Page 1

VIN

I/O Control

From Input

Supply

(3.0 V-6.0 V)

Temp

Sensor

TS

DCDC2

VN

VN_SW

DCDC1

VB_SW

VB

From Input

Supply

(3.0 V-6.0 V)

VDDH_D

VDDH_DRV

VDDH_FB

Positive

Charge

Pump

VPOS

LDO1

VEE_D

VEE_DRV

VEE_FB

Negative

Charge

Pump

VCOM

VCOM

VCOM_PANEL

VNEG

LDO2

VCOM

Product

Folder

Sample &

Buy

Technical

Documents

Tools &

Software

Support &

Community

SLVSB04A –JULY 2011–REVISED AUGUST 2015

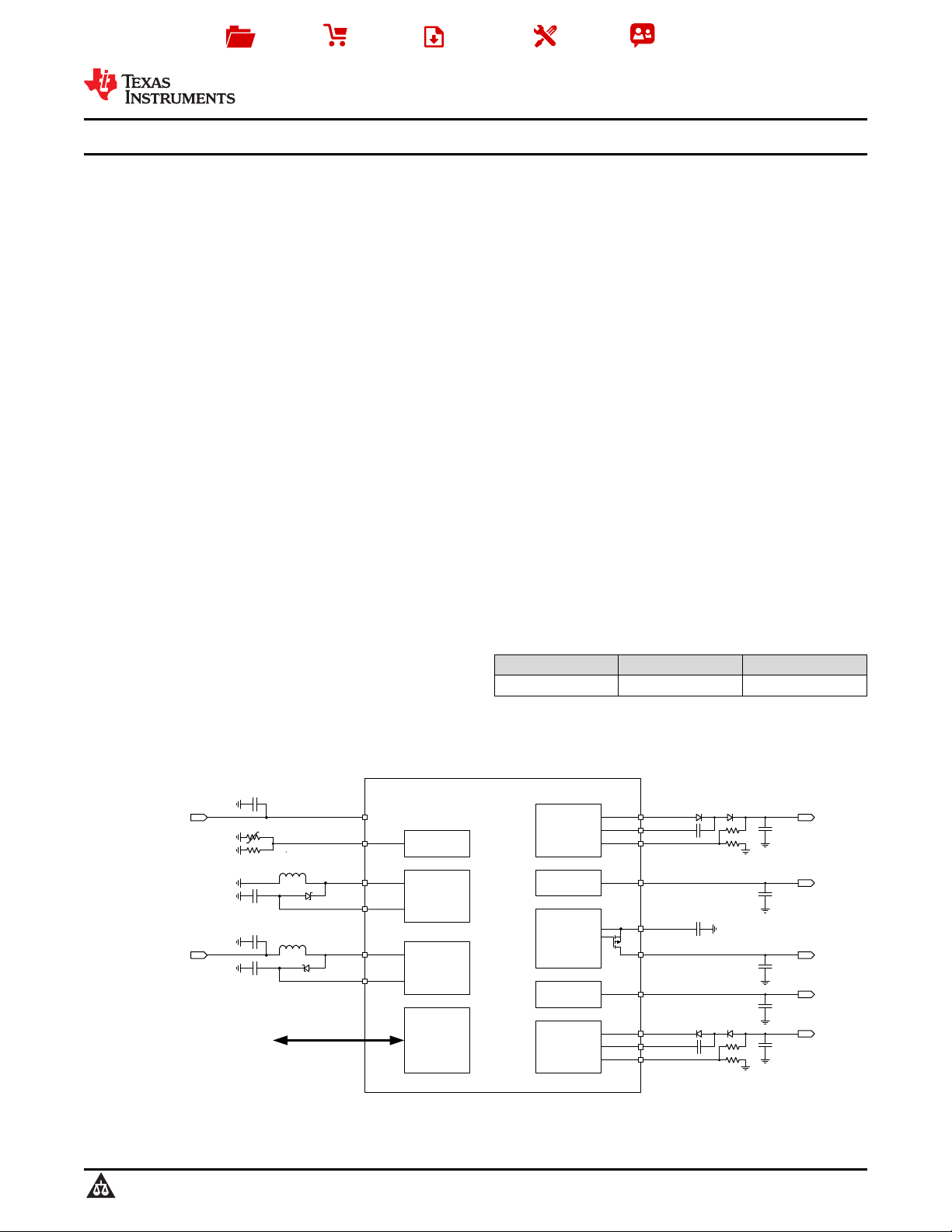

TPS65186 PMIC for E Ink®Vizplex™ Enabled Electronic Paper Display

1 Features 2 Applications

1

• Single Chip Power-Management Solution for

E Ink®Vizplex™ Electronic Paper Displays Panels

• Generates Positive and Negative Gates, Source • EPD Power Supplies

Driver Voltages, and Back-Plane Bias From a

Single, Low-Voltage Input Supply

• Supports 9.7 Inch and Larger Panel Size

• 3-V to 6-V Input Voltage Range

• Boost Converter for Positive Rail Base

• Inverting Buck-Boost Converter for Negative Rail Software Timing Controller (OMAP™)

Base

• Two Adjustable LDOs for Source Driver Supply

– LDO1: 15 V, 120 mA (VPOS)

– LDO2: –15 V, 120 mA (VNEG)

• Accurate Output Voltage Tracking

– VPOS – VNEG = ±50 mV

• Two Charge Pumps for Gate Driver Supply

– CP1: 22 V, 10 mA (VDDH)

– CP2: –20 V, 12 mA, (VEE)

• Adjustable VCOM Driver for Accurate PanelBackplane Biasing

– 0 V to –5.11 V

– ± 1.5% accuracy (±10 mV)

– 9-Bit Control (10-mV Nominal Step Size)

• Integrated 10-Ω, 3.3-V Power Switch for Disabling

System Power Rail to E-Ink Panel

• Power Supply for Active Matrix E Ink Vizplex

• E-Book Readers

• EPSON®S1D13522 (ISIS) Timing Controller

• EPSON®S1D13521 (Broadsheet) Timing

Controller

• Application Processors With Integrated or

3 Description

The TPS65186 device is a single-chip power supply

designed to for E Ink Vizplex displays used in

portable e-reader applications, and the device

supports panel sizes up to 9.7 inches and greater.

Two high-efficiency DC-DC boost converters

generate ±16-V rails that are boosted to 22 V and

–20 V by two change pumps to provide the gate

driver supply for the Vizplex panel. Two tracking

LDOs create the ±15-V source driver supplies that

support up to 120-mA of output current. All rails are

adjustable through the I2C interface to accommodate

specific panel requirements.

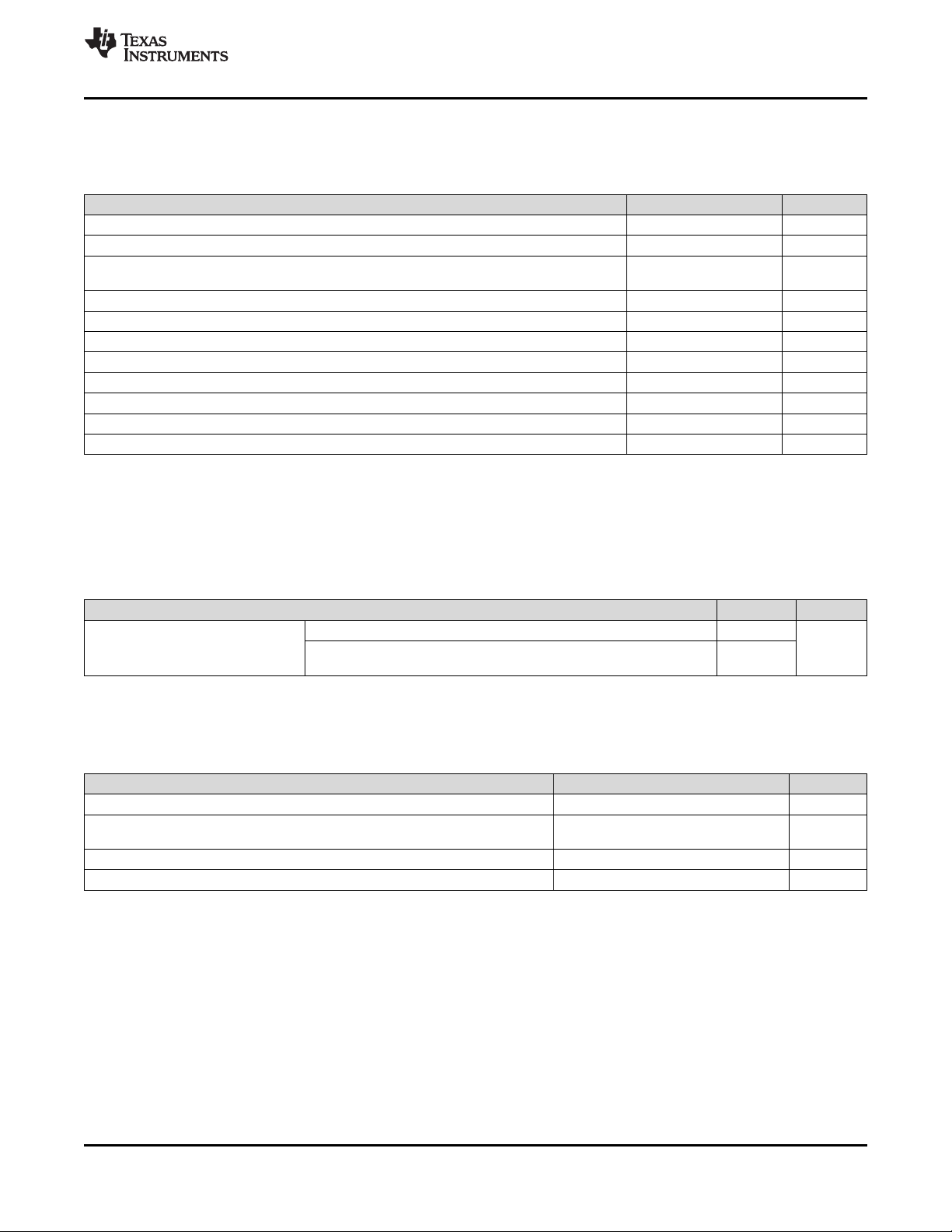

Device Information

PART NUMBER PACKAGE BODY SIZE (NOM)

TPS65186 VQFN (48) 7.00 mm × 7.00 mm

(1) For all available packages, see the orderable addendum at

the end of the data sheet.

(1)

TPS65186

Typical Application Schematic

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

Page 2

TPS65186

SLVSB04A –JULY 2011–REVISED AUGUST 2015

www.ti.com

Table of Contents

1 Features.................................................................. 1

2 Applications ........................................................... 1

3 Description ............................................................. 1

4 Revision History..................................................... 2

5 Description (continued)......................................... 3

6 Pin Configuration and Functions......................... 3

7 Specifications......................................................... 5

7.1 Absolute Maximum Ratings ...................................... 5

7.2 ESD Ratings.............................................................. 5

7.3 Recommended Operating Conditions....................... 5

7.4 Thermal Information.................................................. 6

7.5 Electrical Characteristics........................................... 6

7.6 Timing Requirements: Data Transmission.............. 10

7.7 Typical Characteristics............................................ 12

8 Detailed Description............................................ 15

8.1 Overview ................................................................. 15

8.2 Functional Block Diagram....................................... 16

8.3 Feature Description................................................. 17

8.4 Device Functional Modes........................................ 24

8.5 Programming........................................................... 26

8.6 Register Maps......................................................... 27

9 Application and Implementation ........................ 44

9.1 Application Information............................................ 44

9.2 Typical Application ................................................. 44

10 Power Supply Recommendations ..................... 46

11 Layout................................................................... 46

11.1 Layout Guidelines ................................................. 46

11.2 Layout Example .................................................... 46

12 Device and Documentation Support................. 47

12.1 Device Support...................................................... 47

12.2 Community Resources.......................................... 47

12.3 Trademarks........................................................... 47

12.4 Electrostatic Discharge Caution............................ 47

12.5 Glossary................................................................ 47

13 Mechanical, Packaging, and Orderable

Information........................................................... 47

4 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from Original (July 2011) to Revision A Page

• Added ESD Ratings table, Feature Description section, Device Functional Modes, Application and Implementation

section, Power Supply Recommendations section, Layout section, Device and Documentation Support section, and

Mechanical, Packaging, and Orderable Information section.................................................................................................. 1

• Changed R

from “TBD” to “5 Ω”........................................................................................................................................ 8

OUT

2 Submit Documentation Feedback Copyright © 2011–2015, Texas Instruments Incorporated

Product Folder Links: TPS65186

Page 3

VREF – 1

nINT – 2

VNEG – 3

VNEG_IN – 4

WAKEUP – 5

DGND – 6

INT_LDO – 7

AGND1 – 8

N/C – 9

VIN – 10

N/C – 11

23 – PBKG

22 – PWRUP

21 – N/C

20 – N/C

19 – N/C

18 – SDA

17 – SCL

16 – VCOM_PWR

15 – N/C

14 – VCOM

13 – N/C

24 – PWR_GOODVDDH_IN – 37

N/C – 38

N/C – 39

VB_SW – 40

PGND1 – 41

VB – 42

VPOS_IN – 43

VPOS – 44

VIN3P3 – 45

V3P3 – 46

TS – 47

AGND2 – 48

36 – VDDH_DRV

26 – N/C

35 – VDDH_D

34 – VDDH_FB

33 – PGND2

32 – VEE_FB

31 – VEE_D

27 – VIN_P

30 – VEE_DRV

29 – VEE_IN

28 – VN

25 – VN_SW

TPS65186

www.ti.com

SLVSB04A –JULY 2011–REVISED AUGUST 2015

5 Description (continued)

Accurate back-plane biasing is provided by a linear amplifier that can be adjusted from 0 V to –5.11 V with 9-bit

control through the serial interface; it can also source or sink current depending on panel condition. The

TPS65186 supports automatic panel kickback voltage measurement, which eliminates the need for manual

VCOM calibration in the production line. The measurement result can be stored in nonvolatile memory to become

the new VCOM power-up default value.

TPS65186 is available in a 48-pin 7-mm × 7-mm2VQFN with 0.5-mm pitch.

