Page 1

T R I Q U I N T S E M I C O N D U C T O R , I N C .

1

For additional information and latest specifications, see our website: www.triquint.com

MIXED SIGNAL

PRODUCTS

Features

• 1 Gs/s conversion rate

• 8-bit resolution

• DC differential non-linearity

1

/2 LSB (0.2%)

• DC integral non-linearity

1 LSB (0.4%)

• Settling time 2 ns to 0.4% (est.)

• Spurious-free dynamic range

(SFDR) 45 dBc typical

• ECL-compatible inputs

• Synchronous blanking input

• 1.3 W power dissipation

• 44-pin multilayer ceramic

package or unpackaged die

Applications

• Display generation

• Waveform and signal synthesis

• Video signal reconstruction

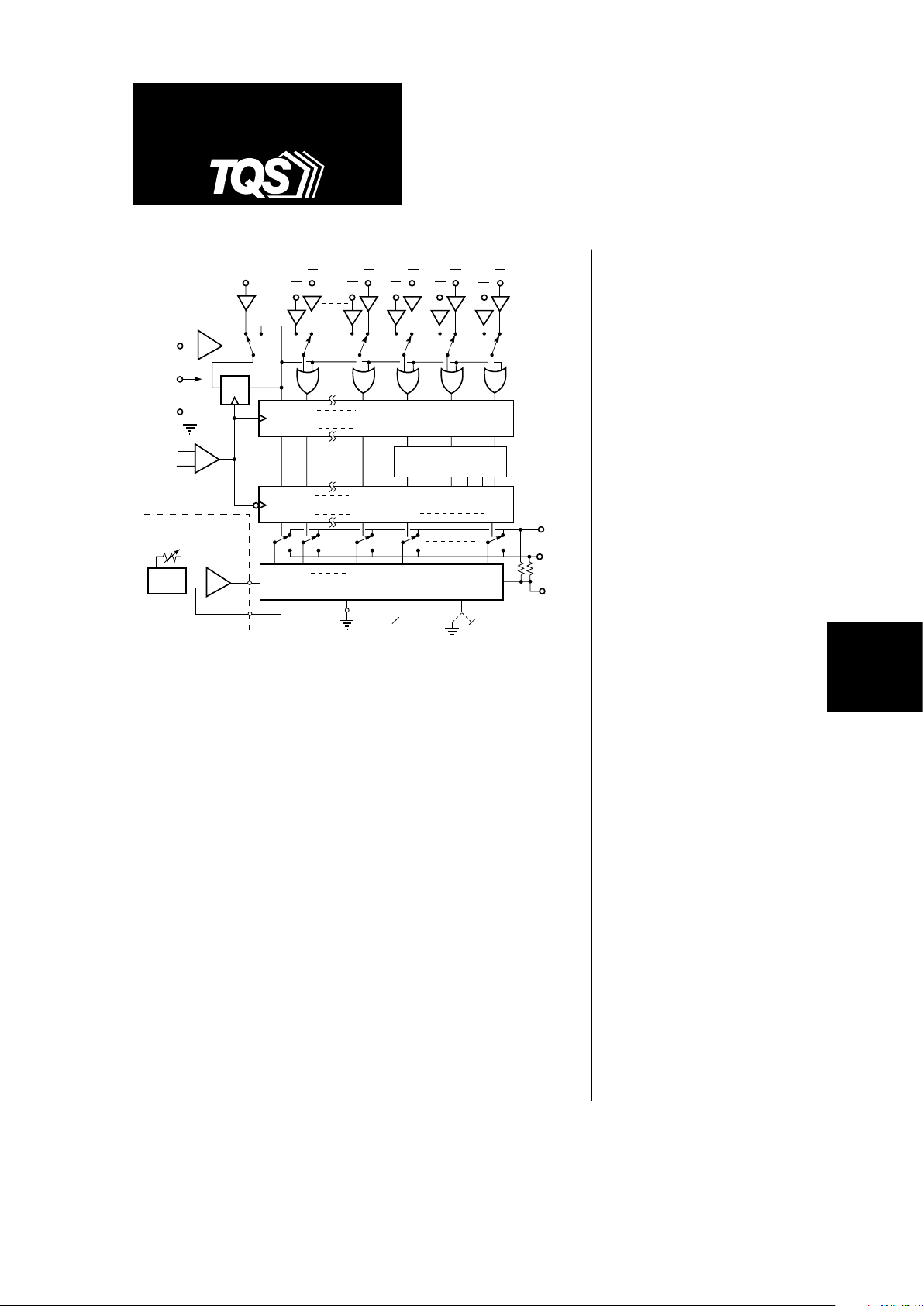

BLANK

A5 A6

B6

A7 (MSB)

B7

MULTIPLEXER

ECL INPUT

BUFFERS

BLANKING

LOGIC

MASTER

LATCH

SLAVE

LATCH

V

(-5 V)

A

BLANK DISABLE

V

V

I

V

BANDGAP

REFERENCE

FULL-SCALE ADJUST

V

CLK

CLK

SELA

BLANK D0 D4

QBLANK Q0 Q4

D5 D6 D7

Q5 Q6 Q7

BINARY-TO-N-OF-7

SEGMENT ENCODER

S1 S2 S3 S4 S5 S6 S7

QS1

QS7

+

–

I

I4

IS1

IS7

+

–

CURRENT-SOURCE ARRAY

50

50

OUT

V

OUT

V

B5B4

BLANK

I0

SENSE

REF

B0

A0

A4

GND

GND

SS

AA

AA

REF

D Q

(-5V)

(EXT. CONTROL LOOP)

D

BLANK D0 D4

QBLANK Q0 Q4

TriQuint's TQ6122 GIGADAC™ is a monolithic, 8-bit digital-to-analog

converter capable of conversion rates to at least 1000 Megasamples/

second. The TQ6122 DAC may be used for display generation, waveform

and signal synthesis, and video signal reconstruction. The TQ6122 features

a 2:1 data MUX at the input for ease of interface and offers synchronous

blanking capability for maximum ease of use in video applications. It drives

complementary 1 V peak-to-peak swings into 50-ohm loads; on-chip 50ohm reverse terminations provide extremely fast settling time.

Due to the inherently high speed of TriQuint's one-micron gate

Enhancement / Depletion-mode gallium arsenide process, the TQ6122

offers guaranteed operation at clock rates of 1000 MHz, with typical room

temperature conversion rates of 1.5 Gs/s without multiplexing and 1.3 Gs/s

when using multiplexed inputs. The TQ6122 features output rise and fall

times of 500 ps (10% – 90%), symmetric complementary output transitions,

and glitch impulse values less than 10 pV/sec. When used for sine wave

synthesis, typical spurious and harmonic free dynamic range is ≥45 dBc.

The TQ6122 may be retrofitted into designs which currently use TriQuint's

TQ6111, 2, 3, 4M DACs with minimal changes to power supply levels and

input and output connections. The part is available in a 44-pin ceramic

package or as unpackaged die.

TQ6122

1 Gigasample/sec,

8-bit Digital-to-Analog

Converter

Page 2

TQ6122

2

For additional information and latest specifications, see our website: www.triquint.com

Specifications

Table 1. Absolute Maximum Ratings

(1,2)

Symbol Description Min Typ Max Units

A

GND

, D

GND

Analog and digital ground –2 +2 V

V

SS

Digital power –7 V

V

AA

Analog power –10 V

VO, VO (MAX) Analog output (1 V F.S.) –2.5 +2.5 V

VI (MAX) Digital input levels VSS –0.5 +0.5 V

II (MAX) Digital input currents –1 +1 mA

P

D

Power dissipation 3.0 W

T

C

Case backside temperature –65 +135 °C

T

S

Storage temperature –65 +150 °C

Notes: 1. Unless otherwise specified: A

GND

= D

GND

= 0 V, VSS = VAA = –5 V, VFS = 1 V pk–pk, case temperature = 27 °C.

2. Exceeding the absolute maximum ratings may damage the device. The value shown for a particular

parameter is determined with all other parameters at their nominal values.

