Page 1

SLUS564C − JULY 2003 − REVISED OCTOBER 2008

FEATURES

Wide Input Voltage Range: 4.5-V to 28-V

D

D Selectable Dual and DDR Modes

D Selectable Fixed Frequency Voltage Mode

D Advanced Power Good Logic Monitors both

Channels

D Selectable Autoskip Mode

D Integrated Boot Strap Diodes

D 180° Phase Shift Between Channels

D Integrated 5-V, 60-mA Regulator

D Input Feedforward Control

D 1% Internal 0.85-V Reference

D R

Overcurrent Detection (4200 ppm/°C)

DS(on)

D Integrated OVP, UVP and Power Good Timers

D 30-pin TSSOP Package

APPLICATIONS

Notebook Computers System Bus and I/O

D

D DDR I or DDR II Termination

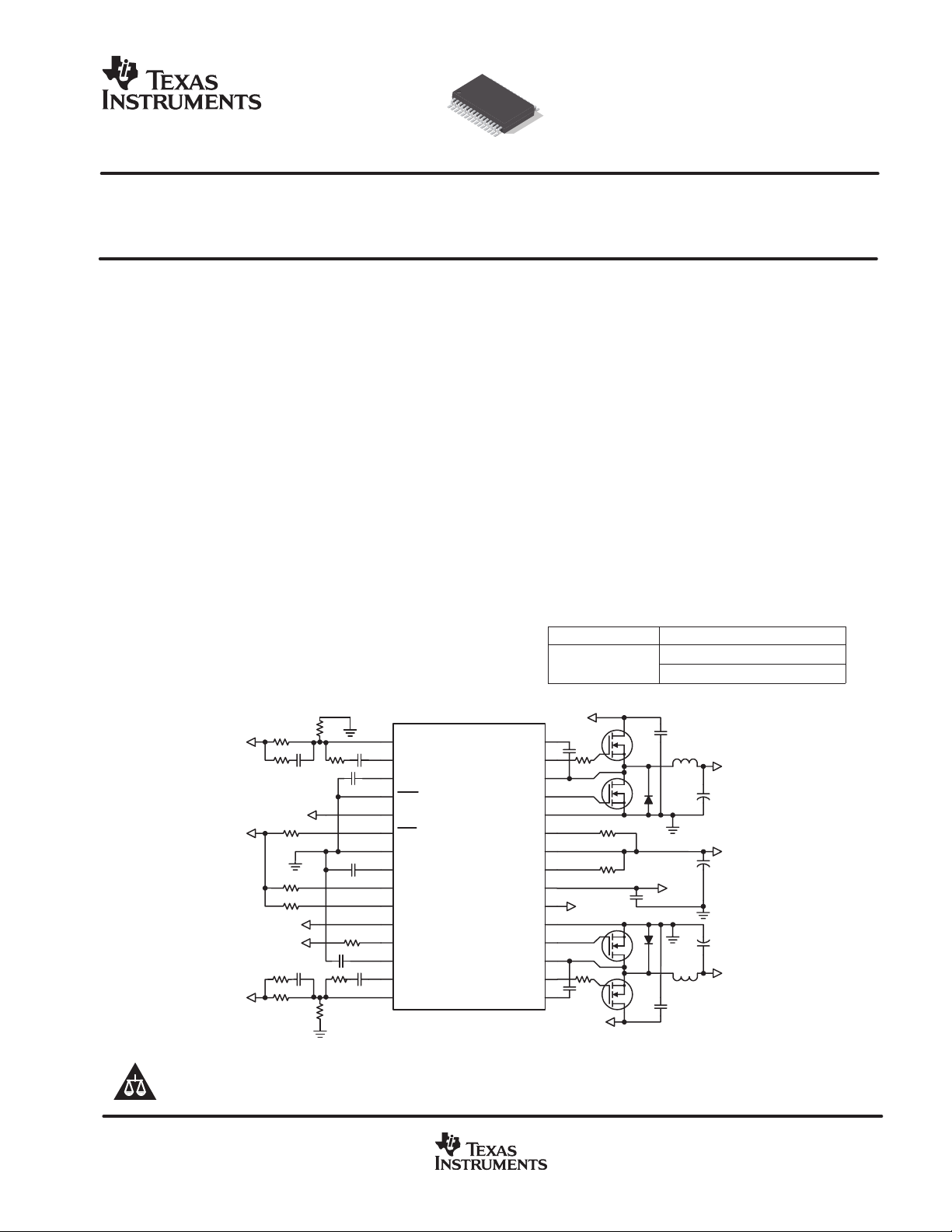

SIMPLIFIED

APPLICATION

DIAGRAM

VO1

VO2

VIN

VO1

VO2

VREG5

1

INV1

2

COMP1

3

SSTRT1

4

SKIP

5

VO1_VDDQ

6

DDR

7

GND

8

REF_X

9

ENBL1

10

ENBL2

11

VO2

12

PGOOD

13

SSTRT2

14

COMP2

15

INV2

TPS51020

DESCRIPTION

The TPS51020 is a multi-function dualsynchronous step-down controller for notebook

system power. The part is specifically designed

for high performance, high efficiency applications

where the loss associated with a current sense

resistor is unacceptable. The TPS51020 utilizes

feed forward voltage mode control to attain high

efficiency without sacrificing line response.

Efficiency at light load conditions can be

maintained high as well by incorporating autoskip

operation. A selectable, Suspend to RAM (STR)

supported, DDR option provides a one chip

solution for all switching applications from

5-V/3.3-V supply to a complete DDR termination

solution.

ORDERING INFORMATION

TA PLASTIC TSSOP (DBT)

VBST1

OUT1_U

LL1

OUT1_D

OUTGND1

TRIP1

VIN

TRIP2

VREG5

REG5_IN

OUTGND2

OUT2_D

LL2

OUT2_U

VBST2

−40°C to 85°C

VIN

30

29

28

27

26

25

24

23

22

21

EXT_5V

20

19

18

17

16

VIN

TPS51020DBTR (T&R)

VREG5

TPS51020DBT

VO1

VIN

VO2

UDG−03144

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

!"#$%&" ' ()##*& %' "! +),-(%&" .%&*/

#".)(&' ("!"#$ &" '+*(!(%&"' +*# &0* &*#$' "! *1%' '&#)$*&'

'&%.%#. 2%##%&3/ #".)(&" +#"(*''4 ."*' "& *(*''%#-3 (-).*

&*'&4 "! %-- +%#%$*&*#'/

www.ti.com

Copyright 2003, Texas Instruments Incorporated

1

Page 2

V

Ouput voltage range

V

I/O Voltage

SLUS564C − JULY 2003 − REVISED OCTOBER 2008

ABSOLUTE MAXIMUM RATINGS

Over operating free-air temperature range unless otherwise noted. All voltage values are with respect to the network ground terminal unless

otherwise noted.

Input voltage range

Ouput voltage range

Output current range

Operating free-air temperature range, T

Storage temperature range, T

Junction temperature range, T

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds 300

(1)

TPS51020 UNIT

VBST1, VBST2 −0.3 to 35

VBST1, VBST2 (wi th respect to LL ) −0.3 to 7

VIN, TRIP1, TRIP2, ENBL1, ENBL2, DDR −0.3 to 30

SKIP, INV1, INV2 −0.3 to 7

OUT1_U, OUT2_U −1 to 35

OUT1_U, OUT2_U (wi th respect to LL ) −0.3 to 7

LL1, LL2 −1 to 30

REF_X −0.3 to 15

PGOOD, VO1_VDDQ, VO2, OUT1_D, OUT2_D, COMP1, COMP2, VREG5,

SSTRT1, SSTRT2

OUTGND1, OUTGND2 −0.3 to 0.3

VREG5 70

REF_X 7

A

stg

J

−0.3 to 7

−40 to 85

−55 to 150

−40 to 125

V

mA

°C

RECOMMENDED OPERATING CONDITIONS

MIN TYP MAX UNIT

Supply voltage, VIN 4.5 28

Supply voltage, VBST1, VBST2 4.5 33

ENBL1, ENBL2, DDR, TRIP1, TRIP2 −0.1 28

OUT1_U, OUT2_U −0.8 33

OUT1_U, OUT2_U (wi th respect to LL ) −0.1 5.5

LL1, LL2 −0.8 28

I/O Voltage

Source current

Operating free-air temperature, T

(1)

Stresses beyond those listed under absolute maximum ratings may cause permanent damage to the device. These are stress ratings only,

and functional operation of the device at these or any other conditions beyond those indicated under ”recommended operating conditions” is

not implied. Exposure to Absolute Maximum Rated conditions for extended periods may affect device reliability

REF_X −0.1 12

SSTRT1, SSTRT2, COMP1, COMP2 −0.1 5.5

SKIP, INV1, INV2 −0.1 5.5

PGOOD VO1_VDDQ, VO2 −0.1 5.5

OUT1_D, OUT2_D, VREG5 −0.1 5.5

VREG5 60

REF_X 5

A

−40 85 °C

DISSIPATION RATING TABLE

PACKAGE

30-pin DBT 874 mW 7.0 mW/°C 454 mW

TA < 25°C

POWER RATING

FACTOR ABOVE TA = 25°C

DERATING

TA = 85°C

POWER RATING

V

mA

2

www.ti.com

Page 3

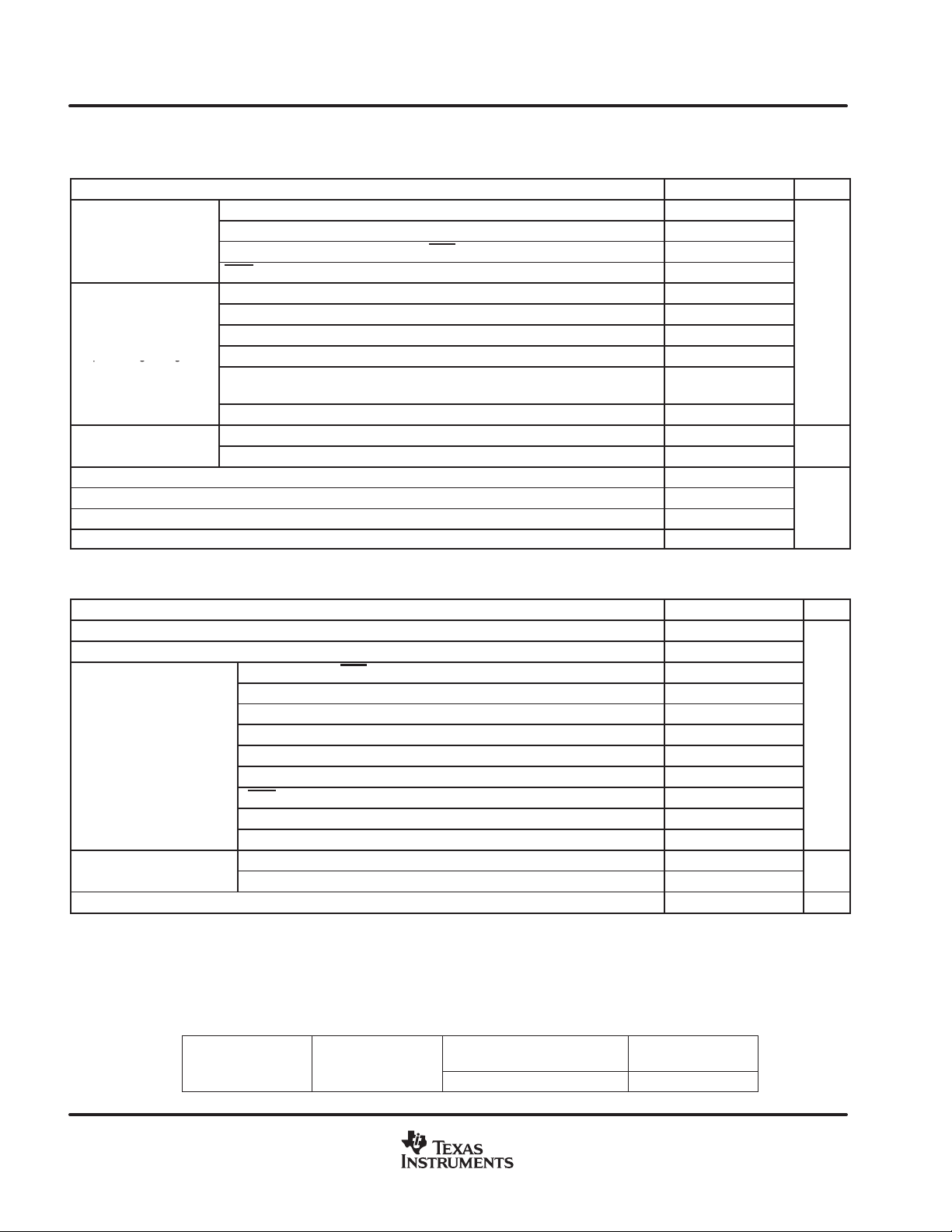

TSSOP (0.5 mm)

