Page 1

GeneralĆPurpose LowĆV oltage

1.1Vto3.6VI/O16ĆBit

22ĆKSPS DSP CODEC

TLV320AIC11

Data Manual

2000 AAP Data Converter Group

SLWS100

Page 2

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERTAIN APPLICA TIONS USING SEMICONDUCT OR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 2000, Texas Instruments Incorporated

Page 3

Contents

Section Title Page

1 Introduction 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Features 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

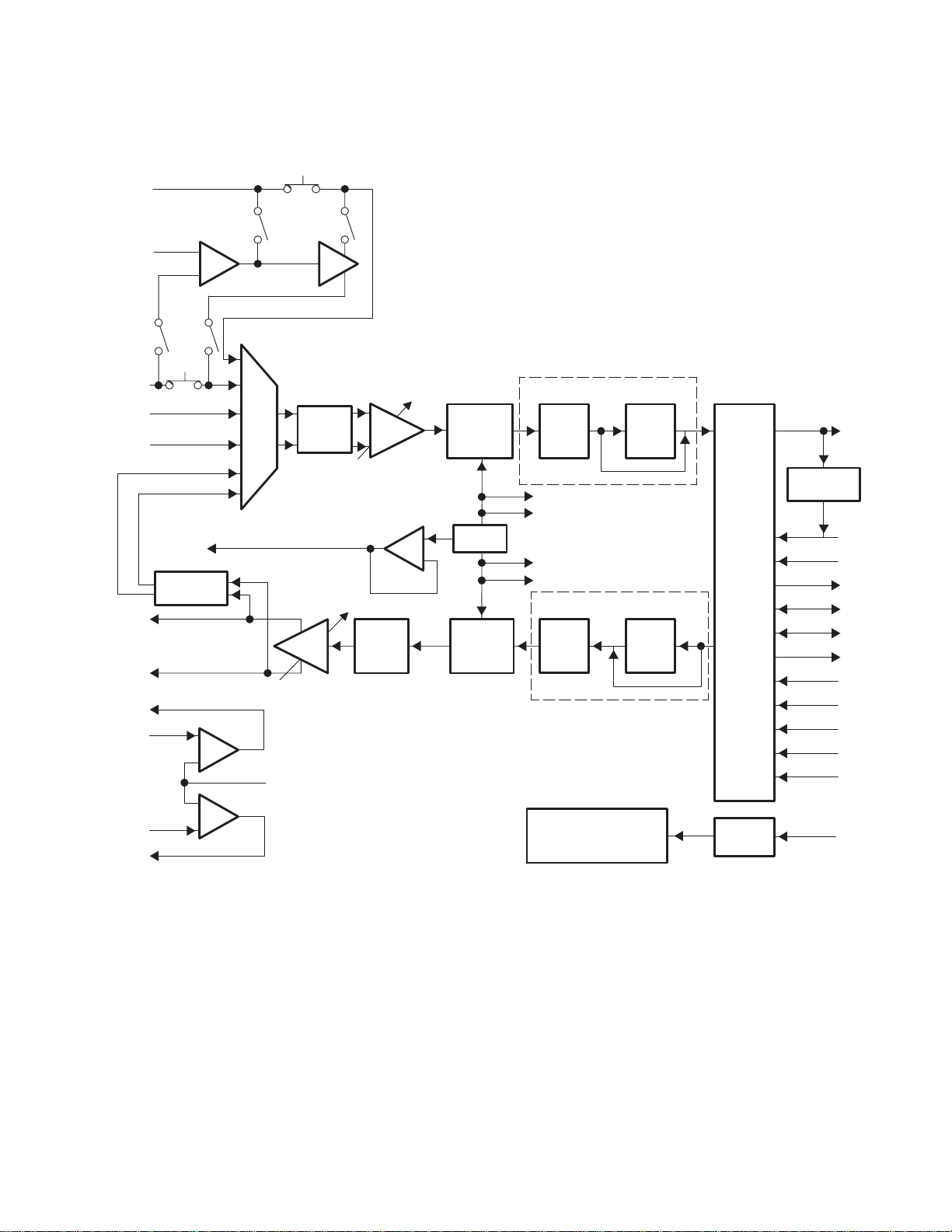

1.2 Functional Block Diagram 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Terminal Assignments 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Ordering Information 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 Terminal Functions 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6 Definitions and Terminology 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7 Register Functional Summary 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Functional Description 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Device Functions 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1 Operating Frequencies 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.2 ADC Signal Channel 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.3 DAC Signal Channel 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.4 MIC Input 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.5 Antialiasing Filter 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.6 Sigma-Delta ADC 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.7 Decimation Filter 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.8 Sigma-Delta DAC 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.9 Interpolation Filter 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.10 Analog and Digital Loopback 2–5. . . . . . . . . . . . . . . . . . . . . . . . .

2.1.11 FIR Overflow Flag 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.12 Bypass Mode 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.13 Automatic Cascading Detection (ACD) 2–6. . . . . . . . . . . . . . . .

2.1.14 Low-Power Mode 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.15 Event-Monitor Mode 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Reset and Power-Down Functions 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 Software and Hardware Reset 2–7. . . . . . . . . . . . . . . . . . . . . . . .

2.2.2 Software and Hardware Power Down 2–7. . . . . . . . . . . . . . . . . .

2.3 Clock Source 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Data Out (DOUT) 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.1 Data Out, Master Mode 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.2 Data Out, Slave Mode 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Data In (DIN) 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 FC (Hardware Secondary Communication Request) 2–8. . . . . . . . . . . . .

2.7 Frame-Sync Function for TLV320AIC11 2–8. . . . . . . . . . . . . . . . . . . . . . . .

2.7.1 Frame-Sync (FS) Function—Continuous-Transfer Mode

(Master Only) 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iii

Page 4

2.7.2 Frame-Sync (FS) Function—Fast-Transfer Mode

(Slave Only) 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.3 Frame-Sync (FS) Function—Master Mode 2–11. . . . . . . . . . . . .

2.7.4 Frame-Sync (FS) Function—Slave Mode 2–11. . . . . . . . . . . . . .

2.7.5 Frame-Sync Delayed (FSD) Function, Cascade Mode 2–12. . .

2.8 Multiplexed Analog Input and Output 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8.1 Multiplexed Analog Input 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8.2 Analog Output 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8.3 Single-Ended Analog Input 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8.4 Single-Ended Analog Output 2–14. . . . . . . . . . . . . . . . . . . . . . . . .

3 Serial Communications 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Primary Serial Communication 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Secondary Serial Communication 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Register Programming 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 Hardware Secondary Serial Communication Request 3–4. . . .

3.2.3 Software Secondary Serial Communication Request 3–5. . . .

3.3 Direct Configuration Mode 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Continuous Data Transfer Mode 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 DIN and DOUT Data Format 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.1 Primary Serial Communication DIN and

DOUT Data Format 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.2 Secondary Serial Communication DIN and

DOUT Data Format 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.3 Direct Configuration DCSI Data Format 3–8. . . . . . . . . . . . . . . .

4 Specifications 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Absolute Maximum Ratings Over Operating Free-Air

Temperature Range 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Recommended Operating Conditions 4–1. . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Electrical Characteristics Over Recommended Operating

Free-Air Temperature Range 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.1 Digital Inputs and Outputs, Fs = 8 kHz,

Output Not Loaded 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.2 ADC Path Filter, Fs = 8 kHz 4–2. . . . . . . . . . . . . . . . . . . . . . . . .

4.3.3 ADC Dynamic Performance, Fs = 8 kHz 4–2. . . . . . . . . . . . . . .

4.3.4 ADC Channel Characteristics 4–3. . . . . . . . . . . . . . . . . . . . . . . .

4.3.5 DAC Path Filter, Fs = 8 kHz 4–3. . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.6 DAC Dynamic Performance 4–3. . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.7 DAC Channel Characteristics 4–4. . . . . . . . . . . . . . . . . . . . . . . .

4.3.8 Op-Amp Interface (A1, A3, A4) 4–4. . . . . . . . . . . . . . . . . . . . . . .

4.3.9 Op-Amp Interface (A1, A3, A4) 4–4. . . . . . . . . . . . . . . . . . . . . . .

4.3.10 Power-Supply Rejection 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.11 Power Supply 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Timing Requirements 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.1 Master Mode Timing Requirements 4–5. . . . . . . . . . . . . . . . . . .

4.4.2 Slave Mode Timing Requirements 4–5. . . . . . . . . . . . . . . . . . . .

iv

Page 5

5 Parameter Measurement Information 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Mechanical Information 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A—Register Set A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

List of Illustrations

Figure Title Page

2–1 Timing Sequence of ADC Channel (Primary Communication Only) 2–1. . . . . .

2–2 Timing Sequence of ADC Channel (Primary and

Secondary Communication) 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–3 Timing Sequence of DAC Channel (Primary Communication Only) 2–3. . . . . .

