Page 1

www.ti.com

1

2

3

4

8

7

6

5

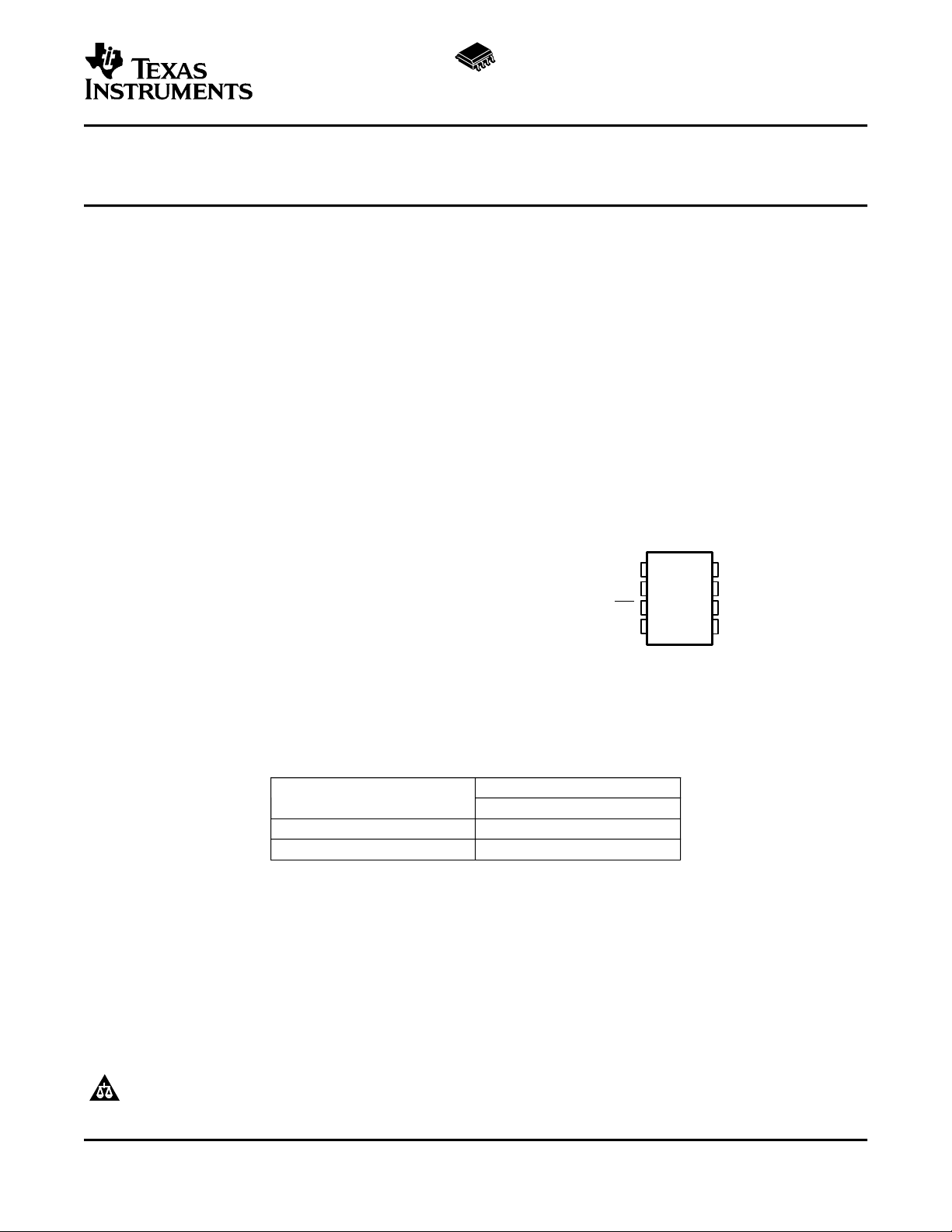

DIN

SCLK

CS

OUTA

V

DD

OUTB

REF

AGND

D PACKAGE

(TOP VIEW)

SLAS224B – JUNE 1999 – REVISED JANUARY 2004

2.7-V TO 5.5-V LOW-POWER DUAL 10-BIT DIGITAL-TO-ANALOG CONVERTER WITH

INTERNAL REFERENCE AND POWER DOWN

TLV5637

FEATURES

• Dual 10-Bit Voltage Output DAC

• Programmable Internal Reference

• Programmable Settling Time:

– 0.8 µs in Fast Mode

– 2.8 µs in Slow Mode

• Compatible With TMS320 and SPI™ Serial

Ports

• Differential Nonlinearity <0.1 LSB Typ

• Monotonic Over Temperature

APPLICATIONS

• Digital Servo Control Loops

• Digital Offset and Gain Adjustment

• Industrial Process Control

• Machine and Motion Control Devices

• Mass Storage Devices

DESCRIPTION

The TLV5637 is a dual 10-bit voltage output DAC

with a flexible 3-wire serial interface. The serial

interface allows glueless interface to TMS320 and

SPI™, QSPI™, and Microwire™ serial ports. It is

programmed with a 16-bit serial string containing 2

control and 10 data bits.

The resistor string output voltage is buffered by a x2

gain rail-to-rail output buffer. The buffer features a

Class AB output stage to improve stability and reduce

settling time. The programmable settling time of the

DAC allows the designer to optimize speed versus

power dissipation. With its on-chip programmable

precision voltage reference, the TLV5637 simplifies

overall system design.

Because of its ability to source up to 1 mA, the

reference can also be used as a system reference.

Implemented with a CMOS process, the device is

designed for single supply operation from 2.7 V to 5.5

V. It is available in an 8-pin SOIC package to reduce

board space in standard commercial and industrial

temperature ranges.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

SPI, QSPI are trademarks of Motorola, Inc.

