Page 1

● 8 A Continuous On-State Current

● 80 A Surge-Current

● Glass Passivated Wafer

● 400 V to 800 V Off-State Voltage

● Max I

of 20 mA

GT

TIC116 SERIES

SILICON CONTROLLED RECTIFIERS

APRIL 1971 - REVISED JUNE 2000Copyright © 2000, Power Innovations Limited, UK

TO-220 PACKAGE

(TOP VIEW)

K

A

G

1

2

3

Pin 2 is in electrical contact with the mounting base.

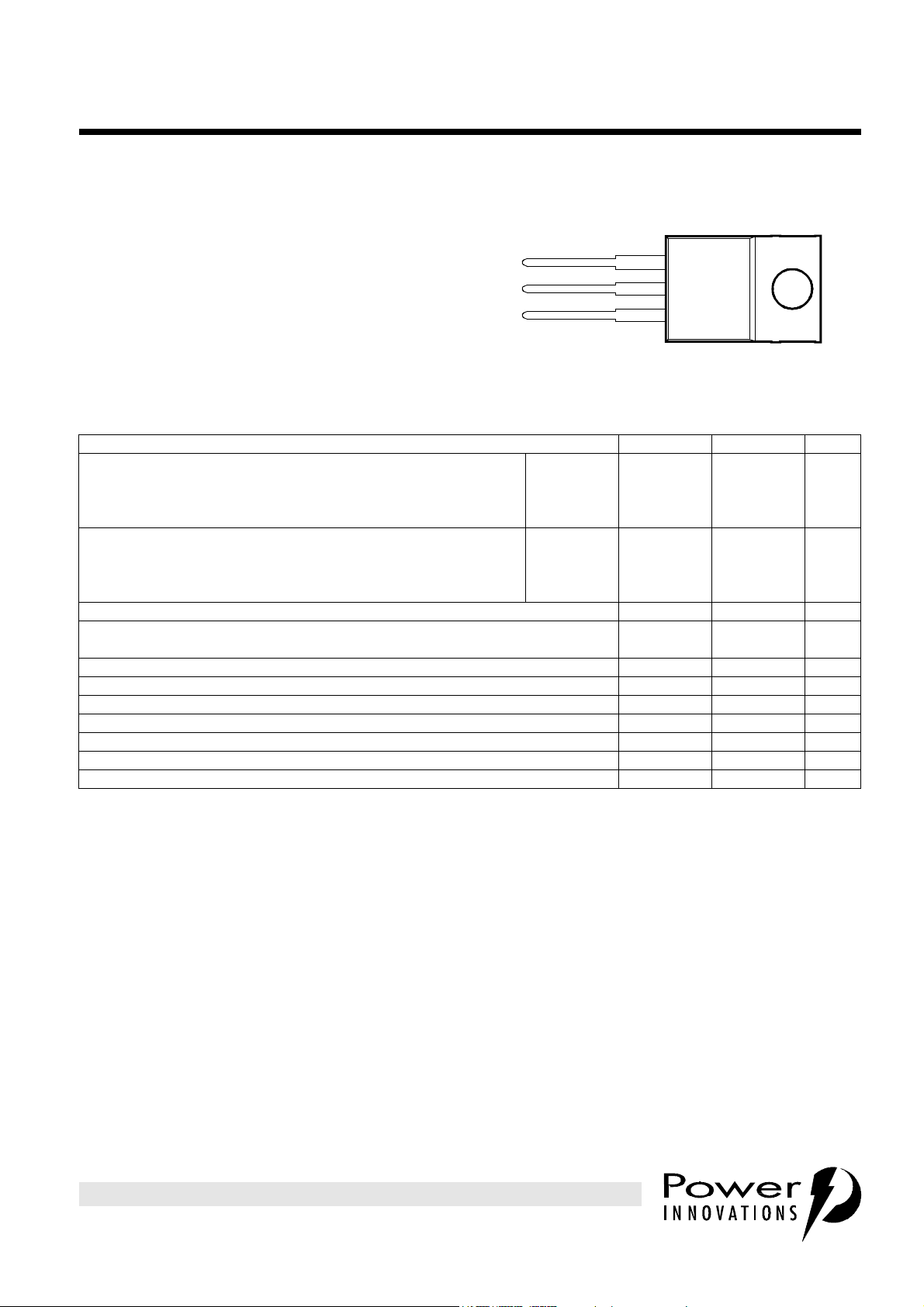

absolute maximum ratings over operating case temperature (unless otherwise noted)

