Page 1

D

Drive Capability and Output Counts:

– 80 mA (Current Sink) × 16 Bits

– 120 mA (Current Sink) × 8 Bits

D

Constant Current Output Range:

– 5 mA to 80 mA/10 mA to 120 mA

(Selectable by MODE Terminal) (Current

Value Setting for All Output Terminals

Using External Resistor and Internal

Brightness Control Register)

D

Constant Current Accuracy ±4% (Maximum

Error Between Bits)

D

Voltage Applied to Constant Current Output

Terminals:

– Minimum 0.4 V (Output Current 5 mA to

40 mA)

– Minimum 0.7 V (Output Current 40 mA to

80 mA)

D

256 Gray Scale Display:

– Pulse Width Control 256 Steps

D

Brightness Adjustment:

– Output Current Adjustment for 32 Steps

(Adjustment for Brightness Deviation

Between LED Modules)

– 8 Steps Brightness Control by 8 Times

Speed Gray Scale Control Clock

(Brightness Adjustment for Panel)

D

Error Output Signal Check:

– Check Error Output Signal Line Such as

Protection Circuit When Operating

D

Data Output Timing Selectable:

– Select Data Output Timing for Shift

Register Relative to Clock

description

LED DRIVER

SLLS401 – NOVEMBER 1999

D

OVM (Output Voltage Monitor):

– Monitor Voltage on Constant Current

Output Terminals (Detect LED

Disconnection and Short Circuit)

D

WDT (Watchdog Timer):

– Turn Output Off When Scan Signal

Stopped

D

TSD (Thermal Shut Down):

– Turn Output Off When Junction

T emperature Exceeds Limit

D

Data Input:

– Clock Synchronized 1 Bit Serial Input

(Shmitt-Triggered Input)

D

Data Output:

– Clock Synchronized 1 Bit Serial Output

(3-State Output)

D

Input Signal Level:

– CMOS Level

D

Power Supply Voltage . . . 4.5 V to 5.5 V

D

Maximum Output Voltage . . . 17 V

D

Data Transfer Rate . . . 15 MHz (Max

D

Gray Scale Clock Frequency ...8 MHz

(Max)

D

Operating Free-Air Temperature Range

–20°C to 85°C

D

64-Pin HTQFP Package (PD = 4.9 W,

T

= 25°C)

A

TLC5905

The TLC5905 is a constant current driver that incorporates shift register, data latch, constant current circuitry

with a current value adjustable and 256 gray scale display that uses pulse width control. The output current can

be selected as maximum 80 mA with 16 bits or 120 mA with 8 bit. The current value of the constant current output

is set by one external resistor. After this device is mounted on a printed-circuit board (PCB), the brightness

deviation between LED modules (ICs) can be adjusted using an external data input, and the brightness control

for the panel can be accomplished by the brightness adjustment circuitry. Also, the device incorporates the

output voltage monitor (OVM) used for LED open detection (LOD) by monitoring constant current output.

Moreover, the device incorporates watchdog timer (WDT) circuitry , which turns constant current output off when

the scan signal stops during dynamic scanning operation, and thermal shutdown (TSD) circuitry, which turns

constant current output off when the junction temperature exceeds the limit.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Copyright 1999, Texas Instruments Incorporated

1

Page 2

TLC5905

LED DRIVER

SLLS401 – NOVEMBER 1999

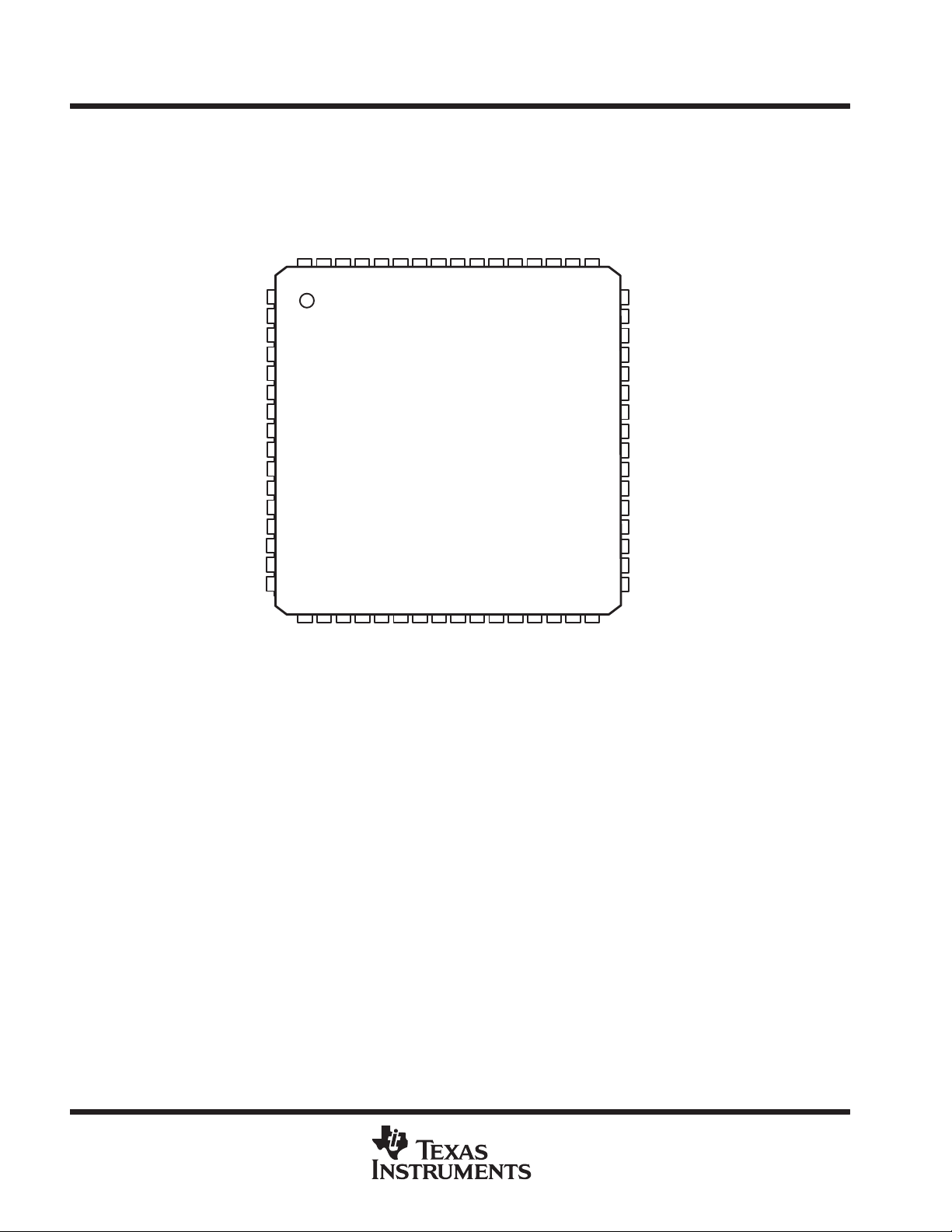

pin assignments

PAP PACKAGE

(TOP VIEW)