Microwire is a trademark of National Semiconductor Corporation.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

AVAILABLE OPTIONS

T

A

0°C to 70°C TLV5637CD

40°C to 85°C TLV5637ID

PACKAGE

SOIC (D)

Copyright © 1999–2004, Texas Instruments Incorporated

Page 2

www.ti.com

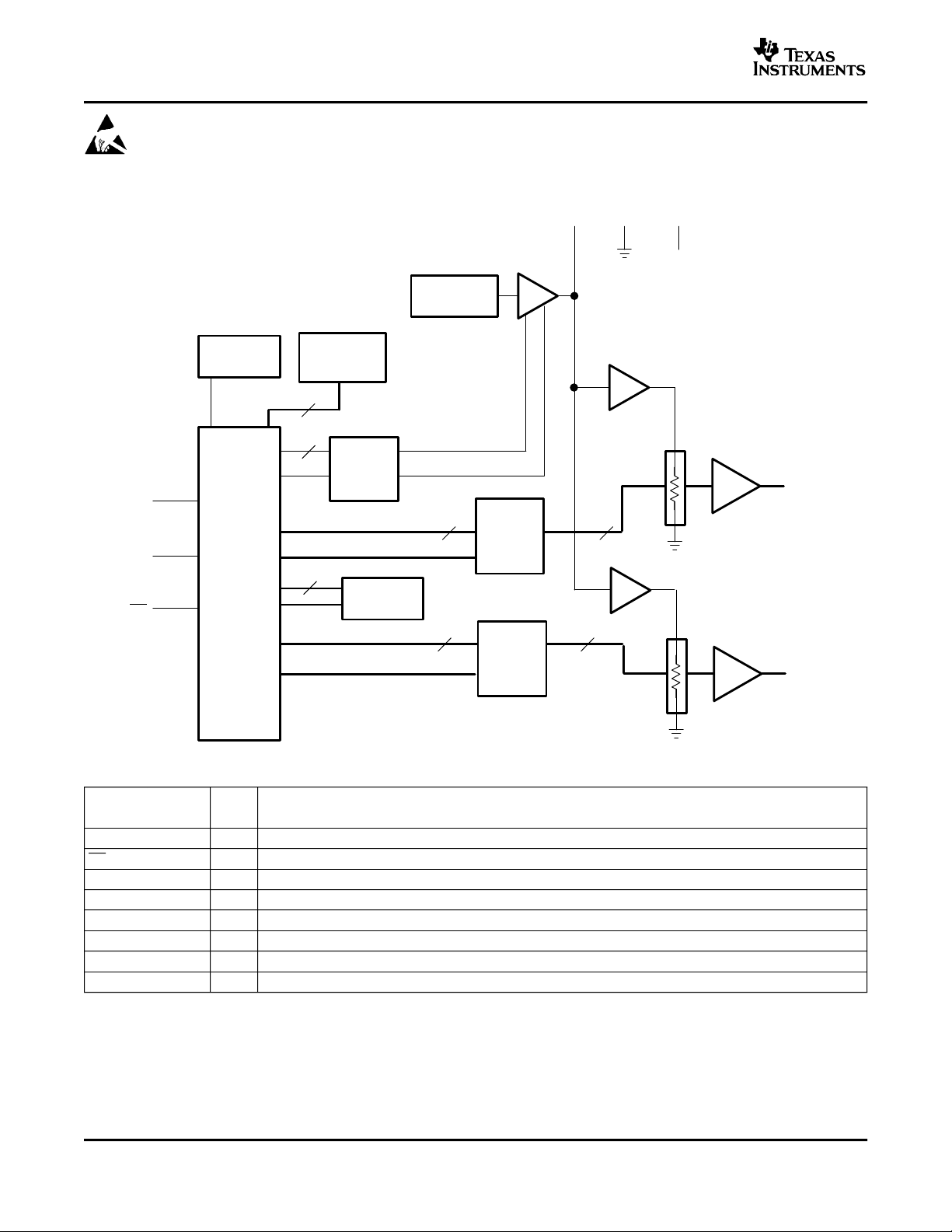

Serial

Interface

and

Control

10-Bit

DAC B

Latch

SCLK

DIN

CS

OUTA

Power-On

Reset

x2

10

2-Bit

Control

Latch

Power

and Speed

Control

2

Voltage

Bandgap

PGA With

Output Enable

10-Bit

DAC A

Latch

10

REF AGND V

DD

2

10 10

OUTB

x2

Buffer

10

TLV5637

SLAS224B – JUNE 1999 – REVISED JANUARY 2004

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

FUNCTIONAL BLOCK DIAGRAM

Terminal Functions

TERMINAL

NAME NO.