DBT PACKAGE

(TOP VIEW)

INV1

COMP1

SSTRT1

SKIP

VO1_VDDQ

DDR

GND

REF_X

ENBL1

ENBL2

VO2

PGOOD

SSTRT2

COMP2

INV2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

VBST1

OUT1_U

LL1

OUT1_D

OUTGND1

TRIP1

VIN

TRIP2

VREG5

REG5_IN

OUTGND2

OUT2_D

LL2

OUT2_U

VBST2

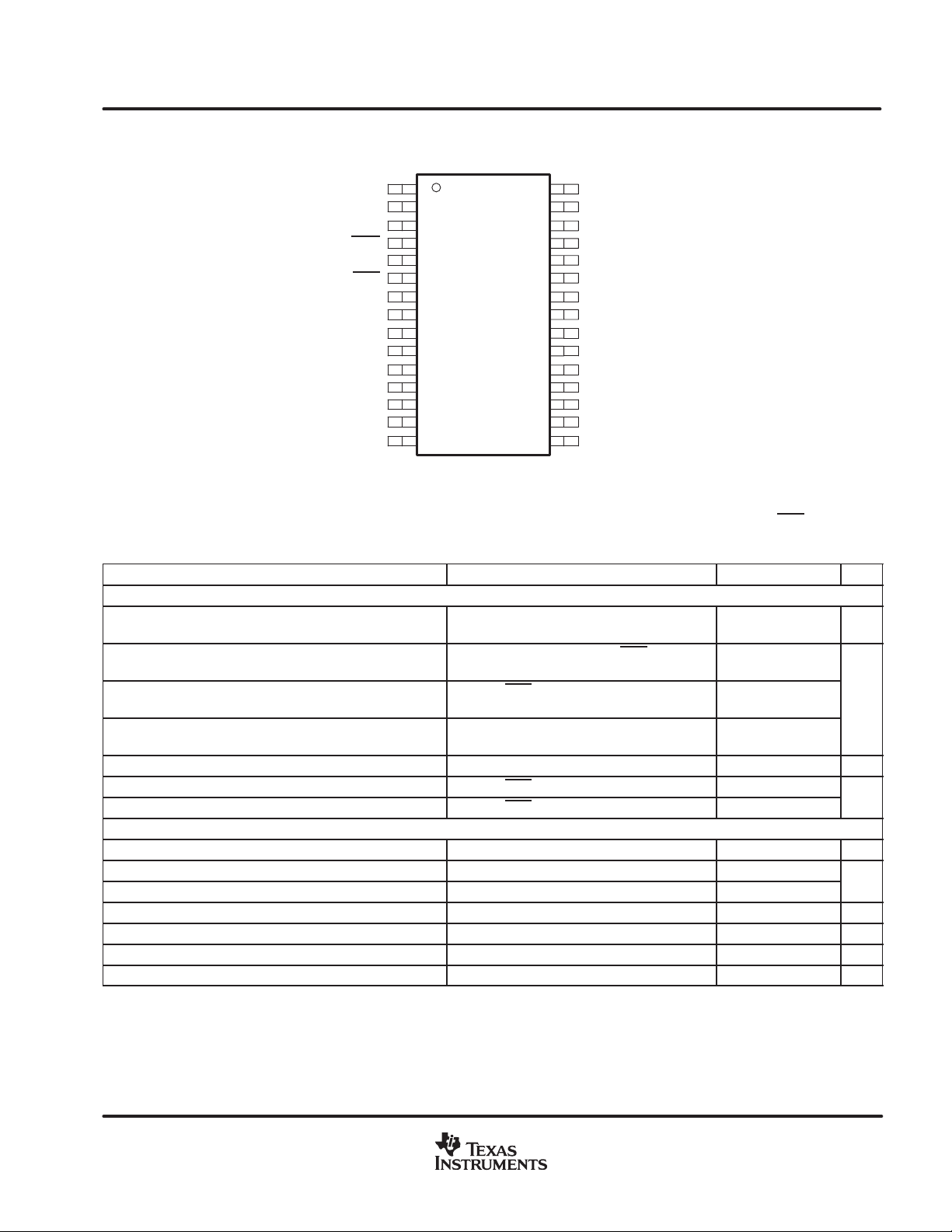

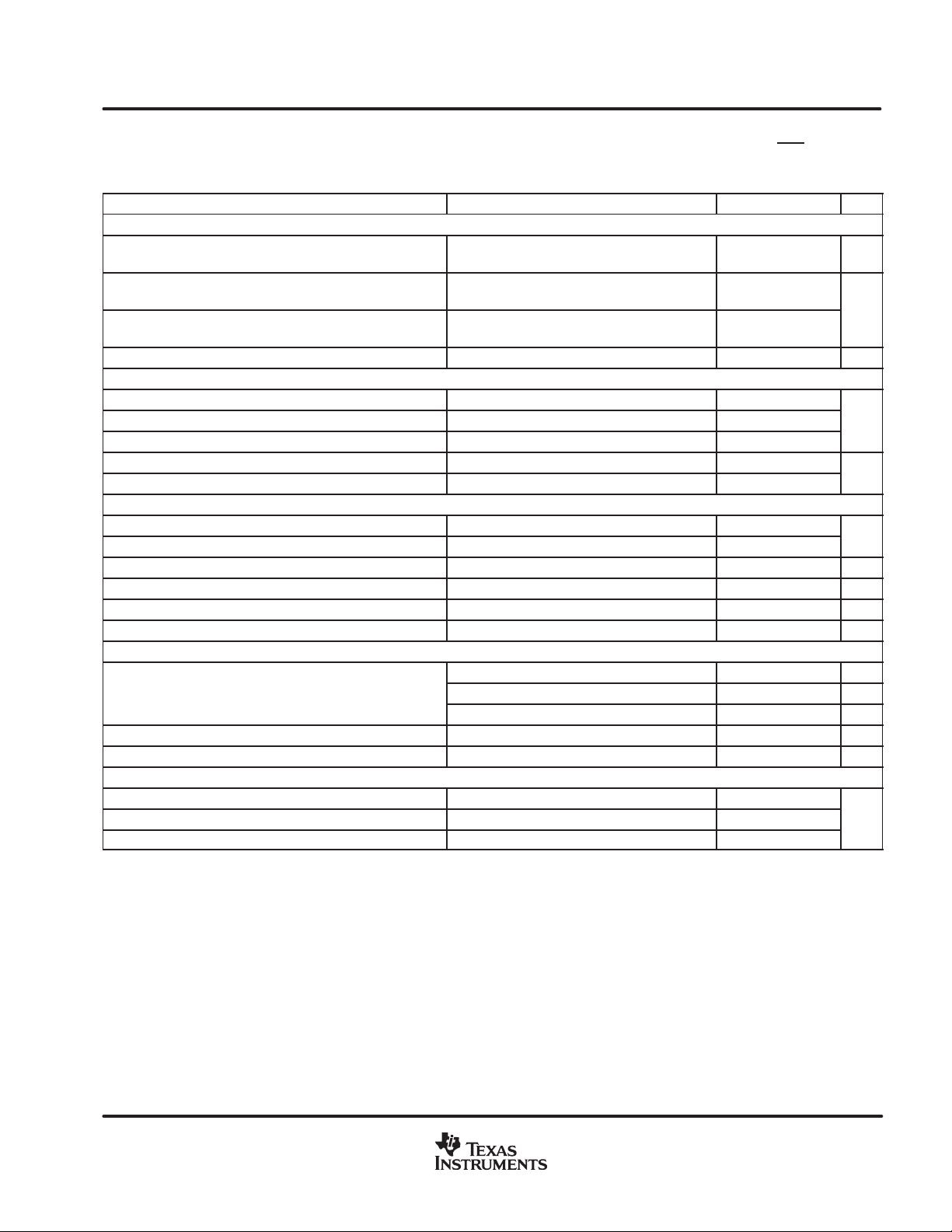

ELECTRICAL CHARACTERISTICS

TA = −40°C to 85°C, 4.5 V < VIN < 20 V, C

INVx = COMPx, RSSTRTx = OPEN, TRIP1 = TRIP2 = VIN, LLx = GND, VBSTx = LLx+5, C

OUTGNDx = 0 V , VO1_VDDQ = VO2 = 0 V (unless otherwise stated)

PARAMETER

INPUT CURRENTS

I

VIN

I

VIN(STBY)VIN

I

VIN(SHDN)VIN

I

VIN(REG5)

I

REG5

I

VBSTx

I

VBSTx

VREG5 INTERNAL REGULATOR

V

VREG5

V

LD5

V

LN5

V

THL

V

HYS(UV)

V

TH(SW)

V

HYS(SW)

VIN supply current

standby current

shutdown current

VIN supply current, REG5_IN as 5-V input

current

REG5_IN input supply current REG5V_IN = 5 V, OSC = OFF 1.0 1.7 mA

VBST supply current ENBLx = DDR = VIN 0.05 1.00

VBST shutdown current ENBLx = DDR = 0 V 0.05 1.00

VREG5 voltage I

Load regulation 0 mA ≤ I

Line regulation I

UVLO threshold voltage High to low 3.45 3.65 3.85 V

UVLO hysteresis 100 200 300 mV

Switchover voltage REG_IN voltage 4.2 4.5 4.8 V

Switchover hysteresis 50 250 mV

= 0.1 µF, C

VIN

= 2.2 µF, C

VREG5

REG5V_IN = OPEN, TRIPx = VIN,

OSC = OFF

ENBLx = 0 V, DDR = VIN,

REG5V_IN = OPEN, OSC = OFF

ENBLx = DDR = 0 V,

REG5V_IN = OPEN

REG5V_IN = 5 V, OSC = OFF 200 500

= 0 A 4.8 5.0 5.2 V

OUT

OUT

= 20 mA, 7 V≤VIN ≤ 28 V 0.4% 2.0%

OUT

= 0.01 µF, PGOOD = 0.2 V, ENBLx = DDR = VIN,

REF_X

TEST CONDITIONS MIN TYP MAX UNIT

≤ 50 mA, VIN = 12 V 0.6% 2.5%

SLUS564C − JULY 2003 − REVISED OCTOBER 2008

(OUTx_U, OUTx_D)