NC

OUT3

63 62 61 60 5964 58 56 55 5457

1

NC

OUT4

GNDLED

OUT5

OUT6

GNDLED

OUT7

OUT8

GNDLED

OUT9

OUT10

GNDLED

OUT11

NC

NC

NC

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17 18

19

NC

OUT12

NC – No internal connection

GNDLED

OUT2

OUT1

21 22 23 24

20

OUT13

OUT14

GNDLED

GNDLED

OUT0NCNC

NC

OUT15

GNDLED

BCENA

GNDLOG

MODEVTSENANCSIN

53 52 51 50 49

25 26 27 28 29

IREF

CCLED

WDCAP

V

GNDANA

CCLOG

30 31 32

NC

CCANA

V

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

SOUT

MCENA

TEST2

SOMODE

GSCLK

BLANK

RSEL1

RSEL0

SCLK

XENABLE

XOE

WDTRG

XLATCH

XDOWN1

XDOWN2

TEST1

BOUT

GSOUT

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 3

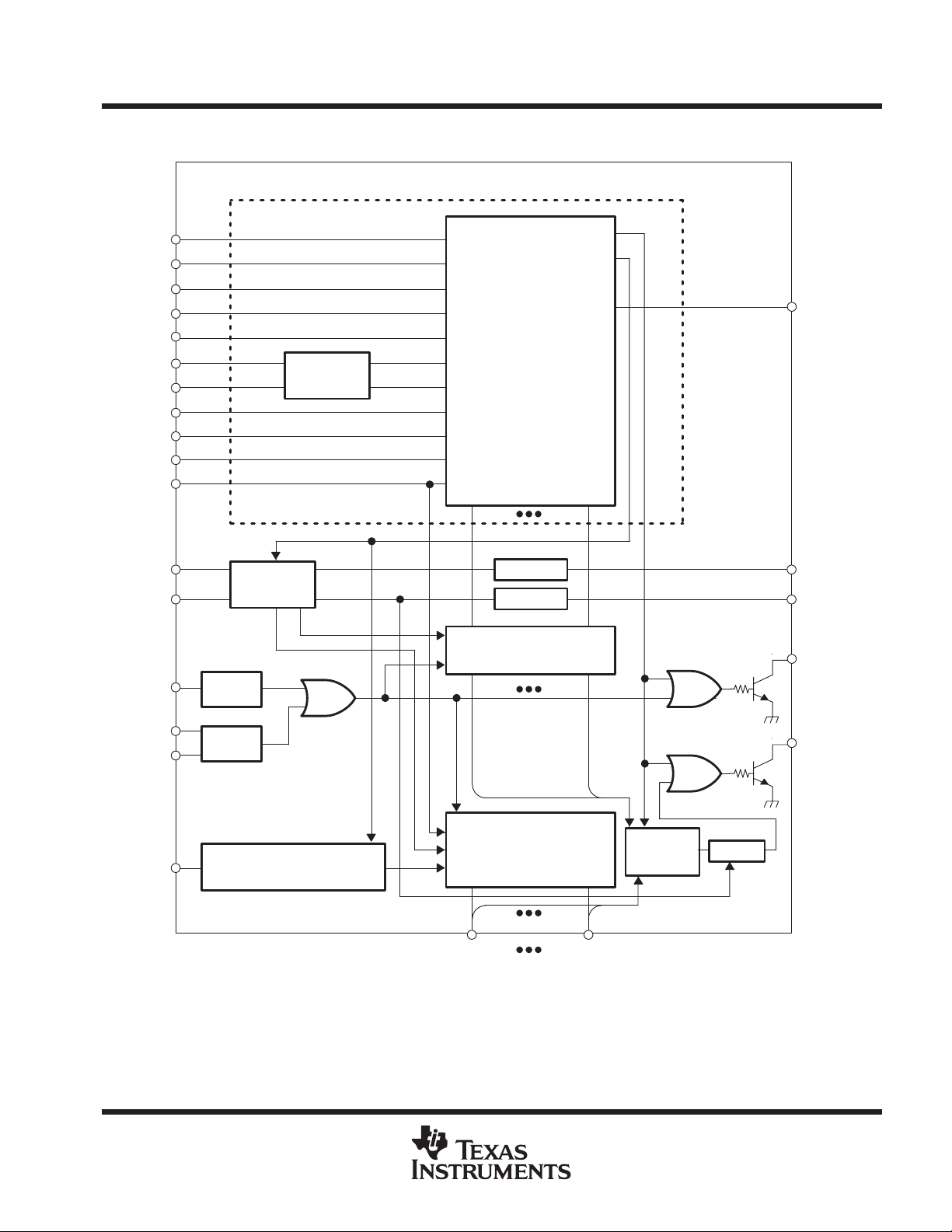

functional block diagram

TLC5905

LED DRIVER

SLLS401 – NOVEMBER 1999

Shift Register and Data Latch

MCENA

BCENA

RSEL0

RSEL1

SIN

XENABLE

SCLK

SOMODE

XOE

XLATCH

MODE

GSCLK

BLANK

TSENA

Gray Scale

TSD

8 bits

Counter

SCLK

Controller

OVM

Shift Register

Data Latch

Brightness Control

Shift Register

Data Latch

Gray Scale Control

Shift Register

Data Latch

DELEY

DELEY BOUT

16 x 8 bits

Comparator

SOUT

GSOUT

XDOWN1

WDTRG

WDCAP

IREF

NOTE: All the input terminals are with Schmitt-triggered inverter except IREF and WDCAP.

WDT

Current Reference

Circuit

Constant Current Driver

16 bits

OUT0 OUT15

16 bits

OVM Comp

XDOWN2

LATCH

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

3

Page 4

TLC5905

LED DRIVER

SLLS401 – NOVEMBER 1999

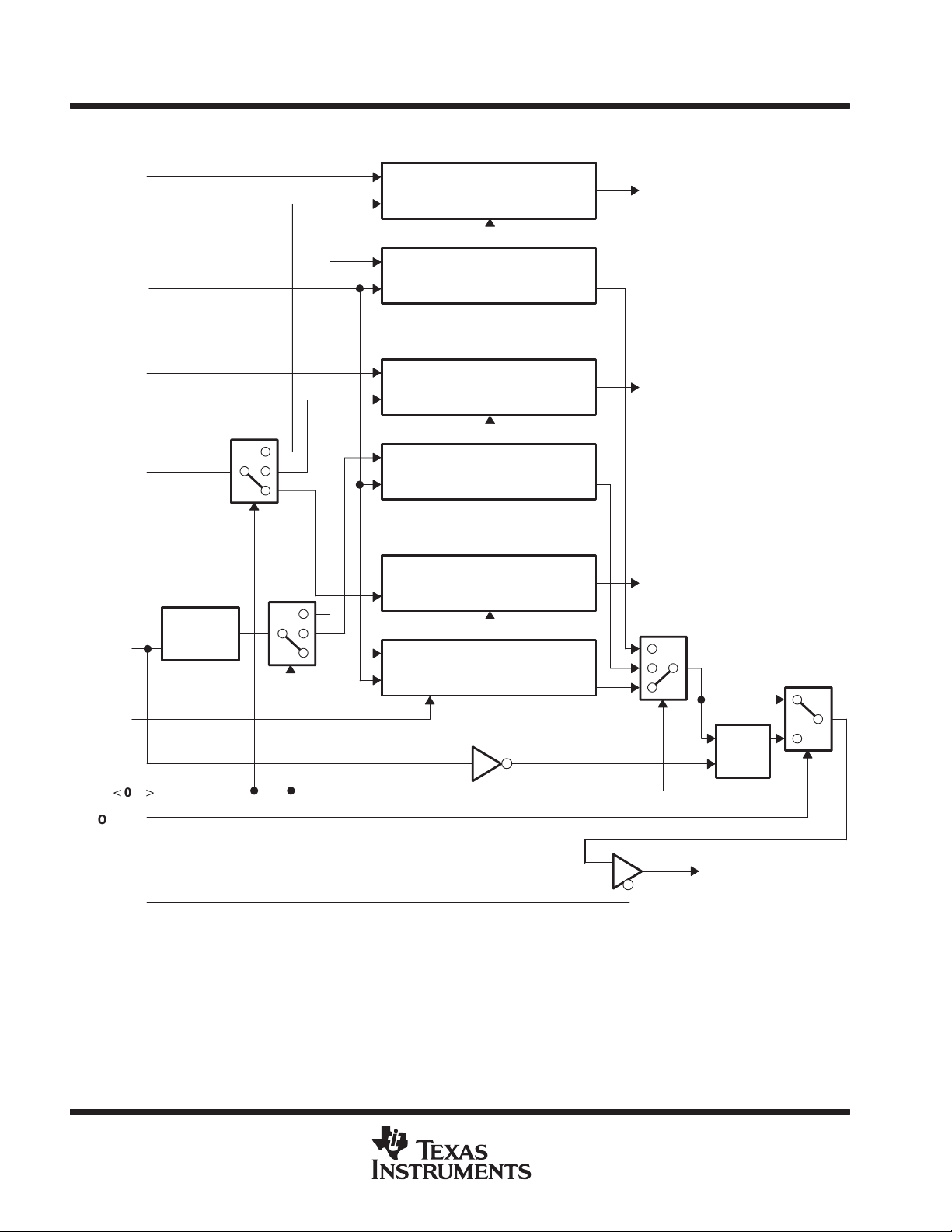

functional block diagram for shift register and data latch

MCENA

SIN

BCENA

XLATCH

XENABLE

SCLK

SCLK

Controller

OVM Data Latch

(1 x 8 bit)

OVM Shift Register

(8 x 1 bit)

Brightness Control Data Latch

(1 x 8 bit)

Brightness Control Shift Register

(8 x 1 bit)

Gray Scale Control Data Latch

(16 x 8 bit)

Gray Scale Control Shift Register

(128 x 1 bit / 64 x 1 bit)

16 bit OVM Comparator

XDOWN1, 2 Output Driver

Constant Current Driver Control

Gray Scale Clock Counter

16 x 8 bit Data Comparator

MODE

RSELt0–1

SOMODE

NOTE: Enclosed in ( ) is dependent on MODE pin selection.

u

XOE

(see Note)

