Datasheet TLP270M, TLP270G-1, TLP270G, TLP200M, TLP200G-1 Datasheet (SGS Thomson Microelectronics)

...Page 1

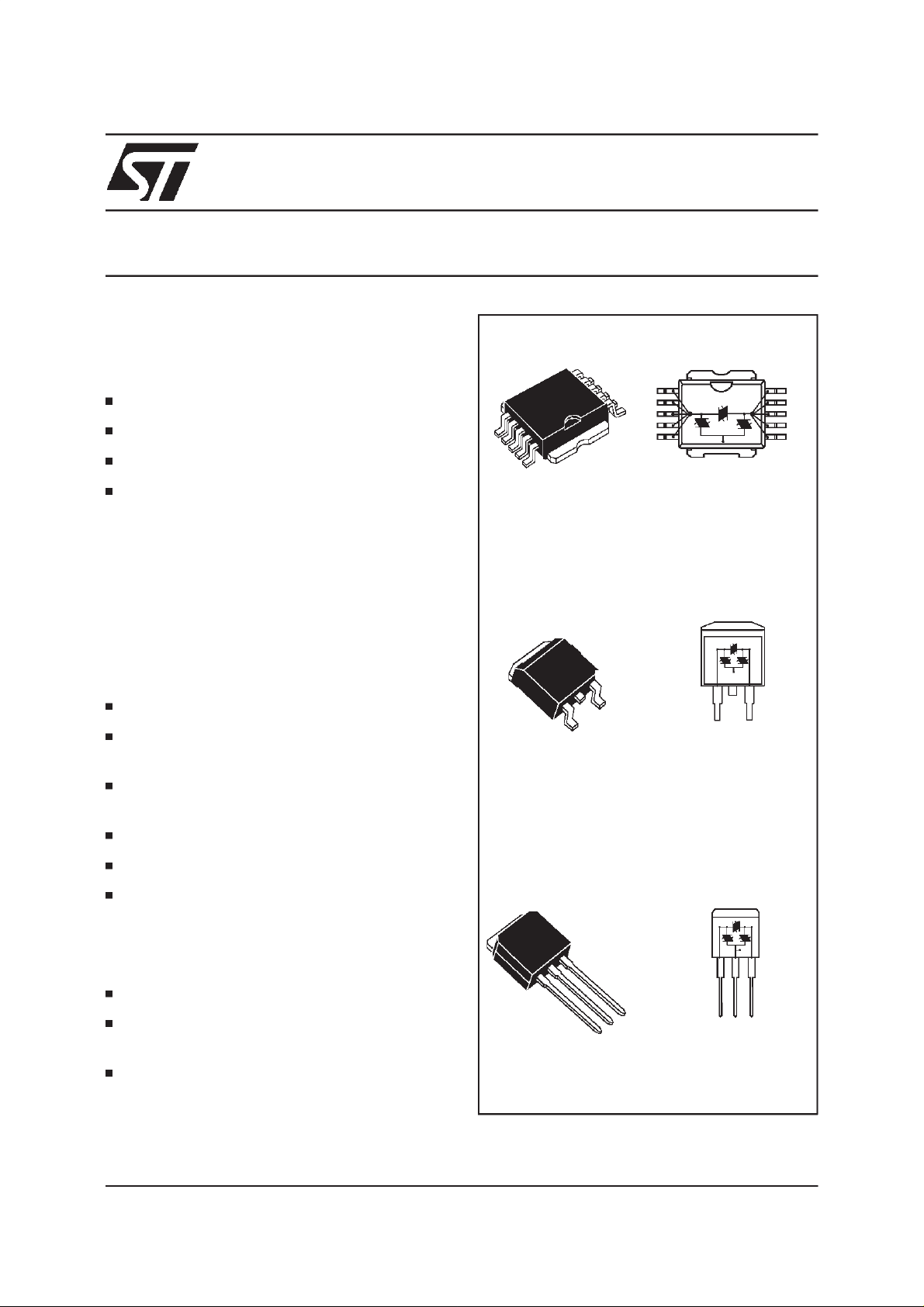

TLPxxM/G/G-1

ApplicationSpecific Discretes

A.S.D.

MAINAPPLICATIONS

Anysensitive telecomequipmentrequiringprotectionagainst lightning :

Analogand ISDN line cards

MainDistributionFrames

Terminaland transmissionequipment

Gas-tubereplacement

DESCRIPTION

The TLPxxM/G/G-1 series are tripolar transient

surge arrestors used for primary and secondary

protectionin sensitivetelecomequipment.

FEATURES

TRIPOLARCROWBAR PROTECTION

VOLTAGE RANGE SELECTED FOR

TELECOMAPPLICATIONS

PROTECTIONfor TELECOM LINE

TRIPOLAR OVERVOLTAGE

GND

TIP

PowerSO-10TMTLPxxM

GND

TAB

GND

D2PAK TLPxxG

RINGTIP

RINGTIP

RING

RINGTIP

RINGTIP

RINGTIP

REPETITIVEPEAK PULSE CURRENT:

= 100A (10/ 1000µs)

I

PP

HOLDINGCURRENT: I

= 150mA

H

LOWCAPACITANCE: C = 110 pF typ.