RATING SYMBOL VALUE UNIT

TIC116D

Repetitive peak off-state voltage

Repetitive peak reverse voltage

Continuous on-state current at (or below) 70°C case temperature (see Note 1) I

Average on-state current (180° conduction angle) at (or below) 70°C case temperature

(see Note 2)

Surge on-state current at (or below) 25°C case temperature (see Note 3) I

Peak positive gate current (pulse width

Peak gate power dissipation (pulse width

Average gate power dissipation (see Note 4) P

Operating case temperature range T

Storage temperature range T

Lead temperature 1.6 mm from case for 10 seconds T

NOTES: 1. These values apply for continuous dc operation with resistive load. Above 70°C derate linearly to zero at 110°C.

2. This value may be applied continuously under single phase 50 Hz half-sine-wave operation with resistive load. Above 70°C derate

linearly to zero at 110°C.

3. This value applies for one 50 Hz half-sine-wave when the device is operating at (or below) the rated value of peak reverse voltage

and on-state current. Surge may be repeated after the device has returned to original thermal equilibrium.

4. This value applies for a maximum averaging time of 20 ms.

≤ 300 µs) I

≤ 300 µs) P

TIC116M

TIC116S

TIC116N

TIC116D

TIC116M

TIC116S

TIC116N

V

DRM

V

RRM

T(RMS)

I

T(AV)

TM

GM

GM

G(AV)

C

stg

L

400

600

700

800

400

600

700

800

80 A

-40 to +110 °C

-40 to +125 °C

230 °C

MDC1ACA

V

V

8 A

5 A

3 A

5 W

1 W

PRODUCT INFORMATION

Information is current as of publication date. Products conform to specifications in accordance

with the terms of Power Innovations standard warranty. Production processing does not

necessarily include testing of all parameters.