1 bit

S/R

SOUT

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 5

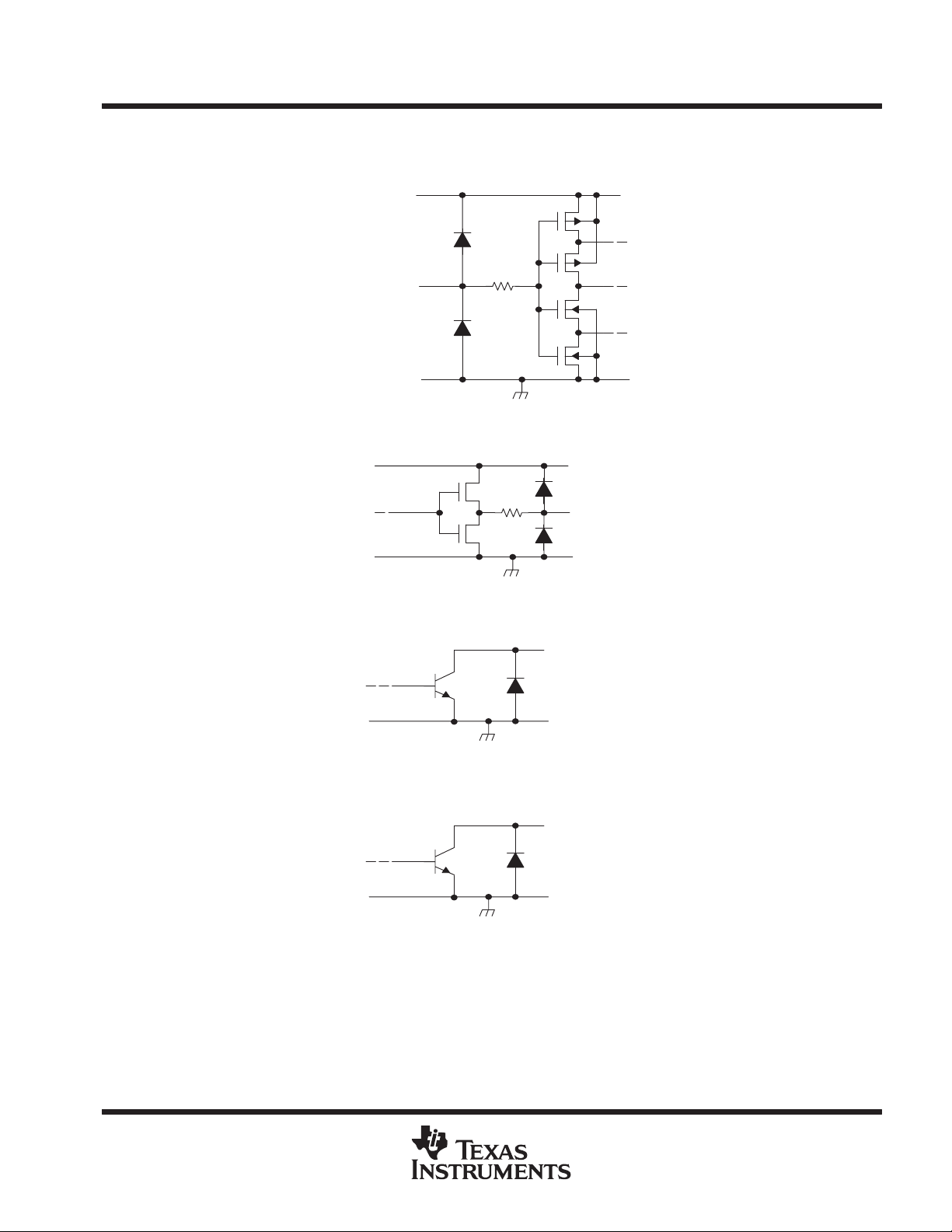

equivalent input and output schematic diagrams

TLC5905

LED DRIVER

SLLS401 – NOVEMBER 1999

Input

SOUT, GSOUT, BOUT

XDOWN1, XDOWN2

VCCLOG

INPUT

GNDLOG

VCCLOG

OUTPUT

GNDLOG

OUTn

XDOWN1, XDOWN2

GNDLOG

OUTn

GNDLED

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

5

Page 6

TLC5905

I/O

DESCRIPTION

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

LED DRIVER

SLLS401 – NOVEMBER 1999

TERMINAL

NAME NO.

ÁÁÁÁ

BCENA

ÁÁÁÁ

ÁÁÁÁ

BLANK

BOUT

GSCLK

ÁÁÁÁ

GNDANA

GNDLED

GNDLOG

GSOUT

IREF

ÁÁÁÁ

MCENA

ÁÁÁÁ

MODE

NC

ÁÁÁÁ

OUT0 – OUT15

ÁÁÁÁ

ÁÁÁÁ

RSEL0

RSEL1

ÁÁÁÁ

ÁÁÁÁ

SCLK

ÁÁÁÁ

ÁÁÁÁ

SIN

SOMODE

ÁÁÁÁ

SOUT

ÁÁÁÁ

TEST1

TEST2

THERMAL PAD

TSENA

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

1,7,10,16,17,24,

ÁÁÁÁ

29,50,56,57,64

2,4,5,8,9,12,13

ÁÁÁÁ

15,18,20,21,23

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

package bottom

ÁÁÁÁ

55

45

34

46

28

3,6,11,14,

19,22,59,62

54

33

25

31

53

58,60,61,63,

43

44

42

49

47

32

35

48

51

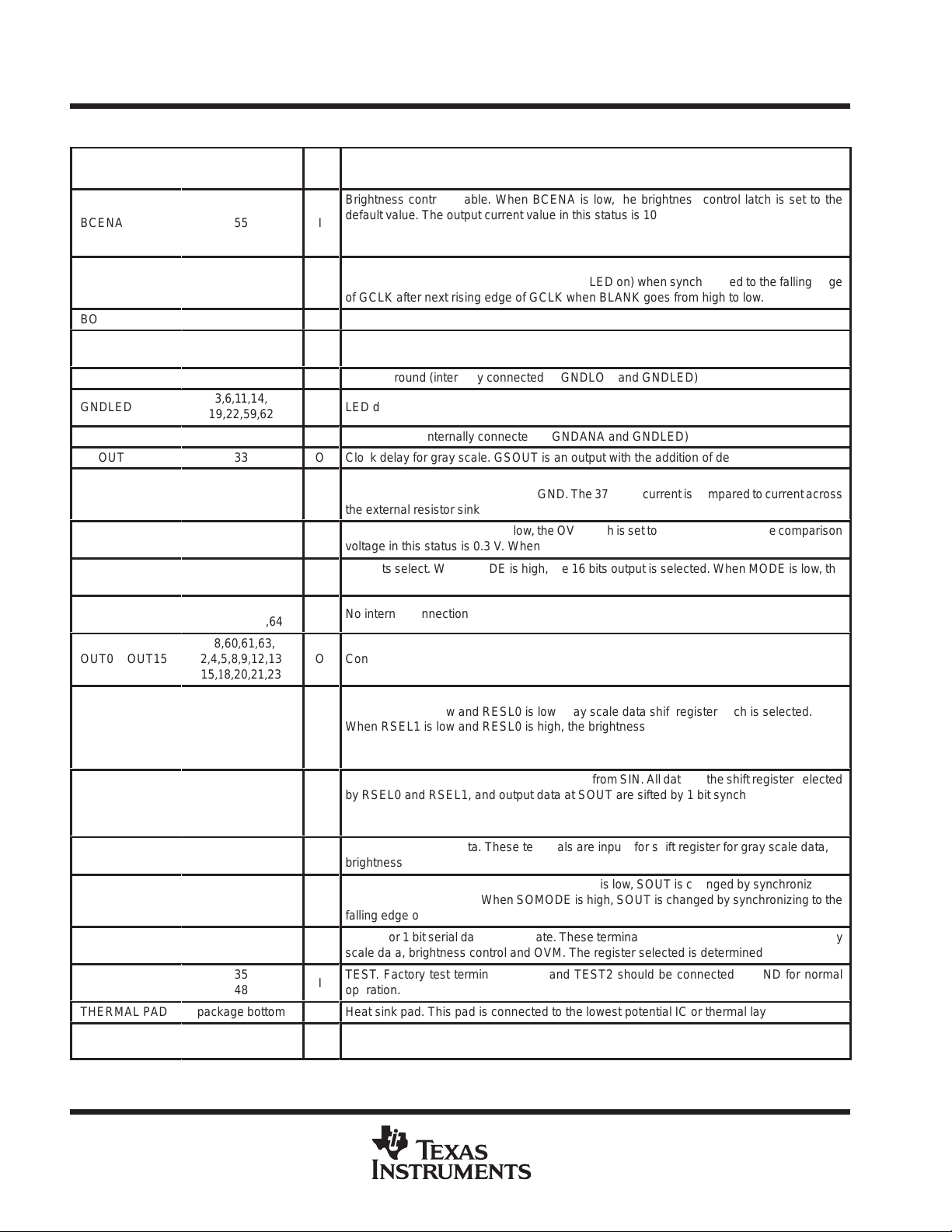

Terminal Functions

Brightness control enable. When BCENA is low, the brightness control latch is set to the

Á

Á

Á

Á

I/O

Á

Á

ÁÁББББББББББББББББББББ

Á

Á

Á

Á

Á

Á

Á

Á

Á

ББББББББББББББББББББ

default value. The output current value in this status is 100% of the value set by an external

I

resistor. The frequency division ratio of GSCLK is1/1. When BCENA is high, writing to

ББББББББББББББББББББ

brightness control latch is enabled.

Blank(Light off). When BLANK is high, all the output of the constant current driver is turned

ББББББББББББББББББББ

off. The constant current output is turned on (LED on) when synchronized to the falling edge

I

of GCLK after next rising edge of GCLK when BLANK goes from high to low.

O

Blank signal delay. BOUT is an output with the addition of delay time to BLANK.

Clock input for gray scale. The gray scale display is accomplished by lighting the LED on until

I

ББББББББББББББББББББ

the number of GSCLK counted is equal to data latched.

Analog ground (internally connected to GNDLOG and GNDLED)

LED driver ground (internally connected to GNDANA and GNDLOG)

Logic ground (internally connected to GNDANA and GNDLED)

O

Clock delay for gray scale. GSOUT is an output with the addition of delay time to GSCLK.

Constant current value setting. LED current is set to the desired value by connecting an

external resistor between IREF and GND. The 37 times current is compared to current across

ББББББББББББББББББББ

the external resistor sink on the output terminal.

OVM enable. When MCENA is low, the OVM latch is set to the default value. The comparison

I

ББББББББББББББББББББ

voltage in this status is 0.3 V. When MCENA is high, writing to OVM latch is enabled.

8/16 bits select. When MODE is high, the 16 bits output is selected. When MODE is low, the

I

8 bits output is selected.

No internal connection

O

Constant current output

ББББББББББББББББББББ

Shift register data latch switching.

ББББББББББББББББББББ

When RSEL1 is low and RESL0 is low, gray scale data shift register latch is selected.

When RSEL1 is low and RESL0 is high, the brightness control register latch is selected.

I

ББББББББББББББББББББ

When RSEL1 is high and RSEL0 is low, the OVM register latch is selected.

When RSEL1 is high and RSEL0 high, no register latch is selected.

ББББББББББББББББББББ

Clock input for data transfer. The input data is from SIN. All data on the shift register selected

by RSEL0 and RSEL1, and output data at SOUT are sifted by 1 bit synchronizing to SCLK.

I

ББББББББББББББББББББ

The data except the SOUT is synchronized to the rising edge. The edge for data from SOUT

is determined by the level of SOMODE.

ББББББББББББББББББББ

Input for 1 bit serial data. These terminals are inputs for shift register for gray scale data,

I

brightness control and OVM. The register selected is determined by RSEL0, 1.

Timing select for data output. When SOMODE is low , SOUT is changed by synchronizing to

the rising edge of SCLK. When SOMODE is high, SOUT is changed by synchronizing to the

I

ББББББББББББББББББББ

falling edge of SCLK.

Output for 1 bit serial data with 3–state. These terminals are outputs for shift register for gray

O

ББББББББББББББББББББ

scale data, brightness control and OVM. The register selected is determined by RSEL0, 1.

TEST. Factory test terminal. TEST1 and TEST2 should be connected to GND for normal

I

operation.

Heat sink pad. This pad is connected to the lowest potential IC or thermal layer.

TSD (thermal shutdown) enable. When TSENA is high, TSD is enabled. When TSENA is low,

I

ББББББББББББББББББББ

TSD is disabled.

