Page 1

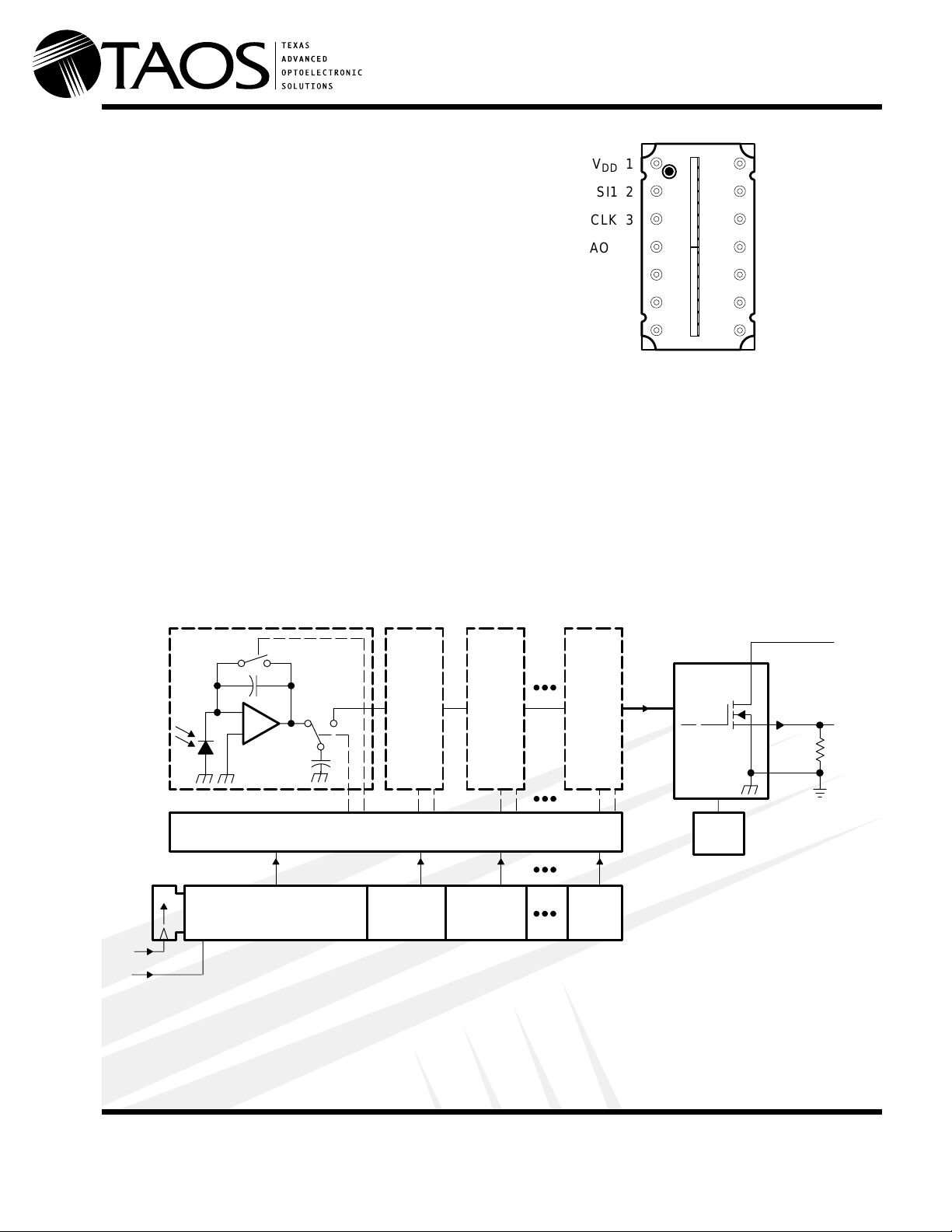

TSL202R

128 1 LINEAR SENSOR ARRAY

TAOS032B – AUGUST 2002

128 × 1 Sensor-Element Organization

(TOP VIEW)