2–4 Timing Sequence of DAC Channel (Primary and Secondary

Communication) 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–5 Typical Microphone Interface 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–6 Cascading 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–7 Event Monitor Mode Timing 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–8 Internal Power-Down Logic 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

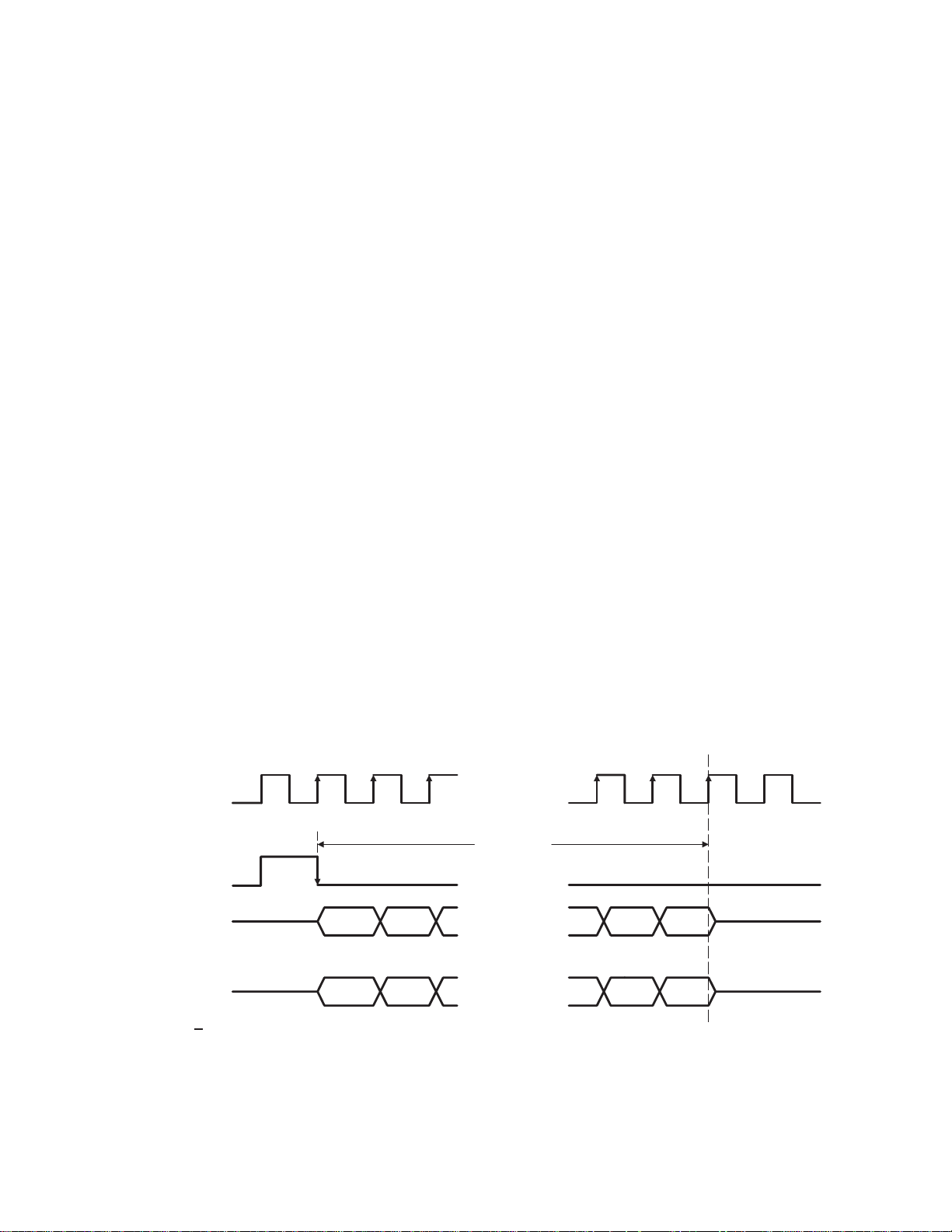

2–9 Timing Diagram for the FS Pulse Mode (M1M0 = 00) 2–9. . . . . . . . . . . . . . . . . .

2–10 Timing Diagram for the SPI_CP0 Mode (M1M0 = 01) 2–9. . . . . . . . . . . . . . . . .

2–11 Timing Diagram for the SPI_CP1 Mode (M1M0 = 10) 2–10. . . . . . . . . . . . . . . . .

2–12 Timing Diagram for the FS Frame Mode (M1M0 = 11) 2–10. . . . . . . . . . . . . . . .

2–13 Master Device Frame-Sync Signal With Primary and Secondary

Communication ( No Slaves) 2–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–14 Master Device’s FS Output to DSP and FSD Output to the Slave 2–11. . . . . . .

2–15 Cascade Mode Connection (to DSP Interface) 2–12. . . . . . . . . . . . . . . . . . . . . . .

2–16 Master-Slave Frame-Sync Timing 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–17 INP and INM Internal Self-Biased Circuit (2.5 V for 5-V Operation

and 1.5 V for 3-V Operation) 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–18 Differential Output Drive (Ground-Referenced) 2–13. . . . . . . . . . . . . . . . . . . . . . .

2–19 Single-Ended Input 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–20 Single-Ended Output 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–1 Primary Serial Communication Timing 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–2 Hardware and Software Secondary Communication Request 3–2. . . . . . . . . . .

3–3 Device 3/Register 1 Read Operation Timing Diagram 3–3. . . . . . . . . . . . . . . . . .

3–4 Device 3/Register 1 Write Operation Timing Diagram 3–4. . . . . . . . . . . . . . . . . .

3–5 FS Output When Hardware Secondary Serial Communication

Is Requested Only Once (No Slave) 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–6 Output When Hardware Secondary Serial Communication Is

Requested (Three Slaves) 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–7 FS Output During Software Secondary Serial Communication Request

(No Slave) 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

v

Page 6

3–8 Direct Configuration 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–9 Direct Configuration Mode Timing 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–10 Continuous Data Transfer Mode Timing 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–11 Primary Communication DIN and DOUT Data Format 3–8. . . . . . . . . . . . . . . .

3–12 Secondary Communication DIN and DOUT Data Format 3–8. . . . . . . . . . . . . .

3–13 Direct Communication DCSI Data Format 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . .

5–1 FS and FSD Timing 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–2 Serial Communication Timing 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–3 FFT–ADC Channel, Fs = 8 kHz, Input = –3 dB 5–2. . . . . . . . . . . . . . . . . . . . . . . .

5–4 FFT–DAC Channel, Fs = 8 kHz, Input = –3 dB 5–2. . . . . . . . . . . . . . . . . . . . . . . .

5–5. FFT–ADC Channel, Fs = 8 kHz, Input = –1 dB 5–3. . . . . . . . . . . . . . . . . . . . . . .

5–6 FFT–DAC Channel, Fs = 8 kHz, Input = 0 dB 5–3. . . . . . . . . . . . . . . . . . . . . . . . .

List of Tables

Table Title Page

2–1 Serial Interface Modes 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–1 Least Significant Bit Control Function 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

Page 7

1 Introduction

The TL V320AIC1 1 provides high resolution signal conversion from digital-to-analog (D/A) and from analog-to-digital

(A/D) using oversampling sigma-delta technology. It allows 2-to-1 MUX inputs with built-in antialiasing filter and

amplification for general-purpose applications such as telephone hybrid interface, electret microphone preamp, etc.

Both IN and AUX inputs accept normal analog signals. This device consists of a pair of 16-bit synchronous serial

conversion paths (one for each direction), and includes an interpolation filter before the DAC and a decimation filter

after the ADC. The FIR filters can be bypassed to offer flexibility and power savings. Other overhead functions

provided on-chip include timing (programmable sample rate, continuous data transfer, and FIR bypass) and control

(programmable-gain amplifier, communication protocol, etc.). The sigma-delta architecture produces high-resolution

analog-to-digital and digital-to-analog conversion at low system cost.

The TL V320AIC1 1 design enhances communication with the DSP. The continuous data transfer mode fully supports

TI’s DSP autobuffering (ABU) to reduce DSP interrupt service overhead. The automatic cascading detection (ACD)

makes cascade programming simple and supports a cascade operation of one master and up to seven slaves. The

direct-configuration mode for host interface uses a single-wire serial port to directly program internal registers without

interference from the data conversion serial port, or without resetting the entire device. The event monitor mode

allows the DSP to monitor external events like telephone’s ring and off-hook detection.

In the lower-power mode, the TLV320AIC11 converts data at a sampling rate of 8 KSPS consuming only 39 mW.

The programmable functions of this device are configured through a serial interface that can be gluelessly interfaced

to any DSP that accepts 4-wire serial communications, such as the TMS320UC54x. The options include software

reset, device power-down, separate control for ADC and DAC turnoff, communications protocol, signal-sampling

rate, gain control, and system-test modes, as outlined in Appendix A.

The TLV320AIC11 is particularly suitable for a variety of applications in hands-free car kits, VOIP, cable modem,

speech, and telephony area including low-bit rate, high-quality compression, speech enhancement, recognition, and

synthesis. Its low-group delay characteristic makes it suitable for single or multichannel active-control applications.

The wide range of low-voltage I/O (1.1 V–3.6 V) enables the AIC11 to interface with a single power supply, or with

dual power supplies for mixed low-voltage DSP systems such as the TMS320UC54x. This feature eliminates the

need for external level-shifting and reduces power consumption.

The TL V320AIC11 is characterized for commercial operation from 0°C to 70°C, and industrial operation from –40°C

to 85°C.

1.1 Features

• 16-bit oversampling sigma-delta A/D converter

• 16-bit oversampling sigma-delta D/A converter

• Maximum output conversion rate:

– 22 ksps with on-chip FIR filter

– 88 ksps with FIR bypassed

• Voiceband bandwidth in FIR-bypassed mode and final sampling rate at 8 ksps

– 90-dB SNR/ADC and 87-dB SNR/DAC with DSP’s FIR (FIR bypassed @ 88 ksps/5 V)

– 87-dB SNR/ADC and 85-dB SNR/DAC with DSP’s FIR (FIR bypassed @88 ksps/3.3 V)

• On-chip FIR produced 84-dB SNR for ADC and 85-dB SNR for DAC over 11-kHz BW

• Built-in functions including PGA, antialiasing analog filter, and op-amps for general-purpose interface (such

as MIC interface and hybrid interface)

1–1

Page 8

• Glueless serial port interface to DSPs (TI TMS320UC54x or standard DSPs)

• Automatic cascading detection (ACD) makes cascade programming simple and allows up to 8 devices to

be connected in cascade.

• On-fly reconfiguration modes include secondary-communication mode and direct-configuration mode (host

interface).