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 7

I/O

DESCRIPTION

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

TERMINAL

NAME NO.

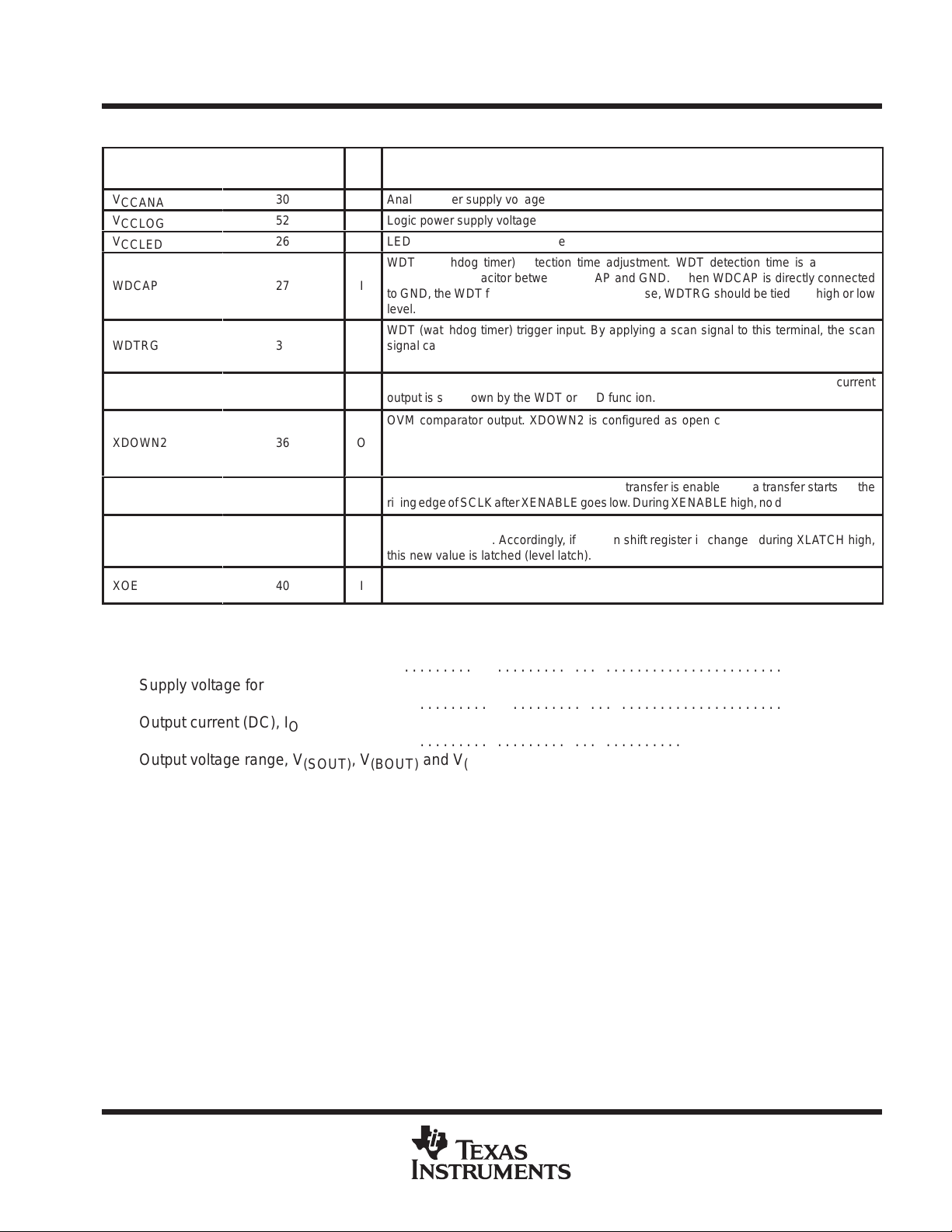

V

CCANA

V

CCLOG

V

CCLED

ÁÁÁÁ

WDCAP

ÁÁÁÁ

WDTRG

ÁÁÁÁ

XDOWN1

ÁÁÁÁ

XDOWN2

ÁÁÁÁ

XENABLE

ÁÁÁÁ

XLATCH

ÁÁÁÁ

XOE

ÁÁÁÁ

30

52

26

ÁÁÁÁ

27

ÁÁÁÁ

39

ÁÁÁÁ

37

ÁÁÁÁ

36

ÁÁÁÁ

41

ÁÁÁÁ

38

ÁÁÁÁ

40

ÁÁÁÁ

LED DRIVER

SLLS401 – NOVEMBER 1999

Terminal Functions (Continued)

Analog power supply voltage

Logic power supply voltage

LED driver power supply voltage

WDT (watchdog timer) detection time adjustment. WDT detection time is adjusted by

connecting a capacitor between WDCAP and GND. When WDCAP is directly connected

ББББББББББББББББББББ

I

to GND, the WDT function is disabled. In this case, WDTRG should be tied to a high or low

ББББББББББББББББББББ

level.

WDT (watchdog timer) trigger input. By applying a scan signal to this terminal, the scan

signal can be monitored by turning the constant current output off and protecting the LED

I

ББББББББББББББББББББ

from damage by burning when the scan signal is stopped during constant period designed.

Shutdown. XDOWN1 is configured as an open collector. It goes low when constant current

O

output is shut down by the WDT or TSD function.

ББББББББББББББББББББ

OVM comparator output. XDOWN2 is configured as open collector. It monitors terminal

voltage when constant current output is turned on. XDOWN2 goes low when this voltage is

O

ББББББББББББББББББББ

lower than the level selected by the OVM latch. When BLANK is set high, the previous level

is held.

SCLK enable. When XENABLE is low, data transfer is enabled. Data transfer starts on the

I

ББББББББББББББББББББ

rising edge of SCLK after XENABLE goes low. During XENABLE high, no data is transferred.

Latch. When XLATCH is high, data on shift register goes through latch. When XLATCH is

low, data is latched. Accordingly, if data on shift register is changed during XLATCH high,

I

ББББББББББББББББББББ

this new value is latched (level latch).

Data output enable. When XOE is low, the SOUT terminal is drived. When XOE is high, the

I

ББББББББББББББББББББ

SOUT terminal goes to high-impedance state.

TLC5905

absolute maximum ratings over operating free-air temperature (unless otherwise noted)

Logic supply voltage, V

CC(LOG)

Supply voltage for constant current circuit, V

Analog supply voltage, V

Output current (DC), I

CC(ANA)

OL(C)

Input voltage range, VI – 0.3 V to V

Output voltage range, V

Output voltage range, V

(SOUT)

(OUTn)

Storage temperature range, T

– 0.3 V to 7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CC(LED)

– 0.3 V to 7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

– 0.3 V to 7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

90 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

, V

(BOUT)

and V

–40°C to 125°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

stg

and V

(XDOWNn)

(GSOUT)

– 0.3 V to V

– 0.3 V to 18 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CC(LOG)

CC(LOG)

†

+ 0.3 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

+ 0.3 V. . . . . . . . . . . . . . . . . . .

Continuous total power dissipation at (or below) TA = 25°C 4.9 W. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power dissipation rating at (or above) TA = 25°C 39.4 mW/°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTE 1: All voltage values are with respect to GNDLOG terminal.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

7

Page 8

TLC5905

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

mA

Low-level output current, I

SCLK clock frequenc

f

MH

GSCLK clock frequenc

f(

MH

GSCLK pulse duration (high or low level), t

ns

LED DRIVER

SLLS401 – NOVEMBER 1999

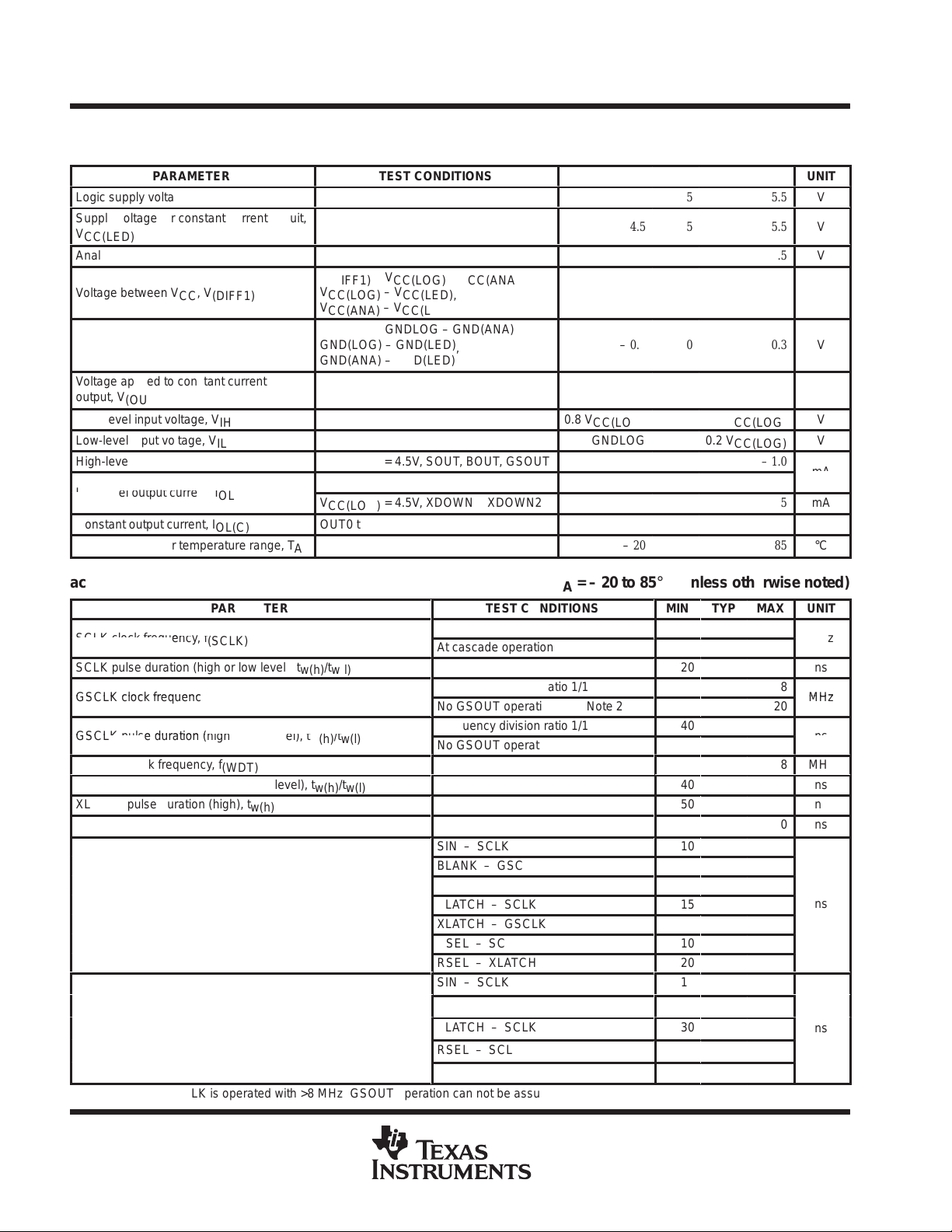

recommended operating conditions

dc characteristics

PARAMETER

Logic supply voltage, V

Supply voltage for constant current circuit,

ББББББББББ

V

CC(LED)