Table 2. DC Characteristics

(1)

Symbol Description Test Conditions Min. Typ. Max. Unit

V

AA

Analog supply Note 2 –5.25 –4.75 V

I

AA

VAA current VFS = 1 V pk–pk 50 62 80 mA

V

SS

Digital supply Note 2 –5.5 –4.5 V

I

SS

VSS current 145 200 265 mA

P

D

Power dissipation 0.9 1.3 1.85 W

V

ECLREF

ECL reference level Note 3, Figure 1 –1.5 –1.3 –1.1 V

I

ECLREF

ECL ref. input bias current Note 3, Figure 1 ∆V

ECLREF

= ±0.2 V –5 0 +5 mA

R

ECLREF

ECL ref. input resistance Figure 1 50 Ω

C

ECLREF

ECL ref. input capacitance 2 pF

VIH(DC) Data input HIGH (ECL) DC value (V

ECLREF

= –1.3 V) –1100 –500 mV

VIL(DC) Data input LOW (ECL) DC value (V

ECLREF

= –1.3 V) V

TT

–1500 mV

V

CLKH

(DC), Clock HIGH input Differential clock, Note 4 V

ECLREF

+0.3 –0.7 V

V

CLKH

(DC)

V

CLKL

(DC), Clock LOW input Differential clock, Note 4 V

TT

V

ECLREF

–0.3 V

V

CLKL

(DC)

I

IN

Data, clock input bias current VIH = –800 mV, VIL = –1800 mV –25 +25 uA

C

IN

Data, clock input capacitance In multilayer ceramic package 0.5 pF

V

OUT

(MAX), Maximum absolute output level Note 5 +1 V

V

OUT

(MAX)

V

OUT

(MIN), Minimum absolute output level Note 5 –1.5 V

V

OUT

(MIN)

(Continued on next page)

Page 3

TQ6122

3

For additional information and latest specifications, see our website: www.triquint.com

MIXED SIGNAL

PRODUCTS

V

FS

Full-scale output swing Data bits only, 0–0/1–1 input step 0 1 1.125 V pk–pk

RL = 50 Ω load

V

ZS

Zero-scale offset VFS = 1 V, no external offset, –35 mV

V

BLANK_DISABLE

= 0 V

∆DV

BLANK

Blanking interval Blank input = 1, Notes 6, 7 9 10.4 12 %V

FS

V

BLANK_DISABLE

Blank current disable control Blank current ON –5 (VAA)V

Blank current OFF 0 (A

GND

)V

V

REF

V

REF

input voltage VFS = 1 V peak-to-peak V

AA

+0.7 V

AA

+1.0 V

AA

+1.4 V

VFS = 0 V peak-to-peak V

AA

–1 V

V

SENSE

V

SENSE

output VFS = 1 V peak-to-peak V

AA

+0.8 V

AA

+1.1 V

I

VREF

V

REF

input current V

REF

= V

AA

+0.65 10 uA

V

REF

= V

AA

+1.1 1 mA

I

REF

Ext. reference current output VFS = 1 V peak-to-peak 2 2.5 5 mA

V

IREF

I

REF

terminal voltage –1.5 +1 V

R

OUT, ROUT

V

OUT, VOUT

output resistance 44 50 57 Ω

Matching of R

OUT, ROUT

0.2 2.5 %

C

OUT

V

OUT, VOUT

output capacitance 0.3 pF

Resolution 8 Bits

Monotonicity 8 Bits

DNL Differential non-linearity (± 1/2 LSB) 0.2 % F.S.

INL Integral non-linearity (± 1 LSB) 0.4 % F.S.

Full-scale symmetry VFS = 1 V peak-to-peak, Note 8 –4 +4 mV

VFS temperature coefficient Note 9

Notes: 1. Unless otherwise specified: VAA = –5V ± 5%, VSS = –5 V ±10%, VTT = –2V ± 5%, VFS = 1 V pk–pk, T

CASE

= 0 to +85 °C

2. See the "Power Supplies, Ground and Bypassing" section later in this datasheet for discussion of power supplies.

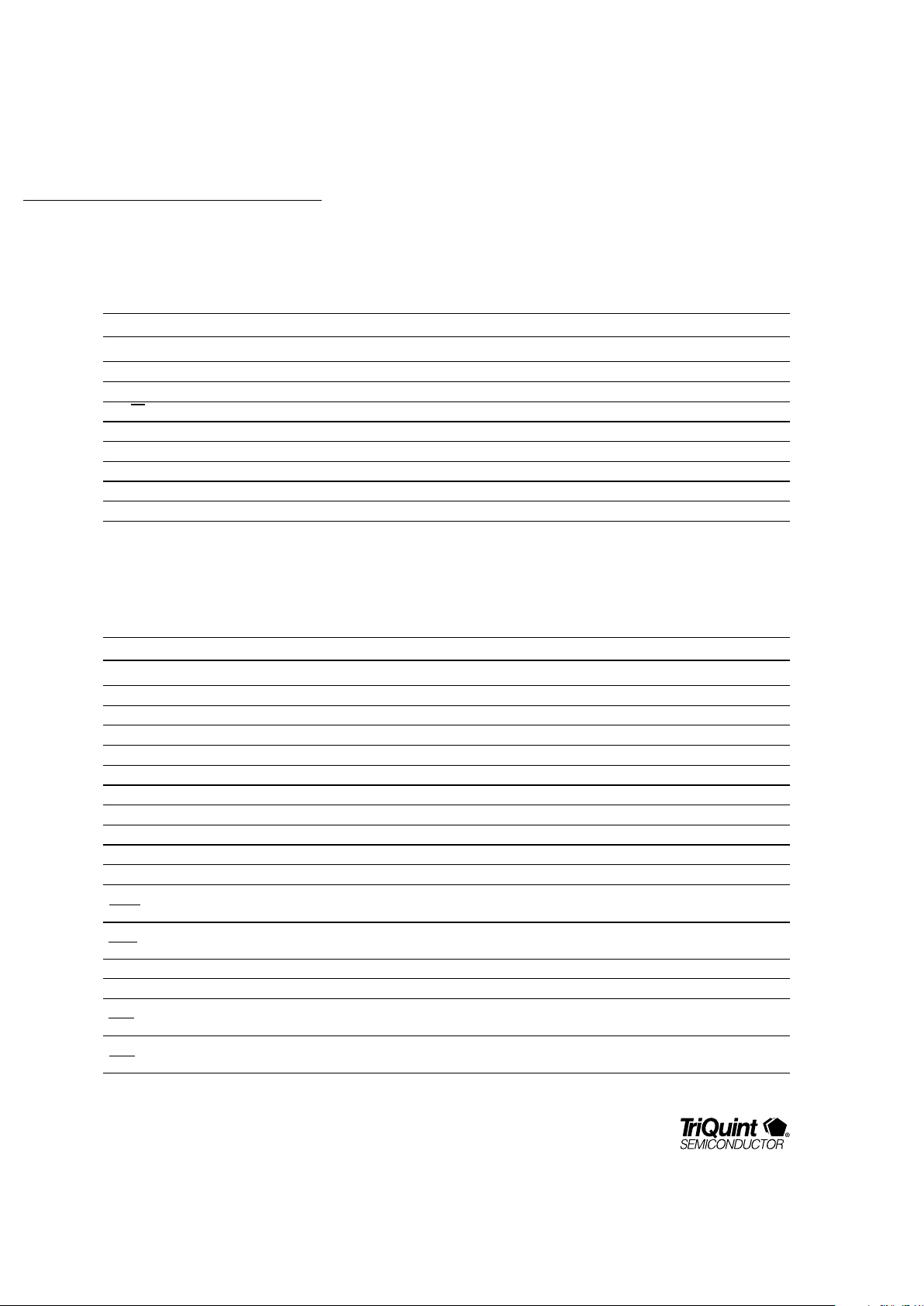

3. The ECL reference input establishes the switching point for the ECL line receivers used at the DATA, BLANK, and

SELECT inputs. (See Figure 1.) I

ECLREF

is the current required to change the internal ECLREF value by about ±200 mV.

4. Values shown are for differential clock drive, and apply to both CLOCK and CLOCK inputs. For single-ended drive,

the HIGH level should be at least (V

ECLREF

+0.5) volts, but must not exceed –700 mV. The LOW level should be

(V

ECLREF

–0.5) volts, but must not go below VTT, where VTT is the ECL termination voltage (nominal VTT = –2 V).

5. V

OUT

(

MAX

), V

OUT

(

MAX

), V

OUT

(

MIN

), V

OUT

(

MIN

) represent the limits on the absolute output levels, including offset.

6. Blanking interval is the voltage change (as a percentage of the full-scale output swing) added to V

FS

when BLANK is asserted.

7. The BLANK DISABLE input turns OFF the blank current (DV

BLANK

= 0) when held at A

GND

, and turns it ON when pulled to VAA.

8. Full-scale symmetry is a measure of the balance between V

OUT

and V

OUT

. For a full-scale input change (00000000 –> 1111111),

␣␣␣␣the change in V

OUT

will match the change in V

OUT

to within ± 4 mV (1 LSB @ 1 V peak-to-peak).

