Page 1

INTEGRATED CIRCUITS

DATA SH EET

TSA5515T

1.3 GHz bi-directional I

controlled synthesizer

Product specification

File under Integrated Circuits, IC02

2

C-bus

November 1991

Page 2

Philips Semiconductors Product specification

1.3 GHz bi-directional I2C-bus controlled synthesizer

GENERAL DESCRIPTION

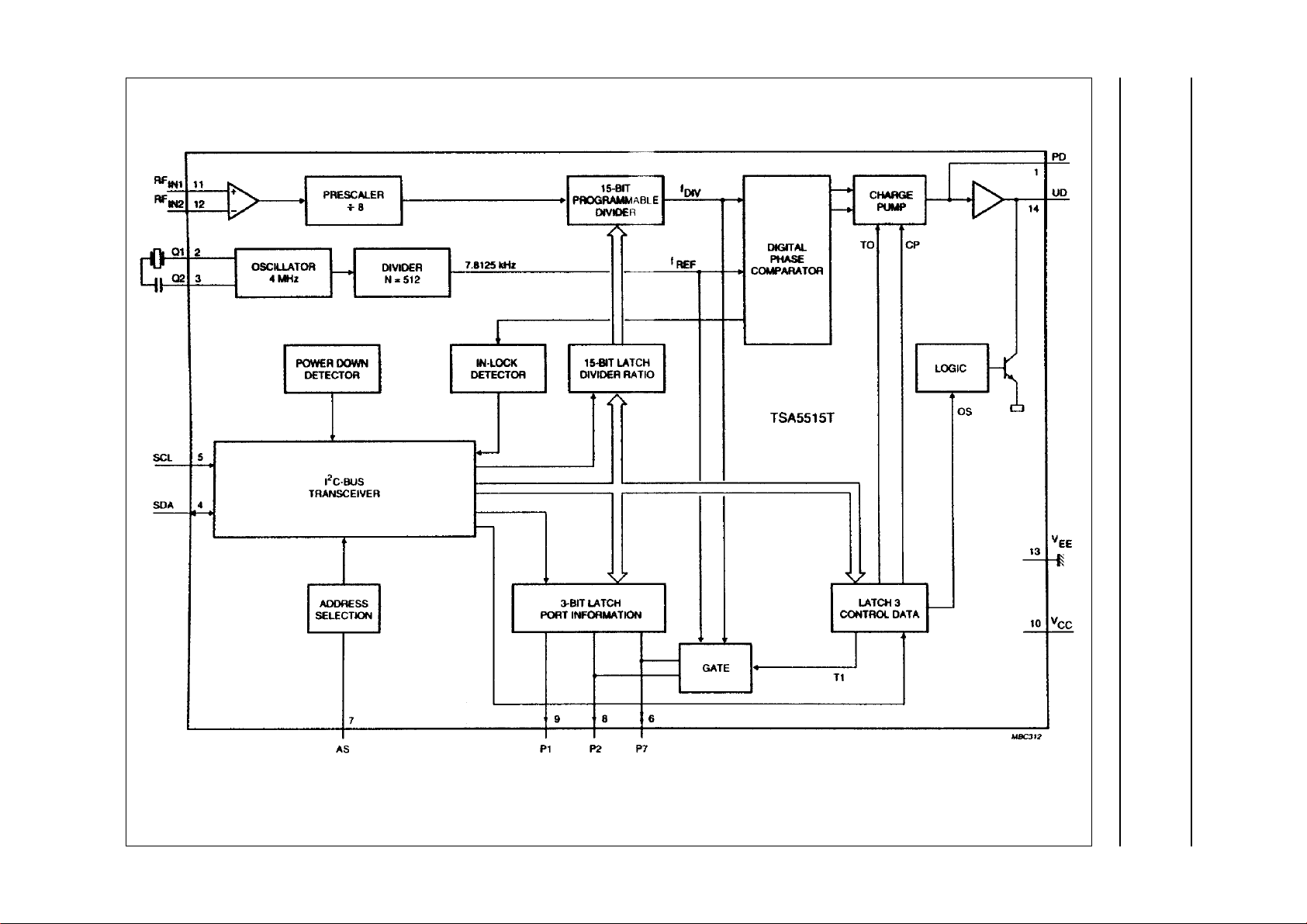

The TSA5515T is a single chip PLL frequency synthesizer

designed for TV tuning systems. Control data is entered

via the I2C-bus; five serial bytes are required to address

the device, select the oscillator frequency, programme the

three output ports and set the charge-pump current. A flag

is set when the loop is “in-lock”. Another flag is set when a

power dip occurs on the supply line. These flags are read

out of the TSA5515T on SDA line (one status byte) during

a READ operation. The device has 4 programmable

addresses, programmed by applying a specific voltage on

the AS pin. The phase comparator operates at

7.8125 kHz when a 4 MHz crystal is used.

