Page 1

DATA SH EET

Preliminary specification

File under Integrated Circuits, IC02

1999 Sep 24

INTEGRATED CIRCUITS

TDA9178

YUV one chip picture improvement

based on luminance vector-, colour

vector- and spectral processor

Page 2

1999 Sep 24 2

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

TDA9178

FEATURES

• Picture content dependent non-linear Y, U and V

processing by luminance histogram analysis

• Variable gamma control

• Adaptive black and white stretch control

• Skin tone correction

• Green enhancement

• Blue stretch

• Luminance Transient Improvement (LTI)

• Smart peaking for detail enhancement

• Colour Transient Improvement (CTI)

• SCAn VElocity Modulation (SCAVEM) output

• Line Width Control (LWC)

• Video Dependent Coring (VDC)

• Colour Dependent Sharpness (CDS)

• Noise measurement

• Feature Mode (FM) detector

• Cue Flash (CF) detector

• Three additional pins for access to 6-bit ADC and

I2C-bus

• Adjustable chrominance delay

• TV standard independent

• I2C-bus controlled

• 1fH and 2f

H

• DEmonstration MOde (DEMO).

GENERAL DESCRIPTION

The TDA9178 is a transparent analog video processor

with YUV input and output interfaces. It offers three main

functions: luminance vector processing, colour vector

processing and spectral processing. Beside these three

main functions, there are some additional functions.

In the luminancevector processor, the luminance transfer

function is controlled in a non-linear way by the

distribution, in 5 discrete histogram sections, of the

luminance values measured in a picture. As a result, the

contrast ratio of the most important parts of the scene will

be improved. Black restoration is available in the event of

a set-up in the luminance signal.

A variable gamma function, after the histogram

conversion,offersthepossibilitiesofalternativebrightness

control or factory adjustment of the picture tube.

The adaptive black stretch function of the TDA9178 offers

the possibility of having a larger ‘weight’ for the black parts

of the video signal; the white stretch function offers an

additional overall gain for increased light production.

To maintain a proper colour reproduction, the saturation of

theU- and V-colour difference signals is also controlledas

a function of the actual non-linearity in the luminance

channel.

In the colour vector processor, the dynamic skin tone

correction locally changes the hue of colours that match

skin tones to the correct hue. The green enhancement

circuit activates medium saturated green towards to more

saturated green. The blue stretch circuit can be activated

which shifts colours near white towards blue.

The spectral processor provides 1D luminance transient

improvement, luminance detail enhancement by smart

peaking and a 1 D colour transient improvement.

The TDA9178 can be used as a cost effective alternative

to (but also in combination with) scan velocity modulation.

In the spectral processor line width control (or aperture

control) can be user defined. The TDA9178 is capable of

adjusting the amount of coring according to the video level

with the video dependent coring. The TDA9178 is also

capable to give extra sharpness in the cases of saturated

red and magenta parts of the screen using the colour

dependent sharpness feature.

An embedded noise detector measures noise during the

field retrace in parts which are expected to be free from

video or text information. With the noise detector a variety

of ‘smart noise control’ architectures can be set up.

A feature mode detector is available for detecting signal

sources like VCR (in still picture mode) that re-insert the

levels of the retrace part. For this kind of signals the noise

measurement of the TDA9178 is not reliable.

An output signal (on the I2C-bus and on a separate pin) is

available that detects when the picture content has been

changed significantly, called cue flash.

An embedded 6-bit ADC can be used for interfacing three

analog low frequency voltage signals (e.g. ambient light

control or beam current voltage level) to the I2C-bus.

Page 3

1999 Sep 24 3

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

TDA9178

In the demonstration mode all the features selected by the user are automatically toggled between on and off.

The TDA9178 concept has a maximum flexibility which can be controlled by the embedded I2C-bus. The supply voltage

is 8 V. The device is mounted in a 24-lead SDIP package, or in a 24-lead SO package.

QUICK REFERENCE DATA

ORDERING INFORMATION

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

CC

supply voltage 7.2 8.0 8.8 V

V

i(Y)

luminance input voltage (excluding sync) AMS = 0 − 0.315 0.45 V

AMS = 1 − 1.0 1.41 V

V

i(UV)

UV input voltage −−1.9 V

V

FS(ADC)

full-scale ADC input voltage − 2.0 − V

TYPE

NUMBER

PACKAGE

NAME DESCRIPTION VERSION

TDA9178 SDIP24 plastic shrink dual in-line package; 24 leads (400 mil) SOT234-1

TDA9178T SO24 plastic small outline package; 24 leads; body width 7.5 mm SOT137-1

Page 4

1999 Sep 24 4

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

TDA9178

This text is here in white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here in

_white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here inThis text is here in

white to forcelandscapepages to be rotated correctly when browsing through the pdf in the Acrobat reader. white to force landscape pages to be ...

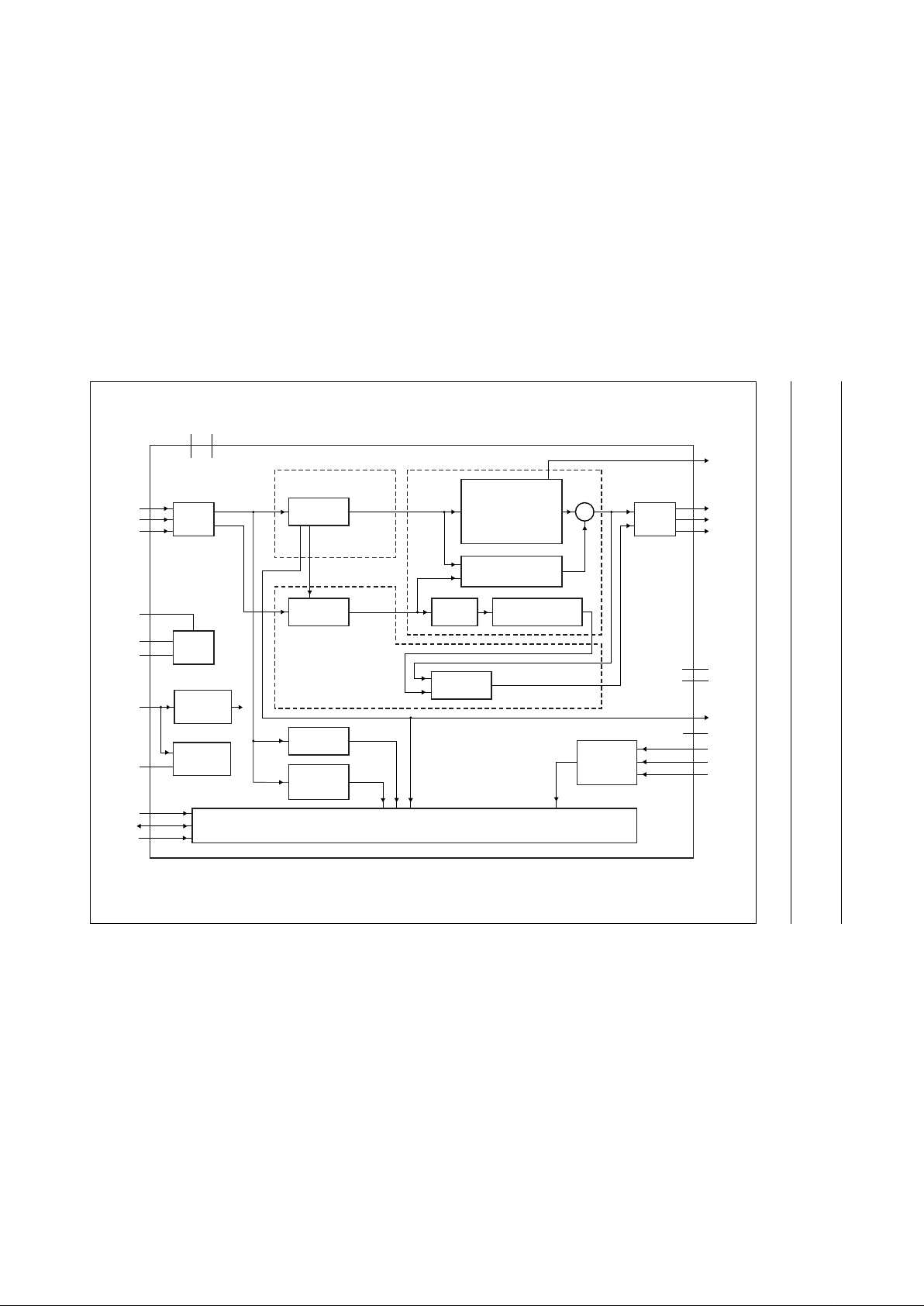

BLOCK DIAGRAM

handbook, full pagewidth

MGR897

VIDEO DEPENDENT

CORING

LUMINANCE TRANSIENT

IMPROVEMENT

SMART PEAKING

COLOUR DEPENDENT

SHARPNESS

COLOUR

PROCESSING

SATURATION

CORRECTION

LUMINANCE

PROCESSING

OUTPUT

STAGE

COLOUR TRANSIENT

IMPROVEMENT

DELAY

CONTROL

YOUT

UOUT

VOUT

19

SOUT

21

CF

22

17

16

NOISE

MEASURING

FEATURE

MODE

DETECTION

INPUT

STA GE

YIN

UIN

VIN

6

n.c.12n.c.