9. The VFS temperature coefficient is determined primarily by the external reference and loop control op amp.

Table 2. DC Characteristics

(1)

(continued)

Symbol Description Test Conditions Min Typ Max Unit

Page 4

TQ6122

4

For additional information and latest specifications, see our website: www.triquint.com

Symbol Description Test Conditions Min Typ Max Unit

F

CLK

(MAX) Maximum clock frequency Unmuxed operation 1000 1500 MHz

Muxed operation 1000 1300 MHz

T

RCLK,DATA

Clock, data input rise time 20% to 80% 300 ps

T

FCLK,DATA

Clock, data input fall time 20% to 80% 300 ps

T

WH

Duration of clock HIGH Percentage of clock period 40 50 60 %

T

WL

Duration of clock LOW Percentage of clock period 40 50 60 %

T

SETUP

Data, control setup time See Figure 7 ps

T

HOLD

Data, control hold time See Figure 7 ps

T

ROUT

Output rise time 10% to 90% 300 ps

T

FOUT

Output fall time 10% to 90% 300 ps

T

SETTLE

Output settling time Within ±0.4% of final value 2 ns

Glitch impulse 10 pV/sec

Notes: 1. Unless otherwise specified: VAA = –5V ± 5%, VSS = –5 V + 10% , VFS = 1 V p–p, T

CASE

= 0 to +85 °C,

V

ECL

= –1.3 V, VIH = –0.8 V, VIL = –1.8 V

2. Applies to packaged parts only.

V

IH

V

IL

V

ECL

(-1.3 V NOMINAL)

V

IH

V

IL

(MIN)

(MAX)

V

IH

(MAX)

V

IH

(MIN)

EXTERNAL ECL

REFERENCE

INPUT

I

2 pF

ECL INPUT BUFFERS

R

C

50 Ω

-1.3V

(Nominal,

internal)

ECLREF,

ECLREF

50 Ω

A7, B7

A0, B0

V

SS

ECLREF

–

+

+

–

50 Ω

SELA

BLANK

-5 V

Figure 2. Definition of VIH, VIL for Data and BLANK Inputs

Figure 1. ECL Reference Input Equivalent Circuit

Table 3. AC Characteristics

(1,2)

Page 5

TQ6122

5

For additional information and latest specifications, see our website: www.triquint.com

MIXED SIGNAL

PRODUCTS

(B) TQ6122 Video DAC Operation (0.679 V Full-Scale)

Blanking current is enabled by connecting BLANK DISABLE to V

AA

.

Input Code V

OUT

(1)

V

OUT

(1)

Full Scale 11111111 –0.679 V –0.071 V

Full Scale – 1 LSB 11111110 –0.676 V –0.074 V

Half Scale + 1 LSB 10000001 –0.343 V –0.407 V

Half Scale 10000000 –0.341 V –0.409 V

Half Scale – 1 LSB 01111111 –0.338 V –0.412 V

Zero Scale + 1 LSB 00000001 –0.003 V –0.747 V

Zero Scale 00000000 ␣ 0.000 V –0.750 V

BLANK = HIGH X . . . . . X –0.750 V ␣ 0.000 V

Input Code V

OUT

(1)

V

OUT

(1)

Full Scale 11111111 –0.996 V ␣ 0.000 V

Full Scale – 1 LSB 11111110 –0.992 V –0.004 V

Half Scale + 1 LSB 10000001 –0.504 V –0.492 V

Half Scale 10000000 –0.500 V –0.496 V

Half Scale –1 LSB 01111111 –0.496 V –0.500 V

Zero Scale + 1 LSB 00000001 –0.004 V –0.992 V

Zero Scale 00000000 ␣ 0.000 V –0.996 V

Figure 3. Typical Digital Input Circuit (Including CLOCK Inputs)

50

50

50

500

500

MICROSTRIP

INPUT

DAC

INPUT PROTECTION

NETWORK

V

TT

–5 V

V

SS

R

IN,

C

IN

TO INPUT

BUFFER

–2 V

(A) TQ6122 Instrumentation DAC operation (1 V Full-Scale)

Blanking current is shunted to ground by tying BLANK DISABLE to A

GND

and forcing BLANK = 0.

Notes: 1. All values shown for V

OUT

and V

OUT

assume identical load resistors (RL1 and RL2 in Figure 5),

and no externally imposed output offset voltage (V

OS

in Figure 5). Zero-scale offset is ignored.

Figure 4. V

OUT

, V

OUT

, and Input Code Relationships for (A) Typical Instrumentation and (B) Video Configurations

Page 6

TQ6122

6

For additional information and latest specifications, see our website: www.triquint.com

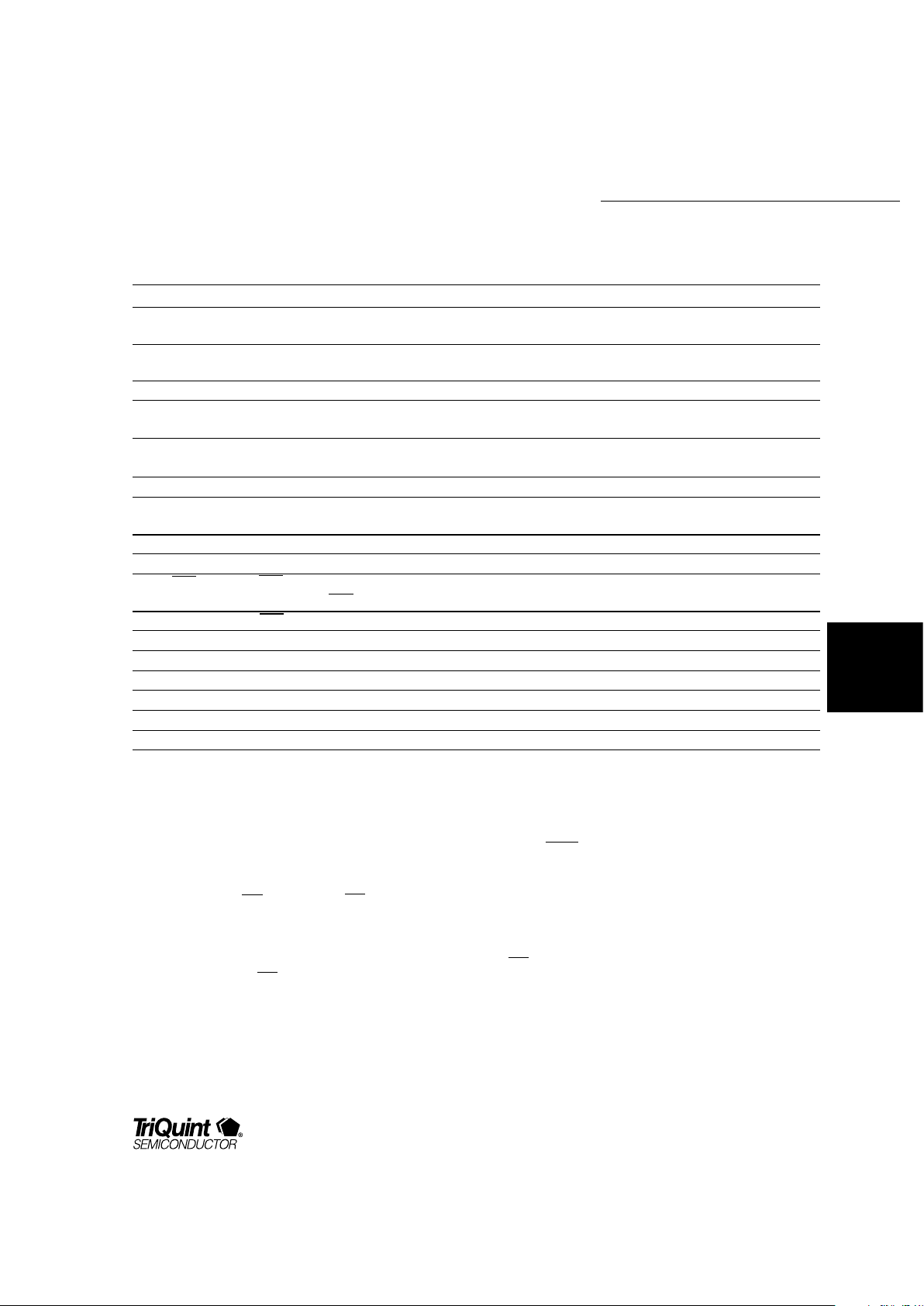

Figure 5. Output Equivalent Circuit, Showing Terminated 50-ohm Transmission Line Loads

Figure 6. Definition of T

WH

and T

WL

T

WL(CLK)

T

WH(CLK)

50%

DIGITAL

INPUT

NON-INVERTING OUTPUT (V )

INVERTING OUTPUT (V )

BOUNDARY

OF DAC

OUT

I

OUT,ROUT

C

50

R

T1

50

R

T2

Z = 50

0

1000 pF

OS (SEE FIG. 18)

(–3V TO +4V)

V

(FOR NO OUTPUT OFFSET)

50

R

L1

50

R

L2

0.1uF

"FAR-END" TERMINATIONS

100 pF

OUT

I

Z = 50

0

OUT

OUT

AGND

Page 7

TQ6122

7

For additional information and latest specifications, see our website: www.triquint.com

MIXED SIGNAL

PRODUCTS

Figure 7. TQ6122 Data and Control Timing

Symbol Description Typical @ 25 °C Unit

T

DS

Data setup time

(1)

0␣ps

TDHData hold time

(2)

+325 ␣ ps

T

SS

SELA setup time

(1,3)

+350 ␣ ps

T

SH

SELA hold time

(2,3)

–100 ␣ ps

Notes: 1. Setup time is defined to be positive for data or control transitions occurring before the negative-going edge of the clock.

2. Hold time is defined to be positive for data or control transitions occurring

after the negative-going edge of the clock.

3. While SELA does not strictly have a setup and hold time, it is convenient to express its allowed transition

region limits in these terms.