=1 nF, REG5_IN = 0V, GND =

1.4 2.2 mA

350 550

0.05 1.00

µA

µA

www.ti.com

3

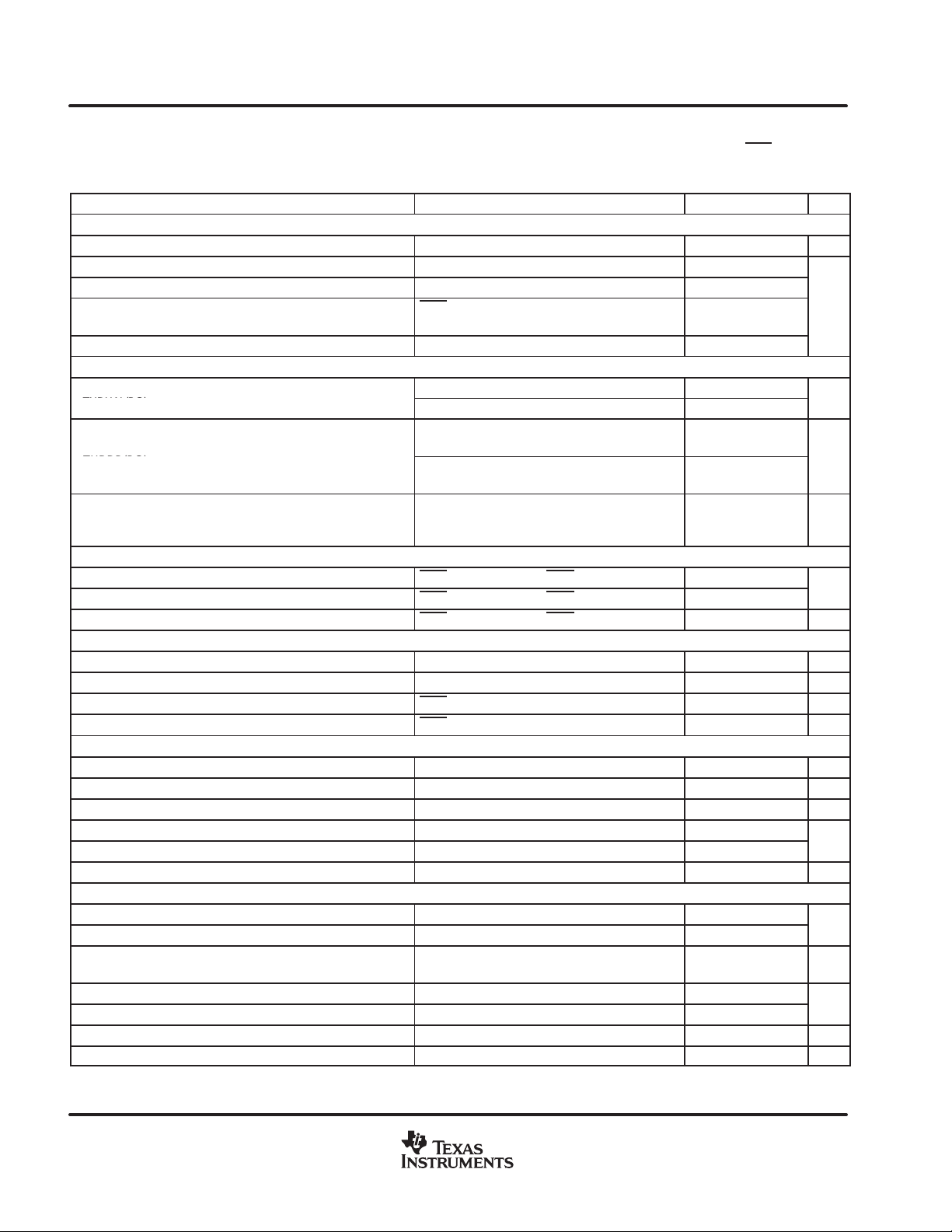

Page 4

)

)

SLUS564C − JULY 2003 − REVISED OCTOBER 2008

ELECTRICAL CHARACTERISTICS (continued)

TA = −40°C to 85°C, 4.5 V < VIN < 20 V, C

INVx = COMPx, RSSTRTx = OPEN, TRIP1 = TRIP2 = VIN, LLx = GND, VBSTx = LLx+5, C

OUTGNDx = 0 V , VO1_VDDQ = VO2 = 0 V (unless otherwise stated)

PARAMETER UNITMAXTYPMINTEST CONDITIONS

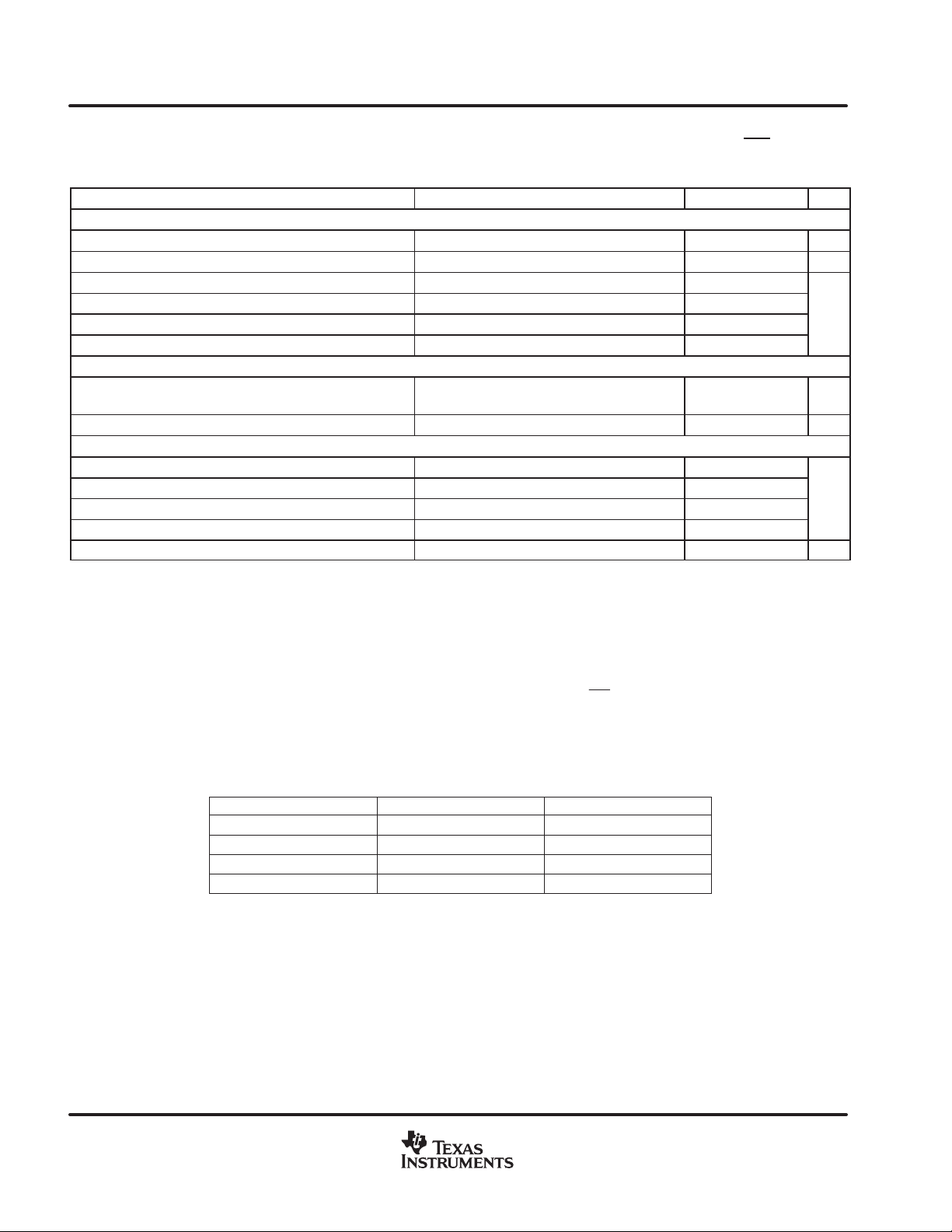

REF_X REFERENCE VOLTAGE

V

REF10

V

LD10

V

LN10

V

REFVTT

V

REFVTT

POWERGOOD COMPARATORS

V

THDUAL(PG

V

THDDR(PG

T

PG(del)

DIGITAL CONTROL INPUTS

V

IH

V

IL

I

INLEAK

VO1_VDDQ and VO2

R

VOUT

V

VOUTOK

V

VO2LEAK

R

VOUT

UNDERVOLTAGE AND OVERVOLTAGE PROTECTION

V

OVPDUAL

V

OVPDDR

T

OVP(del)

V

UVPDUAL

V

UVPDDR

T

UVP(del)

OVERCURRENT and INPUT VOLTAGE UVLO PROTECTION

I

TRIPSNK

I

TRIPSRC

TC

ITRIP

V

OCPHI

V

OCPLO

V

VINUVLO

V

VINHYS

10-V reference voltage VIN = 14 V, I

Load regulation 0 mA ≤ I

Line regulation I

VTT reference voltage

VTT reference load regulation 0 mA ≤ IO ≤ 3 mA 0.75%

PGOOD threshold (dual mode)

PGOOD threshold (DDR)

PGOOD delay time

High-level input voltage, logic DDR, ENBL1, ENBL2, SKIP 2.2

Low-level input voltage, logic DDR, ENBL1, ENBL2, SKIP 0.3

Logic input leakage current DDR, ENBL1, ENBL2, SKIP= 5 V |1.0| µA

VOx sink impedance V

VOx low restart voltage Fault condition removed, restart 0.25 0.32 0.40 V

VOx input leakage current DDR= VIN, VOx = 5 V |1.0| µA

VO1_VDDQ input impedance DDR= 0 1.5 MΩ

OVP trip output threshold (dual) Sensed at INVx 945 970 1010 mV

OVP trip output threshold (DDR) VO1_VDDQ = 2.5 V 1.31 1.36 1.41 V

OVP propagation delay time

UVP trip output threshold (dual) Sensed at INVx 510 553 595

UVP trip output threshold (DDR) VO1_VDDQ = 2.5 V 750 813 875

UVP propagation delay time 4096 clks

TRIPx sink current V

TRIPx source current V

TRIP current temperature coeficient

High-level OCP comparator offset voltage

Low-level OCP comparator offset voltage

VIN UVLO trip threshold REF5V_IN = 4.8 V 3.7 3.9 4.1 V

VIN UVLO trip hysteresis 100 200 300 mV

= 0.1 µF, C

VIN

(1)

(1)

= 2.2 µF, C

VREG5

OUT

= 100 µA, 14 V≤VIN ≤28 V 5%

OUT

DDR = 0 V wrt VO1_VDDQ input divided by 2

V

= 2.5 V

VO1

Undervoltage PGOOD 765 786 808

Overvoltage PGOOD

Undervoltage PGOOD,

VO1_VDDQ = 2.5 V

Overvoltage PGOOD,

VO1_VDDQ = 2.5 V

INVx > undervoltage PGOOD,

Delay time from SSTRTx > 1.5 V to PGOOD

going high

= 0.5 V, fault engaged 6 10 Ω

VOUTx

= VIN − 100 mV, TA = 25°C 11 13 15

TRIPx

= 100 mV, TA = 25°C 10 13 16

TRIPx

TA = 25°C 4200

(1)

(1)

= 0.01 µF, PGOOD = 0.2 V, ENBLx = DDR = VIN,

REF_X

≤ 2 mA, VIN = 18 V -12% -20%

(OUTx_U, OUTx_D)

= 0 A 8.5 10.0 11.0 V

OUT

=1 nF, REG5_IN = 0V, GND =

1.5%

892 920 945

1.12 1.14 1.16

1.28 1.31 1.33

2048 clks

20 µs

0 |3.0|

0 |5.0|

mV

V

V

mV

µA

ppm/

°C

mV

4

www.ti.com

Page 5

mV

MAX

DC

MAX

Maximum duty cycle

kHz

SLUS564C − JULY 2003 − REVISED OCTOBER 2008

ELECTRICAL CHARACTERISTICS (continued)

TA = −40°C to 85°C, 4.5 V < VIN < 20 V, C

INVx = COMPx, RSSTRTx = OPEN, TRIP1 = TRIP2 = VIN, LLx = GND, VBSTx = LLx+5, C

OUTGNDx = 0 V , VO1_VDDQ = VO2 = 0 V (unless otherwise stated)

PARAMETER UNITMAXTYPMINTEST CONDITIONS

0.85-V REFERENCE CONTROL LOOP

V

REFCH1

V

REFTC1

V

REFLN1

V

CHMM

CONTROL LOOP: SKIP HYSTERSTIC COMPARATOR AND ZERO CURRENT COMPARATOR

V

LLHYS

V

LLOFF

V

ZOFF

T

HLTOLL

T

HLTOHL

CONTROL LOOP ERROR AMPLIFIER

I

EASRC

I

EASNK

F

UGB

A

OL

CMR

COMP

I

INVLEAK

CONTROL LOOP: DUTY CYCLE, VOLTAGE RAMP, CHANNEL PHASE AND PWM DELAY PATH

DC

PH

CH

T

MIN

TIMERS: INTERNAL OSCILLATOR

f

OSC(hi)

f

OSC(lo)

f

OSC(tc)

(1)

Ensured by design. Not production tested.