13

8

9

WINDOW

GENERATION

SC

1

SUPPL Y

V

CC

V

EE

20

15

18

SDA

14

ADR

7

SCL

11

ANALOG

TO

DIGITAL

CONVERTER

ADEXT1

ADEXT2

ADEXT3

3

n.c.

2

n.c.

23

n.c.

24

4

5

spectral processingluminance vector processing

colour vector

processing

black stretch

histogram processing

gamma control

skin tone correction

green enhancement

blue stretch

Y

U, V

cue flash

I2C-BUS CONTROL

DEC

DIG

CALIBRATE

TP

10

+

Fig.1 Block diagram.

Page 5

1999 Sep 24 5

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

TDA9178

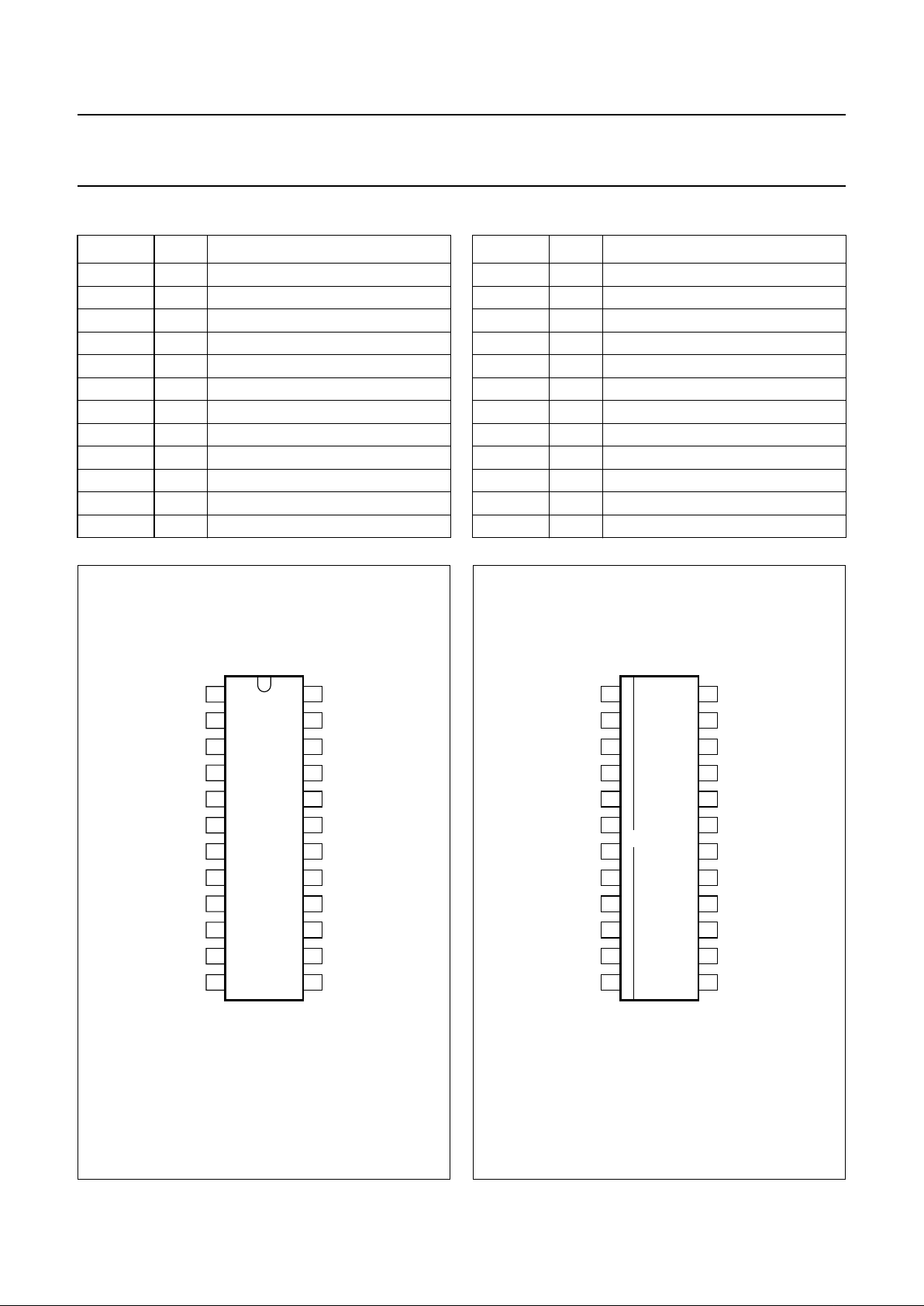

PINNING

SYMBOL PIN DESCRIPTION

SC 1 sandcastle input

n.c. 2 not connected

ADEXT1 3 ADC input 1

ADEXT2 4 ADC input 2

ADEXT3 5 ADC input 3

YIN 6 luminance input

ADR 7 address selection input

UIN 8 U signal input

VIN 9 V signal input

TP 10 test pin

SCL 11 serial clock input (I

2

C-bus)

n.c. 12 not connected

n.c. 13 not connected

SDA 14 serial data input/output (I

2

C-bus)

DEC

DIG

15 decoupling digital supply

VOUT 16 V signal output

UOUT 17 U signal output

V

EE

18 ground

YOUT 19 luminance output

V

CC

20 supply voltage

SOUT 21 SCAVEM output

CF 22 cue flash output

n.c. 23 not connected

n.c. 24 not connected

SYMBOL PIN DESCRIPTION

Fig.2 Pin configuration (SOT234-1).

handbook, halfpage

SC

n.c.

ADEXT1

ADEXT2

ADEXT3

YIN

ADR

UIN

VIN

TP

SCL

n.c.

n.c.

n.c.

CF

SOUT

YOUT

V

EE

V

CC

UOUT

VOUT

DEC

DIG

SDA

n.c.

1

2

3

4

5

6

7

8

9

10

11

12

24

23

22

21

20

19

18

17

16

15

14

13

TDA9178

MGR898

Fig.3 Pin configuration (SOT137-1).

handbook, halfpage

SC

n.c.

ADEXT1

ADEXT2

ADEXT3

YIN

ADR

UIN

VIN

TP

SCL

n.c.

n.c.

n.c.

CF

SOUT

YOUT

V

EE

V

CC

UOUT

VOUT

DEC

DIG

SDA

n.c.

1

2

3

4

5

6

7

8

9

10

11

12

24

23

22

21

20

19

18

17

16

15

14

13

TDA9178T

MGR899

Page 6

1999 Sep 24 6

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

TDA9178

FUNCTIONAL DESCRIPTION

Y input selection and amplification

The gain of the luminance input amplifier and output

amplifier can be adjusted to signal amplitudes of

0.315 and 1.0 V typically (excluding sync) by I2C-bus

bit AMS. The sync part is processed transparently to the

output, independently of the feature settings.

The Y, U and V input signals are clamped during the

burstkey period, defined by the sandcastle reference and

should be DC-coupled (the circuit uses internal clamp

capacitors). During the clamp pulse (see Figs 7, 8, 9

and 10) an artificial black level is inserted in the Y input

signal to correctly preset the internal circuitry.

Luminance vector processor

Intheluminancevectorprocessorthetransfer is controlled

bya black stretch, the histogramprocessing and a gamma

control circuit. The luminance vector processor also

creates the cue flash signal.

BLACK STRETCH

Ablack detector measures and stores thelevelof the most

black part of the scene within an internal defined fixed

window in each field into a time constant. The time

constant and the response time of the loop are internally

fixed. Any difference between this value and the value

measured during the clamp is regarded as black offset.

In a closed loop offsets until a predefined value of the fullscale value are fed back to the input stage for

compensation.The loop gain is afunction of the histogram

and variable gamma settings. The black offset correction

can be switched on and off by the I2C-bus bit BON.

Related to the corrected black offset the nominal signal

amplitude is set again to 100% full scale through an

amplitude stretch function. Luminance values beyond full

scale are unaffected. Additionally, the measured black

offset is also used to set the adaptive black stretch gain

(see also Section “Adaptive black stretch”).