200 Dots-Per-Inch (DPI) Sensor Pitch

High Linearity and Uniformity

Wide Dynamic Range...2000:1 (66 dB)

Output Referenced to Ground

Low Image Lag . . . 0.5% Typ

Operation to 5 MHz

VDD 1

SI1 2

CLK 3

AO1 4

GND 5

14 NC

13 SO1

12 GND

11 NC

10 SI2

Single 5-V Supply

Replacement for TSL202

SO2 6

NC 7

NC – No internal connection

Description

The TSL202R linear sensor array consists of two sections of 64 photodiodes and associated charge amplifier

circuitry arranged to form a contiguous 128 ×1 array. The pixels measure 120 µm (H) by 70 µm (W) with 125-µm

center-to-center spacing and 55-µm spacing between pixels. Operation is simplified by internal control logic that

requires only a serial-input (SI) signal and a clock.

The TSL202R is intended for use in a wide variety of applications including mark detection and code reading,

optical character recognition (OCR) and contact imaging, edge detection and positioning as well as optical linear

and rotary encoding.

9 NC

8 AO2

Functional Block Diagram (each section — pin numbers apply to section 1)

Pixel 1

Integrator

Reset

_

+

Sample/

Output

Switch Control Logic

3

CLK 64-Bit Shift Register

2

SI

Pixel

2

Pixel

3

Q3Q2Q1

Pixel

64

Q64

Analog

Bus

Output

Amplifier

Gain

Trim

1

V

AO

GND

DD

4

5

R

L

(External

330

Load)

The

LUMENOLOGY

Company

Texas Advanced Optoelectronic Solutions Inc.

800 Jupiter Road, Suite 205 Plano, TX 75074 (972) 673-0759

www.taosinc.com

Copyright 2002, TAOS Inc.