Analog power supply, V

Voltage between VCC, V

ББББББББББ

Voltage between GND, V

ББББББББББ

Voltage applied to constant current

output, V

ББББББББББ

(OUTn)

High-level input voltage, V

Low-level input voltage, V

High-level output current, I

p

Constant output current, I

Operating free–air temperature range, T

CC(LOG)

CC(ANA)

(DIFF1)

(DIFF2)

IH

IL

OH

OL

OL(C)

БББББББББÁÁÁÁ

V

(DIFF1)

V

CC(LOG)

БББББББББ

V

CC(ANA)

V

(DIFF2)

GND(LOG) – GND(LED),

БББББББББ

GND(ANA) – GND(LED)

OUT0 to OUT15 off

БББББББББ

V

CC(LOG)

V

CC(LOG)

V

CC(LOG)

OUT0 to OUT15

A

TEST CONDITIONS

= V

– V

– V

CC(LOG)

CC(LED),

CC(LED)

– V

CC(ANA)

= GNDLOG – GND(ANA)

= 4.5V, SOUT, BOUT, GSOUT

= 4.5V, SOUT, BOUT, GSOUT

= 4.5V, XDOWN1, XDOWN2

MIN

ÁÁÁ

ÁÁÁ

ÁÁÁÁÁÁÁÁÁ

0.8 V

CC(LOG)

GNDLOG

4.5

4.5

4.5

– 0.3

– 0.3

NOM

Á

Á

Á

5

5

ÁÁÁ

5

0

ÁÁÁ

0

ÁÁÁ

0.2 V

MAX

V

CC(LOG)

CC(LOG)

5

– 20

5.5

5.5

5.5

0.3

0.3

17

– 1.0

1.0

80

85

UNIT

V

V

Á

V

V

Á

V

Á

V

Á

V

V

5

mA

mA

°C

ac characteristics, V

CC(LOG)

PARAMETER

y,

(SCLK)

SCLK pulse duration (high or low level), t

y,

GSCLK)

p

WDTRG clock frequency, f

(WDT)

WDTRG pulse duration (high or low level), t

XLATCH pulse duration (high), t

Rise/fall time, tr/t

f

w(h)

= V

CC(ANA)

w(h)/tw(l)

w(h)/tw(l)

w(h)/tw(l)

= V

CC(LED)

= 4. 5 V to 5 . 5 V, T

TEST CONDITIONS

At single operation

At cascade operation (SOMODE = L)

Frequency division ratio 1/1

No GSOUT operation (see Note 2)

Frequency division ratio 1/1

No GSOUT operation (see Note 2)

SIN – SCLK

BLANK – GSCLK

XENABLE – SCLK

Setup time, t

su

XLATCH – SCLK

XLATCH – GSCLK

RSEL – SCLK

RSEL – XLATCH

SIN – SCLK

XENABLE – SCLK

Hold time, t

h

XLATCH – SCLK

RSEL – SCLK

RSEL – XLATCH

NOTE 2: When GSCLK is operated with >8 MHz, GSOUT operation can not be assured.

= – 20 to 85°C (u n l e s s o t h e r w i s e n o t e d)

A

MIN

TYP

MAX

UNIT

15

10

20

8

20

40

20

8

MHz

40

50

100

10

20

15

15

10

10

20

10

20

30

20

20

z

ns

z

ns

ns

ns

ns

ns

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 9

Á

Á

Á

Á

Á

VOLLow-level output voltage

V

Á

Á

Á

Á

Á

(LOG)

y(g)

I

Supply current (analog)

mA

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

()

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

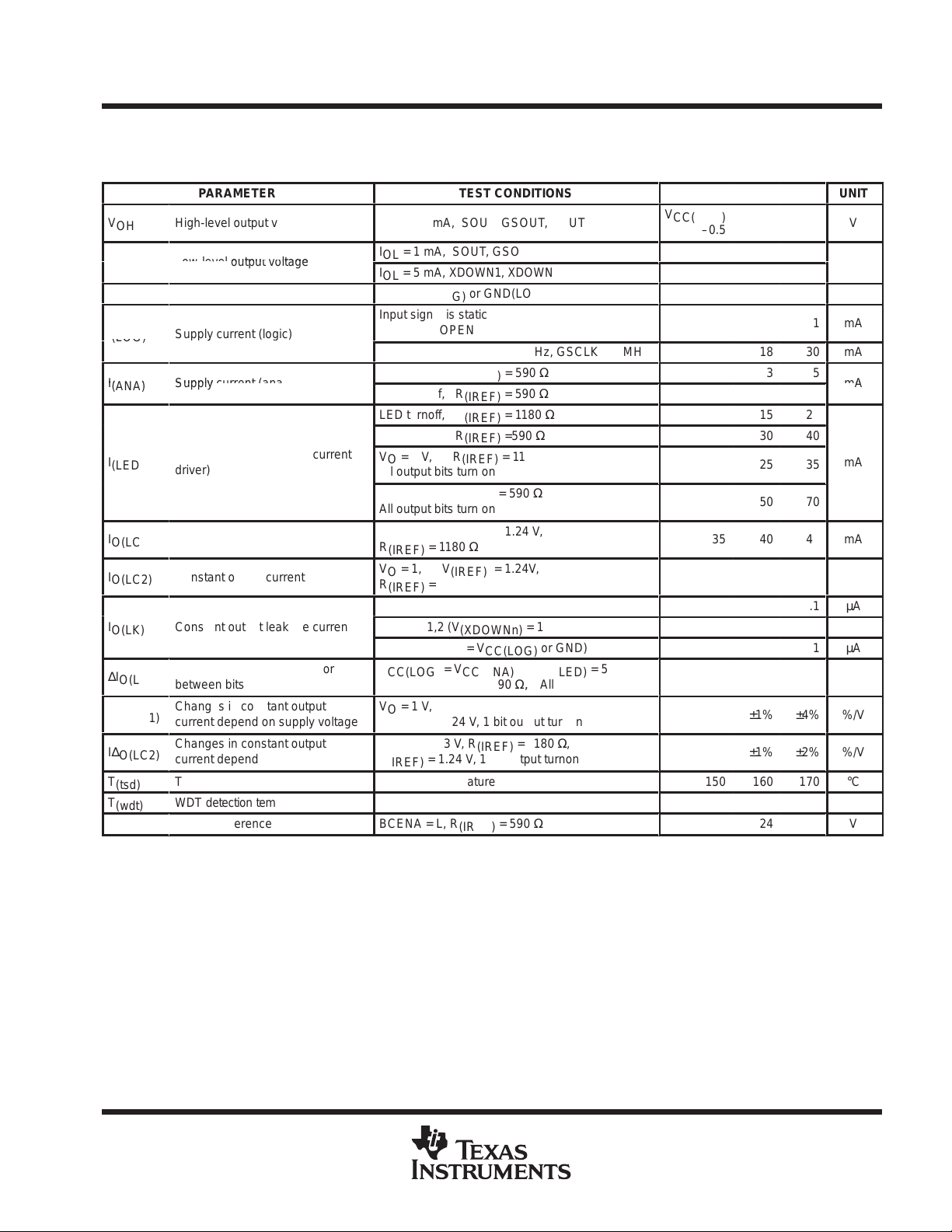

electrical characteristics,

= V

p

= V

CC(ANA)

CC(ANA)

MIN/MAX:V

TYP: V

V

I

I

I

I

I

I

∆I

I∆

I∆

T

T

V

OH

ÁÁ

I

ÁÁ

(ANA)

(LED)

ÁÁ

O(LC1)

ÁÁ

O(LC2)

O(LK)

O(LC)

ÁÁ

O(LC1)

O(LC2)

ÁÁ

(tsd)

(wdt)

(IREF)

CC(LOG)

High-level output voltage

Input current

Supply current (logic)

Supply current (constant current

driver)

Constant output current

Constant output current

Constant output leakage current

Constant output current error

between bits

Changes in constant output

current depend on supply voltage

Changes in constant output

current depend on output voltage

TSD detection temperature

WDT detection temperature

Voltage reference

CC(LOG)

PARAMETER

БББББББ

БББББББ

pp

БББББББ

БББББББ

БББББББ

БББББББ

= V

= V

= 4.5 V to 5.5 V, T

CC(LED)

CC(LED)

A

= 5 V, TA = 25°C (unless otherwise noted)

TEST CONDITIONS

IOH = –1 mA, SOUT, GSOUT, BOUT

БББББББББББ

IOL = 1 mA, SOUT, GSOUT, BOUT

IOL = 5 mA, XDOWN1, XDOWN2

VI = V

CC(LOG)

or GND(LOG)