HISTOGRAM PROCESSING

For the luminance signal the histogram distribution is

measured in real-time over five segments within an

internally defined fixed window in each field. During the

period that the luminance is in one segment, a

corresponding internal capacitor is loaded by a current

source. At the end of the field five segment voltages are

stored into on-board memories. The voltages stored in the

memories determine the non-linear processing of the

luminance signal to achieve a picture with a maximum of

information (visible details).

Each field the capacitors are discharged and the

measurement starts all over again.

Parts in the scene that do not contribute to the information

inthatscene,likesub or side titles,should be omitted from

the histogram measurement. No measurements are

performed outside the internal fixed window period.

Very rapid picture changes, also related to the field

interlace,canresultinflickereffects.The histogram values

are averaged at the field rate thus cancelling the flicker

effects.

Adaptive black stretch

The so-called adaptive black stretch gain is one of the

factors that control the gamma of the picture. This gain is

controlled by the measured black offset value in the black

stretch circuit and theI2C-bus adaptive black stretchDAC:

bits BT5 to BT0. For pictures with no black offset the black

stretchgainequalsunitysothegammaisnotchanged and

the DAC setting has no influence. In case of a black offset,

the black stretch gain is increased so the gamma of the

pictureis reduced. This procedure results in amaximumof

visible details over the whole range of luminances.

However, depending on personal taste, sometimes higher

values of gamma are preferred. Therefore the amount of

gamma reduction can be adjusted by the DAC.

Adaptive white-point stretching

Forpictureswithmany details in white parts, the histogram

conversion procedure makes a transfer with large gain in

the white parts. The amount of light coming out of the

scene is reduced accordingly. The white stretcher

introduces additional overall gain for increased light

production, and so violating the principle of having a

full-scale reference. The white-point stretching can be

switched on or off by means of the I2C-bus bit WPO.

Standard deviation

Forscenesin which segments of the histogram distribution

areverydominant with respect to the others, the non-linear

amplification should be reduced in comparison to scenes

with a flat histogram distribution. The standard deviation

detectormeasuresthe spread of the histogram distribution

and modulates the user setting of the non-linear amplifier.

Non-linear amplifier

Thestoredsegmentvoltagesdeterminetheindividualgain

of each segment in such a way that continuity is granted

for the complete luminance range.

Page 7

1999 Sep 24 7

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

TDA9178

The maximum and minimum gain of each segment is

limited. Apart from the adaptive white-point stretching the

black and white references are not affected by the

non-linear processing. The amount of non-linearity can be

controlled by the I2C-bus non-linearity DAC:

bits NL5 to NL0.

VARIABLE GAMMA

On top of the histogram conversion a variable gamma

function is applied for an alternative brightness control, or

for factory adjustment. It is intended as an alternative for

the DC-offset of the classic brightness user control.

It maintains the black and white references. The gamma

ranges from 0.5 to 1.5. The gamma can be set by the

I2C-bus variable gamma DAC: bits VG5 to VG0.

CUE FLASH

In the present TV environment there is a lot of measured

information like ambient light and noise. This information

can be used to make an update of settings of the several

algorithms after a picture has changed. The cue flash

signal detects when a picture changes significantly. When

the picture content has changed, the I2C-bus bit CF is set

to logic 1 in the status register. After reading the status

register, bit CF is reset to logic 0. On the output pin CF the

cue flash information is present (active LOW) for only one

line in the vertical retrace part. This pin is configured as an

open drain output and therefore should be pulled up to the

5 V supply.

Spectral processor

In the spectral processor the luminance transfer is

controlled by smart peaking, colour dependent sharpness

and luminance transient improvement, defined by the

sharpness improvement processor. The colour transfer is

controlled by a colour transient improvement circuit; an

additional output is available to provide a SCAVEM circuit.

ADJUSTABLE CHROMINANCE DELAY

The colour vector processor drives a delay line for

correctingdelayerrors between the luminance input signal

and the chrominance input signals (U and V).

The chrominance delay can be adjusted in 6 steps of

12 ns (1fH) or 6 ns (2fH) by the I2C-bus bits CD2 to CD0.

SHARPNESS IMPROVEMENT PROCESSOR

The sharpness improvement processor increases the

slope of large luminance transients of vertical objects and

enhancestransientsof details in natural scenes by contour

correction.

It comprises three main processing units: the step

improvement processor, the contour processor and the

smart sharpness controller.

Transient improvement processor

The step improvement processor (see Fig.11) comprises

two main functions:

• MINMAX generator

• MINMAX fader.

The MINMAX generator utilizes all taps of an embedded

luminance delay line to calculate the minimum and

maximumenvelopeofallsignalsmomentarilystored in the

delay line. The MINMAX fader chooses between the

minimum and maximum envelopes, depending on the

polarity of a decision signal derived from the contour

processor. Figures 12, 13 and 14 show some waveforms

of the step improvement processor and illustrate that fast

transients result with this algorithm. The MINMAX

generator also outputs a signal that represents the

momentary envelope of the luminance input signal.

This envelope information is used by the smart sharpness

controller.

Line width control (also called aperture control) can be

performed by I2C-bus line width DAC: bits LW5 to LW0.

This control can be used to compensate for horizontal

geometryerrorscausedby the gamma, for blooming of the

spot of the CRT, or for compensating SCAVEM.

Contour processor

The contour processor comprises two contour generators

with different frequency characteristics. The contour

generator generates a second-order derivative of the

incoming luminance signal which is supplied to the smart

sharpness controller. In the smart sharpness controller,

this signal is added to the properly delayed original

luminance input signal, making up the peaking signal for

detail enhancement. The peaking path features a low

peaking frequency of 2 MHz (at 1fH), or a high peaking

frequency of 3 MHz (at 1fH), selectable by I2C-bus

bit CFS.

The contour generators utilize three taps of the embedded

luminance delay line. Figure 15 illustrates the normalized

frequency transfer of the filter.

Page 8

1999 Sep 24 8

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

TDA9178

Smart sharpness controller

The smart sharpness controller (see Fig.16) is a fader

circuit that fades between peaked luminance and

step-improved luminance, controlled by the output of a

step discriminating device known as the step detector.

It also contains a variable coring level stage.

The step detector is basically a differentiator, so both

amplitude of the step and its slope add to the detection

criterion. The smart sharpness controller has four user

controls:

• Steepness control, performed by the I2C-bus DAC:

bits SP5 to SP0

• Peaking control, performed by the I2C-bus DAC:

bits PK5 to PK0

• Video dependent coring, switched on or switched off by

the I2C-bus bit VDC

• Coring level control, performed by the I2C-bus DAC:

bits CR5 to CR0.

Thesteepness setting controls the amountof steepness in

the edge-correction processing path.

The peaking setting controls the amount of contour

correction for proper detail enhancement. The envelope

signal generated by the step improvement processor

modulates the peaking setting in order to reduce the

amount of peaking for large sine wave excursions.

With video dependent coring, it is possible to have more

reduction of the peaking in the black parts of a scene than

inthewhiteparts,andthereforeautomaticallyreducing the

visibility of the background noise.

The coring setting controls the coring level in the peaking

path for rejection of high-frequency noise.

All four settings facilitate reduction of the impact of the

sharpness features, e.g. for noisy luminance signals.

COLOUR DEPENDENT SHARPNESS

The colour dependent sharpness circuit increases the

luminance sharpness in saturated red and magenta parts

of the screen. Because of the limited bandwidth of the

colour signals, there is no need to increase the high

frequenciesofthecolour signals. Instead, the details in the

luminance signal will be enhanced. In this circuit a limited

number of colours are enhanced (red and magenta).

Contrarytonormal peaking algorithm, extra gain is applied

for low frequencies (2 MHz at 1fH). This is needed,

because the information that is lacking below 2 MHz (at

1fH) is most important. In large coloured parts the normal

peaking is still active to enhance the fine details.

The smart peaking algorithm has been designed such that

the luminance output amplitude will never exceed 110% of

the luminance input signal amplitude. Therefore the

normal peaking range (12 dB) will be reduced at large

transients, and in case of colour dependent sharpness

there is even more reduction.

However, by setting bit OSP (Overrule Smart Peaking)

onecan undo the extra peaking reduction in case ofcolour

dependant sharpness. It must be emphasized that setting

OSP may lead to unwanted large luminance output

signals, for instance in details in red coloured objects.

COLOUR TRANSIENT IMPROVEMENT

The colour transient improvement circuit (see Fig.17)

increases the slope of the colour transients of vertical

objects. Each channel of the CTI circuit basically consists

oftwodelaycells:anelectronicpotentiometerandanedge

detector circuit that controls the wiper position of the

potentiometer.Normally the wiper of the potentiometerwill

be in position B (mid position), so passing the input

signal B to the output with a single delay. The control

signal is obtained by the signals A and C.