1

Page 2

TIC116 SERIES

SILICON CONTROLLED RECTIFIERS

APRIL 1971 - REVISED JUNE 2000

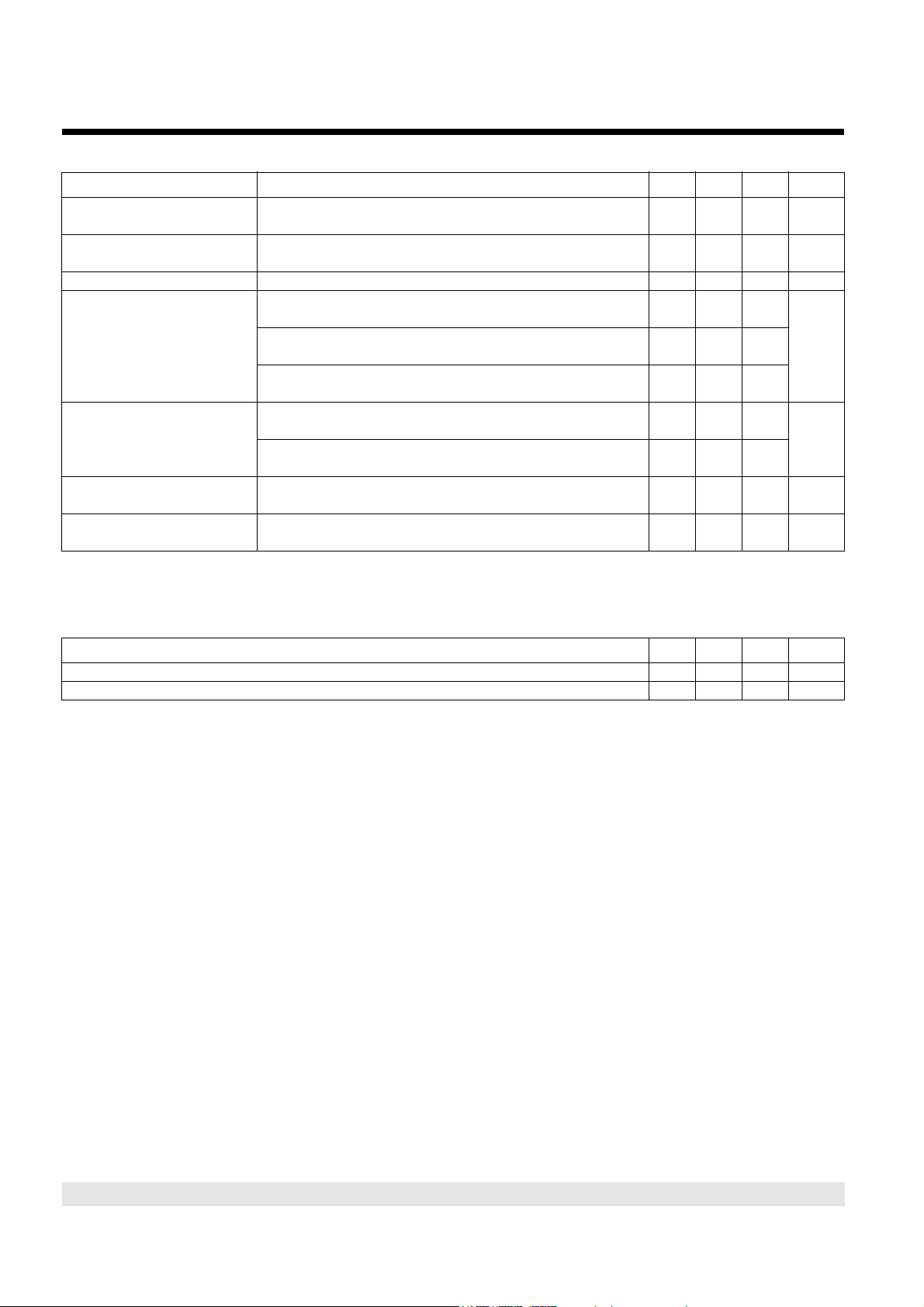

electrical characteristics at 25°C case temperature (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

I

I

dv/dt

Repetitive peak

DRM

off-state current

Repetitive peak

RRM

reverse current

Gate trigger current VAA = 12 V R

I

GT

Gate trigger voltage

V

GT

Holding current

I

H

On-state

V

T

voltage

Critical rate of rise of

off-state voltage

NOTE 5: This parameter must be measured using pulse techniques, t

the current carrying contacts, are located within 3.2 mm from the device body.

= rated V

V

D

= rated V

V

R

V

= 12 V

AA

≥ 20 µs

t

p(g)

= 12 V

V

AA

≥ 20 µs

t

p(g)

= 12 V

V

AA

≥ 20 µs

t

p(g)

V

= 12 V

AA

Initiating I

= 12 V

V

AA

Initiating I

= 8 A (see Note 5) 1.7 V

I

T

= rated V

V

D

DRM

RRM

= 100 mA

T

= 100 mA

T

D

IG = 0 TC = 110°C 2 mA

= 100 Ω t

L

R

= 100 Ω T

L

R

= 100 Ω

L

R

= 100 Ω T

L

IG = 0 TC = 110°C 400 V/µs

= 300 µs, duty cycle ≤ 2 %. Voltage sensing-contacts, separate from

p

TC = 110°C 2 mA

≥ 20 µs 8 20 mA

p(g)