1

Page 2

TSL202R

128 1 LINEAR SENSOR ARRAY

TAOS032B – AUGUST 2002

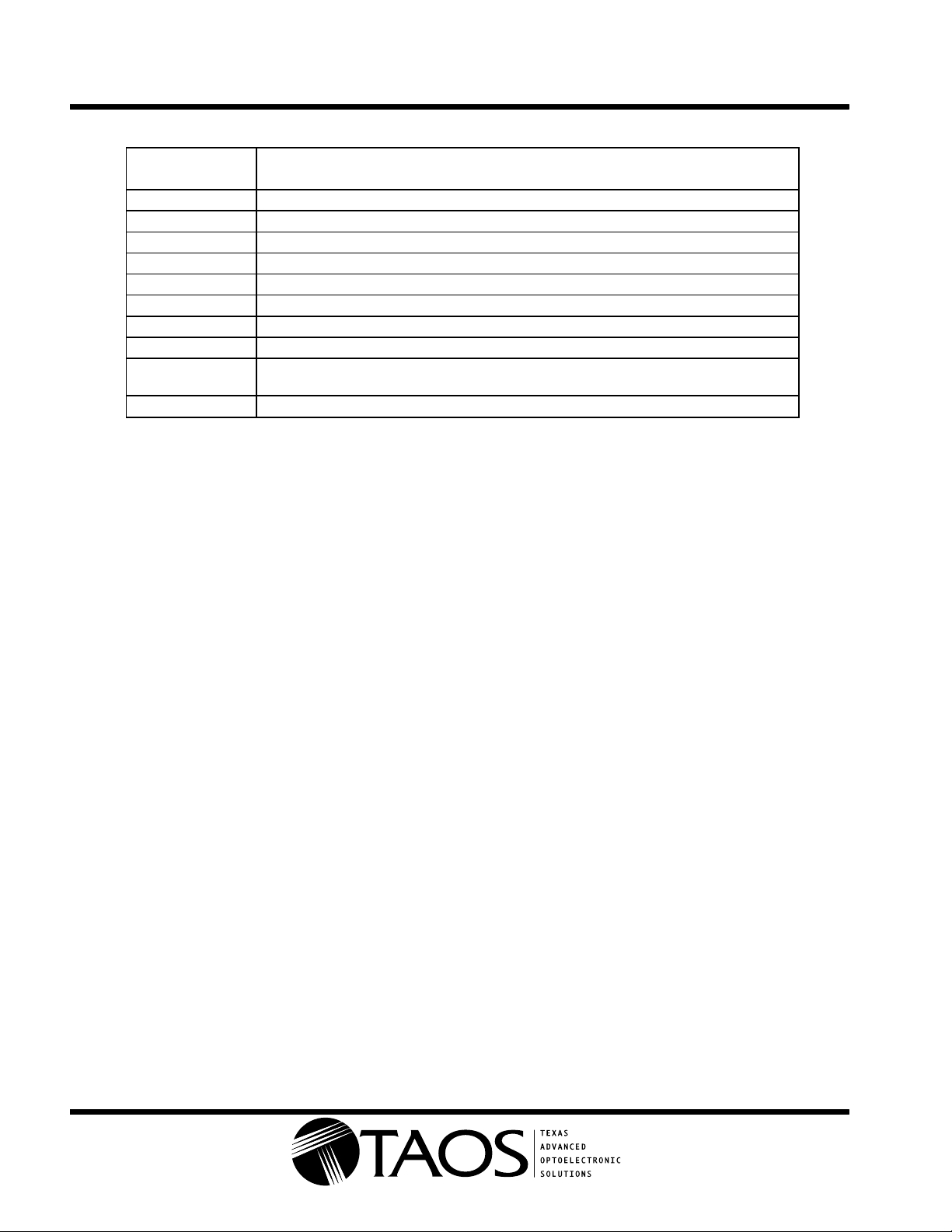

Terminal Functions

TERMINAL

NAME NO. DESCRIPTION

AO1 4 Analog output of section 1

AO2 8 Analog output of section 2

CLK 3 Clock. Clk controls charge transfer, pixel output, and reset.

GND 5,12 Ground (substrate). All voltages are referenced to GND.

NC 7, 9, 11, 14 No internal connection

SI1 2 Serial input (section 1). SI1 defines the start of the data-out sequence.

SI2 10 Serial input (section 2). SI2 defines the start of the data-out sequence.

SO1 13 Serial output (section 1). SO1 provides a signal to drive the SI2 input.

SO2 6

V

DD

1 Supply voltage. Supply voltage for both analog and digital circuitry.

Detailed Description

Serial output (section 2). SO2 provides a signal to drive the SI input of another device for

cascading or as an end-of-data indication.

The sensor consists of 128 photodiodes arranged in a linear array. Light energy impinging on a photodiode

generates photocurrent, which is integrated by the active integration circuitry associated with that pixel. During

the integration period, a sampling capacitor connects to the output of the integrator through an analog switch.

The amount of charge accumulated at each pixel is directly proportional to the light intensity and the integration

time. The integration time is the interval between two consecutive output periods.

The output and reset of the integrators is controlled by a 128-bit shift register and reset logic. An output cycle

is initiated by clocking in a logic 1 on SI for one positive going clock edge (see Figures1 and 2)†. As the SI pulse

is clocked through the 128-bit shift register, the charge on the sampling capacitor of each pixel is sequentially

connected to a charge-coupled output amplifier that generates a voltage output, AO. When the bit position goes

low, the pixel integrator is reset. On the 129th clock rising edge, the SI pulse is clocked out of the shift register

and the output assumes a high-impedance state. Note that this 129th clock pulse is required to terminate the

output of the 128th pixel and return the internal logic to a known state. A subsequent SI pulse can be presented

as early as the 130th clock pulse, thereby initiating another pixel output cycle.

The voltage developed at analog output (AO) is given by:

V

= V

where:

out

V

out

V

drk

R

E

e

t

int

is the analog output voltage for white condition

is the analog output voltage for dark condition

is the device responsivity for a given wavelength of light given in V/(µJ/cm2)

e

is the incident irradiance in µW/cm

is integration time in seconds

+ (Re) (Ee) (t

drk

2

)

int

AO is driven by a source follower that requires an external pulldown resistor (330-Ω typical). The output is

nominally 0 V for no light input, 2 V for normal white-level, and 3.4 V for saturation light level. When the device

is not in the output phase, AO is in a high impedance state.