When an edge occurs the value of the control signal will

fade between +1 and −1 and finally will become zero

again. A control signal value of +1 fades the wiper in

position C, passing the two times delayed input signal to

the output. A control signal of −1 fades the wiper in

position A, so an undelayed input signal is passed to the

output. The result is an output signal which has steeper

edges than the input signal. Contrary to other existing

CTI algorithms, the transients remain time correct with

respect to the luminance signal, as the algorithm steepens

edges proportionally, without discontinuity.

SCAVEM

A luminance output is available for SCAVEM processing.

This luminance signal is not affected by the spectral

processing functions.

Colour vector processor

The colour processing part contains skin tone correction,

green enhancement and blue stretch. The colour vector

processing is dependent on the amplitude and sign of the

colour difference signals. Therefore, both the polarity and

the nominal amplitude of the colour difference signals are

relevant when using the colour vector processor facility.

Page 9

1999 Sep 24 9

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

TDA9178

SKIN TONE CORRECTION

Skintones are very sensitive fortransmission (hue) errors,

because we have an absolute feeling for skin tones.

To make a picture look free of hue error, the goal is to

make sure that skin tones are put at a correct colour.

The dynamic skin tone correction circuit achieves this goal

by instantaneously and locally changing the hue of those

colours which are located in the area in the UV plane that

matches skin tones (see Fig.4).

The correction is dependent on luminance, saturation and

distance to the preferred axis and can be done towards

twodifferentangles. The preferred angle can be chosen by

bit ASK in the I2C-bus settings. The settings are

123° (ASK = 0) and 117° (ASK = 1). The enclosed

correction area can be increasedto 140% with the I2C-bus

bit SSK(so-called:Size). The enclosed detection ‘angle’ of

the correcting area can be increased to 160% with the

I2C-bus bit WSK (so-called: Width). The skin tone

correction can be switched on or off with the I2C-bus

bit DSK.

GREEN ENHANCEMENT

The green enhancement circuit (see Fig.5) is intended to

shift low saturated green colours towards more saturated

green colours. This shift is achieved by instantaneously

andlocallychangingthosecolourswhicharelocatedinthe

area in the UV plane that matches low saturated green.

The saturation shift is dependent on the luminance,

saturation and distance to the detection axis of 208°.

The direction of shift in the colour is fixed by hardware.

The amount of green enhancement can be increased to

160% by the I2C-bus bit GGR. The enclosed detection

‘angle’ of the correcting area can be increased to 160%

withthe I2C-busbit WGR (so-called: Width). The enclosed

correction area can be increasedto 140% with the I2C-bus

bit SGR (so-called: Size). The green enhancement can be

switched on or switched off with the I2C-bus bit DGR.

BLUE STRETCH

The blue stretch circuit (see Fig.6) is intended to shift

colours near white towards more blueish coloured white to

give a brighter impression. This shift is achieved by

instantaneously and locally changing those colours which

are located in the area in the UV plane that matches

colours near white. The shift is dependent on the

luminance and saturation. The direction of shift (towards

an angle of 330°) in the colour is fixed by hardware.

The amount of blue stretch can be increased to 160% by

the I2C-bus bit GBL.

Theenclosed correction area can be increased to 140% by

the I2C-bus bit SBL (so-called: Size). The blue stretch can

be switched on or off by the I2C-bus bit DBL.

SATURATION CORRECTION

The non-linear luminance processing done by the

histogram modification and variable gamma, influences

the colour reproduction; mainly the colour saturation.

Therefore, the U and V signals are linear processed for

saturation compensation.

Noise measuring

A video line which is supposed to be free from video

information(‘emptyline’)is used to measure the amount of

noise. The measured RMS value of the noise can be used

for reducing several features, by the I

2

C-bus interface,

such as luminance vector processing and spectral

processing. For the TDA9178 the empty line is chosen

three lines after recognition of the vertical blanking from

the sandcastle pulse input. Figures 7, 8, 9 and 10 show

the measurement locations for different broadcast norms.

The noise detector is capable of measuring the

signal-to-noise ratio between −45 and −20 dB. The output

scale runs linearly with dB. The noise samples are

averagedforover20 fields to reduce the fluctuations in the

measurement process. It is obvious, that for signal

sources (like VCR in still picture mode) that re-insert the

levels of the retrace part, the measurement is not reliable

(see Section “Feature mode detector”). The result of the

averaging process will update the contents of the I

2

C-bus

register: bits ND5 to ND0 at a rate of

1

⁄32 of the field

frequency. If a register access conflict occurs, the data of

the noise register is made invalid by setting the flag bit DV

(Data Valid) to zero.

Feature mode detector

A detector is available for detecting signal sources (like

VCR in still picture mode) that re-inserted the levels of the

retrace part. For this kind of signals the noise

measurement of the TDA9178 is not reliable, but this

detector sets bit FM in the ND-register to logic 1.

For normal video signals bit FM is set to logic 0.

This circuit measures transients (like synchronization

pulses) on the luminance input during the internal V-pulse.

Thefeaturemodedetector is setting bit FM to logic 1 when

no transients are present during 2 lines in the vertical

retrace part over 3 fields (like the synchronization pulses).

Page 10

1999 Sep 24 10

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

TDA9178

Successive approximation ADC

Pins ADEXT1, ADEXT2 and ADEXT3 are connected to a

6-bit successive approximation ADC via a multiplexer.

The multiplexertogglesbetweentheinputswitheachfield.

At each field flyback, a conversion is started for two of the

three inputs and the result is stored in the corresponding

bus register ADEXT1, ADEXT2 or ADEXT3. The input pin

ADEXT1 is updated every field, while input fields

ADEXT2 and ADEXT3 are updated once in two

consecutive fields (see Figs 7, 8, 9 and 10). Once in

32 fields the ADEXT2 input is not updated, because then

the noise measurement is updated.

In this way, any slow varying analog signal can be given

access to the I2C-bus. If a register access conflict occurs,

the data of that register is made invalid by setting the flag

bit DV (Data Valid) to zero.

Smart noise control

With the help of the internal noise detector and a

user-preferred noise algorithm, the user can make a fully

automatic I2C-bus feature reduction, briefly called ‘Smart

Noise Control’.

Demonstration mode

By the I2C-bus bit DEM all the picture improvement

features can be demonstrated in one picture. By setting

bit DEM to logic 1, all the features selected bythe user are

active for 5 s in 1fH mode (in 2fH mode: 2.5 s), and for

another 5 s in 1fH mode (in 2fH mode: 2.5 s) all features

selected are turned off (then the TDA9178 is ‘transparent’

to the incoming signal).

Internal window

To determine the histogram levels and the black offset the

TDA9178 performs several measurements. An internally

defined window serves to exclude parts in the scene like

‘subtitling’ or ‘logos’. The internal window can be regarded

as a weighting function which has a value of one within a

square near the centre of the screen and which gradually

decreases to zero towards the edges.

When bit WLB (Window Letter Box) is made logic 1, the

height of the window is reduced by a factor of

2

⁄3.

This prevents the contribution of the black bars above and

below a 16 : 9 scene to the measurements.

I2C-bus

The I2C-bus is always instandby mode and responds on a

properly addressed command. Bit PDD (Power-Down

Detected) in the status register is set each time an

interruptionofthe power supply occurs and is reset only by

reading the status register. A 3-bit identification code can

also be read from the status register, which code can be

used to automatically configure the application by

software.

The input control registers can be written sequentially by

the I2C-bus by the embedded automatic subaddress

increment feature or by addressing them directly.

The output control functions cannot be addressed

separately. Reading out the output control functions

always starts at subaddress 00H and all subsequent

words are read out by the automatic subaddress

increment procedure.

The bits in the I2C-bus are preset to logic 0 at power-on

except for bits AMS and VG5: therefore the TDA9178 is in

1.0 V luminance signal range and the variable gamma is

set to 20H (gamma correction 0%).

I

2

C-BUS SPECIFICATION

The slave address of the IC is given in Table “Slave

address”. If pin ADR of the TDA9178 is connected to

ground, the I2C-bus address is 40H; if pin ADR is

connected to pin DEC

DIG

, the I2C-bus address is E0H.

The circuit operates on clock frequencies up to 400 kHz.

Slave address

Auto-increment mode is available for subaddresses.