• Continuous data-transfer mode for use with autobuffering (ABU) to reduce DSP interrupt service overhead

• Event-monitor mode provides external-event control, such as RING/OFF-HOOK detection

• Programmable ADC and DAC conversion rate

• Programmable input and output gain control

• Separate software control for ADC and DAC power-down

• Low-voltage (DV

• Analog (A V

• Digital (DV

DD1

DD2

) 1.1-V to 3.6-V digital I/O

DD1

and AV

) 3 V to 5.5 V core power supply

DD2

) 3 V to 5.5 V core power supply

• Power dissipation (PD) of 39 mW typical for 8-ksps at 3.3 V

• Hardware power-down mode to 0.2 mW

• Internal and external reference voltage (V

ref

)

• Differential and single-ended analog input/output

• 2s-complement data format

• Test mode, which includes digital loopback and analog loopback

• 600-ohm output driver

• VHDL code for serial interface available

1–2

Page 9

1.2 Functional Block Diagram

Receiver or MIC Amp

AURXFP

AURXCP

AURXM

INP

INM

OUTP

OUTM

DTXOP

DTXIM

DTXIP

DTXOM

+

A1

–

VMID

@ 5 mA

Analog

Loopback

Transmitter Amp

–

A3

+

+

A4

–

MUX

1.5 V

or

2.5V

Anti-

Aliasing

Filter

PGA

PGA

Low

Pass

Filter

A2

Sigma-

Delta

ADC

Vref

Sigma-

Delta

DAC

Decimation Filter

Sync

Filter

ADREFP

ADREFM

DAREFP

DAREFM

Interpolation Filter

Sync

Filter

Internal Clock Circuit

FIR

Filter

FIR

Filter

Interface

Circuit

Div

256xN

Digital

Loopback

DOUT

DIN

M/S

FSD

FS

SCLK

FLAG

DCSI

ALTI

FC

M0

M1

MCLK

1–3

Page 10

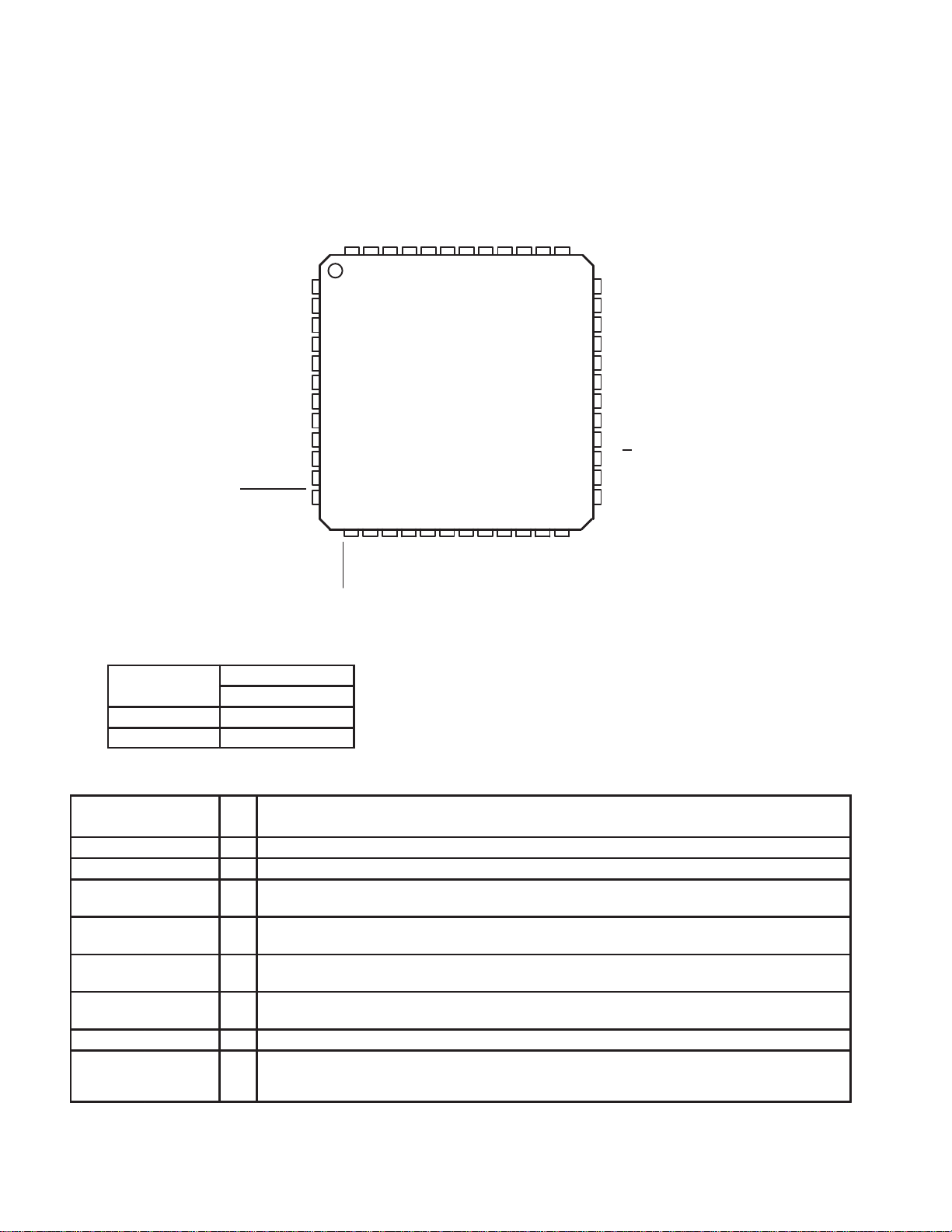

1.3 Terminal Assignments

T

I/O

DESCRIPTION

INM

INPAVAV

PFB PACKAGE

(TOP VIEW)

DD1

SS

NC

VMID

AV

SS

NC

SS

AV

NC

FILT

NC

AURXFP

AURXM

AURXCP

DTXOP

DTXOM

DTXIP

DTXIM

OUTP

OUTM

M0

M1

PWRDWN

NOTE: All NC pins should be left unconnected.

1.4 Ordering Information

A

0°C to 70°C TLV320AIC11C

–40°C to 85°C TLV320AIC11I

PACKAGE

48-TQFP PFB

47 46 45 44 4348 42

1

2

3

4

5

6

7

8

9

10

11

12

14 15

13

SS

DV

RESET

17 18 19 20

16

DD1

DOUT

DV

DIN

NC

SCLK

MCLK

40 39 3841

22 23 24

21

FSD

FS

37

FC

FLAG

36

35

34

33

32

31

30

29

28

27

26

25

NC

NC

AV

DD2

AV

SS

NC

NC

DV

DD2

DV

SS

NC

M/S

ALTIN

DCSI

1.5 Terminal Functions

TERMINAL

NAME NO.

ALTIN 26 I Serial input in the

AURXCP 3 I Receiver-path/GP amplifier noninverting input. It needs to be connected to AVSS if not used.

AURXM 2 I Receiver-path amplifier A1 inverting input, or inverting input to auxiliary analog input. It needs to be connected

AURXFP 1 I Receiver-path amplifier A1 feedback, or noninverting input to auxiliary analog input. It needs to be connected

AV

DD1

AV

DD2

AV

SS

DCSI 25 I Direct configuration serial input for directly programming of internal control registers

DIN 17 I Data input. DIN receives the DAC input data and register data from the external digital signal processor (DSP),

1–4

45

34

33, 40, 42,46I Analog ground

to AVSS if not used. It can also be used for general-purpose amplification.

to AVSS if not used. It can also be used for general-purpose amplification.

I Analog ADC power supply (3 V to 5.5 V)

and is synchronized to SCLK and FS. Data is latched at the falling edge of SCLK when FS is low. DIN is at high

impedance when FS is not activated.

event monitor

mode

Page 11

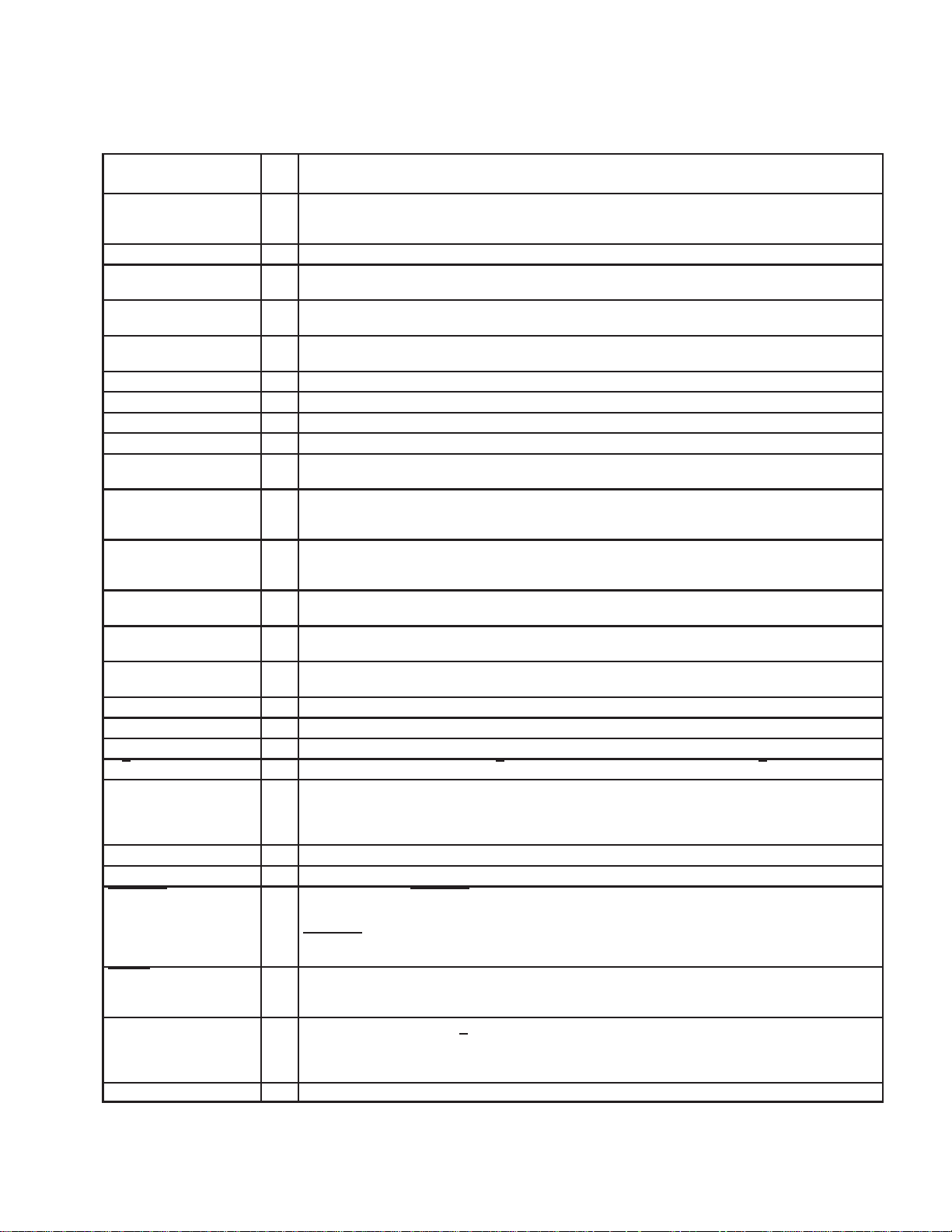

1.5 Terminal Functions (Continued)

I/O

DESCRIPTION

TERMINAL

NAME NO.