Input signal is static, TSENA = H,

БББББББББББ

WDCAP = OPEN

Data transfer, SCLK = 15 MHz, GSCLK = 8 MHz

LED turnon, R

LED turnoff, R

LED turnoff, R

LED turnoff, R

VO = 1 V, R

All output bits turn on

БББББББББББ

VO = 1 V, R

All output bits turn on

VO = 1 V, V

БББББББББББ

R

(IREF)

VO = 1, V

R

(IREF)

(IREF)

= 1180 Ω

(IREF)

= 590 Ω

OUT0 to OUT15 (V

XDOWN1,2 (V

SOUT (V

V

VO = 1V , R

БББББББББББ

VO = 1 V, R

V

OUTn

CC(LOG)

= V

(IREF)

(IREF)

= 1.24 V, 1 bit output turnon

(IREF)

VO= 1 V to 3 V, R

БББББББББББ

V

= 1.24 V, 1 bit output turnon

(IREF)

= 590 Ω

(IREF)

= 590 Ω

(IREF)

= 1180 Ω

(IREF)

=590 Ω

(IREF)

= 1180 Ω

(IREF)

= 590 Ω

(IREF)

= 1.24 V,

= 1.24V,

= 15 V)

(OUTn)

(XDOWNn)

= V

CC(ANA)

= 15 V)

= V

or GND)

CC(LED)

CC(LOG)

= 590 Ω, All output bits turnon

= 1180 Ω,

= 1180 Ω,

(IREF)

Junction temperature

No external capacitor

BCENA = L, R

(IREF)

= 590 Ω

= –20 to 85°C

= 5 V,

LED DRIVER

SLLS401 – NOVEMBER 1999

MIN

V

CC(LOG)

ÁÁ

ÁÁÁÁÁÁ

ÁÁÁÁ

ÁÁ

ÁÁÁÁ

ÁÁÁÁ

TYP

–0.5

ÁÁÁÁÁ

18

3

3

15

30

25

50

35

70

Á

40

80

±1%

±1%

±1%

150

160

5

10

1.24

MAX

Á

Á

Á

Á

TLC5905

UNIT

0.5

0.5

±1

1

Á

30

5

5

20

40

35

Á

70

45

Á

90

0.1

1

1

±4%

Á

±4%

±2%

170

15

%/V

%/V

Á

V

µA

mA

mA

mA

mA

mA

µA

µA

µA

°C

ms

V

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

9

Page 10

TLC5905

LED DRIVER

SLLS401 – NOVEMBER 1999

switching characteristics, CL = 15pF,

MIN/MAX: V

TYP: V

trRise time

tfFall time

tdPropagation delay time

NOTE 3: Until SOUT will be turned on (drive) or turned off (Hi–Z).

CC(LOG)

CC(LOG)

= V

= V

CC(ANA)

PARAMETER

CC(ANA)

= V

= V

CC(LED)

CC(LED)

= 4.5 V to 5.5 V, T

= 5 V, T

= –20 to 85°C

= 25°C (unless otherwise noted)

A

TEST CONDITIONS

SOUT

GSOUT, BOUT

OUTn (see Figure 1)

SOUT

GSOUT, BOUT

OUTn (see Figure 1)

OUTn+1 – OUTn

BLANK↑ – OUT0

BLANK – BOUT

GSCLK↓ – OUT0

GSCLK – GSOUT

SCLK – SOUT

XOE↓ – SOUT (see Note 3)

XOE↑ – SOUT (see Note 3)

GSCLK – XDOWN2

A

MIN

20

20

15

10

10

TYP

250

200

350

350

12

13

10

35

40

40

30

20

15

MAX

8

5000

30

30

20

25

60

500

70

500

70

50

35

25

UNIT

ns

ns

ns

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 11

TLC5905

LED DRIVER

SLLS401 – NOVEMBER 1999

PARAMETER MEASUREMENT INFORMATION

V

CC

90%

10%

100%

50%

0%

V

CC

IREF OUTn

590 Ω

GND

Figure 1. Rise Time and Fall Time Test Circuit for OUTn

V

IH

V

t

r

t

w(h)

t

f

t

IL

w(l)

100%

50%

0%

V

IH

V

IL

100%

50%

51 Ω

15 pF

0%

VIH or V

VIL or V

t

d

OH

OL

VIH or V

VIL or V

OH

OL

Figure 2. Timing Requirements

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

11

Page 12

TLC5905

LED DRIVER

SLLS401 – NOVEMBER 1999

PRINCIPLES OF OPERATION

constant current output selection by user (80 mA x16 bits or 120 mA x 8 bits)

When the MODE terminal is set to high, output is selected as 80 mA x 16 bits. When the MODE terminal is set

to low, output is selected as 120 mA x 8 bits. By this setting, the shift register latch for gray scale data is changed

to the configuration corresponding to the bit selected. Note that two constant output terminals should be tied

to LED such as OUT0-to-OUT1 and OUT2-to-OUT3 because they operate in pairs when the 8-bit output mode

is selected. Also, in this case, the current value on constant current output is the same as in 16-bit output mode.

Therefore, when output current of 120 mA is desired, the resister connected to the IREF terminal should be set

to the same value as the output current of 60 mA.

Table 1. Operation Mode Selection

MODE

H

L

80 mA × 16 bits

120 mA × 8 bits

OUTPUT

On the constant current output terminals (OUT0–15), approximately 37 times the current that flows through

external resistor, R

(connected between IREF and GND), can flow. The external resistor value is calculated

IREF

using the following equation.

R

(Ω) ≅ 37 × 1.24 (V) / I

(IREF)

(A) where BCENA is low.

OL(C)

Note that more current flows if IREF is connected directly to GND.

constant output current operation

The constant current output turns on (sink constant current), if all the gray scale data latched into the gray scale

latch is not zero on the falling edge of the gray scale clock after the next rising edge of the gray scale clock when

BLANK goes from high to low . After that, the number of the falling edge is counted by the 8-bit gray scale counter.

Then, output counted corresponding to the gray scale data is turned off (stop to sink constant current). If the

shift register for gray scale is updated during XLA TCH high, data on the gray scale data latch is also updated

affecting the number of the gray scale of constant current output. Accordingly, during on-state of constant

current output, XLA TCH should be kept at a low level and the gray scale data latch should be held. If there are

constant current output terminals unconnected (includes LED disconnection), the LED should be turned on after

writing zero to the gray scale data latch corresponding to the output unconnected. Unless this action is taken,

supply current on the constant current driver will increase resulting in influencing the current value for the

constant current output when turned on.

shift register latch

The device provides three kinds of shift register latchs including the gray scale data, brightness control, and

OVM. To write data into the shift register, SCLK and SIN are utilized. The selection of the shift register will be

done by RSEL0 and RSEL1 as shown in Table 2. Note that RSEL0 and RSEL1 should be changed when both

SCLK and XLATCH are low.

Table 2. Shift Register Latch Selection

RSEL0

L

L

H

H

12

RSEL1

L

H

L

H

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

SHIFT REGISTER LATCH SELECTED

Shift register latch for gray scale data

Shift register latch for brightness control

Shift register latch for OVM

N/A (SOUT is tied to low level)

Page 13

LED DRIVER

SLLS401 – NOVEMBER 1999

PRINCIPLES OF OPERATION

shift register latch for gray scale data

The shift register latch for gray scale data is set as a 64 x 1 bit configuration in the 8-bit mode, and as a 128

x 1 bit configuration in the 16-bit mode. The gray scale data, configured as 8 bits, represents the time when

constant current output is being turned on, and the data range is 0 to 255 (00h to FFh). When the gray scale

data is 0, the time is shortest, and the output is not turned on(light off). On the other hand, when the gray scale

data is 255, the time is longest, and it turns on during time of 255 clocks from GSCLK. The configuration of shift

register and latch for gray scale data is shown in Figure 3.

Latch for Gray Scale Data

TLC5905

XLATCH

SOUT

XLATCH

SOUT

OUT15 Data

(8 bits)

Shift Register for Gray Scale Data

MSB

128 121

Latch for Gray Scale Data

OUT15,14 Data

(8 bits)

Shift Register for Gray Scale Data

MSB

64 57

OUT14 Data

(8 bits)

120 113 16 9

16 Bit Mode (MODE=H, RSEL0 and RSEL1=L)

OUT13,12 Data

(8 bits)

56 49 16 9

8 Bit Mode (MODE=L, RSEL0 and RSEL1=L)

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

OUT1 Data

(8 bits)

OUT3,2 Data

(8 bits)

OUT0 Data

(8 bits)

LSB

8 0

OUT1,0 Data

(8 bits)

LSB

8 0

SCLK

SIN

SCLK

SIN

Figure 3. Relationship Between Shift Register and Latch for Gray Scale Data

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

13

Page 14

TLC5905

LED DRIVER

SLLS401 – NOVEMBER 1999

PRINCIPLES OF OPERATION

shift register latch for brightness control and OVM

The shift register latch for both the brightness control and OVM (output voltage monitor) is configured with a

1 x 1 byte. In the shift register latch for brightness control, the division ratio of GSCLK can be set and the output

current value on constant current output can be adjusted. In the shift register latch for OVM, the comparison

voltage at the OVM comparator on constant current output terminals (OUT0 to OUT15) can be set and the output

signal for both XDOWN1 and XDOWN2 can be forced to a low level. When powered up, the latch data is

indeterminate and shift register is not initialized. When these functions are used, data should be written to the

shift register latch prior to turning the constant current output on (BLANK=L). Also, it is inhibited from rewriting

the latch value for brightness control when the constant current output is turned on. When these functions are

not used, latch value can be set to the default value setting of BCENA or MCENA or to low level (tied to GND).

The configuration of the shift register and latch for brightness control and monitor control is shown in Figure 4.

Latch for Brightness Control

GSCLK Division Ratio Data Set Current Data Adj usted On Con stant Curr ent O utput

GSCLK Division Ratio Data Set

XLATCH

00011111

MSB LSB MSB LSB

(see Note)

Shift Register for Brightness Control

SOUT

XLATCH

SOUT

NOTE: Indicates default value at BCENA low if brightness control latch, at MCENA low if OVM latch.