A 0.1 µF bypass capacitor should be connected between VDD and ground as close as possible to the device.

†

For proper operation, after meeting the minimum hold time condition, SI must go low before the next rising edge of the clock.

Copyright 2002, TAOS Inc.

2

www.taosinc.com

The

LUMENOLOGY

Company

Page 3

TSL202R

128 1 LINEAR SENSOR ARRAY

TAOS032B – AUGUST 2002

Absolute Maximum Ratings

†

Supply voltage range, VDD –0.3 V to 6 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input voltage range, VI –0.3 V to VDD + 0.3V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input clamp current, IIK (VI < 0 or VI > VDD) –20 mA to 20 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output clamp current, IOK (VO < 0 or VO > VDD) –25 mA to 25 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Voltage range applied to any output in the high impedance or

power-off state, VO –0.3 V to VDD + 0.3V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous output current, I

(V

= 0 to VDD) –25 mA to 25 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

O

O

Continuous current through VDD or GND –40 mA to 40 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog output current range, IO –25 mA to 25 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating free-air temperature range, TA –25°C to 85°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature range, T

–25°C to 85°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

stg

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds 260°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ESD tolerance, human body model 2000 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “Recommended Operating Conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

Recommended Operating Conditions (see Figure 1 and Figure 2)

MIN NOM MAX UNIT

Supply voltage, V

Input voltage, V

High-level input voltage, V

Low-level input voltage, V

Wavelength of light source, λ 400 1000 nm

Clock frequency, f

Sensor integration time, serial, t

Sensor integration time, parallel, t

Operating free-air temperature, T

Load resistance, R

Load capacitance, C

DD

I

IH

IL

clock

int

int

A

L

L

4.5 5 5.5 V

0 V

2 V

0 0.8 V

5 5000 kHz

0.026 100 ms

0.013 100 ms

0 70 °C

300 4700 Ω

DD

DD

420 pF

V

V

The

LUMENOLOGY

Company

www.taosinc.com

Copyright 2002, TAOS Inc.