A6 A5 A4 A3 A2 A1 A0 R/W

ADR 1 ADR 0 0 0 0 X

Page 11

1999 Sep 24 11

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

TDA9178

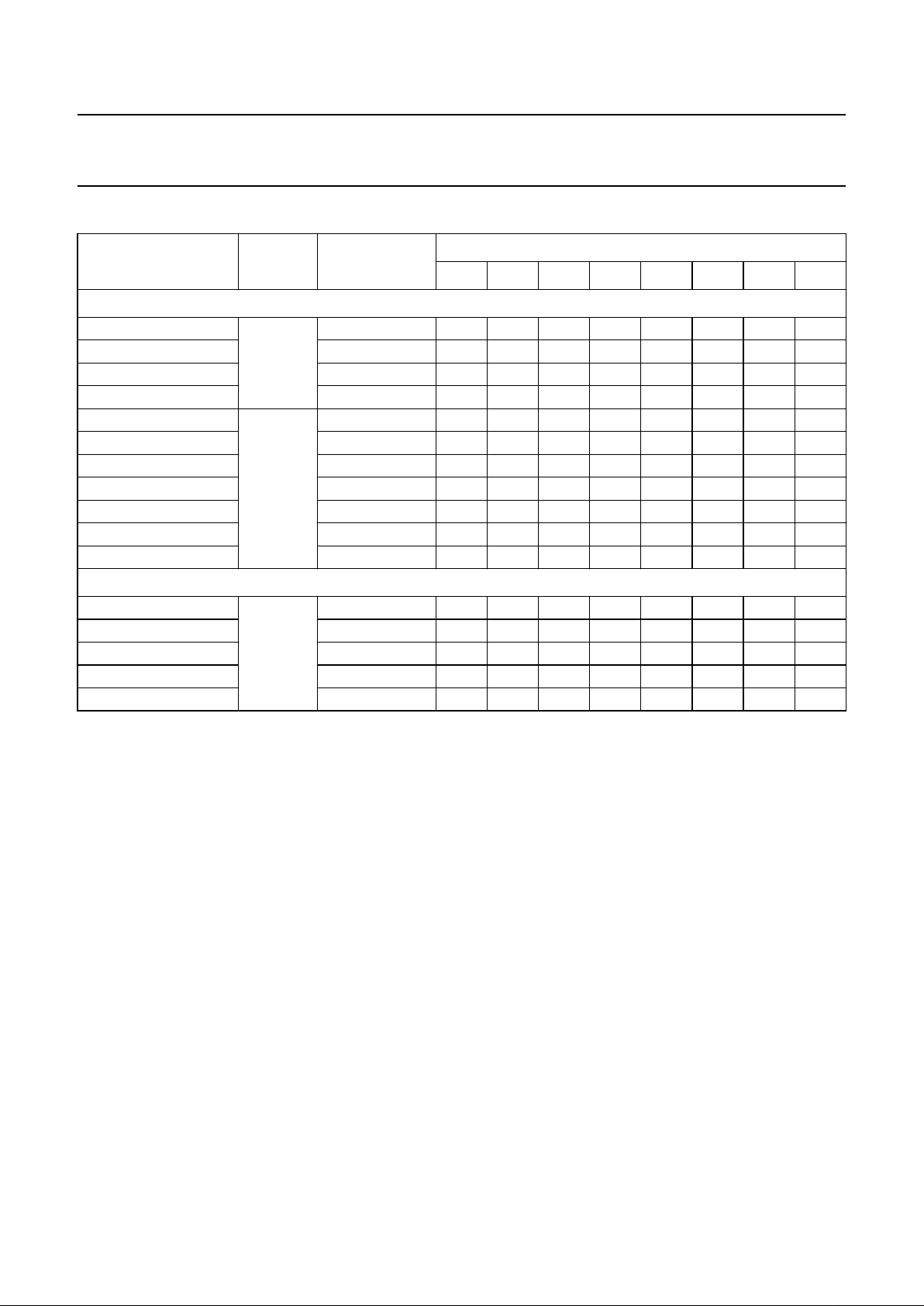

Control functions

FUNCTIONS TYPE SUBADDRESS

DATA BYTE

D7 D6 D5 D4 D3 D2 D1 D0

Inputs

Control 1 REG 00 DEM VDC WLB FHS CFS LDH 0 AMS

Control 2 01 0 0 OSP WPO 0 CD2 CD1 CD0

Control 3 02 SGR WGR GGR DGR SSK WSK ASK DSK

Control 4 03 0 0 BON CTI CDS SBL GBL DBL

Adaptive black stretch DAC 04 0 0 BT5 BT4 BT3 BT2 BT1 BT0

Non-linearity amplifier 05 0 0 NL5 NL4 NL3 NL2 NL1 NL0

Variable gamma 06 0 0 VG5 VG4 VG3 VG2 VG1 VG0

Peaking 07 0 0 PK5 PK4 PK3 PK2 PK1 PK0

Steepness 08 0 0 SP5 SP4 SP3 SP2 SP1 SP0

Coring 09 0 0 CR5 CR4 CR3 CR2 CR1 CR0

Line width 0A 0 0 LW5 LW4 LW3 LW2 LW1 LW0

Outputs

Status REG 00 X X X CF ID2 ID1 ID0 PDD

Noise detection 01 FM DV ND5 ND4 ND3 ND2 ND1 ND0

ADEXT1 (output) 02 X DV AD5 AD4 AD3 AD2 AD1 AD0

ADEXT2 (output) 03 X DV AD5 AD4 AD3 AD2 AD1 AD0

ADEXT3 (output) 04 X DV AD5 AD4 AD3 AD2 AD1 AD0

Page 12

1999 Sep 24 12

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

TDA9178

Input signals

Table 1 Amplitude mode selection

Table 2 Luminance determined histogram

Table 3 Contour filter selection

Table 4 Line frequency selection

Table 5 Window letterbox format

Table 6 Video dependent coring on/off

Table 7 Demonstration mode on/off

Table 8 Chrominance delay

Table 9 Overrule smart peaking

Table 10 White-point stretch on/off

Table 11 Dynamic skin tone on/off

Table 12 Dynamic skin tone angle

Table 13 Dynamic skin tone width

Table 14 Dynamic skin tone size

Table 15 Green enhancement on/off

AMS FUNCTION

0 0.315 V luminance (black to white) at

YIN

1 1.0 V luminance (black to white) at YIN

LDH FUNCTION

0 histogram segments fixed

1 histogram segments determinedby peak

white

CFS FUNCTION

0 peaking frequency is 2 MHz at 1f

H

or

4 MHz at 2f

H

1 peaking frequency is 3 MHz at 1fHor

6 MHz at 2f

H

FHS FUNCTION

01f

H

12f

H

WLB FUNCTION

0 normal internal window format

1 ‘Letterbox’ internal window format

VDC FUNCTION

0 video dependent coring off

1 video dependent coring on

DEM FUNCTION

0 DEMO off

1 DEMO on: auto-toggle selected features

on/off (cycle is 10 s at 1fHor 5 s at 2fH)

CD2 CD1 CD0 FUNCTION

0 0 0 40 ns at 1f

H

or 20 ns at 2f

H

111−32 ns at 1fHor +16 ns at 2f

H

OSP FUNCTION

0 smart peaking (maximum peaking

reduced if Coxing)