DOUT 16 O Data output. DOUT transmits the ADC output bits and registers data, and is synchronized to SCLK and FS.

DTXIM 7 I Transmitter-path amplifier A3 analog inverting input. It can also be used for general-purpose amplification.

DTXIP 6 I Transmitter-path amplifier A4 analog noninverting input. Can also be used for general-purpose

DTXOP 4 O Transmitter-path amplifier A3 feedback for positive output. It can also be used for general-purpose

DTXOM 5 O Transmitter path amplifier A4 feedback for negative output. It can also be used for general-purpose

DV

DD1

DV

DD2

DV

SS

FC 24 I Hardware request for secondary communication

FILT 38 O Bandgap filter. FILT is provided for decoupling of the bandgap reference, and provides 2.5 V. The optimal

FLAG 23 O Controlled by bit D4 of control register 3. If D4=0 (default), the FLAG pin outputs the communication flag that

FS 22 I/O Frame sync. When FS goes low, DIN begins receiving data bits and DOUT begins transmitting data bits. In

FSD 21 O Frame-sync delayed output. The FSD output synchronizes a slave device to the frame sync of the master

INM 48 I Inverting input to analog modulator. INM requires an external R-C antialias filter with low output impedance if

INP 47 I Noninverting input to analog modulator. INP requires an external R-C antialias filter with low output

M0 10 I Combine with M1 to select serial interface mode (frame-sync mode)

M1 11 I Combine with M0 to select serial interface mode (frame-sync mode)

MCLK 20 I Master clock. MCLK derives the internal clocks of the sigma-delta analog interface circuit.

M/S 27 I Master/slave select input. When M/S is high, the device is the master, and when M/S is low, it is a slave.

NC 18, 28, 31,

OUTM 9 O DAC’s inverting output. OUTM is functionally identical with and complementary to OUTP.

OUTP 8 O DAC’s noninverting output. OUTP can also be used alone for single-ended operation.

PWRDWN 12 I Power down. When PWRDWN is pulled low, the device goes into a power-down mode, the serial interface is

RESET 13 I Reset. The reset function is provided to initialize all the internal registers to their default values. The serial

SCLK 19 I/O Shift clock. SCLK signal clocks serial data into DIN and out of DOUT during the frame-sync interval. When

VMID 43 O Reference voltage output at AVDD/2

15 I Dedicated 1.1-V to 3.6-V digital power supply for low-voltage I/O

30 I Dedicated 3-V to 5.5-V digital power supply for core CODEC

14, 29 I Digital ground

32, 35, 36,

37, 39, 41,

44

Data is sent out at the rising edge of SCLK when FS is low. DOUT is at high impedance when FS is not

activated.

amplification.

amplification.

amplification.

capacitor value is 0.1 µF (ceramic). This voltage node should be loaded only with a high-impedance dc load.

goes low/high to indicate primary-communication/secondary-communication interval, respectively. If D4=1,

the FLAG pin outputs the value of D3.

master mode, FS is internally generated and is low during data transmission to DIN and from DOUT . In slave

mode, FS is externally generated.

device. FSD is applied to the slave FS input and has the same duration as the master FS signal.

the internal antialias filter is bypassed.

impedance if the internal antialias filter is bypassed.

No connection

disabled, and most of the high-speed clocks are disabled. However, all register values are sustained and the

device resumes full-power operation without reinitialization when PWRDWN is pulled high again.

PWRDWN resets the counters only and preserves the programmed register contents. See paragraph 2.2.2

for more information.

port can be configured to the default state accordingly. See Appendix A,

Reset and Power-Down Functions

configured as an output (M/S high), SCLK is generated internally by multiplying the frame-sync signal

frequency by 256 (cascade devices < 5) or 512 (cascade devices > 4). When configured as an input (M/S

low), SCLK is generated externally and must be synchronous with the master clock and frame sync.

for detailed descriptions.

Register Set

, and Subsection 2.2.1,

1–5

Page 12

1.6 Definitions and Terminology

Data transfer interval The time during which data is transferred from DOUT to DIN. The interval is 16 shift clocks

and the data transfer is initiated by the falling edge of the FS signal.

Signal data This refers to the input signal and all of the converted representations through the ADC

channel, and the signal through the DAC channel to the analog output. This is in contrast

with the purely-digital software control data.

Primary

communication

Secondary

communication

SPI Serial peripheral interface

Frame/pulse sync Frame/pulse sync refers only to the falling edge of the signal FS that initiates the data-

Frame/pulse sync and

sampling period

f

s

ADC channel ADC channel refers to all signal-processing circuits between the analog input and the

DAC channel DAC channel refers to all signal-processing circuits between the digital data word applied

Host A host is any processing system that interfaces to DIN, DOUT, SCLK, FS, and/or MCLK.

Dxx Bit position in the primary data word (xx is the bit number).

DSxx Bit position in the secondary data word (xx is the bit number).

d The alpha character

PGA Programmable gain amplifier

FIR Finite-duration impulse response

DCSI Direct configuration serial interface for host control

Primary communication refers to the digital data-transfer interval. Since the device is synchronous, the signal data words from the ADC channel and to the DAC channel occur simultaneously .

Secondary communication refers to the digital control and configuration data-transfer interval into DIN, and the register read-data cycle from DOUT . The data transfer occurs when

requested by hardware or software.

transfer interval. The primary FS starts the primary communication, and the secondary FS

starts the secondary communication.

Frame/Pulse sync and sampling period is the time between falling edges of successive

primary FS signals and it is always equal to 256xSCLK if the number of cascading devices

is less than 5, or 512 xSCLK if the number of cascading devices is greater than 4.

The sampling frequency

digital conversion result at DOUT.

to DIN and the differential output analog signal available at OUTP and OUTM.

d

represents valid programmed or default data in the control-register

format (see Section 3.2,

Secondary Serial Communication

) when discussing other data bit

portions of the register.

1–6

Page 13

1.7 Register Functional Summary

There are five control registers, which are used as follows:

Register 0 The no-op register . Addressing register 0 allows secondary-communication request without altering any

other registers.

Register 1 Control register 1. The data in this register has the following functions:

• Produce the output flag to indicate a decimator FIR filter overflow (read cycle only)

• Enable of general-purpose op-amps A1, A3, and A4

• Enable/bypass ADC’s analog antialiasing filter

• Select normal or auxiliary analog input

• Control 16-bit or (15+1)-bit mode of DAC operation

• Enable/bypass the decimator FIR filter

• Enable/bypass the interpolator FIR filter

Register 2 Control register 2. The data in this register has the following functions:

• Control of the low-power mode that converts data at the rate of 8 ksps

• Control of the N-divide register that determines the filter clock rate and sample period

Register 3 Control register 3. The data in this register has the following functions:

• Software reset and power down

• Selection of analog loopback, digital loopback, and event monitor mode

• Control of continuous data transfer mode

• Control of the value of one-bit general-purpose output flag

• Control the output of FLAG pin

• Enable/disable ADC path

• Enable/disable DAC path

• Control of 16-bit or (15+1)-bit mode of ADC operation

Register 4 Control register 4. The data in this register has the following functions:

• Control of the 4-bit gain of input amplifier

• Control of the 4-bit gain of output amplifier

1–7

Page 14

1–8

Page 15

2 Functional Description

2.1 Device Functions

2.1.1 Operating Frequencies

The sampling frequency represented by the frequency of the primary communication is derived from the master clock

(MCLK) input with the following equation:

Fs = Sampling (conversion) frequency = MCLK/(256 × N), N = 1, 2..., 32

The inverse of the sampling frequency is the time between the falling edges of two successive primary frame-sync

signals. This time is the conversion period. For example, to set the conversion rate to 8 kHz, MCLK = 256 × N × 8000.

NOTE: The value of N is defined in control register 2 and its power-up value is 32.

2.1.2 ADC Signal Channel

Both IN (INP, INM) and AUX (AURXFP, AURXM) inputs can use the built-in antialiasing filter that can be bypassed

by writing a 1 to bit D5 of control register 1. The AUX input can also be connected to the general-purpose amplifier

A1 for general-purpose applications, such as electret-microphone interface and 2-to-4-wire hybrid interface, by

writing a 1 to bit D6 of control register 1. Bit D4 of control register 1 selects between IN or AUX for the ADC. The

selected input signal is amplified by the PGA and applied to the ADC input. The ADC converts the signal into

discrete-output digital words in 2s-complement data format, corresponding to the analog-signal value at sampling

time. These 16-bit (or 15-bit) digital words, representing sampled values of the analog input signal after PGA, are

clocked out of the serial port (DOUT) at the positive edge of SCLK during the frame-sync (FS) interval at the rate of

one bit for each SCLK and one word for each primary communication. During secondary communication, the data

previously programmed into the registers can be read out. If a register read is not required, all 16 bits are cleared to

0 in the secondary communication. This read operation is accomplished by sending the appropriate register address

(D11-D9) with the read bit (D12) set to 1 during present secondary communication. The timing sequence is shown

in Figures 2–1 and 2–2.

