Page 1

TL2218-285, TL2218-285Y

EXCALIBUR CURRENT-MODE SCSI TERMINATOR

SLVS072C – DECEMBER 1992 – REVISED OCTOBER 1995

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Copyright 1995, Texas Instruments Incorporated

8–1

available features

• Fully Integrated 9-Channel SCSI

Termination

• No External Components Required

• Maximum Allowed Current Applied at First

High-Level Step

• 6-pF Typical Power-Down Output

Capacitance

• Wide V

term

†

(Termination Voltage)

Operating Range, 3.5 V to 5.5 V

• TTL-Compatible Disable Feature

• Compatible With Active Negation

• Thermal Regulation

description

The TL2218-285 is a current-mode 9-channel monolithic terminator specially designed for single-ended

small-computer-systems-interface (SCSI) bus termination. A user-controlled disable function is provided to

reduce standby power. No impedance-matching resistors or other external components are required for its

operation as a complete terminator.

The device operates over a wide termination-voltage (V

term

†

) range of 3.5 V to 5.5 V , offering an extra 0.5 V of

operating range when compared to the minimum termination voltage of 4 V required by other integrated active

terminators. The TL2218-285 functions as a current-sourcing terminator and supplies a constant output current

of 23 mA into each asserted line. When a line is deasserted, the device senses the rising voltage level and begins

to function as a voltage source, supplying a fixed output voltage of 2.85 V. The TL2218-285 features

compatibility with active negation drivers and has a typical sink current capability of 20 mA.

The TL2218-285 is able to ensure that maximum current is applied at the first high-level step. This performance

means that the device should provide a first high-level step exceeding 2 V even at a 10-MHz rate. Therefore,

noise margins are improved considerably above those provided by resistive terminators.

A key difference between the TL2218-285 current-mode terminator and a Boulay terminator is that the

TL2218-285 does not incorporate a low dropout regulator to set the output voltage to 2.85 V. In contrast with

the Boulay termination concept, the accuracy of the 2.85 V is not critical with the current-mode method used

in the TL2218-285 because this voltage does not determine the driver current. Therefore, the primary device

specifications are not the same as with a voltage regulator but are more concerned with output current.

The DISABLE

terminal is TTL compatible and must be taken low to shut down the outputs. The device is

normally active, even when DISABLE

is left floating. In the disable mode, only the device startup circuits remain

active, thereby reducing the supply current to just 500 µA. Output capacitance in the shutdown mode is typically

6 pF.

The TL2218-285 has on-board thermal regulation and current limiting, thus eliminating the need for external

protection circuitry . A thermal regulation circuit that is designed to provide current limiting, rather than an actual

thermal shutdown, is included in the individual channels of the TL2218-285. When a system fault occurs that

leads to excessive power dissipation by the terminator, the thermal regulation circuit causes a reduction in the

asserted-line output current sufficient to maintain operation. This feature allows the bus to remain active during

a fault condition, which permits data transfer immediately upon removal of the fault. A terminator with thermal

shutdown does not allow for data transfer until sufficient cooling has occurred. Another advantage offered by

the TL2218-285 is a design that does not require costly laser trimming in the manufacturing process.

The TL2218-285 is characterized for operation over the virtual junction temperature range of 0°C to 125°C.

†

This symbol is not presently listed within EIA/JEDEC standards for letter symbols.

