage on DP_HT and DM_HT pins. I

is equal to the current on the DP_CON and DM_CON pins. IIis equal to the current on the DP_HT and DM_HT pins.

O

Copyright © 2012, Texas Instruments Incorporated Submit Documentation Feedback 7

Product Folder Link(s): TSU6111A

Page 8

TSU6111A

SCDS331A –FEBRUARY 2012–REVISED AUGUST 2012

www.ti.com

GENERAL OPERATION

The TSU6111A will automatically detect accessories plugged into the phone via the mini/micro USB 5 pin

connector. The type of accessory detected will be stored in I2C registers within the TSU6111A for retrieval by the

host. The TSU6111A has a network of switches that are automatically opened and closed based on the

accessory detection. See Table 1 for details of which switches are open during each mode of operation. The

TSU6111A also offers a manual switching mode that allows the host processor to decide which switches should

be opened and closed. The manual switching settings are executed through the I2C interface.

STANDBY MODE

Standby mode is the default mode upon power up and occurs when no accessory has been detected. During this

mode, the VBUS and ID lines are continually monitored through comparators to determine when an accessory is

inserted. Power consumption is minimal during standby mode.

POWER SUPERVISOR

TSU6111A uses VBAT as the primary supply voltage. VBUS is the secondary supply. VDDIO is used for I2C

communication.