LOWLEAKAGECURRENT: I

=5µA max

R

BENEFITS

No ageing and no noise.

If destroyed, the TLPxxM/G/G-1 falls into short

circuit,still ensuringprotection.

Access to Surface Mount applications thanks to

TM

the PowerSO-10

TM: ASD and PowerSO-10 are trademarks of ST Microelectronics.

September 1998 - Ed : 3C

andD2PAKpackage.

2

I

PAK TLPxxG-1

GND

TAB

GND RINGTIP

1/14

Page 2

TLPxxM/G/G-1

COMPLIESWITH THE

FOLLOWINGSTANDARDS:

PeakSurge

Voltage

(V)

Voltage

Waveform

(µs)

Current

Waveform

(µs)

Admissible

Ipp

(A)

Necessary

Resistor

CCITTK20 4000 10/700 5/310 100 VDE0433

4000 10/700 5/310 100 VDE0878 4000 1.2/50 1/20 100 IEC-1000-4-5 level 4

level 4

FCC Part68, lightningsurge

type A

FCC Part68, lightningsurge

1500

800

1000 5/320 5/320 25 -

10/700

1.2/50

10/160

10/560

5/310

8/20

10/160

10/560

100

100

200

100

type B

BELLCORETR-NWT-001089

FIRSTLEVEL

BELLCORETR-NWT-001089

2500

1000

2/10

10/1000

2/10

10/1000

500

100

5000 2/10 2/10 500 SECONDLEVEL

CNETI31-24 4000 0.5/700 0.8/310 100 -

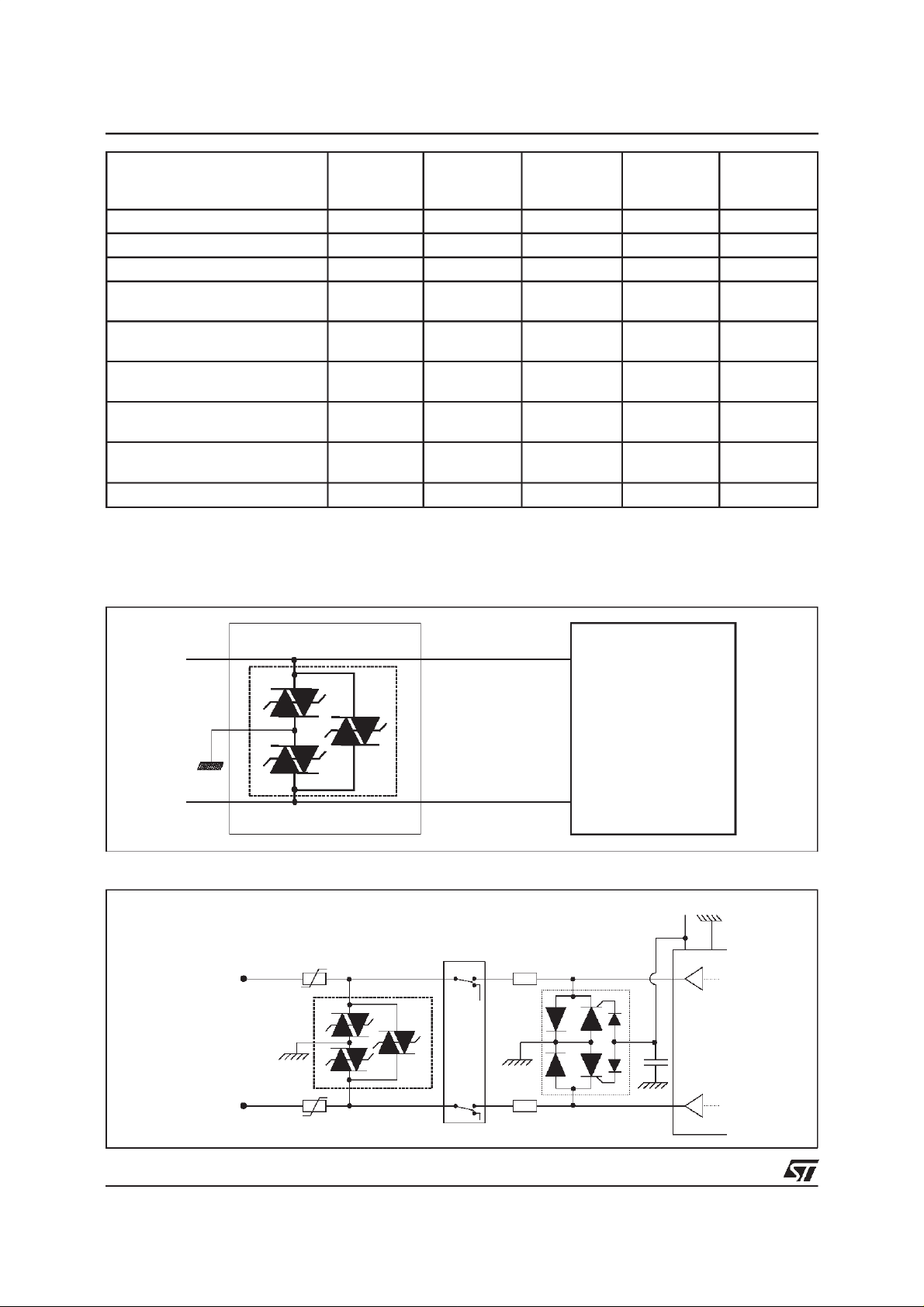

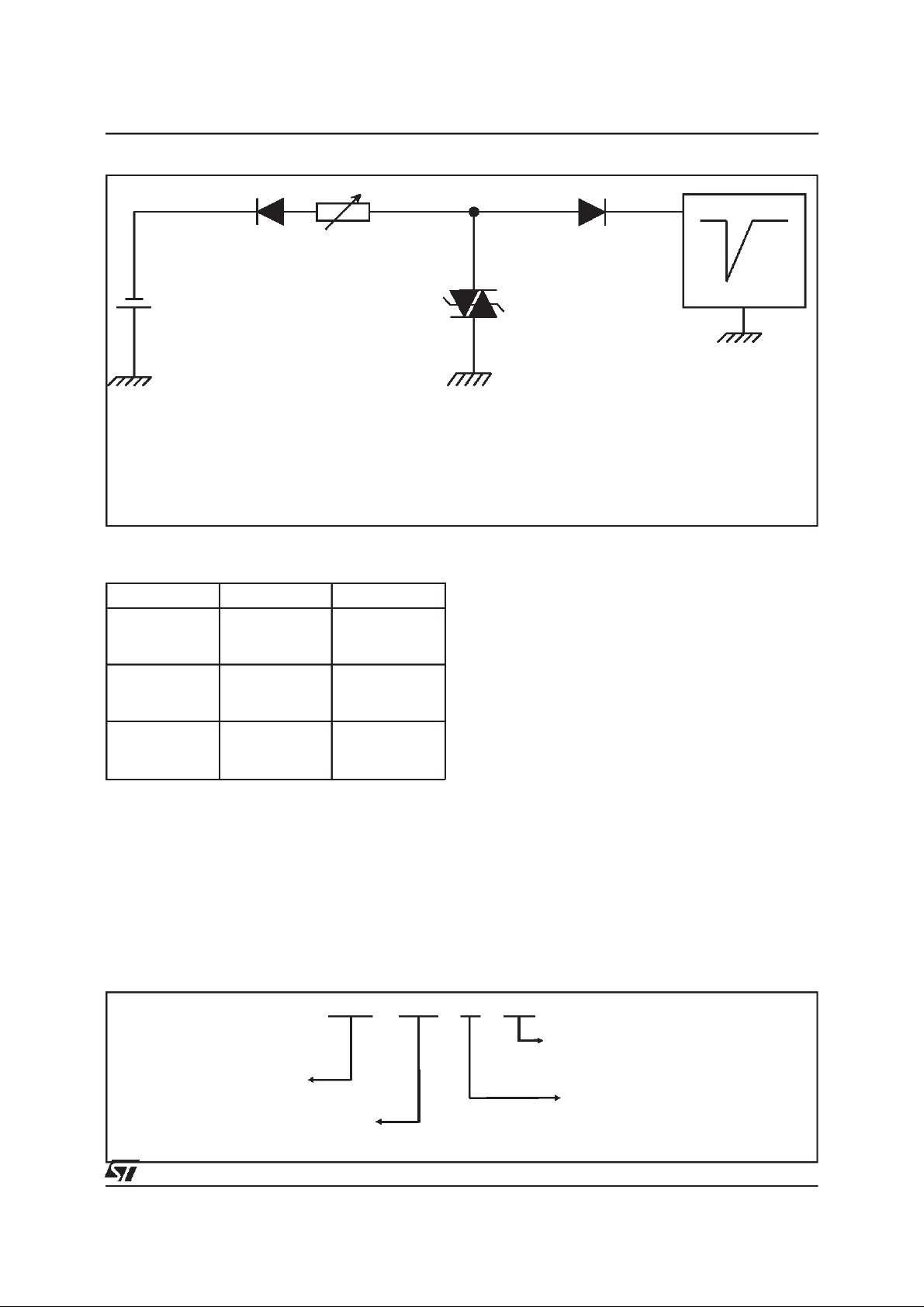

TYPICALAPPLICATION

Primaryprotection module

(Ω)