SS

T

SELA

DATA

CLOCK

SH

T

DH

T

DS

T

Page 8

TQ6122

8

For additional information and latest specifications, see our website: www.triquint.com

Mechanical Characteristics

The TQ6122 DAC is packaged in a proprietary 44-pin

multilayer ceramic package which provides high-speed,

controlled-impedance interconnects and integral power

supply bypassing. The leads are set on 0.050” centers,

and are formed for gull-wing surface mounting. Figure

8 shows the pinout diagram of the packaged IC as seen

from the top, opposite the cavity side; Figure 9 lists pin

numbers, names and I/O levels. Figure 10 illustrates

the pertinent dimensions of the package and Figure 11

shows the mounting footprint.

Since the TQ6122 dissipates on the order of 1.3 W,

adequate heat sinking is essential for proper operation

of the device. Figure 12 shows one possible heat sink

arrangement based on a multi-finned “Top Hat” heat

sink available from Thermalloy. An environment with a

minimum of 100 fpm (feet per minute) of forced air

cooling is assumed; >200 fpm is preferred.

Figure 8. TQ6122 Pinout

23

12

11

34

PIN 1

VAA

IREF

ECL REF

A0

A1

DGND

A2

A3

A4

A5

VSS

VSS

CLOCK

CLOCK

N/C

SELA

DGND

BLANK

B7

B6

B5

VSS

TQ6122AM

TOP VIEW

OF MLC-44 PACKAGE

AS IT SITS ON

CIRCUIT BOARD

(CAVITY IS DOWN)

VAA

VREF

VSENSE

BLANK DISABLE

AGND

VOUT

VOUT

AGND

AGND

AGND

VSS

VSS

A6

A7

DGND

B0

B1

DGND

B2

B3

B4

VSS

Notes: 1. A7, B7 = MSB inputs

2. N/C = no internal connection

Pin Signal Interface Level (Typ.)

1, 11, 12, V

SS

–5 V

33, 34, 44

2 B5 600 mV pk–pk centered at –1.3 V @ DC

3 B6 600 mV pk–pk centered at –1.3 V @ DC

4 B7 (MSB) 600 mV pk–pk centered at –1.3 V @ DC

5 BLANK 600 mV pk–pk centered at –1.3 V @ DC

6, 28, D

GND

0 V

37, 40

7 SELA 600 mV pk–pk centered at –1.3 V @ DC

8 — No connection

9 CLOCK 1V pk–pk centered at –1.3 V @ AC

10 CLOCK 1V pk–pk centered at –1.3 V @ AC

13–15, 18 A

GND

0 V

16 V

OUT

0 V to –1 V

17 V

OUT

–1 V to 0 V

19 BLANK Enable = V

AA (IBLANK

= ON)

DISABLE Disable = A

GND (IBLANK

= OFF)

20 V

SENSE

VAA + 0.8, for VFS = 1 V pk–pk

Figure 9. TQ6122 Pin Descriptions

Pin Signal Interface Level (Typ.)

21 V

REF

VAA +1, for VFS = 1V pk–pk

22, 23 V

AA

–5 V

24 I

REF

2.5 mA for VFS = 1V pk–pk

25 ECL REF –1.3 V

26 A0 (LSB) 600 mV pk–pk centered at –1.3 V @ DC

27 A1 600 mV pk–pk centered at –1.3 V @ DC

29 A2 600 mV pk–pk centered at –1.3 V @ DC

30 A3 600 mV pk–pk centered at –1.3 V @ DC

31 A4 600 mV pk–pk centered at –1.3 V @ DC

32 A5 600 mV pk–pk centered at –1.3 V @ DC

35 A6 600 mV pk–pk centered at –1.3 V @ DC

36 A7 (MSB) 600 mV pk–pk centered at –1.3 V @ DC

38 B0 (LSB) 600 mV pk–pk centered at –1.3 V @ DC

39 B1 600 mV pk–pk centered at –1.3 V @ DC

41 B2 600 mV pk–pk centered at –1.3 V @ DC

42 B3 600 mV pk–pk centered at –1.3 V @ DC

43 B4 600 mV pk–pk centered at –1.3 V @ DC

Page 9

TQ6122

9

For additional information and latest specifications, see our website: www.triquint.com

MIXED SIGNAL

PRODUCTS

0.65

SQUARE

0.015

0.060

0.125

0.805

NOMINAL

0.005

TOP VIEW

PIN 12

0.035

All Dimensions in Inches

PIN 1

0.050

Figure 11. Mounting Footprint

Figure 10. Package Dimensions

Package Outline

(For Reference Only)

PIN 12

PIN 23

0.350

0.425

All Dimensions in Inches

PIN 34

SOLDER PAD

0.050

0.025

PIN 1

Figure 12. Heat-Sink Mounting Arrangement (heat sink not included)

THERMALLOY TYPE 2291C TOP

THERMALLOY

TYPE 2291C

BASE

THERMAL

ADHESIVE

DAC IC

Use Loctite “Output” Thermal

Conductive Adhesive (Loctite item

number 00241) or equivalent to

attach heat sink base to IC.

Page 10

TQ6122

10

For additional information and latest specifications, see our website: www.triquint.com

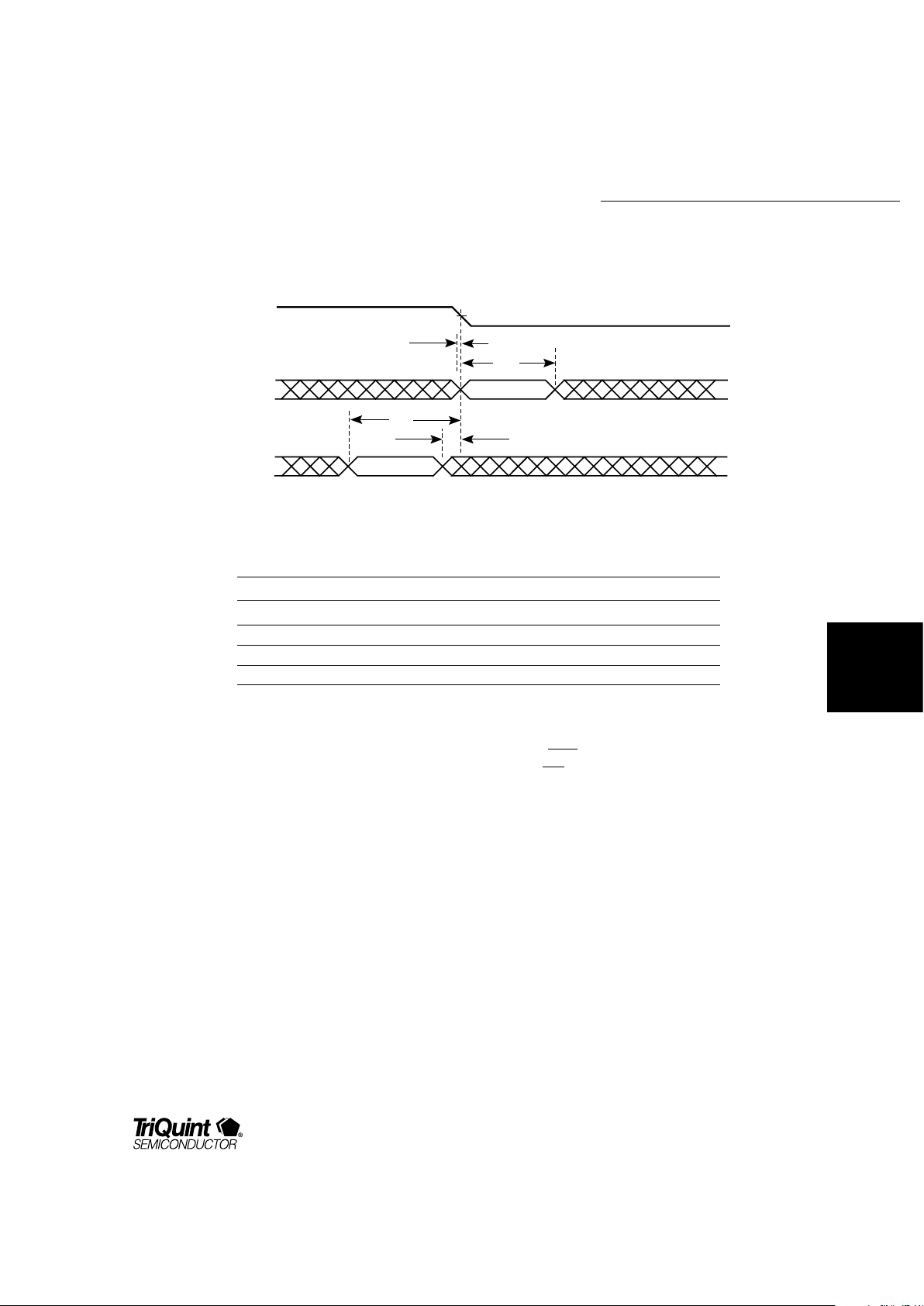

Circuit Description

The TQ6122 DAC is based on a current-steering architecture in which weighted currents are switched by an

array of differential-pair switches into either the V

OUT

or V

OUT

output, depending on the state of the input data

and blanking bits. Essentially, the DAC is comprised

of

six circuit blocks: the input buffer, the data multiplexer,

blanking logic, master/slave latch array with segment

encode logic, differential-pair switches, and the current

source array. (See figure on page 1.)