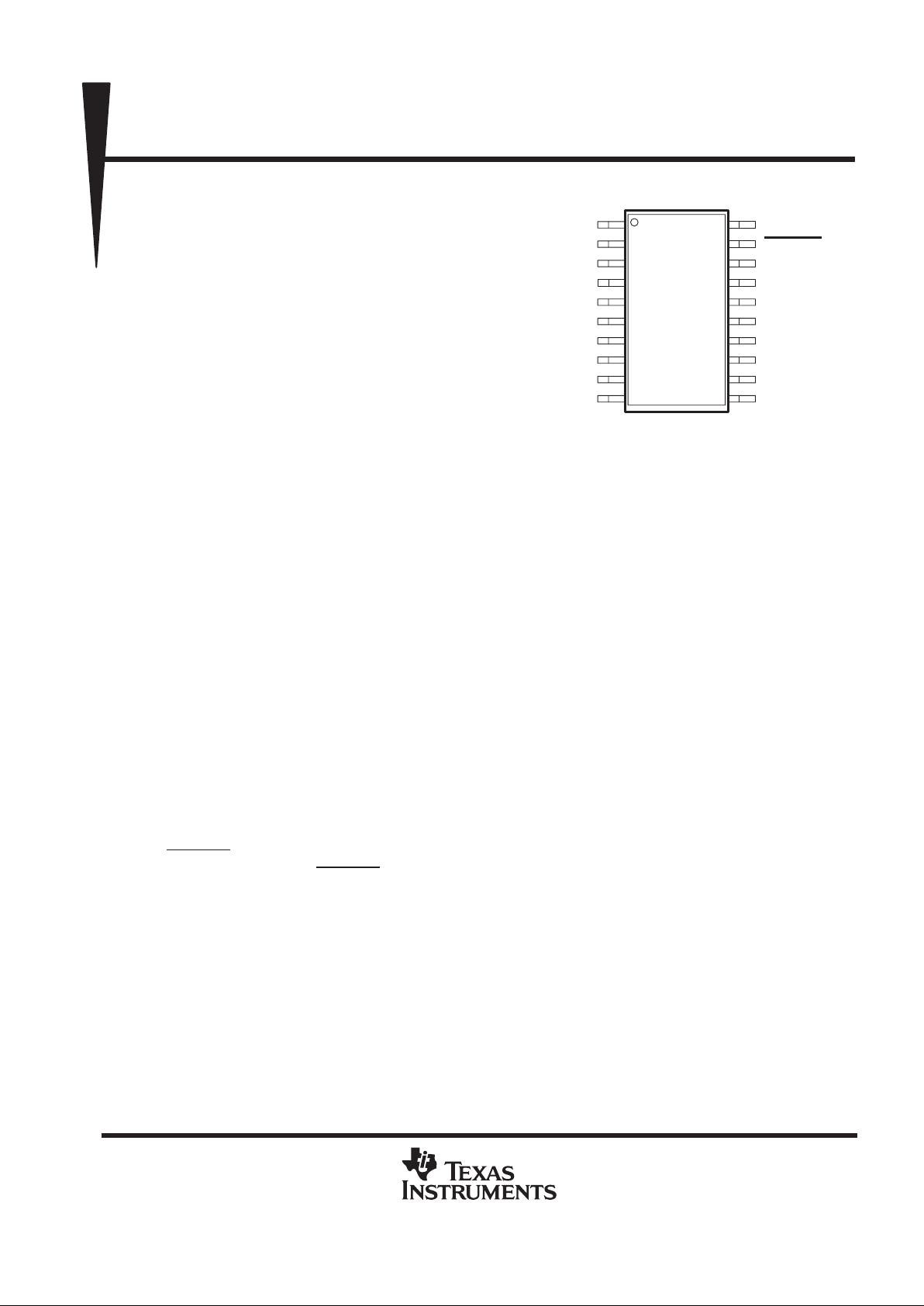

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

TERMPWR

NC

NC

D0

D1

D2

D3

D4

NC

GND

TERMPWR

DISABLE

NC

D8

D7

NC

D6

D5

NC

GND

PW PACKAGE

(TOP VIEW)

1

NC – No internal connection

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

Page 2

TL2218-285, TL2218-285Y

EXCALIBUR CURRENT -MODE SCSI TERMINATOR

SLVS072C – DECEMBER 1992 – REVISED OCTOBER 1995

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

8–2

AVAILABLE OPTIONS

T

J

SURFACE MOUNT

(PW)

†

CHIP FORM

(Y)

0°C to 125°C TL2218-285PWLE TL2218-285Y

†

The PW package is only available left-end taped and reeled.