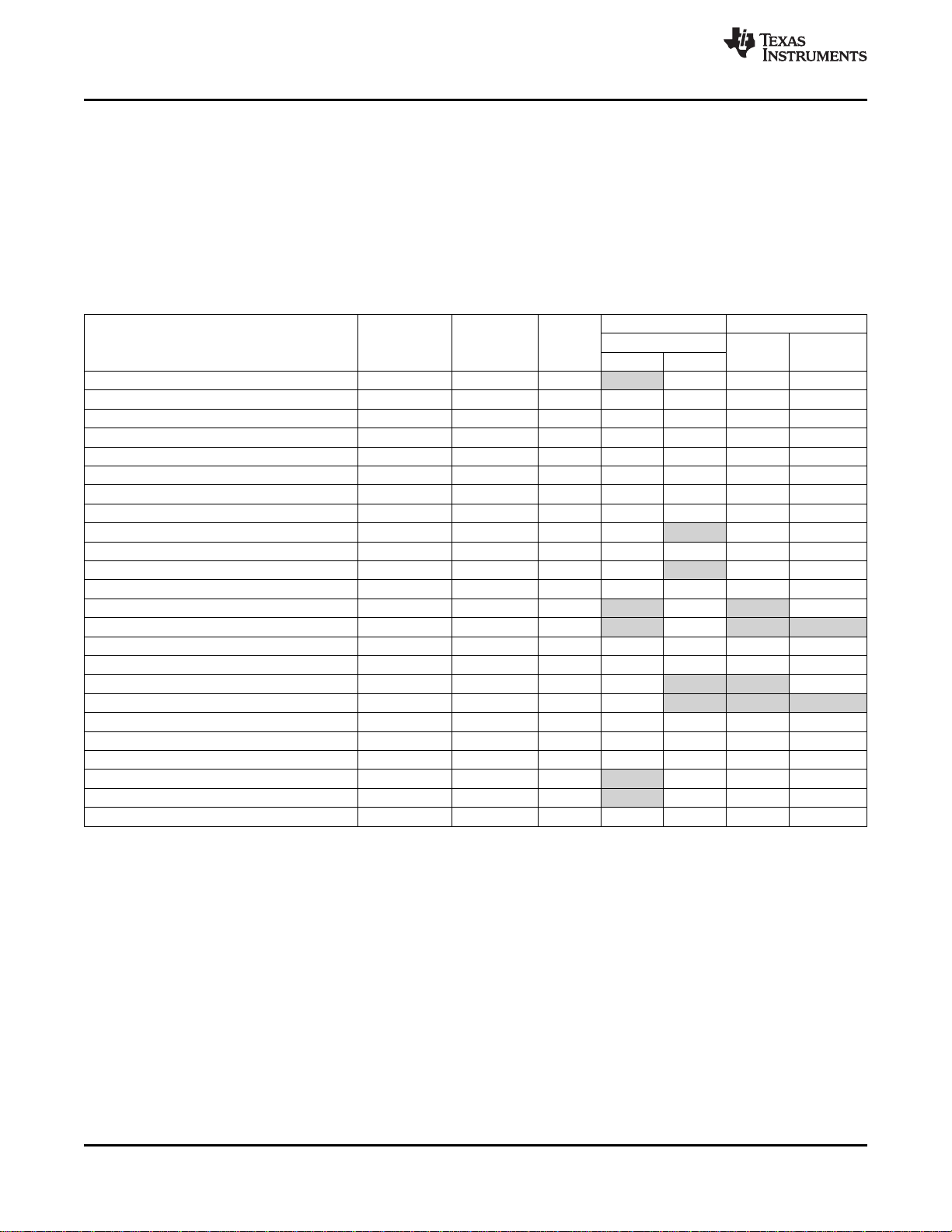

Table 1. Function Table

TSU6111A

VBAT VBUS VDDIO DETECTION I2C COMMENTS

Yes No No Enabled Not enabled VBAT is supply

Yes Yes No Enabled Not enabled VBAT is supply

Yes No Yes Enabled Enabled VBAT is supply

Yes Yes Yes Enabled Enabled VBAT is supply

No Yes No Enabled Not enabled VBUS is supply

No Yes Yes Not valid

No No Yes Not valid

No No No Power Down Reset

8 Submit Documentation Feedback Copyright © 2012, Texas Instruments Incorporated

Product Folder Link(s): TSU6111A

Page 9

TSU6111A

www.ti.com

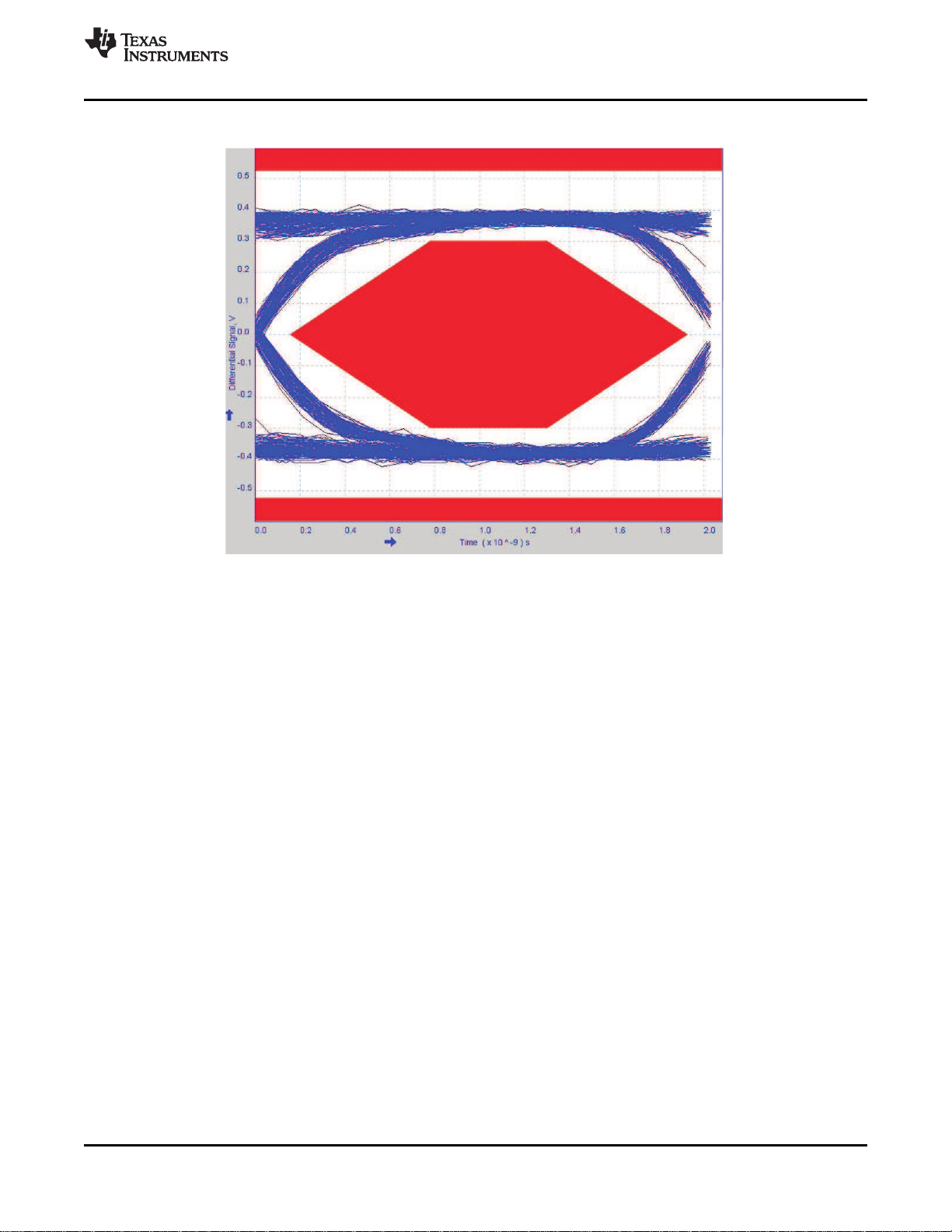

EYE DIAGRAM USB 2.0 HIGH SPEED

SCDS331A –FEBRUARY 2012–REVISED AUGUST 2012

Copyright © 2012, Texas Instruments Incorporated Submit Documentation Feedback 9

Product Folder Link(s): TSU6111A

Page 10

TSU6111A

SCDS331A –FEBRUARY 2012–REVISED AUGUST 2012

www.ti.com

ACCESSORY ID DETECTION

If V

low and an accessory is attached, then use an ADC for impedance sensing on the ID pin to identify which

accessory is attached.

is high and the attachment is not a charger, then determine the impedance on the ID pin. If V

BUS_IN

BUS_IN

IMPEDANCE BUCKETS FOR EACH ACCESSORY

In order to implement ID detection, each accessory should contain a ID impedance resistor value (refer

toTable 2) which has a 5% tolerance accuracy.

Table 2. Accessory ID and Switch States

ACCCESSORY IMPEDANCE TOLERANCE DP/DM

DETECTED RESISTOR

ON ID (%)

OTG 0 — 0 ON OFF OFF OFF

MHL 1K 5% 0 OFF OFF OFF OFF

Audio Device Type 3 28.7K 5% 1110 OFF OFF OFF OFF

Reserved Accessory #1 34K 5% 1111 OFF OFF OFF OFF

Reserved Accessory #2 40.2K 5% 10000 OFF OFF OFF OFF

Reserved Accessory #3 49.9K 5% 10001 OFF OFF OFF OFF

Reserved Accessory #4 64.9K 5% 10010 OFF OFF OFF OFF

Audio Device Type 2 80.27K 5% 10011 OFF OFF OFF OFF

Phone Powered Device 102K 5% 10100 OFF ON OFF OFF

TTY Converter 121K 5% 10101 OFF OFF OFF OFF

UART Cable 150K 5% 10110 OFF ON OFF OFF

Type 1 Charger 200K 5% 10111 OFF OFF OFF OFF

Factory Mode Cable - Boot Off USB 255K 5% 11000 ON OFF ON OFF

Factory Mode Cable - Boot On USB 301K 5% 11001 ON OFF ON ON

Audio/Video Cable 365K 5% 11010 OFF OFF OFF OFF

Type 2 Charger 442K 5% 11011 OFF OFF OFF OFF

Factory Mode Cable - Boot Off UART 523K 5% 11100 OFF ON ON OFF

Factory Mode Cable - Boot On UART 619K 5% 11101 OFF ON ON ON

Stereo Headset with Remote (Audio Device Type 1) 1000.07K 10% 11110 OFF OFF OFF OFF

Mono/Stereo Headset (Audio Device Type 1) 1002K 10% 11110 OFF OFF OFF OFF

No ID — — 11111 OFF OFF OFF OFF

USB Standard Downstream Port — — 11111 ON OFF OFF OFF

USB Charging Downstream Port — — 11111 ON OFF OFF OFF

Dedicated Charging Port — — 11111 OFF OFF OFF OFF

ADC

VALUE

SWITCH STATE FACTORY CABLE

USB UART

JIG BOOT

is

10 Submit Documentation Feedback Copyright © 2012, Texas Instruments Incorporated

Product Folder Link(s): TSU6111A

Page 11

TSU6111A

www.ti.com

SCDS331A –FEBRUARY 2012–REVISED AUGUST 2012

Power-On Reset

When power (from 0 V) is applied to V

until V

has reached V

BAT

. Once V

POR

registers and I2C state machine initialize to their default states.

After the initial power-up phase, V

(V

) for a power-reset cycle.