3

Page 4

TSL202R

128 1 LINEAR SENSOR ARRAY

TAOS032B – AUGUST 2002

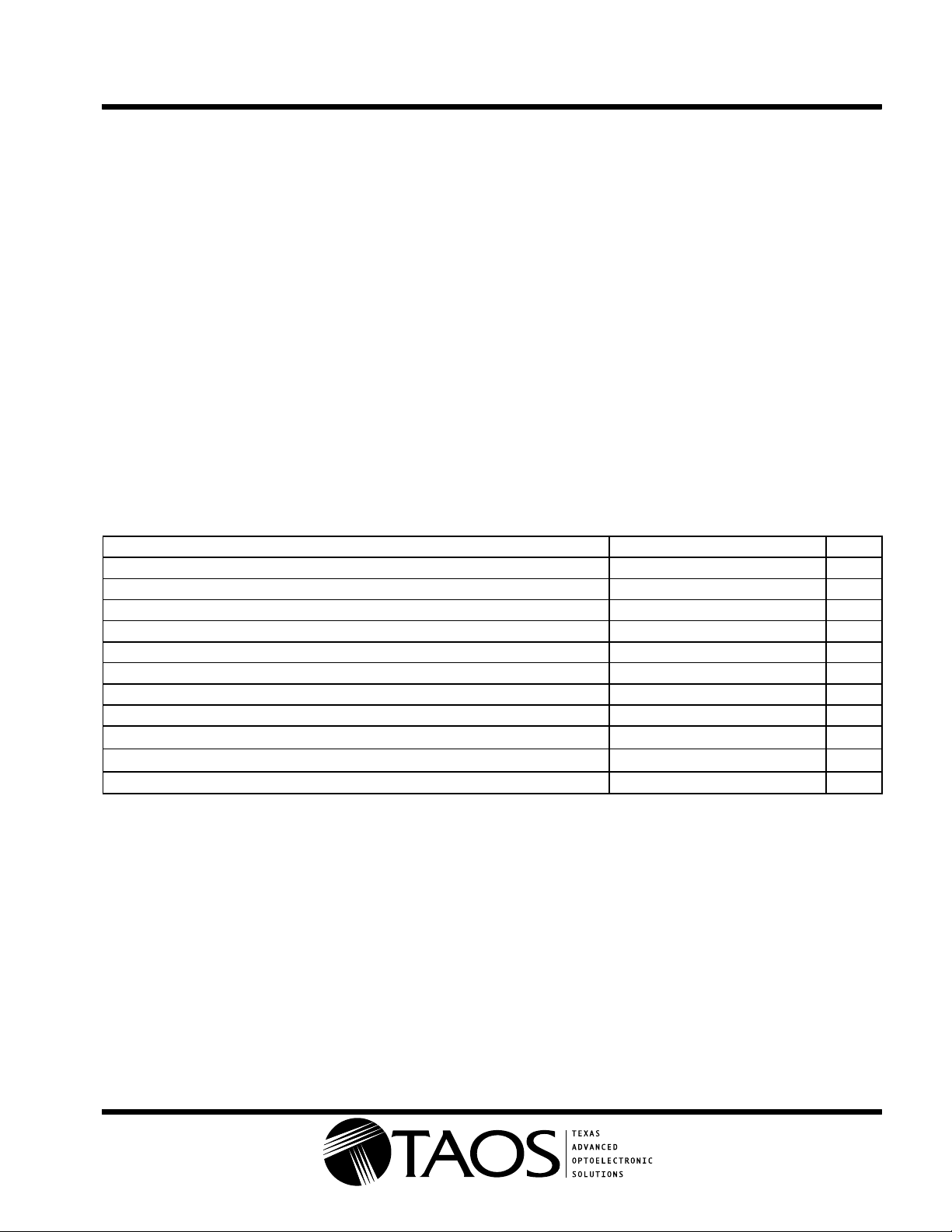

Electrical Characteristics at f

= 330 Ω, Ee = 16.5 µW/cm2 (unless otherwise noted)

R

L

= 1 MHz, VDD = 5 V, TA = 25°C, λp = 640 nm, t

clock

= 5 ms,

int

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

V

Analog output voltage (white, average over 128 pixels) See Note 1 1.6 2 2.4 V

out

Analog output voltage (dark, average over 128 pixels) 0 50 150 mV

drk

PRNU Pixel response nonuniformity See Notes 2 & 3 ±4% ±10%

Nonlinearity of analog output voltage See Note 3 ±0.4% FS

Output noise voltage See Note 4 1 mVrms

R

Responsivity 18 23 30

e

(µJ/cm2)

SE Saturation exposure See Note 5 142 nJ/cm

V

Analog output saturation voltage 2.5 3.4 V

sat

DSNU Dark signal nonuniformity All pixels See Note 6 25 120 mV

IL Image lag See Note 7 0.5%

I

DD

I

IH

I

IL

V

V

C

C

Supply current, output idle 5 8 mA

High-level input current VI = V

DD

Low-level input current VI = 0 10 µA

High-level output voltage, SO1 and SO2

OH

Low-level output voltage, SO1 and SO2

OL

Input capacitance, SI 5 pF

i(SI)

Input capacitance, CLK 10 pF

i(CLK)

p

p

IO = 50 µA 4.5 4.95

IO = 4 mA 4.6

IO = 50 µA 0.01 0.1

IO = 4 mA 0.4

10 µA

NOTES: 1. The array is uniformly illuminated with a diffused LED source having a peak wavelength of 640 nm.

2. PRNU is the maximum difference between the voltage from any single pixel and the average output voltage from all pixels of the

device under test when the array is uniformly illuminated at the white irradiance level. PRNU includes DSNU.