Input Buffers

The input buffers compare the ECL data and control

input signals with the ECLREF level, amplify the difference, and translate this signal to the logic levels used

within the IC. By default, the ECL reference is set by an

internal generator; however, for best performance and

maximum noise margin over temperature, power supply,

and device-to-device variations, the user should

provide

an external level. For general-purpose applications, a

simple resistive divider between D

GND

and VTT will

suffice. For extreme environments or for maximum

performance, the ECLREF level should be slaved to the

centerpoint of the incoming data. Refer to the “Digital

Inputs and Terminations” discussion later in this

document for additional information.

Note that the data inputs are complemented to indicate

that an increasing input value results in the V

OUT

level

moving more negative.

Data Multiplexer

The DAC makes provision for accepting data from

either of two sources: from a single 8-bit-wide word at

the full conversion rate, or from two 8-bit-wide halfspeed words which are multiplexed together inside the

DAC under the control of the SELA input. In use, the

SELA input is set HIGH to select the A-Word data and

LOW to select the B-Word. It is generally best to use

the A-Word input when operating the DAC unmultiplexed,

although the B-Word supports full-rate transfers.

Blanking Logic

A separate BLANK input is included to allow the DAC to

be used in video display applications. When asserted

LOW, the BLANK input has no effect on the operation of

the DAC, and the state of the input data words controls

the positions of the current switches. When BLANK is

asserted HIGH, however, all internal data bits and the

internal blanking bit are synchronously forced HIGH at

the next negative-going clock transition, causing the

V

OUT

output to go to its most negative level. This level

is the sum of the normal level associated with an input

code of 11111111 plus the increment due to the

blanking current being steered away from the V

OUT

output to V

OUT

. See Figure 4 (B).

In order to provide more latitude in the timing of the

BLANK signal, the BLANK input is sampled only when

the A-Word is selected. When the B-Word is selected,

the state of the BLANK input at the time the SELA

control line goes LOW is held stable until SELA again

goes HIGH. In situations where blanking is not used,

it is important that the BLANK input be tied to a solid

logic LOW to prevent accidental assertion of BLANK =

HIGH. Note also that when the DAC is used in the

unmultiplexed mode, the data should be brought in on

the A-Word inputs, since with SELA = LOW (as would

be the case for B-Word operation), a transient HIGH

level at the BLANK input would never be cleared and

the DAC would lock up.

The BLANK_DISABLE pin is normally tied to the V

AA

rail, allowing I

BLANK

to flow to the differential-pair

switch and then to the selected output. For applications

which do not use blanking, however, the standing

offset in the V

OUT

output due to the unswitched

Page 11

TQ6122

11

For additional information and latest specifications, see our website: www.triquint.com

MIXED SIGNAL

PRODUCTS

blanking current would be undesirable. For cases such

as these, the blanking current may be completely

turned off by connecting the BLANK_DISABLE pin to

A

GND

.

Master/Slave Latch With Encode Logic

A nine-wide master latch registers the data coming from

the multiplexer and blanking logic. The latch outputs

are

then split into two groups. The top three bits are translated into a seven-level thermometer code by a binaryto-N-of-seven encoder, while the lower five data bits

and the blanking bit are simply delayed. The seven

encoder outputs and the six delayed data and blanking

bits are re-registered in a slave latch to minimize skew,

which, in turn, reduces the glitch impulse. Latch timing

is set up such that the slave latch is in the “sample” mode

when the input clock is LOW, meaning that the

analog

output is updated at the falling edge of the clock.

Current Switches

The thermometer code outputs of the slave latch array

drive seven switches, each of which steers a current

equal to 1/8 of the full-scale step amplitude. The five

encoded data bits, on the other hand, switch currents

with effective binary weightings from 1/16 of full scale

down to 1/128 of full scale. The blanking bit steers a

current which is nominally 10.4% of the full-scale

amplitude.

Current-Source Array

The current-source array is the heart of the DAC from

an analog standpoint, and is responsible for generating

the segment, bit, and blanking currents. The maximum

full-scale current I

FS

(less I

BLANK

) is about 45 mA,

providing a 1.125 volt maximum swing into the 50ohm external load. The blanking current is nominally

10.4% of I

FS

, corresponding to a 10-unit IRE blanking

interval of 71 mV when the full-scale output is set to

0.679 volt. The I

REF

current tracks IFS, with a nominal

value of 2.5 mA for I

FS

= 40 mA (i.e., 6.25% of IFS).

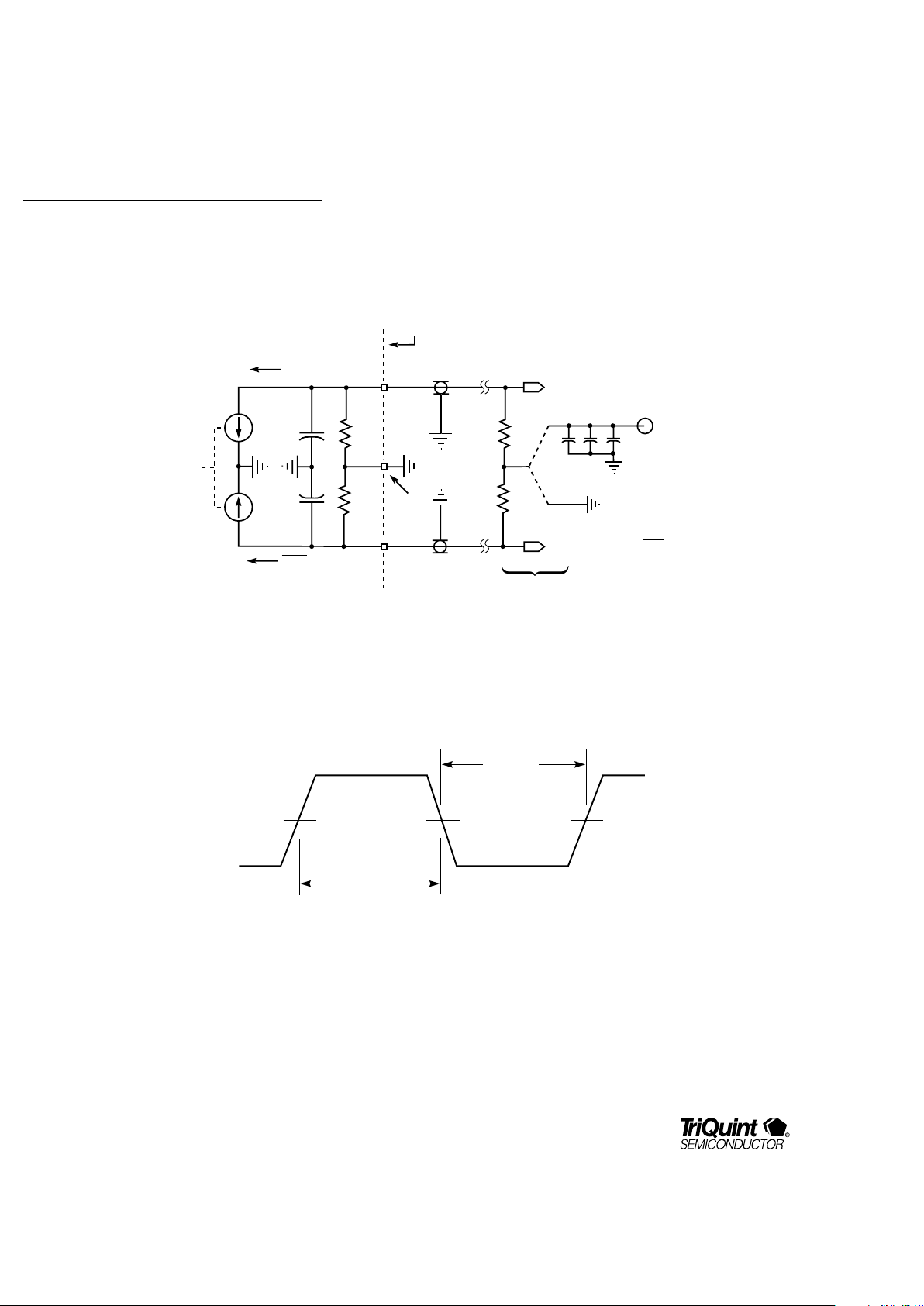

Figure 13 (A) illustrates the basic circuit of the currentsource array, which consists of a set of current sources

ranging from the 5 mA segment currents to the binaryweighted current sources for the lower-order bits. The

circuit design utilizes source degeneration, averaging,

and linear gradient cancellation techniques to obtain

matching consistent with up to 10-bit linearity.