(2)

Maximum 450-kHz frequency can be achieved when both channels are enabled.

(3)

270 kHz is the default frequency during start-up for both channels.

(4)

See Table 1.

(5)

See PWM detailed description

Error amplifier reference, channel 1 initial

accuracy

Error amplifier reference, channel 1

change with accuracy

Error amplifier reference, channel 1

change with line

Channel 2 to channel 1 voltage mismatch 0 |5.0| mV

Skip hysteresis comparator hysteresis

Lload hysteresis comparator offset

Zero current comparator offset

PWM skip delay time 8

Skip to PWM delay time 1

COMPx source current 0.2 0.9

COMPx sink current 0.2 0.7

Unity gain bandwidth

Open loop gain

COMPx voltage range

INVx input current |0.5| µA

Maximum duty cycle

Channel to channel phase difference

OUTX_U minimum pulse width

Fast oscillator frequency initial accuracy

Slow oscillator frequency initial accuracy R

Oscillator frequency over line and temperature Trimmed for 360 kHz 306 360 414

(1)

(1)

(4)

(1)(6)

= 0.1 µF, C

VIN

(1)

(1)

(1)

(5)

(1)

= 2.2 µF, C

VREG5

Measure COMP1, COMP1= INV1,

TA = 25°C

f

= 270 kHz

OSC

f

= 360 kHz

OSC

f

= 450 kHz

OSC

PWM phase reversal only 180 °

(2)

R

SSTRTx

SSTRTx

= OPEN 450

= 1MΩ or V

= 0.01 µF, PGOOD = 0.2 V, ENBLx = DDR = VIN,

REF_X

(3)

(2)

(OUTx_U, OUTx_D)

= 3 V 270

SSTRT

=1 nF, REG5_IN = 0V, GND =

0.84 0.85 0.86 V

0.5%

0.1%

1 2 3

0 1

10 18

2.5 MHz

80 dB

0.4 VREG5−3 V

86% 88%

84% 85%

80% 82%

100 ns

mV

clks

mA

kHz

www.ti.com

5

Page 6

SLUS564C − JULY 2003 − REVISED OCTOBER 2008

ELECTRICAL CHARACTERISTICS (continued)

TA = −40°C to 85°C, 4.5 V < VIN < 20 V, C

INVx = COMPx, RSSTRTx = OPEN, TRIP1 = TRIP2 = VIN, LLx = GND, VBSTx = LLX+5, C

OUTGNDx = 0 V, VO1_VDDQ = VO2 = 0 V (unless otherwise stated)

PARAMETER

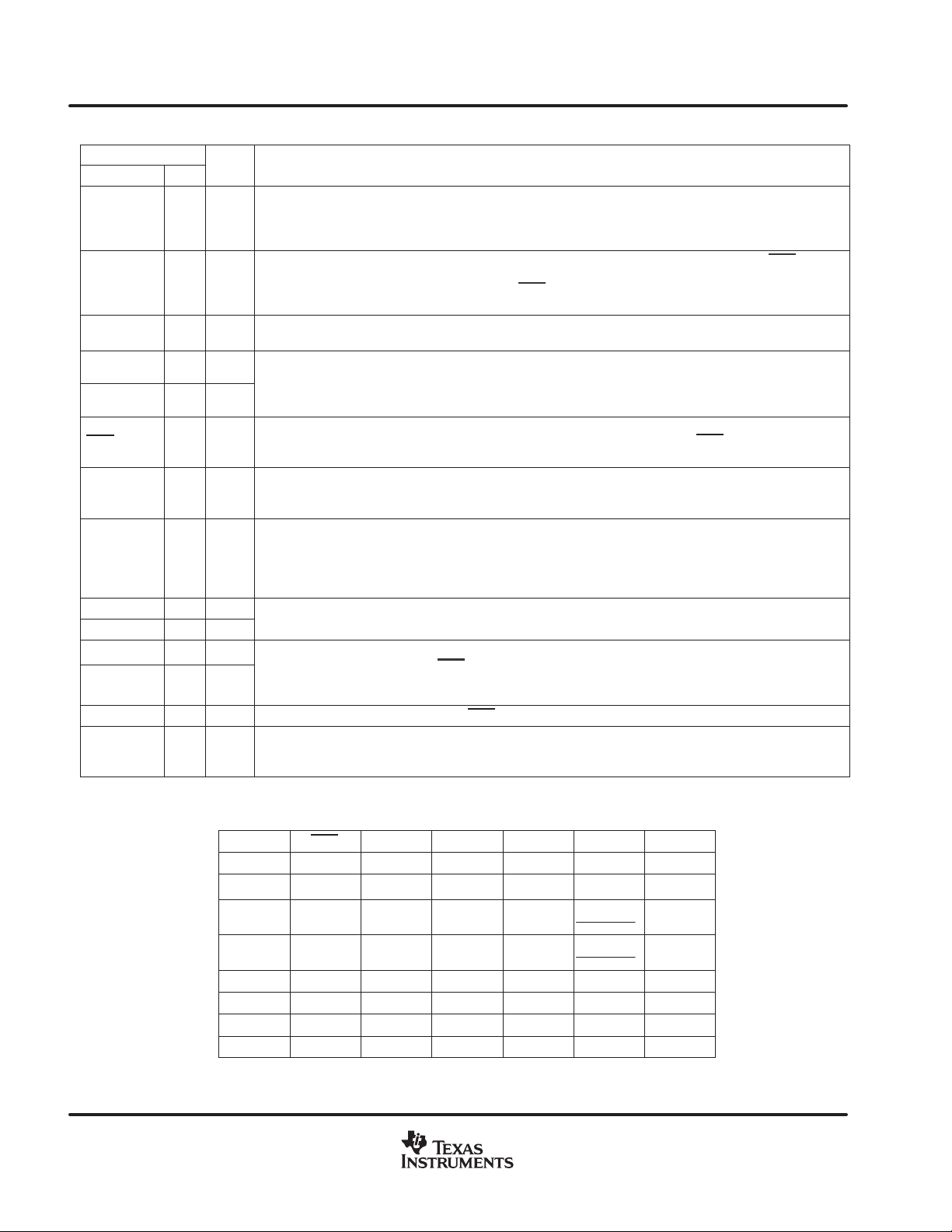

TIMERS: SOFT-START RAMP GENERATOR

I

SSQ

I

SSDQ

V

REFTRK

V

SSOK

V

SSFIN

V

SSCLP

OUTPUTS: INTERNAL BST DIODE

V

FBST

I

RBST

OUTPUTS: N-CHANNEL MOSFET GATE DRIVERS

R

USRC

R

DSRC

R

USNK

R

DSNK

T

DEAD

(1)

Ensured by design. Not production tested.

(2)

Maximum 450-kHz frequency can be achieved only when both channels are enabled.

(3)

270 kHz is the default frequency during start-up for both channels.

(4)

See Table 1.

(5)

See PWM detailed description

(6)

Feedforward Gain can be approximated as follows:

V

RAMP

At the running duty cycle, the V

(7)

See waveform point A in Figure 1

(8)

See waveform point B in Figure 1

(9)

See waveform point C in Figure 1

SSTRTx charge current V

SSTRTx discharge current V

SSTRTx at SMPS regulation point voltage

SSTRTx OK to restart voltage 0.23 0.29 0.35

SSTRTx finished voltage

SSTRTx frequency select voltage

Forward voltage

Reverse current V

OUTx_U source impedance 3 10

OUTx_D source impedance 3 10

OUTx_U sink impedance 2.5 5.0

OUTx_D sink impedance 2.5 5.0

Gate non-overlap dead time 100 ns

= K1×VIN+B1, V

OFFSET

=K2×VIN×+B2 where K1=0.017, K2=0.01, B1=0.35 V, B2=0.4 V.

COMP

= 0.1 µF, C

VIN

(8)

(9)

should be approximately: V

VREG5

(7)

= 2.2 µF, C

SSTRTx

SSTRTx

(V

VREF5

TA = 25°C

RBST

= 0.01 µF, PGOOD = 0.2 V, ENBLx = DDR = VIN,

REF_X

TEST CONDITIONS MIN TYP MAX UNIT

= 1 V 1.8 2.3 2.9 µA

= 0.5 V 0.1 mA

− V

= 30 V 0.1 0.5 µA

COMP

VBSTx

+ V

OUT

), V

VREF5

ǒ

K1 )

(OUTx_U, OUTx_D)

= 5 V , IF = 10 mA

B1

Ǔ

(

)

VIN

K2 VIN ) B2

=1 nF, REG5_IN = 0V, GND =

1.00 1.22 1.45

1.4 1.5 1.6

3.35 3.60 3.80

0.80 0.85 V

)

V

Ω

Table 1. Frequency Selection

SSTRT1 SSTRT2 FREQUENCY (kHz)

C

1 MΩ || C

C

1 MΩ || C

(10)

Although selection is made by placing a 1M resistor in parallel with the SSTRTx timing

capacitor, the softstart time to 0.85V is altered by about only 20%.

6

only C

SSTRT

to GND C

SSTRT

only 1 MΩ || C

SSTRT

to GND 1 MΩ || C

SSTRT

only 450

SSTRT

only 360

SSTRT

SSTRT

SSTRT

www.ti.com

to GND 360

to GND 270

(10)

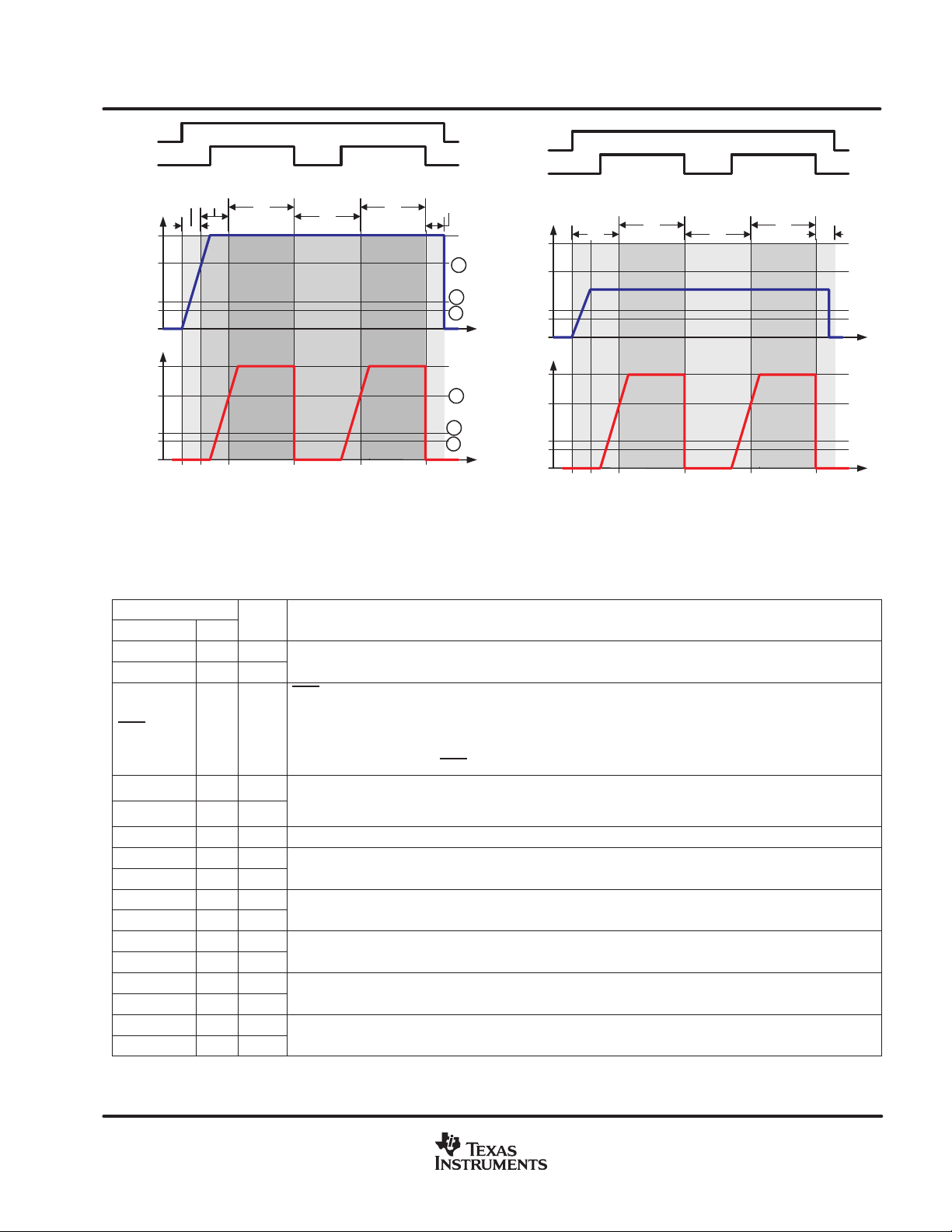

Page 7

I/O

DESCRIPTION

f

that channel attempts to turn on. If both ENBL1 and ENBL2 are low then the 10-V (or (VO1_VDDQ)/2 output)