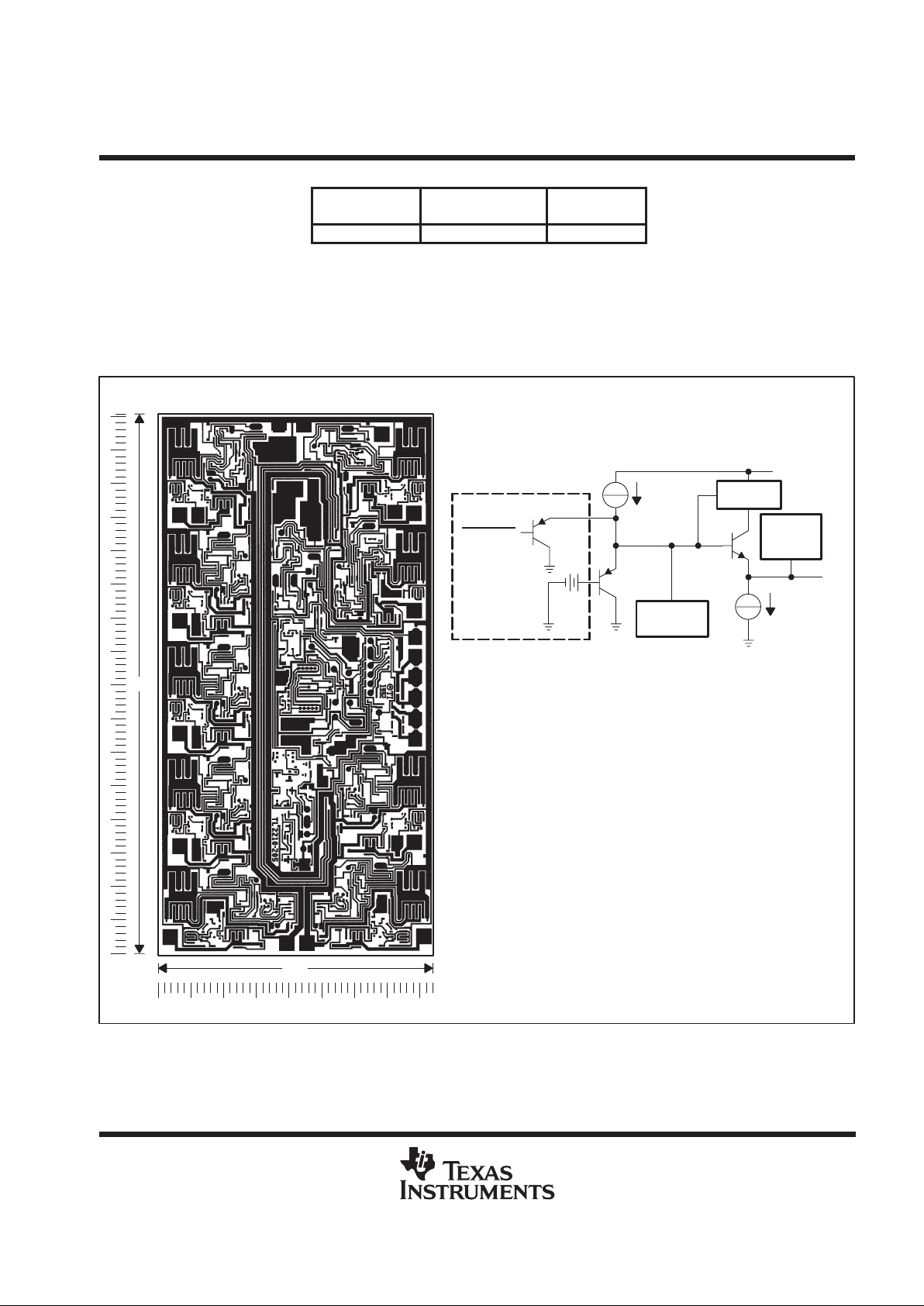

TL2218-285Y chip information

This chip, when properly assembled, displays characteristics similar to the TL2218-285. Thermal compression

or ultrasonic bonding may be used on the doped aluminum bonding pads. The chip may be mounted with

conductive epoxy or a gold-silicon preform.

BONDING PAD ASSIGNMENTS

CHIP THICKNESS: 11 MILS TYPICAL

BONDING PADS: 4 × 4 MILS MINIMUM

TJmax = 150°C

TOLERANCES ARE ±10%.