+

–

V

OUT

V

OUT

BLANK

DIFF-PAIR SWITCH

(TYPICAL, 15 PLACES)

I

REF

I

BLANK

I

SEG 1

I

SEG 7

I

B4

I

B3

I

B0

CASCODES

2.5 mA

(NOM)

V

REF

V

SENSE

0.8 V NOM,

FOR 1 V F.S. OUT

EXT

REF.

– 5V

V

AA

2W

3.56W

4W

4W

2W

W

RS

RS

RS

2RS

1.77

2

RS

2

V

BIAS

(INTERNAL)

BLANK

RS

RLSB

Figure 13 (A). Current-Source Array Circuit — V

SENSE

-Based Control Method

Page 12

TQ6122

12

For additional information and latest specifications, see our website: www.triquint.com

The absolute value of the current-source array output is

determined using an off-chip (silicon) reference

generator and op amp in a feedback-loop arrangement.

In Figure 13 (A), the drop across the source

degeneration resistors is compared with the level set

by the external reference. Under conditions of 1 V

peak-to-peak full-scale output swing, the voltage

between the V

SENSE

and VAA pins of the DAC will be in

the range of 0.8 V to 1.1 V, with V

REF

being in the range

of 0.7 V to 1.4 V (i.e., V

REF

may lie above or below

V

SENSE

by several hundred millivolts). Note that, for this

control method, the I

REF

terminal must be connected to

ground.

An alternative means of controlling the current-source

array output is shown in Figure 13(B), with the

advantage that now the reference current is being

sensed

after

flowing through a path identical to that of

the bit and segment currents. Thus, any error which

may have occurred due to leakage will be directly

corrected. Here, the V

SENSE

pin is left disconnected and

the I

REF

current flows to ground through a stable

resistor. The value of the resistor should be chosen to

drop about 1 volt under the desired operating

conditions, but under no circumstances should the

voltage at the I

REF

pin be allowed to drop below

–1.5 V, or the linear relationship between I

REF

and I

FS

will be degraded.

The primary limitation on the maximum output current

is the adjustment range of V

SENSE

: if the value of

{V

SENSE

– VAA} exceeds about 1.2 V, the bottom currentsource FETs begin to lose “headroom” by running up

against the sources of the cascode transistors, causing

the total current to begin limiting, as well as degrading,

the linearity. If the designer is willing to accept

somewhat degraded linearity and/or slightly higher

power dissipation, V

AA

may be taken down to –6 volts

or so, allowing V

REF

to be adjusted to give {V

SENSE

–

V

AA

} a maximum value of about 1.5 V. This translates to

an output current of about 50 mA or 1.25 V peak-topeak into the load. Note that under these conditions,

the device will not sustain any damage, but full-spec

operation of the DAC is not guaranteed.

Figure 13 (B). Current-Source Array Circuit — I

REF

-Based Control Method

+

–

V

OUT

V

OUT

BLANK

I

REF

I

BLANK

2.5 mA

(NOM)

V

REF

V

SENSE

< 1.5 V

EXT

REF.

– 5V

V

AA

V

BIAS

(INTERNAL)

BLANK

(N/C)

Page 13

TQ6122

13

For additional information and latest specifications, see our website: www.triquint.com

MIXED SIGNAL

PRODUCTS

Figure 14. Basic DAC Setup

Notes: 1. All resistors to VTT are 50-ohm, 1/8 Watt, surface-mount, mounted as close to the IC as possible.

2. All V

SS

and VTT capacitors are rated ≥15 V. All VAA capacitors are rated ≥ 25 V.

3. Use either surface-mount components or keep minimum-length leads on all resistors and capacitors.

4. For best noise isolation, the analog supply (V

AA

) and digital supply (VSS) should connect at

only one point, via decoupling networks such as ferrite beads.

5. The input circuitry for B0–B7, BLANK, and SELA are the same as for A0–A7.

6. For questions regarding board layout, please contact the factory.

IREF

VAA

VREF

VSENSE

BLK.DIS.

AGND

VOUT

VOUT

AGND

AGND

DGND

VSS

1uF

1µF

V PLANE

50

A5

A4

A3

A2

A1

A0

EXT.

ECL

REF.

DGND

ECL

REF.

1µF

.01µF

1000 pF

50

SELA

BLANK

CLK

CLK

1000

pF

B5

B6

B7

+

–

MC1403A

V PLANE

V

V (V + 2.5 V)

MC33071

1uF

2.5 K

V

V

620

(V +1 V)

V

V

V

(I = ON)

(I = OFF)

Z = 50

Short microstrip or

buried stripline

+ –

1 K Adjust for desired

full-scale output

VSS

DGND

DGND

VSS

VSS

DGND

DGND

NOTE 5

A6

A7

B0

B1

B2

B3

B4

50

NOTE 5

NOTE 5

u = Microstrip or other

transmission line

u

u

u

u

u

u

uuuu

uu

u

u

u

u

u

u

u

u

NOTE 5

V

AA

V

AA

O

OUT

OUT

BLANK

BLANK

CC

EE

2.5 K

AA

AA

AA

AAOUT

1 K

AA

Split power supply planes here to minimize noise

coupling into analog circuitry.

Use a common plane for analog and digital grounds.

SS

V PLANE

SS

V PLANE

SS

V PLANE

AA

L

1

L

2

-5 V

SUPPLY

L , L = Fair-Rite 2743001111

1

2

V = -5 +0.5 V

SS

V = -5 +0.25 V

AA

A7, B7 = MSB

V PLANE

SS

V PLANE

TT

V = -2 V

TT

V PLANE

TT

V PLANE

TT

1000 pF

.01µF

1000 pF

.01µF

.01µF

1000 pF

1000 pF

.01µF

.01µF

.01µF

1000 pF

Application Information

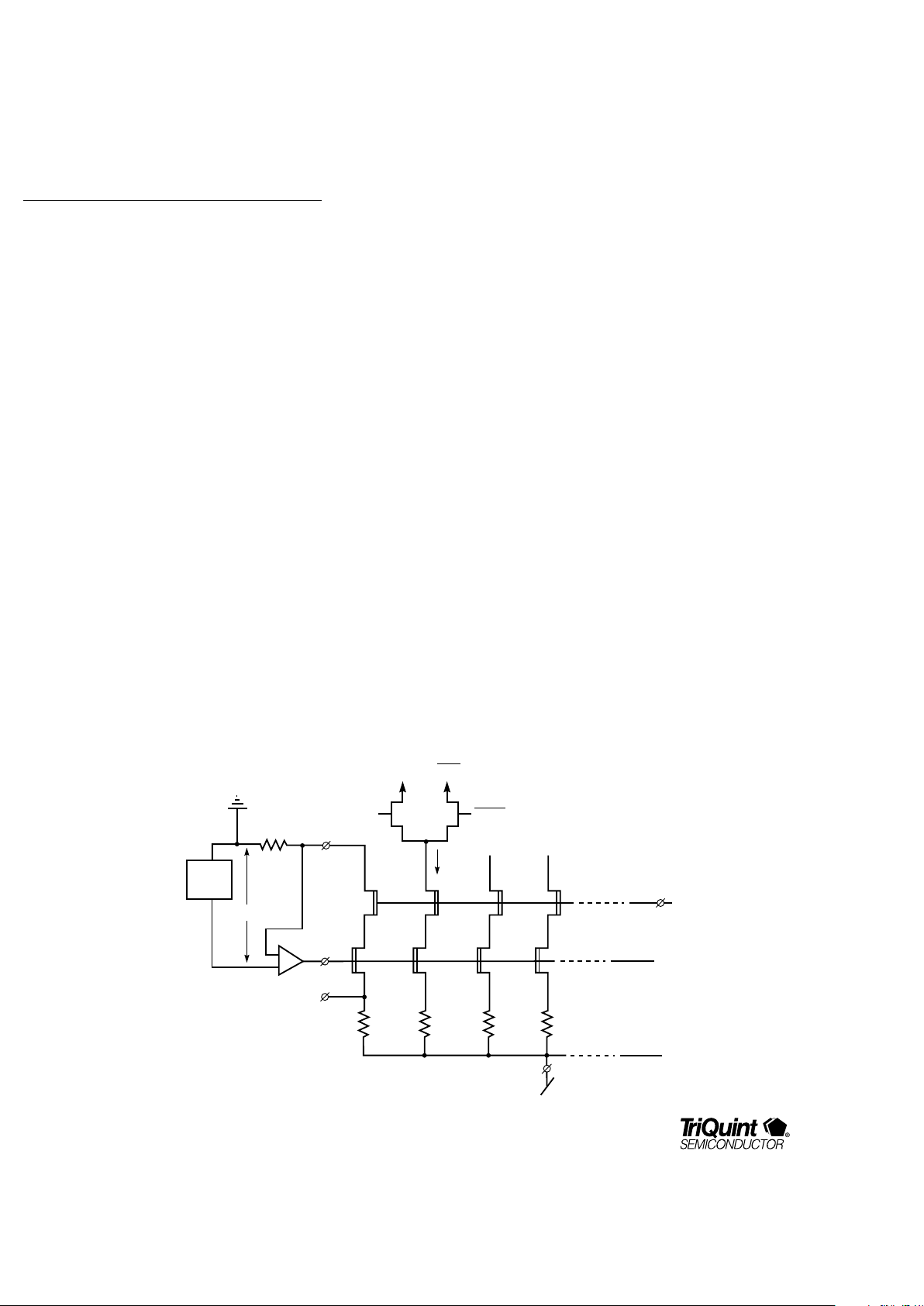

Figure 14 illustrates the basic connection of the DAC,

showing details for power supplies, data and clock

inputs, and outputs terminated in 50-ohm transmission

line loads. Some issues relating to circuit board layout

are also addressed.