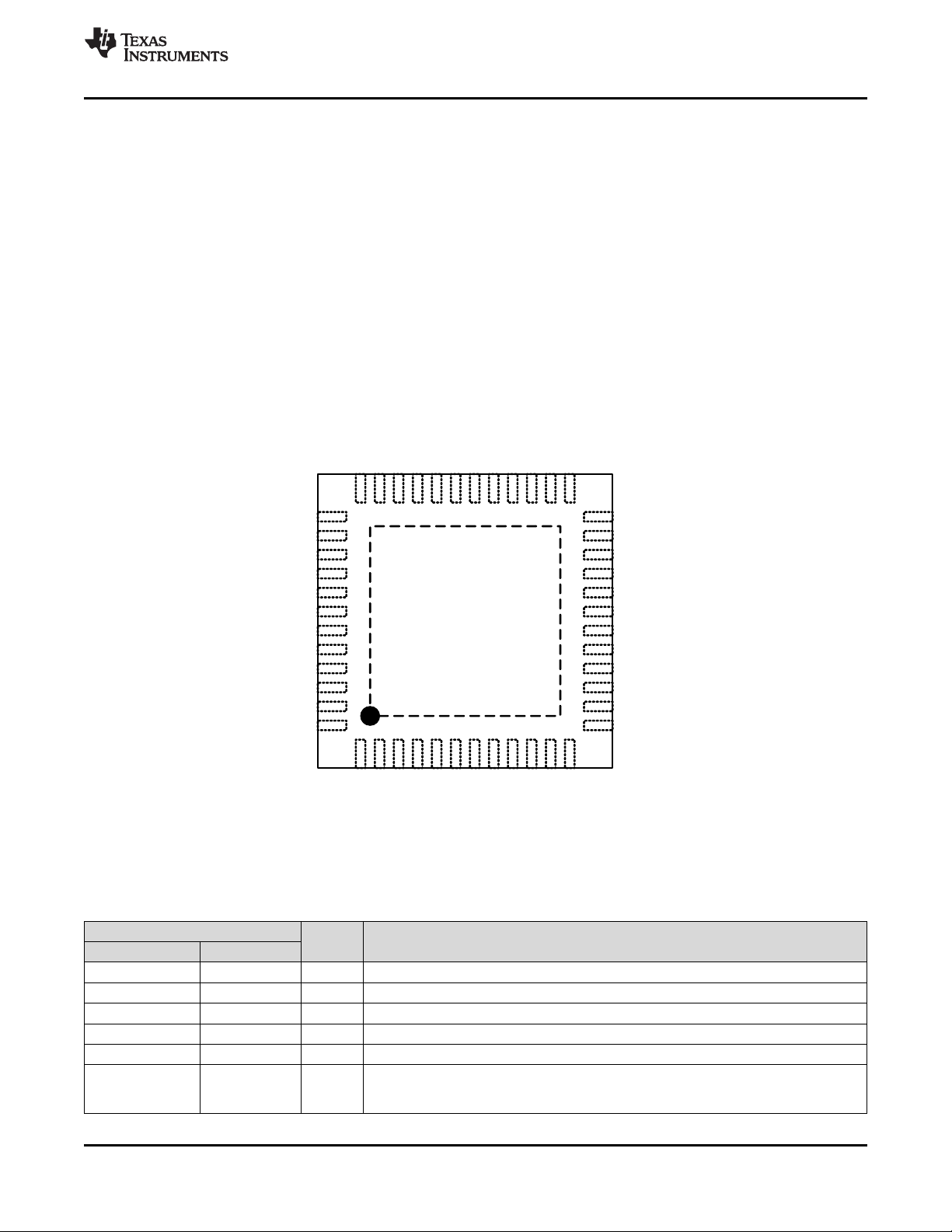

6 Pin Configuration and Functions

RGZ Package

48-Pin VQFN

Top View

PIN

NAME NO.

AGND1 8 — Analog ground for general analog circuitry

AGND2 48 — Reference point to external thermistor and linearization resistor

DGND 6 — Digital ground. Connect to ground plane.

INT_LDO 7 O Filter pin for 2.7-V internal supply

nINT 2 O Open drain interrupt pin (active low)

9, 11, 13, 15,

38, 39

N/C 19, 20, 21, 26, — Not internally connected

Copyright © 2011–2015, Texas Instruments Incorporated Submit Documentation Feedback 3

Pin Functions

I/O DESCRIPTION

Product Folder Links: TPS65186

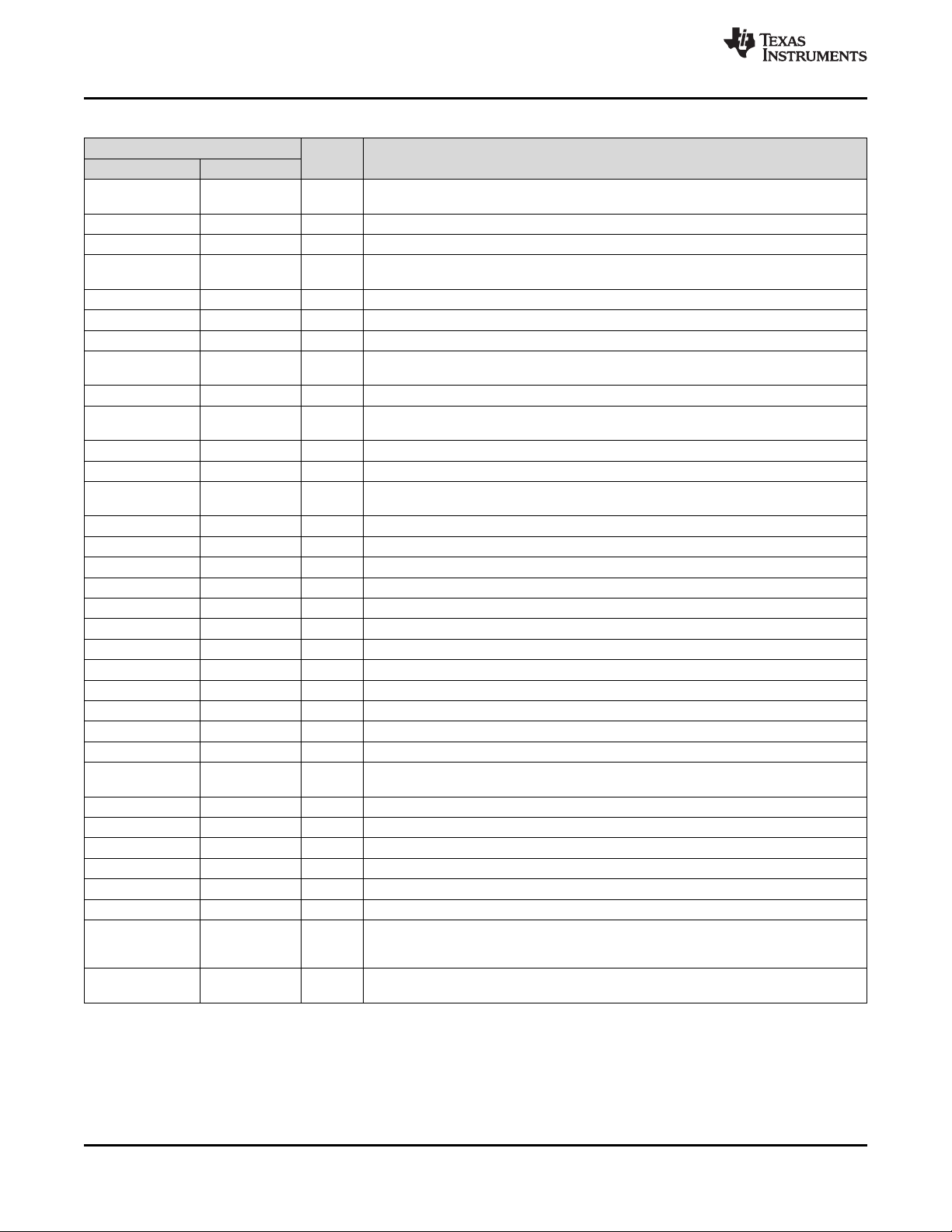

Page 4

TPS65186

SLVSB04A –JULY 2011–REVISED AUGUST 2015

Pin Functions (continued)

PIN

NAME NO.

PBKG 23 —

PGND1 41 — Power ground for DCDC1

PGND2 33 — Power ground for CP1 (VDDH) and CP2 (VEE) charge pumps

PWR_GOOD 24 O

PWRUP 22 I Power-up pin. Pull this pin high to power up all output rails.

SCL 17 I Serial interface (I2C) clock input

SDA 18 I/O Serial interface (I2C) data input/output

TS 47 I

V3P3 46 O Output pin of 3.3-V power switch

VB 42 I

VB_SW 40 O Boost converter switch out (DCDC1)

VCOM 14 I Filter pin for panel common-voltage driver

VCOM_CTRL 12 I

VCOM_PWR 16 I Internal supply input pin to VCOM buffer. Connect to the output of DCDC2.

VDDH_D 35 O Base voltage output pin for positive charge pump (CP1)

VDDH_DRV 36 O Driver output pin for positive charge pump (CP1)

VDDH_FB 34 I Feedback pin for positive charge pump (CP1)

VDDH_IN 37 I Input supply pin for positive charge pump (CP1)

VEE_D 31 I Base voltage output pin for negative charge pump (CP2)

VEE_DRV 30 O Driver output pin for negative charge pump (CP2)

VEE_FB 32 I Feedback pin for negative charge pump (CP2)

VEE_IN 29 I Input supply pin for negative charge pump (CP2) (VEE)

VIN 10 I Input power supply to general circuitry

VIN3P3 45 I Input pin to 3.3-V power switch

VIN_P 27 I Input power supply to inverting buck-boost converter (DCDC2)

VN 28 I

VNEG 3 O Negative supply output pin for panel source drivers

VNEG_IN 4 I Input pin for LDO2 (VNEG)

VN_SW 25 O Inverting buck-boost converter switch out (DCDC2)

VREF 1 O Filter pin for 2.25-V internal reference to ADC

VPOS 44 O Positive supply output pin for panel source drivers

VPOS_IN 43 I Input pin for LDO1 (VPOS)

WAKEUP 5 I commands after WAKEUP pin is pulled high but power rails remain disabled until

PowerPad — —

(1) There will be 0-ns of deglitch for PWRx.

(2) There will be 62.52-µs of deglitch for VCOM_CTRL.

(3) There will be 93.75-µs of deglitch for WAKEUP.

I/O DESCRIPTION

Die substrate. Connect to VN (–16 V) with short, wide trace. Wide copper trace will

improve heat dissipation.

Open-drain power good output pin. Pin is pulled low when one or more rails are disabled

or not in regulation. DCDC1, DCDC2, and VCOM have no effect on this pin.

(1)

Thermistor input pin. Connect a 10-kΩ NTC thermistor and a 43-kΩ linearization resistor

between this pin and AGND.

Feedback pin for boost converter (DCDC1) and supply for VPOS LDO and VDDH charge

pump

VCOM enable. Pull this pin high to enable the VCOM amplifier. When pin is pulled low

and VN is enabled, VCOM discharge is enabled.

(2)

Feedback pin for inverting buck-boost converter (DCDC2) and supply for VNEG LDO and

VEE charge pump

Wake-up pin (active high). Pull this pin high to wake up from sleep mode. IC accepts I2C

PWRUP pin is pulled high.

(3)

PowerPad, internally connected to PBKG. Connect to VN with short, wide trace. Wide

copper trace will improve heat dissipation. PowerPad must not be connected to ground.

(1)

www.ti.com

4 Submit Documentation Feedback Copyright © 2011–2015, Texas Instruments Incorporated

Product Folder Links: TPS65186

Page 5

TPS65186

www.ti.com

SLVSB04A –JULY 2011–REVISED AUGUST 2015

7 Specifications

7.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted)

Input voltage at VIN

Ground pins to system ground –0.3 0.3 V

Voltage at SDA, SCL, WAKEUP, PWRUP, VCOM_CTRL, VDDH_FB, VEE_FB,

PWR_GOOD, nINT

Voltage on VB, VB_SW, VPOS_IN, VDDH_IN –0.3 20 V

Voltage on VN, VEE_IN, VCOM_PWR, VNEG_IN –20 0.3 V

Voltage from VIN_P to VN_SW –0.3 30 V

Peak output current Internally limited mA

Continuous total power dissipation 2 W

TJOperating junction temperature –10 125 °C

TAOperating ambient temperature

T

Storage temperature –65 150 °C

stg

(1) Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under Recommended Operating

Conditions is not implied. Exposure to absolute maximum rated conditions for extended periods may affect device reliability.

(2) All voltage values are with respect to network ground terminal.

(3) TI recommends that copper plane in proper size on board be in contact with die thermal pad to dissipate heat efficiently. Thermal pad is

electrically connected to PBKG, which is supposed to be tied to the output of buck-boost converter. Thus wide copper trace in the buck-

boost output will help heat dissipated efficiently.

(2)

, VIN_P, VIN3P3 –0.3 7 V

(3)

(1)(2)

MIN MAX UNIT

–0.3 3.6 V

–10 85 °C

7.2 ESD Ratings

Human body model (HBM), per ANSI/ESDA/JEDEC JS-001

V

(ESD)

Electrostatic discharge V

Charged device model (CDM), per JEDEC specification JESD22- ±500

(2)

C101

(1) JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

(2) JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

(1)

7.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)

MIN NOM MAX UNIT

Input voltage at VIN, VIN_P, VIN3P3 3 3.7 6 V

Voltage at SDA, SCL, WAKEUP, PWRUP, VCOM_CTRL, VDDH_FB,

VEE_FB, PWR_GOOD, nINT

T

A

T

J

Operating ambient temperature –10 85 °C

Operating junction temperature –10 125 °C

0 3.6 V

VALUE UNIT

±2000

Copyright © 2011–2015, Texas Instruments Incorporated Submit Documentation Feedback 5

Product Folder Links: TPS65186

Page 6

TPS65186

SLVSB04A –JULY 2011–REVISED AUGUST 2015

www.ti.com

7.4 Thermal Information

TPS65186

THERMAL METRIC

(1)

RGZ [VQFN] UNIT

48 PINS

R

θJA

R

θJC(top)

R

θJB

ψ

JT

ψ

JB

R

θJC(bot)

Junction-to-ambient thermal resistance 30 °C/W

Junction-to-case (top) thermal resistance 15.6 °C/W

Junction-to-board thermal resistance 6.6 °C/W

Junction-to-top characterization parameter 0.2 °C/W

Junction-to-board characterization parameter 6.6 °C/W

Junction-to-case (bottom) thermal resistance 0.9 °C/W

(1) For more information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics application

report, SPRA953.

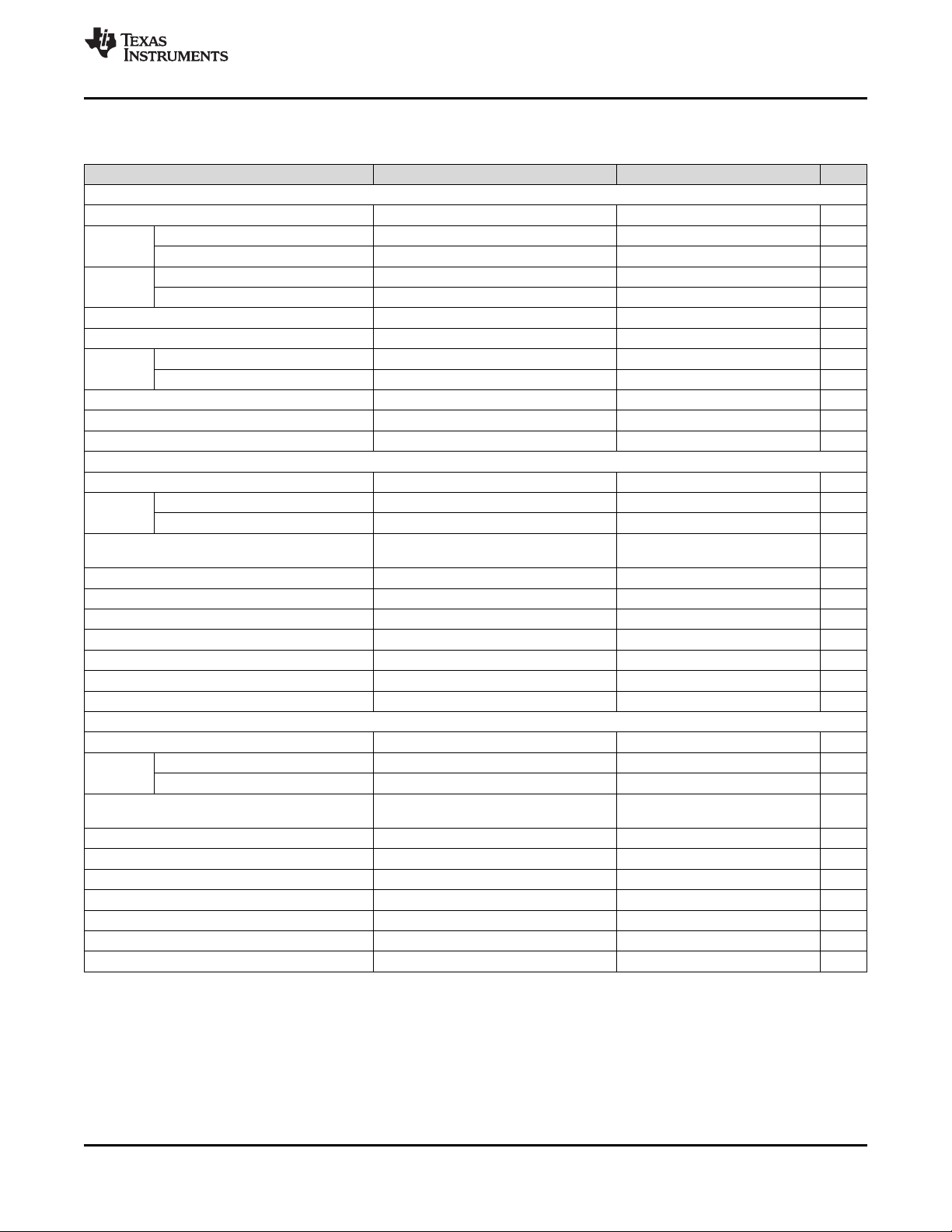

7.5 Electrical Characteristics

VIN= 3.7 V, TA= –10°C to 85ºC, Typical values are at TA= 25ºC (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

INPUT VOLTAGE

V

IN

V

UVLO

V

HYS

INPUT CURRENT

I

Q

I

STD

I

SLEEP

INTERNAL SUPPLIES

VI

NT_LDO

C

INT_LDO

V

REF

C

REF

DCDC1 (POSITIVE BOOST REGULATOR)

V

IN

PG

V

OUT

I

OUT

R

DS(ON)

I

LIMIT

f

SW

L

DCDC1

C

DCDC1

ESR Output capacitor ESR 20 mΩ

(1) Contact TI for 1-A, 2-A, or 2.5-A option.