ALL DIMENSIONS ARE IN MILS.

Thermal

Regulation

Feedback

Active

Negation

Clamp

TERMPWR

1, 20

4

19

V

ref

DISABLE

D0

Common to All Channels

161

84

(1)

(4)

(5)

(6)

(7)

(8)

(10)(11)

(13)

(14)

(16)

(17)

(19)

(20)

Page 3

TL2218-285, TL2218-285Y

EXCALIBUR CURRENT -MODE SCSI TERMINATOR

SLVS072C – DECEMBER 1992 – REVISED OCTOBER 1995

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

8–3

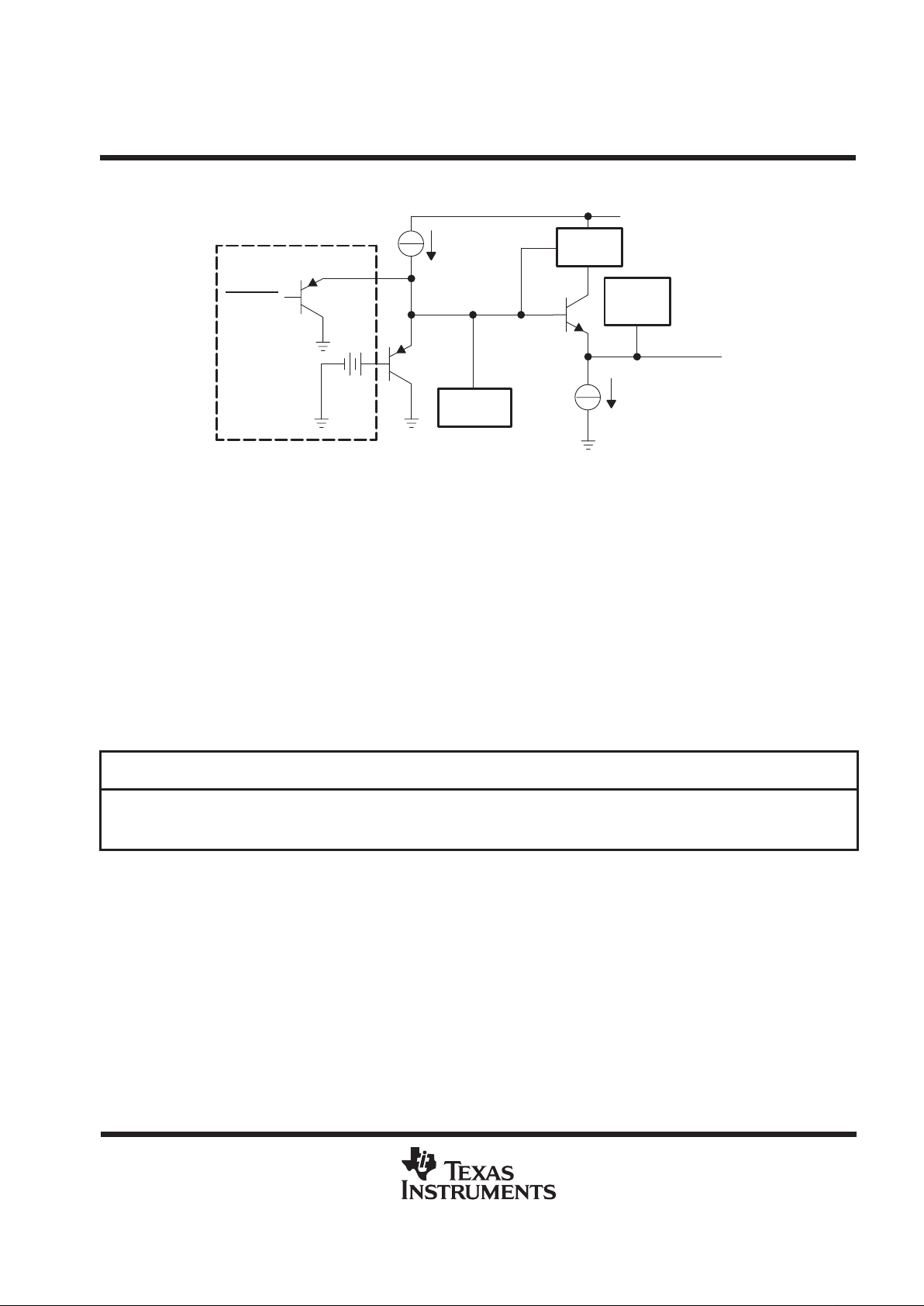

functional block diagram (each channel)