ENBL1

ENBL2

5.0

3.6

1.5

1.2

0

5.0

− Soft-Start Voltage − V

3.6

SSTRT

V

1.5

1.2

0

fSW − Switching Frequency − kHz

270 360

t1t0 t3t2 t4 t5

470

360

SSTRT1

470 270

SSTRT2

t − Time

R

SSTRT1

= R

SSTRT2

= OPEN = 450 kHz

Figure 1

SLUS564C − JULY 2003 − REVISED OCTOBER 2008

ENBL1

ENBL2

fSW − Switching Frequency − kHz

5.0

C

B

A

C

B

A

3.6

1.5

1.2

0

5.0

− Soft-Start Voltage − V

3.6

SSTRT

V

1.5

1.2

0

270

t1t0 t3t2 t4 t5

360

270

SSTRT1

t − Time

R

SSTRT1

= 1 MΩ, R

SSTRT2

Figure 2

360

270

SSTRT2

= OPEN = 360 kHz

TERMINAL FUNCTIONS

TERMINAL

NAME NO.

COMP1 2 O

COMP2 14 O

DDR 6 I

ENBL1 9 I

ENBL2 10 I

GND 7 O Signal ground pin.

INV1 1 I

INV2 15 I

LL1 28 I/O

LL2 18 I/O

OUT1_D 27 O

OUT2_D 19 O

OUT1_U 29 O

OUT2_U 17 O

OUTGND1 26 O

OUTGND2 20 O

Error amplifier output. Connect feedback network to this pin and INVx for compensation of control loop.

DDR selection pin. If this pin is grounded, the device runs in DDR Mode. The error amplifier reference for VO2

is (VO1_VDDQ)/2, the REF_X output voltage becomes (VO1_VDDQ)/2 and skip mode is disabled for VO2,

Also, VREG5 is turned off when both ENBLx are at low in this mode. If this pin is at 2.2-V or higher, the device

runs in ordinary dual SMPS mode (dual mode), then the error amplifier reference for VO2 is connected to internal 0.85-V reference, the REF_X output voltage becomes 10 V, VREG5 is kept on regardless of ENBLx status.

CAUTION: Do not toggle DDR

TTL Enable Input. If ENBLx is greater than 2.2 V, then the VREG5 is enabled (DDR mode) and the SMPS o

voltage as well as the oscillator are turned off. (See Table 2)

Error amplifier inverting input. Also input for skip comparator, and OVP/UVP comparators.

Switch-node connection for high-side driver and overcurrent protection circuitry.

Synchronous N-channel MOSFET driver output.

High-side N-channel MOSFET driver output.

Ground return for OUTx_D.

while ENBL1 or ENBL2 are high. (See Table 2)

www.ti.com

7

Page 8

I/O

DESCRIPTION

t

time. A constant current fed to this capacitor ramps the reference during startup. Frequency selection is de-

time. A constant current fed to this capacitor ramps the reference during startup. Frequency selection is de-

the channel can start-up again. If DDR is low, then the VO1_VDDQ pin must be connected to the VDDQ output

-

SLUS564C − JULY 2003 − REVISED OCTOBER 2008

TERMINAL FUNCTIONS (continued)

TERMINAL

NAME NO.

Power good output. This is an open drain pull-down pin for power good. It remains low during soft-start until

PGOOD 12 O

REF_X 8 O

REG5_IN 21 I

SSTRT1 3 I

SSTRT2 13 I

SKIP 4 I

TRIP1 25 I

TRIP2 23 I

VBST1 30 I

VBST2 16 I

VO1_VDDQ 5 I

VO2

VREG5 22 O Internal, 60-mA, 5-V regulator output. DDR, ENBL1 or ENBL2 high ( > 2.2V) turns on the 5 V regulator.

VIN 24 I

11 I

both outputs become within ±7.5%. If INV1 or INV2 is out of regulation, or VREG5V goes under UVLO then this

pin goes low. The internal delay timer counts 2048 clks at low to high (by design, no delay for high to low). If

ENBLx is low, and the power good output is high, then the power good signal for that channel is ignored.

10-V N-channel MOSFET bias or (VO1_VDDQ)/2 reference output. If dual mode is selected (DDR > 2.2 V)

then this pin provides a low 10-V current (< 2 mA) bias, dropped down from VIN, for the SO – S5 switched

N-channel MOSFETs. If DDR mode is selected (DDR

of 3 mA source current. This bias/reference is shut off when ENBL1 and ENBL2 are both low. (See Table 2)

External 5V regulator Input. If this pin is above 4.7 V, then the 5 V circuit bias switches from the VREF5 to the

supply presented to REG5_IN.

Soft-start/frequency select input. Connect a capacitor between SSTRTx and ground for adjusting the softstar

scribed in Table 1. The soft-start capacitor is discharged upon UVLO/OVP/UVP, or when ENBLx is asserted

low.

Skip mode selection pin. Ground for automatic control between PWM mode in heavy load and hysteretic operation in light load. Tie high for PWM only operation for the entire load condition. If DDR

mode is disabled for Channel 2.

Channel 1 overcurrent trip point voltage input. Connect a resistor between TRIP1 and the high-side N-channel

MOSFET input conversion voltage for high-side N-channel MOSFET UVP current limit shut down. Connect

resistor between TRIP1 and GND for low-side N-channel MOSFET overcurrent latch shutdown.

Channel 2 overcurrent trip point voltage input. Connect a resistor between TRIP2 and the high-side N-channel

MOSFET input conversion voltage for high-side N-channel MOSFET UVP current limit shut down with a 180°

channel phase shift. Connect resistor between TRIP2 and GND for low-side N-channel MOSFET over current

latch shut-down. The oscillator voltage ramp adjustment (the feed-forward feature) for channel 2 is disabled

when this pin is tied to ground via a resistor.

Supply Input for high-side N-channel FET driver. Typically connected via charge pump from LLx.

Output discharge pin. Connect this pin to the SMPS output. The output is discharged to at least 0.3 V before

since this pin works as the VDDQ feedback to generate the VTT reference voltage and VO2 should be con

nected to GND since VTT must remain in a high-impedance state during S3 mode.

High-voltage input. Typically the battery voltage. This pin serves as inputs for the VREF5 regulator, the REF_X

regulator and positive input for overcurrent comparators. Precaution should be taken for tracing between this

pin and the high-side N-channel MOSFET drain where positive node of TRIPx resistors are located.

= GND) then this pin becomes (VO1_VDDQ)/2 capable

is grounded, then skip

Table 2. Reference Regulator Control

MODE DDR ENBL1 ENBL2 VREF5 REF_X OSC

DDR LOW LOW LOW OFF OFF OFF

DDR LOW LOW HIGH ON

DDR LOW HIGH LOW ON

DDR LOW HIGH HIGH ON

DUAL HIGH LOW LOW ON OFF OFF

DUAL HIGH LOW HIGH ON 10 V ON

DUAL HIGH HIGH LOW ON 10 V ON

DUAL HIGH HIGH HIGH ON 10 V ON

8

www.ti.com

OFF

VO1_DDR

2

VO1_DDR

2

ON

ON

ON

Page 9

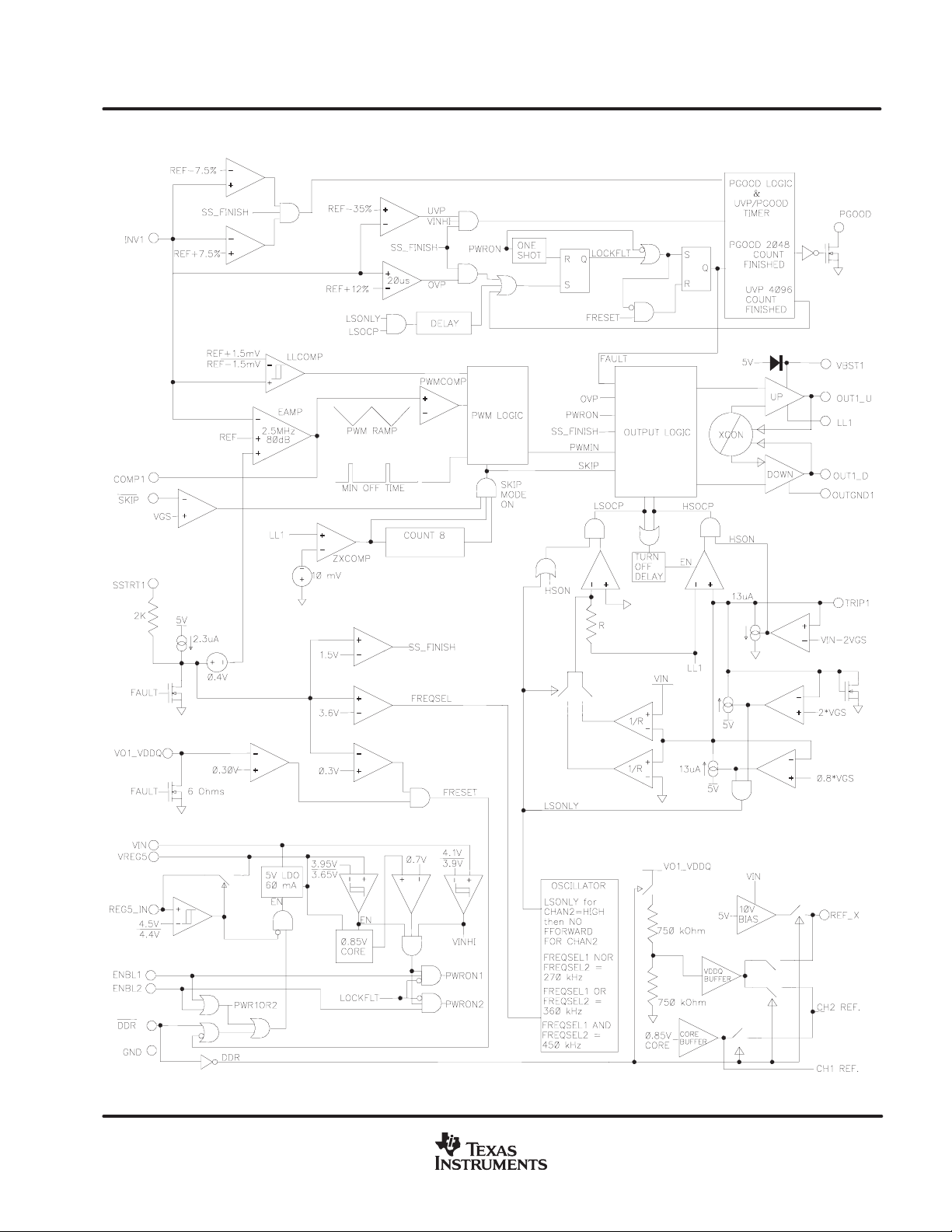

FUNCTIONAL BLOCK DIAGRAM

SLUS564C − JULY 2003 − REVISED OCTOBER 2008

Shows Channel 1 (VO1_VDDQ) and the supporting circuitry.

www.ti.com

9

Page 10

SLUS564C − JULY 2003 − REVISED OCTOBER 2008

APPLICATION INFORMATION

PWM OPERATION

The PWM control block utilizes a fixed-frequency, feed-forward, voltage-mode control scheme with a

wide-bandwidth, low-impedance output error amplifier as the voltage servo control block. This scheme allows

the highest efficiency down conversion while maintaining excellent line regulation and fast transient response.

