Page 1

TLP721(D4,M)SERIES,TLP733(D4,M)SERIES,TLP747(D4,M)SERIES

TOSHIBA PHOTOCOUPLER

TLP721(D4,M)SERIES,TLP733(D4,M)SERIES,TLP747(D4,M)SERIES

ATTACHMENT

Types : TLP721, TLP721F, TLP733, TLP733F, TLP734, TLP734F, TLP747G, TLP747GF, TLP747J,

This data sheet refers to black mold-resin devices, TLPxxx (D4xxx, M) that previously has a white-resin mold

and have been changed. When designing new products please use black mold-resin devices.

Type designations for 'Option: (D4)

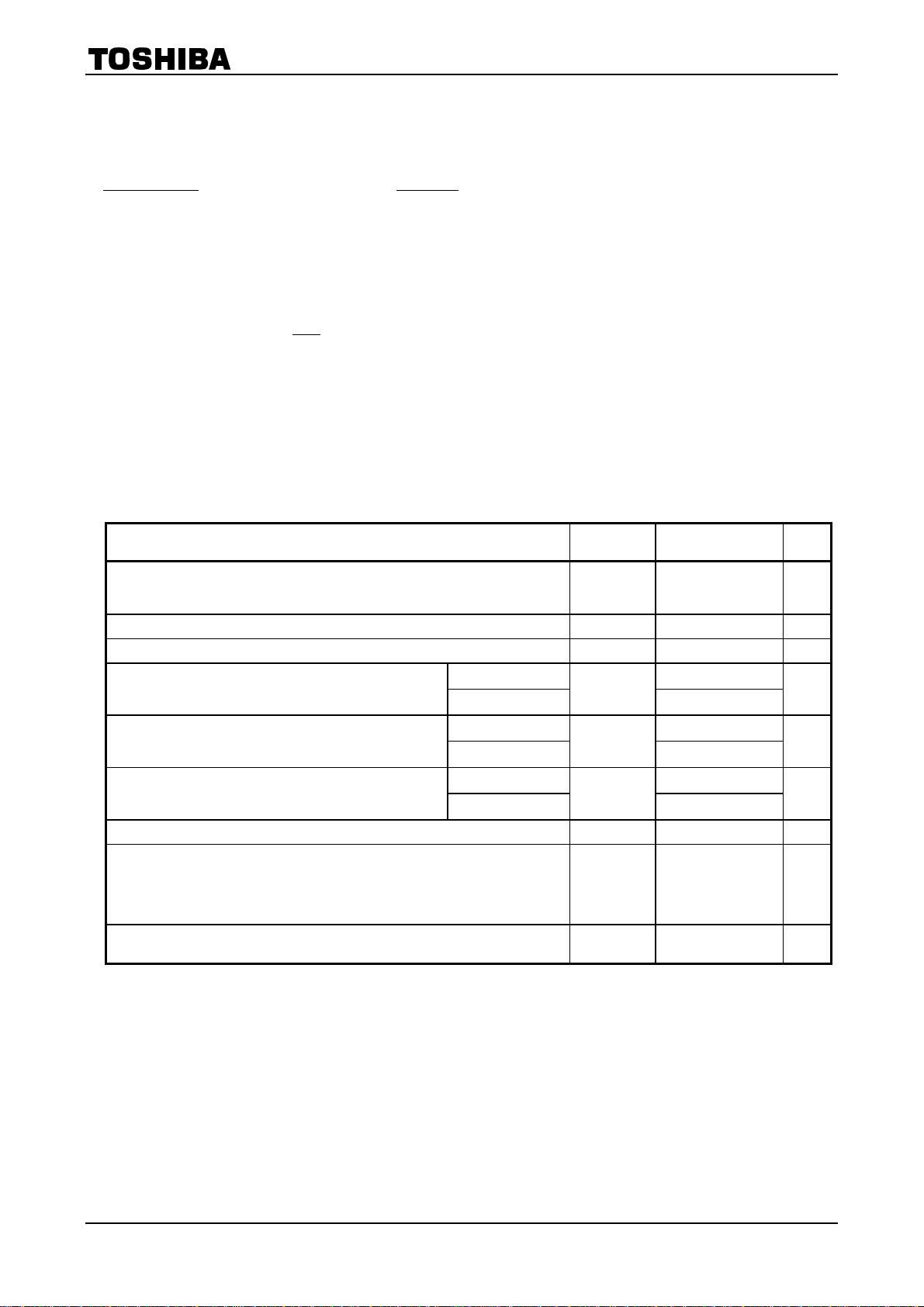

VDE0884 ISOLATION CHARACTERISTICS

: SPECIFICATIONS FOR VDE0884 OPTION: (D4)

TLP747JF

', which are tested under VDE0884 requirements.