-

-

-

-

-

-

TLPxxM/G/G-1

Main Distribution Frame

Analog line card protection

LINE A

TLPxxM/G/G-1

PTC

RING

RELAY

LCP1511D

Analog

Line

Card

220

-Vbat

SLIC

nF

2/14

LINE B

PTC

Page 3

TYPICALAPPLICATION

ISDN: U interfaceprotection

TLPxxM/G/G-1

TLPxxM/G/G-1

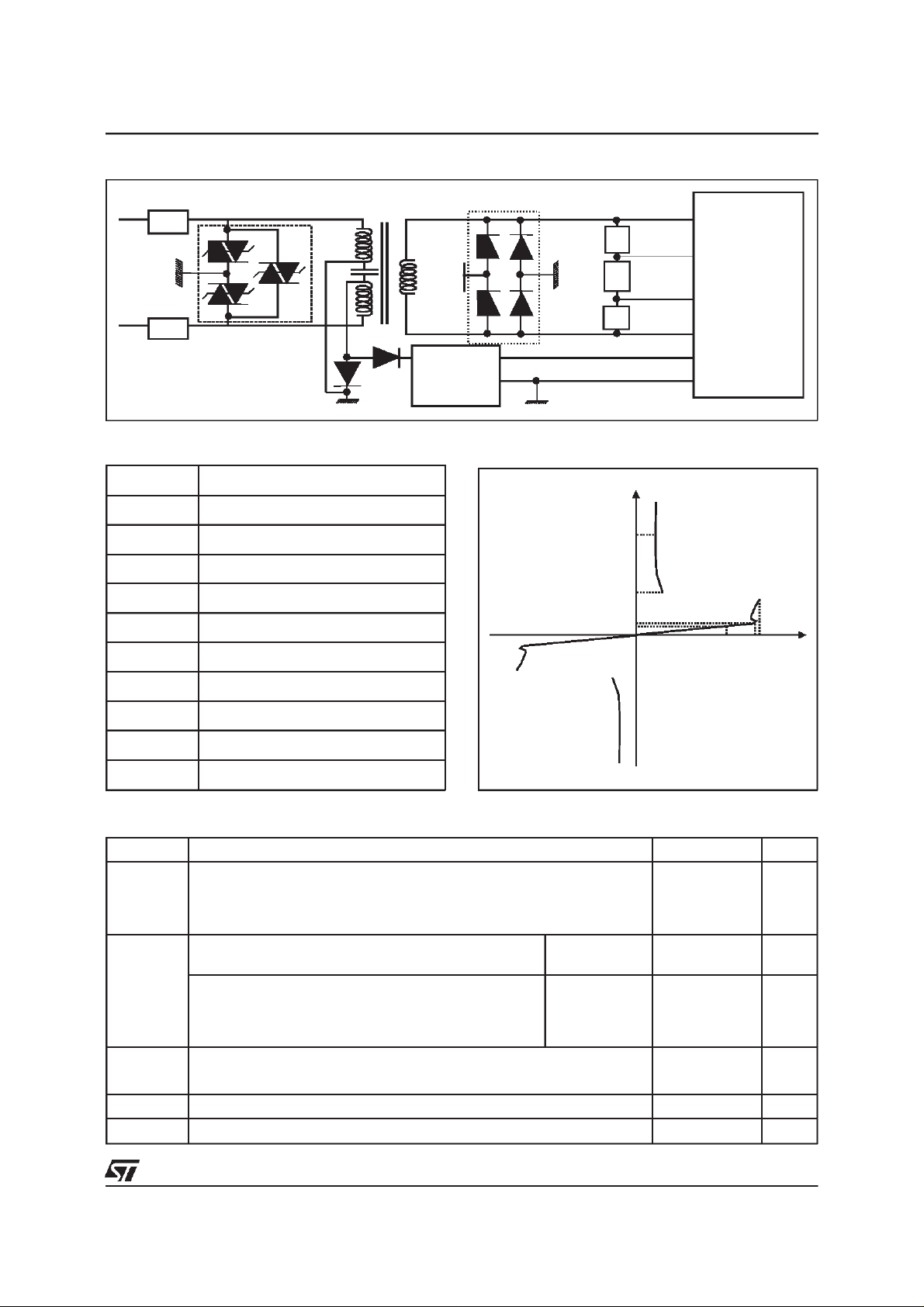

PARAMETER MEASUREMENT INFORMATION

Symbol Description

I

PP

I

TSM

I

I

RM

I

V

R

H

BR

Peak pulse current

Maximumpeak on-statecurrent

Leakagecurrent

Leakagecurrent

Holdingcurrent

Breakdownvoltage

1/2 DA108S1

+5V

Power

Feeder

R3

R4

R5

IRM

IPP

IR

Internal

circuitry

IH

VRM

VRVBO

V

R

V

RM

V

BO

Continuousreversevoltage

Maximumstand-off voltage

Breakovervoltage

C Capacitance

ABSOLUTE MAXIMUMRATINGS

(T

amb

=25°C)

Symbol Parameter Value Unit

I

PP

I

TSM

Peakpulse current(longitudinal& transversalmode) :

10/1000µs (opencircuitvoltagewaveform1 kV 10/1000µs)

8/20µs (opencircuit voltagewaveform4 kV 1.2/50µs)

2/10µs (opencircuit voltage waveform2.5kV 2/10 µs)