FEATURES

• Complete 1.3 GHz single-chip system

• Low power 5 V, 35 mA

2

• I

C-bus programming

• In-lock flag

• Varicap drive disable

• Low radiation

• Address selection for Picture-In-Picture (PIP), DBS

tuner, etc.

• 3 bus-controlled output ports

• Power-down flag

• Available in SOT108A package

APPLICATIONS

• TV tuners

• VCR tuners

TSA5515T

QUICK REFERENCE DATA

SYMBOL PARAMETER MIN. TYP. MAX. UNIT

V

CC

I

CC

supply voltage − 5 − V

supply current − 35 − mA

∆f frequency range 64 − 1300 MHz

V

I (RMS)

input voltage level (RMS value)

80 MHz to 150 MHz 12 − 300 mV

150 MHz to 1 GHz 9 − 300 mV

1 GHz to 1.3 GHz 40 − 300 mV

f

XTAL

I

O

crystal oscillator 3.2 4 4.48 MHz

open-collector output current

P7 −−5mA

P1, P2 −−20 mA

T

T

R

amb

stg

th j-a

operating ambient temperature range −10 − 80 °C

storage temperature range −40 − 125 °C

thermal resistance − 110 − K/W

ORDERING INFORMATION

PACKAGE

EXTENDED TYPE NUMBER

PINS PIN POSITION MATERIAL CODE

TSA5515T 14 SO plastic SOT108A

(1)

Note

1. SOT108-1; 1996 December 3.

November 1991 2

Page 3

November 1991 3

Philips Semiconductors Product specification

1.3 GHz bi-directional I

2

C-bus controlled synthesizer

Fig.1 Block diagram

TSA5515T

Page 4

Philips Semiconductors Product specification

1.3 GHz bi-directional I2C-bus controlled synthesizer

TSA5515T

LIMITING VALUES

In accordance with Absolute Maximum System (IEC 134).

SYMBOL PARAMETER MIN. MAX. UNIT

V

CC

V

P1

V

P2

V

P4

V

P5

V

P7

V

P6

V

P11

V

P14

I

6L

I

8L

I

4L

T

stg

T

j

supply voltage −0.3 6 V

charge-pump output voltage −0.3 V

crystal (Q1) input voltage −0.3 V

CC

CC

serial data input/output −0.3 6 V

serial clock input −0.3 6 V

address selection −0.3 6 V

output ports P7, P2, P1 −0.3 16 V

prescaler inputs −0.3 2.5 V

drive output −0.3 V

CC

output port P7 (open collector) −110mA

output port P2, P1 (open collector) −125mA

SDA output (open collector) −15 mA

storage temperature range −40 125 °C

junction temperature − 125 °C

V

V

V

THERMAL RESISTANCE

SYMBOL PARAMETER THERMAL RESISTANCE

R

th j-a

from junction to ambient in free air 110 K/W

HANDLING

Every pin withstands the ESD test in accordance with MIL-STD-883C, category A (> 1500 V).

November 1991 4

Page 5

Philips Semiconductors Product specification

1.3 GHz bi-directional I2C-bus controlled synthesizer

PINNING

SYMBOL PIN DESCRIPTION

PD 1 charge-pump output

Q1 2 crystal oscillator input 1

Q2 3 crystal oscillator input 2

SDA 4 serial data input/output

SCL 5 serial clock input

P7 6 port output

AS 7 input for address selection

P2 8 port output

P1 9 port output

V

CC

RF

IN1

RF

IN2

GND 13 ground

UD 14 drive output

10 voltage supply

11 UHF/VHF signal input 1

12 UHF/VHF signal input 2 (decoupled)

TSA5515T

Fig.2 Pinning diagram.

November 1991 5

Page 6

Philips Semiconductors Product specification

1.3 GHz bi-directional I2C-bus controlled synthesizer

FUNCTIONAL DESCRIPTION

The TSA5515T is controlled via the two-wire I2C-bus. For

programming, there is one module address (7 bits) and the

R/W bit for selecting READ or WRITE mode.