Page 14

TQ6122

14

For additional information and latest specifications, see our website: www.triquint.com

Power Supplies, Ground and Bypassing

To minimize noise coupling, the digital and analog

power supplies should be returned to a single-point

ground, and power supply buses to the IC should have

minimum impedance (power planes are best).

The supplies themselves should be well bypassed at high

and low frequencies, which requires the use of several

different parallel capacitors as shown. The values are not

particularly critical; however, due to the fact that a

capacitor looks inductive above its self-resonant

frequency, one needs to use several different values in

parallel, ranging from microfarads to nanofarads, in

order to provide adequate wideband bypassing.

For best results, use leadless ceramic chip capacitors

for bypassing, although leaded components will work

satisfactorily if higher noise can be tolerated. A common

ground plane has been found to give the best performance.

For best results and minimum noise, the digital and

analog supplies should be physically separated on the

circuit board. When using a common –5␣ V feed, the

V

SS

and VAA planes should be isolated by ferrite beads

(Fair-Rite P/N 2743001111 or equivalent) as shown in

Figure 14. Using separate LM337MT regulators downstream of the ferrite beads will provide better isolation.

Digital Inputs and Terminations

The TQ6122 DAC is designed to accept ECL logic levels

at all data and control inputs. All ECL inputs, with the

exception of the clock (see below), are single-ended

and are compared to the ECL threshold reference of

–1.3␣ Volts (nominal) in the input buffers of the DAC.

The ECL reference input equivalent circuit is shown in

Figure 1. Several options are available to the user for

externally setting the ECL reference level. The simplest

option is that of a voltage divider between D

GND

and

V

TT

, setting the ECL termination voltage as shown in

Figure␣ 15 (A). The nominal value for ECLREF is –1.3␣ V;

however, due to input offset variations among the input

buffers or variations in V

TT

, some adjustment above or

below –1.3 V may give the best results.

A good way to settle ECLREF is to slave the ECL reference level to the center (switching) point of the input

data signal. This may be accomplished in two ways:

either use the V

BB

generator output of the device which

is generating the ECL signals supplied to the DAC, or

use an inverter with input and output connected

together to generate a level equal to the switching

threshold. See Figure␣ 15 (B). Note that the ECLREF

generator should be able to source and sink up to

approximately 5␣ mA, since the input resistance is about

50␣ ohms, against an internal –1.3␣ V (nominal) voltage

source. An additional op amp may be used to give

more flexibility or more robust drive. See Figure␣ 15 (C).

Figure 15. External ECL Reference Generator

(A) (B) (C)

200

50

V

ECL Reference

input or unused

clock (CLK) input

EXTERNAL ECL

INVERTER

50

(OPTIONAL OP AMP)

DAC

INPUT

ECLREF

–

+

TT

-2 V

V

TT

-2 V

Page 15

TQ6122

15

For additional information and latest specifications, see our website: www.triquint.com

MIXED SIGNAL

PRODUCTS

Clock Input

In order to realize the full speed potential of the DAC, a

clock with an input swing of at least 1 V peak-to-peak,

nominally centered on –1.3 V, is required. The clock

may be applied in either single-ended or differential

fashion. Because a differential clock provides maximum

speed and best control of the relationship between clock

and output transitions, as well as minimum noise,

it is

the preferred solution. For single-ended clock drive, the

customer must drive the unused CLOCK input with an

external ECL reference level, which may be generated

using a resistive divider or, for best results, an external

inverter tied back on itself. See Figure 15.

Input Line Termination

As shown in Figure 14, data, control, and clock inputs

should be terminated in 50 ohms to V

TT

, consistent

with good ECL practice. For best results, keep

terminations physically small — surface-mount “chip”

resistors work very well — and locate them as close to

the IC as possible. The V

TT

bus should also be locally

bypassed to digital ground, using chip capacitors

placed close to the terminations. The DAC offers good

performance for –2.5 V

< VTT < –2 V, where the use of

V

TT

< –2 V may allow the designer to eke out the last

bit of performance in a noisy or marginal drive-level

environment.

Current-Source Control Loop

As illustrated previously in Figure 13, and shown in

detail in Figure 16, the bit current sources are

controlled by placing them in a feedback loop which

compares the drop across a current-sensing resistor

with a stable reference. For nominal 1 Volt full-scale

output swing, the V

REF

-to-VAA voltage will be in the 0.8

to 1 V range, and may be derived from a zener or,

better still, a bandgap reference such as the 2.5 V

Motorola MC1403A. The output of the bandgap

reference will have to be divided down before being

applied to the control op amp, and some means should

be provided to trim the output to compensate for V

OUT

load resistor variations.

The op amp must have input common-mode and

output drive ranges which extend down to within at

least 0.5 Volt of the negative rail for maximum control

range. For best noise immunity, both the reference

generator and the op amp should share a point

connection to the V

AA

rail, close to the DAC. The

Motorola MC33071 op amp is suitable for this

application. Standard linear design techniques should

be used to minimize thermal drift and offset. Note that

the temperature coefficient of the nichrome resistors

used in the DAC is on the order of +6 ppm/°C. Figure 16

shows a typical reference control loop circuit.

IREF

VAA

VREF

VSENSE

BLK.DIS.

AGND

VOUT

VOUT

AGND

AGND

DGND

+

–

MC1403A

V PLANE

V

V (V + 2.5 V)

MC33071

1uF

0.01

1000

2.5 K

V

V

620

(V +1 V)

V

+ –

1 K

V

AA

CC

EE

2.5 K

AA

AA

AA

AAOUT

1 K

AA

(I = ON)

(I = OFF)

V

AA

BLANK

BLANK

V

V

OUT

OUT

Fig. 16. Typical External Current-Source Control Loop

Figure 17 illustrates the relationship between control

input V

REF

and the full-scale output swing. Note that the

full-scale swing may be reduced below 0.25 V peak-topeak by pulling V

REF

below VAA. However, this

necessitates a separate negative supply for the control

Page 16

TQ6122

16

For additional information and latest specifications, see our website: www.triquint.com

op amp and reference generator, which may decrease

the V

AA

supply rejection. In circuits which use different

negative rails for the DAC V

AA

supply and the op amp,

V

REF

should be clamped to no more than two diode

drops below V

AA

, and a current-limiting resistor should

be included at either the op amp output or between its

negative supply input and supply input. In the event of

turn-on transients and large excursions in the op amp

supply before V

AA

has settled out, these precautions

will help prevent breakdown of circuitry within the DAC.

Figure 17. Typical V

REF

-to-VAA Transfer Characteristics

1.25

1.125

1.00

0.75

0.50

-1.0 0 0.5 1.0 1.25

V

OUT

(Volts p-p)

(Maximum recommended)

0.25

V to V

(Volts)

REF

AA

Full-Scale Output Adjust

The procedure for setting the full-scale output range is

quite straightforward, and involves monitoring the

output level(s) using a DVM. With the DAC connected

to its actual V

OUT

and V

OUT

load(s), the output is

alternately switched between steady state zero- and

full-scale levels, and the reference is adjusted until the

desired full-scale transition amplitude is obtained. The

clock must be running and the BLANK input set to “0”.

Alternatively, for a DDS application, a spectrum

analyzer or a power meter may be used to monitor the

full-scale output power.

Blanking Current Programming

The blanking current (I

BLANK

in Figure 13) is turned off

by connecting the BLANK_DISABLE pin to A

GND

to

divert the current away from the blank switch and the

output of the DAC, and turned on by connecting

BLANK_DISABLE to V

AA

.

Output Equivalent Circuit

Figure 5 illustrates the equivalent circuit of the two DAC

outputs. Each of the bit current sources is switched

into either the V

OUT

or the V

OUT

output, depending on

the data stored in the slave latches. A pair of internal

50-ohm resistors are connected from V

OUT

and V

OUT

to

analog ground (A

GND

), and provide reverse termination

for the analog output transmission lines. Although in

principle there is no restriction on the load impedance

applied at the outputs, in practice, the best

performance will be obtained when driving a 50-ohm

terminated transmission line. This is very important

from a settling standpoint, since reflections from non50-ohm loads will superimpose with new transitions

and interfere with settling. The general rule for

terminating the outputs is “the cleaner, the better.”

