Page 1

Advance Product Information

q

)

()

q

)

Feb 4, 2000

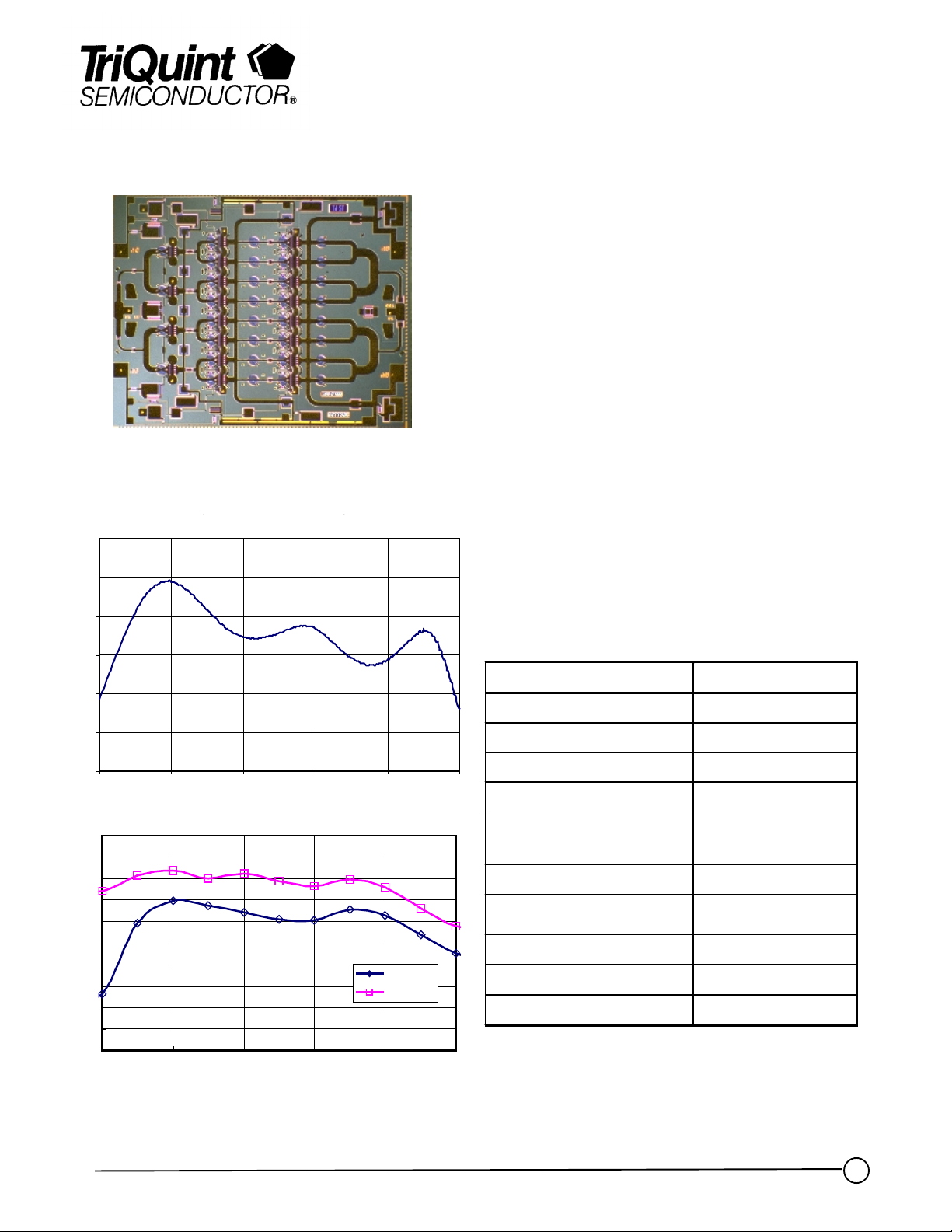

33-36 GHz 2W Power Amplifier TGA1141

Key Features

• 0.25 um pHEMT Technology

• 17 dB Nominal Gain

• 31 dBm Pout @ P1dB,

• Psat 33dBm @ 6V , 34dBm @7V

• Bias 6 - 7V @ 1.5A

Primary Applications

• Military Radar Systems

Chip Dimensions 4.13 mm x 3.3 mm

22

20

18

16

14

Small-signal Gain (dB)

12

10

30 32 34 36 38 40

35

34

33

32

31

30

29

Pout (dBm)

28

27

26

25

32 33 34 35 36 37

Wafer Lot 9918802-1, -2, -3, +6V, ~ 880mA

uency (GHz

Fre

uency (GHz

Fr e

P1 dB _ a v e

Psat_av e

• Ka Band Sat-Com

• Point-to-Point Radio

Performance Summary Table

Description

Frequency range

Small signal gain

Input return loss

Output return loss

Output power

PAE

Operating temperature range

Ids

Vds

Die size

Performance Evaluation

Fixtured with Flare TFNs

33 to 36 GHz

> 17 dB nom, 34 - 35.2 GHz

> 17 dB nom, 33 - 36 GHz

~ 5 dB nom, 34 - 35.2 GHz

~ 5 dB nom. 33 – 36 GHz

> 8 dB nom, 34 - 35.2 GHz

> 7 dB nom, 33 - 36 GHz

32.3dBm min. 34 –35.2 GHz

31.5dBm min, 34 – 35.2 GHz

over temp.

> 20% +25C

Tested under –26, +25, &

+100C

Predict: -43C

< 1.5 A max over operating

frequency and Temp. range

+ 6 V

4.134 mm x 3.300 mm

13.6mm

2

Note: Devices designated as EPU are typically early in their characterization process prior to finalizing all electrical and process

specifications. Specifications are subject to change without notice

TriQuint Semiconductor Texas : Phone (972)994-8465 Fax (972)994 8504 Web: www.triquint.com

1

Page 2

Advance Product Information

()

q

)

()

Measured Average Small Signal Data

Wafer Lot 9918802-1, -2, -3, +6V, ~ 880mA

22

20

18

Feb 4, 2000

TGA1141

S21

S11,S22

16

14

Small-signal Gain (dB)

12

10

30 32 34 36 38 40

Fre

uency (GHz

Wafer Lot 9918802-1, -2, -3, +6V, ~ 880mA

0

-2

-4

-6

-8

S11

S22

-10

Input & Output Return Loss (dB)

-12

-14

30 32 34 36 38 40

Note: Devices designated as EPU are typically early in their characterization process prior to finalizing all electrical and process

specifications. Specifications are subject to change without notice.

TriQuint Semiconductor Texas : Phone (972)994-8465 Fax (972)994 8504 Web: www.triquint.com

Frequency (GHz)

2

Page 3

Advance Product Information

(

)

q

)

Feb 4, 2000

Pout

PAE

Measured Power Data

35

34

33

32

31

30

29

Pout (dBm)

28

27

26

25

32 33 34 35 36 37

30

28

26

24

22

20

PAE (%)

18

16

14

12

10

32 33 34 35 36 37

35

Fr e

uency (GHz

Freque ncy (GHz)

P1dB_ave

Ps at_ave

PAE@P1dB

PA E@ Ps at

TGA1141

34.5

34

Psat vs Vd

Note: Devices designated as EPU are typically early in their characterization process prior to finalizing all electrical and process

specifications. Specifications are subject to change without notice.

TriQuint Semiconductor Texas : Phone (972)994-8465 Fax (972)994 8504 Web: www.triquint.com

33.5

33

32.5

(dBm)

out

32

P

31.5

31

30.5

30

32 33 34 35 36 37

Freque ncy (GHz)

+6V

+7V

3

Page 4

Advance Product Information

()

(

)

Pout, Gain vs. Pin at -26C, +25C and +100C

w9918802-1 Dev 2505: 34.0GHz +6V

Feb 4, 2000

TGA1141

35

33

31

29

27

25

23

Pout (dBm)

21

19

17

15

0 5 10 15 20 25

20

19

18

17

16

15

14

13

12

11

10

Pout +25C

Pout +100C

Pout - 26C

Gai n +2 5 C

Gain (dB)

Gain +100C

Gain -26C

dBm

Pi n

Pout vs. Temperature Data Summary Matrix:

T= -26C T= +25C T= +100C

Freq (GHz) min Pout mean Pout min Pout mean Pout min Pout mean Pout

34 33 33 32.7 32.8 31.9 32

34.6 32.8 32.9 32.5 32.6 31.7 31.8

35.2 32.5 32.7 32.3 32.4 31.5 31.6

Ave. Pout (dBm) 32.8 32.9 32.5 32.6 31.7 31.8

Note: Devices designated as EPU are typically early in their characterization process prior to finalizing all electrical and process

specifications. Specifications are subject to change without notice.

TriQuint Semiconductor Texas : Phone (972)994-8465 Fax (972)994 8504 Web: www.triquint.com

4

Page 5

Advance Product Information

Feb 4, 2000

TGA1141

Chip Assembly and Bonding Diagram

GaAs MMIC devices are susceptible to damage from Electrostatic Discharge. Proper precautions should

be observed during handling, assembly and test.

Note: Devices designated as EPU are typically early in their characterization process prior to finalizing all electrical and process

specifications. Specifications are subject to change without notice.

TriQuint Semiconductor Texas : Phone (972)994-8465 Fax (972)994 8504 Web: www.triquint.com

5

Page 6

Advance Product Information

Assembly Process Notes

Reflow process assembly notes:

•=

AuSn (80/20) solder with limited exposure to temperatures at or above 300ΓC

•=

alloy station or conveyor furnace with reducing atmosphere

•=

no fluxes should be utilized

•=

coefficient of thermal expansion matching is critical for long-term reliability

•=

storage in dry nitrogen atmosphere

Component placement and adhesive attachment assembly notes:

•=

vacuum pencils and/or vacuum collets preferred method of pick up

•=

avoidance of air bridges during placement

•=

force impact critical during auto placement

•=

organic attachment can be used in low-power applications

•=

curing should be done in a convection oven; proper exhaust is a safety concern

•=

microwave or radiant curing should not be used because of differential heating

•=

coefficient of thermal expansion matching is critical

Feb 4, 2000

Interconnect process assembly notes:

•=

thermosonic ball bonding is the preferred interconnect technique

•=

force, time, and ultrasonics are critical parameters

•=

aluminum wire should not be used

•=

discrete FET devices with small pad sizes should be bonded with 0.0007-inch wire

•=

maximum stage temperature: 200ΓC

GaAs MMIC devices are susceptible to damage from Electrostatic Discharge. Proper precautions should

be observed during handling, assembly and test.

Note: Devices designated as EPU are typically early in their characterization process prior to finalizing all electrical and process

specifications. Specifications are subject to change without notice.

TriQuint Semiconductor Texas : Phone (972)994-8465 Fax (972)994 8504 Web: www.triquint.com

6

Loading...

Loading...