DDIO

BAT

, an internal power-on reset holds the TSU6111A in a reset condition

BAT

has reached V

BAT

, the reset condition is released, and the TSU6111A

POR

must be lowered to below 0.2 V and then back up to the operating voltage

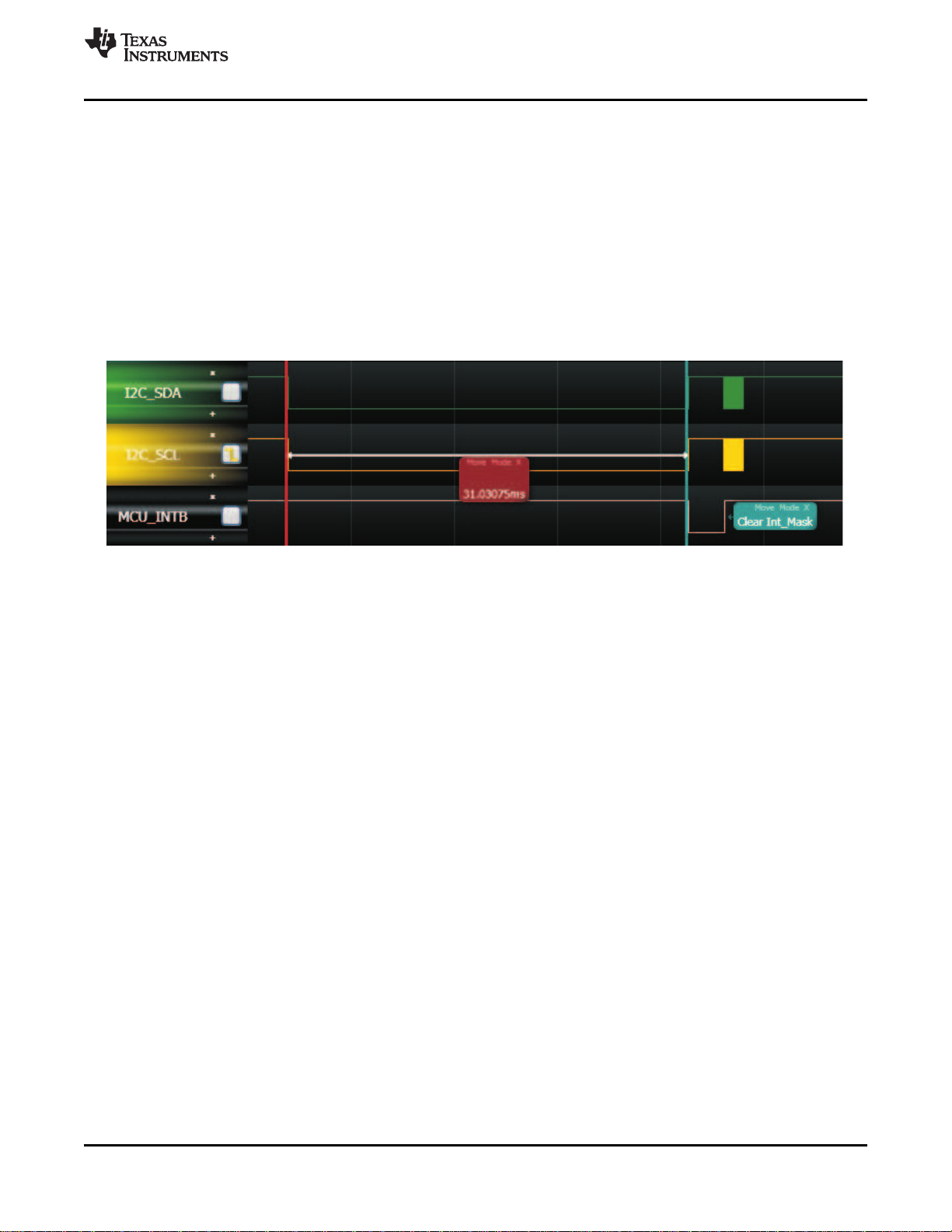

Software Reset

The TSU6111A has software reset feature.

• Hold low both I2C_SCL and I2C_SDA for more than 30ms to reset digital logic of the TSU6111A.

After resetting the digital logic, INTB will keep low until INT_Mask bit of Control register (0x02) is cleared.

Figure 1. Software Reset

Copyright © 2012, Texas Instruments Incorporated Submit Documentation Feedback 11

Product Folder Link(s): TSU6111A

Page 12

SDA

SCL

Data Line Charge

SDA

SCL

S P

Start Condition Stop Condition

TSU6111A

SCDS331A –FEBRUARY 2012–REVISED AUGUST 2012

www.ti.com

Standard I2C Interface Details

The bidirectional I2C bus consists of the serial clock (SCL) and serial data (SDA) lines. The SCL and SDA lines

must be connected to a positive supply via a pull-up resistor when connected to the output stages of a device.

Data transfer may be initiated only when the bus is not busy.

I2C communication with this device is initiated by the master sending a START condition, a high-to-low transition

on the SDA input/output while the SCL input is high (see Figure 2). After the start condition, the device address

byte is sent, MSB first, including the data direction bit (R/W). This device does not respond to the general call

address. After receiving the valid address byte, the device responds with an ACK, a low on the SDA input/output

during the high of the ACK-related clock pulse.

Figure 2. Definition of Start and Stop Conditions

The data byte follows the address ACK. The R/W bit is kept low for transfer from the master to the slave. The

data byte is followed by an ACK sent from this device. Data is sent only if complete bytes are received and

acknowledged. The output data is valid at time (tpv) after the low-to-high transition of SCL, during the clock cycle

for the ACK.

On the I2C bus, only one data bit is transferred during each clock pulse. The data on the SDA line must remain

stable during the high pulse of the clock period, as changes in the data line at this time are interpreted as control

commands (START or STOP, see Figure 3).

Figure 3. Bit Transfer

A Stop condition, a low-to-high transition on the SDA input/output while the SCL input is high, is sent by the

master (see Figure 2).

The number of data bytes transferred between the start and the stop conditions from transmitter to receiver is not

limited. Each byte of eight bits is followed by one ACK bit. The transmitter must release the SDA line before the

receiver can send an ACK bit.

A slave receiver address must generate an ACK after the reception of each byte. The device that acknowledges

has to pull down the SDA line during the ACK clock pulse so that the SDA line is stable low during the high pulse

of the ACK-related clock period (see Figure 4). Setup and hold times must be taken into account.

12 Submit Documentation Feedback Copyright © 2012, Texas Instruments Incorporated

Product Folder Link(s): TSU6111A

Page 13

SDA

ST 0 1 0 0 1 0 1 0 A 1 0 0 0 1 0 0 0 A D7 D6 D5 D4 D3 D2 D1 D0 A D7 D6 D5 D4 D3 D2 D1 D0 A

Start

Slave Address

W/R

Ack. from slave

Sub Address

Ack

from

slave

Auto-Inc.