3. Nonlinearity is defined as the maximum deviation from a best-fit straight line over the dark-to-white irradiance levels, as a percent

of analog output voltage (white).

4. RMS noise is the standard deviation of a single-pixel output under constant illumination as observed over a 5-second period.

5. Minimum saturation exposure is calculated using the minimum V

, the maximum V

sat

, and the maximum Re.

drk

6. DSNU is the difference between the maximum and minimum output voltage in the absence of illumination.

7. Image lag is a residual signal left in a pixel from a previous exposure. It is defined as a percent of white-level signal remaining after

a pixel is exposed to a white condition followed by a dark condition:

IL

V

V

out (white)

out (IL)

V

V

drk

100

drk

V/

2

V

V

Timing Requirements (see Figure 1 and Figure 2)

t

su(SI)

t

h(SI)

t

w

tr, t

NOTES: 8. Input pulses have the following characteristics: tr = 6 ns, tf = 6 ns.

Copyright 2002, TAOS Inc.

4

Setup time, serial input (see Note 8) 20 ns

Hold time, serial input (see Note 8 and Note 9) 0 ns

Pulse duration, clock high or low 50 ns

Input transition (rise and fall) time 0 500 ns

f

9. SI must go low before the rising edge of the next clock pulse.

www.taosinc.com

MIN NOM MAX UNIT

The

LUMENOLOGY

Company

Page 5

TSL202R

128 1 LINEAR SENSOR ARRAY

TAOS032B – AUGUST 2002

Dynamic Characteristics over recommended ranges of supply voltage and operating free-air

temperature (see Figure 2)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

t

s

t

pd(SO)

Analog output settling time to ±1% RL = 330 Ω, CL = 10 pF 185 ns

Propagation delay time, SO1, SO2 50 ns

TYPICAL CHARACTERISTICS

CLK

SI

129 Clock Cycles

AO

CLK

t

su(SI)

SI1 (SI2)

SO1 (SO2)

Hi-Z

t

1 (65) 2 (66) 64 (128) 65 (129)

w

2.5 V

2.5 V 2.5 V

2.5 V

t

h(SI)

t

s

Figure 1. Timing Waveforms

t

pd(SO)

t

s

t

pd(SO)

Hi-Z

5 V

2.5 V

0 V

5 V

0 V

AO1 (A02)

The

LUMENOLOGY

Pixel 1 (65)

Company

Pixel 64 (128)

Figure 2. Operational Waveforms (each section)

www.taosinc.com

Copyright 2002, TAOS Inc.

5

Page 6

TSL202R

128 1 LINEAR SENSOR ARRAY

TAOS032B – AUGUST 2002

PHOTODIODE SPECTRAL RESPONSIVITY

1

TA = 25°C

0.8

0.6

TYPICAL CHARACTERISTICS

ANALOG OUTPUT SETTLING TIME

LOAD CAPACITANCE AND RESISTANCE

600

VDD = 5 V

V

= 1 V

out

500

400

300

vs

470 pF

220 pF

100 pF

0.4

Normalized Responsivity

0.2

0

300 500 700 900

λ – Wavelength – nm

Figure 3

200

— Settling Time to 1% — ns

s

t

100

1100400 600 800 1000

0

0 400 800 1200

200 600 1000

RL – Load Resistance – Ω

10 pF

Figure 4

Copyright 2002, TAOS Inc.

6

www.taosinc.com

The

LUMENOLOGY

Company

Page 7

128 1 LINEAR SENSOR ARRAY

TAOS032B – AUGUST 2002

APPLICATION INFORMATION

Power Supply Considerations

For optimum device performance, power-supply lines should be decoupled by a 0.01-µF to 0.1-µF capacitor

with short leads mounted close to the device package (see Figure 5 and Figure 6).