The decimation FIR filter can be bypassed by writing a

be turned off for power savings by writing

0 1 15 16

SCLK

FS

DOUT

(16-bit)

DOUT

(15+1-bit)

NOTES: A. M/S is used to indicate whether the 15-bit data comes from a master or a slave device (master: M/S=1, slave: M/S=0).

B. The MSB (D15) is stable (the host can latch the data in at this time) at the falling edging of SCLK number 0; the last bit (D0,M/S)

is stable at the falling edging of SCLK number 15.

D15

MSB LSB

D15

MSB

01

to bits D2 and D1 of control register 3.

D14

D14

1

to bit D2 of control register 1. The whole ADC channel can

……

16 SCLKs

……

……

……

D1

LSB

D0

M/SD1

Figure 2–1. Timing Sequence of ADC Channel (Primary Communication Only)

2–1

Page 16

Primary Secondary

Primary

16 SCLKs

FS

DOUT

(16-bit)

DOUT

(15+1-bit)

NOTES: A. M/S bit (D15) in the secondary communication is used to indicate whether the register data (address and content) come from a

master device or a slave device if read bit is set. Otherwise, it is all 0s except M/S bit (master: M/S=1, slave: M/S=0).

B. The number of SCLKs between FS (primary) and FS (secondary) is 128 if cascading devices are less than 5, or 256 if cascading

devices are greater than 4.

C. The number of SCLKs per data sampling period is 256 if cascading devices are less than 5, or 512 if cascading devices are greater

than 4.

16–bit ADC Data

15–bit ADC Data + M/S

# SCLKs (See Note B)

# SCLKs Per Sampling Period (See Note C)

16 SCLKs

M/S+ Register Data/

M/S+ All 0 (See Note A)

M/S+ Register Data/

M/S+ All 0 (See Note A)

Figure 2–2. Timing Sequence of ADC Channel (Primary and Secondary Communication)

2.1.3 DAC Signal Channel

DIN received the 16-bit serial data word (2s complement) from the host during the primary communication interval.

These 16-bit digital words, representing analog output signal before PGA, are clocked into the serial port (DIN) at

the falling edge of SCLK during the frame-sync interval, one bit for each SCLK and one word for each primary

communication interval. The data are converted to a pulse train by the sigma-delta DAC comprised of a

digital-interpolation filter and a digital 1-bit modulator. The output of the modulator is then passed to an internal

low-pass filter to complete the signal reconstruction. Finally, the resulting analog signal is applied to the input of a

programmable-gain amplifier is capable of differentially driving a 600-ohm load at OUTP and OUTM. The timing

sequence is shown in Figure 2–3.

During secondary communication, the digital control and configuration data, together with the register address, are

clocked in through DIN (see Appendix A for register map). These 16-bit data are used either to initialize the register

or read out register content through DOUT . If a register initialization is not required, a no-operation word (D15-D9 are

all set to 0) can be used. If D12 is set to 1, the content of the control register, specified by D7-D0, will be send out

through DOUT during the same secondary communication (see section 2.1.5). The timing sequence is shown in

Figure 2–4.

The interpolation FIR filter can be bypassed by writing a

1

to bit D1 of control register 1. The whole DAC channel can

be turned off for power savings by writing 10 to bits D2 and D1 of control register 3.

2–2

Page 17

SCLK

0 1 15 16

14

……

16 SCLKs

FS

DIN

(16-bit)

DIN

(15+1-bit)

NOTE A: d0 = 0 means no secondary-communication request (software secondary-request control, see Section 3.2).

D15

MSB LSB

D15

MSB

D14

D14

……

……

……

D1

LSB

D0

D0=0D1

(see Note A)

Figure 2–3. Timing Sequence of DAC Channel (Primary Communication Only)

Primary Secondary

FS

DIN (16-bit)

(see Note A)

DIN

(15+1-bit)

16 SCLKs

16–bit DAC Data

15–bit DAC Data +

D0 = 1 (See Note B)

# SCLKs Between

FS (Primary) and

FS (Secondary)

(see Note C)

16 SCLKs

Register Read/Write

Register Read/Write

Primary

# SCLKs Between Sampling Period (See Note D)

NOTES: A. FC has to be set high for a secondary communication request when 16-bit DAC data format is used (see Section 3.2).

B. D0 = 1 means secondary communication request (software secondary request control, see Section 3.2)

C. The number of SCLKs between FS (Primary) and FS (Secondary) is 128 if cascading devices are less than 5, or 256 if cascading

devices are greater than 4.

D. The number of SCLKs per data sampling period is 256 if cascading devices are less than 5, or 512 if cascading devices are greater

than 4.

Figure 2–4. Timing Sequence of DAC Channel (Primary and Secondary Communication)

2–3

Page 18

2.1.4 MIC Input

The auxiliary inputs (AURXFP, AURXCP, and AURXM) can be programmed to interface with a microphone such as

an electret microphone, as illustrated in Figure 2–5, by writing a 1 to both bit D6 and bit D4 of control register 1.

TLV320AIC11

10 kΩ

AURXFP

0.1 µF

Electret

Microphone

1 kΩ

Electret

Microphone

10 kΩ

20 kΩ

MIC_BIAS VMID

AURXM

AURXCP

(a) Inverting Configuration

1 µF

10 kΩ

20 kΩ

AURXFP

AURXM

AURXCP

AVDD

TLV320AIC11

–

+

–

+

S2D

Anti-

Aliasing

Filter

S2D

PGA

Sigma-

Delta

ADC

Vref

2–4

1 kΩ

10 kΩ

10 kΩ

MIC_BIAS VMID

(b) Noninverting Configuration

Figure 2–5. Typical Microphone Interface

Anti-

Aliasing

Filter

PGA

Sigma-

Delta

ADC

Vref

Page 19

2.1.5 Antialiasing Filter

The built-in antialiasing filter has a 3-dB cutoff frequency of 70 kHz.

2.1.6 Sigma-Delta ADC

The sigma-delta analog-to-digital converter is a sigma-delta modulator with 128× oversampling. The ADC provides

high-resolution, low-noise performance using oversampling techniques. Due to the oversampling employed, only

single-pole RC filters are required on the analog inputs.

2.1.7 Decimation Filter

The decimation filters reduce the digital data rate to the sampling rate. This is accomplished by decimating with a ratio

of 1:64. The output of the decimation filter is a 16-bit 2s-complement data word clocking at the sample rate selected

for that particular data channel. The BW of the filter is 0.45 × FS and scales linearly with the sample rate.

2.1.8 Sigma-Delta DAC

The sigma-delta digital-to-analog converter is a sigma-delta modulator with 128× oversampling. The DAC provides

high-resolution, low-noise performance using oversampling techniques.

2.1.9 Interpolation Filter

The interpolation filter resamples the digital data at a rate of 64 times the incoming sample rate. The high-speed data

output from the interpolation filter is then used in the sigma-delta DAC. The BW of the filter is 0.45 x FS and scales

linearly with the sample rate.

2.1.10 Analog and Digital Loopback

The analog and digital loopbacks provide a means of testing the modem data ADC/DAC channels and can be used

for in-circuit system level tests. The analog loopback routes the DAC low-pass filter output into the analog input where

it is then converted by the ADC to a digital word. The digital loopback routes the ADC output to the DAC input on the

device. Analog loopback is enabled by writing

is enabled by writing 10 to bits D7 and D6 in control register 3 (see Appendix A).

01

to bits D7 and D6 respectively in control register 3. Digital loopback

2.1.11 FIR Overflow Flag

The decimator FIR filter sets an overflow flag (bit D7) in control register 1 to indicate that the input analog signal has

exceeded the range of the internal decimation-filter calculations. When the FIR overflow flag has been set in the

register, it remains set until the register is read by the user. Reading this value resets the overflow flag.

If FIR overflow occurs, the input signal has to be attenuated either by the PGA or some other method.

2.1.12 Bypass Mode

An option is provided to bypass the FIR filter sections of the decimation and interpolation filters. This mode is selected

through bits D1 and D2 of control register 1, and effectively increases the frequency of FS signal to 4 times the normal

FIR-filter output rate. The sinc filters of the two paths can not be bypassed.

2–5

Page 20

2.1.13 Automatic Cascading Detection (ACD)

The TLV320AIC11’s ACD makes cascade programming easy and supports the operation of up to 8 devices in

cascade. See Appendix A for register map description.

CLKOUT

CLKX

CLKR

TMS320UC54x

(or Master Clock Source)

DX

DR

FSX

FSR

FS

SCLK

MCLK

DIN

DOUT

FSD

M/S M/S M/S M/S

DVDD

MCLK

DIN

DOUT

FS

Slave 6 Slave 1 Slave 0Master

SCLK

MCLK

DIN

DOUT

FSD FSD

FS

SCLK

MCLK

DIN

DOUT

FS

SCLK

FSD

Figure 2–6. Cascading

2.1.14 Low-Power Mode

T o select the low-power mode, in which the AIC1 1 typically consumes 39 mW , set bit D7 of control register 2 to 1 and

set the sampling rate at 8 ksps.

2.1.15 Event-Monitor Mode

This mode is only available during the register-write cycle, and is enabled by writing 11 to bits D6 and D7 of control

register 3. The event monitor mode is provided for applications that need hardware control and monitoring of external

events. By allowing the device to drive the FLAG terminal (set through bit D3 of the control register 3), the host DSP

is capable of system control through the same serial port that connects the device. Along with this control is the

capability of monitoring the value of the ALTIN terminal during a secondary communication cycle. One application

of this function is in monitoring RING DETECT or OFFHOOK DETECT from a phone-answering system. FLAG allows

response to these incoming control signals. Figure 2–7 shows the timing associated with this operating mode.

FS

DOUT

ALTDI

NOTE A: When DIN performs a write operation (sets D12 to 0) during secondary communication.

Primary Secondary

16 bits

Figure 2–7. Event Monitor Mode Timing

2–6

Page 21

2.2 Reset and Power-Down Functions

2.2.1 Software and Hardware Reset

The TLV320AIC11 resets the internal counters and registers in response to either of two events:

• A low-going reset pulse is applied to terminal RESET

• A 1 is written to the programmable-software reset bit (D3 of control register 1)

Either event resets the control registers and clears all the sequential circuits in the device. Reset signals should be

at least 6 master-clock periods long, and it is recommended to synchronize the reset signal with the master clock in

master/slave cascade. For devices in cascade, it takes at least two FS cycles to apply software reset to all devices,

with the master being always programmed last.