Ack

from

slave

Data to Timing Set 1

Register

Data to Timing Set 2

Register

Date Byte Date Byte

Register Address

(Timing Set 1 Reg)

SCL

ST

SDA

0 1 0 0 1 0 1 0 A 0 0 0 0 0 0 1 0 A D7 D6 D5 D4 D3 D2 D1 D0 A D7 D6 D5 D4 D3 D2 D1 D0 A SP

Start

Slave Address

W/R

Ack. from slave

Sub Address

Ack

from

slave

Auto-Inc.

Register Address

(Control Reg)

Ack

from

slave

Ack

from

slave

StopData to Control

Register

Data to Control Register

Date Byte Date Byte

Data Output

by Transmitter

Data Output

by Receiver

SCL From

Master

Start

Condition

Clock Pulse for

Acknowledgment

ACK

NACK

1 2 8 9

TSU6111A

www.ti.com

SCDS331A –FEBRUARY 2012–REVISED AUGUST 2012

Figure 4. Acknowledgment on I2C Bus

Writes

Data is transmitted to the TSU6111A by sending the device slave address and setting the LSB to a logic 0 (see

Figure 5 for device address). The command byte is sent after the address and determines which register

receives the data that follows the command byte. The next byte is written to the specified register on the rising

edge of the ACK clock pulse.

Figure 5. Repeated Data Write to a Single Register

Figure 6. Burst Data Write to Multiple Registers

Reads

The bus master must first send the TSU6111A slave address with the LSB set to logic 0. The command byte is

sent after the address and determines which register is accessed. After a restart, the device slave address is

sent again but, this time, the LSB is set to logic 1. Data from the register defined by the command byte then is

sent by the TSU6111A. Data is clocked into the SDA output shift register on the rising edge of the ACK clock

pulse (See Figure 7).

Copyright © 2012, Texas Instruments Incorporated Submit Documentation Feedback 13

Product Folder Link(s): TSU6111A

Page 14

SDA

ST 0 1 0 0 1 0 1 0 A 0 0 0 0 0 0 1 1 A SP 0 1 0 0 1 0 1 1 A D7 D6 D5 D4 D3 D2 D1 D0

Start

Slave Address

W/R

Ack. from slave

Sub Address

Ack

from

slave

Auto-Inc.

Slave Address

W/R

Ack. from slaveStop

Date Byte

A A

Ack. from master

D7 D6 D5 D4 D3 D2 D1 D0

Date Byte

NAD7 D6 D5 D4 D3 D2 D1 D0

Date Byte

Data from Interrupt 1 Reg.

Ack. from master No Ack. from master (Message ends)

Continued

SP

Stop

ST

StartRegister Address

(Interrupt 1 Reg)

Data from Interrupt 1 Reg.Data from Interrupt 1 Reg.

SCL

SDA

ST 0 1 0 0 1 0 1 0 A 1 0 0 0 0 0 1 1 A RS 0 1 0 0 1 0 1 1 A D7 D6 D5 D4 D3 D2 D1 D0

Start

Slave Address

W/R

Ack. from slave

Sub Address

Ack

from

slave

Auto-Inc.

Slave Address

W/R

Ack. from slave

Re-Start

Date Byte

A A

Ack. from master

D7 D6 D5 D4 D3 D2 D1 D0

Date Byte

NA

D7 D6 D5 D4 D3 D2 D1 D0

Date Byte

Data from Interrupt 1 Reg.

Data from Interrupt 2 Reg. Data from Int Mask 1 Reg.

Ack. from master No Ack. from master (Message ends)

Continued

SP

Stop

Register Address

(Interrupt 1 Reg)

SDA

ST 0 1 0 0 1 0 1 0 A 0 0 0 0 0 0 1 1 A RS 0 1 0 0 1 0 1 1 A D7 D6 D5 D4 D3 D2 D1 D0

Start

Slave Address

W/R

Ack. from slave

Sub Address

Ack

from

slave

Auto-Inc.

Slave Address

W/R

Ack. from slave

Re-Start

Date Byte

A A

Ack. from master

D7 D6 D5 D4 D3 D2 D1 D0

Date Byte

NAD7 D6 D5 D4 D3 D2 D1 D0

Date Byte

Data from Interrupt 1 Reg.

Data from Interrupt 1 Reg. Data from Interrupt 1 Reg.

Ack. from master

No Ack. from master (message ends)

Continued

SP

Stop

Register Address

(Interrupt 1 Reg)

TSU6111A

SCDS331A –FEBRUARY 2012–REVISED AUGUST 2012

Figure 7. Repeated Data Read from a Single Register – Combined Mode

www.ti.com

Figure 8. Burst Data Read from Multiple Registers – Combined Mode

Figure 9. Repeated Data Read from a Single Register – Split Mode

14 Submit Documentation Feedback Copyright © 2012, Texas Instruments Incorporated

Product Folder Link(s): TSU6111A

Page 15

SCL

SDA ST 0 1 0 0 1 0 1 0 A 1 0 0 0 0 0 1 1 A SP 0 1 0 0 1 0 1 1 A D7 D6 D5 D4 D3 D2 D1 D0

Start

Slave Address

W/R

Ack. from slave

Sub Address

Ack

from

slave

Auto-Inc.

Slave Address

W/R

Ack. from slaveStop

Date Byte

A A

Ack. from master

D7 D6 D5 D4 D3 D2 D1 D0

Date Byte

NAD7 D6 D5 D4 D3 D2 D1 D0

Date Byte

Data from Interrupt 1 Reg.

Data from Interrupt 2 Reg. Data from Int Mask 1 Reg.

Ack. from master No Ack. from master (Message ends)

Continued

SP

Stop

ST

StartRegister Address

(Interrupt 1 Reg)

TSU6111A

www.ti.com

SCDS331A –FEBRUARY 2012–REVISED AUGUST 2012

Figure 10. Burst Data Read from Multiple Registers – Split Mode

Notes (Applicable to Figure 5–Figure 10):

• SDA is pulled low on Ack. from slave or Ack. from master.

• Register writes always require sub-address write before first data byte.

• Repeated data that writes to a single register continues indefinitely until a Stop or a Re-Start.

• Repeated data reads from a single register continues indefinitely until No Ack. from master.

• Burst data writes start at the specified register address, then advance to the next register address, even to

the read-only registers. For these registers, data write appears to occur; however, no data is changed by the

writes. After register 14h is written, writing resumes to register 01h and continues until a Stop or a Re-Start.