1 overrule smart peaking

WPO FUNCTION

0 white-point stretch on

1 white-point stretch off

DSK FUNCTION

0 skin tone off

1 skin tone on

ASK FUNCTION

0 angle correction 123°

1 angle correction 117°

WSK FUNCTION

0 default detection angle

1 60% increased detection angle

SSK FUNCTION

0 default area

1 40% increased area

DGR FUNCTION

0 green enhancement off

1 green enhancement on

Page 13

1999 Sep 24 13

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

TDA9178

Table 16 Green enhancement gain

Table 17 Green enhancement width

Table 18 Green enhancement size

Table 19 Blue stretch on/off

Table 20 Blue stretch gain

Table 21 Blue stretch size

Table 22 Colour dependent sharpness on/off

Table 23 Colour transient improvement on/off

GGR FUNCTION

0 default enhancement

1 60% increased gain

WGR FUNCTION

0 default detection angle

1 60% increased detection angle

SGR FUNCTION

0 default area

1 40% increased area

DBL FUNCTION

0 blue stretch off

1 blue stretch on

GBL FUNCTION

0 default gain

1 60% increased gain

SBL FUNCTION

0 default area

1 40% increased area

CDS FUNCTION

0 colour dependent sharpness off

1 colour dependent sharpness on

CTI FUNCTION

0 colour transient improvement off

1 colour transient improvement on

Table 24 Black offset compensation on/off

Table 25 Adaptive black stretch

Table 26 Non-linearity amplifier

Table 27 Variable gamma

Table 28 Peaking amplitude

Table 29 Steepness correction

Table 30 Coring level

BON FUNCTION

0 black offset compensation off

1 black offset compensation on

BT5 BT4 BT3 BT2 BT1 BT0 FUNCTION

0000000%

111111100%

NL5 NL4 NL3 NL2 NL1 NL0 FUNCTION

0000000%

111111100%

VG5 VG4 VG3 VG2 VG1 VG0 FUNCTION

000000−100%

111111100%

PK5 PK4 PK3 PK2 PK1 PK0 FUNCTION

0000000%

111111100%

SP5 SP4 SP3 SP2 SP1 SP0 FUNCTION

0000000%

111111100%

CR5 CR4 CR3 CR2 CR1 CR0 FUNCTION

0000000%

11111130%

Page 14

1999 Sep 24 14

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

TDA9178

Table 31 Line width correction

Output signals

Table 32 Power-down detection

Table 33 Identification code

Table 34 Cue flash

LW5 LW4 LW3 LW2 LW1 LW0 FUNCTION

00000033% duty

factorat 2 MHz

sine wave/1f

H

11111167% duty

factorat 2 MHz

sine wave/1f

H

PDD FUNCTION

0 no power-down detected since last read

1 power-down detected

ID2 ID1 ID0 FUNCTION

0 1 0 TDA9178/N1

CF FUNCTION

0 no cue flash since last read

1 cue flash detected

Table 35 Noise detector

Table 36 ADEXT1, ADEXT2 and ADEXT3

Table 37 Data valid bit of

noise detector/ADEXT1, 2 and 3 registers

Table 38 Feature mode detector

ND5 ND4 ND3 ND2 ND1 ND0 FUNCTION

000000−45 dB

111111−20 dB

AD5 AD4 AD3 AD2 AD1 AD0 FUNCTION

000000external

voltage = 0 V

111111external

voltage = 2 V

DV FUNCTION

0 data not valid because of possible register

access collision

1 data is valid

FM FUNCTION

0 normal video signal detected

1 feature mode detected (noise detector is

not reliable)

LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 134); all voltages referenced to ground.

HANDLING

All pins are protected against ESD by means of internal clamping diodes. The protection circuit meets the following

specification:

Human body model: C = 100 pF; R = 1.5 kΩ; all pins >3000 V

Machine model: C = 200 pF; R = 0 Ω; all pins >200 V.

At an ambient temperature of 90 °C, all pins meet the following specification:

I

trigger

> 100 mA or V

pin

> 1.5V

CC(max)

I

trigger

< −100 mA or V

pin

< −0.5V

CC(max)

SYMBOL PARAMETER MIN. MAX. UNIT

V

CC

supply voltage −0.5 +8.8 V

V

n

voltage on any pin −0.5 VCC+ 0.5 V

T

stg

storage temperature −55 +150 °C

T

amb

operating ambient temperature −10 +70 °C

T

j

operating junction temperature − 150 °C

Page 15

1999 Sep 24 15

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

TDA9178

THERMAL CHARACTERISTICS

QUALITY SPECIFICATION

In accordance with

“SNW-FQ-611 part E”

.

CHARACTERISTICS

VCC=8V; T

amb

=25°C; unless otherwise specified.

SYMBOL PARAMETER CONDITIONS VALUE UNIT

R

th(j-a)

thermal resistance from junction to ambient in free air

TDA9178 (SDIP24) 56 K/W

TDA9178T (SO24) 65 K/W

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supply

S

UPPLY VOLTAGE (PIN V

CC

)

V

CC

supply voltage 7.2 8.0 8.8 V

I

CC

supply current 1fH mode − 100 − mA

2f

H

mode − 105 − mA

DIGITAL SUPPLY DECOUPLING (PIN DEC

DIG

)

V

DECDIG

decoupling voltage − 5 − V

I

DECDIG

decoupling load current −−1mA

Input and output selection

LUMINANCE INPUT (PIN YIN)

V

i(Y)

input voltage (excluding sync) AMS = 0 − 0.315 0.45 V

AMS = 1 − 1.0 1.41 V

I

i(bias)(Y)

input bias current no clamp −−0.1 µA

LUMINANCE OUTPUT (PIN YOUT)

V

o(cl)

output voltage level during

clamping

AMS = 1 − 2.7 − V

AMS = 0 − 0.8 − V

G

Y(i-o)

luminance gain input to output transparent

at AMS = 1;

at 1 V (p-p)

0.93 1.04 1.15

transparent

at AMS = 0;

at 0.3 V (p-p)

0.96 1.07 1.18

S/N(Y) signal-to-noise ratio of luminance

output

transparent 52 −−dB

B

Y

luminance bandwidth 1fH mode (−1 dB);

transparent

5 −−MHz

2f

H

mode (−1 dB);

transparent

6 −−MHz

E

bl

black level error transparent −1.0 0 +1.0 %

Page 16

1999 Sep 24 16

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

TDA9178

R

o

output resistance −−150 Ω

I

o(bias)

output bias current 1.3 −−mA

C

L

load capacitance −−15 pF

COLOUR DIFFERENCE INPUTS U AND V(PINS UIN AND VIN)

V

i(U)(p-p)

input voltage U

(peak-to-peak value)

− 1.33 1.9 V

V

i(V)(p-p)

input voltage V

(peak-to-peak value)

− 1.05 1.9 V

I

i(bias)

input bias current no clamp −−0.1 µA

COLOUR DIFFERENCE OUTPUTS U AND V(PINS UOUT AND VOUT)

V

o(cl)

output voltage level during

clamping

− 2.7 − V

G

UV(i-o)

gain inputs to output transparent 0.90 1.00 1.10

E

offset

offset error transparent −1 0 +1 %

∆G

track

UV gain tracking error transparent −−5%

B

UV

bandwidth 1fH mode;

transparent (−3 dB)

2.5 −−MHz

2f

H

mode;

transparent (−3 dB)

5 −−MHz

R

o

output resistance −−150 Ω

I

o(bias)

output bias current 1.3 −−mA

C

L

load capacitance −−15 pF

Luminance vector processing

BLACK STRETCH

BLOS

cor(i)

input black offset correction 8 10 12 %

HISTOGRAM

White-point stretch

G

WP(max)

maximum luminance gain for white

stretch

maximum non-linearity

setting gain

− 1.1 −

Non-linear amplifier

G

nla(min)

minimum segment gain maximum non-linearity

setting gain

− 0.4 −

G

nla(max)

maximum segment gain maximum non-linearity

setting gain

− 2.0 −

G

nla

non-linear control curve 63 steps − 0 to 100 − %

VARIABLE GAMMA

G

g(var)(min)L

minimum variable gamma setting − 0.5 −

G

g(var)(max)

maximum variable gamma setting − 1.5 −

G

nla

non-linear control curve 63 steps − 0 to 100 − %

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Page 17

1999 Sep 24 17

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

TDA9178

Colour vector processing

SKIN TONE; note 1 and Fig.4

ϕ

cor

correction angle ASK = 0; DSK = 1 − 123 − deg

ASK = 1; DSK = 1 − 117 − deg

ϕ

ap

correction range (or aperture angle) DSK = 1; SSK = 1;

WSK = 0

− 45 − deg

GREEN ENHANCEMENT; note 1 and Fig.5

ϕ

cor

correction angle DGR = 1 − 208 − deg

ϕ

ap

correction range (or aperture angle) DGR = 1; SGR = 0;

WGR = 0

− 45 − deg

BLUE STRETCH; note 2 and Fig.6

ϕ

(str)

stretch angle DBL = 1 − 330 − deg

Spectral processing

GENERAL

Q

max

maximum contour amplitude at

centre frequency

note 3 − 12 − dB

Contour filter low frequency peaking

f

pc(l)

peaking centre frequency 1fH mode; CFS = 0 − 2.0 − MHz

2f

H

mode; CFS = 0 − 4.0 − MHz

Contour filter high frequency peaking

f

pc(h)

peaking centre frequency 1fH mode; CFS = 1 − 3.0 − MHz

2f

H

mode; CFS = 1 − 6.0 − MHz

Step detector

f

dc

detection centre frequency 1fH mode − 1.18 − MHz

2f

H

mode − 2.36 − MHz

PEAKING

G

PK

peaking control curve 63 steps − 0 to 100 − %

CORING

G

CR

coring control curve 63 steps − 0to45 − %

LUMINANCE TRANSIENT IMPROVEMENT

t

r(min)

minimum rise time 10% to 90% note 4 − 30 − ns

G

SP

steepness control curve 63 steps − 0 to 100 − %

Line width control

t

sd(max)

maximum step displacement 1fH mode − 140 − ns

2f

H

mode − 70 − ns

G

LW

line width control curve (duty factor) 63 steps at 1 MHz

sine wave at 1f

H

− 33 to 67 − %

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Page 18

1999 Sep 24 18

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

TDA9178

COLOUR TRANSIENT IMPROVEMENT

t

r(min)

minimum rise time 10% to 90% note 5 − 50 − ns

COLOUR DEPENDENT SHARPNESS

f

pc

peaking centre frequency 1fH mode − 2.0 − MHz

2f

H

mode − 4.0 − MHz

Q

max

maximum contour amplitude at

centre frequency

note 3 − 6 − dB

SCAVEM

SCAVEM OUTPUT (PIN SOUT)