Input voltage range 3 3.7 6 V

Undervoltage lockout threshold VINfalling 2.9 V

Undervoltage lockout hysteresis VINrising 400 mV

Operating quiescent current into VINDevice switching, no load 5.5 mA

Operating quiescent current into VINDevice in standby mode 130 µA

Shutdown current Device in sleep mode 3.5 10 µA

Internal supply 2.7 V

Nominal output capacitor Capacitor tolerance ±10% 1 4.7 µF

Internal supply 2.25 V

Nominal output capacitor Capacitor tolerance ±10% 3.3 4.7 µF

Input voltage range 3 3.7 6 V

Power good threshold Fraction of nominal output voltage 90%

Power good time-out Not tested in production 50 ms

Output voltage range 16 V

DC set tolerance –4.5% 4.5%

Output current 250 mA

MOSFET ON-resistance VIN= 3.7 V 350 mΩ

Switch current limit 1.5

(1)

Switch current accuracy –30% 30%

Switching frequency 1 MHz

Inductor 2.2 µH

Nominal output capacitor Capacitor tolerance ±10% 1 2 × 4.7 µF

A

6 Submit Documentation Feedback Copyright © 2011–2015, Texas Instruments Incorporated

Product Folder Links: TPS65186

Page 7

TPS65186

www.ti.com

SLVSB04A –JULY 2011–REVISED AUGUST 2015

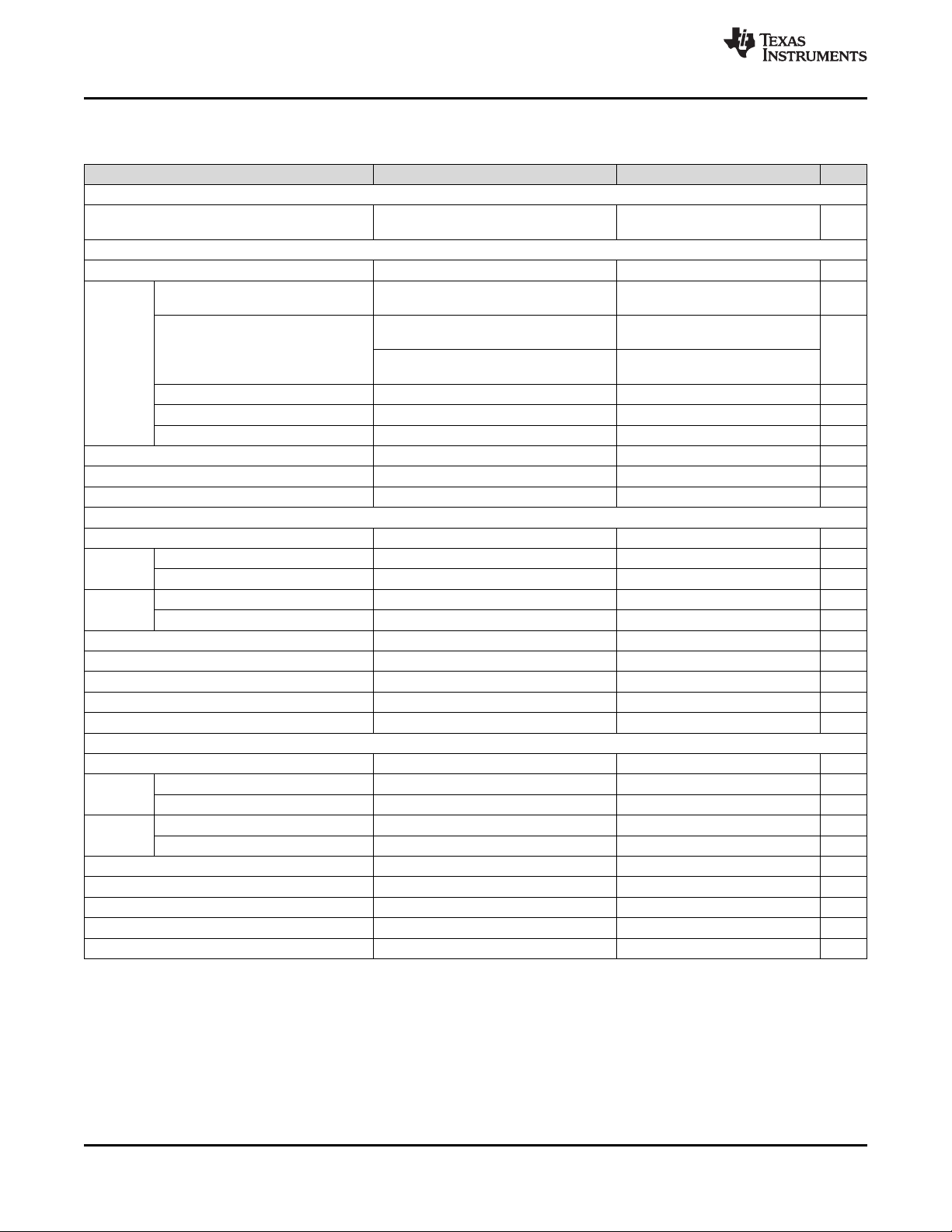

Electrical Characteristics (continued)

VIN= 3.7 V, TA= –10°C to 85ºC, Typical values are at TA= 25ºC (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

DCDC2 (INVERTING BUCK-BOOST REGULATOR)

V

IN

PG

V

OUT

I

OUT

R

DS(ON)

I

LIMIT

L

DCDC1

C

DCDC1

ESR Capacitor ESR 20 mΩ

LDO1 (VPOS)

V

POS_IN

PG

V

SET

V

INTERVAL

V

OUTTOL

V

DROPOUT

V

LOADREG

I

LOAD

I

LIMIT

C

LDO1

LDO2 (VNEG)

V

NEG_IN

PG

V

SET

V

INTERVAL

V

OUTTOL

V

DROPOUT

V

LOADREG

I

LOAD

I

LIMIT

C

LDO2

Input voltage range 3 3.7 6 V

Power good threshold Fraction of nominal output voltage 90%

Power good time-out Not tested in production 50 ms

Output voltage range –16 V

DC set tolerance –4.5% 4.5%

Output current 250 mA

MOSFET ON-resistance VIN= 3.7 V 350 mΩ

Switch current limit 1.5

(1)

Switch current accuracy –30% 30%

Inductor 4.7 µH

Nominal output capacitor Capacitor tolerance ±10% 1 3x4.7 µF

Input voltage range 15.2 16 16.8 V

Power good threshold Fraction of nominal output voltage 90%

Power good time-out Not tested in production 50 ms

Output voltage set value 14.25 15 15 V

VIN= 16 V,

VSET[2:0] = 0x3h to 0x6h

Output voltage set resolution VIN= 16 V 250 mV

Output tolerance V

Dropout voltage I

Load regulation – DC I

= 15 V, I

SET

= 120 mA 250 mV

LOAD

= 10% to 90% 1%

LOAD

= 20 mA –1% 1%

LOAD

Load current range 120 mA

Output current limit 120 mA

Nominal output capacitor Capacitor tolerance ±10% 1 4.7 µF

Input voltage range 16.8 16 –15.2 V

Power good threshold Fraction of nominal output voltage 90%

Power good time-out Not tested in production 50 ms

Output voltage set value –15 –15 –14.25 V

VIN= –16 V

VSET[2:0] = 0x3h to 0x6h

Output voltage set resolution VIN= –16 V 250 mV

Output tolerance V

Dropout voltage I

Load regulation – DC I

= –15 V, I

SET

= 120 mA 250 mV

LOAD

= 10% to 90% of I

LOAD

= –20 mA –1% 1%

LOAD

LOAD,MAX

1%

Load current range 120 mA

Output current limit 120 mA

Nominal output capacitor Capacitor tolerance ±10% 1 4.7 µF

A

Copyright © 2011–2015, Texas Instruments Incorporated Submit Documentation Feedback 7

Product Folder Links: TPS65186

Page 8

TPS65186

SLVSB04A –JULY 2011–REVISED AUGUST 2015

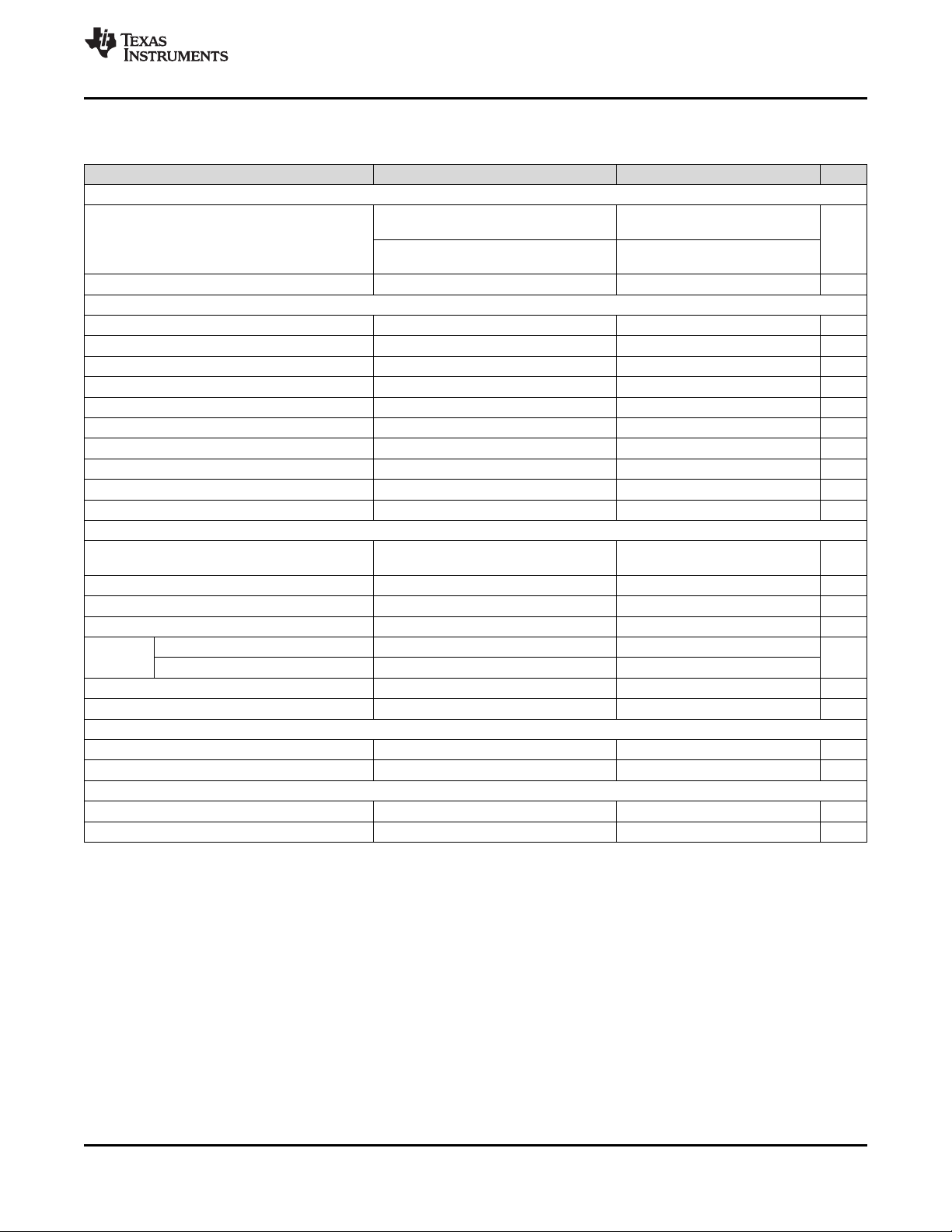

Electrical Characteristics (continued)

VIN= 3.7 V, TA= –10°C to 85ºC, Typical values are at TA= 25ºC (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

LD01 (POS) AND LDO2 (VNEG) TRACKING

V

= ±15 V,

V

DIFF

Difference between VPOS and VNEG –50 50 mV

VCOM DRIVER

I

VCOM

Drive current 15 mA

Allowed operating range –5.5 1 V

Accuracy

V

COM

Output voltage range –5.11 0 V

Resolution 1LSB 10 mV

Max number of EEPROM writes V

R

R

C

OUT

IN

VCOM

Output impedance VCOM_CTRL = high, Hi-Z = 0 5 Ω

Input impedance, HiZ state HiZ = 1 150 MΩ

Nominal output capacitor Capacitor tolerance ±10% 3.3 4.7 µF

CP1 (VDDH) CHARGE PUMP

V

DDH_IN

PG

V

FB

V

DDH_OUT

I

LOAD

f

SW

C

D

C

O

Input voltage range 15.2 16 16.8 V

Power good threshold Fraction of nominal output voltage 90%

Power good time-out Not tested in production 50 ms

Feedback voltage 0.998 V

Accuracy I

Output voltage range V

Load current range 10 mA

Switching frequency 560 kHz

Driver capacitor 10 nF

Output capacitor 1 2.2 µF

CP2 (VEE) NEGATIVE CHARGE PUMP

V

EE_IN

PG

V

FB

V

EE_OUT

I

LOAD

f

SW

C

D

C

O

Input voltage range 16.8 –16 –15.2 V

Power good threshold Fraction of nominal output voltage 90%

Power good time-out Not tested in production 50 ms

Feedback voltage –0.994 V

Accuracy I

Output voltage range V

Load current range 12 mA

Switching frequency 560 kHz

Driver capacitor 10 nF

Nominal output capacitor Capacitor tolerance ±10% 1 2.2 µF

SET

I

= ±20 mA, 0°C to 60°C

LOAD

Outside this range VCOM is shut down

and VCOMF interrupt is set

VCOM[8:0] = 0x07Dh

(–1.25 V), VIN= 3.4 V to 4.2 V, no load

VCOM[8:0] = 0x07Dh

(–1.25 V), VIN= 3 V to 6 V, no load

calibration 100

COM

= 2 mA –2% 2%

LOAD

= 22 V, I

SET

= 2 mA –2% 2%

LOAD

= –20 V, I

SET

= 2 mA 21 22 23 V

LOAD

= 3 mA –21 –20 –19 V

LOAD

www.ti.com

–0.8% 0.8%

–1.5% 1.5%

8 Submit Documentation Feedback Copyright © 2011–2015, Texas Instruments Incorporated

Product Folder Links: TPS65186

Page 9

TPS65186

www.ti.com

SLVSB04A –JULY 2011–REVISED AUGUST 2015

Electrical Characteristics (continued)