Loop compensation is programmed by connecting a filter network between the COMPx pin and the INVx pin.

The wide bandwidth error amplifier handles conventional Type II compensation or Type III compensation when

using ceramic capacitors for the converter output. For channel one, the reference signal for the control loop is

always a precision 0.85-V internal reference, while the channel two loop reference is either the 0.85-V reference

or, in the case of DDR

amplifier appears at the COMPx pin and is compared to a buffered version of the 0.6-V oscillator ramp. When

TRIP2 pin is tied to VIN through a resistor, the voltage ramp is further modulated by the input voltage, VIN, to

maintain a constant modulator gain. If the TRIP2 pin is connected to ground through a resistor , then the voltage

ramp remains fixed regardless of VIN value.

The oscillator frequency is internally fixed and can be selected at 270 kHz, 360 kHz or 470 kHz by insertion of

a clamping resistor on the SSTRTx pin per Table 1. For example, 470 kHz can be attained when both SSTR Tx

voltages exceed 3.5 V, as described in WAVEFORM1. The controller begins with 270 kHz in the first stage of

the softstart, and then increases to 470 kHz at the steady state. When 270 kHz is selected, both of SSTRTx

voltages are kept below 3.5 V so that the frequency is the same 270 kHz for the entire operation.

mode, one half the VO1_VDDQ voltage, (VO1_VDDQ)/2. The output signal of the error

Two channels are operated in 180 degrees out-of-phase interleave switching mode. This interleaving helps

reduce the input current ripple requirement for the input capacitor . However, because the PWM loop determines

both the turn-off AND turn-on of the high-side MOSFET, this 180 degree operation may not be apparent by

looking at the LLx nodes only. Rather , the turn-of f cycle of one channel always corresponds to the turn-on cycle

of the other channel and vise-versa. As a result, input ripple is reduced and dynamic response is improved over

a broad input voltage range.

MAXIMUM DUTY CYCLE

Because most notebook applications typically run from three to four cell Li−Ion or run from a 20-V adapter , 100%

duty cycle operation is not required. Rather, the TPS51020 is optimized for low duty ratio step-down conversion.

As a result of limiting the duty cycle, the flying BST capacitor is refreshed reliably and the low-side over current

detection circuitry is capable of detecting an overcurrent condition even if the output is stuck between the

regulation point and UVP. The maximum duty cycle for each operating frequency is 88% for 270 kHz, 85% for

360 kHz and 82% for 470 kHz.

It should be noted that if the system is operating close to maximum (or minimum) duty cycle, it may be difficult

for the converter to respond quickly during line/load transients or state changes (such as frequency switching

during soft start or PWM to SKIP mode transitions). This slow response is due to the dynamic range of the COMP

pin and is usually not a result of poor phase compensation. In the case of minimum duty cycle operation, the

slow response is due to the minimum pulse width of the converter (100 ns TYP). In this case (counter intuitively),

it may be advisable to slow down the switching frequency of the converter in order to improve response time.

10

www.ti.com

Page 11

SLUS564C − JULY 2003 − REVISED OCTOBER 2008

APPLICATION INFORMATION

SKIP MODE OPERATION

If the SKIP pin is set HIGH, the SMPS operates in the fixed PWM mode. While a LOW signal is applied, the

controller operates in autoskip mode. In the autoskip mode, the operation changes from constant frequency

PWM mode to an energy-saving skip mode automatically by detecting the edge of discontinuous current mode.

During the skip mode, the hysteretic comparator monitors output voltage to trigger high side on at the next

coming oscillator pulse after the lower level is detected. Several sequential pulses may be seen, especially in

the intermediate load level, before output capacitor is charged up to the higher level and waits for next cycle.

In the skip mode, frequency varies with load current and input voltage.

Skip mode for SMPS_2 is disabled regardless of the SKIP

and DDR Mode section). This is because current sink capability is required for V

needs to be kept on when the inductor current flows inversely. SMPS_1 is still capable of skip mode operation

while DDR Mode.

pin status if DDR mode is selected (see Dual Mode

, so that rectifying MOSFET

TT

CASCADE CONFIGURATION

If the TRIP2 pin is tied through a resistor to the input voltage, the TPS51020 assumes that the conversion voltage

for channel two is the VIN voltage, usually VBATT. Conversely, i f TRIP2 is tied through a resistor to ground, the

controller assumes that the conversion voltage for channel two is the output voltage of channel one or some

other stable bus voltage.

DUAL MODE AND DDR MODE

TPS51020 provides one-chip solution for system power supply, such as for 5 V, 3.3 V or 1.8 V, and a dual

switcher DDR power supply. By simply selecting DDR

the instructions below, TPS51020 gives a complete function set required for the DDR termination supply such

as VDDQ/2 tracking V

is set high ( > 2.2 V), the TPS51020 runs in dual mode, that is, each converter produces an independent

If DDR

output voltage with respect to the internal 0.85-V reference. Bypass REF_X to ground by 0.01-µF. The

VO1_VDDQ or VO2 terminal should be connected to their corresponding switcher output. The 10-V reference

output can be used as FET switch biasing for power control during sleep states (see Figure 5). During this dual

mode, selection of autoskip mode or PWM mode made by SKIP

is set low ( < 0.3V), the TPS51020 operates as a dual switcher DDR supply; VDDQ from SMPS_1 and

If DDR

V

from SMPS_2 (DDR Mode). In this mode, the reference voltage for SMPS_2 is switched to (VO1_VDDQ)/2

TT

to track exactly half the voltage of SMPS_1, divided by internal resistors. VO1_VDDQ should be connected to

SMPS_1 output terminal to accomplish this. REF_X outputs the (VO1_VDDQ)/2 voltage after a buffer (5-mA

max). SKIP

from the output. Power source of SMPS_2 can either be the battery voltage (independent configuration), or the

VDDQ (cascade configuration) by user’s preference. When using the independent configuration, TRIP2 needs

to be connected to the VIN node via trip resistor. In case of cascade configuration, tie TRIP2 to GND via trip

resistor (see Figure 7).

controls only SMPS_1 and SMPS_2 is forced to operate in PWM mode so that current can be sink

CAUTION:Do NOT toggle DDR HIGH while ENBL1 or ENBL2 is high (see Table 2). REF_X

output switches to high voltage (10 V) and be applied to V

source/sink capability and VTT reference output.

TT

signal and some external configuration change following

applies to both SMPS_1 and SMPS_2.

directly

TTREF

www.ti.com

11

Page 12

SLUS564C − JULY 2003 − REVISED OCTOBER 2008

APPLICATION INFORMATION

5-V LINEAR REGULATOR (VREG5)

The VREG5 voltage is the bias for all the low voltage circuitry in the TPS51020 as well as the DC boost voltage

for the MOSFET gate drivers. Total available current is 60 mA. Bypass this pin to GND by 4.7-µF. The under

voltage lockout (UVLO) circuit monitors the output of this regulator to protect internal circuitry from low input

voltages. If 5 V i s applied to REG5_IN from either the SMPS output or an alternate 5 V, then the linear regulator

is turned off and the VREG5 pin is switched over to REG_IN. This operation enhances the efficiency of the

overall power supply system because the bulk of the quiescent current now runs from the 5-V output instead

of VIN (VBAT). In this configuration, ensure that VREG5_IN is less than or equal to V

EXTERNAL 5V INPUT (REG5_IN)

When a 5-V bus is available, VIN does not need to be connected to the battery. In this configuration, VIN should

be connected to REG5_IN.

LOW-SIDE N-CHANNEL FET DRIVER

VIN

.

The low-side driver is designed to drive high current low R

voltage is 5.5 V. The drive capability is represented by its internal resistance, which are 3 Ω for VREG5 to

OUTx_D and 2.5 Ω for OUTx_D to OUTGNDx. A dead time is internally generated between top MOSFET off

to bottom MOSFET on, and bottom MOSFET off to top MOSFET on, in order to prevent shoot through.

The low-side driver is typically turned off during all fault modes except for OVP. When an OVP condition exists,

the low-side driver of the offending channel turns on and attempts to blow the protection fuse of the input supply.

N-channel MOSFET(s). The maximum drive

DS(on)

HIGH-SIDE N-CHANNEL FET DRIVER

The high-side driver is designed to drive high current, low R

a floating driver, a 5-V bias voltage is delivered from VREG5 supply. The instantaneous drive current is supplied

by the flying capacitor between VBSTx and LLx pins, 0.1-µF ceramic for typical applications. The boost diodes

are integrated and are sufficient for enhancing the high-side MOSFET. However, external boost diodes can also

be added from VREG5 to each VBSTx in case higher gate-to-source votlage is required.

The drive capability is represented by its internal resistance, which are as follows: 3 Ω for VBST to OUTx_U

and 2.5 Ω for OUTx_U to LLx. The maximum voltage that can be applied between OUTx_U pin and OUTGNDx

pin is 35 V.

N-channel MOSFET(s). When configured as

DS(on)

12

www.ti.com

Page 13

SLUS564C − JULY 2003 − REVISED OCTOBER 2008

APPLICATION INFORMATION

ENABLE AND SOFT-START

Each SMPS is switched into standby mode separately by grounding the corresponding ENBLx pin. The 5-V

supply is enabled if either the DDR

Softstart of each SMPS is achieved by slowly ramping the error amplifier reference voltage by following a

buffered version of the SSTRTx pin voltage. Designers can achieve their own start-up sequencing by simply

provide external timing signals since the startup times do not depend on the load current. The softstart time is

programmable by external capacitor connected from SSTRTx pin to the ground. Each SSTRTx pin sources

constant current, typically 2.3 µA. The output voltage of the SMPS ramps up from 0 V to its target regulation

voltage as the SSTRTx pin voltage increases from 0 V to 1.2 V. This gives the softstart time formula to be,

T

C

The soft-start capacitor is discharged upon UVLO, OVP or UVP is detected as well as ENBLx is set low.

SSTRT

(Farads) +

SSTRT

, ENBL1 or ENBL2 pin(s) goes high ( >2.2 V).

(sec) 2.3 10

1.2

*6

OUTPUT DISCHARGE (SOFT-STOP)

When an SMPS is turned off by ENBLx asserted low or the part enters a fault mode, both top and bottom drivers

are turned off. This may leave the output in a high impedance state that allows the voltage to persist for some

time. Output voltage should be discharged prior to the next power up. To achieve this, connect the output to the

VO1_VDDQ or VO2 pins.

These pins turn on a 6-Ω resistor to ground during an off or fault condition. Both the VO1_VDDQ and VO2 pin

must be discharged to 0.3 V before the TPS51020 restarts. The TPS51020 has the flexibility of adding a resistor

in series with the VOx pin and the output voltage in order to reduce the discharge current and reduce the total

power dissipation within the device. It should be noted that when this resistor is added the discharged voltage

threshold changes according to the following equation:

where

D R

D R

V

DISCHARGE

EXTERNAL

= 6 Ω

DS(on)

ǒ

R

EXTERNAL

+

is the series resistor between VOx and the output

R

DS(on)

) R

DS(on)

Ǔ

0.3

www.ti.com

13

Page 14

SLUS564C − JULY 2003 − REVISED OCTOBER 2008

APPLICATION INFORMATION

10-V N-CHANNEL FET BIAS or (VOUT1)/2 VTT VOLTAGE REFERENCE (REF_X)

TPS51020’s REF_X provides two functions depending on the operational mode. One is a linear regulator that

supply 10-V for FET switch biasing in the dual mode, the other is V

is high ( > 2.2 V) then the REF_X output is a convenient 10-V, 2-mA (maximum) output, useful for biasing

If DDR

N-channel FET switches typically used to manage S0, S3 and S5 sleep states where the main supply is switched

to many outputs. When V

is low, then the REF_X output becomes the VDDQ/2 (VO1_VDDQ/2) reference. This output is capable

If DDR

of 5-mA source current and is left on even if channel two (V

is < 12 V, REF_X approximately tracks VIN−2 V.