8th bit

Latch for OVM

Shift Register for OVM

8th bit 7th bit 6th bit 5th bit 4th bit 3rd bit 2nd bit 1st bit

7th bit 6th bit 5th bit 4th bit 3rd bit 2nd bit 1st bit

Monitor Control Data

N/A

0001

MSB LSB

Figure 4. Relationship Between Shift Register and Latch for Brightness Control and OVM

write data to shift register latch

The shift register latch written is selected using the RSEL0 and RSEL1 terminal. The data is applied to the SIN

data input terminal and clocked into the shift register synchronizing to the rising edge of SCLK after XENABLE

is pulled low. The shift register for gray scale data is 64 bit length in the 8 bit mode resulting in 64 times of SCLK,

and 128 bit length in the16 bit mode resulting in 128 times of SCLK. Brigtness control and monitor control results

in eight times the SCLK input. At number of SCLK input for each case, data can be written into the shift register.

In this condition, when XLA TCH is pulled high, data in the shift register is clocked into latch (data through), and

when XLATCH is pulled low, data is held (latch).

SCLK

SIN

(see Note)

SCLK

SIN

14

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 15

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

LED DRIVER

SLLS401 – NOVEMBER 1999

PRINCIPLES OF OPERATION

brightness control function

By writing data into the brightness control latch, current on all constant current outputs can be adjusted to control

the variation of brightness between ICs and the division ratio for the gray scale clock can be set to control the

variation of brightness for the total panel system.

output current adjustment on all constant current outputs – brightness adjustment between ICs

By using the lower 5 bits of the brightness control latch, output current can be adjusted to 32 steps as 1 step

of 1.6% current ratio between 100% and 51.6% when the output current is set to 100% of an external resistor.

By using this function, the brightness control between modules (ICs) can be adjusted, sending the desired data

externally even if ICs are mounted on a print-circuit board. When BCENA is pulled low, the output current is set

to 100%.

Table 3. Relative Current Ratio For Total Constant Current Output

TLC5905

CODE

MSB 00000 LSB

.

.

ÁÁÁÁ

.

.

ÁÁÁÁ

11110

11111

†

BCENA is low.

†

CURRENT RATIO%

51.6

.

БББББ

БББББ

.

.

.

98.4

100

20 (mA)

10.3

.

.

ÁÁ

.

.

ÁÁ

19.3

20.0

80 (mA)

41.3

.

.

ÁÁ

.

.

ÁÁ

78.7

80.0

V

(TYP)

IREF

0.63

.

.

ÁÁÁ

.

.

ÁÁÁ

1.22

1.24

frequency division ratio setting for gray scale clock – panel brightness adjustment

By using the upper 3 bits of the brightness control latch, the gray scale clock can be divided into 1/1 to 1/8. If

the gray scale clock is set to 8 times the speed (256 × 8 = 2048) of frequency during horizontal scanning time,

the brightness can be adjusted to 8 steps by selecting the frequency division ratio. Therefore, the total panel

brightness can be adjusted at once, and applied to the brightness of day or night. When BCENA is pulled low,

the gray scale clock is not divided. When BCENA is pulled high, the brightness can be adjusted as shown in

Table 4.

Table 4. Relative Brightness Ratio For Total Constant Current Output

CODE

ÁÁÁÁ

MSB 000 LSB

ÁÁÁÁ

ÁÁÁÁ

.

.

.

.

110

111

†

BCENA is low.

FREQUENCY

DIVISION RATIO

БББББ

†

БББББ

БББББ

1/1

.

.

.

.

1/7

1/8

RELATIVE BRIGHTNESS RATIO

ББББББББ

(%)

12.5

ББББББББ

ББББББББ

.

.

.

.

87.5

100

OVM (output voltage monitor) function

By writing data into the OVM latch, the comparison voltage for voltage comparator of OUT0 to OUT15 can be

set and the output signal for XDOWN1 and XDOWN2 can be checked.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

15

Page 16

TLC5905

LED DRIVER

SLLS401 – NOVEMBER 1999

PRINCIPLES OF OPERATION

OVM (output voltage monitor) function (continued)

OVM comparator

The OVM comparator compares the voltage on the constant current output terminal during turnon with

comparison voltage set by the OVM latch. When the voltage on the constant current output terminal is lower,

XDOWN2 goes low. As shown in Figure 5, the comparator is provided in every output portion, and the

comparison result corresponding to the output to be turned on appears in the XDOWN2 terminal. Since the

XDOWN2 terminal is an open-collector output, outputs of multiple ICs are brought together.

The output terminal for comparison result is XDOWN2 only . The voltage on all the constant current output can

be checked to monitor XDOWN2, turning output on in turn. The voltage on the constant current output, when

turned on, can also be measured, resulting in a change to the comparison voltage set by the OVM latch. Using

this function, the sensing (LOD function) LED disconnection (output voltage is below 0.3 V) and short circuit

(output voltage is extremely high) can be detected and specifies which LED has encountered this failure. Also,

by monitoring the output voltage and controlling the voltage across anode of the LED to minimize the voltage

on the constant current output (approximately 0.7 V at I

minimized. Furthermore, by setting BLANK to low during LED on, the previous comparison result can be held.

Thus, synchronizing timing to check XDOWN2 from the system to the LED lighting timing is not required. Note

that the gray scale data being turned on should be a minimum of 5 µs since the XDOWN2 output is required

approximately 5 µs after the constant current output is turned on. The comparison result is also required

approximately 5 µs after latch data is changed.

= 80 mA), the rising temperature of the chip can be

O

OUT0

Internal OUT0

Turn ON Signal

OUT1

Internal OUT1

Turn ON Signal

OUT14

Internal OUT014

Turn ON Signal

OUT15

Internal OUT015

Turn ON Signal

–

+

–

+

–

+

–

+

Comparison Voltage

XDOWN2

D

Q

LATCH

BLANK

When BLANK is high, hold the data

When BLANK is low, data is out.

16

Figure 5. OVM Functional Diagram

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 17

XDOWN1

XDOWN2

LED DRIVER

SLLS401 – NOVEMBER 1999

PRINCIPLES OF OPERATION

OVM (output voltage monitor) function (continued)

output signal check for XDOWN1, XDOWN2

XDOWN1 or XDOWN2 can be forced to a low level by setting the appropriate latch value for OVM. This allows

investigation of the correct connection of XDOWN1 or XDOWN2 to the external system. Since both XDOWN1

and XDOWN2 terminal are open-collector outputs, outputs of multiple ICs are brought together.

OVM comparator setting

Setting the OVM latch is shown in Table 5. Note that the comparison voltage is set to the default value of 0.3 V

when MCENA tied to a low level.

Table 5. OVM Setting

TLC5905

MONITOR CONTROL DATA

MSB

†

MCENA is low.

0000

0001

0010

0011

0100

0101

0110

0111

1000

1001

1010

1011

1100

1101

1110

1111

†

LSB

SOUT output timing selection

COMPARISON

VOLTAGE

NO COMPARISON

0.3 V

0.4 V

0.5 V

0.6 V

0.7 V

0.8 V

0.9 V

1.0 V

1.1 V

1.2 V

1/3 × V

CC(ANA)

1/2 × V

CC(ANA)

2/3 × V

CC(ANA)

0.3 V

0.3 V

DEPEND ON TSD/WDT

DEPEND ON TSD/WDT

DEPEND ON TSD/WDT

DEPEND ON TSD/WDT

DEPEND ON TSD/WDT

DEPEND ON TSD/WDT

DEPEND ON TSD/WDT

DEPEND ON TSD/WDT

DEPEND ON TSD/WDT

DEPEND ON TSD/WDT

DEPEND ON TSD/WDT

DEPEND ON TSD/WDT

DEPEND ON TSD/WDT

DEPEND ON TSD/WDT

L

DEPEND ON TSD/WDT

HI–Z

DEPEND ON OVM COMPARATOR

DEPEND ON OVM COMPARATOR

DEPEND ON OVM COMPARATOR

DEPEND ON OVM COMPARATOR

DEPEND ON OVM COMPARATOR

DEPEND ON OVM COMPARATOR

DEPEND ON OVM COMPARATOR

DEPEND ON OVM COMPARATOR

DEPEND ON OVM COMPARATOR

DEPEND ON OVM COMPARATOR

DEPEND ON OVM COMPARATOR

DEPEND ON OVM COMPARATOR

DEPEND ON OVM COMPARATOR

DEPEND ON OVM COMPARATOR

L

The timing for the SOUT output can be switched by selecting the SOMODE level. When SOMODE is low, SOUT

is clocked out synchronizing to the rising edge of SCLK. When SOMODE is high, SOUT is clocked out

synchronizing to the falling edge of SCLK. When the shift operation with SOMODE high, data can be protected

from shift error even if the SCLK signal is buffered in serial externally . In this case, when ICs are connected in

cascade, the maximum data transfer speed will be slower than the case of SOMODE low.

protection

This device incorporates WDT and TSD functions. If the WDT or TSD is turned on, then the constant current

output is stopped and XDOWN1 goes low. Therefore, by monitoring XDOWN1 terminal, these failures can be

detected immediately . Since the XDOWN1 output is configured as an open collector, outputs of multiple ICs are

brought together.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

17

Page 18

TLC5905

LED DRIVER

SLLS401 – NOVEMBER 1999

PRINCIPLES OF OPERATION

protection (continued)

WDT (watchdog timer)

The constant current output is forced to turn off and XDOWN1 goes low when the fixed period elapsed after the

signal applied to WDTRG has not been changed. Therefore, by a connecting scan signal (signal to control line

displayed) to WDTRG, the stop of the scan signal can be detected and the constant current output is turned

off preventing the LED from burning and damage by continuous LED turnon at the dynamic scanning operation.