VIN= 3.7 V, TA= –10°C to 85ºC, Typical values are at TA= 25ºC (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

VIN3P3 TO V3P3 SWITCH

VIN3P3 = 3.3 V, ID= 10 mA

R

DS(ON)

MOSFET ON-resistance Ω

Over full temperature range

VIN3P3 = 2.7 V, ID= 10 mA

Over full temperature range

R

DIS

THERMISTOR MONITOR

A

TMS

Offset

V

TMS_HOT

V

TMS_COOL

V

TMS_MAX

R

NTC_PU

R

LINEAR

ADC

ADC

TMST

Discharge impedance to ground V3P3EN = 0 800 1000 1200 Ω

(2)

Temperature to voltage ratio Not tested in production –0.0161 V/°C

Offset Temperature = 0°C 1.575 V

TMS

Temp hot trip voltage (T = 50°C) TEMP_HOT_SET = 0x8C 0.768 V

Temp hot escape voltage (T = 45°C) TEMP_COOL_SET = 0x82 0.845 V

Maximum input level 2.25 V

Internal pullup resistor 7.307 kΩ

External linearization resistor 43 kΩ

ADC resolution Not tested in production, 1 bit 16.1 mV

RES

ADC conversion time Not tested in production 19 µs

DEL

Accuracy Not tested in production –1 1 LSB

TOL

LOGIC LEVELS AND TIMING CHARTERISTICS (SCL, SDA, nINT, PWR_GOOD, PWRUP)

V

OL

V

IL

V

IH

I

(bias)

t

deglitch

f

SCL

Output low threshold level 0.4 V

Input low threshold level 0.4 V

Input high threshold level 1.2 V

Input bias current VIO= 1.8 V 1 µA

Deglitch time, WAKEUP pin Not tested in production 500

Deglitch time, PWRUP pin Not tested in production 400

SCL clock frequency 400 kHz

IO= 3 mA, sink current

(SDA, nINT, PWR_GOOD)

I2C slave address 7-bit address 0 × 48h

OSCILLATOR

f

OSC

Oscillator frequency 9 MHz

Frequency accuracy TA= –40°C to 85°C –10% 10%

THERMAL SHUTDOWN

T

SHTDWN

Thermal trip point 150 °C

Thermal hysteresis 20 °C

(2) 10-kΩ Murata NCP18XH103F03RB thermistor (1%) in parallel with a linearization resistor (43 kΩ, 1%) are used at TS pin for panel

temperature measurement.

(3) Contact TI for alternate address of 0 × 68h.

10.5

12.3

(3)

µs

Copyright © 2011–2015, Texas Instruments Incorporated Submit Documentation Feedback 9

Product Folder Links: TPS65186

Page 10

t

f

t

HD;STA

t

LOW

t

r

t

HD;DAT

t

SU;DAT

t

HIGH

t

SU;STA

t

HD;STA

t

SP

t

SU;STO

t

r

t

BUF

t

f

S S

r

SP

SDA

SCL

TPS65186

SLVSB04A –JULY 2011–REVISED AUGUST 2015

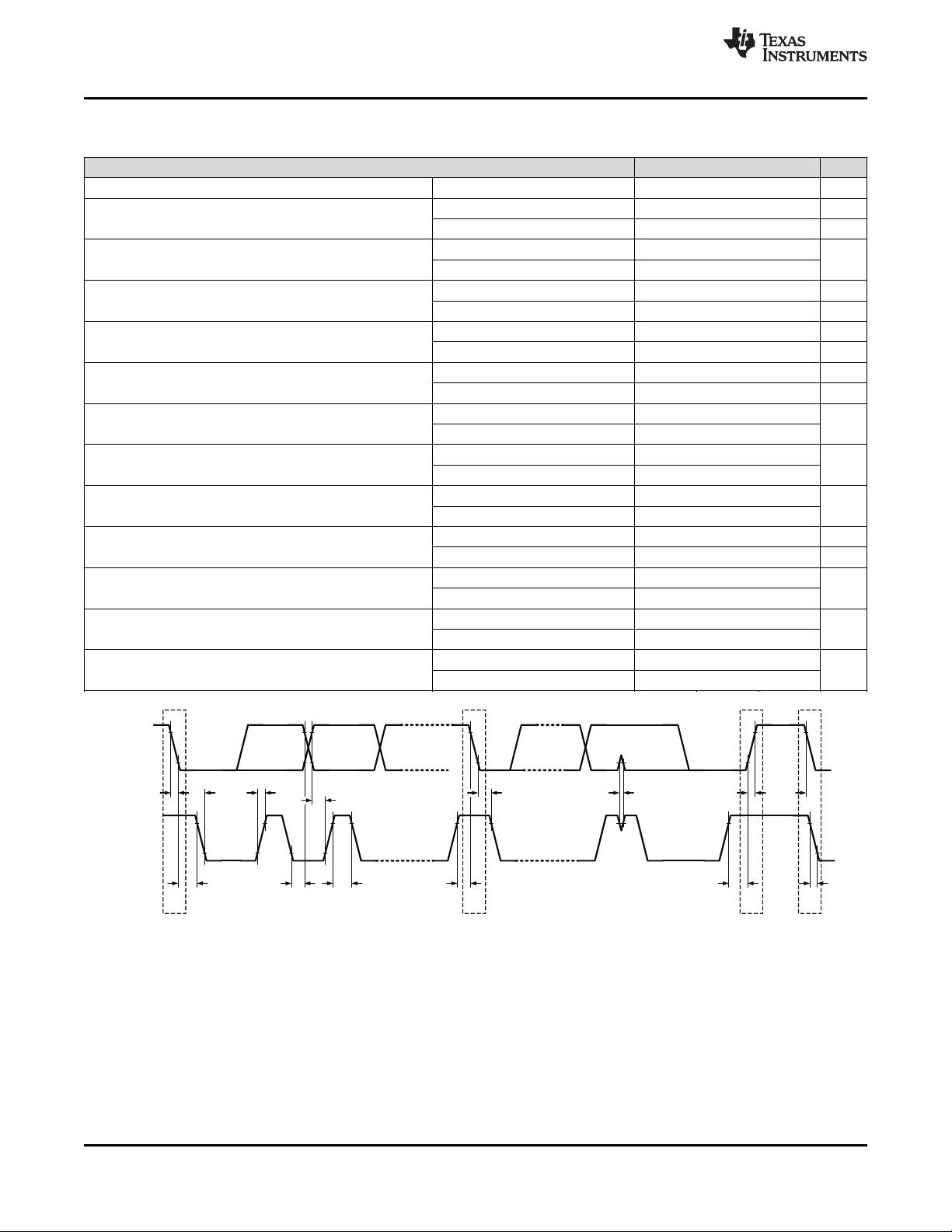

7.6 Timing Requirements: Data Transmission

V

= 3.6 V ±5%, TA= 25ºC, CL= 100 pF (unless otherwise noted)

BAT

f

(SCL)

t

HD;STA

t

LOW

t

HIGH

t

SU;STA

t

HD;DAT

t

SU;DAT

t

r

t

f

t

SU;STO

t

BUF

t

SP

C

b

Serial clock frequency 100 400 kHz

Hold time (repeated) START condition. After this

period, the first clock pulse is generated.

LOW period of the SCL clock µs

HIGH period of the SCL clock

Setup time for a repeated START condition

Data hold time

Data setup time ns

Rise time of both SDA and SCL signals ns

Fall time of both SDA and SCL signals ns

Setup time for STOP condition

Bus Free Time Between Stop and Start Condition µs

Pulse width of spikes that must be suppressed by

the input filter

Capacitive load for each bus line pF

SCL = 100 kHz 4 µs

SCL = 400 kHz 600 ns

SCL = 100 kHz 4.7

SCL = 400 kHz 1.3

SCL = 100 kHz 4 µs

SCL = 400 kHz 600 ns

SCL = 100 kHz 4.7 µs

SCL = 400 kHz 600 ns

SCL = 100 kHz 0 3.45 µs

SCL = 400 kHz 0 900 ns

SCL = 100 kHz 250

SCL = 400 kHz 100

SCL = 100 kHz 1000

SCL = 400 kHz 300

SCL = 100 kHz 300

SCL = 400 kHz 300

SCL = 100 kHz 4 µs

SCL = 400 kHz 600 ns

SCL = 100 kHz 4.7

SCL = 400 kHz 1.3

SCL = 100 kHz n/a n/a

SCL = 400 kHz 0 50

SCL = 100 kHz 400

SCL = 400 kHz 400

www.ti.com

MIN NOM MAX UNIT

ns

Figure 1. I2C Data Transmission Timing

10 Submit Documentation Feedback Copyright © 2011–2015, Texas Instruments Incorporated

Product Folder Links: TPS65186

Page 11

VIN

PWRUP

WAKEUP

VNEG

VEE

VPOS

VDDH

PWR _GOOD

VN

VB

1.8ms

DDLY2

DDLY3

DDLY4

DDLY1

300us max)(

STANDBY ACTIVE

SLEEP

ACTIVE

UDLY2

UDLY3

UDLY1

UDLY4

I2C

300us max)(

UDLY2

UDLY1

UDLY4

UDLY3

50ms

www.ti.com

TPS65186

SLVSB04A –JULY 2011–REVISED AUGUST 2015

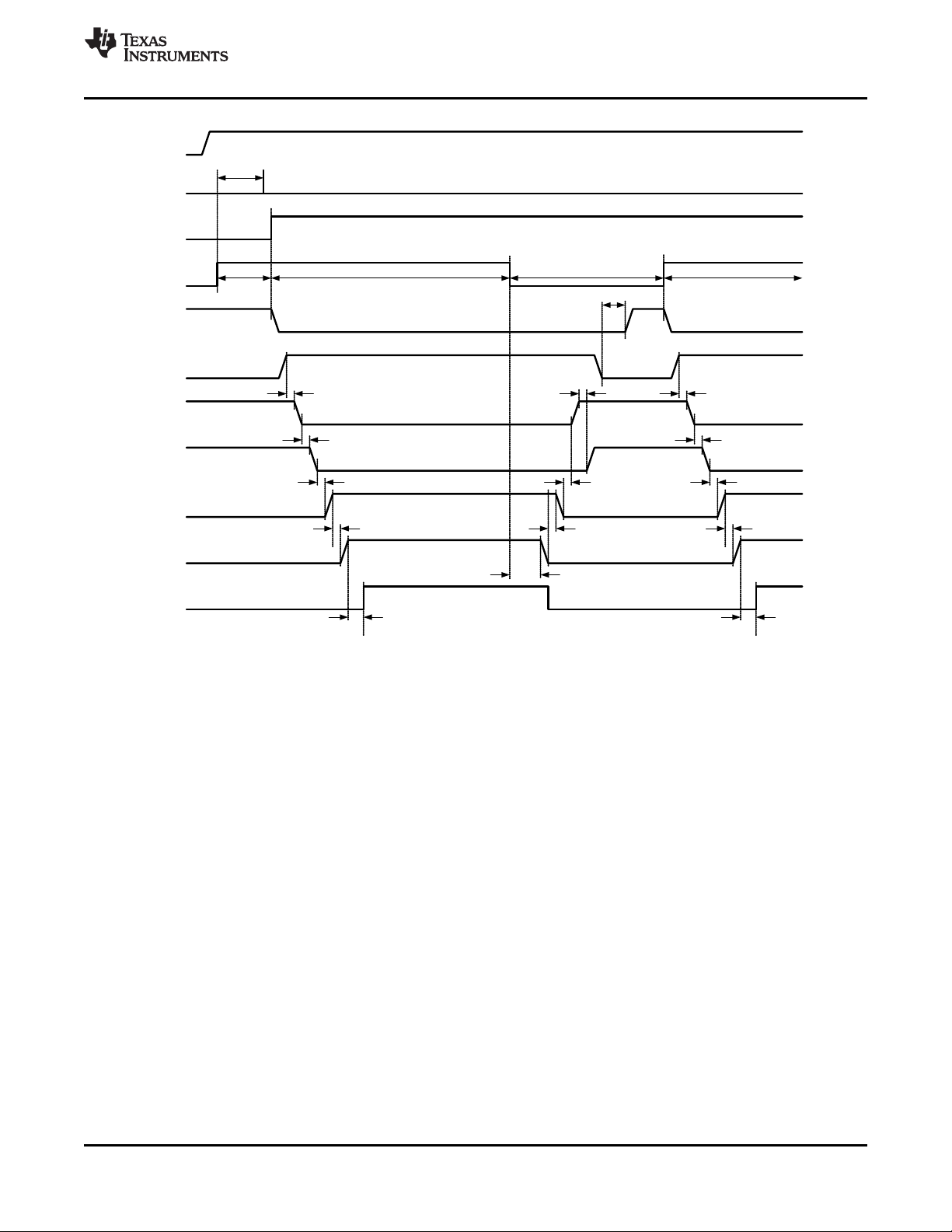

Minimum delay time between WAKEUP rising edge and IC ready to accept I2C transaction.

In this example, the first power-up sequence is started by pulling the PWRUP pin high (rising edge). Power-down is

initiated by pulling the WAKEUP pin low (device enters sleep mode). The second power-up sequence is initiated by

pulling the WAKEUP pin high while the PWRUP pin is also high (power up from sleep to active).