Mainspowerinduction

t = 200ms 0.7 A

100

250

500

VRMS= 300V,R = 600Ω

Mainspowercontact

V

= 220V,R =10Ω (Fail-Safethreshold) t = 200 ms

RMS

=220V, R = 600

V

RMS

T

stg

Storagetemperaturerange - 55 to+ 150 °C

Ω

t = 15 mn 0.42 A

31 A

Tj Maximumoperatingjunctiontemperature 150 °C

T

L

T

OP

Maximumleadtemperaturefor solderingduring10 s 260 °C

Operatingtemperaturerange - 40 to+ 85 °C

A

A

A

3/14

Page 4

TLPxxM/G/G-1

THERMALRESISTANCE

Symbol Parameter Value Unit

Rth (j-c) Junctionto case TLPxxM

TLPxxG

TLPxxG-1

Rth (j-a) Junctionto ambient TLPxxM

TLPxxG

TLPxxG-1

seetable page 14

seetable page 14

seetable page 14

1.0

1.0

1.0

C/W

°

°C/W

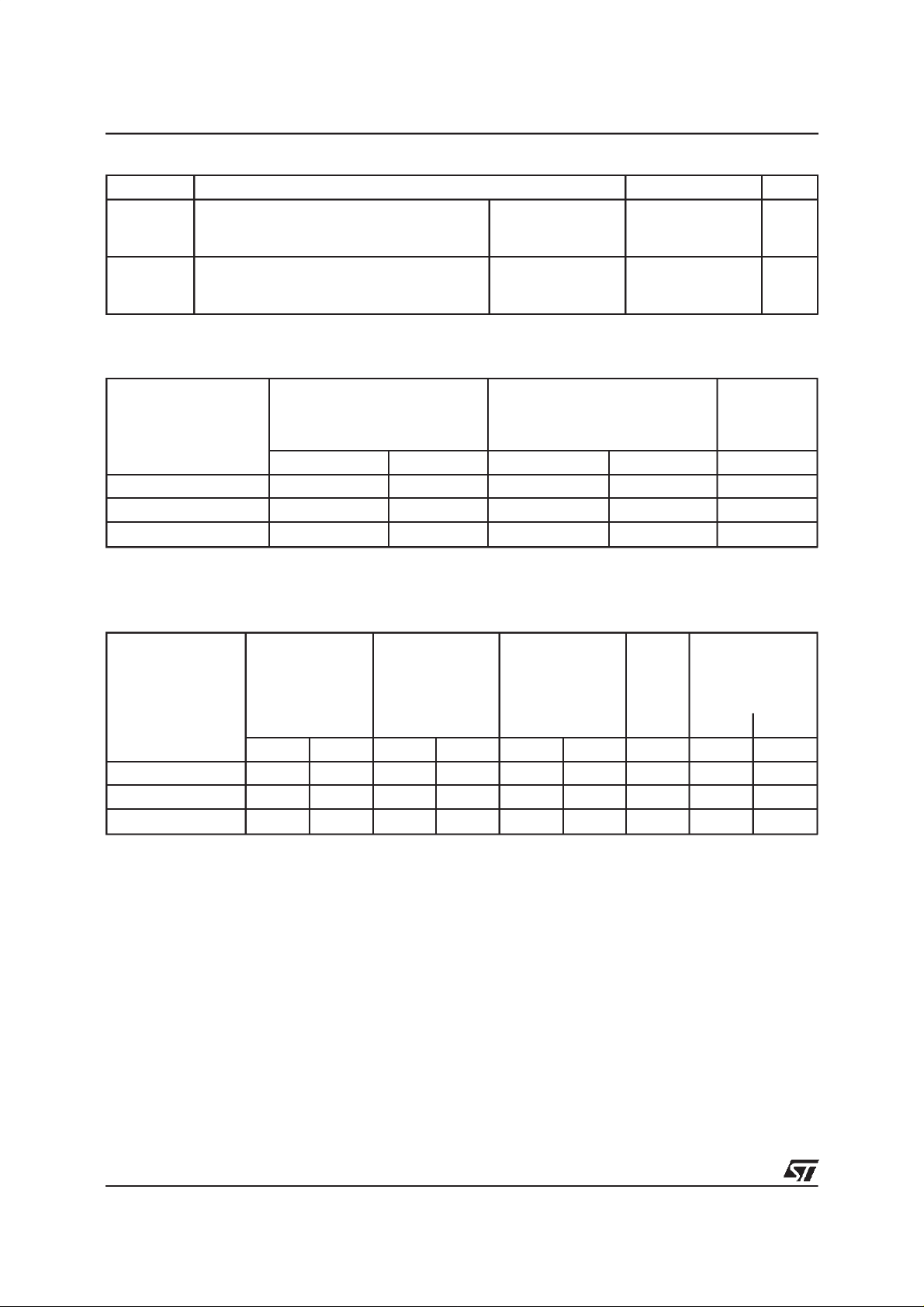

ELECTRICAL CHARACTERISTICS BETWEEN TIP AND RING

@V

I

Type

RM

max. max. typ.

RM

(T

amb

IR@V

=25°C)

R

note

µAVµAVpF

TLP140M/G/G-1

TLP200M/G/G-1

TLP270M/G/G-1

Note : VR= 50 V bias, V

= 1V, F = 1 MHz.

RMS

ELECTRICALCHARACTERISTICS BETWEEN TIP AND GND, RINGAND GND(T

I

RM

Type

max.