Thermal

Regulation

Feedback

Active

Negation

Clamp

TERMPWR

1, 20

4

19

V

ref

DISABLE

D0

Common to All Channels

absolute maximum ratings over operating free-air temperature range (unless otherwise noted)

(see Figures 1, 2, and 3)

†

Continuous termination voltage 10 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous output voltage range 0 V to 5.5 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous disable voltage range 0 V to 5.5 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous total power dissipation See Dissipation Rating Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating virtual junction temperature range, T

J

–55°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature range, T

stg

–60°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds 260°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

DISSIPATION RATING TABLE

POWER RATING T ≤ 25°C DERATING FACTOR T = 70°C T = 85°C T = 125°C

PACKAGE

AT POWER RATING ABOVE T = 25°C POWER RATING POWER RATING POWER RATING

T

A

828 mW 6.62 mW/°C 530 mW 430 mW 166 mW

PW

T

C

4032 mW 32.2 mW/°C 2583 mW 2100 mW 812 mW

T

L

‡

2475 mW 19.8 mW/°C 1584 mW 1287 mW 495 mW

‡

R

θJL

is the thermal resistance between the junction and device lead. T o determine the virtual junction temperature (TJ) relative to the device lead

temperature, the following calculations should be used: TJ = PD x R

θJL

+ TL, where PD is the internal power dissipation of the device and TL is

the device lead temperature at the point of contact to the printed wiring board. R

θJL

is 50.5°C/W.

Page 4

TL2218-285, TL2218-285Y

EXCALIBUR CURRENT -MODE SCSI TERMINATOR

SLVS072C – DECEMBER 1992 – REVISED OCTOBER 1995

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

8–4

600

400

200

0

25 50 75 100

800

1000

1200

125 150

1800

1600

1400

2000

2200

2400

FREE-AIR TEMPERATURE

DISSIPATION DERATING CURVE

TA – Free-Air Temperature – °C

Maximum Continuous Power Dissipation – mW

1200

800

400

0

25 50 75 100

1600

2000

2400

125 150

3600

3200

2800

4000

4400

4800

CASE TEMPERATURE

DISSIPATION DERATING CURVE

TC – Case Temperature – ° C

R

θJA

= 151°C/W

R

θJC

= 31°C/W

Maximum Continuous Power Dissipation – mW

Figure 1 Figure 2

1200

800

400

0

25 50 75 100

2000

125 150

3600

3200

2800

4000

4400

4800

LEAD TEMPERATURE

DISSIPATION DERATING CURVE

TL – Lead Temperature – ° C

2400

1600

†

R

θJL

= 50.5°C/W

Maximum Continuous Power Dissipation – mW

Figure 3

†

R

θJL

is the thermal resistance between the junction and device lead. T o determine the virtual junction temperature (TJ) relative to the device lead

temperature, the following calculations should be used: TJ = PD x R

θJL

+ TL, where PD is the internal power dissipation of the device, and TL is

the device lead temperature at the point of contact to the printed wiring board. R

θJL

is 50.5°C/W.