The detection time can be set using an external capacitor, Cext. The typical value is approximately 10 ms without

a capacitor, 160 ms with a1000 pF capacitor and 1500 ms with a 0.01 µF capacitor. During static operation,

the WDT function is disabled connecting WDCAP to GND (high or low level should be applied to WDTRG). Note

that normal operation will be resumed changing the WDTRG level when WDT functions.

WDT operational time T (ms) ≅ 10 + 0.15 x Cext (pF)

TLC5905

1500

Scan Signal

WDTRG

WDCAP

160

10

0 0.001 0.01

Cext – External Capacitor – µF

Cext

Figure 6. WDT Operational Time and Usage Example

TSD (thermal shutdown)

When the junction temperature exceeds the limit, TSD functions and turns the constant current output off, and

XDOWN1 goes low . When TSD is used, TSENA is pulled high. When TSD is not used, TSENA is pulled low.

T o recover from constant current output of f-state to normal operation, the power supply should be turned off or

TSENA should be pulled low once.

18

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 19

LED DRIVER

SLLS401 – NOVEMBER 1999

PRINCIPLES OF OPERATION

noise reduction

concurrent switching noise reduction

The concurrent switching noise has potential to occur when multiple outputs turn on or off at the same time. To

prevent this noise, the device has delay output terminals such as XGSOUT and BOUT for GSCLK (gray scale

clock) and BLANK (blanking signal) respectively . By connecting these outputs to GSCLK and BLANK terminals

of next stage IC, it allows differences in the switching time between ICs to be made. When GSCLK is output

to GSOUT through the device, duty will be changed between input and output, and the number of stages to be

connected will be limited depending on frequency.

output slope

When output current is 80 mA, the time to change constant current output to turnon and turnoff is approximately

150 ns and 250 ns respectively . It is effective in reducing concurrent switching noise that occurrs when multiple

outputs turn or off at the same time.

delay between constant current output

The constant current output has a delay time of approximately 30 ns between outputs. It means approximately

450 ns delay time exists between OUT0 and OUT15. This time difference by delay is effective for reduction of

concurrent switching noise as well as the output slope. This delay time has the same value in 8 bits or 16 bits

operation mode.

TLC5905

power supply

The followings should be taken into consideration.

D

V

CC(LOG)

differences between these terminals.

D

The bypass capacitor should be located between power the supply and GND to eliminate the variation of

power supply voltage.

GND

Although GNDLOG, GNDANA and GNDLED are internally tied together, these terminals should be externally

connected to reduce noise influence.

thermal pad

The thermal pad should be connected to GND to eliminate the noise influence since it is connected to the bottom

side of IC chip. Also, desired thermal effect will be obtained by connecting this pad to the PCB pattern with better

thermal conductivity .

, V

CC(ANA)

and V

CC(LED)

should be supplied by a single power supply to minimize voltage

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

19

Page 20

TLC5905

LED DRIVER

SLLS401 – NOVEMBER 1999

noise reduction (continued)

PRINCIPLES OF OPERATION

4.9

2.5

0

0 25 85–20

TA – Free–Air Temperature – °C

NOTES: A. This is based on simulation. When a TI recommended PCB is used, derate linearly at the rate of 39.4 mW/°C for operation above

25°C free-air temperature.

V

CC(LOG)=VCC(ANA)=VCC(LED)

B. The thermal impedance will be varied depending on mounting conditions. Since PAP package established low thermal

impedance by radiating heat from the thermal pad, the thermal pad should be soldered to the pattern with a low thermal

impedance.

C. The material for PCB should be selected considering the thermal characteristics since the temperature will rise around the

thermal pad.

= 5 V, I

O(LC)

= 80 mA, I

is typical value.

C(C)

3.2

1.48

0

Figure 7. Power Rating – Free-Air Temperature

20

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 21

noise reduction (continued)

90

90

80

70

60

50

40

30

TLC5905

LED DRIVER

SLLS401 – NOVEMBER 1999

PRINCIPLES OF OPERATION

20

10

0

0.1

R

– kΩ

IREF

Conditions : VO = 1 V, V

I

(mA)

OLC

R

NOTE: The output current is in 16 bit mode. When in 8 bit mode (MODE=L), the output current is the sum of both outputs. This sum current should

be set from 10 mA to 120 mA. The resistor, R

(IREF)

(kW)

(IREF)

^

R

^

= 1.24 V

V

(IREF)

(IREF)

I

O(LC)

47

(V)

(kW)

(mA)

37

, should be located as close to the IREF terminal as possible to avoid the noise influence.

(IREF)

10.01.0

Figure 8. Current on Constant Current Output vs External Resistor

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

21

Page 22

22

POST OFFICE BOX 655303 DALLAS, TEXAS 75265

RSEL0

RSEL1

XOE

XENABLE

TLC5905

LED DRIVER

SLLS401 – november 1999

tsu(XENABLE–SCLK)

•

SCLK

SIN

XLATCH

SOUT

HI–Z

td(XOE↓–SOUT) td(SCLK–SOUT)

NOTE : MODE = H

t

tsu(SIN–SCLK)

SD00_A SD01_A SD02_A SD7F_A SD00_B SD7D_B SD7E_B SD7F_B SD00_C SD01_CSD7E_A

th(SIN–SCLK)

(SCLK) t

w(l)

th(XLATCH–SCLK)

1/f(

DCLK)

(SCLK)

w(h)

tsu(XLATCH–SCLK)

t

(XLATCH)

w(h)

SD00_A SD01_A SD7E_A SD7F_A SD00_B

th(XENABLE–SCLK)

td(XOE↑–SOUT)

Figure 9. Timing Diagram (Shift Register for Gray Scale Data)

Page 23

MCENA

RSEL0

POST OFFICE BOX 655303 DALLAS, TEXAS 75265

• 23

RSEL1

XOE

XENABLE

tsu(RSEL–SCLK)

SCLK

SIN

XLATCH

MCL_0

MCL_1–3

SOUT

Default Value 1

(Monitor Control Latch–Internal Signal)

Default Value 0

HI–Z

tsu(RSEL–XLATCH) th(RSEL–XLATCH)

SD01_ASD00_A

td(XOE↓–SOUT) td(SCLK–SOUT) td(XOE↑–SOUT)

SD07_A

SD00_A

th(XLATCH–SCLK)

t

(XLATCH)

w(h)

SD01_A SD06_A SD07_A SD00_B SD01_B

SD01_C SD02_C SD03_C SD04_CSD00_CSD07_BSD01_BSD00_B

Default Value 1

Default Value 0

th(RSEL–SCLK)

SLLS401 – november 1999

LED DRIVER

SD03_B

TLC5905

Figure 10. Timing Diagram (Shift Register for Monitor Control)

Page 24

24

BCENA

TLC5905

LED DRIVER

SLLS401 – november 1999

POST OFFICE BOX 655303 DALLAS, TEXAS 75265

•

RSEL0

RSEL1

XOE

XENABLE

tsu(RSEL–SCLK)

SCLK

SIN

XLATCH

BCL_0–4

BCL_5–7

Default Value 1

(Monitor Control Latch–Internal Signal)

Default Value 0

tsu(RSEL–XLATCH) th(RSEL–XLATCH)

SD01_ASD00_A

td(XOE↓–SOUT) td(SCLK–SOUT) td(XOE↑–SOUT)

SD07_A

th(XLATCH–SCLK)

t

(XLATCH)

w(h)

SD01_C SD02_C SD03_C SD04_CSD00_CSD07_BSD01_BSD00_B

Default Value 1

Default Value 0

th(RSEL–SCLK)

SOUT

HI–Z

SD00_A

SD01_A SD06_A SD07_A SD00_B SD01_B

Figure 11. Timing Diagram (Shift Register for Brightness Control)

SD03_B

Page 25

XLATCH

BLANK

tsu(XLATCH–GSCLK)

POST OFFICE BOX 655303 DALLAS, TEXAS 75265

• 25

GSCLK

WDTRG

t

w(l)

OUT0

OUT1

......

OUT15

XDOWN1

(WDTRG)

1/f(

WDT)

td(BLANK–OUT0)

td(OUTn+1–OUTn)

......

t

w(h)

(WDTRG)

tsu(BLANK–GSCLK)

OFF OFF

td(GSCLK–OUT0)

ON (see Note A)

td(BLANK–OUT0)

td(GSCLK–OUT0)

OFF

(see

Note A)

t

w(l)

(GSCLK)

td(OUTn+1–OUTn)

OFF OFF

OFF OFF OFF

ON (see Note A)

ON (see Note A)

OFF

...... ......

(see

Note A)

(see

Note A)

HI–Z

1/f(

t

w(dt)

GSCLK)

t

w(h)

Note A)

(GSCLK)

(see

(see

Note A)

Note A)

(see

XDOWN2

td(GSCLK–XDOWN2)

td(BLANK–BOUT)

BOUT

td(GSCLK–GSOUT)

GSOUT

NOTES: A. ON or OFF, or ON time is varied dpend on the gray scale data and BLANK.

B. LED disconnection

Figure 12. Timing Diagram (Constant Current Output)

(see NoteB)

(see NoteB)

SLLS401 – november 1999

LED DRIVER

TLC5905

Page 26

TLC5905

LED DRIVER

SLLS401 – NOVEMBER 1999

MECHANICAL DATA

PAP (S-PQFP-G64) PowerPAD PLASTIC QUAD FLATPACK

64

49

1,05

0,95

0,50

48

0,27

0,17

33

32

17

1

7,50 TYP

10,20

SQ

9,80

12,20

SQ

11,80

16

M

0,08

Seating Plane

Thermal Pad

(See Note D)

0,15

0,05

0,13 NOM

Gage Plane

0,25

0°–7°

0,75

0,45

1,20 MAX

NOTES: A. All linear dimensions are in millimeters.

PowerPAD is a trademark of Texas Instruments Incorporated.

26

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion.

D. The package thermal performance may be enhanced by bonding the thermal pad to an external thermal plane.

This pad is electrically and thermally connected to the backside of the die and possibly selected leads.

E. Falls within JEDEC MS-026

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

0,08

4147702/A 01/98

Page 27

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...