AGND 5 P Ground

CS 3 I Chip select. Digital input active low, used to enable/disable inputs

DIN 1 I Digital serial data input

OUTA 4 I DAC A analog voltage output

OUTB 7 O DAC B analog voltage output

REF 6 I/O Analog reference voltage input/output

SCLK 2 I Digital serial clock input

V

DD

2

I/O/P DESCRIPTION

8 P Positive power supply

Page 3

www.ti.com

TLV5637

SLAS224B – JUNE 1999 – REVISED JANUARY 2004

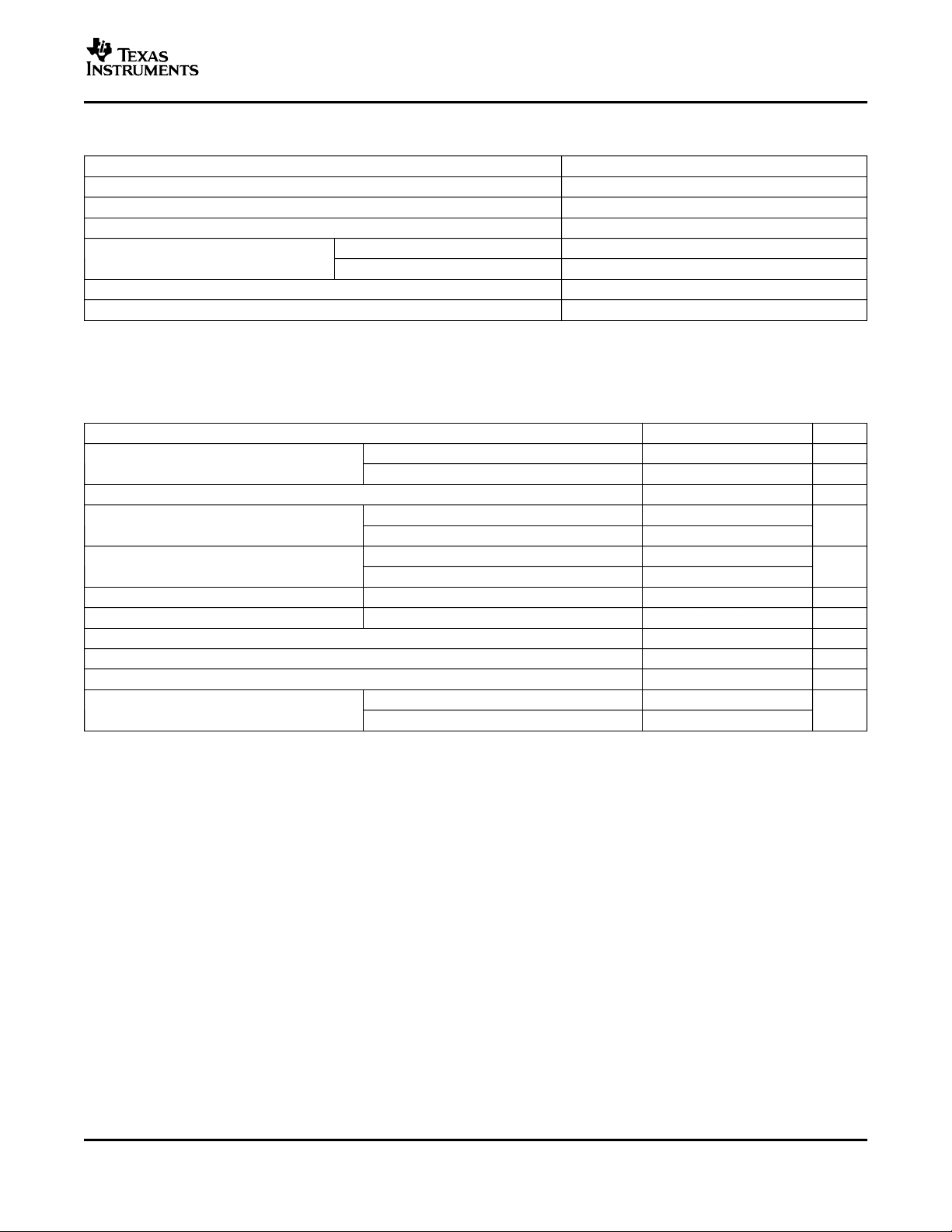

ABSOLUTE MAXIMUM RATINGS

over operating free-air temperature range (unless otherwise noted)

Supply voltage (V

Reference input voltage range - 0.3 V to V

Digital input voltage range - 0.3 V to V

Operating free-air temperature range, T

Storage temperature range, T

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds 260°C

(1) Stresses beyond those listed under, , absolute maximum ratings” may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under, , recommended operating

conditions” is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

to AGND) 7 V

DD

TLV5637C 0°C to 70°C

A

TLV5637I -40°C to 85°C

stg

(1)

UNIT

+ 0.3 V

DD

+ 0.3 V

DD

-65°C to 150°C

RECOMMENDED OPERATING CONDITIONS

MIN NOM MAX UNIT

V

= 5 V 4.5 5 5.5 V

Supply voltage, V

DD

Power on threshold voltage, POR 0.55 2 V

High-level digital input voltage, V

Low-level digital input voltage, V

Reference voltage, V

Reference voltage, V

Load resistance, R

Load capacitance, C

Clock frequency, f

to REF terminal V

ref

to REF terminal V

ref

L

L

CLK

Operating free-air temperature, T

IH

IL

A

(1) Due to the x2 output buffer, a reference input voltage ≥ (V

internal reference must be disabled, if an external reference is used.

DD

V

= 3 V 2.7 3 3.3 V

DD

DV

= 2.7 V 2

DD

DV

= 5.5 V 2.4

DD

DV

= 2.7 V 0.6

DD

DV

= 5.5 V 1

DD

= 5 V (see

DD

= 3 V (see

DD

(1)

) AGND 2.048 VDD-1.5 V

(1)