V

o(cl)

output voltage level during

clamping

− 2.2 − V

G

Y

gain luminance input to SCAVEM

output

0.93 1.04 1.15

B

Y

bandwidth 1fH mode (−1 dB) 5 −−MHz

2f

H

mode (−1 dB) 6.0 −−MHz

R

o

output resistance −−150 Ω

I

o(bias)

output bias current 0.8 −−mA

C

L

load capacitance −−15 pF

t

d(SOUT-YOUT)

delay w.r.t. YOUT −−20 − ns

Successive approximation ADC

ADC INPUTS (PINS ADEXT1, ADEXT2 AND ADEXT3)

V

FS

full-scale input voltage range with respect to ground − 2.0 − V

I

i(bias)

input bias current −−0.1 µA

RES data path resolution − 6 − bit

DLE differential linearity error −−1 LSB

ILE integral linearity error −−1 LSB

f

con

conversion frequency ADEXT1 − 1f

V

− Hz

ADEXT2; ADEXT3 − 0.5f

V

− Hz

Q

adt

conversion time (video lines) each channel − 8 − lines

Timing

SANDCASTLE INPUT (PIN SC)

I

i(bias)

input bias current −−1µA

V

sc(bn)

detection level for blank no clamping 0.9 1.15 1.40 V

V

sc(bc)

detection level for clamp − 0.9V

top

− V

t

W(bk)

burst key pulse width 1fH mode 1.8 −−µs

2f

H

mode 0.9 −−µs

t

V

vertical retrace time 6 −−lines

V

bk(var)(p-p)

ripple on sandcastle burst key level

(peak-to-peak value)

−−0.04V

top

V

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Page 19

1999 Sep 24 19

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

TDA9178

Notes

1. The amount of correction depends on the parameters of the incoming YUVsignals; therefore it is not possible to give

exact figures for the correction angle. The aperture angle of the correction range of 45° (±22.5°) is just given as an

indication and is valid for an input signal with a luminance signal amplitude of 75% and a colour saturation of 50%.

2. The amount of correction depends on the parameters of the incoming YUVsignals; therefore it is not possible to give

exact figures for the correction angle.

3. The contour signal cannot be measured separately from the luminance input signal. The contour signal is also

processed by the smart noise controller. The frequency transfer in the peaking mode of the luminance signal can be

derived from the frequency transfer of the selected contour signal, taking into account the summation of the contour

signal and the luminance input signal. The frequency transfer is most easily measured by sine excitation with a

relatively small signal amplitude of 10% of the selected dynamic range of the luminance input, to avoid interaction

with the step detector.

4. Peaking set to minimum. Input signal is a sine wave with the nominal peak-to-peak amplitude corresponding to the

selected input range.

5. Input signal is a 250 kHz block with a rise time of 260 ns and a nominal peak-to-peak amplitude corresponding to the

selected input range.

Overall output group delay performance

t

d(YUV)

input to output delay of YUV signals 1fH mode; transparent − 300 − ns

2f

H

mode; transparent − 180 − ns

t

dm(UV-Y)

adjustment delay U and V signals

w.r.t. Y signal

1fH mode; transparent −32 0 +40 ns

2f

H

mode; transparent −16 0 +20 ns

Noise measurement

R

noise

range of noise detector see Figure 18 −45 −−20 dB

t

con

conversion time − 32f

V

− s

Cue flash

CUE FLASH OUTPUT (PIN CF); OPEN COLLECTOR

V

o(max)

maximum output voltage pull-up to external

supply

−−5.5 V

I

sink(max)

maximum sink current −−1mA

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Page 20

1999 Sep 24 20

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

TDA9178

Fig.4 Skin tone correction range for a correction angle of 123°.

handbook, full pagewidth

MGR900

V

−U

red

I-axis

fully saturated colours

yellow

Fig.5 Green enhancement correction range.

handbook, full pagewidth

MGR901

−V

−U

green

detection-axis

fully saturated colours

yellow

Page 21

1999 Sep 24 21

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

TDA9178

Fig.6 Blue stretch correction range.

handbook, full pagewidth

MGR902

−V

U

cyan

detection-axis

fully saturated colours

blue

Page 22

1999 Sep 24 22

Philips Semiconductors Preliminary specification

YUV one chip picture improvementbased on luminance

vector-, colour vector- and spectral processor

TDA9178

This text is here in white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here in

_white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here inThis text is here in

white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader. white to force landscape pages to be ...

handbook, full pagewidth

MGR903

noise detector

measuring

ADEXT1

conversion

ADEXT2,

ADEXT3

conversion

cue flash output

internal V-pulse

+ FM detection

burst key pulse

clamping pulse

video input

sandcastle input

NTSC-signal, field A

Fig.7 Timing pulses for NTSC input signal, field A.

Page 23

1999 Sep 24 23

Philips Semiconductors Preliminary specification

YUV one chip picture improvementbased on luminance

vector-, colour vector- and spectral processor

TDA9178

This text is here in white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here in

_white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here inThis text is here in

white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader. white to force landscape pages to be ...

handbook, full pagewidth

MGR904

noise detector

measuring

ADEXT1

conversion

ADEXT2,

ADEXT3

conversion

cue flash output

internal V-pulse

+ FM detection

burst key pulse

clamping pulse

video input

sandcastle input

NTSC-signal, field B

Fig.8 Timing pulses for NTSC input signal, field B.

Page 24

1999 Sep 24 24

Philips Semiconductors Preliminary specification

YUV one chip picture improvementbased on luminance

vector-, colour vector- and spectral processor

TDA9178

This text is here in white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here in

_white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here inThis text is here in

white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader. white to force landscape pages to be ...

handbook, full pagewidth

PAL-signal, field A

noise detector

measuring

ADEXT1

conversion

ADEXT2,

ADEXT3

conversion

cue flash output

internal V-pulse

+ FM detection

burst key pulse

clamping pulse

video input

sandcastle input

MGR933

Fig.9 Timing pulses for PAL and SECAM input signal, field A.

Page 25

1999 Sep 24 25

Philips Semiconductors Preliminary specification

YUV one chip picture improvementbased on luminance

vector-, colour vector- and spectral processor

TDA9178

This text is here in white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here in

_white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here inThis text is here in

white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader. white to force landscape pages to be ...

handbook, full pagewidth

MGR934

PAL-signal, field B

noise detector

measuring

ADEXT1

conversion

ADEXT2,

ADEXT3

conversion

cue flash output

internal V-pulse

+ FM detection

burst key pulse

clamping pulse

video input

sandcastle input

Fig.10 Timing pulses for PAL and SECAM input signal, field B.

Page 26

1999 Sep 24 26

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

TDA9178

Fig.11 Block diagram of the step improvement processor.

handbook, full pagewidth

MGR905

MINMAX

SELECTOR

MINMAX

Y

envelope

Y

step

CLAMPS

FADER

line width

control

DELAY

Y

in

Fig.12 Response signals for maximum step improvement, no peaking and nominal line width.

handbook, halfpage

0 0.5

1000

800

200

0

400

600

MGR906

1.0 1.5 2.0

t (µs)

(1)

(2)

V

o

(mV)

(1) 90% of nominal amplitude.

(2) 30% of nominal amplitude.

Page 27

1999 Sep 24 27

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

TDA9178

Fig.13 Response signals for maximum step improvement, no peaking and minimum line width.

handbook, halfpage

0 0.5

1000

800

200

0

400

600

1.0 1.5 2.0

t (µs)

V

o

(mV)

(1)

(2)

MGR907

(1) 90% of nominal amplitude.

(2) 30% of nominal amplitude.

Fig.14 Response signals for maximum step improvement, no peaking and maximum line width.

handbook, halfpage

0 0.5

1000

800

200

0

400

600

1.0 1.5 2.0

t (µs)

V

o

(mV)

(1)

(2)

MGR908

(1) 90% of nominal amplitude.

(2) 30% of nominal amplitude.

Page 28

1999 Sep 24 28

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

TDA9178

Fig.15 Frequency transfers of contour filter at f = 2.0 MHz.

handbook, halfpage

100

0

MGR909

10

5

10

6

10

7

20

40

60

80

f (Hz)

contour

(%)

(1)

(2)

(1) 1fHmode.

(2) 2fHmode.