= - 40°C

C

= 110°C

C

T

= - 40°C

C

0.2

2.5

0.8 1.5

100

40

V

mA

thermal characteristics

R

R

Junction to case thermal resistance 3 °C/W

θJC

Junction to free air thermal resistance 62.5 °C/W

θJA

PARAMETER MIN TYP MAX UNIT

PRODUCT INFORMATION

2

Page 3

SILICON CONTROLLED RECTIFIERS

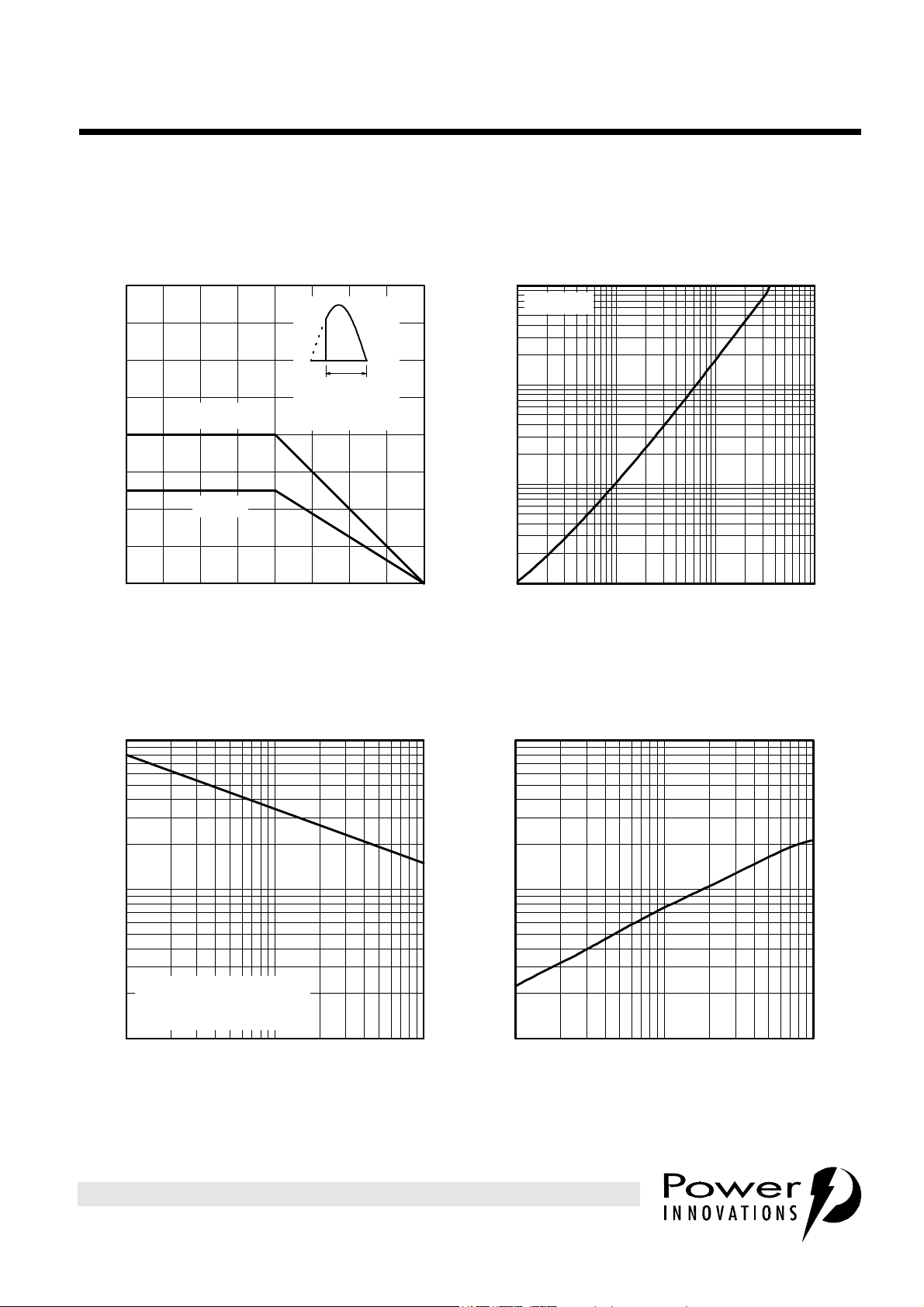

AVERAGE ON-STATE CURREN

T

MAX ANODE POWER LOSS

P

- Max Continuous Anode Power Dissipated- W

SURGE ON-STATE CURRENT

I

- Peak Half-Sine-Wave Current - A

TRANSIENT THERMAL RESISTANC

E

THERMAL INFORMATION

TIC116 SERIES

APRIL 1971 - REVISED JUNE 2000

DERATING CURVE

16

14

12

10

Continuous DC

8

6

4

- Maximum Average On-State Current - A

2

T(AV)

I

0

30 40 50 60 70 80 90 100 110

ΦΦ = 180°

TC - Case Temperature - °C

0° 180°

ΦΦ

Conduction

Angle

Figure 1. Figure 2.