) AGND 1.024 VDD-1.5 V

2 kΩ

TLV5637C 0 70

TLV5637I 40 85

- 0.4 V)/2 causes clipping of the transfer function. The output buffer of the

DD

100 pF

20 MHz

V

V

°C

3

Page 4

www.ti.com

TLV5637

SLAS224B – JUNE 1999 – REVISED JANUARY 2004

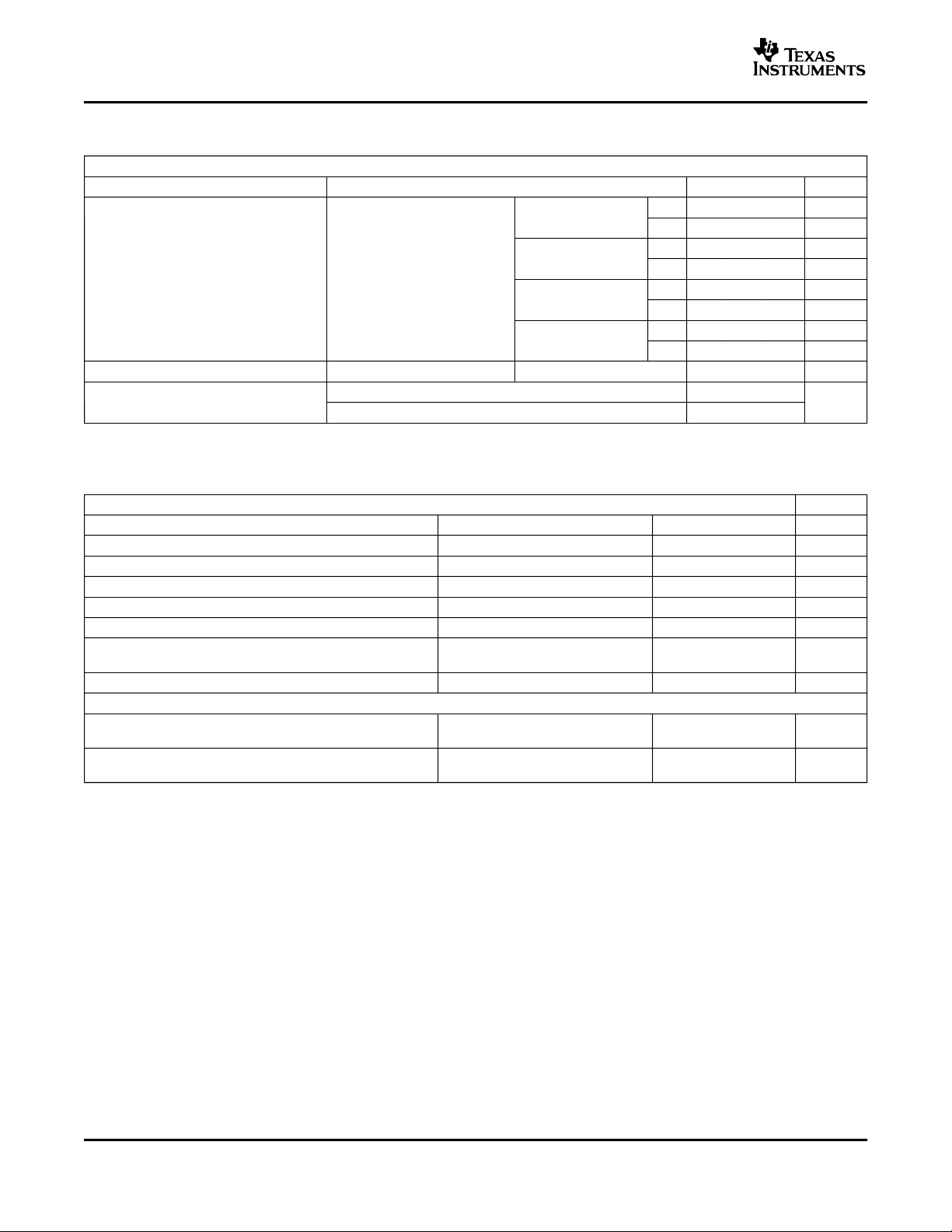

ELECTRICAL CHARACTERISTICS

over recommended operating conditions (unless otherwise noted)

POWER SUPPLY

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

= 5 V, Int. ref.

DD

V

= 3 V, Int. ref.

V

V

DD

DD

DD

= 5 V, Ext. ref.

= 3 V, Ext. ref.

I

DD

Power supply current

No load, All inputs = AGND or

VDD, DAC latch = 0x800

Power-down supply current 0.01 10 µA

PSRR Power supply rejection ratio dB

Zero scale, See

Full scale, See

(1) Power supply rejection ratio at zero scale is measured by varying V

EZS(V

min))/V

(2) Power supply rejection ratio at full scale is measured by varying V

DD

EG(V

min))/V

DD

max]

DD

max]

DD

(1)

(2)

and is given by: PSRR = 20 log [(E

DD

and is given by: PSRR = 20 log [(E

DD

STATIC DAC SPECIFICATIONS

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Resolution 10 bits

INL Integral nonlinearity, end point adjusted See

DNL Differential nonlinearity See

E

Zero-scale error (offset error at zero scale) See

ZS

EZSTC Zero-scale-error temperature coefficient See

E

EGT

Gain error See

G

Gain error temperature coefficient See

C

(1)

(2)

(3)

(4)

(5)

(6)

OUTPUT SPECIFICATIONS

V

Output voltage RL= 10 kΩ 0 V

O

Output load regulation accuracy VO= 4.096 V, 2.048 V, RL= 2 kΩ ±0.25

(1) The relative accuracy or integral nonlinearity (INL) sometimes referred to as linearity error, is the maximum deviation of the output from

the line between zero and full scale excluding the effects of zero code and full-scale errors. Tested from code 32 to 4095.

(2) The differential nonlinearity (DNL) sometimes referred to as differential error, is the difference between the measured and ideal 1 LSB

amplitude change of any two adjacent codes. Monotonic means the output voltage changes in the same direction (or remains constant)

as a change in the digital input code.

(3) Zero-scale error is the deviation from zero voltage output when the digital input code is zero.

(4) Zero-scale-error temperature coefficient is given by: E

(5) Gain error is the deviation from the ideal output (2V

(6) Gain temperature coefficient is given by: EGTC = [EG(T

TC = [E

ZS

- 1 LSB) with an output load of 10 k excluding the effects of the zero-error.

ref

) - EG(T

max

(T

) - E

(T

ZS

max

)]/V

× 10

min

ref

)]/V

ZS

min

ref

6

/(T

- T

max

Fast 4.2 7 mA

Slow 2 3.6 mA

Fast 3.7 6.3 mA

Slow 1.7 3.0 mA

Fast 3.8 6.3 mA

Slow 1.7 3.0 mA

Fast 3.4 5.7 mA

Slow 1.4 2.6 mA

(V

ZS

G(VDD

6

× 10

/(T

- T

max

).

min

).

min

65

65

max) -

DD

max) -

±0.4 ±1 LSB

±0.1 ±0.5 LSB

±24 mV

10 ppm/°C

±0.6

10 ppm/°C

VDD-

0.4

% full

scale V

% full

scale V

4

Page 5

www.ti.com

TLV5637

SLAS224B – JUNE 1999 – REVISED JANUARY 2004

ELECTRICAL CHARACTERISTICS (CONTINUED)

over recommended operating conditions (unless otherwise noted)

REFERENCE PIN CONFIGURED AS OUTPUT (REF)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

ref(OUTL)

V

ref(OUTH)

I

ref(source)

I

ref(sink)

PSRR Power supply rejection ratio 65 dB

REFERENCE PIN CONFIGURED AS INPUT (REF)

V

Input voltage 0 V

I

R

Input resistance 10 MΩ

I

C

Input capacitance 5 pF

I

Reference input bandwidth REF = 0.2 Vpp+ 1.024 V dc

Reference feedthrough REF = 1 Vppat 1 kHz + 1.024 V dc, See

(1) Reference feedthrough is measured at the DAC output with an input code = 0x000.