5 120 50 140 35

5 180 50 200 35

5 230 50 270 35

=25°C)

amb

@V

RM

IR@V

R

V

BO

I

BO

@

IH C @ V

max. max. max. min. typ.

note 1 note 2 note 3 note 4 note 5

µAVµAV VmAmApFpF

TLP140M/G/G-1

5 120 50 140 200 500 150 110 40

TLP200M/G/G-1 5 180 50 200 290 500 150 110 40

TLP270M/G/G-1

Note 1: IRmeasured at VRguaranteesV

Note 2: Measured at 50 Hz.

Note 3: See functional holdingcurrent test circuit.

Note 4: VR= 0V bias, V

Note 5: VR= 50V bias, V

5 230 50 270 400 500 150 110 40

BR min>VR

= 1V, F = 1 MHz.

RMS

= 1V, F = 1 MHz (TIPor RING (-) / GND (+)).

RMS

.

C

R

4/14

Page 5

FUNCTIONAL HOLDING CURRENT (IH) TEST CIRCUIT: GO-NO GOTEST

R

V

BAT

=

-48V

D.U.T .

TLPxxM/G/G-1

-V

P

Surge

generator

This is a GO-NOGO test which allowsto confirmthe holdingcurrent (IH)level in a functionaltest circuit.

TESTPROCEDURE:

- Adjust the currentlevelat theI

- FiretheD.U.T. with a surgecurrent: I

value by short circuitingthe D.U.T.

H

=10A, 10/1000µs.

PP

- The D.U.T.will come back to the off-statewithin a durationof 50ms max.

MARKING

Package Types Marking

PowerSO-10 TLP140M

TLP200M

TLP270M

2

PAK TLP140G

D

TLP200G

TLP270G

2

PAK TLP140G-1

I

TLP200G-1

TLP270G-1

TLP140M

TLP200M

TLP270M

TLP140G

TLP200G

TLP270G

TLP140G

TLP200G

TLP270G

ORDERCODE

TripolarLine Protection

TPL 270 M-TR

BreakdownVoltage

Packaging:

-TR=tapeandreelonlyfor”M”versi on(600pcs)

= tube(50 pcs)

Package:

M: PowerSO10

2

PAK

G:D

2

G-1: I

PAK

5/14

Page 6

TLPxxM/G/G-1

Fig.1: Maximum peak on-statecurrent versus

pulseduration.

ITSM(A)

100

90

80

70

60

50

40

30

20

10

0

0.01 0.1 1 10 100 1000

TIP or RING

vs GND

t(s)

F=50Hz

Tj initial=25°C

Fig.3-1 :junction capacitanceversus applied reversevoltage(typical values)(TLP140M/G/G-1).

C(pF)

200

100

50

LINE+ /GND-

LINE / LINE

LINE- / GND+

F=1MHz

Vosc=1VRMS

Tj=25°C

Fig.2: Relativevariation of IHversusT

IH (Tamb) / IH (25°C)

2

1.8

1.6

1.4

1.2

1

0.8

0.6

0.4

-40-200 20406080

Fig.3-2 :

junctioncapacitanceversus appliedre-

Tamb(°C)

amb

.

versevoltage(typical values)(TLP200M/G/G-1).

C(pF)

200

100

50

LINE+ / GND-

LINE / LINE

LINE- /GND+

F=1MHz

Vosc=1VRMS

Tj=25°C

20

VR(V)

10

1 10 100 200

Fig.3-3 :junction capacitanceversus applied reversevoltage(typical values)(TLP270M/G/G-1).

C(pF)

200

100

50

LINE / LINE

LINE- / GND+

LINE+ / GND-

20

VR(V)

10

1 10 100 300

F=1MHz

Vosc=1VRMS

Tj=25°C

20

VR(V)

10

1 10 100 200

Fig.4: Test diagram for breakover voltage

measurement.

TIP

10 / 1000 µs

100 A

surgegenerator

BO

V

TIP RING

GND

RING

V

BO

TIP - GND

6/14

Page 7

TLPxxM/G/G-1

Fig.5-1 : Breakovervoltagemeasurement

(TLP140M/G/G-1).

Vbr/Vbr

2.6

2.4

2.2

2

1.8

1.6

1.4

1.2

1

0.01 0.1 1 10 100 1,000 10,000 100,000

TIP RING

TIP+ GND -

TIP- GND +

dV/dt

Fig.5-3 : Breakovervoltagemeasurement

(TLP270M/G/G-1).

Vbo/Vbr

2.6

2.4

2.2

2

1.8

1.6

1.4

1.2

1

0.01 0.1 1 10 100 1,000 10,000 100,000

TIP RING

TIP+ GND -

TIP- GND +

dV/dt

Fig. 5-2 :

Breakovervoltage measurement

(TLP200M/G/G-1).

Vbo/Vbr

2.6

2.4

2.2

2

1.8

1.6

1.4

1.2

1

0.01 0.1 1 10 100 1,000 10,000 100,000

TIP RING

TIP+ GND -

TIP- GND +

dV/dt

7/14

Page 8

TLPxxM/G/G-1

PACKAGEMECHANICAL DATA

2

D

PAK Plastic

E

L2

L

L3

A1

B2

B

G

2.0 MIN.

FLAT ZONE

C2

DIMENSIONS

A

REF.