• Burst data reads starts at the specified register address, then advances to the next register address. Once

register 14h is read, reading resumes from register 01h and continues until No Ack. from master.

Copyright © 2012, Texas Instruments Incorporated Submit Documentation Feedback 15

Product Folder Link(s): TSU6111A

Page 16

TSU6111A

SCDS331A –FEBRUARY 2012–REVISED AUGUST 2012

I2C Register Map

ADDR REGISTER TYPE BIT7 BIT6 BIT5 BIT4 BIT3 BIT2 BIT1 BIT0

01h Device ID R 00010010 Version ID Vendor ID

02h Control R/W xxx11111 Switch Open Raw Data Manual S/W Wait INT Mask

03h Interrupt 1 R xxxxxx00 Detach Attach

04h Interrupt 2 R xx0xx000 CONNECT ADC_Change Charging_A/V

05h Interrupt Mask 1 R/W xxxxxx00 Detach Attach

06h Interrupt Mask 2 R/W xx0xx000 CONNECT ADC_Change Charging_A/V

07h ADC R xxx11111 ADC Value

08h Timing Set 1 R/W xxxx0000 Device Wake Up

09h Timing Set 2 R/W 0000xxxx Switching Wait

0Ah Device Type 1 R 00000000 USG OTG DCP CDP UART USG Audio Type2 Audio Type1

0Bh Device Type 2 R 00000000 Audio/Video TTY PPD JIG_USB_OFF JIG_USB_ON

0Ch Button 1 R 00000000 7 6 5 4 3 2 1 Send_End

0Dh Button 2 R x0000000 Unknown Error 12 11 10 9 8

13h Manual S/W 1 R/W 000000xx D– Switching D+ Switching

14h Manual S/W 2 R/W xxxx00xx BOOT_SW JIG-ON

15h Device Type 3 R xxxxxx00 VBUS MHL

(1)(2)(3)

RESET

VALUE

Audio

Type3

Reserved_

Attach

Reserved_

Attach

JIG_UART_ JIG_UART_

OFF ON

www.ti.com

(1) Do not use blank register bits.

(2) Write “0” to the blank register bits.

(3) Values read from the blank register bits are not defined and invalid.

16 Submit Documentation Feedback Copyright © 2012, Texas Instruments Incorporated

Product Folder Link(s): TSU6111A

Page 17

TSU6111A

www.ti.com

SCDS331A –FEBRUARY 2012–REVISED AUGUST 2012

Slave Address

NAME

Slave address 8 0 1 0 0 1 0 1 R/W

SIZE

(BITS)

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

DESCRIPTION

Device ID

Address: 01h

Reset Value: 00010010

Type: Read

BIT NO. NAME SIZE (BITS) DESCRIPTION

2-0 Vendor ID 3 A unique number for vendor 010 for Texas Instruments

7-3 Version ID 5 A unique number for chip version 00001b for TSU6111A

Control

Address: 02h

Reset Value: xxx11111

Type: Read/Write

BIT NO. NAME SIZE (BITS) DESCRIPTION

0 INT Mask 1 0: Unmask interrupt

1: Mask interrupt

1 Wait 1 0: Wait until host re-sets this bit(WAIT bit) high

1: Wait until Switching timer is expired

2 Manual S/W 1 0: Manual Switching

1: Automatic Switching

3 RAW Data 1 0: Report the status changes on ID to Host

1: Don't report the status changes on ID

4 Switch Open 1 0: Open all Switches

1: Automatic Switching by accessory status

7-5 Reserved

Copyright © 2012, Texas Instruments Incorporated Submit Documentation Feedback 17

Product Folder Link(s): TSU6111A

Page 18

TSU6111A

SCDS331A –FEBRUARY 2012–REVISED AUGUST 2012

Interrupt 1

Address: 03h

Reset Value: xxxxxx00

Type: Read and Clear

BIT NO. NAME SIZE (BITS) DESCRIPTION

0 Attach 1 1: Accessory is attached

1 Detach 1 1: Accessory is detached

7-2 Unused 6 Unused

Interrupt 2

Address: 04h

Reset Value:xx0xx000

Type: Read and Clear

BIT NO. NAME SIZE (BITS) DESCRIPTION

0 Charging_A/V 1 1: Charger detected when A/V cable is attached

1 Reserved_Attach 1 1: Reserved Device is attached

2 ADC_Change 1 1: ADC value is changed when RAW data is enabled

4-3 Unused 2

5 Connect 1 1: Switch is connected(closed)

7-6 Unused 2

www.ti.com

18 Submit Documentation Feedback Copyright © 2012, Texas Instruments Incorporated

Product Folder Link(s): TSU6111A

Page 19

TSU6111A

www.ti.com

Interrupt Mask 1

Address: 05h

Reset Value:xxxxxx00

Type: Read/Write

BIT NO. NAME SIZE (BITS) DESCRIPTION

0 Attach 1 0: Unmask Attach Interrupt

1: Mask Attach Interrupt

1 Detach 1 0: Unmask Key press Interrupt

1: Mask Detach Interrupt

7-2 Unused 6 Unused

Interrupt Mask 2

Address: 06h

Reset Value:xx0xx000

Type: Read/Write

BIT NO. NAME SIZE (BITS) DESCRIPTION

0 Charging_A/V 1 0: Unmask A/V_Charging Interrupt

1: Mask A/V_Charging Interrupt

1 Reserved_Attach 1 0: Unmask Reserved_Attach Interrupt

1: Mask Reserved_Attach Interrupt

2 ADC_Change 1 0: Unmask ADC_Change Interrupt

1: Mask ADC_Change Interrrupt

4-3 Unused 2

5 Connect 1 0: Unmask Connect Interrupt

1: Mask Connect Interrupt

7-6 Unused 2

SCDS331A –FEBRUARY 2012–REVISED AUGUST 2012

Copyright © 2012, Texas Instruments Incorporated Submit Documentation Feedback 19