DIGITAL INPUTS

I

IH

I

IL

C

i

Low reference voltage 1.003 1.024 1.045 V

High reference voltage V

> 4.75 V 2.027 2.048 2.069 V

DD

Output source current 1 mA

Output sink current 1 mA

Load capacitance 100 pF

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

DD-1.5

Fast 1.3 MHz

Slow 525 kHz

(1)

80 dB

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

High-level digital input current VI= V

DD

Low-level digital input current VI= 0 V 1 µA

Input capacitance 8 pF

V

1 µA

5

Page 6

www.ti.com

t

wL

SCLK

CS

DIN

D15 D14 D13 D12 D1 D0 XX

1

X

2 3 4 5 15 16

X

t

wH

t

su(D)th(D)

t

su(CS-CK)

t

su(C16-CS)

TLV5637

SLAS224B – JUNE 1999 – REVISED JANUARY 2004

ELECTRICAL CHARACTAERISTICS (CONTINUED)

over recommended operating conditions (unless otherwise noted)

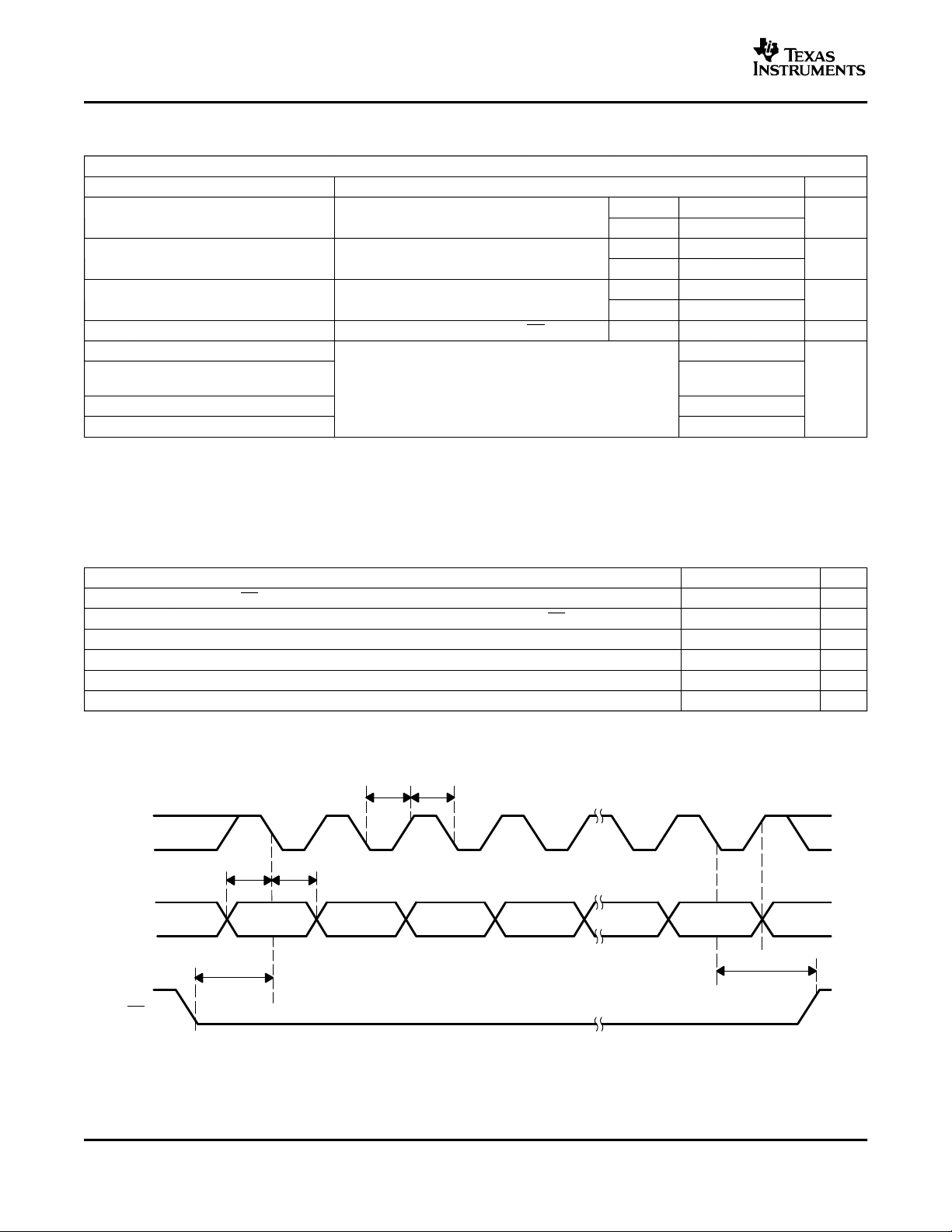

ANALOG OUTPUT DYNAMIC PERFORMANCE

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

t

t

Output settling time, full scale RL= 10 kΩ, CL= 100 pF, See

s(FS)

Output settling time, code to code RL= 10 kΩ, CL= 100 pF, See

s(CC)

SR Slew rate RL= 10 kΩ, CL= 100 pF, See

Glitch energy DIN = 0 to 1, f

= 100 kHz, CS = V

CLK

(1)

(2)

(3)

SNR Signal-to-noise ratio 53 56

S/(N+

D)

Signal-to-noise + distortion 50 54

fs= 480 kSPS, f

= 1 kHz, RL= 10 kΩ, CL= 100 pF dB

out

THD Total harmonic distortion 61 50

SFDR Spurious free dynamic range 51 62

(1) Settling time is the time for the output signal to remain within ±0.5 LSB of the final measured value for a digital input code change of

0x020 to 0xFDF or 0xFDF to 0x020 respectively. Not tested, assured by design.