WRITE mode:

R/

W = 0 (see Table 1)

After the address transmission (first byte), data bytes can

be sent to the device. Four data bytes are needed to fully

program the TSA5515T. The bus transceiver has an

auto-increment facility, which permits the programming of

the TSA5515T within one single transmission

(address + 4 data bytes).

byte 2 or byte 4. The meaning of the bits in the data bytes

is given in Table 1. The first bit of the first data byte

transmitted indicates whether frequency data (first bit = 0)

or charge pump and port information (first bit = 1) will

follow. Until an I

controller, additional data bytes can be entered without the

need to re-address the device. This allows a smooth

frequency sweep for fine tuning. At power-on, the ports are

set to the high impedance state.

The 7.8125 kHz reference frequency is obtained by

dividing the output of the 4 MHz crystal oscillator by 512.

Because the input of the UHF/VHF signal is first divided by

8, the step size is 62.5 kHz. A 3.2 MHz crystal can offer a

step size of 50 kHz.

2

C-bus STOP condition is sent by the

TSA5515T

The TSA5515T can also be partly programmed on the

condition that the first data byte following the address is

Table 1 Write data format

MSB LSB

Address 1 1000MA1MA00 Abyte 1

Programmable

0 N14 N13 N12 N11 N10 N9 N8 A byte 2

divider

Programmable

N7 N6 N5 N4 N3 N2 N1 N0 A byte 3

divider

Charge-pump

1 CP T1 T0 X X X OS A byte 4

and test bits

Output ports control

P7XXXXP2P1X Abyte 5

bits

MA1, MA0 programmable address bits (see Table 3)

A acknowledge bit

N14 to N0 programmable divider bits

N = N14 × 2

14

+N13 × 213+...+N1 × 21+N0

CP charge-pump current

CP = 0 50 µA

CP = 1 220 µA

P7, P2, P1 = 1 open-collector outputs are active

P7, P2, P1 = 0 outputs are in high impedance state

T1, T0, OS = 0 0 0 normal operation

T1=1, P2=f

, P7 = f

ref

DIV

T0 = 1 3-state charge-pump

OS = 1 operational amplifier output is switched off (varicap drive disable)

Note

1. X = don’t care

November 1991 6

Page 7

Philips Semiconductors Product specification

1.3 GHz bi-directional I2C-bus controlled synthesizer

READ mode:

R/

W = 1 (see Table 2)

Data can be read out of the TSA5515T by setting the R/W

bit to 1. After the slave address has been recognized, the

TSA5515T generates an acknowledge pulse and the first

data byte (status word) is transferred on the SDA line

(MSB first). Data is valid on the SDA line during a high

position of the SCL clock signal.

A second data byte can be read out of the TSA5515T if the

processor generates an acknowledge on the SDA line.

End of transmission will occur if no acknowledge from the

Table 2 Read data format

MSB LSB

Address 11000MA1MA01Abyte 1

Status byte POR FL 111111−byte 2

Notes

1. POR power-on-reset flag. (POR = 1 on power-on)

2. FL in-lock flag (FL = 1 when the loop is phase-locked).

processor occurs. The TSA5515T will then release the

data line to allow the processor to generate a STOP

condition.

The POR flag (power-on-reset) is set to 1 when V

below 3 V and at power-on. It is reset when an end of data

is detected by the TSA5515T (end of a READ sequence).

Control of the loop is made possible with the in-lock flag

FL, which indicates (FL = 1) when the loop is

phase-locked.

TSA5515T

CC

goes

MSB is transmitted first.

Address selection (see Table 3)

The module address contains programmable address bits (MA1 and MA0), which offer the possibility of having several

synthesizers (up to 4) in one system. The relationship between MA1 and MA0 and the input voltage on AS input is given

in Table 3.

Table 3 Address selection

MA1 MA0 Voltage applied on AS pin

0 0 0 to 0.1 V

0 1 open

1 0 0.4 to 0.6 V

1 1 0.9 VCC to V

CC

CC

CC

November 1991 7

Page 8

Philips Semiconductors Product specification

1.3 GHz bi-directional I2C-bus controlled synthesizer

TSA5515T

Fig.3 Typical application diagram.