2.2.2 Software and Hardware Power Down

With the exception of the digital interface, the device enters the power-down mode when D1 and D2 in control register

3 are set to 1. When PWRDWN is taken low, the entire device is powered down. In either case, the register contents

are preserved and the output of the monitor amplifier is held at the midpoint voltage to minimize pops and clicks.

The amount of power drawn during software power down is higher than it is during a hardware power down because

of the current required to keep the digital interface active. Additional differences between software and hardware

power-down modes are detailed in the following paragraphs. Figure 2–8 represents the internal power-down logic.

PWRDWN

Software Power Down

(For Control Register 3, D1 & D2)

Internal TLV320AIC11

D1 and D2 are

programmed through a

secondary write operation

Figure 2–8. Internal Power-Down Logic

2.2.2.1 Software Power Down

When D1 and D2 of control register 3 are set to 1, TL V320AIC1 1 enters the software power-down mode. In this state,

the digital-interface circuit is still active, while the internal ADC and DAC channels and differential outputs OUTP and

OUTM are disabled, and DOUT and FSD are inactive. Register data in secondary serial communications is still

accepted, but data in primary serial communications is ignored. The device returns to normal operation when D1 and

D2 of control register 3 are reset.

2.2.2.2 Hardware Power Down

When PWRDWN is held low, the device enters the hardware power-down mode. In this state, the internal-clock

control circuit and the differential outputs OUTP and OUTM are disabled. All other digital I/Os are either disabled, or

remain in the same state they were in immediately before power down. DIN can not accept any data input. The device

can only be returned to normal operation by taking and holding PWRDWN high. When not holding the device in the

hardware power-down mode, PWRDWN

should be tied high.

2–7

Page 22

2.3 Clock Source

MCLK is the external master-clock input. The clock circuit generates and distributes the necessary clocks throughout

the device. When the device is in the master mode, SCLK and FS are output and derived from MCLK in order to

provide clocking of the serial communications between the device and a DSP (digital signal processor). When in the

slave mode, SCLK and FS are all inputs. The SCLK can be connected to a faster clock source to speed up serial

communication between the slave and the master while the internal clock is maintained at 256 clocks per FS period

for internal processing. In SPI mode, the device is a slave and SCLK is connected to the SPICLK source.

2.4 Data Out (DOUT)

DOUT is placed in the high-impedance state after completing transmission of the LSB. In primary communication the

data word is the ADC conversion result. In secondary communication the data is the register read results when

requested by the read/write (R/W) bit. If a register read is not requested, the low eight bit of the secondary word is

all zeroes. The state of the master/slave (M/S) terminal is reflected by the MSB in secondary communication (DOUT ,

bit D15), and by the LSB in primary communication (DOUT, bit D0).

2.4.1 Data Out, Master Mode

In the master mode, DOUT is taken from the high-impedance state by the falling edge of the master frame-sync (FS).

The most significant data bit then appears first on DOUT.

2.4.2 Data Out, Slave Mode

In the slave mode, DOUT is taken from the high-impedance state by the falling edge of the external frame-sync (FS).

The most significant data bit then appears first on DOUT.

2.5 Data In (DIN)

In a primary communication, the data word is the input digital signal to the DAC channel. If (15+1)-bit data format is

used, the LSB (D0) is used to request a secondary communication. In a secondary communication, the data is the

control and configuration data that sets the device for a particular function (see Section 3,

The LSB of control register 1 determines whether it is a 15-bit or a 16-bit input.

Serial Communications

2.6 FC (Hardware Secondary Communication Request)

The FC input provides for hardware requests for secondary communications. FC works in conjunction with the LSB

of the primary data word. FC should be tied low if not used.

2.7 Frame-Sync Function for TLV320AIC11

The frame-sync signal (FS) indicates the device is ready to send or receive data. FS is an output if the M/S pin is

connected to HI (master mode), and an input if the M/S pin is connected to LO (slave mode). The output FSD is a

delay version of the first frame-sync signal (FS) that is output 32 SCLKs after the first FS, and serves as the

frame-sync input to the next slave (see Figure 2–17). The data transferred out of DOUT and into DIN begins on the

falling edge of the FS signal. It can be configured as a frame or as a pulse signal, as determined by pins M0 and M1.

In normal operation, the digital serial interface consists of the shift clock (SCLK), the frame-sync signal (FS), the

ADC-channel data output (DOUT), and the DAC-channel data input (DIN). During the primary frame–synchronization

interval, SCLK clocks the ADC channel results out through DOUT , and clocks 16-bit/(15+1) DAC data in through DIN.

During the secondary frame-sync interval, SCLK clocks the register data out through DOUT in normal operation. If

the read bit (D12) is set to 1 and the device transfers control and device parameter in through DOUT. The timing

sequence is shown in Figures 2-1, 2-2, 2-3, and 2-4.

).

2–8

Page 23

The TLV320AIC11 has three serial-interface modes that support most modern DSP engines. This modes can be

selected by M0 and M1. In mode 0 (Figure 2–9), FS is one-bit wide and it is active high one SCLK period before the

first bit (MSB) of each data transmission. In modes 1 (Figure 2–10) and 2 (Figure 2–1 1), the TL V320AIC11 operates

as a slave to interface with an SPI master in which FS is the SPISEL that determines the sampling rate. SCLK needs

to be free-running. In mode 3 (Figure 2–12), FS is low during data transmission into DIN and DOUT.

Table 2–1. Serial Interface Modes

MODE M1 M0 FRAME SYNC (FS) FORMAT

0 0 0 Pulse mode

1 0 1 SPI_CP0 mode (SPI mode 0)

2 1 0 SPI_CP1 mode (SPI mode 1)

3 1 1 Frame mode

SCLK

FS

DIN/DOUT

(16-bit)

0 1 15 16

14

……

16 SCLKs

……

D15

MSB LSB

D14

Figure 2–9. Timing Diagram for the FS Pulse Mode (M1M0 = 00)

01 15

SPICLK

(SCLK)

SPISEL

(FS)

DIN/DOUT

(16-bit)

D15

MSB LSB

D14

……

14

……

16 SCLKs

……

……

D1

D1

D0

D0

Figure 2–10. Timing Diagram for the SPI_CP0 Mode (M1M0 = 01)

2–9

Page 24

SPICLK

(SCLK)

SPISEL

(FS)

01 15

14

……

16 SCLKs

……

DIN/DOUT

(16-bit)

D15

MSB LSB

D14

……

D1

D0

Figure 2–11. Timing Diagram for the SPI_CP1 Mode (M1M0 = 10)

SCLK

FS

DIN/DOUT

(16-bit)

0 1 15 16

……

16 SCLKs

……

D15

MSB LSB

D14

……

14

D1

D0

Figure 2–12. Timing Diagram for the FS Frame Mode (M1M0 = 11)

NOTE: In frame mode, if AIC11 is in slave mode, DIN/DOUT should be delayed by one SCLK from the falling edge of FS.

2.7.1 Frame-Sync (FS) Function—Continuous-Transfer Mode (Master Only)

1

Writing a

transmitted and received contiguously with no inactivity between bits at the very next FS, and no further frame sync

FSs are generated. Secondary communication is not available. To disable the continuous transfer mode, use the

direct-configuration mode (See section 3.3) or reset the device.

to bit D5 of control register 3 enables the continuous-transfer mode. In this mode, the data bits are

2.7.2 Frame-Sync (FS) Function—Fast-Transfer Mode (Slave Only)

By connecting the fast clock to the SCLK pin, data can be transmitted and received at a higher rate than 256 x Fs

in the slave mode for a stand-alone AIC11.