(2) Settling time is the time for the output signal to remain within ± 0.5 LSB of the final measured value for a digital input code change of

one count. Not tested, assured by design.

(3) Slew rate determines the time it takes for a change of the DAC output from 10% to 90% full-scale voltage.

Fast 0.8 2.4

Slow 2.8 5.5

Fast 0.4 1.2

Slow 0.8 1.6

Fast 12

Slow 1.8

DD

5 nV-S

µs

µs

V/µs

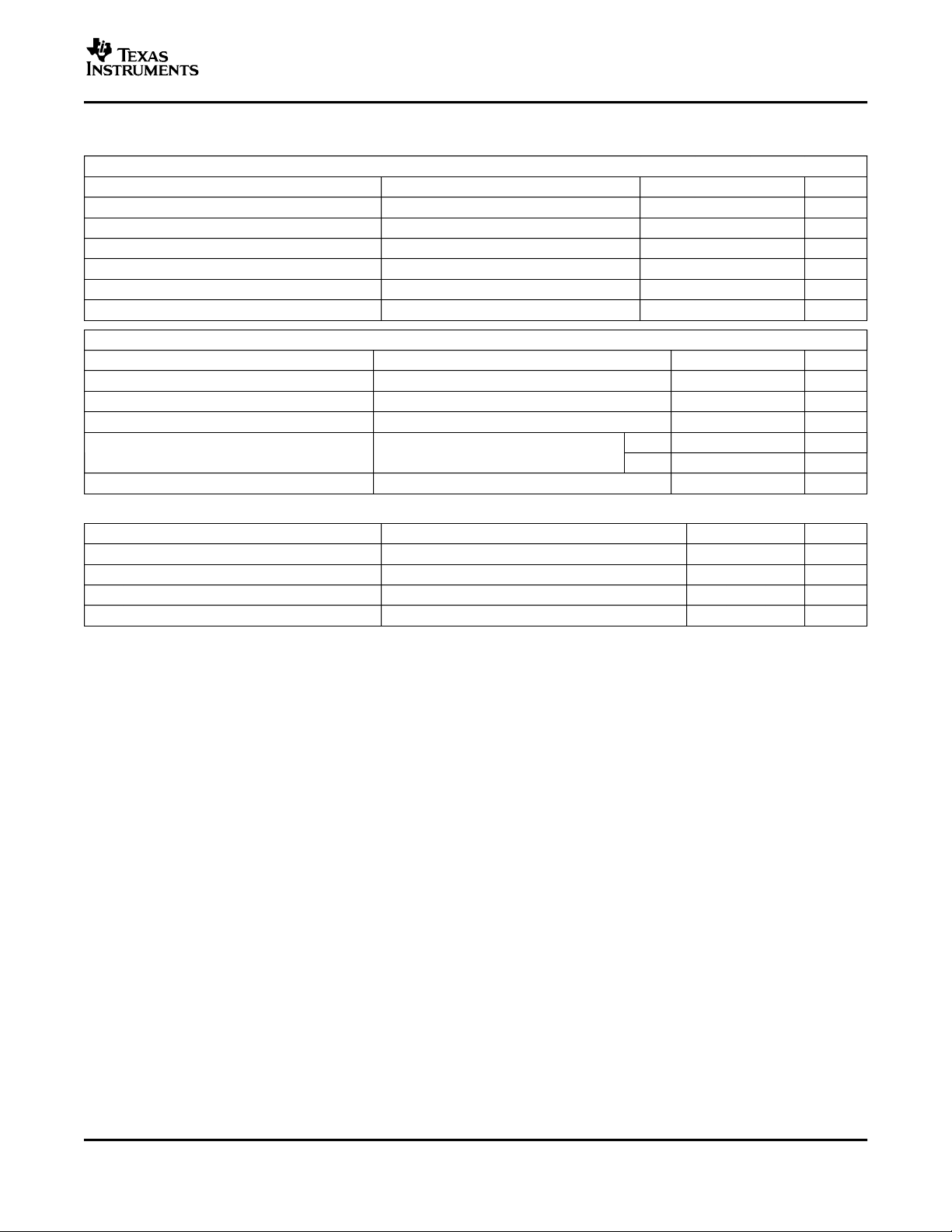

DIGITAL INPUT TIMING REQUIREMENTS

t

su(CS-CK)

t

su(C16-CS)

t

wH

t

wL

t

su(D)

t

h(D)

MIN NOM MAX UNIT

Setup time, CS low before first negative SCLK edge 10 ns

Setup time, 16

th

negative SCLK edge (when D0 is sampled) before CS rising edge 10 ns

SCLK pulse width high 25 ns

SCLK pulse width low 25 ns

Setup time, data ready before SCLK falling edge 10 ns

Hold time, data held valid after SCLK falling edge 5 ns

PARAMETER MEASUREMENT INFORMATION

6

Figure 1. Timing Diagram

Page 7

www.ti.com

Fast Mode

Slow Mode

VDD = 5 V

V

ref

= Int. 2 V

Input Code = 1023 (Both DACs)

2.5

2

1

0.5

–40–30 –20–10 0 10 20

– Supply Current – mA

3

4

SUPPLY CURRENT

vs

FREE-AIR TEMPERATURE

4.5

30 40 50 90

3.5

1.5

60 70 80

I

DD

TA – Free-Air Temperature – °C

Fast Mode

Slow Mode

VDD = 3 V

V

ref

= Int. 1 V

Input Code = 1023 (Both DACs)

2.5

2

1

0.5

–40–30 –20–10 0 10 20

– Supply Current – mA

3

4

SUPPLY CURRENT

vs

FREE-AIR TEMPERATURE

4.5

30 40 50 90

3.5

1.5

60 70 80

I

DD

TA – Free-Air Temperature – °C

1.4

1

0.4

0

0 10 20 30 40

– Power Down Supply Current – mA

2.2

2.4

POWER DOWN SUPPLY CURRENT

vs

TIME

2.6

50 60 70 80

2

1.8

1.6

1.2

0.8

0.6

0.2

t – Time – µs

I

DD

2.058

2.054

2.052

2.05

0 0.5 1 1.5 2 2.5 3

– Output Voltage – V

2.06

2.062

Source Current – mA

OUTPUT VOLTAGE

vs

LOAD CURRENT

2.064

3.5 4

2.056

V

O

Fast Mode

Slow Mode

VDD = 3 V

V

ref

= Int. 1 V

Input Code = 4095

TLV5637

SLAS224B – JUNE 1999 – REVISED JANUARY 2004

TYPICAL CHARACTERISTICS

Figure 2. Figure 3.