November 1991 8

Page 9

Philips Semiconductors Product specification

1.3 GHz bi-directional I2C-bus controlled synthesizer

TSA5515T

CHARACTERISTICS

V

= 5V;T

CC

= 25 °C; unless otherwise specified

amb

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

CC

T

amb

supply voltage range 4.5 − 5.5 V

operating ambient temperature

−10 − 80 °C

range

f

CLK

clock input frequency range 64 − 1300 MHz

N divider 256 − 32767

I

CC

f

XTAL

Z

I

V

I (RMS)

supply current 25 35 50 mA

crystal oscillator frequency 3.2 4 4.48 MHz

input impedance (pin 2) −480 −400 −320 Ω

input voltage level (RMS value) VCC = 4.5 to 5.5 V;

T

= −10 to 80 °C

f = 80 to 150 MHz 12 − 300/2.6 mV

f = 150 to 1000 MHz 9 − 300/2.6 mV

amb

see typical sensitivity

curve in Fig.4

f = 1000 to 1300 MHz 40 − 300/2.6 mV

R

I

C

I

prescaler input impedance see Smith chart in Fig.5 − 50 −Ω

input capacitance − 2 − pF

Output ports (open collector) (see note 1)

I

LO

V

OL

leakage current V6H = 13.5 V −−10 µA

output voltage LOW (P7) I6L = 5 mA

−−0.5 V

note 2

output voltage LOW (P2, P1) I

= 20 mA

8L

−−0.5 V

note 2

Address selection input (AS)

I

IH

I

IL

input current HIGH V7H = 5 V −−20 µA

input current LOW V7L = 0 −20 −− µA

Bus inputs SCL, SDA

V

IH

V

IL

I

IH

I

IL

input voltage HIGH 3 − 5.5 V

input voltage LOW −−1.5 V

input current HIGH V5H = 5 V;

input current LOW V5L = 0;

Output SDA (open collector)

I

LO

V

4L

V

14

leakage current V4H = 5.5 V −−10 µA

output voltage I4L = 3 mA −−0.4 V

output voltage V1L = 0 −−100 mV

VCC = 0

V

= 5 V;

5H

VCC = 5 V

VCC = 0

V

= 0;

5L

VCC = 5 V

−−10 µA

−−10 µA

−10 −− µA

−10 −− µA

November 1991 9

Page 10

Philips Semiconductors Product specification

1.3 GHz bi-directional I2C-bus controlled synthesizer

TSA5515T

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Charge-pump output PD

I

IH

I

IL

V

O

I

1leak

input current HIGH (absolute value) CP = 1 90 220 300 µA

input current LOW (absolute value) CP = 0 22 50 75 µA

output voltage in-lock 1.5 − 2.5 V

off-state leakage current T0 = 1 −5 − 5nA

Operational amplifier output UD (test mode: T0 = 1)

V

14

output voltage V1L = 0 −−100 mV

output voltage when switched off T0 = 1;

−−200 mV

OS = 1;

V

= 2 V

1L

h

FE

operational amplifier current gain

I14/(I1 - I

1leak

)

T0 = 1;

OS = 0;

2000 −−

V1L = 2 V;

I14= 10 µA

Notes to the characteristics

1. When a port is active, the collector voltage must not exceed 6 V.

2. A maximum of 1 port at the same time may sink 5 or 20 mA, to guarantee VO = 0.5 V.

November 1991 10

Page 11

Philips Semiconductors Product specification

1.3 GHz bi-directional I2C-bus controlled synthesizer

VCC = 4.5 to 5.5 V;

= −10 to 80°C.

T

amb

TSA5515T

VCC = 5 V;

reference value = 50 Ω.

Fig.4 Prescaler Smith chart of typical input impedance.

Fig.5 Prescaler typical input sensitivity curve.

November 1991 11

Page 12

Philips Semiconductors Product specification

1.3 GHz bi-directional I2C-bus controlled synthesizer

TSA5515T

FLOCK FLAG DEFINITION (FL)

When the FL flag is 1, the maximum frequency deviation (∆f) from stable frequency can be expressed as follows:

∆fK

⁄()ICPC1 C2+()C1 C2×()⁄××±=

VCOKO

where;

K

I

K

VCO

CP

O

= oscillator slope (Hz/V)

= charge-pump current (A)

=4×10

6

C1 and C2 = loop filter capacitors

Fig.6 Loop filter

FLOCK FLAG APPLICATION

• K

= 16 MHz/V (UHF band)

VCO

• ICP = 220 µA

• C1 = 180 nF

• C2 = 39 nF

•∆f = ±27.5 kHz.