IN

switcher) is turned off. REF_X is turned off if ENBL1

TT

and ENBL2 are both low (see Table 2).

POWERGOOD

The TPS51020 has advanced powergood logic that allows single powergood circuit to monitor both SMPS

output voltages (see Figure 3 ).

reference voltage in the DDR mode.

TT

VOUT1

VOUT2

PGOOD Delay Counter

PGOOD

ENBL1

ENBL2

2048 c

2048 c

Resets Delay Counter

t0 t1 t2

Figure 3. PowerGood Timing Diagram

The PGOOD terminal is an open drain output. The PGOOD pin remains low until both power supplies have

started and have been in regulation ( ±7.5%) for 2048 clock pulses.

14

www.ti.com

Page 15

SLUS564C − JULY 2003 − REVISED OCTOBER 2008

APPLICATION INFORMATION

If one channel is enabled in the period between T0 and T1, (the other channel’s ramp time plus delay time,) the

PGOOD delay counter restarts counting softstart finish after the last channel has finished softstart. Enabling

after T1 is ignored by PGOOD until the channel finishes its softstart. If either of the SMPS output goes out by

± 7.5% or UVLO is detected while ENBLx is high, PGOOD pulls low. If a channel is disabled while the other is

still active PGOOD maintains it’s logic state and only monitor the active channel.

PROTECTION FUNCTIONS

The TPS51020 is equipped with input undervoltage lock out (UVLO), output undervoltage protection (UVP) and

overvoltage (OVP) protection. Overcurrent is detected using R

protected by triggering UVP, or latch off in some cases. The states of output drive signal depends on which

protection was involved. Please refer to each protection description below for the detail.

When the input voltage UVLO is tripped, the TPS51020 resets and waits for the voltage to rise up over the

threshold voltage and restart the device. Alternatively , if output UVP or OVP is triggered, the device latches off

after a delay time defined by the internal fault counter counting the PWM oscillator pulses. The VREF5 and

REF_X is kept on in this latch off condition. The fault latch can be reset by toggling both of ENBLx pins in DDR

mode. The fault latch can be reset by either toggling VIN or bringing DDR

to bring DDR

If a false trip of the UVLO appears due to input voltage sag during turn-on of the high-side MOSFET such as

a large load transient, first consider adding several micro-farads of input capacitance close to the MOSFET’s

drain. Also consider adding a small V

should be connected to the same node as VIN pin of the device when this filter is applied. The filter resistor

should be as small as possible since a voltage drop across this resistor biases the OCP trip point.

high prior to ENBLx when TPS51020 is being used in dual mode.

filter, ex. a 2.2-Ω resistor and a 2.2-µF, for decoupling. The trip resistors

IN

of the external power MOSFETs and

DS(on)

, ENBL1 and ENBL2 all low. Be sure

UNDERVOLTAGE LOCKOUT PROTECTION

There are two undervoltage lock out protections (UVLO) in TPS51020. One is for VIN, which has a typical trip

threshold voltage 3.9 V and trip hysteresis 200 mV. The other is for VREF5, which has a typical trip threshold

voltage 3.65 V and trip hysteresis 300 mV. If either is triggered, the device resets and waits for the voltage to

rise up over the threshold voltage and restart the part. Please note this protection function DOES NOT trigger

the fault counter to latch off the part.

OVERVOLTAGE PROTECTION

For overvoltage protection (OVP), the TPS51020 monitors INVx voltage. When the INVx voltage is higher than

0.95V (+12%), the OVP comparator output goes high (after a 20-µs delay) and the circuit latches the top

MOSFET driver OFF, and bottom driver ON for the SMPS detected overvoltage. In addition, the output

discharge (softstop) function is enabled to discharge the output capacitor. The fault latch can be reset by either

toggling VIN or bringing DDR

TPS51020 is being used in dual mode.

, ENBL1 and ENBL2 all low. Be sure to bring DDR high prior to ENBLx when

UNDERVOLTAGE PROTECTION

For undervoltage protection (UVP), the TPS51020 monitors INVx voltage. When the INVx voltage is lower than

0.55 V (−35 %), the UVP comparator output goes high, and the internal FLT timer starts to count PWM oscillator

pulses. After 4096 clock pulses, the part latches off. Both top and bottom drivers are turned off at this condition.

Output discharge (soft-stop) function is enabled to discharge the output capacitor. The fault latch can be reset

by either toggling VIN or bringing DDR

when TPS51020 is being used in dual mode.

, ENBL1 and ENBL2 all low. Be sure to bring DDR high prior to ENBLx

www.ti.com

15

Page 16

SLUS564C − JULY 2003 − REVISED OCTOBER 2008

APPLICATION INFORMATION

OVERCURRENT PROTECTION

Overcurrent protection (OCP) is achieved by comparing the drain to source voltage of the high-side and low-side

MOSFET to a set point voltage. This voltage appears at the TRIPx pin and is defined by the conversion voltage,

typically VIN, minus the I × R drop of the I

conversion voltage. The offset of the internal comparators also plays a role in determining the overall accuracy

and set point of the OCP limit.

When the drain-to-source voltage of the synchronous MOSFET exceeds the set point voltage created by the

I × R drop (usually 20 mV to around 150 mV), the synchronous MOSFET on-time is extended into the next pulse

and the high-side MOSFET OCP comparator is enabled. If during the subsequent high-side on-time the

drain-to-source voltage of the high-side MOSFET exceeds the set point voltage, then the high-side on-time

pulse is terminated. This low-side extension/high-side termination action has the effect of decreasing the output

voltage until the UVP circuit is activated to turn off both the high-side and low-side drivers. The TPS51020 I

current has a temperature coefficient of 4200 PPM/°C.

current flowing through the external resistor connected to the

TRIP

TRIP

The threshold voltage for the OCP comparator is set by I × R drop across the trip resistor. The I

12.5-µA (typ) at R.T. so that the OCP point is given by following formula,

I

)

*6

RIPPLE

2

Ǔ

R

DS(on)

R

+

TRIP

Precaution should be taken with board layout in order to design OCP point as desired. The conversion voltage

point must avoid high current path. Any voltage difference between the conversion point and VIN input for the

TPS51020 is included in the threshold voltage. VIN plane layout should consider the other channels

high-current path as well.

A brief discussion is required for TRIP2 function. When TRIP2 is connected, via a resistor to GND, only low-side

OCP is used. This is the case for cascade configuration been selected. In this mode, UVP does not play a roll

in the shut off action and there is only a short delay between the over current trigger level been hit and the power

MOSFETs turn off. However, as with UVP, the SSTRTx pins are discharged and both SMPS goes though a

restart.

ǒ

I

OCP

12.5 10

TRIP

LAYOUT CONSIDERATIONS

Below are some points to consider before the layout of the TPS51020 design begins.

D Signal GND and power GND should be isolated as much as possible, with a single point connection

between them.

D All sensitive analog components such as INV, SSTRT, SKIP, DDR, GND, REF_X, ENBL and PGOOD

should be reference to signal GND and be as short as possible.

current is

D The source of low-side MOSFET, the Schottky diode anode, the output capacitor and OUTGND should be

referenced to power GND and be as short and wide as possible, otherwise signal GND is subject to the noise

of the outputs.

D PCB trace defined as the node of LL should be as short and wide as possible.

D Connections from the drivers to the gate of the power MOSFET should be as short and wide as possible

to reduce stray inductance and the noise at the LL node.

D The drain of high-side MOSFET, the input capacitor and the trip resistor should be as short and wide as

16

possible. For noise reduction, a 22-pF capacitor C

www.ti.com

can be placed in parallel with the trip resistor.

TRIP

Page 17

SLUS564C − JULY 2003 − REVISED OCTOBER 2008

APPLICATION INFORMATION

D The output voltage sensing trace and the feedback components should be as short as possible and be

isolated from the power components and traces.

D The low pass filter for VIN should be placed close to the TPS51020 and be referenced to signal GND.

D The bootstrap capacitor C

D VREG5 requires at least 4.7-µF bypass capacitor which should be placed close to the TPS51020 and be

referenced to signal GND.

D The discharge (VO1_VDDQ, VO2) should better have a dedicated trace to the output capacitor. In case of

limiting the discharge current, series resistors should be added.

D Ideally, all of the area directly under the TPS51020 chip should also be signal GND.

1

INV1

2

COMP1

3

SSTRT1

4

SKIP

5

VO1_VDDQ

6

DDR

7

Signal GND

GND

8

REF_X

9

ENBL1

10

ENBL2

11

VO2

12 19OUT2_DPGOOD

13

SSTRT2

14

COMP2

15

INV2

(connected from VBST to LL) should be placed close to the TPS51020.

BST

TPS51020

VBST1

OUT1_U

LL1

OUT1_D

OUTGND1

TRIP1

VIN

TRIP2

VREG5

REG5_IN

OUTGND2

LL2

OUT2_U

VBST2

30

C

Cvreg5

C

BST2

BST1

Rvin

Cvinbp

29

28

27

26

25

24

23

22

21

20

18

17

16

Cin1

L_FET1

L_FET2

Cin2

H_FET1

Cin

H_FET2

L01

Power GND

L02

Co1

Co2

Rtrip1 Ctrip1

Rtrips Ctrip2

CH1 Output Voltage (+)

+

CH1 Output Voltage (GND)

−

Input Voltage (+)

+

Input Voltage (GND)

−

CH2 Output Voltage (GND)

−

CH2 Output Voltage (+)

+

Figure 4. PCB Trace Guideline

www.ti.com

17

Page 18

25

−H

SLUS564C − JULY 2003 − REVISED OCTOBER 2008

APPLICATION INFORMATION

R102

100k

GND

R101

C12

R101

100k

6800p

R01

R02

100k

C22

C01a : Sanyo 35SVPD22M

C01c, C02, C03, C27 : Taiyo Yuden GMK325BJ225MH−B

C04a, C05a : Panasonic EEFUE0J151R

Q01, Q03 : Fairchild FDS6612A

Q02, Q04 : Fairchild FDS6690S

L01, L02 : Sumida CEP125−4R0MC−H

C14

3900p

49.7k

330

R03

10k

C15

0.01u

C19

0.01u

R09

10k

330

2200p

C20

3300p

R11

28.8k

R10

Figure 5. Typical Application Circuit: Dual (5V/6A + 3.3V/6A) from VBAT

R04

1.8k

(10V_REF)

R08

C01a

22u

R202

R200

GND

Q10

Q11

51k

Q12

GND

51k

Q15

R201

GND

Q13

Q14

R203

GND

Q01

R12

C08

1

TPS51020

INV1

2

COMP1

3

SSTRT1

4

SKIP

5

VO1_VDDQ

6

DDR

7

GND

8

REF_X

9

ENBL1

10

ENBL2

11

VO2

12

PGOOD

13

SSTRT2

14

COMP2

15

INV2

2.7k

OUTGND1

OUTGND2

R07

OUT1_U

OUT1_D

REG5_IN

OUT2_D

OUT2_U

VBST1

TRIP1

TRIP2

VREG5

VBST2

LL1

LL2

100k

0.1u

30

29

28

27

26

25

24

VIN

C11

R14

23

22

21

20

19

18

17

16

0.1u

R15

C02

2.2ux2

15

Q02

R13

18k

18k

15

R16

C27

0

C01c

0

Q04

C03

2.2ux2

Q03

L01

4u

C04a

C04c

0.01u

150u

GND

2.2u

C13

4.7u

GND

C05c

C05a

L02

4u

150u

0.01u

VBAT

8 V to 20 V

5V_OUT

5V_X

51k

3.3V_OUT

3.3V_X

51k

R102

GND

100k

R101

100k

C12

4700p

R01

C14

R02

7.62k

1.2k

R03

3.9k

C15

C19

R10

R11

1.2k

C22

2200p

4700p

0.01u

(VO1_VDDQ/2_REF)