Figure 2. Power-Up and Power-Down Timing Diagram

Copyright © 2011–2015, Texas Instruments Incorporated Submit Documentation Feedback 11

Product Folder Links: TPS65186

Page 12

TPS65186

SLVSB04A –JULY 2011–REVISED AUGUST 2015

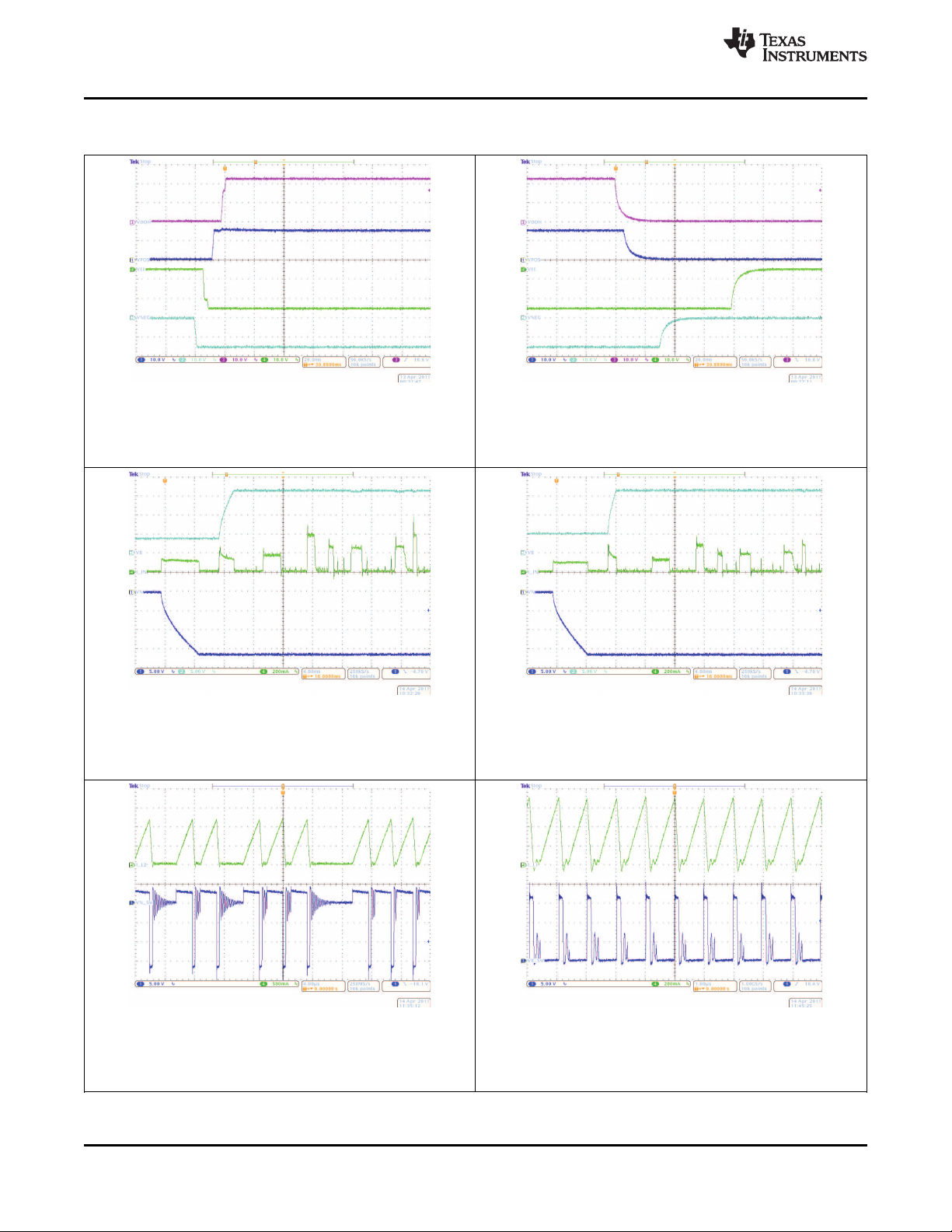

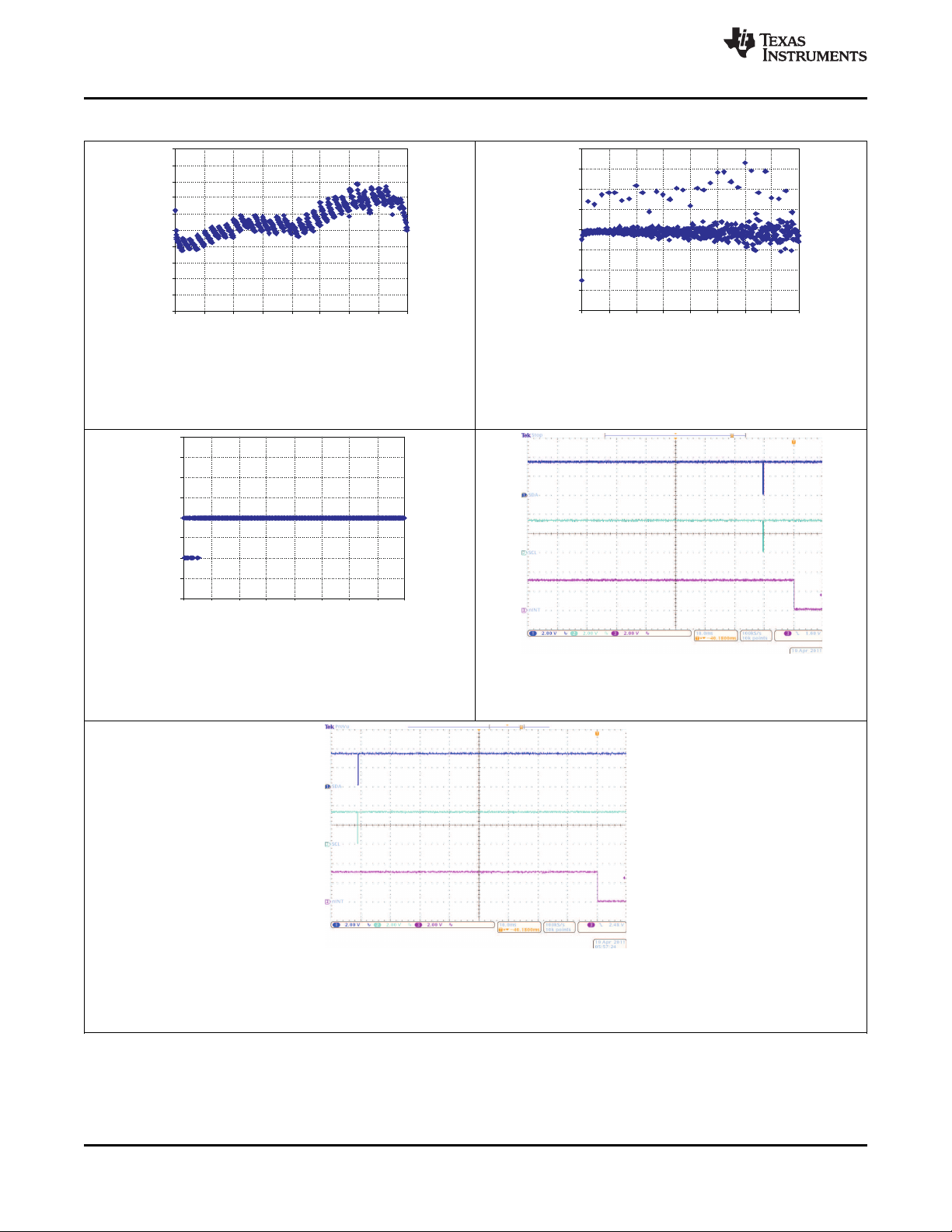

7.7 Typical Characteristics

Figure 3. Default Power-Up Sequence Figure 4. Default Power-Down Sequence

www.ti.com

VIN= 3.7 V CIN= 100 µF VIN= 5 V CIN= 100 µF

Figure 5. Inrush Current Figure 6. Inrush Current

VIN= 3 V R

LOAD, VPOS

= 330 Ω R

LOAD, VNEG

= 330 Ω VIN= 3 V R

LOAD, VPOS

= 330 Ω R

No Load on VDDH, VEE No Load on VDDH, VEE

Figure 7. Switching Waveforms, VN Figure 8. Switching Waveforms, VB

LOAD, VNEG

= 330 Ω

12 Submit Documentation Feedback Copyright © 2011–2015, Texas Instruments Incorporated

Product Folder Links: TPS65186

Page 13

-5 0

-4 0

-3 0

-2 0

-1 0

0

1 0

2 0

3 0

4 0

5 0

0 25 50 75 100 12 5 1 50 1 75

C urr e nt [ m A]

VPOS + VNEG[mV]

IPO S= INEG

IPO S s we ep, INE G= 15m A

IPO S= 15m A, IN EG s wee p

0

5

10

15

20

25

1 1.5 2 2.5 3 3.5 4

VIN3P3[V]

R[ ], (VIN3p3-V3P3)/10mAW

www.ti.com

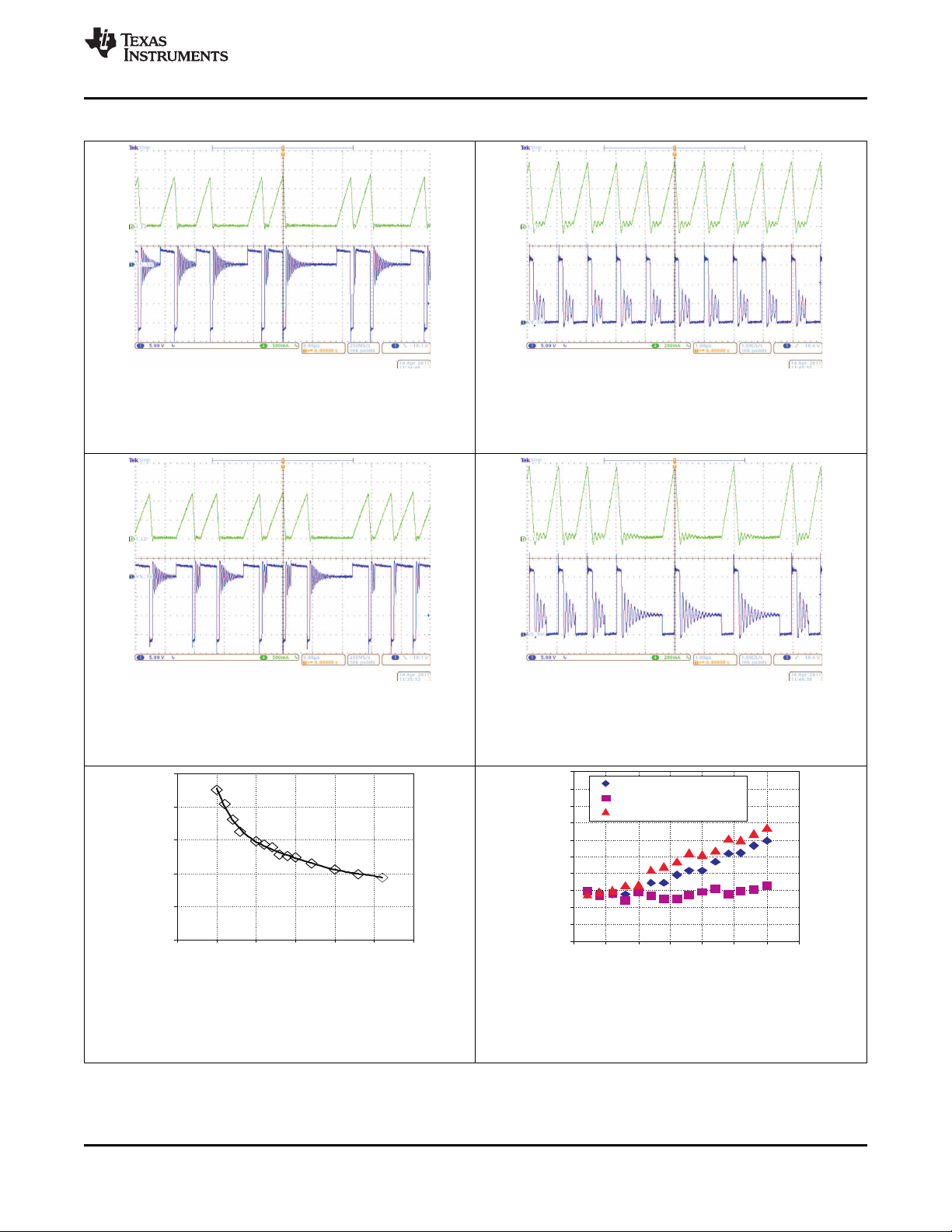

Typical Characteristics (continued)

TPS65186

SLVSB04A –JULY 2011–REVISED AUGUST 2015

VIN= 3.7 V R

No Load on VDDH, VEE No Load on VDDH, VEE

Figure 9. Switching Waveforms, VN Figure 10. Switching Waveforms, VB

VIN= 5 V R

No Load on VDDH, VEE No Load on VDDH, VEE

Figure 11. Switching Waveforms, VN Figure 12. Switching Waveforms, VB

LOAD, VPOS

LOAD, VPOS

= 330 Ω R

= 330 Ω R

LOAD, VNEG

LOAD, VNEG

= 330 Ω VIN= 3.7 V R

= 330 Ω VIN= 5 V R

LOAD, VPOS

LOAD, VPOS

= 330 Ω R

= 330 Ω R

LOAD, VNEG

LOAD, VNEG

= 330 Ω

= 330 Ω

VIN= 3.7 V I

Copyright © 2011–2015, Texas Instruments Incorporated Submit Documentation Feedback 13

Figure 13. 3p3V Switch Impedance

LOAD, V3p3

= 10 mA

VIN= 3.7 V

Figure 14. Source Driver Supply Tracking

Product Folder Links: TPS65186

Page 14

-2

-1. 5

-1

-0. 5

0

0. 5

1

1. 5

2

0 640 12 80 192 0 25 60 3200 3840 44 80 512 0

Fo rce d Ki ckba c k V ol tag e [m V]

Measurement error [LSB]

-5

-4

-3

-2

-1

0

1

2

3

4

5

0 64 128 192 25 6 320 38 4 44 8 51 2

VC OM CO DE

INL[mV]

-0. 2

-0 .15

-0. 1

-0 .05

0

0 .05

0. 1

0 .15

0. 2

0 6 4 12 8 1 92 2 56 3 20 38 4 4 48 51 2

V COM CO DE

DNL[LSB]

TPS65186

SLVSB04A –JULY 2011–REVISED AUGUST 2015

Typical Characteristics (continued)

www.ti.com

VIN= 3.7 V R

LOAD, VCOM

= 1 kΩ VIN= 3.7 V R

LOAD, VCOM

= 1 kΩ

Figure 15. VCOM Integrated Non-Linearity Figure 16. VCOM Differential Non-Linearity

VIN= 3.7 V

VIN= 3.7 V AVG[1:0] = 00 (Single Measurement)

Time from ACQ Bit Set to ACQC Interrupt Received

Figure 17. Kickback Voltage Measurement Error

Figure 18. Kickback Voltage Measurement Timing

14 Submit Documentation Feedback Copyright © 2011–2015, Texas Instruments Incorporated

VIN= 3.7 V AVG[1:0] = 11 (Eight Measurements)

Time from ACQ Bit Set to ACQC Interrupt Received

Figure 19. Kickback Voltage Measurement Timing

Product Folder Links: TPS65186

Page 15

TPS65186

www.ti.com

SLVSB04A –JULY 2011–REVISED AUGUST 2015

8 Detailed Description

8.1 Overview

The TPS65186 device provides two adjustable LDOs, inverting buck-boost converter, boost converter, thermistor

monitoring, and flexible power-up and power-down sequencing. The system can be supplied by a regulated input

voltage ranging from 3 V to 6 V. The device is characterized across a –10°C to 85°C temperature range, best

suited for personal electronic applications.

The I2C interface provides comprehensive features for using the TPS65186. All rails can be enabled or disabled.

Power-up and power-down sequences can also be programmed through the I2C interface, as well as thermistor

configuration and interrupt configuration. Voltage adjustment can also be controlled by the I2C interface.

The adjustable LDOs can supply up to 120 mA of current. The default output voltages for each LDO can be

adjusted through the I2C interface. LDO1 (VPOS) and LDO2 (VNEG) track each other in a way that they are of

opposite sign but same magnitude. The sum of VLDO1 and VLOD2 is guaranteed to be less than 50 mV.

There are two charge pumps: VDDH and VEE 10 mA and 12 mA respectively. These charge pumps boost the

DC-DC boost converters ±16-V rails to provide a gate channel supply.

The power good functionality is open-drain output, if any of the four power rails (CP1, CP2, LDO1, LDO2) are not

in regulation, encounters a fault, or is disabled the pin is pulled low. PWR_GOOD remains low if one of the rails

is not enabled by the host and only after all rails are in regulation PWR_GOOD is released to Hi-Z state (pulled

up by external resistor).

The TPS65186 provides circuitry to bias and measure an external NTC to monitor the display panel temperature

in a range from –10°C to 85°C with and accuracy of ±1°C from 0°C to 50°C. Temperature measurement are

triggered by the controlling host and the last temperature reading is always stored in the TMST_VALUE register.

Interrupts are issued when the temperature exceeds the programmable HOT, or drops below the programmable

COLD threshold, or when the temperature has changed by more than a user-defined threshold from the baseline

value.

This device is offered in a 48-Pin, 0.5-mm Pitch, 7 mm × 7 mm × 0.9 mm (VQFN) RGZ package.