Product Folder Link(s): TSU6111A

Page 20

TSU6111A

SCDS331A –FEBRUARY 2012–REVISED AUGUST 2012

ADC Value

Address: 07h

Reset Value: xxx11111

Type: Read

BIT NO. NAME SIZE (BITS) DESCRIPTION

4-0 ADC value 5 ADC value read from ID

7-5 Unused 3

Timing Set 1

Address: 08h

Reset Value: xxxx0000

Type: Read/Write

BIT NO. NAME SIZE (BITS) DESCRIPTION

3-0 Device Wake Up 4 Device wake up duration

7-4 Unused 4

Timing Set 2

Address: 09h

Reset Value: 0000xxxx

Type: Read/Write

BIT NO. NAME SIZE (BITS) DESCRIPTION

3-0 Unused 4

7-4 Switching wait 4 Waiting duration before switching

www.ti.com

Time Table

SETTING VALUE DEVICE WAKE UP SWITCHING WAIT

0000 50 ms 10 ms

0001 100 ms 30 ms

0010 150 ms 50 ms

0011 200 ms 70 ms

0100 300 ms 90 ms

0101 400 ms 110 ms

0110 500 ms 130 ms

0111 600 ms 150 ms

1000 700 ms 170 ms

1001 800 ms 190 ms

1010 900 ms 210 ms

1011 1000 ms –

1100 – –

1101 – –

1110 – –

1111 – –

(1) Maximum variation of these timing is ±20%

(1)

20 Submit Documentation Feedback Copyright © 2012, Texas Instruments Incorporated

Product Folder Link(s): TSU6111A

Page 21

TSU6111A

www.ti.com

SCDS331A –FEBRUARY 2012–REVISED AUGUST 2012

Device Type 1

Address: 0Ah

Reset Value: 00000000

Type: Read

BIT NO. NAME SIZE (BITS) DESCRIPTION

0 Audio type 1 1 Audio device type 1

1 Audio type 2 1 Audio device type 2

2 USB 1 USB host

3 UART 1 UART

4 Unused 1 Unused

5 CDP 1 Charging Downstream Port (USB Host Hub Charger)

6 DCP 1 Dedicated Charging Port

7 USB OTG 1 USB on-the-go device

Device Type 2

Address: 0Bh

Reset Value:00000000

Type: Read

BIT NO. NAME SIZE (BITS) DESCRIPTION

0 JIG_USB_ON 1 Factory mode cable

1 JIG_USB_OFF 1 Factory mode cable

2 JIG_UART_ON 1 Factory mode cable

3 JIG_UART_OFF 1 Factory mode cable

4 PPD 1 Phone-powered device

5 TTY 1 TTY converter

6 Audio/Video 1 A/V cable

7 Audio type 3 1 Audio device type 3

Copyright © 2012, Texas Instruments Incorporated Submit Documentation Feedback 21

Product Folder Link(s): TSU6111A

Page 22

TSU6111A

SCDS331A –FEBRUARY 2012–REVISED AUGUST 2012

Button 1

Address: 0Ch

Reset Value: 00000000

Type: Read and Clear

BIT NO. NAME SIZE (BITS) DESCRIPTION

0 Send_End 1 Send_End key is pressed

1 1 1 Number 1 key is pressed

2 2 1 Number 2 key is pressed

3 3 1 Number 3 key is pressed

4 4 1 Number 4 key is pressed

5 5 1 Number 5 key is pressed

6 6 1 Number 6 key is pressed

7 7 1 Number 7 key is pressed

Button 2

Address: 0Dh

Reset Value:x0000000

Type: Read and Clear

BIT NO. NAME SIZE (BITS) DESCRIPTION

0 8 1 Number 8 key is pressed

1 9 1 Number 9 key is pressed

2 10 1 Number 10 key is pressed

3 11 1 Number 11 key is pressed

4 12 1 Number 12 key is pressed

5 Error 1 Error key is pressed

6 Unknown 1 Unknown key is pressed

7 Unused

www.ti.com

22 Submit Documentation Feedback Copyright © 2012, Texas Instruments Incorporated

Product Folder Link(s): TSU6111A

Page 23

TSU6111A

www.ti.com

Manual S/W 1

Address: 13h

Reset Value: 000000xx

Type: Read/Write

BIT NO. NAME SIZE (BITS) DESCRIPTION

1-0 Unused 2

4-2 D+ Switching 3 000: Open all switch

001: D+ is connected to D+ of USB port

010: Open all switch

011: D+ is connected to RxD of UART

7-5 D– Switching 3 000: Open all switch

001: D– is connected to D– of USB port

010: Open all switch

011: D– is connected to TxD of UART

Manual S/W 2

Address: 14h

Reset Value: xxxx00xx

Type: Read/Write

BIT NO. NAME SIZE (BITS) DESCRIPTION

1-0 Unused 2

2 JIG 1 TSU6111A:

0: High Impedance

1: GND

3 BOOT 1 0: Low

1: High

7-4 Unused 4

SCDS331A –FEBRUARY 2012–REVISED AUGUST 2012

Device Type 3

Address: 15h

Reset Value: xxxxxx00

Type: Read

BIT NO. NAME SIZE (BITS) DESCRIPTION

0 MHL 2 MHL device

1 VBUS 1 VBUS valid

7-1 Unused 7 Unused

Copyright © 2012, Texas Instruments Incorporated Submit Documentation Feedback 23