0.01u

C20

6800p

19.7k

R04

4.7k

1

TPS51020

INV1

2

COMP1

3

SSTRT1

4

SKIP

5

VO1_VDDQ

6

DDR

7

GND

8

REF_X

9

ENBL1

10

ENBL2

11

VO2

12

PGOOD

13

SSTRT2

14

COMP2

15

INV2

R08

3.9k

OUTGND1

OUTGND2

R07

VBST1

OUT1_U

OUT1_D

TRIP1

TRIP2

VREG5

REG5_IN

OUT2_D

OUT2_U

VBST2

LL1

VIN

LL2

C11

100k

R12

15

C08

0.1u

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

0.1u

R14

(EXT_5V)

R15

R13

18k

18k

15

C02

2.2ux2

C27 C01c

C03

2.2ux2

Q03

Q01

Q02

R16

0

0 2.2u

Q04

GND

L01

5.6u

C04b

C04a

150u

C13

4.7u

C05b

C05a

150u

L02

5.6u

Figure 6. Typical Application Circuit: DDR(2.5V/6A + 1.25V/6A) from VBAT

C01a

22u

GND

C04c

0.01u

150u

GND

GND

C05c

150u

0.01u

C01a : Sanyo 35SVPD22M

C01c, C02, C03, C27 : Taiyo Yuden GMK325BJ2

C04a, C05a, C04b, C05b : Panasonic EEFUE0J151R

Q01, Q03 : Fairchild FDS6612A

Q02, Q04 : Fairchild FDS6690S

L01, L02 : Sumida CEP125−5R6MC

VBAT

8 V to 20 V

2.5V_OUT

1.25V_OUT

18

www.ti.com

Page 19

R102

GND

100k

R101

100k

SLUS564C − JULY 2003 − REVISED OCTOBER 2008

APPLICATION INFORMATION

VBAT

C01a

C05c

GND

0.01u

GND

0.01u

C12

4700p

R01

R02

7.62k

1.2k

R03

3.9k

C15

C19

R10

R11

1.2k

19.7k

C22

2200p

R04

C14

4.7k

4700p

0.01u

(VO1_VDDQ/2_REF)

0.01u

C20

R08

6800p

1

TPS51020

INV1

2

COMP1

3

SSTRT1

4

SKIP

5

VO1_VDDQ

6

DDR

7

GND

8

REF_X

9

ENBL1

10

ENBL2

11

VO2

12

PGOOD

13

SSTRT2

14

COMP2

15

INV2

3.9k

R07

VBST1

OUT1_U

LL1

OUT1_D

OUTGND1

TRIP1

VIN

TRIP2

VREG5

REG5_IN

OUTGND2

OUT2_D

LL2

OUT2_U

VBST2

100k

C11

R12

15

C08

0.1u

30

29

28

27

26

25

24

23

22

21

(EXT_5V)

20

19

18

17

16

0.1u

R15

R13

R14

C04d

15

2.5V_OUT

C02

GND

Q01

2.2ux2

Q02

18k

150u

R16

0

0

Q04

Q03

18k

L01

5.6u

C04b

C05a

C04c

150u

150u

GND

4.7u

C05b

150u

150u

C04a

C01cC27

2.2u

C13

GND

L02

5.6u

8 V to 20 V

22u

2.5V_OUT

1.25V_OUT

C01a : Sanyo 35SVPD22M

C01c, C02, C27 : Taiyo Yuden GMK325BJ225MH−B

C04a, C05a, C04b, C05b,C04d : Panasonic EEFUE0J151R

Q01, Q03 : Fairchild FDS6612A

Q02, Q04 : Fairchild FDS6690S

L01, L02 : Sumida CEP125−5R6MC−H

Figure 7. Typical Application Circuit: DDR (2.5V/6A + 1.25V/3A) Cascade

www.ti.com

19

Page 20

SLUS564C − JULY 2003 − REVISED OCTOBER 2008

TYPICAL CHARACTERISTICS

SUPPLY CURRENT

JUNCTION TEMPERATURE

2.5

V

= 12 V

VIN

2.0

1.5

− Input Supply Current − mA

1.0

VIN

I

0.5

0 50 100 150−50

TJ − Junction Temperature − °C

Figure 8

vs

SHUTDOWN CURRENT

JUNCTION TEMPERATURE

140

V

REG5V_IN = Open

120

100

80

− Shutdown Current − nA

60

40

VIN(SHTDWN)

I

20

0

− V

ENBLx

DDR

0 50 100 150−50

TJ − Junction Temperature − °C

vs

= 0 V

Figure 9

25

20

15

10

− TRIP1 Sink Current − µA

5

TRIPSINK

I

0

V

TRIP

TRIP CURRENT

vs

JUNCTION TEMPERATURE

− V

= 0.1 V

VIN

0 50 100 150−50

TJ − Junction Temperature − °C

Figure 10

−2.50

−2.45

−2.40

−2.35

−2.30

−2.25

− SSRTx Charge Current − µA

−2.20

SSQ

I

−2.15

−2.10

SOFTSTART CURRENT

JUNCTION TEMPERATURE

V

= 12 V

VIN

V

SSTRTx

= 1 V

0 50 100 150−50

TJ − Junction Temperature − °C

Figure 11

vs

20

www.ti.com

Page 21

100 k

10 k

1 k

100

− Softstart Time − µs

SS

t

10

1

V

VIN

TA = 25°C

1

SOFTSTART TIME

vs

SOFTSTART CAPACITANCE

= 12 V

10

C

SSTRT

100 1 k 10 k 100 k

− Softstart Capacitance − pF

Figure 12

TYPICAL CHARACTERISTICS

500

V

= 12 V

VIN

450

400

350

300

− Oscillator Frequency − kHz

OSC

250

f

200

SLUS564C − JULY 2003 − REVISED OCTOBER 2008

OSCILLATOR FREQUENCY

vs

JUNCTION TEMPERATURE

f

OSC(HI)

f

OSC(TYP)

f

OSC(LO)

0 50 100 150−50

TJ − Junction Temperature − °C

Figure 13

UNDERVOLTAGE PROTECTION THRESHOLD

vs

JUNCTION TEMPERATURE

900

V

= 12 V

VIN

850

800

750

700

650

600

− Undervoltage Protection Trip Voltage − mV

550

UVP

V

500

0 50 100 150−50

TJ − Junction Temperature − °C

DDR = LO

V

VO1_VDDQ

Figure 14

= 2.5 V

DDR = HI

OVERVOLTAGE PROTECTION THRESHOLD

1400

1300

1200

1100

1000

900

− Overvoltage Protection Trip Voltage − mV

OVP

V

800

JUNCTION TEMPERATURE

vs

V

= 12 V

VIN

0 50 100 150−50

TJ − Junction Temperature − °C

Figure 15

DDR = LO

V

VO1_VDDQ

= 2.5 V

DDR = HI

www.ti.com

21

Page 22

SLUS564C − JULY 2003 − REVISED OCTOBER 2008

TYPICAL CHARACTERISTICS

5.2

5.1

5.0

4.9

4.8

4.7

4.6

− VREG5 Output Voltage − V

4.5

VREG5

V

4.4

4.3

V

= 12 V

VIN

TA = 25°C

−20 −40 −60 −80 −1000

I

VREG

VREG5 OUTPUT VOLTAGE

vs

VREG5 OUTPUT CURRENT

− VREG5 Output Current − mA

Figure 16

V

OUT1

50 mV/div

f

= 290 kHz

OSC

VIN = 20 V, V

1 A ≤ I

OUT1

= 2.5 V

OUT1

≤ 6 A, 1A/ms

t − Time − 100 ms / div

Figure 17. Load Transient Response

I

OUT1

2 A/div

V

OUT1

1 V/div

PGOOD

2 V/ div

t − Time − 5 ms / div

Figure 18. Simultaneous Startup

V

OUT2

500 mV/div

V

OUT1

1 V/div

PGOOD

2 V/ div

t − Time − 5 ms / div

Figure 19. Offset Startup

V

OUT2

500 mV/div

22

www.ti.com

Page 23

V

VIN

Efficiency − %

= 8 V

ENBL1

5 V/div

V

= 20 V

VIN

V

OUT1

2 V/div

t − Time − 5 ms / div

Figure 20. Soft-Stop

TYPICAL CHARACTERISTICS

VDDQ (1 V/div)

f

OSC

V

VO1

ENBL2

5 V/div

V

OUT2

2 V/div

= 290 kHz

= 5 V

VDDQ Disabled S5

Figure 21. Cascade Configuration DDR Mode

SLUS564C − JULY 2003 − REVISED OCTOBER 2008

VTT Disabled S3

VTT (1 V/div)

t − Time − 5 ms / div

Shudown

100

V

VIN

80

60

40

Efficiency − %

20

0

PWM MODE EFFICIENCY

vs

OUTPUT CURRENT

= 8 V

V

= 20 V

VIN

V

= 12 V

VIN

0.1 1 100.01

I

− Output Current − A

OUT

Figure 22

f

OSC

V

VO1

= 290 kHz

= 5 V

100

80

60

40

Efficiency − %

20

0

AUTOSKIP MODE EFFICIENCY

vs

OUTPUT CURRENT

V

f

OSC

V

VO1

VIN

V

VIN

V

VIN

= 8 V

0.1 1 100.01

I

− Output Current − A

OUT

= 20 V

Figure 23

= 12 V

= 290 kHz

= 5 V

www.ti.com

23

Page 24

SLUS564C − JULY 2003 − REVISED OCTOBER 2008

100

V

VIN

80

60

40

Efficiency − %

20

0

PWM MODE EFFICIENCY

vs

OUTPUT CURRENT

= 8 V

V

V

= 20 V

VIN

0.1 10.01

I

− Output Current − A

OUT

Figure 24

VIN

f

OSC

V

VO1

= 12 V

= 290 kHz

= 2.5 V

10

100

80

60

40

Efficiency − %

20

0

AUTOSKIP MODE EFFICIENCY

vs

OUTPUT CURRENT

V

= 8 V

VIN

V

= 12 V

VIN

f

OSC

V

VO1

0.1 1 100.01

I

− Output Current − A

OUT

Figure 25

V

= 20 V

VIN

= 290 kHz

= 2.5 V

24

www.ti.com

Page 25

PACKAGE OPTION ADDENDUM

www.ti.com

24-Jan-2013

PACKAGING INFORMATION

Orderable Device Status

TPS51020DBT ACTIVE TSSOP DBT 30 60 Green (RoHS

TPS51020DBTG4 ACTIVE TSSOP DBT 30 60 Green (RoHS

TPS51020DBTR ACTIVE TSSOP DBT 30 2000 Green (RoHS

TPS51020DBTRG4 ACTIVE TSSOP DBT 30 2000 Green (RoHS

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

Package Type Package

(1)

Drawing

Pins Package Qty Eco Plan

(2)

& no Sb/Br)

& no Sb/Br)

& no Sb/Br)

& no Sb/Br)

Lead/Ball Finish MSL Peak Temp

(3)

CU NIPDAU Level-2-260C-1 YEAR -40 to 85 PS51020

CU NIPDAU Level-2-260C-1 YEAR -40 to 85 PS51020

CU NIPDAU Level-2-260C-1 YEAR -40 to 85 PS51020

CU NIPDAU Level-2-260C-1 YEAR -40 to 85 PS51020

Op Temp (°C) Top-Side Markings

(4)

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check http://www.ti.com/productcontent for the latest availability

information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements for all 6 substances, including the requirement that

lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and package, or 2) lead-based die adhesive used between

the die and leadframe. The component is otherwise considered Pb-Free (RoHS compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame retardants (Br or Sb do not exceed 0.1% by weight

in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder temperature.

(4)

Only one of markings shown within the brackets will appear on the physical device.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is provided. TI bases its knowledge and belief on information

provided by third parties, and makes no representation or warranty as to the accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and

continues to take reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on incoming materials and chemicals.

TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI to Customer on an annual basis.

Samples

Addendum-Page 1

Page 26

PACKAGE OPTION ADDENDUM

www.ti.com

24-Jan-2013

Addendum-Page 2

Page 27

Page 28

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2013, Texas Instruments Incorporated

Page 29

Loading...

Loading...