Figure 4. Figure 5.

7

Page 8

www.ti.com

4.122

4.12

4.116

4.114

0 0.5 1 1.5 2 2.5 3

4.124

4.126

4.128

3.5 4

4.118

– Output Voltage – V

Source Current – mA

OUTPUT VOLTAGE

vs

LOAD CURRENT

V

O

Fast Mode

Slow Mode

VDD = 5 V

V

ref

= Int. 2 V

Input Code = 4095

1.5

1

0.5

0

0 0.5 1 1.5 2 2.5 3

2

2.5

3

3.5 4

– Output Voltage – V

Sink Current – mA

OUTPUT VOLTAGE

vs

LOAD CURRENT

V

O

Fast Mode

Slow Mode

VDD = 3 V

V

ref

= Int. 1 V

Input Code = 0

3.5

2

1

0

0 0.5 1 1.5 2 2.5 3

4

4.5

5

3.5 4

3

2.5

1.5

0.5

– Output Voltage – V

Sink Current – mA

OUTPUT VOLTAGE

vs

LOAD CURRENT

V

O

Fast Mode

Slow Mode

VDD = 5 V

V

ref

= Int. 2 V

Input Code = 0

–40

–50

–80

–100

100 1000

THD+N – Total Harmonic Distortion and Noise – dB

–20

–10

f – Frequency – Hz

TOTAL HARMONIC DISTORTION AND NOISE

vs

FREQUENCY

0

10000 100000

–30

–60

–70

–90

Fast Mode

Slow Mode

VDD = 5 V

V

ref

= 1 V dc + 1 V p/p Sinewave

Output Full Scale

TLV5637

SLAS224B – JUNE 1999 – REVISED JANUARY 2004

TYPICAL CHARACTERISTICS (continued)

8

Figure 6. Figure 7.

Figure 8. Figure 9.

Page 9

www.ti.com

–40

–50

–80

–100

100 1000

THD – Total Harmonic Distortion – dB

–20

–10

f – Frequency – Hz

TOTAL HARMONIC DISTORTION

vs

FREQUENCY

0

10000 100000

–30

–60

–70

–90

Fast Mode

Slow Mode

VDD = 5 V

V

ref

= 1 V dc + 1 V p/p Sinewave

Output Full Scale

–0.4

–1

0 256 512

INL – Integral Nonlinearity Error – LSB

0

0.6

Digital Code

INTEGRAL NONLINEARITY ERROR

1

768 1024

0.8

0.4

0.2

–0.2

–0.6

–0.8

TYPICAL CHARACTERISTICS (continued)

TLV5637

SLAS224B – JUNE 1999 – REVISED JANUARY 2004

Figure 10.

Figure 11.

9

Page 10

www.ti.com

–0.1

–0.2

0 256 512

DNL – Differential Nonlinearity Error – LSB

0

0.15

Digital Code

DIFFERENTIAL NONLINEARITY ERROR

0.2

768 1024

0.1

0.05

–0.05

–0.15

TLV5637

SLAS224B – JUNE 1999 – REVISED JANUARY 2004

TYPICAL CHARACTERISTICS (continued)

Figure 12.

10

Page 11

www.ti.com

2 REF

CODE

0x1000

[V]

TMS320

DSP

FSX

CLKX

DX

TLV5637

SCLK

DIN

CS

SPI

I/O

SCK

MOSI

TLV5637

SCLK

DIN

CS

Microwire

I/O

SK

SO

TLV5637

SCLK

DIN

CS

f

sclkmax

1

t

whmin

t

wlmin

20 MHz

f

updatemax

1

16t

whmin

t

wlmin

1.25 MHz

TLV5637

SLAS224B – JUNE 1999 – REVISED JANUARY 2004

APPLICATION INFORMATION

GENERAL FUNCTION

The TLV5637 is a dual 10-bit, single supply DAC, based on a resistor string architecture. It consists of a serial

interface, a speed and power-down control logic, a programmable internal reference, a resistor string, and a

rail-to-rail output buffer.

The output voltage (full scale determined by reference) is given by:

Where REF is the reference voltage and CODE is the digital input value in the range 0x000 to 0xFFF. Because it

is a 10-bit DAC, only D11 to D2 are used. D0 and D1 are ignored. A power-on reset initially puts the internal

latches to a defined state (all bits zero).

SERIAL INTERFACE

A falling edge of CS starts shifting the data bit-per-bit (starting with the MSB) to the internal register on the falling

edges of SCLK. After 16 bits have been transferred or CS rises, the content of the shift register is moved to the

target latches (DAC A, DAC B, BUFFER, CONTROL), depending on the control bits within the data word.

Figure 13 shows examples of how to connect the TLV5637 to TMS320, SPI™, and Microwire™.

Figure 13. Three-Wire Interface

Notes on SPI™ and Microwire™: Before the controller starts the data transfer, the software has to generate a

falling edge on the I/O pin connected to CS. If the word width is 8 bits (SPI™ and Microwire™), two write

operations must be performed to program the TLV5637. After the write operation(s), the holding registers or the

control register are updated automatically on the 16

th

positive clock edge.

SERIAL CLOCK FREQUENCY AND UPDATE RATE

The maximum serial clock frequency is given by:

The maximum update rate is:

Note, that the maximum update rate is just a theoretical value for the serial interface, as the settling time of the

TLV5637 has to be considered, too.

