Page 1

Advance Product Information

)

L

R

D

August 29, 2000

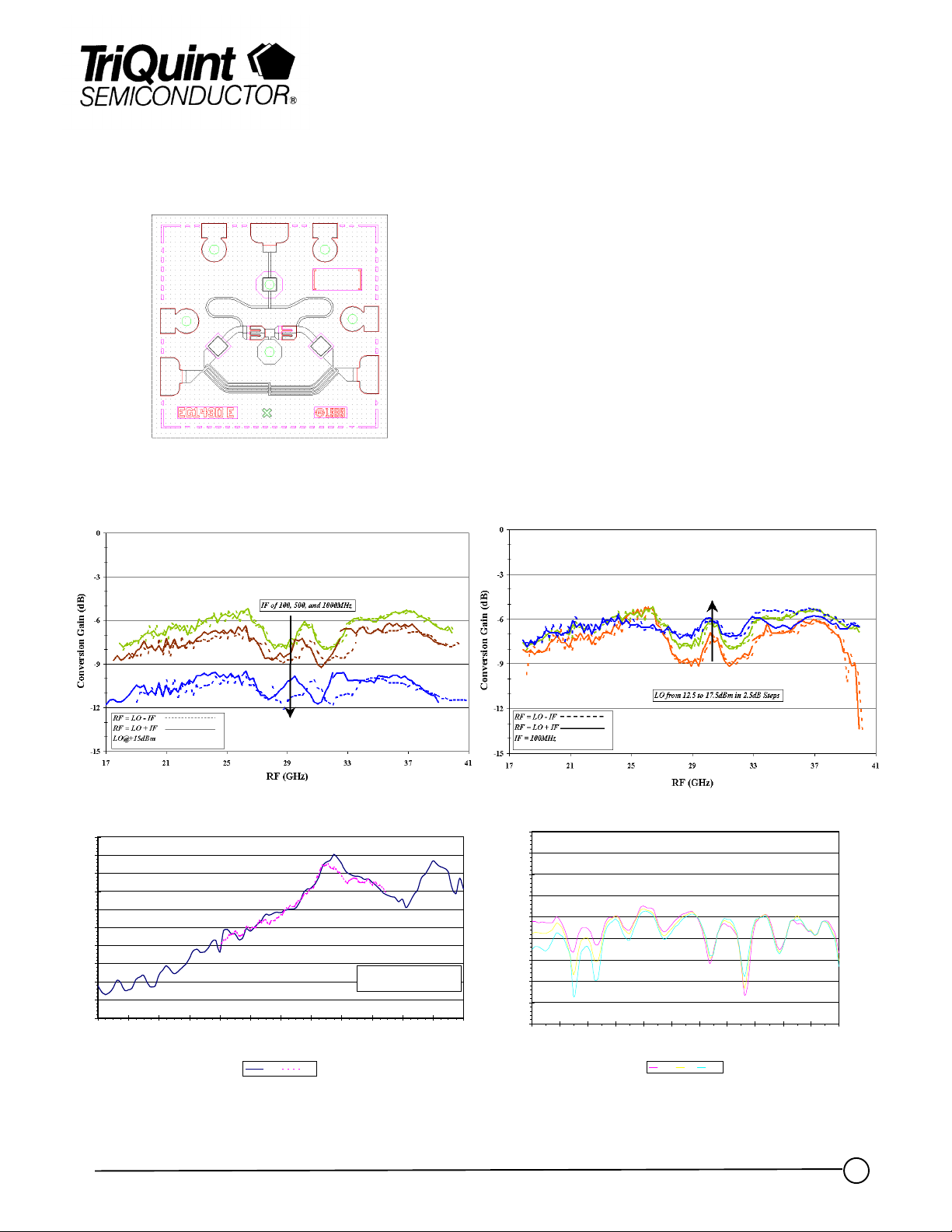

Single-Balanced Down Converter TGC1430E

Key Features and Performance

• 0.25um pHEMT Technology

• 20-40 GHz RF/LO Range

• DC -1GHz IF

• -8 dB conversion Gain at 500MHz IF

• +15dBm LO drive

Primary Applications

• Point-to-Point Radio

Chip Dimensions 1.26 mm x 1.19 mm

• Point-to-Multipoint Communications

Conversion Gain vs IF Frequency

50

45

40

35

30

25

20

Isolatio n (dB

15

10

5

0

2 6 10 14 18 22 26 30 34 38 42 4 6 50

Fre quency ( GHz)

R2I L2I

O Drive Level = +15dBm

F Drive Level = -15dBm

RF and LO to IF Isolation

0

-5

-10

-15

-20

-25

-30

LO Return Loss (dB)

-35

-40

-45

18 20 22 24 26 28 30 32 34 36 38 40

Conversion Gain vs LO Drive

rive Level (dBm):

Freque ncy (GHz)

12.5 15 17.5

LO Return Loss

Note: Devices designated as EPU are typically early in their characterization process prior to finalizing all electrical and process

specifications. Specifications subject to change without notice

TriQuint Semiconductor Texas : Phone (972)994-8465 Fax (972)994 8504 Web: www.triquint.com

1

Page 2

Advance Product Information

August 29, 2000

TGC1430E

TGC1430E - Recommended Assembly Drawing

Note: Devices designated as EPU are typically early in their characterization process prior to finalizing all electrical and process

specifications. Specifications subject to change without notice

TriQuint Semiconductor Texas : Phone (972)994-8465 Fax (972)994 8504 Web: www.triquint.com

Page 3

Advance Product Information

Assembly Process Notes

Reflow process assembly notes:

•=

AuSn (80/20) solder with limited exposure to temperatures at or above 300ΓC

•=

alloy station or conveyor furnace with reducing atmosphere

•=

no fluxes should be utilized

•=

coefficient of thermal expansion matching is critical for long-term reliability

•=

storage in dry nitrogen atmosphere

Component placement and adhesive attachment assembly notes:

•=

vacuum pencils and/or vacuum collets preferred method of pick up

•=

avoidance of air bridges during placement

•=

force impact critical during auto placement

•=

organic attachment can be used in low-power applications

•=

curing should be done in a convection oven; proper exhaust is a safety concern

•=

microwave or radiant curing should not be used because of differential heating

•=

coefficient of thermal expansion matching is critical

August 29, 2000

TGC1430E

Interconnect process assembly notes:

•=

thermosonic ball bonding is the preferred interconnect technique

•=

force, time, and ultrasonics are critical parameters

•=

aluminum wire should not be used

•=

discrete FET devices with small pad sizes should be bonded with 0.0007-inch wire

•=

maximum stage temperature: 200ΓC

GaAs MMIC devices are susceptible to damage from Electrostatic Discharge. Proper precautions should

be observed during handling, assembly and test.

Note: Devices designated as EPU are typically early in their characterization process prior to finalizing all electrical and process

specifications. Specifications are subject to change without notice.

TriQuint Semiconductor Texas : Phone (972)994-8465 Fax (972)994 8504 Web: www.triquint.com

Loading...

Loading...