Product Folder Link(s): TSU6111A

Page 24

MICRO

USB

V+

DN

DP

ID

GND

TSU6111A

INTB

DP_HOST

DM_HOST

RxD

TxD

VBUS

DM_CON

DP_CON

ID_CON

GND

AP OR

BASEBAND

1pF ~

10pF

ESD

2.2 Ω

1p F

ESD

2.2 Ω

1p F

ESD

2.2 Ω

1p F

ESD

1µF ~

10µF

1.7 ~ 3.6V

SCL

SDA

JIG

INTB

DP_HOST

DM_HOST

RxD

TxD

SCL

SDA

JIG

1k Ω ~

10kΩ

VDDIO

VDDIO

VBAT

1µF~

10µF

1µF~

10µF

Battery

BOOT

BOOT

VBAT

1k Ω ~

10k Ω

1k Ω ~

10k Ω

0.1µF

0.1µF

0.1µF

TSU6111A

SCDS331A –FEBRUARY 2012–REVISED AUGUST 2012

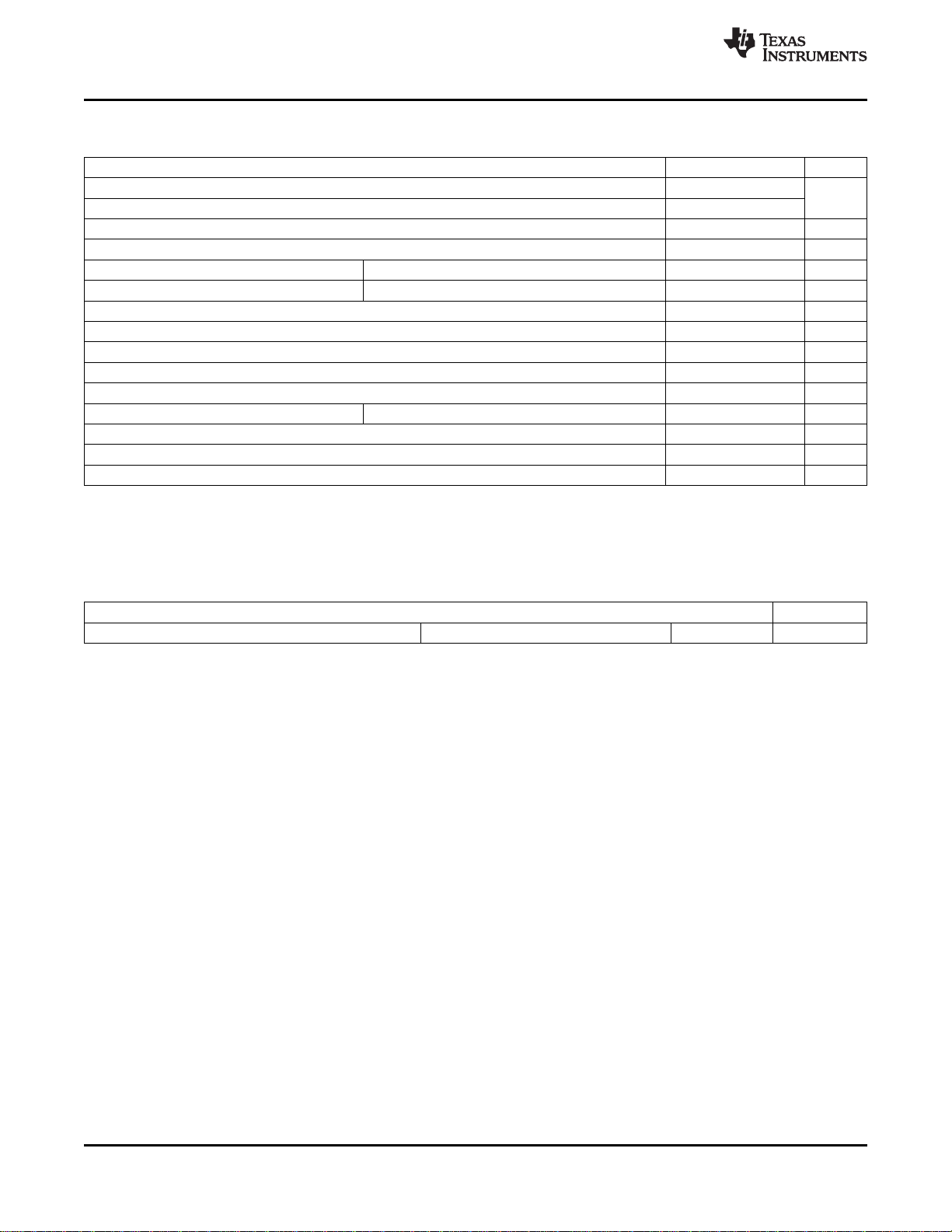

APPLICATION SCHEMATIC

PIN NAME PIN NO. CRITICAL COMPONENT

V

BUS_IN

V

DDIO

V

BAT

Jig 7 1kΩ

SCL 10 1kΩ

SDA 11 1kΩ

DM_CON 14

DP_CON 15

ID_CON 16

(1) Optional components

1µF~10µF

13 ESD Protection Diode

0.1µF

1µF~10µF

8

0.1µF

1µF~10µF

5 Battery

0.1µF

2.2Ω

ESD Protection Diode

2.2Ω

ESD Protection Diode

(1)

2.2Ω

ESD Protection Diode

www.ti.com

24 Submit Documentation Feedback Copyright © 2012, Texas Instruments Incorporated

Product Folder Link(s): TSU6111A

Page 25

TSU6111A

www.ti.com

SCDS331A –FEBRUARY 2012–REVISED AUGUST 2012

SCHEMATIC GUIDELINES

1. V

elements. The capacitors act as a shunt to block off the noise. The 0.1µF capacitor smoothes out high

frequencies and has a lower series inductance. The 1µF~10µF capacitors smoothes out the lower

frequencies and has a much higher series inductance. Placing both capacitors will provide better load

regulation across the frequency spectrum.

2. JIG is an open-drain output and therefore requires a 1kΩ ~ 10kΩ pull-up resistor to VBAT.

3. SCL and SDA require 1kΩ ~ 10kΩ pull-up resistors to VDDIO to prevent floating inputs.

4. V

ballasting to protect the chip and internal circuitry.

(a) For ID_CON, if there is less stress on the ID pin then the external 2.2Ω resistor is optional.

5. DM_CON, DP_CON, and ID_CON are recommended to have a 1pF external ESD Protection Diode rated for

8kV IEC protection to prevent failure in case of an 8kV IEC contact discharge.

6. VBUS_IN is recommended to have a 1pF ~ 10pF external ESD Protection Diode rated for 8kV IEC protection

to prevent failure in case of an 8kV IEC contact discharge.

, V

BUS_IN

, DM_CON, and DP_CON are recommended to have an external resistor 2.2Ω to provide extra

BUS_IN

DDIO

, and V

require 1µF~10µF and 0.1µF decoupling capacitors to reduce noise from circuit

BAT

RECOMMENDED OPERATING CONDITIONS

PARAMETER DESCRIPTION MIN MAX UNIT

V

BUS_IN

V

BAT

V

DDIO

ID_CON_Cap ID_CON capacitance 1 nF

USB_I/O USB path signal range 0 3.6 V

Temperature Operating Temperature –40 85 °C

VBUS voltage 4.0 6.5 V

VBAT voltage 3.0 4.4 V

VDDIO voltage 1.65 3.6 V

Copyright © 2012, Texas Instruments Incorporated Submit Documentation Feedback 25

Product Folder Link(s): TSU6111A

Page 26

DECOUPLING

CAPACITORS

MICRO USB

CONNECTOR

Place the USB connector as close as

possible to the DUT

DUT PAD

45 Degree Turns

on USB signals

USB DP & DM lines

length matched

TSU6111A

SCDS331A –FEBRUARY 2012–REVISED AUGUST 2012

PCB ROUTING GUIDELINES

Routing Guidelines for USB Signal Integrity

1. All the USB lines DP_CON, DM_CON, DP_HT, DM_HT, TxD, and RxD

– Must have 45Ω single ended characteristic impedance

– Must have 90Ω differential ended impedance

– To fulfill USB 2.0 requirements

2. TSU6111A location

– Close to the USB connector as possible

– Keep the distance between the USB controller and the device less than 1 inch

– Shortening the length of the trace will reduce effect of stray noise and radiate less EMI