TI03AA

vs

ON-STATE CURRENT

100

TJ = 110°C

10

1

A

0·1

0·1 1 10 100

IT - Continuous On-State Current - A

TI03AB

vs

CYCLES OF CURRENT DURATION

100

10

TM

T

≤≤ 70°C

C

No Prior Device Conduction

Gate Control Guaranteed

1

1 10 100

Consecutive 50 Hz Half-Sine-Wave Cycles

Figure 3. Figure 4.

TI03AC

vs

CYCLES OF CURRENT DURATION

10

1

- Transient Thermal Resistance - °C/W

θ

θJC(t)

R

0·1

1 10 100

Consecutive 50 Hz Half-Sine-Wave Cycles

TI03AD

PRODUCT INFORMATION

3

Page 4

TIC116 SERIES

GATE TRIGGER CURRENT

GATE TRIGGER VOLTAGE

HOLDING CURRENT

I

- Holding Current - mA

PEAK ON-STATE VOLTAGE

SILICON CONTROLLED RECTIFIERS

APRIL 1971 - REVISED JUNE 2000

TYPICAL CHARACTERISTICS

vs

CASE TEMPERATURE

VAA =12 V

R

= 100 ΩΩ

L

t

≥≥ 20 µs

p(g)

10

- Gate Trigger Current - mA

GT

I

1

-50 -25 0 25 50 75 100 125

TC - Case Temperature - °C

Figure 5. Figure 6.

TC03AA

vs

CASE TEMPERATURE

1

0·8

0·6

0·4

- Gate Trigger Voltage - V

GT

V

0·2

VAA =12 V

R

= 100 ΩΩ

L

t

≥≥ 20 µs

p(g)

0

-50 -25 0 25 50 75 100 125

TC - Case Temperature - °C

TC03AB

vs

CASE TEMPERATURE

100

VAA = 12 V

Initiating IT = 100 mA

10

H

1

-50 -25 0 25 50 75 100 125

TC - Case Temperature - °C

Figure 7. Figure 8.

TC03AD

vs

PEAK ON-STATE CURRENT

2·5

TC = 25 °C

tP = 300 µs

Duty Cycle ≤≤ 2 %

2

1·5

1

- Peak On-State Voltage - V

TM

V

0·5

0

0·1 1 10 100

ITM - Peak On-State Current - A

TC03AE

PRODUCT INFORMATION

4

Page 5

TIC116 SERIES

NOTE A: The centre pin is in electrical contact with the mounting tab.

SILICON CONTROLLED RECTIFIERS

APRIL 1971 - REVISED JUNE 2000

MECHANICAL DATA

TO-220

3-pin plastic flange-mount package

This single-in-line package consists of a circuit mounted on a lead frame and encapsulated within a plastic

compound. The compound will withstand soldering temperature with no deformation, and circuit performance

characteristics will remain stable when operated in high humidity conditions. Leads require no additional

cleaning or processing when used in soldered assembly.

TO-220

3,96

ø

3,71

18,0 TYP.

0,97

0,66

10,4

10,0

1 2 3

1,47

1,07

2,74

2,34

5,28

4,68

2,95

2,54

6,1

5,6

4,70

4,20

1,32

1,23

6,6

6,0

15,32

14,55

14,1

12,7

0,64

0,41

2,90

2,40

ALL LINEAR DIMENSIONS IN MILLIMETERS

PRODUCT INFORMATION

5

Page 6

TIC116 SERIES

SILICON CONTROLLED RECTIFIERS

APRIL 1971 - REVISED JUNE 2000

IMPORTANT NOTICE

Power Innovations Limited (PI) reserves the right to make changes to its products or to discontinue any

semiconductor product or service without notice, and advises its customers to verify, before placing orders, that the

information being relied on is current.

PI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with PI's standard warranty. Testing and other quality control techniques are utilized to the extent PI

deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except as mandated by government requirements.

PI accepts no liability for applications assistance, customer product design, software performance, or infringement

of patents or services described herein. Nor is any license, either express or implied, granted under any patent

right, copyright, design right, or other intellectual property right of PI covering or relating to any combination,

machine, or process in which such semiconductor products or services might be or are used.

PI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, INTENDED, AUTHORIZED, OR WARRANTED TO BE

SUITABLE FOR USE IN LIFE-SUPPORT APPLICATIONS, DEVICES OR SYSTEMS.

Copyright © 2000, Power Innovations Limited

PRODUCT INFORMATION

6

Loading...

Loading...