Page 5

TL2218-285, TL2218-285Y

EXCALIBUR CURRENT -MODE SCSI TERMINATOR

SLVS072C – DECEMBER 1992 – REVISED OCTOBER 1995

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

8–5

recommended operating conditions

MIN MAX UNIT

Termination voltage 3.5 5.5 V

High-level disable input voltage, V

IH

2 V

term

V

Low-level disable input voltage, V

IL

0 0.8 V

Operating virtual junction temperature, T

J

0 125 °C

electrical characteristics, V

term

= 4.75 V, VO = 0.5 V, TJ = 25°C

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Output high voltage 2.5 2.85 V

All data lines open 9

TERMPWR supply current

All data lines = 0.5 V 228

mA

DISABLE = 0 V 500 µA

Output current –20.5 –23 –24 mA

p

DISABLE = 4.75 V 1

Disable input current (see Note 1)

DISABLE = 0 V 600

µ

A

Output leakage current DISABLE = 0 V 100 nA

Output capacitance, device disabled VO = 0 V, 1 MHz 6 pF

Termination sink current, total VO = 4 V 20 mA

NOTE 1: When DISABLE is open or high, the terminator is active.

Page 6

TL2218-285, TL2218-285Y

EXCALIBUR CURRENT -MODE SCSI TERMINATOR

SLVS072C – DECEMBER 1992 – REVISED OCTOBER 1995

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

8–6

THERMAL INFORMATION

The need for smaller surface-mount packages for use on compact printed-wiring boards (PWB) causes an

increasingly difficult problem in the area of thermal dissipation. In order to provide the systems designer with a better

approximation of the junction temperature rise in the thin-shrink small-outline package (TSSOP), the junction-to-lead

thermal resistance (R

θJL

) is provided along with the more typical values of junction-to-ambient and junction-to-case

thermal resistances, R

θJA

and R

θJC

.

R

θJL

is used to calculate the device junction temperature rise measured from the leads of the unit. Consequently , the

junction temperature is dependent upon the board temperature at the leads, R

θJL

, and the internal power dissipation

of the device. The board temperature is contingent upon several variables, including device packing density,

thickness, material, area, and number of interconnects. The R

θJL

value depends on the number of leads connecting

to the die-mount pad, the lead-frame alloy , area of the die, mount material, and mold compound. Since the power level

at which the TSSOP can be used is highly dependent upon both the temperature rise of the PWB and the device itself,

the systems designer can maximize this level by optimizing the circuit board. The junction temperature of the device

can be calculated using the equation T

J

= (PD × R

θJL

) + TL where TJ = junction temperature, PD = power dissipation,

R

θJL

= junction-to-lead thermal resistance, and TL = board temperature at the leads of the unit.

The values of thermal resistance for the TL2218-285 PW are as follows:

Thermal Resistance Typical Junction Rise

R

θJA

151°C/W

R

θJC

31 °C/W

R

θJL

50.5°C/W

TYPICAL CHARACTERISTICS

Table of Graphs

FIGURE

I

O

Output current vs Input voltage 4

V

O

Output voltage vs Input voltage 5

I

O

Output current vs Junction temperature 6

V

O

Output voltage vs Junction temperature 7

Page 7

TL2218-285, TL2218-285Y

EXCALIBUR CURRENT -MODE SCSI TERMINATOR

SLVS072C – DECEMBER 1992 – REVISED OCTOBER 1995

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

8–7

TYPICAL CHARACTERISTICS

20

18

16

14

3 3.5 4 4.5

– Output Current – mA

22

OUTPUT CURRENT

vs

INPUT VOLTAGE

24

5 5.5

TJ = 25°C

VI – Input Voltage – V

2

1

0

3 3.5 4 4.5

VO – Output Voltage – V

OUTPUT VOLTAGE

vs

INPUT VOLTAGE

4

5 5.5

3

TJ = 25°C

V

O

VI – Input Voltage – V

I

O

Figure 4 Figure 5

15

10

5

0255075

20

OUTPUT CURRENT

vs

JUNCTION TEMPERATURE

25

100 125

V

term

= 4.75 V

TA = T

J

TJ – Junction Temperature – °C

3

2.5

2

0255075

3.5

4

100 125

V

term

= 4.75 V

TA = T

J

VO – Output Voltage – V

V

O

TJ – Junction Temperature – °C

OUTPUT VOLTAGE

vs

JUNCTION TEMPERATURE

– Output Current – mA

I

O

Figure 6 Figure 7

Page 8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

8–8

Page 9

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1998, Texas Instruments Incorporated

Loading...

Loading...