3. Minimize use of VIAs for USB related signals

– Differential transmission lines should be matched as close as possible

– For optimum USB2.0 performance, use no VIAs

www.ti.com

26 Submit Documentation Feedback Copyright © 2012, Texas Instruments Incorporated

Product Folder Link(s): TSU6111A

Page 27

TSU6111A

www.ti.com

SCDS331A –FEBRUARY 2012–REVISED AUGUST 2012

REVISION HISTORY

Changes from Original (February 2012) to Revision A Page

• Updated ORDERABLE PART NUMBER and TOP-SIDE MARKING in the ORDERING INFORMATION table. ................ 1

Copyright © 2012, Texas Instruments Incorporated Submit Documentation Feedback 27

Product Folder Link(s): TSU6111A

Page 28

PACKAGE OPTION ADDENDUM

www.ti.com

10-Dec-2020

PACKAGING INFORMATION

Orderable Device Status

TSU6111ARSVR ACTIVE UQFN RSV 16 3000 RoHS & Green NIPDAU Level-1-260C-UNLIM -40 to 85 ZTN

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

Package Type Package

(1)

Drawing

Pins Package

Qty

Eco Plan

(2)

Lead finish/

Ball material

(6)

MSL Peak Temp

(3)

Op Temp (°C) Device Marking

(4/5)

(2)

RoHS: TI defines "RoHS" to mean semiconductor products that are compliant with the current EU RoHS requirements for all 10 RoHS substances, including the requirement that RoHS substance

do not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, "RoHS" products are suitable for use in specified lead-free processes. TI may

reference these types of products as "Pb-Free".

RoHS Exempt: TI defines "RoHS Exempt" to mean products that contain lead but are compliant with EU RoHS pursuant to a specific EU RoHS exemption.

Green: TI defines "Green" to mean the content of Chlorine (Cl) and Bromine (Br) based flame retardants meet JS709B low halogen requirements of <=1000ppm threshold. Antimony trioxide based

flame retardants must also meet the <=1000ppm threshold requirement.

(3)

MSL, Peak Temp. - The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder temperature.

(4)

There may be additional marking, which relates to the logo, the lot trace code information, or the environmental category on the device.

(5)

Multiple Device Markings will be inside parentheses. Only one Device Marking contained in parentheses and separated by a "~" will appear on a device. If a line is indented then it is a continuation

of the previous line and the two combined represent the entire Device Marking for that device.

(6)

Lead finish/Ball material - Orderable Devices may have multiple material finish options. Finish options are separated by a vertical ruled line. Lead finish/Ball material values may wrap to two

lines if the finish value exceeds the maximum column width.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is provided. TI bases its knowledge and belief on information

provided by third parties, and makes no representation or warranty as to the accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and

continues to take reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on incoming materials and chemicals.

TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI to Customer on an annual basis.

Samples

Addendum-Page 1

Page 29

PACKAGE MATERIALS INFORMATION

www.ti.com 3-Aug-2017

TAPE AND REEL INFORMATION

*All dimensions are nominal

Device Package

Type

TSU6111ARSVR UQFN RSV 16 3000 177.8 12.4 2.0 2.8 0.7 4.0 12.0 Q1

Package

Drawing

Pins SPQ Reel

Diameter

(mm)

Reel

Width

W1 (mm)

A0

(mm)B0(mm)K0(mm)P1(mm)W(mm)

Pin1

Quadrant

Pack Materials-Page 1

Page 30

PACKAGE MATERIALS INFORMATION

www.ti.com 3-Aug-2017

*All dimensions are nominal

Device Package Type Package Drawing Pins SPQ Length (mm) Width (mm) Height (mm)

TSU6111ARSVR UQFN RSV 16 3000 202.0 201.0 28.0

Pack Materials-Page 2

Page 31

PACKAGE OUTLINE

PIN 1 INDEX AREA

0.55

0.45

0.05

0.00

SCALE 5.000

UQFN - 0.55 mm max heightRSV0016A

ULTRA THIN QUAD FLATPACK - NO LEAD

B

1.85

1.75

A

2.65

2.55

C

SEATING PLANE

0.05 C

2X 1.2

SYMM

5

4

12X 0.4

0.55

0.45

SYMM

℄

1

16

2X 1.2

NOTES:

1. All linear dimensions are in millimeters. Any dimensions in parenthesis are for reference only. Dimensioning and tolerancing

per ASME Y14.5M.

2. This drawing is subject to change without notice.

℄

8

13

PIN 1 ID

(45° X 0.1)

15X

9

12

0.45

0.35

0.25

16X

0.15

0.07 C A B

0.05

4220314/C 02/2020

(0.13) TYP

www.ti.com

Page 32

(0.7)

16

SYMM

℄

EXAMPLE BOARD LAYOUT

UQFN - 0.55 mm max heightRSV0016A

ULTRA THIN QUAD FLATPACK - NO LEAD

13

SEE SOLDER MASK

DETAIL

16X (0.2)

(R0.05) TYP

0.05 MAX

ALL AROUND

12X (0.4)

1

4

15X (0.6)

5

(1.6)

8

LAND PATTERN EXAMPLE

EXPOSED METAL SHOWN

SCALE: 25X

ALL AROUND

METAL EDGE

12

SYMM

℄

9

0.05 MIN

(2.4)

METAL UNDER

SOLDER MASK

EXPOSED METAL

NON SOLDER MASK

DEFINED

(PREFERRED)

SOLDER MASK

OPENING

EXPOSED

METAL

SOLDER MASK DEFINED

SOLDER MASK DETAILS

NOTES: (continued)

3. For more information, see Texas Instruments literature number SLUA271 (www.ti.com/lit/slua271).

www.ti.com

SOLDER MASK

OPENING

4220314/C 02/2020

Page 33

(0.7)

16

EXAMPLE STENCIL DESIGN

UQFN - 0.55 mm max heightRSV0016A

ULTRA THIN QUAD FLATPACK - NO LEAD

13

16X (0.2)

12X (0.4)

(R0.05) TYP

1

4

15X (0.6)

5

SYMM

℄

(1.6)

SOLDER PASTE EXAMPLE

BASED ON 0.125 MM THICK STENCIL

SCALE: 25X

12

SYMM

9

8

(2.4)

℄

4220314/C 02/2020

NOTES: (continued)

4. Laser cutting apertures with trapezoidal walls and rounded corners may offer better paste release. IPC-7525 may have alternate

design recommendations.

www.ti.com

Page 34

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE

DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS”

AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY

IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD

PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate

TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable

standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you

permission to use these resources only for development of an application that uses the TI products described in the resource. Other

reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third

party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims,

damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on

ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable

warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2020, Texas Instruments Incorporated

Loading...

Loading...