Copyright © 2011–2015, Texas Instruments Incorporated Submit Documentation Feedback 15

Product Folder Links: TPS65186

Page 16

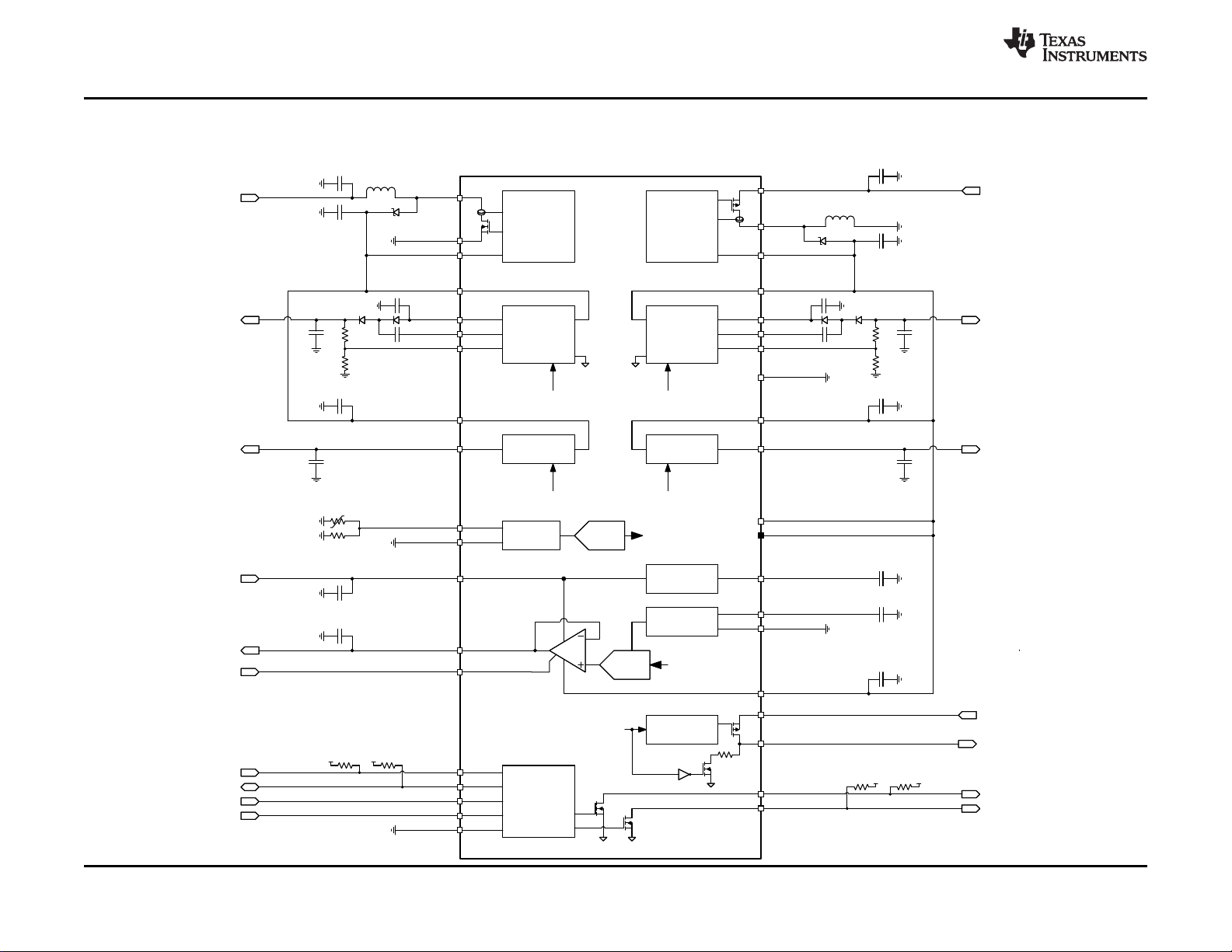

DCDC2

VIN_P

10uF

4.7uF

VPOS

10nF 2.2uF

1M

52.3k

VEE_D

VEE_DRV

VEE_FB

4.7uH

VN_SW

From Battery

(3.0V-6. 0V)

VEE (-20V)

VPOS (15V )

DCDC1

4.7uF

2.2uH

PGND1

VB_SW

10uF

10nF2.2uF

1M

47.5k

VDDH_D

VDDH_DRV

VDDH_FB

From Battery

(3.0V-6.0V )

VDDH (22 V)

VDDH_EN VEE_EN

PGND2 PGND2

VPOS_EN

VB

LDO1

VEE

CHARGE

PUMP

VN

PBKG

PGND2

4.7uF

VNEG_IN

VDDH_IN

VNEG

VNEG (-15V )

VNEG_EN

LDO2

PowerPad®

TEMP

SENSOR

43k

10k NTC

TS

AGND2 ADC

TMST_VALUE[7:0]

4.7uF

4.7uF

VPOS_IN

VIN

10uF

VCOM_PWR

4.7uF

From Input Supply

(3.0V-6. 0V)

4.7uF

VREF

AGND1

DAC

VCOM

VCOM[8:0]

VCOM_CTRL

4.7uF

From uC

VREF

4.7uF

INT_LDO

INT_LDO

VEE_IN

VDDH

CHARGE

PUMP

4.7uF

3.3V supply from system

To EPD panel

VIN3P3

V3P3

GATE DRIVER

V3P3_EN

1k

SCL

From uC

From/to uC or DSP

SDA

10k

VIO

PWR_GOOD

10k

VIO

DIGITAL

CORE

WAKEUP

INT

10k

VIO

10k

VIO

From uC

PWRUP

From uC

To uC

To uC

DGND

100n 100n

To panel back- plane

(0 to -5.11 V)

TPS65186

SLVSB04A –JULY 2011–REVISED AUGUST 2015

8.2 Functional Block Diagram

www.ti.com

16 Submit Documentation Feedback Copyright © 2011–2015, Texas Instruments Incorporated

Product Folder Links: TPS65186

Page 17

TPS65186

www.ti.com

SLVSB04A –JULY 2011–REVISED AUGUST 2015

8.3 Feature Description

8.3.1 Wake-Up and Power-Up Sequencing

The power-up and power-down order and timing is defined by user register settings. The default settings support

the E Ink Vizplex panel and typically do not need to be changed.

In SLEEP mode the TPS65186 is completely turned off, the I2C registers are reset, and the device does not

accept any I2C transaction. Pull the WAKEUP pin high with the PWRUP pin low and the device enters STANDBY

mode that enables the I2C interface. Write to the UPSEQ0 register to define the order in which the output rails

are enabled at power-up and to the UPSEQ1 registers to define the power-up delays between rails. Finally, set

the ACTIVE bit in the ENABLE register to 1 to execute the power-up sequence and bring up all power rails.

Alternatively, pull the PWRUP pin high (rising edge).

After the ACTIVE bit has been set, the negative boost converter (VN) is powered up first, followed by the positive

boost (VB). The positive boost enable is gated by the internal power-good signal of the negative boost. Once VB

is in regulation, it issues an internal power-good signal and after delay time UDLY1 has expired, STROBE1 is

issued. The rail assigned to STROBE1 will power up next and after its power-good signal has been asserted and

delay time UDLY2 has expired, STROBE2 is issued. The sequence continues until STROBE4 has occurred and

the last rail has been enabled.

To power down the device, set the STANDBY bit of the ENABLE register to 1 or pull the PWRUP pin low (falling

edge) and the TPS65186 will power down in the order defined by DWNSEQx registers. The delay times DDLY2,

DDLY3, and DDLY4 are weighted by a factor of DFCTR which allows the user to space out the power down of

the rails to avoid crossing during discharge. DFCTR is located in register DWNSEQ1. The positive boost (VB) is

shut down together with the last rail at STROBE4. However, the negative boost (VN) remains up and running for

another 50 ms. Then VN is powered down and the device enters STANDBY or SLEEP mode, depending on the

WAKEUP pin.

If either the ACTIVE bit is set or the PWRUP pin is pulled high while the device is powering down, the powerdown sequence (STROBE1-4) is completed first, followed by a power-up sequence. VB and VN may or may not

be powered down and depending on the relative timing of STROBE4 to the new power-up event.

During power-up, if the STANDBY bit is set or the PWRUP pin is pulled low, the power-up sequence is aborted

and the power-down sequence starts immediately.

8.3.2 Dependencies Between Rails

Charge pumps, LDOs, and VCOM driver are dependent on the positive and inverting buck-boost converters and

several dependencies exist that affect the power-up sequencing. These dependencies are the following:

• Inverting buck-boost (DCDC2) must be in regulation before positive boost (DCDC1) can be enabled.

Internally, DCDC1 enable is gated by DCDC2 power good.

• Positive boost (DCDC1) must be in regulation before LDO2 (VNEG) can be enabled. Internally LDO2 enable

is gated DCDC1 power good.

• Positive boost (DCDC1) must be in regulation before VCOM can be enabled. Internally VCOM enable is

gated by DCDC1 power good.

• Positive boost (DCDC1) must be in regulation before negative charge pump (CP2) can be enabled. Internally

CP2 enable is gated by DCDC1 power good.

• Positive boost (DCDC1) must be in regulation before positive charge pump (CP1) can be enabled. Internally

CP1 enable is gated by DCDC1 power good.

• LDO2 must be in regulation before LDO1 can be enabled. Internally LDO1 enable is gated by LDO2 power

good.

Copyright © 2011–2015, Texas Instruments Incorporated Submit Documentation Feedback 17

Product Folder Links: TPS65186

Page 18

UDLY1

ACTIVE bit

or

WAKEUP high

VN PG VB PG

UDLY2

STROBE 1 STROBE 2

UDLY3

STROBE 3

UDLY4

STROBE 4

PG4

STANDBY bit

or

WAKEUP low

STROBE 2STROBE 1

DDLY1 DDLY2 DDLY3

STROBE 3 STROBE 4

DDLY4

50ms

VB

powers up

1strail

powers up

2ndrail

powers up

3ndrail

powers up

4thrail

powers up

4thrail

powers down

3ndrail

powers down

2ndrail

powers down

1strail

powers down

VB

powers down

VN

powers down

VN

powers up

TPS65186

SLVSB04A –JULY 2011–REVISED AUGUST 2015

Feature Description (continued)

www.ti.com

8.3.3 Soft Start

TPS65186 supports soft start for all rails, that is, inrush current is limited during startup of DCDC1, DCDC2,

LDO1, LDO2, CP1, and CP2. If DCDC1 or DCDC2 are unable to reach power-good status within 50 ms, the

corresponding UV flag is set in the interrupt registers, the interrupt pin is pulled low, and the device enters

STANDBY mode. LDO1, LDO2, positive and negative charge pumps also have a 50-ms power-good time-out

limit. If either rail is unable to power up within 50 ms after it has been enabled, the corresponding UV flag is set

and the interrupt pin is pulled low. However, the device will remain in ACTIVE mode in this case.

8.3.4 VPOS/VNEG Supply Tracking

LDO1 (VPOS) and LDO2 (VNEG) track each other in a way that they are of opposite sign but same magnitude.

The sum of VLDO1 and VLOD2 is guaranteed to be less than 50 mV.

TOP: Power-up sequence is defined by assigning strobes to individual rails. STROBE1 is the first strobe to occur after

ACTIVE bit is set and STROBE4 is the last event in the sequence. Strobes are assigned to rails in UPSEQ0 register

and delays between STROBES are defined in UPSEQ1 register.

BOTTOM: Power-down sequence is independent of power-up sequence. Strobes and delay times for power down

sequence are set in DWNSEQ0 and DWNSEQ1 register.

Figure 20. Power-Up and Power-Down Sequence

18 Submit Documentation Feedback Copyright © 2011–2015, Texas Instruments Incorporated

Product Folder Links: TPS65186

Page 19

VIN

10uF

VCOM_PWR

4.7uF

To panel back-plane

(-0.5 V to -5.0 V, 15 mA)

From Input Supply

(3.0 V-6.0 V)

4.7uF

VREF

AGND1

DAC

VCOM

VCOM[8:0]

VCOM_CTRL

4.7uF

From uC

VREF

4.7uF

INT_LDO

INT_LDO

From VN (-17V)

TPS65186

www.ti.com

SLVSB04A –JULY 2011–REVISED AUGUST 2015

Feature Description (continued)

8.3.5 V3P3 Power Switch

The integrated power switch is used to cut the 3.3-V supply to the EPD panel and is controlled through the

V3P3_EN pin of the ENABLE register. In SLEEP mode the switch is automatically turned off and its output is

discharged to ground. The default power-up state is OFF. To turn the switch ON, set the V3P3_ENbit to 1.

8.3.6 VCOM Adjustment

VCOM is the output of a power-amplifier with an output voltage range of 0 V to –5.11 V, adjustable in 10-mV

steps. In a typical application VCOM is connected to the VCOM terminal of the EPD panel and the amplifier is

controlled through the VCOM_CTRL pin. With VCOM_CTRL high, the amplifier drives the VCOM pin to the

voltage specified by the VCOM1 and VCOM2 register.

For ease of design, the VCOM_CTRL pin may also be tied to the battery or IO supply. In this case, VCOM is

enabled with STROBE4 during the power-up sequence and disabled on STROBE1 of the power-down sequence.

Therefore VCOM is the last rail to be enabled and the first to be disabled.

8.3.6.1 Kick-Back Voltage Measurement

TPS65186 can perform a voltage measurement on the VCOM pin to deter87/mine the kick-back voltage of the

panel. This allows in-system calibration of VCOM. To perform a kick-back voltage measurement, follow these

steps:

• Pull the WAKEUP pin and the PWRUP pin high to enable all output rails.

• Set the Hi-Z bit in the VCOM2 register. This puts the VCOM pin in a high-impedance state.

• Drive the panel with the Null waveform. Refer to E-Ink specification for detail.

• Set the ACQ bit in the VCOM2 register to 1. This starts the measurement routine.

• When the measurement is complete, the ACQC (Acquisition Complete) bit in the INT1 register is set and the

nINT pin is pulled low.

• The measurement result is stored in the VCOM[8:0] bits of the VCOM1 and VCOM2 register.

The measurement result is not automatically programmed into nonvolatile memory. Changing the power-up

default is described in Storing the VCOM Power-Up Default Value in Memory.

8.3.6.2 Storing the VCOM Power-Up Default Value in Memory

The power-up default value of VCOM can be user-set and programmed into nonvolatile memory. To do so, write

the default value to the VCOM[8:0] bits of the VCOM1 and VCOM2 register, then set the PROG bit in VCOM2

register to 1. First, all power rails are shut down, then the VCOM[8:0] value is committed to nonvolatile memory

such that it becomes the new power-up default. Once programming is complete, the PRGC bit in the INT1

register is set and the nINT pin is pulled low. To verify that the new value has been saved properly, first write the

VCOM[8:0] bits to 0x000h, then pull the WAKEUP pin low. After the WAKEUP pin is pulled back high, read the

VCOM[8:0] bits to verify that the new default value is correct.

Copyright © 2011–2015, Texas Instruments Incorporated Submit Documentation Feedback 19

Figure 21. Block Diagram of VCOM Circuit

Product Folder Links: TPS65186

Page 20

Pull WAKEUP= HIGH

Pull PWRUP= HIGH

Write HiZ = 1

Device enters ACTIVE mode

All power rails are up except VCOM

VCOM pin is in HiZ state

Processor drives panel with NULL waveform

Write ACQ = 1 Starts A/D conversion

Wait for ACQC interrupt

Indicates A/D conversion is complete

If AVG[1:0] is <> 00, interrupt is issed

after all conversions are complete and

average has been calcutated.