Millimeters Inches

Min. Typ. Max. Min. Typ. Max.

A 4.30 4.60 0.169 0.181

A1 2.49 2.69 0.098 0.106

A2 0.03 0.23 0.001 0.009

D

B 0.70 0.93 0.027 0.037

B2 1.40 0.055

C 0.45 0.60 0.017 0.024

C2 1.21 1.36 0.047 0.054

C

R

D 8.95 9.35 0.352 0.368

E 10.00 10.28 0.393 0.405

G 4.88 5.28 0.192 0.208

L 15.00 15.85 0.590 0.624

A2

L2 1.27 1.40 0.050 0.055

L3 1.40 1.75 0.055 0.069

R 0.40 0.016

V2

V2 0° 8° 0° 8°

FOOT-PRINT D

10.30

2

PAK

8.90

16.90

5.08

1.30

3.70

8/14

Page 9

PACKAGEMECHANICAL DATA

2

PAK Plastic

I

TLPxxM/G/G-1

DIMENSIONS

REF.

A 4.30 4.60 0.169 0.181

A1 2.49 2.69 0.098 0.106

B 0.70 0.93 0.028 0.037

B1 1.20 1.38 0.047 0.054

B2 1.25 1.40 0.049 0.055

C 0.45 0.60 0.018 0.024

C2 1.21 1.36 0.048 0.054

D 8.95 9.35 0.352 0.368

e 2.44 2.64 0.096 0.104

E 10.00 10.28 0.394 0.405

L 13.10 13.60 0.516 0.535

L1 3.48 3.78 0.137 0.149

L2 1.27 1.40 0.050 0.055

V5° 5°

V4 45° 45°

Millimeters Inches

Min. Typ. Max. Min. Typ. Max.

9/14

Page 10

TLPxxM/G/G-1

PACKAGEMECHANICALDATA

Power-SO10

10

B

0.10 A B

6

H

A1

E

1

eB

E2

5

DETAIL ”A”

E3 E1

SEATING

PLANE

A

C

0.25 M

D

h

D1

Q

A

F

SEATING

PLANE

A1

L

DETAIL”A”

E4

a

DIMENSIONS

REF.

Millimeters Inches

Min. Typ. Max. Min. Typ. Max.

A 3.35 3.65 0.131 0.143

A1 0.00 0.10 0.00 0.0039

B 0.40 0.60 0.0157 0.0236

C 0.35 0.55 0.0137 0.0217

D 9.40 9.60 0.370 0.378

D1 7.40 7.60 0.291 0.299

E 9.30 9.50 0.366 0.374

E1 7.20 7.40 0.283 0.291

E2 7.20 7.60 0.283 0.299

10/14

DIMENSIONS

REF.

Millimeters Inches

Min. Typ. Max. Min. Typ. Max.

E3 6.10 6.35 0.240 0.250

E4 5.90 6.10 0.232 0.240

e 1.27 0.05

F 1.25 1.35 0.0492 0.0531

H 13.80 14.40 0.543 0.567

h 0.50 0.019

L 1.20 1.80 0.0472 0.0708

Q 1.70 0.067

a0° 8°0° 8°

Page 11

TLPxxM/G/G-1

FOOTPRINT

MOUNTINGPADLAYOUT

RECOMMENDED

Dimensionsin millimeters Dimensionsin millimeters

SHIPPINGTUBE

Power-SO10

HEADERSHAPE

C

B

A

Surfacemountfilm taping: contactsales office

A

B

C

Lengthtube

Quantityper tube

DIMENSIONS(mm)

TYP

18

12

0,8

532

50

11/14

Page 12

TLPxxM/G/G-1

SOLDERINGRECOMMENDATION

The soldering process causes considerable thermal stress to a semiconductor component. This

has to be minimized to assure a reliable and extended lifetime of the device. The PowerSO-10

package can be exposed to a maximumtemperature of 260°Cfor 10 seconds. However a proper

soldering of the package could be done at 215°C

for 3 seconds. Any solder temperature profile

shouldbe withinthese limits. As reflow techniques

are most common in surface mounting, typical

heating profiles are given in Figure 1,either for

mountingon FR4 or on metal-backed boards. For

each particular board, the appropriate heat profile

has to be adjusted experimentally. The present

proposalisjusta startingpoint. Inanycase,the followingprecautions haveto be considered:

- alwayspreheatthe device

- peaktemperatureshould be at least30 °C

higherthan the melting point of the solder

alloychosen

- thermalcapacityof the base substrate

Fig. 1 : Typicalreflow solderingheat profile

Voids pose a difficult reliability problem for large

surface mount devices. Such voids under the

package result in poor thermal contact and the

high thermal resistance leads to component failures.The PowerSO-10is designedfromscratchto

besolelya surfacemountpackage,hencesymmetry inthe x-and y-axis givesthe packageexcellent

weightbalance.Moreover, the PowerSO-10offers

the unique possibilityto control easily the flatness

and quality of the soldering process. Both the top

and the bottom soldered edgesof thepackageare

accessible for visual inspection (soldering meniscus).