2–10

Page 25

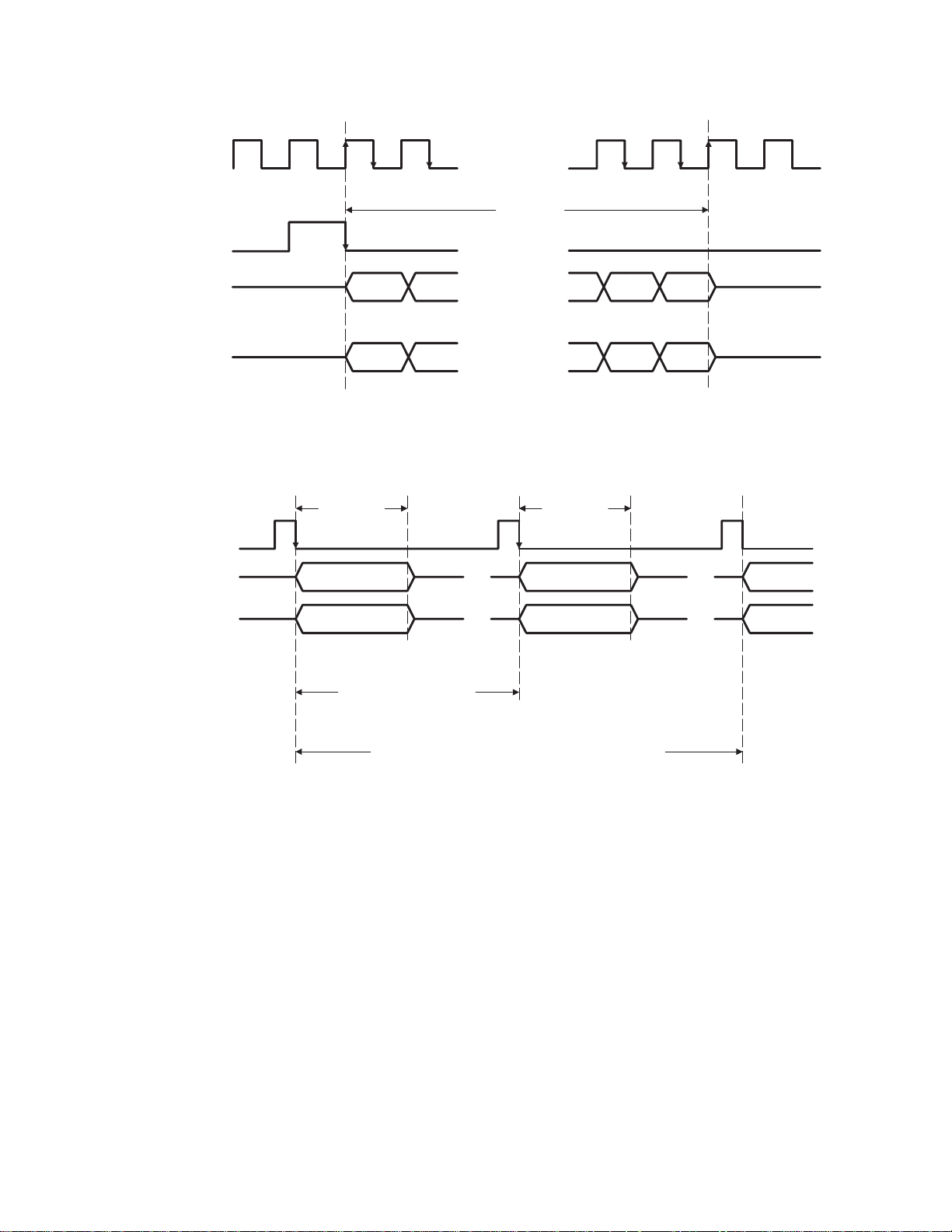

2.7.3 Frame-Sync (FS) Function—Master Mode

The master mode in the TLV320AIC11 is selected by connecting pin M/S pin to HI. In the master mode, the

TL V320AIC11 generates the frame-sync signal (FS) to the DSP that goes low on the rising edge of SCLK and remains

low during a 16-bit data transfer.

16 SCLKs

(see Note A)

FS

FS

(see Note B)

DIN/DOUT

NOTES: A. Primary and secondary serial communications

B. Primary serial communication only

Primary Secondary

Primary Secondary Primary

16 SCLKs

Primary

Figure 2–13. Master Device Frame-Sync Signal With Primary and Secondary Communication ( No Slaves)

2.7.4 Frame-Sync (FS) Function—Slave Mode

The slave mode is selected by connecting pin M/S to LO. The frame-sync timing is generated externally by the master,

as shown in Figure 2–14 (that is, FSD) and is applied to FS of the slave to control the ADC and DAC timing.

(Master to DSP)

FS

MP

SP MS SS MP

FSD (Master)

to FS (Slave)

32 SCLKs

NOTE: MP: master primary (master-device data is transferred during this period, the DOUT of the slave device is in high-impedance state).

SP: slave primary (slave device data is transferred during this period, the DOUT of master device is in high-impedance state).

MS: master secondary (master device control register information is transferred during this period, the DOUT of slave device is in high impedance state).

SS: slave secondary (slave device control register information is transferred during this period, the DOUT of master device is in high impedance state).

Figure 2–14. Master Device’s FS Output to DSP and FSD Output to the Slave

2–11

Page 26

2.7.5 Frame-Sync Delayed (FSD) Function, Cascade Mode

In cascade mode, the DSP must be able to identify the master and slaves according to the register map shown in

Appendix A. Each device in the cascade contains a 3-bit cascade register (D15-D13 in the register address) that has

been programmed by the ACD (automatic cascade detection) with an address value equal to its position in the

cascade during the device’s power-up initialization (see Section 2.1.1 1). The device address of the master is always

equal to the number of slaves in the cascade. For example, in Figure 2–15, D15-D13 of the master will be

shown in row 4 of Table A-1 (Appendix A). The DSP receives all frame-sync pulses from the master though the

master’s FS. The master FSD is output to the first slave, and the first slave FSD is output to the second slave device,

and so on. Figure 2–15 shows the cascade of 4 TLV320AIC11s in which the closest one to the DSP is the master,

and the rest are slaves. The FSD output of each device is input to the FS terminal of the succeeding device.

Figure 2–16 shows the FSD timing sequence in the cascade.

011

, as

CLKOUT

DX

DR

FSX

FSR

CLKX

CLKR

TMS320UC54x

Master FSD,

Slave 2 FSD,

(or Master Clock Source)

MCLK

DIN

FS

DOUT

FSD

SCLK

M/S M/S M/S M/S

Figure 2–15. Cascade Mode Connection (to DSP Interface)

Master FS

Slave 2 FS

Slave 1 FS

MCLK

DIN

DOUT

FS

DVDD

SCLK

P

M

P

S2

32 SCLKs

FSD FSD

Slave 2 Slave 1 Slave 0Master

P

S1

P

S0

MCLK

DIN

DOUT

FS

SCLK

S

M

S S

S2

MCLK

DIN

DOUT

FS

SCLK

FSD

Slave 1 FSD,

Slave 0 FS

Slave 0 FSD

(See Note)

NOTE: Slave 0 FSD should be left open.

2–12

32 SCLKs

32 SCLKs

32 SCLKs

Figure 2–16. Master-Slave Frame-Sync Timing

Page 27

2.8 Multiplexed Analog Input and Output

The two differential analog inputs (INP and INM, or AUXP and AUXM) are multiplexed into the sigma-delta modulator .

The performance of the AUX channel is similar to the normal-input channel. The gain of the input amplifiers is set

through control register 4.

2.8.1 Multiplexed Analog Input

To produce excellent common-mode rejection of unwanted-signal performance, the analog signal is processed

differentially until it is converted to digital data. The signal applied to the INM and INP terminals should be differential

to preserve the device specifications. The signal source driving the analog inputs (INP and INM, or AUXP and AUXM)

should have a low source impedance to attain the lowest noise performance and accuracy. To obtain maximum

dynamic range, the signal should be ac-coupled to the input terminal. The analog input signal is self-biased to the

mid-supply . Bits D3 and D4 of control register 1 select these input sources. The default condition self-biases the input,

since the register default value selects INP and INM as the sources for the ADC.

V

V

INP

INM

INP

INM

(or ) 1.5 V

TLV320AIC11

2.5 V

Figure 2–17. INP and INM Internal Self-Biased Circuit (2.5 V for 5-V Operation and 1.5 V for 3-V Operation)

2.8.2 Analog Output

OUTP and OUTM are differential outputs and can typically drive a 600-ohm load directly. Figure 2–18 shows the

circuit when the load is ground-referenced.

10 k Ω

10 kΩ

OUTM

10 kΩ

OUTP

+5 V

–

+

–5 V

TLE2062

Load

10 kΩ

Figure 2–18. Differential Output Drive (Ground-Referenced)

2–13

Page 28

2.8.3 Single-Ended Analog Input

The two differential inputs (INP and INM, or AUXP and AUXM) can be configured to work as single-ended inputs by

connecting INP or AUXP to the analog input, and INM or AUXM to the external common-mode input. This is illustrated

in Figure 2–19.

C

Analog Input

Common-Mode Input

100 Ω

INP

INM

Figure 2–19. Single-Ended Input

2.8.4 Single-Ended Analog Output

The differential output of TL V320AIC1 1 can be configured as a single-ended output. This is illustrated in Figure 2–20.

C

OUTP

R

L

OUTM

Figure 2–20. Single-Ended Output

2–14

Page 29

3 Serial Communications

DOUT, DIN, SCLK, SXCLK, FS, and FC are the serial communication signals. SCLK is used to perform internal

processing and data transfer for serial interface between AIC1 1 and DSP . In the pulse/frame FS mode, there are 256

SCLKs per sampling period (512 if there are more than 4 devices in cascade). The digital-output data for the ADC

is taken from DOUT. The digital-input data for the DAC is applied to DIN. The synchronization clock for the serial

communication data and the frame-sync is taken from SCLK. The frame-sync signal that starts the ADC and DAC

data-transfer interval is taken from FS. Primary serial communication is used for signal data transmitted from the ADC

or to the DAC. Secondary communication is used to read or write words that control both the options and the circuit

configurations of the device.

The purpose of the primary and secondary communications is to allow conversion data and control data to be

transferred across the same serial port. A primary transfer is always dedicated to conversion data. A secondary

transfer or an asynchronous communication is used to set up and/or read the register values. A primary transfer

occurs for every conversion period. A secondary transfer occurs only when requested. Secondary serial

communication can be requested either by hardware (FC terminal) or by software (D0 of primary data input to DIN).

The direct configuration mode uses pin DCSI to program control registers instantly.

3.1 Primary Serial Communication

Primary serial communication is used to transmit and receive conversion signal data. The DAC word length depends

on the states of bit D0 in control register 1. After power up or reset, the device defaults to 15-bit mode. When the DAC

word length is 15 bits, the last bit of the primary 16-bit serial communication word is a control bit used to request

secondary serial communication. In the 16-bit mode, all 16 bits of the primary-communication word are used as data

for the DAC, and the hardware terminal FC must be used to request secondary communication.

Figure 3–1 shows the timing relationship for SCLK, FS, DOUT, and DIN in a primary communication. The timing

sequence for this operation is as follows:

• FS is brought low by the TLV320AIC11.

• A 16-bit word is transmitted from the ADC (DOUT), and then a 16-bit word is received from the DAC (DIN).

SCLK

FS

DIN

DOUT

D0D13D15 D14 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1

D0D13D15 D14 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1

Figure 3–1. Primary Serial Communication Timing

3–1

Page 30

3.2 Secondary Serial Communication

Secondary serial communication is used to read or write 16-bit words that program both the options and the circuit

configurations of the device. Register programming always occurs during secondary communication. Four primary

and secondary communication cycles are requested to program the four registers. If the default value for a particular

register is desired, then the register addressing can be omitted during secondary communications. The NOOP

command addresses a pseudo-register (register 0), and no register programming takes place during this secondary

communication. If secondary communication is desired for any device (either master or slave), then a secondary

communication must be requested for all devices, starting with the master. This results in a secondary frame-sync

(FS) for all devices. The NOOP command can be used for devices that do not need a secondary operation.