Read result from VCOM1/2

registers

Pull PWRUP= LOW

Write HiZ = 0

Check result and decide to keep the

value or repeat measurment.

Device enters STANDBY mode

Write PROG= 1

Starts the EEPROM programming cycle.

Power must not be interrupted.

Wait for PRGC interrupt Indicates programming is complete

Pull WAKEUP= LOW Device enters SLEEP mode

Pull WAKEUP= HIGH Device enters STANDBY mode

Read VCOM[8:0]

Compare against written value to

confirm new default has been

programmed correctly.

SETUP

MEASUREMENT

PROGRAMMING

VERIFICATION

TPS65186

SLVSB04A –JULY 2011–REVISED AUGUST 2015

Feature Description (continued)

www.ti.com

Figure 22. VCOM Calibration Flow

20 Submit Documentation Feedback Copyright © 2011–2015, Texas Instruments Incorporated

Product Folder Links: TPS65186

Page 21

TPS65186

www.ti.com

SLVSB04A –JULY 2011–REVISED AUGUST 2015

Feature Description (continued)

8.3.7 Fault Handling and Recovery

The TPS65186 monitors input/output voltages and die temperature; the device will take action if operating

conditions are outside normal limits when the following are encountered:

• Thermal Shutdown (TSD)

• Positive Boost Undervoltage (VB_UV)

• Inverting Buck-Boost Undervoltage (VN_UV)

• Input Undervoltage Lockout (UVLO)

The TPS65186 shuts down all power rails and enters STANDBY mode. Shutdown follows the order defined by

DWNSEQx registers. The exception is VCOM fault witch leads to immediate shutdown of all rails. Once a fault is

detected, the PWR_GOOD and nINT pins are pulled low and the corresponding interrupt bit is set in the interrupt

register. Power rails cannot be re-enabled unless the interrupt bits have been cleared by reading the INT1 and

INT2 register. Alternatively, toggling the WAKEUP pin also resets the interrupt bits. As the PWRUP input is edge

sensitive, the host must toggle the PWRUP pin to re-enable the rails through GPIO control, that is, it must bring

the PWRUP pin low before asserting it again. Alternatively rails can be re-enbled through the I2C interface.

Whenever the TPS65186 encounters undervoltage on VNEG (VNEG_UV), VPOS (VPOS_UV), VEE (VEE_UV),

or VDDH (VDDH_UV), rails are not shut down but the PWR_GOOD and nINT is pulled low with the

corresponding interrupt bit set. The device remains in ACTIVE mode and recovers automatically once the fault

has been removed.

8.3.8 Power Good Pin

The power good pin (PWR_GOOD) is an open-drain output that is pulled high (by an external pullup resistor)

when all four power rails (CP1, CP2, LDO1, LDO2) are in regulation and is pulled low if any of the rails

encounters a fault or is disabled. PWR_GOOD remains low if one of the rails is not enabled by the host and only

after all rails are in regulation PWR_GOOD is released to Hi-Z state (pulled up by external resistor).

8.3.9 Interrupt Pin

The interrupt pin (nINT) is an open-drain output that is pulled low whenever one or more of the INT1 or INT2 bits

are set. The nINT pin is released (returns to Hi-Z state) and fault bits are cleared once the register with the set bit

has been read by the host. If the fault persists, the nINT pin will be pulled low again after a maximum of 32 µs.

Interrupt events can be masked by re-setting the corresponding enable bit in the INT_EN1 and INT_EN2 register,

that is, the user can determine which events cause the nINT pin to be pulled low. The status of the enable bits

affects the nINT pin only and has no effect on any of the protection and monitoring circuits or the INT1/INT2 bits

themselves.

Persisting faults such as thermal shutdown can cause the nINT pin to be pulled low for an extended period of

time which can keep the host in a loop trying to resolve the interrupt. If this behavior is not desired, set the

corresponding mask bit after receiving the interrupt and keep polling the INT1/INT2 register to see when the fault

condition has disappeared. After the fault is resolved, unmask the interrupt bit again.

8.3.10 Panel Temperature Monitoring

The TPS65186 provides circuitry to bias and measure an external Negative Temperature Coefficient Resistor

(NTC) to monitor the display panel temperature in a range from –10°C to 85°C with and accuracy of ±1°C from

0°C to 50°C. Temperature measurement must be triggered by the controlling host and the last temperature

reading is always stored in the TMST_VALUE register. Interrupts are issued when the temperature exceeds the

programmable HOT, or drops below the programmable COLD threshold, or when the temperature has changed

by more than a user-defined threshold from the baseline value. Details are explained under Hot, Cold, and

Temperature-Change Interrupts.

Copyright © 2011–2015, Texas Instruments Incorporated Submit Documentation Feedback 21

Product Folder Links: TPS65186

Page 22

7.307k

2.25V

43k 10k NTC

10

ADCDigital

TS

AGND2

TPS65186

SLVSB04A –JULY 2011–REVISED AUGUST 2015

www.ti.com

Feature Description (continued)

8.3.10.1 NTC Bias Circuit

Figure 23 shows the block diagram of the NTC bias and measurement circuit. The NTC is biased from an

internally generated 2.25-V reference voltage through an integrated 7.307-kΩ bias resistor. A 43-kΩ resistor is

connected parallel to the NTC to linearize the temperature response curve. The circuit is designed to work with a

nominal 10-kΩ NTC and achieves accuracy of ±1°C from 0°C to 50°C. The voltage drop across the NTC is

digitized by a 10-bit SAR ADC and translated into an 8-bit two’s complement by digital per Table 1.

Table 1. ADC Output Value vs Temperature

TEMPERATURE TMST_VALUE[7:0]

< –10°C 1111 0110

–10°C 1111 0110

–9°C 1111 0111

... ...

–2°C 1111 1110

–1°C 1111 1111

0°C 0000 0000

1°C 0000 0001

2°C 0000 0010

... ...

25°C 0001 1001

...

85°C 0101 0101

> 85°C 0101 0101

Figure 23. NTC Bias and Measurement Circuit

A temperature measurement is triggered by setting the READ_THERM bit of the TMST1 register to 1.During the

A/D conversion the CONV_END bit of the TMST1 register reads 0, otherwise it reads 1. At the end of the A/D

conversion the EOC bit in the INT2 register is set and the temperature value is available in the TMST_VALUE

register.

22 Submit Documentation Feedback Copyright © 2011–2015, Texas Instruments Incorporated

Product Folder Links: TPS65186

Page 23

TPS65186

www.ti.com

SLVSB04A –JULY 2011–REVISED AUGUST 2015

8.3.10.2 Hot, Cold, and Temperature-Change Interrupts

Each temperature acquisition is compared against the programmable TMST_HOT and TMST_COLD thresholds

and to the baseline temperature, to determine if the display is within allowed operating temperature range and if

the temperature has changed by more than a user-defined threshold since the last update. The first temperature

reading after the WAKEUP pin has been pulled high automatically becomes the baseline temperature. Any

subsequent reading is compared against the baseline temperature. If the difference is equal or greater than the

threshold value, an interrupt is issued (DTX bit in register INT1 is set to 1) and the latest value becomes the new

baseline. If the difference is less than the threshold value, no action is taken. The threshold value is defined by

DT[1:0] bits in the TMST1 register and has a default value of ±2°C. In summary:

• When the temperature is equal or less than the TMST_COLD[3:0] threshold, the TMST_COLD interrupt bit of

the INT1 register is set, and the nINT pin is pulled low.

• When the temperature is greater than TMST_COLD but lower then TMST_HOT, no action is taken.

• When the temperature is equal or greater than the TMST_HOT[3:0] threshold, the TMST_HOT interrupt bit of

the INT1 register is set, and the nINT pin is pulled low.

• If the last temperature is different from the baseline temperature by ±2°C (default) or more, the DTX interrupt

bit of the INT1 register is set. The latest temperature becomes the new baseline temperature. By default the

DTX interrupt is disabled, that is, the nINT pin is not pulled low unless the DTX_EN bit was previously set

high.

• If the last temperature change is less than ±2°C (default), no action is taken.

8.3.10.3 Typical Application of the Temperature Monitor

In a typical application the temperature monitor and interrupts are used in the following manner:

• After the WAKEUP pin has been pulled high, the Application Processor (AP) writes 0x80h to the TMST1

register (address 0x0Dh). This starts the temperature measurement.

• The AP waits for the EOC interrupt. Alternatively the AP can poll the CONV_END bit in register TMST1. This

will notify the AP that the A/D conversion is complete and the new temperature reading is available in the

TMST_VALUE register (address (0x00h).

• The AP reads the temperature value from the TMST_VALUE register (address (0x00h).

• If the temperature changes by ±2°C (default) or more from the first reading, the processor is notified by the

DTX interrupt. The A/P may or may not decide to select a different set of waveforms to drive the panel.

• If the temperature is outside the allowed operating range of the panel, the processor is notified by the THOT

and TCOLD interrupts, respectively. The processor may or may not decide to continue with the page update.

• When an overtemperature or undertemperature has been detected, the AP must reset the TMST_HOT_EN or

TMST_COLD_EN bits, respectively, to avoid the nINT pin to be continuously pulled low. The TMST_HOT and

TMST_COLD interrupt bits then must be polled continuously, to determine when the panel temperature

recovers to the normal operating range. Once the temperature has recovered, the TMST_HOT_EN or

TMST_COLD_EN bits must be set to 1 again and normal operation can resume.

Copyright © 2011–2015, Texas Instruments Incorporated Submit Documentation Feedback 23

Product Folder Links: TPS65186

Page 24

TPS65186

SLVSB04A –JULY 2011–REVISED AUGUST 2015

www.ti.com

8.4 Device Functional Modes

The TPS65186 has three modes of operation, SLEEP, STANDBY, and ACTIVE. SLEEP mode is the lowestpower mode in which all internal circuitry is turned off. In STANDBY, all power rails are shut down but the device

is ready to accept commands through the I2C interface. In ACTIVE mode one or more power rails are enabled.

8.4.1 SLEEP

This is the lowest power mode of operation. All internal circuitry is turned off, registers are reset to default values

and the device does not respond to I2C communications. TPS65186 enters SLEEP mode whenever WAKEUP

pin is pulled low.

8.4.2 STANDBY

In STANDBY all internal support circuitry is powered up and the device is ready to accept commands through the

I2C interface but none of the power rails are enabled. The device enters STANDBY mode when the WAKEUP pin

is pulled high and either the PWRUP pin is pulled low or the STANDBY bit is set. The device also enters

STANDBY mode if input undervoltage lockout (UVLO), positive boost undervoltage (VB_UV), or inverting buckboost undervoltage (VN_UV) is detected, thermal shutdown occurs, or the PROG bit is set (see Figure 22)

8.4.3 ACTIVE

The device is in ACTIVE mode when any of the output rails are enabled and no fault condition is present. This is

the normal mode of operation while the device is powered up.

8.4.4 Mode Transitions

8.4.4.1 SLEEP → ACTIVE

WAKEUP pin is pulled high with PWRUP pin high. Rails come up in the order defined by the UPSEQx registers

(OK to tie WAKEUP and PWRUP pin together).

8.4.4.2 SLEEP → STANDBY

WAKEUP pin is pulled high with PWRUP pin low. Rails will remain powered down.

8.4.4.3 STANDBY → ACTIVE

WAKEUP pin is high and PWRRUP pin is pulled high (rising edge) or the ACTIVE bit is set. Output rails will

power up in the order defined by the UPSEQx registers.

8.4.4.4 ACTIVE → STANDBY

WAKEUP pin is high and STANDBY bit is set or PWRUP pin is pulled low (falling edge). Rails are shut down in

the order defined by DWNSEQx registers. Device also enters STANDBY in the event of thermal shutdown (TSD),

undervoltage lockout (UVLO), positive boost or inverting buck-boost undervoltage (UV), VCOM fault (VCOMF), or

when the PROG bit is set (see Figure 22).

8.4.4.5 STANDBY → SLEEP

WAKEUP pin is pulled low while none of the output rails are enabled.

8.4.4.6 ACTIVE → SLEEP

WAKEUP pin is pulled low while at least one output rail is enabled. Rails are shut down in the order defined by

DWNSEQx registers.

24 Submit Documentation Feedback Copyright © 2011–2015, Texas Instruments Incorporated

Product Folder Links: TPS65186

Page 25

SLEEP

ACTIVE

Rails = ON

I2C = YES

POWER DOWN

WAKEUP = high &

PWRUP= low

All rails = OFF

V3P3 switch = OFF

I2C = NO

Registers à default

Battery removed

STANDBY

WAKEUP = high &

(ACTIVE bit= 1 || PWRUP( ) )

All rails = OFF

I2C = YES

WAKEUP = high &

(STANDBY bit = 1||

PWRUP(¯) || FAULT )

WAKEUP = low

WAKEUP = high & PWRUP = high

WAKEUP = low

¯

www.ti.com

Device Functional Modes (continued)

TPS65186

SLVSB04A –JULY 2011–REVISED AUGUST 2015

NOTES:

||, & = logic OR, and AND.

(↑), (↓) = rising edge, falling edge

UVLO = Undervoltage Lockout

TSD = Thermal Shutdown

UV = Undervoltage

FAULT = UVLO || TSD || BOOST UV || VCOM fault

Copyright © 2011–2015, Texas Instruments Incorporated Submit Documentation Feedback 25

Figure 24. Global State Diagram

Product Folder Links: TPS65186

Page 26

SLAVE ADDRESS W A REG ADDRESS A SLAVE ADDRESS R A DATA

REGADDR

AS

DATA

REGADDR +n

A DATA

REGADDR +n+1

Ā P

From master to slave

From slave to master

S

W AP

Start

Write (low) AcknowlegeStop

R Read (high)

S

Ā Not Acknowlege

n bytes + ACK

SLAVE ADDRESS W A REG ADDRESS A DATA

REGADDR

AS

DATA

SUBADDR +n

A DATA

SUBADDR +n+1

Ā P

n bytes + ACK

S A6 A5 A4 A3 A2 A1 A0 A S7 S6 S5 S4 S3 S2 S1 S0 A D7 D6 D5 D4 D3 D2 D1 D0 A P

S AStart Condition Acknowledge A6 A0... Device Address

R/nW

Read / not Write

S7 S0... Sub-Address

D7 D0... Data

P Stop Condition

R/nW

Slave Address + R/nW Reg Address Data

TPS65186

SLVSB04A –JULY 2011–REVISED AUGUST 2015

www.ti.com

8.5 Programming

8.5.1 I2C Bus Operation

The TPS65186 hosts a slave I2C interface that supports data rates up to 400 kbit/s and auto-increment

addressing and is compliant to I2C standard 3.0.

Figure 25. Subaddress in I2C Transmission

The I2C Bus is a communications link between a controller and a series of slave terminals. The link is established

using a two-wire bus consisting of a serial clock signal (SCL) and a serial data signal (SDA). The serial clock is

sourced from the controller in all cases where the serial data line is bidirectional for data communication between

the controller and the slave terminals. Each device has an open drain output to transmit data on the serial data

line. An external pullup resistor must be placed on the serial data line to pull the drain output high during data

transmission.

Data transmission is initiated with a start bit from the controller as shown in Figure 27. The start condition is

recognized when the SDA line transitions from high to low during the high portion of the SCL signal. Upon

reception of a start bit, the device will receive serial data on the SDA input and check for valid address and

control information. If the appropriate slave address bits are set for the device, then the device will issue an

acknowledge pulse and prepare to receive the register address. Depending on the R/nW bit, the next byte

received from the master is written to the addressed register (R/nW = 0) or the device responds with 8-bit data

from the register (R/nW = 1). Data transmission is completed by either the reception of a stop condition or the

reception of the data word sent to the device. A stop condition is recognized as a low to high transition of the

SDA input during the high portion of the SCL signal. All other transitions of the SDA line must occur during the

low portion of the SCL signal. An acknowledge is issued after the reception of valid address, sub-address and

data words. The I2C interfaces will auto-sequence through register addresses, so that multiple data words can be

sent for a given I2C transmission. See Figure 26 and Figure 27 for details.