Coplanarity between the substrate and the package canbe easilyverified.The qualityof the solder

joints is very important for two reasons : (I) poor

qualitysolder joints result directlyin poor reliability

and (II) solder thickness affects the thermal resistance significantly.Thus a tight control of this parameter results in thermally efficient and reliable

solderjoints.

Temperature ( C)

250

o

o

245 C

o

215 C

200

Soldering

Cooli ng

150

Epoxy FR4

board

Preheating

100

Metal-backed

50

board

0

0 40 80 120 160 200 2 40 280 320 360

Time (s)

12/14

Page 13

TLPxxM/G/G-1

SUBSTRATES AND MOUNTINGINFORMATION

The use of epoxy FR4 boards is quite commonfor

surface mounting techniques, however, their poor

thermal conductioncompromisesthe otherwise

outstandingthermalperformanceof thePowerSO-

10. Some methodsto overcome this limitation are

discussedbelow.

One possibility to improve the thermal conduction

is the use of large heat spreader areas at the copper layerofthe PC board.Thisleadsto areduction

of thermal resistance to 35 °C for 6 cm

2

of the

board heatsink(seefig. 2).

Use of copper-filledthrough holes on conventional

FR4 techniqueswill increase the metallizationand

Fig.2 :

Mountingon epoxy FR4 head dissipationby extendingthe area of the copper layer

Copper foil

decrease thermal resistance accordingly. Using

a configurationwith 16holesunderthe spreaderof

the package with a pitchof 1.8 mm and a diameter

of 0.7 mm, the thermal resistance (junction heatsink) can be reduced to 12°C/W(see fig. 3).

Besidethe thermal advantage, thissolutionallows

multi-layer boards to be used. However, a drawback of this traditional material prevents its use in

veryhighpower,highcurrentcircuits.Forinstance,

it is not advisable to surface mount devices with

currents greater than 10 A on FR4 boards. A

PowerMosfetorSchottkydiodein a surfacemount

power package can handle up to around 50 A if

bettersubstratesare used.

FR4 board

Fig. 3 :

Mountingon epoxy FR4 by using copper-filledthroughholesfor heattransfer

Copperfoil

heattransferheatsink

FR4board

13/14

Page 14

TLPxxM/G/G-1

A new technologyavailable today is IMS - anInsulated Metallic Substrate. This offers greatly enhanced thermal characteristics for surface

mount components. IMS is a substrateconsisting

of threedifferentlayers,(I)thebasematerialwhich

is available as an aluminiumor a copper plate, (II)

a thermal conductive dielectrical layer and (III) a

copper foil, which can be etched as a circuitlayer.

Using this material a thermal resistanceof 8°C/W

with 40 cm

2

of board floating in air is achievable

(seefig. 4).If evenhigherpower isto be dissipated

an externalheatsink could be appliedwhich leads

to an R

that R

(j-a) of 3.5°C/W (see Fig. 5), assuming

th

(heatsink-air) is equal to Rth(junction-

th

heatsink). This is commonly applied in practice,

leading to reasonable heatsink dimensions. Often

power devices are defined by considering the

maximum junction temperature of the device. In

practice, however, this is far from being exploited.

A summary of various power management capabilities is made in table 1 based on a reasonable

deltaT of 70°Cjunctionto air.

The PowerSO-1 0 concept also represents an

attractive alternative to C.O.B. techniques.

PowerSO-10 offers devices fully tested at low

and high temperature. Mounting is simple - only

conventionalSMT is required - enabling the users

togetrid ofbondwire problemsandtheproblem to

controlthe high temperaturesoft solderingas well.

An optimized thermal management is guaranteed

through PowerSO-10 as the power chips must in

any case be mounted on heat spreaders before

beingmountedonto the substrate.

Fig. 4 : Mountingon metalbacked board Fig. 5 :

externalheatsinkapplied

Copperfoil

Copper foil

Alumini um

Insulation

Mountingon metal backed board with an

FR4board

Aluminium

heatsink

TABLE1

Printedcircuit board material Rth(j-a) P Diss

1.FR4using the recommended pad-layout 50°C/W 1.5W

2

2.FR4with heatsinkon board(6cm

3.FR4with copper-filledthrough holes and externalheatsinkapplied

2

4.IMSfloatingin air(40 cm

)8°C/W 8.8 W

)35°C/W 2.0 W

12°C/W 5.8W

5.IMSwith externalheatsink applied 3.5°C/W 20W

Informationfurnished isbelievedto be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences of

use of such informationnor forany infringementof patents or other rights of thirdparties which mayresult from its use. Nolicense is granted by

implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject to

change without notice. This publication supersedes and replaces all information previously supplied.

STMicroelectronics products are not authorized for use as critical components in life support devices or systems withoutexpress written approval of STMicroelectronics.

The ST logo is a registeredtrademark of STMicroelectronics

1998STMicroelectronics - Printed in Italy - All rights reserved.

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - Canada - China - France - Germany - Italy - Japan - Korea -Malaysia - Malta - Mexico - Morocco -

The Netherlands - Singapore - Spain - Sweden - Switzerland - Taiwan - Thailand -United Kingdom - U.S.A.

http://www.st.com

14/14

Loading...

Loading...