Table 4 Flock flag settings

MIN. MAX. UNIT

Time span between actual phase lock and FL-flag setting 1024 1152 µs

Time span between the loop losing lock and FL-flag resetting 0 128 µs

November 1991 12

Page 13

Philips Semiconductors Product specification

1.3 GHz bi-directional I2C-bus controlled synthesizer

PACKAGE OUTLINE

SO14: plastic small outline package; 14 leads; body width 3.9 mm

D

c

y

Z

14

8

TSA5515T

SOT108-1

E

H

E

A

X

v M

A

pin 1 index

1

e

0 2.5 5 mm

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

mm

A

max.

1.75

0.069

A

0.25

0.10

0.010

0.004

1

A2A

1.45

1.25

0.057

0.049

0.25

0.01

b

3

p

0.49

0.36

0.019

0.0100

0.014

0.0075

UNIT

inches

Note

1. Plastic or metal protrusions of 0.15 mm maximum per side are not included.

(1)E(1)

cD

0.25

8.75

0.19

8.55

0.35

0.34

7

w M

b

p

scale

eHELLpQZywv θ

4.0

1.27

3.8

0.16

0.050

0.15

6.2

5.8

0.244

0.228

A

2

1.05

0.041

Q

A

1

detail X

1.0

0.7

0.4

0.6

0.028

0.039

0.024

0.016

(A )

L

p

L

0.25

0.01 0.004

A

3

θ

0.25 0.1

0.01

(1)

0.7

0.3

0.028

0.012

o

8

o

0

OUTLINE

VERSION

SOT108-1

IEC JEDEC EIAJ

076E06S MS-012AB

REFERENCES

November 1991 13

EUROPEAN

PROJECTION

ISSUE DATE

95-01-23

97-05-22

Page 14

Philips Semiconductors Product specification

1.3 GHz bi-directional I2C-bus controlled synthesizer

SOLDERING

Introduction

There is no soldering method that is ideal for all IC

packages. Wave soldering is often preferred when

through-hole and surface mounted components are mixed

on one printed-circuit board. However, wave soldering is

not always suitable for surface mounted ICs, or for

printed-circuits with high population densities. In these

situations reflow soldering is often used.

This text gives a very brief insight to a complex technology.

A more in-depth account of soldering ICs can be found in

our

“IC Package Databook”

Reflow soldering

Reflow soldering techniques are suitable for all SO

packages.

Reflow soldering requires solder paste (a suspension of

fine solder particles, flux and binding agent) to be applied

to the printed-circuit board by screen printing, stencilling or

pressure-syringe dispensing before package placement.

Several techniques exist for reflowing; for example,

thermal conduction by heated belt. Dwell times vary

between 50 and 300 seconds depending on heating

method. Typical reflow temperatures range from

215 to 250 °C.

Preheating is necessary to dry the paste and evaporate

the binding agent. Preheating duration: 45 minutes at

45 °C.

(order code 9398 652 90011).

Wave soldering

Wave soldering techniques can be used for all SO

packages if the following conditions are observed:

• A double-wave (a turbulent wave with high upward

pressure followed by a smooth laminar wave) soldering

technique should be used.

• The longitudinal axis of the package footprint must be

parallel to the solder flow.

• The package footprint must incorporate solder thieves at

the downstream end.

During placement and before soldering, the package must

be fixed with a droplet of adhesive. The adhesive can be

applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the

adhesive is cured.

Maximum permissible solder temperature is 260 °C, and

maximum duration of package immersion in solder is

10 seconds, if cooled to less than 150 °C within

6 seconds. Typical dwell time is 4 seconds at 250 °C.

A mildly-activated flux will eliminate the need for removal

of corrosive residues in most applications.

Repairing soldered joints

Fix the component by first soldering two diagonallyopposite end leads. Use only a low voltage soldering iron

(less than 24 V) applied to the flat part of the lead. Contact

time must be limited to 10 seconds at up to 300 °C. When

using a dedicated tool, all other leads can be soldered in

one operation within 2 to 5 seconds between

270 and 320 °C.

TSA5515T

November 1991 14

Page 15

Philips Semiconductors Product specification

1.3 GHz bi-directional I2C-bus controlled synthesizer

DEFINITIONS

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

TSA5515T

PURCHASE OF PHILIPS I

Purchase of Philips I

components in the I2C system provided the system conforms to the I2C specification defined by

Philips. This specification can be ordered using the code 9398 393 40011.

2

C COMPONENTS

2

C components conveys a license under the Philips’ I2C patent to use the

November 1991 15

Loading...

Loading...