During a secondary communication, a register can be written to or read from. When writing to a register, DIN contains

the value to be written. The data returned on DOUT is + 0000000000000 (3-bit device address).

There are two methods of initiating a secondary communication, as illustrated in Figure 3–2:

• Asserting a high level on FC (hardware request)

• Asserting the LSB of the DIN 16-bit serial communication high while in the 15-bit mode (software request)

NOTE:

The secondary communication request should not be asserted during the first two samples

after power up.

FC

(Hardware)

Secondary Request

(LSB of DIN)

16-Bit Mode

(Control 1 Register, D0)

Internal TLV320AIC11

Figure 3–2. Hardware and Software Secondary Communication Request

Pulling FC high causes the start of the secondary communication’s 128 or 256 SCLKs (see Figures 2–2 and 2–4)

after the start of the primary communication frame, depending on the number of devices in cascade.

The second method to initiate a secondary communication is asserting the LSB high. A software request is typically

used when the request resolution of the DAC channel is less than 16 bits. Then the least significant bit (D0) can be

used for secondary requests, as shown in Table 3–1. The request is made by placing the device in the 15-bit DAC

mode and making the LSB of DIN high. All devices should be in 15-bit DAC mode, and secondary communication

should be requested for all devices.

Table 3–1. Least Significant Bit Control Function

CONTROL BIT D0 CONTROL BIT FUNCTION

0 No operation (NOOP)

1 Secondary communication request

3–2

Page 31

3.2.1 Register Programming

All register programming occurs during secondary communication through DIN or ALTI, and data are latched and

valid on the falling edge of the SCLK during the frame-sync signal. If the default value of a particular register is desired,

that register does not need to be addressed during the secondary communication interval. The no-op command

(DS15-DS8 all set to 0) addresses the pseudo-register (register 0), and no register programming takes place during

the communication.

In addition, each register can be read back through DOUT during secondary communications by setting the read bit

(D12) to 1. When a register is in the read mode, no data can be written to the register during this cycle. A subsequent

secondary communication is required to return this register to the write mode.

For example, if the contents of control register 1 of device 3 are desired to be read out from DOUT, the following

procedure must be performed through DIN:

• Request secondary communication by setting either D0 = 1(software request), or FC = high (hardware

request) during the primary communication interval.

• During the secondary communication interval (FS), send data in through DIN using the following format:

Device Address RW Register Address X Register Content

0 1 1 1 0 0 1 x x x x x x x x x

DS15 DS0

• Then, during the same frame, the following data will be read from DOUT ; the last 8 bits of DOUT will contain

register 1 data.

Device Address RW Register Address X Register Content

0 1 1 x x x x x d d d d d d d d

DS15 DS0

Figure 3–3 is the timing diagram of this procedure.

FS

DIN

DOUT

PS

Figure 3–3. Device 3/Register 1 Read Operation Timing Diagram

Register 1 Read

Low 8 Bit (D0 – D7) is

the content of register 1

3–3

Page 32

To program control register 1, the following procedure must be performed through DIN:

• Request secondary communication by setting either D0=1(software request), or FC = high (hardware

request) during the primary communication interval.

• At the secondary communication interval (FS), send data in the following format through DIN:

Device Address RW Register Address X Register Content

0 1 1 0 0 0 1 x d d d d d d d d

DS15 DS0

• The following is the data out of DOUT.

Device Address RW Register Address X Register Content

0 1 1 0 x x x x 0 0 0 0 0 0 0 0

DS15 DS0

Figure 3–4 is the timing diagram of this procedure.

FS

DIN

DOUT

PS

Register Write

(Device Addr) + All 0

Figure 3–4. Device 3/Register 1 Write Operation Timing Diagram

3.2.2 Hardware Secondary Serial Communication Request

A secondary communication can be requested by asserting an FC pulse that sets an internal flag. This flag will be

reset as soon as the programming of control registers is finished. Thus, one FC pulse needs to be asserted per

secondary communication request. Figures 3–5 and 3–6 show the FS output from a master device.

FS

FC

Primary Secondary Primary

Secondary

Request

No Secondary

Request

3–4

DOUT

DIN

ADC Data Out

DAC Data In

Register

Read/Write

Register

Read/Write

ADC Data Out

DAC Data In

Figure 3–5. FS Output When Hardware Secondary Serial Communication

Is Requested Only Once (No Slave)

Page 33

P

P

P

P

S

S S

S

P

Master FS

FC

(See Note)

NOTES: A. FC of master device and slave devices should be connected together

B. Primary communication interval = 256 SCLKs if cascading devices < 5

C. Primary communication interval = 512 SCLKs if cascading devices > 4

M

S2

FC pulse needs to be inserted any time

within the primary communication

S1

S0

M

S2

S1

S0

M

Figure 3–6. Output When Hardware Secondary Serial Communication Is Requested (Three Slaves)

3.2.3 Software Secondary Serial Communication Request

The LSB of the DAC data within a primary transfer can request a secondary communication through bit D0 of control

register 1 when the device is in the 15-bit mode.

For all serial communications, the most significant bit is transferred first. For a 16-bit ADC word and a 16-bit DAC word,

D15 is the most significant bit and D0 is the least significant bit. For a 15-bit DAC data word in a primary

communication, D15 is the most significant bit, D1 is the least significant bit. Bit D0 is then used for the secondary

communication request control. All digital data values are in 2s-complement data format (see Figure 3–7).

If the data format is set to 16-bit word, all 16 bits are either ADC or DAC data, and secondary communication can

only be requested by hardware (FC terminal), or control registers can be programmed by the direct configuration

mode.

FS

DIN

Communication Request

PS

Data (D0 = 1)

Secondary

Register

Read/Write

P

Data (D0 = 0)

No Secondary

Communication Request

Figure 3–7. FS Output During Software Secondary Serial Communication Request (No Slave)

3–5

Page 34

3.3 Direct Configuration Mode

For DSP applications that use continuous data transfer mode for autobuffering, or for DMA operations that do not

have the capability to interfere with the data conversion channel by inserting the secondary communication, the

TLV320AIC11’s direct-configuration mode provides a flexible alternative to programming control registers through

pin DCSI. The serial input to DCSI should normally be in a high state, start its valid data with a start bit of logic low,

and pull high as a stop bit after transmission of the LSB. DCSI requires a pullup resistor for 3-state input. The AIC1 1

registers data bits on the falling edge of SCLK. Figure 3–8 shows a typical connection between the TMS320C54x

and the AIC1 1 using DCSI for direct configuration of control registers. Figure 3–9 shows the timing diagram for the

direct configuration mode.

DVDD

1 kΩ

CLKX0

DX0

FSX1

FSR1

DX1

DR1

CLKX1

CLKR1

TMS320UC54x TLV320AIC11

DCSI

DIN

DOUT

SCLK

Figure 3–8. Direct Configuration

SCLK

M/S

FSDFS

DVDD

DCSI

FS

DIN

DOUT

SCLK

TLV320AIC11

M/S

DGND

DCSI

Start Bit = 0 Device

Address

Register

Address

Register Data Stop Bit = 1

D0D13D15 D14 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1

Figure 3–9. Direct Configuration Mode Timing

To program control register 1 of device 3, send data in with the following format through DCSI:

SB Device Address Register Address X Register Content

0 0 1 1 0 0 1 x x x x x x x x x

D15 D0

3–6

Page 35

3.4 Continuous Data Transfer Mode

In continuous data transfer mode, the 16-bit converter data are transferred contiguously with no inactivity between

bits. This mode is available in the stand-alone master with M1M0 = 00 (FS-pulse mode) and selected by setting bit

D5 of control register 3 to 1. The frame sync pulse overlaps the last bit transmitted in the previous 16 bits of data.

The secondary communication request is not allowed in this mode and therefore the direct configuration mode should

be used to program the internal control registers. The continuous data transfer mode is designed to support the TI

DSP McBSP’s autobuffering unit (ABU) operation in which serial port interrupts are not generated with each word

transferred to prevent CPU’s ISR overheads.

SCLK

FS

DIN

DOUT

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

C0

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

Figure 3–10. Continuous Data Transfer Mode Timing

E15 E13 E12

E14C0

E15 E14 E13 E12

3–7

Page 36

3.5 DIN and DOUT Data Format

3.5.1 Primary Serial Communication DIN and DOUT Data Format

(15 + 1)-Bit Mode

DIN

DOUT

(15 + 1)-Bit Mode

DIN

16-Bit Mode

DOUT

16-Bit Mode

D15 – D1 D0

A/D & D/A Data

D15 – D1 D0

D15 – D0

A/D & D/A Data

D15 – D0

Figure 3–11. Primary Communication DIN and DOUT Data Format

3.5.2 Secondary Serial Communication DIN and DOUT Data Format

Secondary

Communication

Request

M/S Bit

Don’t CareReserved

DIN (Read)

R/WDevice Address

DIN (Write)

Device Address

DOUT (Read)

0

Figure 3–12. Secondary Communication DIN and DOUT Data Format

3.5.3 Direct Configuration DCSI Data Format

DCSI (Write)

0 D12

Figure 3–13. Direct Communication DCSI Data Format

Register Address

Register AddressDevice Address

D8D15 D14 D13 1 D11 D10 D9 D7 – D0

Data to the

Register

D8D15 D14 D13 D11 D10 D9 D7 – D0

Register Data

D8D15 D14 D13 X X X X D7 – D0

Data to the

Register

D8D14 D13 D1 1 D10 D9 D7 – D0

3–8

Page 37

4 Specifications

4.1 Absolute Maximum Ratings Over Operating Free-Air Temperature Range

(Unless Otherwise Noted)

†

Supply voltage I/O range, DV

Supply voltage core range, DV

DD1

, AVDD (see Note 1) –0.3 V to 7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DD2

–0.3 V to 4.0 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output voltage range, all digital output signals –0.3V to 4.5 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input voltage range, all digital input signals –0.3V to 4.5 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Case temperature for 10 seconds: package 260°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating free-air temperature range, T

Storage temperature range, T

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTE 1: All voltage values are with respect to VSS.

stg

A

–40°C to 85°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .