Page 1

Advance Product Information

Feb 4, 2000

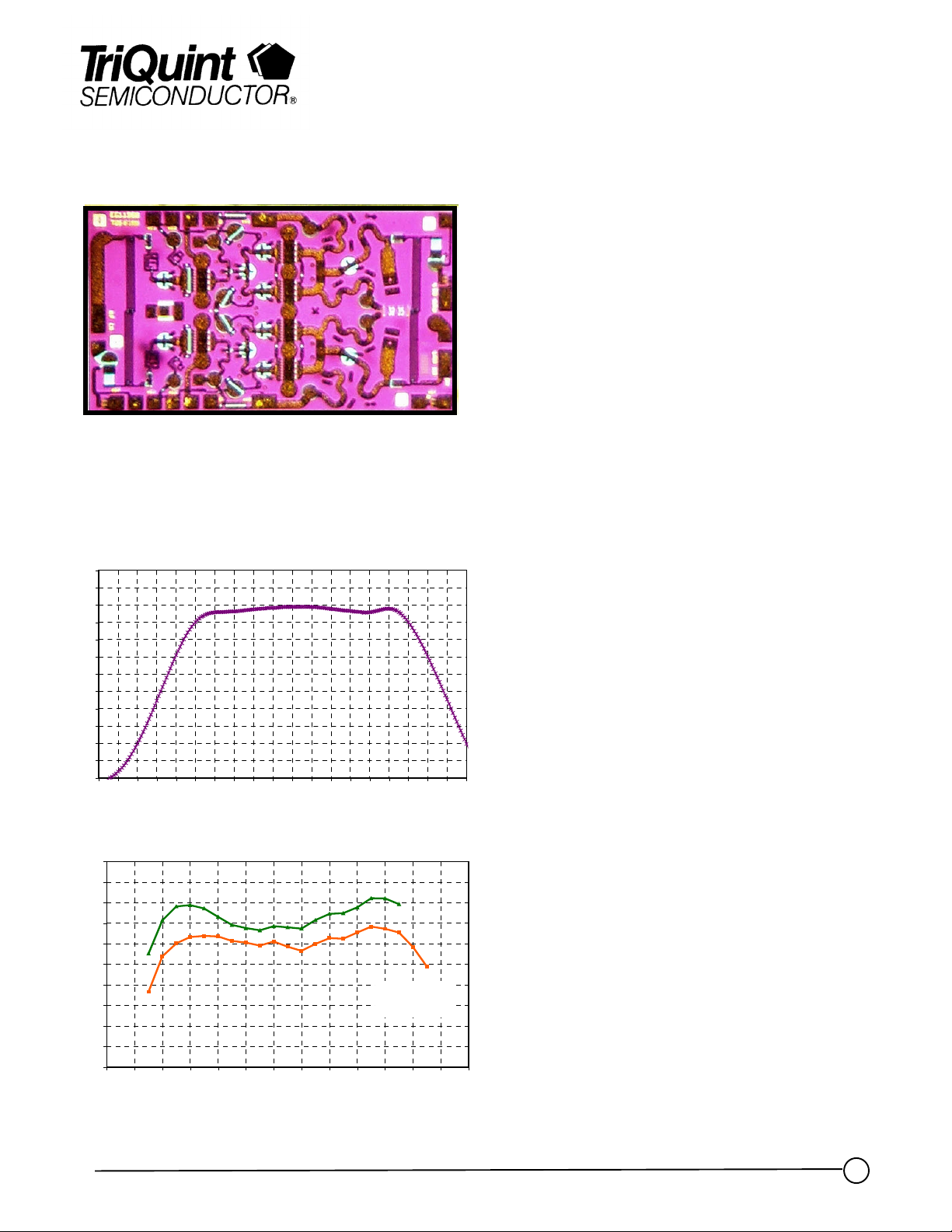

18-27.5 GHz 1W Power Amplifier TGA1135B

Key Features

• 0.25 um pHEMT Technology

• 14 dB Nominal Gain at 23GHz

• 30 dBm Nominal P1dB

• 38dBm OTOI typical

• Typical 15dB Input/Output RL

• Bias 6 - 7V @ 540 mA

• On-chip power detector diode

Chip Dimensions 2.641 mm x 1.480 mm

TGA1135B Fixtured Amplifier Typical Small Signal Data

18

16

14

12

10

8

6

S21 (dB)

4

2

0

-2

-4

-6

13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

32

31.5

31

30.5

30

29.5

P1dB (dBm)

29

28.5

28

27.5

27

16 17 18 19 20 21 22 23 24 25 26 27 28 29

Wafer 993150303, 6V/540mA

Frequency (GHz)

TGA1135B Nominal Ou tput Power

Wafer 993150303, Idq=540mA

Frequency (GHz)

VD = 7V

Note: 1 dB of

compress ion not

reached on some parts

at 27, 27.5 GHz

Primary Applications

• Point-to-Point Radio

• Point-to-Multipoint Communications

• Ka Band Sat-Com

VD = 6V

Note: Devices designated as EPU are typically early in their characterization process prior to finalizing all electrical and process

specifications. Specifications are subject to change without notice

TriQuint Semiconductor Texas : Phone (972)994-8465 Fax (972)994 8504 Web: www.triquint.com

1

Page 2

Advance Product Information

,

Feb 4, 2000

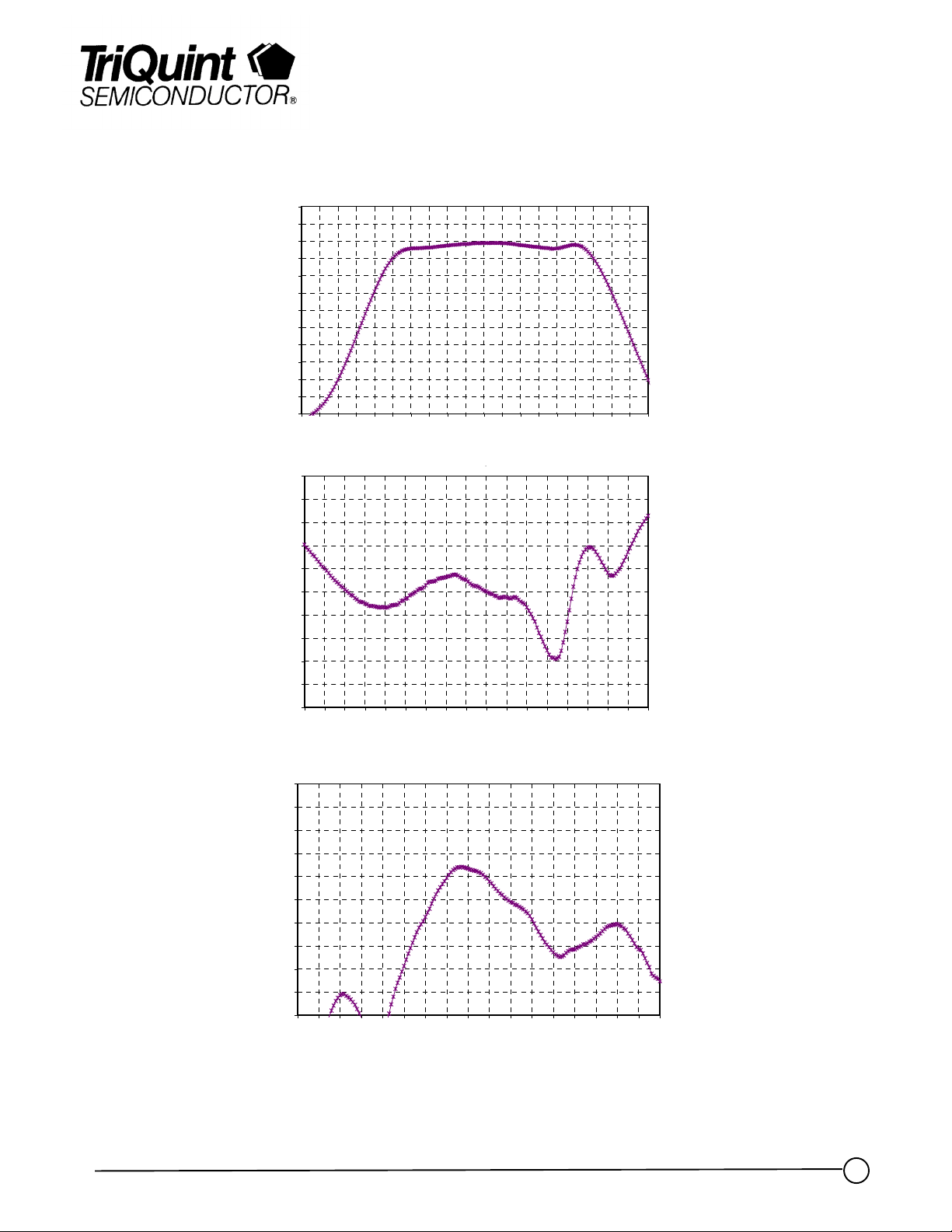

S21

S11

Measured small signal data

6V, 540mA

18

16

14

12

10

8

6

S21 (dB)

4

2

0

-2

-4

-6

13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

-5

-7

-9

-11

-13

-15

S11 (dB)

-17

-19

-21

-23

-25

15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

Frequency (GH z)

Frequency (GHz)

TGA1135B

-5

-7

-9

-11

-13

S22

-15

S22 (dB)

-17

-19

-21

-23

-25

15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

Frequency (GHz)

Note: Devices designated as EPU are typically early in their characterization process prior to finalizing all electrical and process

specifications. Specifications are subject to change without notice.

TriQuint Semiconductor Texas : Phone (972)994-8465 Fax (972)994 8504 Web: www.triquint.com

2

Page 3

32

31.5

31

30.5

Advance Product Information

Feb 4, 2000

TGA1135B

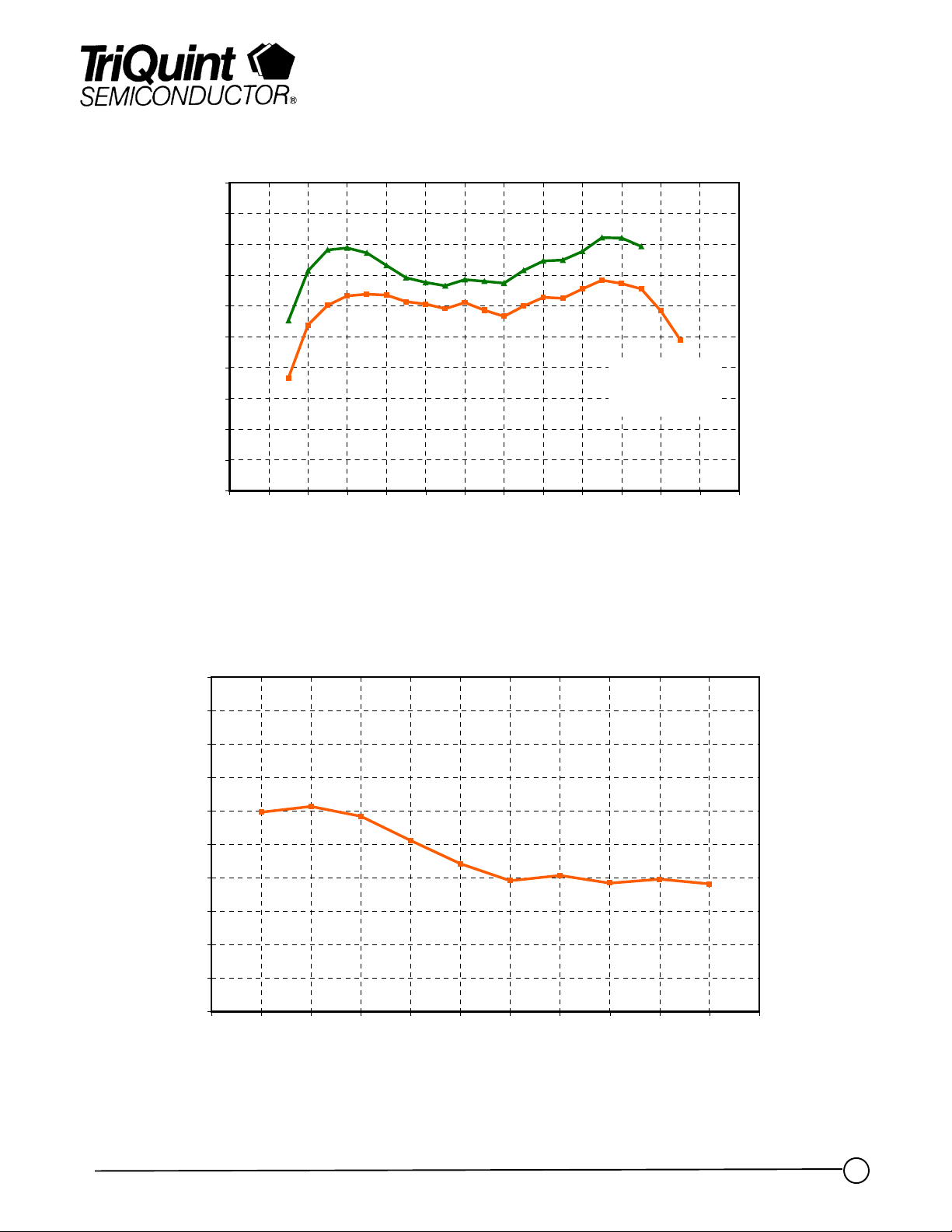

TGA1135B Nominal Output Power

Wafer 993150303, Idq=540mA

VD = 7V

30

29.5

P1dB (dBm)

29

28.5

28

27.5

27

16 17 18 19 20 21 22 23 24 25 26 27 28 29

Frequency (GHz)

Note: 1 dB of

compression not

reached on some parts

at 27, 27.5 GHz

P1dB Measured Data

TOI performance @ Pin SCL=7dBm: Vd=6V, Id=540mA, separation = 10MHz

43

42

41

TGA1135B wafer 993150303 nominal performance

VD = 6V

40

39

38

TOI (dBm)

37

36

35

34

33

17 18 19 20 21 22 23 24 25 26 27 28

Frequency (GHz)

Output TOI Measured Data

Note: Devices designated as EPU are typically early in their characterization process prior to finalizing all electrical and process

specifications. Specifications are subject to change without notice.

TriQuint Semiconductor Texas : Phone (972)994-8465 Fax (972)994 8504 Web: www.triquint.com

3

Page 4

Advance Product Information

VG1 VG2 GND DQ VD

Q1a Q2a

Feb 4, 2000

TGA1135B

DET

OUT

600µµµµm

RF IN

Q1b

600µµµµm

Reference

diode 2

REF3 GND VG1 VG2 GND DQ

Note: no DC current

allowed into the “DQ” pad

Q2b

1200µµµµm

1200µµµµm

Note:

drains not

connected

on lot

9931503

VD

Note: If drain bias is from one side

only, maximum Id is 440mA

PWR

DET

RF OUT

Reference

diode 1

REF2REF1

DC Schematic

Note: Devices designated as EPU are typically early in their characterization process prior to finalizing all electrical and process

specifications. Specifications are subject to change without notice.

TriQuint Semiconductor Texas : Phone (972)994-8465 Fax (972)994 8504 Web: www.triquint.com

4

Page 5

0.686

RF IN

Advance Product Information

Feb 4, 2000

TGA1135B

m)

µ

µ

µ

µ

DET

OUT

0.095

0.612: VG2

0.875: DQ

1.253: VD

(180x100

2.543

2.641

1.480

0.833

PWR DET

(175x100

µµµµ

m)

0.000

0.000

REF 1: 0.220

Dimensions in mm

RF I/O Pad: 200x100 mm

DC Pads: 105x105 mm

Die Area: 3.909 mm

2

VG2: 0.612

DQ: 0.875

0.373

RF OUT

0.098

m)

µ

µ

µ

µ

VD: 1.253

(180x100

REF 2: 2.543

REF 3: 2.360

Note: Devices designated as EPU are typically early in their characterization process prior to finalizing all electrical and process

specifications. Specifications are subject to change without notice.

TriQuint Semiconductor Texas : Phone (972)994-8465 Fax (972)994 8504 Web: www.triquint.com

5

Page 6

Advance Product Information

TGA1135B built-in power detector

Feb 4, 2000

TGA1135B

V

det

100pF

RF

IN

TGA1135B with external test coupler

(amplifier bias connections not shown)

On-chip diode functions as envelope detector

External coupler and DC bias required

100pF

V

bias

RF

OUT

ΩΩΩΩ

EG1135B measured detector voltage offset vs output power with

20dB coupler: Vb=0.8V, f = 20GHz, Coupler loss is uncalibrated,

10

1

0.1

Detector voltage (V)

0.01

8 101214161820222426283032

Note: Devices designated as EPU are typically early in their characterization process prior to finalizing all electrical and process

specifications. Specifications are subject to change without notice.

ΩΩΩΩ

10K

Pout (dBm)

load

10K

Video out

(V

)

det

EG1135B

C=2pF

RF

OUT

External

DC bias

External coupler

TriQuint Semiconductor Texas : Phone (972)994-8465 Fax (972)994 8504 Web: www.triquint.com

(-20dB)

50

ΩΩΩΩ

RF

OUT

6

Page 7

Vg (optional)

0.01µµµµF

0.01µµµµF

DQ

Advance Product Information

Feb 4, 2000

TGA1135B

Vd

Input TFN

Vg

100pF

100pF

0.01µµµµF

DQ

0.01µµµµF

100pF

100pF

Vd

Output TFN

Notes:

1. 1µµµµF capacitor on gate, drain lines not

shown but required

2. 0.01µµµµF capacitor may be connected to

“DQ” port as shown, or may be included

on drain line

3. Vg connection is recommended on

both sides for devices operating at or

above P1dB

Chip Assembly and Bonding Diagram

GaAs MMIC devices are susceptible to damage from Electrostatic Discharge. Proper precautions should

be observed during handling, assembly and test.

Note: Devices designated as EPU are typically early in their characterization process prior to finalizing all electrical and process

specifications. Specifications are subject to change without notice.

TriQuint Semiconductor Texas : Phone (972)994-8465 Fax (972)994 8504 Web: www.triquint.com

7

Page 8

Advance Product Information

Assembly Process Notes

Reflow process assembly notes:

•=

AuSn (80/20) solder with limited exposure to temperatures at or above 300ΓC

•=

alloy station or conveyor furnace with reducing atmosphere

•=

no fluxes should be utilized

•=

coefficient of thermal expansion matching is critical for long-term reliability

•=

storage in dry nitrogen atmosphere

Component placement and adhesive attachment assembly notes:

•=

vacuum pencils and/or vacuum collets preferred method of pick up

•=

avoidance of air bridges during placement

•=

force impact critical during auto placement

•=

organic attachment can be used in low-power applications

•=

curing should be done in a convection oven; proper exhaust is a safety concern

•=

microwave or radiant curing should not be used because of differential heating

•=

coefficient of thermal expansion matching is critical

Feb 4, 2000

Interconnect process assembly notes:

•=

thermosonic ball bonding is the preferred interconnect technique

•=

force, time, and ultrasonics are critical parameters

•=

aluminum wire should not be used

•=

discrete FET devices with small pad sizes should be bonded with 0.0007-inch wire

•=

maximum stage temperature: 200ΓC

GaAs MMIC devices are susceptible to damage from Electrostatic Discharge. Proper precautions should

be observed during handling, assembly and test.

Note: Devices designated as EPU are typically early in their characterization process prior to finalizing all electrical and process

specifications. Specifications are subject to change without notice.

TriQuint Semiconductor Texas : Phone (972)994-8465 Fax (972)994 8504 Web: www.triquint.com

8

Loading...

Loading...