Ex. : TLP734F (D4-GR-LF4, M) D4 : VDE0884 option

GR : CTR rank name

LF4 : standard lead bend name

M : black mold-resin devices

Note : Use Toshiba standard type number for safety standard application.

Ex. TLP734(FD4-GR-LF4, M) → TLP734F

DESCRIPTION SYMBOL RATING UNIT

Application Classification (DIN VDE0110 Teil 2 / 01.89, Table 1)

for rated mains voltage ≤ 300 V

for rated mains voltage ≤ 600 V

Climatic Classification (DIN IEC68 Teil 1 / 09.80) 40 / 100 / 21 ―

Pollution Degree (DIN VDE0110 Teil 2 / 01.89) 2 ―

Maximum Operating Insulation Voltage

Input to output Test Voltage, Method A

Vpr = 1.5 × V

tp = 60s, Partial Discharge < 5pC

Input to output Test Voltage, Method B

Vpr = 1.875 × V

tp = 1s, Partial Discharge < 5pC

Highest Permissible Overvoltage (Transient Overvoltage, tpr = 10s) VTR 8000 Vpk

Safety Limiting Values (Max. permissible ratings in case of fault, also refer to

thermal derating curve)

Current (Input current I

Power (Output or Total Powr Dissipation)

Temperature

Insulation Resistance, VIO = 500V, Ta = 25°C

, Type and Sample Test

IORM

, 100% Production Test

IORM

F

V

IO

RMS

RMS

, Psi = 0)