11

Page 12

www.ti.com

TLV5637

SLAS224B – JUNE 1999 – REVISED JANUARY 2004

APPLICATION INFORMATION (continued)

DATA FORMAT

The 16-bit data word for the TLV5637 consists of two parts:

• Program bits (D15..D12)

• New data (D11..D0)

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

R1 SPD PWR R0 12 Data bits

SPD: Speed control bit 1→ fast mode 0 → slow mode

PWR: Power control bit 1 → power down 0 → normal operation

The following table lists the possible combination of the register select bits:

Register Select Bits

R1 R0 REGISTER

0 0 Write data to DAC B and BUFFER

0 1 Write data to BUFFER

1 0 Write data to DAC A and update DAC B with BUFFER content

1 1 Write data to control register

The meaning of the 12 data bits depends on the register. If one of the DAC registers or the BUFFER is selected,

then the 12 data bits determine the new DAC value:

Data Bits: DAC A, DAC B and BUFFER

D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

New DAC Value 0 0

If control is selected, then D1, D0 of the 12 data bits are used to program the reference voltage:

Data Bits: CONTROL

D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

X X X X X X X X X X REF1 REF0

X: don't care

REF1 and REF0 determine the reference source and, if internal reference is selected, the reference voltage.

12

Page 13

www.ti.com

SLAS224B – JUNE 1999 – REVISED JANUARY 2004

APPLICATION INFORMATION

REFERENCE BITS

REF1 REF0 REFERENCE

0 0 External

0 1 1.024 V

1 0 2.048 V

1 1 External

CAUTION:

If external refeence voltage is applied to the REF pin, external reference MUST be selected.

EXAMPLES OF OPERATION:

1. Set DAC A output, select fast mode, select internal reference at 2.048 V:

a. Set reference voltage to 2.048 V (CONTROL register)

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

1 1 0 1 0 0 0 0 0 0 0 0 0 0 1 0

b. Write new DAC A value and update DAC A output:

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

1 1 0 0 New DAC A output value 0 0

TLV5637

The DAC A output is updated on the rising clock edge after D0 is sampled.

To output data consecutively using the same DAC configuration, it is not necessary to program the

CONTROL register again.

2. Set DAC B output, select fast mode, select external reference:

a. Select external reference (CONTROL register):

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

1 1 0 1 0 0 0 0 0 0 0 0 0 0 0 0

b. Write new DAC B value to BUFFER and update DAC B output:

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

0 1 0 0 New BUFFER content and DAC B output value 0 0

The DAC A output is updated on the rising clock edge after D0 is sampled.

To output data consecutively using the same DAC configuration, it is not necessary to program the

CONTROL register again.

1. Set DAC A value, set DAC B value, update both simultaneously, select slow mode, select internal reference

at 1.024 V:

a. Set reference voltage to 1.024 V (CONTROL register):

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

1 0 0 1 0 0 0 0 0 0 0 0 0 0 0 1

b. Write data for DAC B to BUFFER:

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

0 0 0 1 New DAC B value 0 0

c. Write new DAC A value and update DAC A and B simultaneously:

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

1 0 0 0 New DAC A value 0 0

13

Page 14

www.ti.com

DAC Code

Output

Voltage

0 V

Negative

Offset

TLV5637

SLAS224B – JUNE 1999 – REVISED JANUARY 2004

Both outputs are updated on the rising clock edge after D0 from the DAC A data word is sampled.

2. Set power down mode:

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

X X 1 X X X X X X X X X X X X X

X = Don't care

LINEARITY, OFFSET, AND GAIN ERROR USING SINGLE ENDED SUPPLIES

When an amplifier is operated from a single supply, the voltage offset can still be either positive or negative. With

a positive offset, the output voltage changes on the first code change. With a negative offset, the output voltage

may not change with the first code, depending on the magnitude of the offset voltage.

The output amplifier attempts to drive the output to a negative voltage. However, because the most negative

supply rail is ground, the output cannot drive below ground and clamps the output at 0 V.

The output voltage then remains at zero until the input code value produces a sufficient positive output voltage to

overcome the negative offset voltage, resulting in the transfer function shown in Figure 14 .

Figure 14. Effect of Negative Offset (Single Supply)

This offset error, not the linearity error, produces this breakpoint. The transfer function would have followed the

dotted line if the output buffer could drive below the ground rail.

For a DAC, linearity is measured between zero-input code (all inputs 0) and full-scale code (all inputs 1) after

offset and full scale are adjusted out or accounted for in some way. However, single supply operation does not

allow for adjustment when the offset is negative due to the breakpoint in the transfer function. So the linearity is

measured between full-scale code and the lowest code that produces a positive output voltage.

14

Page 15

www.ti.com

TLV5637

SLAS224B – JUNE 1999 – REVISED JANUARY 2004

DEFINITIONS OF SPECIFICATIONS AND TERMINOLOGY

Integral Nonlinearity (INL)

The relative accuracy or integral nonlinearity (INL), sometimes referred to as linearity error, is the maximum

deviation of the output from the line between zero and full scale excluding the effects of zero code and full-scale

errors.

Differential Nonlinearity (DNL)

The differential nonlinearity (DNL), sometimes referred to as differential error, is the difference between the

measured and ideal 1 LSB amplitude change of any two adjacent codes. Monotonic means the output voltage

changes in the same direction (or remains constant) as a change in the digital input code.

Zero-Scale Error (E

)

ZS

Zero-scale error is defined as the deviation of the output from 0 V at a digital input value of 0.

GAIN ERROR (E

)

G

Gain error is the error in slope of the DAC transfer function.

SIGNAL-TO-NOISE RATIO + DISTORTION (S/N+D)

S/N+D is the ratio of the rms value of the measured input signal to the rms sum of all other spectral components

below the Nyquist frequency, including harmonics but excluding dc. The value for S/N+D is expressed in

decibels.

SPURIOUS FREE DYNAMIC RANGE (SFDR)

Spurious free dynamic range is the difference between the rms value of the output signal and the rms value of

the spurious signal within a specified bandwidth. The value for SFDR is expressed in decibels.

15

Page 16

Page 17

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2004, Texas Instruments Incorporated

Loading...

Loading...