TOP: Master writes data to slave.

BOTTOM: Master reads data from slave.

26 Submit Documentation Feedback Copyright © 2011–2015, Texas Instruments Incorporated

Figure 26. I2C Data Protocol

Product Folder Links: TPS65186

Page 27

S

1-7 8 9 1-7 8 9 1-7 8 9

P

ADDRESS R/W ACK DATA ACK DATA

ACK/

nACK

STOPSTART

SDA

SCL

www.ti.com

SLVSB04A –JULY 2011–REVISED AUGUST 2015

Programming (continued)

Figure 27. I2C Start/Stop/Acknowledge Protocol

8.6 Register Maps

REGISTER ADDRESS (HEX) NAME DESCRIPTION

0 0x00 TMST_VALUE Thermistor value read by ADC

1 0x01 ENABLE Enable/disable bits for regulators

2 0x02 VADJ VPOS/VNEG voltage adjustment

3 0x03 VCOM1 Voltage settings for VCOM

4 0x04 VCOM2 Voltage settings for VCOM + control

5 0x05 INT_EN1 Interrupt enable group1

6 0x06 INT_EN2 Interrupt enable group2

7 0x07 INT1 Interrupt group1

8 0x08 INT2 Interrupt group2

9 0x09 UPSEQ0 Power-up strobe assignment

10 0x0A UPSEQ1 Power-up sequence delay times

11 0x0B DWNSEQ0 Power-down strobe assignment

12 0x0C DWNSEQ1 Power-down sequence delay times

13 0x0D TMST1 Thermistor configuration

14 0x0E TMST2 Thermistor hot temp set

15 0x0F PG Power good status each rails

16 0x10 REVID Device revision ID information

TPS65186

Copyright © 2011–2015, Texas Instruments Incorporated Submit Documentation Feedback 27

Product Folder Links: TPS65186

Page 28

TPS65186

SLVSB04A –JULY 2011–REVISED AUGUST 2015

8.6.1 Thermistor Readout (TMST_VALUE)

Address – 0x00h

DATA BIT D7 D6 D5 D4 D3 D2 D1 D0

FIELD NAME TMST_VALUE[7:0]

READ/WRITE R R R R R R R R

RESET VALUE N/A N/A N/A N/A N/A N/A N/A N/A

FIELD NAME BIT DEFINITION

Temperature read-out

1111 0110 – < -10°C

1111 0110 – -10°C

1111 0111 – -9°C

...

1111 1110 – -2°C

1111 1111 – -1 °C

TMST_VALUE[7:0] 0000 0000 – 0 °C

0000 0001 – 1°C

0000 0010 – 2°C

...

0001 1001 – 25°C

...

0101 0101 – 85°C

0101 0101 – > 85°C

www.ti.com

28 Submit Documentation Feedback Copyright © 2011–2015, Texas Instruments Incorporated

Product Folder Links: TPS65186

Page 29

www.ti.com

8.6.2 Enable (ENABLE)

Address – 0x01h

DATA BIT D7 D6 D5 D4 D3 D2 D1 D0

FIELD NAME ACTIVE STANDBY V3P3_EN VCOM_EN VDDH_EN VPOS_EN VEE_EN VNEG_EN

READ/WRITE R/W R/W R/W R/W R/W R/W R/W R/W

RESET VALUE 0 0 0 0 0 0 0 0

TPS65186

SLVSB04A –JULY 2011–REVISED AUGUST 2015

FIELD NAME BIT DEFINITION

STANDBY to ACTIVE transition bit

ACTIVE

STANDBY

V3P3_EN 1 – switch is ON

VCOM_EN 1 – enabled

VDDH_EN 1 – enabled

VPOS_EN

VEE_EN 1 – enabled

VNEG_EN

(1) Enable bits always reflect actual status of the corresponding rail.

1 – Transition from STANDBY to ACTIVE mode. Rails power up as defined by UPSEQx registers

0 – no effect

NOTE: After transition bit is cleared automatically

STANDBY to ACTIVE transition bit

1 – Transition from STANDBY to ACTIVE mode. Rails power up as defined by DWNSEQx registers

0 – no effect

NOTE: After transition bit is cleared automatically. STANDBY bit has priority over AVTIVE.

VIN3P3 to V3P3 switch enable

0 – switch is OFF

VCOM buffer enable

0 – disabled

VDDH charge pump enable

0 – disabled

VPOS LDO regulator enable

1 – enabled

0 – disabled

NOTE: VPOS cannot be enabled before VNEG is enabled.

VEE charge pump enable

0 – disabled

VNEG LDO regulator enable

1 – enabled

0 – disabled

NOTE: When VNEG is disabled VPOS will also be disabled.

(1)

Copyright © 2011–2015, Texas Instruments Incorporated Submit Documentation Feedback 29

Product Folder Links: TPS65186

Page 30

TPS65186

SLVSB04A –JULY 2011–REVISED AUGUST 2015

8.6.3 Voltage Adjustment Register (VADJ)

Address – 0x02h

DATA BIT D7 D6 D5 D4 D3 D2 D1 D0

FIELD NAME not used not used not used not used not used VSET[2:0]

READ/WRITE R/W R/W R/W R/W R R/W R/W R/W

RESET VALUE 0 0 1 0 0 0

FIELD NAME BIT DEFINITION

not used N/A

not used N/A

not used N/A

not used N/A

not used N/A

VPOS and VNEG voltage setting

000 - not valid

001 - not valid

010 - not valid

VSET[2:0] 011 - ±15.000 V

100 - ±14.750 V

101 - ±14.500 V

110 - ±14.250 V

111 - reserved

www.ti.com

E2

E2

1

E2

1

8.6.4 VCOM 1 (VCOM1)

Address – 0x03h

DATA BIT D7 D6 D5 D4 D3 D2 D1 D0

FIELD NAME VCOM [7:0]

READ/WRITE R/W R/W R/W R/W R/W R/W R/W R/W

RESET VALUE 0

FIELD NAME BIT DEFINITION

VCOM[7:0] VCOM voltage, least significant byte. See VCOM 2 (VCOM2) for details.

E2

E2

1

E2

1

E2

1

1 1 0 1

30 Submit Documentation Feedback Copyright © 2011–2015, Texas Instruments Incorporated

Product Folder Links: TPS65186

Page 31

www.ti.com

8.6.5 VCOM 2 (VCOM2)

Address – 0x04h

DATA BIT D7 D6 D5 D4 D3 D2 D1 D0

FIELD NAME ACQ PROG HiZ AVG[1:0] not used not used VCOM[8]

READ/WRITE R/W R/W R/W R/W R/W R/W R/W R/W

RESET VALUE 0 0 0 0 0 1 0 0

FIELD NAME BIT DEFINITION

ACQ

PROG

HiZ 1 – VCOM pin is placed into hi-impedance state to allow VCOM measurement

AVG[1:0]

not used N/A

not used N/A

VCOM[8:0]

TPS65186

SLVSB04A –JULY 2011–REVISED AUGUST 2015

E2

Kick-back voltage acquisition bit

1 – starts kick-back voltage measurement routine

0 – no effect

NOTE: After measurement is complete bit is cleared automatically and measurement result is

reflected in VCOM[8:0] bits.

VCOM programming bit

1 – VCOM[8:0] value is committed to nonvolatile memory and becomes new power-up default

0 – no effect

NOTE: After programming bit is cleared automatically and TPS65186 will enter STANDBY mode.

VCOM HiZ bit

0 – VCOM amplifier is connected to VCOM pin

Number of acquisitions that is averaged to a single kick-back voltage measurement

00 – 1x

01 – 2x

10 – 4x

11 – 8x

NOTE: When the ACQ bit is set, the state machine repeat the A/D conversion of the kick-back

voltage AVD[1:0] times and returns a single, averaged, value to VCOM[8:0]

VCOM voltage adjustment

VCOM = VCOM[8:0] x -10 mV in the range from 0 mV to –5.110 V

0x000h – 0 0000 0000 – –0 mV

0x001h – 0 0000 0001 – –10 mV

0x002h – 0 0000 0010 – –20 mV

...

0x07Dh - 0 0111 1101 – –1250 mV

...

0x1FEh – 1 1111 1110 – –5100 mV

0x1FFh – 1 1111 1111 – –5110 mV

Copyright © 2011–2015, Texas Instruments Incorporated Submit Documentation Feedback 31

Product Folder Links: TPS65186

Page 32

TPS65186

SLVSB04A –JULY 2011–REVISED AUGUST 2015

8.6.6 Interrupt Enable 1 (INT_EN1)

Address – 0x05h

DATA BIT D7 D6 D5 D4 D3 D2 D1 D0

FIELD NAME DTX_EN TSD_EN HOT_EN UVLO_EN ACQC_EN PRGC_EN

READ/WRITE R R/W R/W R/W R/W R/W R R

RESET VALUE 0 1 1 1 1 1 1 1

www.ti.com

TMST_HOT TMST_COLD

_EN _EN

FIELD NAME BIT DEFINITION

Panel temperature-change interrupt enable

DTX_EN 1 – enabled

0 – disabled

Thermal shutdown interrupt enable

TSD_EN 1 – enabled

0 – disabled

Thermal shutdown early warning enable

HOT_EN 1 – enabled

0 – disabled

Thermistor hot interrupt enable

TMST_HOT_EN 1 – enabled

0 – disabled

Thermistor cold interrupt enable

TMST_COLD_EN 1 – enabled

0 – disabled

VIN undervoltage detect interrupt enable

UVLO_EN 1 – enabled

0 – disabled

VCOM acquisition complete interrupt enable

ACQC_EN 1 – enabled

0 – disabled

VCOM programming complete interrupt enable

PRGC_EN 1 – enabled

0 – disabled

(1) Enabled means nINT pin is pulled low when interrupt occurs.

Disabled means nINT pin is not pulled low when interrupt occurs.

(1)

32 Submit Documentation Feedback Copyright © 2011–2015, Texas Instruments Incorporated

Product Folder Links: TPS65186

Page 33

www.ti.com

8.6.7 Interrupt Enable 2 (INT_EN2)

Address – 0x06h

DATA BIT D7 D6 D5 D4 D3 D2 D1 D0

FIELD NAME VBUVEN VDDHUVEN VNUV_EN VPOSUVEN VEEUVEN VCOMFEN VNEGUVEN EOCEN

READ/WRITE R/W R/W R/W R/W R/W R/W R/W R/W

RESET VALUE 1 1 1 1 1 1 1 1

TPS65186

SLVSB04A –JULY 2011–REVISED AUGUST 2015

FIELD NAME BIT DEFINITION

Positive boost converter undervoltage detect interrupt enable

VBUVEN 1 – enabled

0 – disabled

VDDH undervoltage detect interrupt enable

VDDHUVEN 1 – enabled

0 – disabled

Inverting buck-boost converter undervoltage detect interrupt enable

VNUVEN 1 – enabled

0 – disabled

VPOS undervoltage detect interrupt enable

VPOSUVEN 1 – enabled

0 – disabled

VEE undervoltage detect interrupt enable

VEEUVEN 1 – enabled

0 – disabled

VCOM FAULT interrupt enable

VCOMFEN 1 – enabled

0 – disabled

VNEG undervoltage detect interrupt enable

VNEGUVEN 1 – enabled

0 – disabled

Temperature ADC end of conversion interrupt enable

EOCEN 1 – enabled

0 – disabled

(1) Enabled means nINT pin is pulled low when interrupt occurs.

Disabled means nINT pin is not pulled low when interrupt occurs.

(1)

Copyright © 2011–2015, Texas Instruments Incorporated Submit Documentation Feedback 33

Product Folder Links: TPS65186

Page 34

TPS65186

SLVSB04A –JULY 2011–REVISED AUGUST 2015

8.6.8 Interrupt 1 (INT1)

Address – 0x07h

DATA BIT D7 D6 D5 D4 D3 D2 D1 D0

FIELD NAME DTX TSD HOT TMST_HOT TMST_COLD UVLO ACQC PRGC

READ/WRITE R R R R R R R R

RESET VALUE 0 N/A N/A N/A N/A N/A 0 0

FIELD NAME BIT DEFINITION

Panel temperature-change interrupt

DTX 1 – temperature has changed by 3 deg or more over previous reading

0 – no significance

Thermal shutdown interrupt

TSD 1 – chip is in overtemperature shutdown

0 – no fault

Thermal shutdown early warning

HOT 1 – chip is approaching overtemperature shutdown

0 – no fault

Thermistor hot interrupt

TMST_HOT 1 – thermistor temperature is equal or greater than TMST_HOT threshold

0 – no fault

Thermistor cold interrupt

TMST_COLD 1 – thermistor temperature is equal or less than TMST_COLD threshold

0 – no fault

VIN undervoltage detect interrupt

UVLO 1 – input voltage is below UVLO threshold

0 – no fault

VCOM acquisition complete

ACQC 1 – VCOM measurement is compete

0 – no significance

VCOM programming complete

PRGC 1 – VCOM programming is complete

0 – no significance

www.ti.com

34 Submit Documentation Feedback Copyright © 2011–2015, Texas Instruments Incorporated

Product Folder Links: TPS65186

Page 35

www.ti.com

8.6.9 Interrupt 2 (INT2)

Address – 0x08h

DATA BIT D7 D6 D5 D4 D3 D2 D1 D0

FIELD NAME VB_UV VDDH_UV VN_UV VPOS_UV VEE_UV VCOMF VNEG_UV EOC

READ/WRITE R R R R R R R R

RESET VALUE N/A N/A N/A N/A N/A N/A N/A N/A

FIELD NAME BIT DEFINITION

VB_UV 1 – under-voltage on DCDC1 detected

VDDH_UV 1 – undervoltage on VDDH charge pump detected

VN_UV 1 – undervoltage on DCDC2 detected

VPOS_UV 1 – undervoltage on LDO1(VPOS) detected

VEE_UV 1 – undervoltage on VEE charge pump detected

VCOMF 1 – fault on VCOM detected (VCOM is outside normal operating range)

VNEG_UV 1 – undervoltage on LDO2(VNEG) detected

EOC 1 – ADC conversion is complete (temperature acquisition is complete)

TPS65186

SLVSB04A –JULY 2011–REVISED AUGUST 2015

Positive boost converter undervoltage detect interrupt

0 – no fault

VDDH undervoltage detect interrupt

0 – no fault

Inverting buck-boost converter undervoltage detect interrupt

0 – no fault

VPOS undervoltage detect interrupt

0 – no fault

VEE undervoltage detect interrupt

0 – no fault

VCOM fault detection

0 – no fault

VNEG undervoltage detect interrupt

0 – no fault

ADC end of conversion interrupt

0 – no significance

Copyright © 2011–2015, Texas Instruments Incorporated Submit Documentation Feedback 35

Product Folder Links: TPS65186

Page 36

VNEG

VEE

VPOS

VDDH

6ms 6ms 48ms6ms 6ms 6ms

TPS65186

SLVSB04A –JULY 2011–REVISED AUGUST 2015

8.6.10 Power Up Sequence Register 0 (UPSEQ0)

Address – 0x09h

DATA BIT D7 D6 D5 D4 D3 D2 D1 D0

FIELD NAME VDDH_UP[1:0] VPOS_UP[1:0] VEE_UP[1:0] VNEG_UP[1:0]

READ/WRITE R/W R/W R/W R/W R/W R/W R/W R/W