= 500V, Ta = Tsi

TLPxxx type 890

TLPxxxF type

TLPxxx type 1335

TLPxxxF type

TLPxxx type 1670

TLPxxxF type

V

IORM

Vpr

Vpr

Isi

Psi

Tsi

Rsi

I- IV

I- III

1130

1695

2120

400

700

150

≥10

≥109

12

―

Vpk

Vpk

Vpk

mA

mW

°C

Ω

1

2001-05-14

Page 2

TLP721(D4,M)SERIES,TLP733(D4,M)SERIES,TLP747(D4,M)SERIES

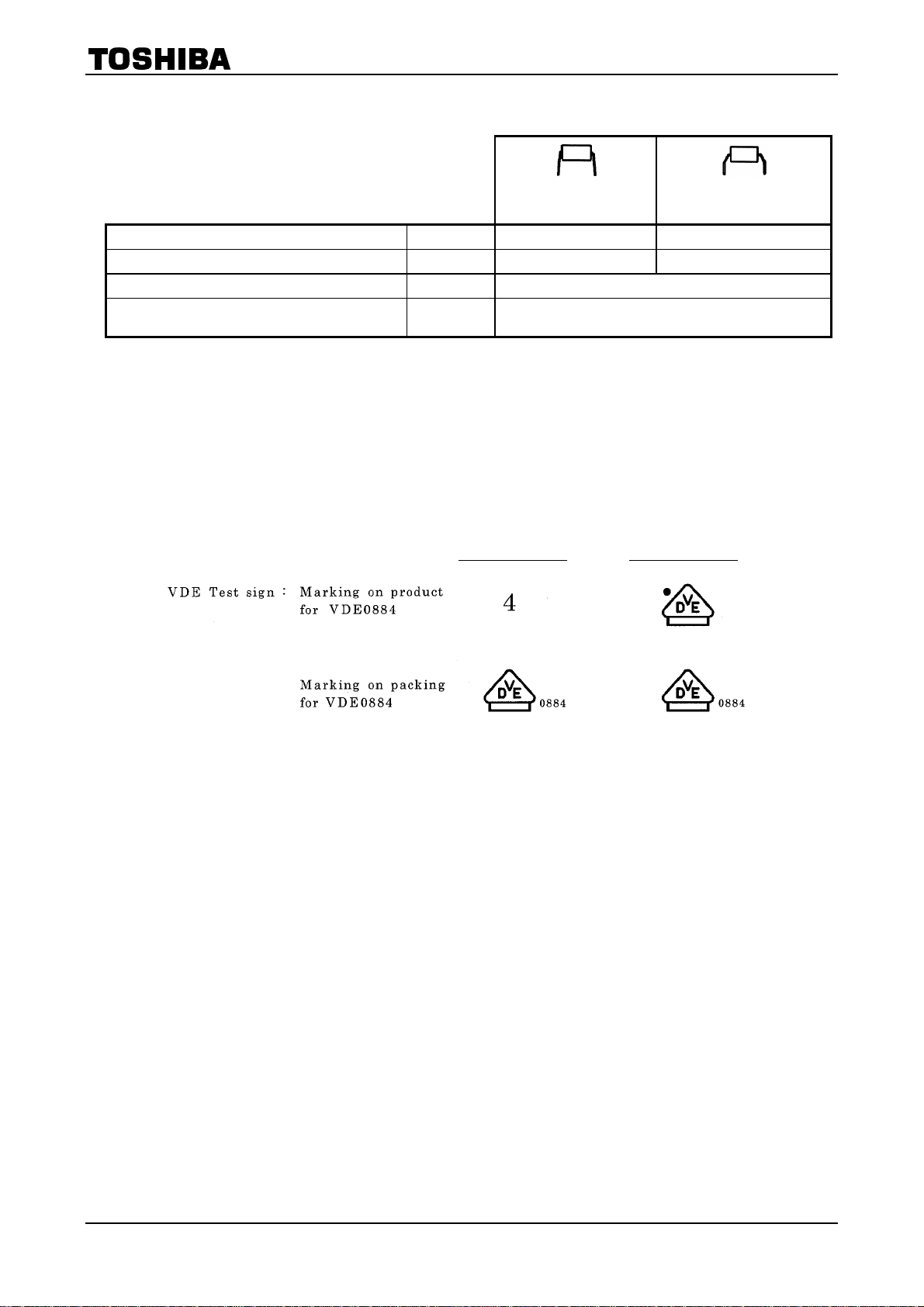

INSULATION RELATED SPECIFICATIONS

7.62mm pitch

TLPxxx type

Minimum Creepage Distance (*) Cr 7.0 mm 8.0 mm

Minimun Clearance (*) Cl 7.0 mm 8.0 mm

Minimum Insulation Thickness ti 0.5 mm

Comperative Tracking Index

(DIN IEC112 / VDE0303, Part 1)

*: in accordance with DIN VDE0110 Teil 1 / 01.89, Table 2, & 4

1. If a printed circuit is incorporated, the creepage distance and clearance may be reduced below this value

(e. g. at a standard distance between soldering eye centres of 7.5mm). If this is not permissible, the user

shall take suitable measures.

2. This photocoupler is suitable for 'safe electrical isolation' only within the safety limit data.

Maintenance of the safety data shall be ensured by means of protective circuits.

CTI

TLP721 SERIES

10.16mm pitch

TLPxxxF type

(VDE0110 Teil 2 / 01.89 Group IIIa)

175

TLP733 SERIES

TLP747 SERIES

2

2001-05-14

Page 3

TLP721(D4,M)SERIES,TLP733(D4,M)SERIES,TLP747(D4,M)SERIES

Figure 1 Partial discharge measurement procedure according to VDE0884

Destructive test for qualification and sampling tests.

Figure 2 Partial discharge measurement procedure according to VDE0884

Non-destructive test for 100% inspection.

Figure 3 Dependency of maximum safety ratings on ambient temperature

3

2001-05-14

Page 4

TLP721(D4,M)SERIES,TLP733(D4,M)SERIES,TLP747(D4,M)SERIES

RESTRICTIONS ON PRODUCT USE

· TOSHIBA is continually working to improve the quality and reliability of its products. Nevertheless, semiconductor

devices in general can malfunction or fail due to their inherent electrical sensitivity and vulnerability to physical

stress. It is the responsibility of the buyer, when utilizing TOSHIBA products, to comply with the standards of

safety in making a safe design for the entire system, and to avoid situations in which a malfunction or failure of

such TOSHIBA products could cause loss of human life, bodily injury or damage to property.

In developing your designs, please ensure that TOSHIBA products are used within specified operating ranges as

set forth in the most recent TOSHIBA products specifications. Also, please keep in mind the precautions and

conditions set forth in the “Handling Guide for Semiconductor Devices,” or “TOSHIBA Semiconductor Reliability

Handbook” etc..

· The TOSHIBA products listed in this document are intended for usage in general electronics applications

(computer, personal equipment, office equipment, measuring equipment, industrial robotics, domestic appliances,

etc.). These TOSHIBA products are neither intended nor warranted for usage in equipment that requires

extraordinarily high quality and/or reliability or a malfunction or failure of which may cause loss of human life or

bodily injury (“Unintended Usage”). Unintended Usage include atomic energy control instruments, airplane or

spaceship instruments, transportation instruments, traffic signal instruments, combustion control instruments,

medical instruments, all types of safety devices, etc.. Unintended Usage of TOSHIBA products listed in this

document shall be made at the customer’s own risk.

· Gallium arsenide (GaAs) is a substance used in the products described in this document. GaAs dust and fumes

are toxic. Do not break, cut or pulverize the product, or use chemicals to dissolve them. When disposing of the

products, follow the appropriate regulations. Do not dispose of the products with other industrial waste or with

domestic garbage.

· The products described in this document are subject to the foreign exchange and foreign trade laws.

000707EBC

· The information contained herein is presented only as a guide for the applications of our products. No

responsibility is assumed by TOSHIBA CORPORATION for any infringements of intellectual property or other

rights of the third parties which may result from its use. No license is granted by implication or otherwise under

any intellectual property or other rights of TOSHIBA CORPORATION or others.

· The information contained herein is subject to change without notice.

4

2001-05-14

Loading...

Loading...