Output Zero-Scale Adjust

The output baseline, or “zero-scale” level, may be

adjusted by returning the far-end termination resistors

to a well-bypassed supply level other than ground. For

this general situation, reference Figure 5, the instantaneous output voltages V

OUT

and V

OUT

are given by:

) –

|

I

OUT

| (RL1 || RT1)

) –

|

I

OUT

| (RL2 || RT2)

V

OUT

= V

OS

(

RL1 + R

T1

R

T1

V

OUT

= V

OS

(

RL2 + R

T2

R

T2

I

OUT =

(

Digital Input

255

) I

FS

I

OUT =

(1 –

Digital Input

255

) I

FS

IFS = Summation of all individual bit currents

Digital Input = Decimal equivalent of the binary input word

Page 17

TQ6122

17

For additional information and latest specifications, see our website: www.triquint.com

MIXED SIGNAL

PRODUCTS

disadvantage of requiring a large supply voltage. In

general, a 1/8 to 1/4 W carbon-composition resistor

with a value of 500 to 1000 ohms will give good

performance. Keep the lead lengths short when attaching to the circuit board and bypass the driven terminal

of the resistors with a 1000 pF to 0.01 µF SMT (surfacemount) capacitor network to the ground plane.

A transistor current source, on the other hand, requires

much less power supply overhead, but adds more

capacitance to the transmission line. If a transistor is

used, it should be a high-F

T

device with low CCB or C

DG

(≤ 0.5 pF, if possible) and installed with short leads.

Capacitive coupling provides a means of obtaining an

output centered on 0 volts. However, simply adding a

coupling capacitor at one (or both) of the outputs will

cause the DC output level to exceed the –1.5 V output

compliance limit. The way to circumvent this problem

is to add an offset current between the DAC output and

the coupling capacitor (as discussed above), or to add

a low-loss 50-ohm pad between the DAC and the

capacitor, as shown in Figure 18(B). A “T” or “π”

attenuator topology is acceptable, having 1␣ dB to 3 dB

of attenuation. The characteristic impedance must be

consistent with the overall system impedance, typically

50 ohms. This approach works, although the lower

limit on the output level tends to be very close to the

–1.5 V compliance limit for ≥1 V full-scale output

swings, so some care and verification will be required.

DAC

0 VOLT

V

0 VOLT

50

MIMIMUM-LOSS PAD (1–3 dB)

MIN

Figure 18(B). AC Coupling of Outputs

Figure 18(A). Alternate Output Offset Current Generators

For the case of RL1 = RL2 = RT1 = RT2 = 50 ohms, VOS is

attenuated by 50%. An overriding factor in setting the

output offset is the requirement that V

OUT

and V

OUT

always remain within the device’s output compliance

range of –1.5 V to +1 V. Note also that in the case of

the video application of the DAC, the value of the

blanking current I

BLANK

and the state of the BLANK

input must be included in the expressions for V

OUT

and

V

OUT

.

An alternative method of offsetting the output involves

injecting an offset current at the output. This may be

done using a current source in the form of either a

resistor or a transistor as shown in Figure 18(A). The

resistor has the advantage of minimizing perturbation

of the transmission line impedance, with the

V

OS

1000 pF

0.01 uF

500 – 1 K

1/8 – 1/4W

Carbon Comp.

50 Ohm

R

1

R

2

R

3

V

T

50 Ohm

R

E

High-F

Low C

Device

JE

T

Short

Lead

Short

Lead

Note: V

MIN

must not exceed the lower output

compliance limit of –1.5 V for proper

operation. If V

MIN

< –1.5 V, decrease

the DAC output swing by adjusting the

V

REF

drive to the control op amp.

Page 18

TQ6122

18

For additional information and latest specifications, see our website: www.triquint.com

Figures 19 through 23 show typical AC performance

of the TQ6122. Figures␣ 19A and 19B illustrate the

response of the DAC to an unmultiplexed counter

input at 1 Gs/s and 1.5␣ Gs/s, respectively.

Blanking is enabled in both cases.

The small glitches appearing at 1/8 of full-scale

intervals are shown in more detail in Figure 22.

Figure 19 (A). Unmuxed Ramp at 1000 Ms/s with

Blanking (Guaranteed, 0 to +85

°

C)

Figure 19(B). Unmuxed Ramp at 1500 Ms/s with

Blanking (Typical, +25

°

C)

Typical AC Performance

Page 19

TQ6122

19

For additional information and latest specifications, see our website: www.triquint.com

MIXED SIGNAL

PRODUCTS

Figure 20(A). Muxed Ramp at 1000 Ms/s with Blanking

Multiplexed behavior is shown in Figure 20A and 20B,

with a counter input muxed against fixed levels at

1000 Ms/s and at 1350 Ms/s, respectively.

In Figure 20A, the ramp is muxed against a steady

state mid-scale value, while in Figure 20B, the steady

state input is 11111111. The apparent droop in the top

level in Figure 20B is an artifact of the sampler.

Figures 19A, 19B, and 20A show the effects of blanking,

while in Figure 20B, the BLANK input is held LOW,

demonstrating the repetitive nature of the waveform.

Figure 20(B). Muxed Ramp at 1350 Ms/s with

Blanking Disabled

Note: In Figure 20(A), A0–A7 are switched, B0–B6 are LOW,

B7is HIGH and BLANK is switched. In Figure 20(B),

A0–A7 are switched, B0–B7 are HIGH, and BLANK is LOW.

Page 20

TQ6122

20

For additional information and latest specifications, see our website: www.triquint.com

Figure 21. Typical Full-Scale Transitions

at V

OUT

and V

OUT (fCLK

= 1000 MHz)

Figure 22. Typical Worst-Case Glitch Impulse

(f

CLK

= 1000 MHz)

Figure 21 illustrates the symmetry of complementary

full-scale transitions at V

OUT

and V

OUT

, while Figure 22

depicts a typical worst-case glitch of 6 pV/sec.

Page 21

TQ6122

21

For additional information and latest specifications, see our website: www.triquint.com

MIXED SIGNAL

PRODUCTS

Figure 23(A). Synthesized Sine Wave Output

Figure 23(A) shows a 1 Gs/s, 58.6 MHz sine wave, and

Figure 23B shows its corresponding spectrum. The

spurious-free dynamic range is 46␣ dBc, a typical value

for the device.

In Figure 23(B), the DAC output is attenuated by 6 dB

going into a spectrum analyzer.

Figure 23(B). Spectrum of a 58.5 MHz Sine Wave

at 1 Gs/s

Page 22

TQ6122

22

For additional information and latest specifications, see our website: www.triquint.com

Figure 25. Chip Dimensions, Topography, and Padout

Notes: 1. Dimensional limits unless otherwise

specified:

+2 mils (+51 µM).

2. Pins labeled N/C are not

connected internally.

Figure 24. Complex Modulated Sine Wave Pattern

at 1000 Mb/s

Figure 24 shows a modulated sine wave as an example

of a more complex waveform.

VAA

VAA

IREF

ECL REF

A0 (LSB)

A1

DGND

DGND

DGND

A2

A3

A4

A5

VSS

VSS

VSS

VSS

CLOCK

CLOCK

N/C

SELA

DGND

DGND

DGND

BLANK

B7 (MSB)

B6

B5

VSS

VSS

VAA

VAA

VREF

VSENSE

BLANK DISABLE

AGND

AGND

AGND

AGND

VOUT

VOUT

VOUT

AGND

AGND

VSS

VSS

VSS

A6

A7 (MSB)

DGND

DGND

B0 (LSB)

B1

DGND

DGND

B2

B3

B4

VSS

VSS

VOUT

DIE SIZE: 129 Mils x 111 Mils (3110 µM x 2660 µM)

Page 23

TQ6122

23

For additional information and latest specifications, see our website: www.triquint.com

MIXED SIGNAL

PRODUCTS

Ordering Information

TQ6122-M

8-bit, 1 Gs/s DAC in 44-pin package

TQ6122-D

8-bit, 1 Gs/s DAC, die only

ETF6122

Engineering Test Fixture with 6122 device

Additional Information

For latest specifications, additional product information,

worldwide sales and distribution locations, and information about TriQuint:

Web: www.triquint.com Tel: (503) 615-9000

Email: sales@tqs.com Fax: (503) 615-8900

For technical questions and additional information on specific applications:

Email: applications@tqs.com

The information provided herein is believed to be reliable; TriQuint assumes no liability for inaccuracies or

omissions. TriQuint assumes no responsibility for the use of this information, and all such information

shall be entirely at the user's own risk. Prices and specifications are subject to change without notice.

No patent rights or licenses to any of the circuits described herein are implied or granted to any third party.

TriQuint does not authorize or warrant any TriQuint product for use in life-support devices and/or systems.

Copyright © 1997 TriQuint Semiconductor, Inc. All rights reserved.

Revision 1.0.A October 1997

Figure 26. Package Labelling (44-pin packaged version)

See Figures 10, 11 and 12 for package dimensions and heat-sink mounting information.

1 TQS USA

TQ6122-M

YYWW XXXX

BEVELED

CORNER

Component Material

Lead Kovar

Lead Plating Lead/tin alloy

YYWW – Date Code

XXXX - Lot Number

Loading...

Loading...