Connection Diagrams

V

DD

TSL202R

Si

CLK

AO1 (Pixels 1–64)

0.1 µF

0.1 µF

R

CLK

L

TSL202R

1

V

SI

2

3

4

5

6

7

DD

SI1

CLK

AO1

GND

SO2

V

DD

Figure 5. Serial Connection

V

DD

TSL202R

1

V

DD

2

SI1

3

CLK

4

AO1

5

GND

6

SO2

7

V

DD

NC

SO1

GND

NC

SI2

NC

AO2

NC

SO1

GND

NC

SI2

NC

AO2

14

13

12

11

10

9

8

14

13

12

11

10

9

8

AO

R

L

AO2 (Pixels 65–128)

The

LUMENOLOGY

Company

Figure 6. Parallel Connection

www.taosinc.com

R

L

Copyright 2002, TAOS Inc.

7

Page 8

TSL202R

128 1 LINEAR SENSOR ARRAY

TAOS032B – AUGUST 2002

MECHANICAL INFORMATION

This assembly consists of 2 sensor chips mounted on a printed-circuit board in a clear molded plastic package.

TOP VIEW

Sensors

C

L

Sensors

to Pin 1

Pixel 1

to Pin 1

SIDE VIEW

14 4.60 MIN

3.62

3.92

0.53

0.28

Pin 1

Indicator

14

19.30

18.29

0.508

0.406

10.67

9.65

Top of Die to

Top of Package

0.89

1.29

14

END VIEW

3.18

2.79

0.50

0.00

BOTTOM

VIEW

1.90

0.76

1234567

7.87

7.37

14 13 12 11 10 9 8

2.16

2

1.42

12 2.54

Nonaccumulative

See Note B

NOTES: A. All linear dimensions are in millimeters.

Copyright 2002, TAOS Inc.

B. The true-position spacing is 2.54 mm between lead centerlines. Each pin centerline is located within 0.25 mm of its true

longitudinal positions.

C. Index of refraction of clear plastic is 1.52.

D. This drawing is subject to change without notice.

Figure 7. Packaging Configuration

The

LUMENOLOGY

Company

8

www.taosinc.com

Page 9

TSL202R

128 1 LINEAR SENSOR ARRAY

TAOS032B – AUGUST 2002

PRODUCTION DATA — information in this document is current at publication date. Products conform to

specifications in accordance with the terms of Texas Advanced Optoelectronic Solutions, Inc. standard

warranty. Production processing does not necessarily include testing of all parameters.

NOTICE

Texas Advanced Optoelectronic Solutions, Inc. (TAOS) reserves the right to make changes to the products contained in this

document to improve performance or for any other purpose, or to discontinue them without notice. Customers are advised

to contact TAOS to obtain the latest product information before placing orders or designing TAOS products into systems.

TAOS assumes no responsibility for the use of any products or circuits described in this document or customer product

design, conveys no license, either expressed or implied, under any patent or other right, and makes no representation that

the circuits are free of patent infringement. TAOS further makes no claim as to the suitability of its products for any particular

purpose, nor does TAOS assume any liability arising out of the use of any product or circuit, and specifically disclaims any

and all liability, including without limitation consequential or incidental damages.

TEXAS ADVANCED OPTOELECTRONIC SOLUTIONS, INC. PRODUCTS ARE NOT DESIGNED OR INTENDED FOR

USE IN CRITICAL APPLICATIONS IN WHICH THE FAILURE OR MALFUNCTION OF THE TAOS PRODUCT MAY

RESUL T I N PERSONAL INJURY OR DEATH. USE OF TAOS PRODUCTS IN LIFE SUPPORT SYSTEMS IS EXPRESSLY

UNAUTHORIZED AND ANY SUCH USE BY A CUSTOMER IS COMPLETELY AT THE CUSTOMER’S RISK.

LUMENOLOGY is a registered trademark, and TAOS, the TAOS logo, and Texas Advanced Optoelectronic Solutions are trademarks of

Texas Advanced Optoelectronic Solutions Incorporated.

The

LUMENOLOGY

Company

www.taosinc.com

Copyright 2002, TAOS Inc.

9

Loading...

Loading...