Fig.16 Block diagram of smart sharpness controller.

handbook, full pagewidth

MGR910

STEP

DETECTOR

FADER

CORING

Y

envelope

Y

step

Y

contour

Y

step

Y

c

delay

cells

coring

control

peaking

control

steepness

control

Page 29

1999 Sep 24 29

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

TDA9178

Fig.17 Block diagram of colour transient improvement.

handbook, halfpage

MGR911

DELAY DELAY

control

AC

B

UV

in

UV

out

Fig.18 Typical noise measurement curve of input noise (dB) versus DAC-value.

handbook, halfpage

MGR912

−50 −40 −30 −10

80

60

20

0

40

−20

S/N (dB)

DACvalue

Page 30

1999 Sep 24 30

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

TDA9178

TEST AND APPLICATION INFORMATION

The TDA9178 is especially designed for YUV applications. A typical application diagram is shown in Fig.19.

Fig.19 YUV application.

handbook, full pagewidth

MGR913

100 Ω

10

µF

100 nF

100

nF

TDA9178

12 13

n.c.

14

SDA

n.c.

223

n.c.

24

n.c.

n.c.

10 15

DEC

DIG

16

VOUT

VOUT

TP

11

SCL

SDA

100 Ω

100 kΩ

SCL

9

VIN

VIN

17

UOUT

UOUT

21

SOUT

SOUT

22

CF

CF

YOUT

0 V

8 V

8

UIN

UIN

YIN

18

V

EE

7

ADR

19

YOUT

6

YIN

sandcastle

1

SC

20

V

CC

ADEXT3

5

ADEXT3

100 kΩ

ADEXT2

4

ADEXT2

100 kΩ

ADEXT1

3

ADEXT1

1

0

Page 31

1999 Sep 24 31

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

TDA9178

PACKAGE OUTLINES

UNIT b

1

cEe M

H

L

REFERENCES

OUTLINE

VERSION

EUROPEAN

PROJECTION

ISSUE DATE

IEC JEDEC EIAJ

mm

DIMENSIONS (mm are the original dimensions)

SOT234-1

92-11-17

95-02-04

b

max.

w

M

E

e

1

1.3

0.8

0.53

0.40

0.32

0.23

22.3

21.4

9.1

8.7

3.2

2.8

0.181.778 10.16

10.7

10.2

12.2

10.5

1.6

4.7 0.51 3.8

M

H

c

(e )

1

M

E

A

L

seating plane

A

1

w M

b

1

e

D

A

2

Z

24

1

13

12

b

E

pin 1 index

0 5 10 mm

scale

Note

1. Plastic or metal protrusions of 0.25 mm maximum per side are not included.

(1) (1)

D

(1)

Z

A

max.

12

A

min.

A

max.

SDIP24: plastic shrink dual in-line package; 24 leads (400 mil)

SOT234-1

Page 32

1999 Sep 24 32

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

TDA9178

UNIT

A

max.

A1A2A

3

b

p

cD

(1)E(1) (1)

eHELLpQ

Z

ywv θ

REFERENCES

OUTLINE

VERSION

EUROPEAN

PROJECTION

ISSUE DATE

IEC JEDEC EIAJ

mm

inches

2.65

0.30

0.10

2.45

2.25

0.49

0.36

0.32

0.23

15.6

15.2

7.6

7.4

1.27

10.65

10.00

1.1

1.0

0.9

0.4

8

0

o

o

0.25 0.1

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

Note

1. Plastic or metal protrusions of 0.15 mm maximum per side are not included.

1.1

0.4

SOT137-1

X

12

24

w M

θ

A

A

1

A

2

b

p

D

H

E

L

p

Q

detail X

E

Z

c

L

v M

A

13

(A )

3

A

y

0.25

075E05 MS-013AD

pin 1 index

0.10

0.012

0.004

0.096

0.089

0.019

0.014

0.013

0.009

0.61

0.60

0.30

0.29

0.050

1.4

0.055

0.419

0.394

0.043

0.039

0.035

0.016

0.01

0.25

0.01

0.004

0.043

0.016

0.01

e

1

0 5 10 mm

scale

SO24: plastic small outline package; 24 leads; body width 7.5 mm

SOT137-1

95-01-24

97-05-22

Page 33

1999 Sep 24 33

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

TDA9178

SOLDERING

Introduction

Thistextgivesaverybriefinsighttoa complex technology.

A more in-depth account of soldering ICs can be found in

our

“Data Handbook IC26; Integrated Circuit Packages”

(document order number 9398 652 90011).

There is no soldering method that is ideal for all IC

packages. Wave soldering is often preferred when

through-holeand surface mount components are mixed on

one printed-circuit board. However, wave soldering is not

always suitable for surface mount ICs, or for printed-circuit

boards with high population densities. In these situations

reflow soldering is often used.

Through-hole mount packages

SOLDERING BY DIPPING OR BY SOLDER WAVE

The maximum permissible temperature of the solder is

260 °C; solder at this temperature must not be in contact

with the joints for more than 5 seconds. The total contact

time of successive solder waves must not exceed

5 seconds.

The device may be mounted up to the seating plane, but

the temperature of the plastic body must not exceed the

specified maximum storage temperature (T

stg(max)

). If the

printed-circuit board has been pre-heated, forced cooling

may be necessary immediately after soldering to keep the

temperature within the permissible limit.

MANUAL SOLDERING

Apply the soldering iron (24 V or less) to the lead(s) of the

package, either below the seating plane or not more than

2 mm above it. If the temperature of the soldering iron bit

is less than 300 °C it may remain in contact for up to

10 seconds. If the bit temperature is between

300 and 400 °C, contact may be up to 5 seconds.

Surface mount packages

REFLOW SOLDERING

Reflow soldering requires solder paste (a suspension of

fine solder particles, flux and binding agent) to be applied

totheprinted-circuit board by screen printing, stencilling or

pressure-syringe dispensing before package placement.

Several methods exist for reflowing; for example,

infrared/convection heating in a conveyor type oven.

Throughput times (preheating, soldering and cooling) vary

between 100 and 200 seconds depending on heating

method.

Typical reflow peak temperatures range from

215 to 250 °C. The top-surface temperature of the

packages should preferable be kept below 230 °C.

WAVE SOLDERING

Conventional single wave soldering is not recommended

forsurfacemountdevices(SMDs)orprinted-circuitboards

with a high component density, as solder bridging and

non-wetting can present major problems.

To overcome these problems the double-wave soldering

method was specifically developed.

If wave soldering is used the following conditions must be

observed for optimal results:

• Use a double-wave soldering method comprising a

turbulent wave with high upward pressure followed by a

smooth laminar wave.

• For packages with leads on two sides and a pitch (e):

– larger than or equal to 1.27 mm, the footprint

longitudinal axis is preferred to be parallel to the

transport direction of the printed-circuit board;

– smaller than 1.27 mm, the footprint longitudinal axis

must be parallel to the transport direction of the

printed-circuit board.

The footprint must incorporate solder thieves at the

downstream end.

• Forpackageswithleadsonfoursides,thefootprintmust

be placed at a 45° angle to the transport direction of the

printed-circuit board. The footprint must incorporate

solder thieves downstream and at the side corners.

During placement and before soldering, the package must

be fixed with a droplet of adhesive. The adhesive can be

applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the

adhesive is cured.

Typical dwell time is 4 seconds at 250 °C.

A mildly-activated flux will eliminate the need for removal

of corrosive residues in most applications.

MANUAL SOLDERING

Fix the component by first soldering two

diagonally-opposite end leads. Use a low voltage (24 V or

less) soldering iron applied to the flat part of the lead.

Contact time must be limited to 10 seconds at up to

300 °C.

When using a dedicated tool, all other leads can be

soldered in one operation within 2 to 5 seconds between

270 and 320 °C.

Page 34

1999 Sep 24 34

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

TDA9178

Suitability of IC packages for wave, reflow and dipping soldering methods

Notes

1. All surface mount (SMD) packages are moisture sensitive. Depending upon the moisture content, the maximum

temperature (with respect to time) and body size of the package, there is a risk that internal or external package

cracks may occur due to vaporization of the moisture in them (the so called popcorn effect). For details, refer to the

Drypack information in the

“Data Handbook IC26; Integrated Circuit Packages; Section: Packing Methods”

.

2. For SDIP packages, the longitudinal axis must be parallel to the transport direction of the printed-circuit board.

3. These packages are not suitable for wave soldering as a solder joint between the printed-circuit board and heatsink

(at bottom version) can not be achieved, and as solder may stick to the heatsink (on top version).

4. If wave soldering is considered, then the package must be placed at a 45° angle to the solder wave direction.

The package footprint must incorporate solder thieves downstream and at the side corners.

5. Wave soldering is only suitable for LQFP, QFP and TQFP packages with a pitch (e) equal to or larger than 0.8 mm;

it is definitely not suitable for packages with a pitch (e) equal to or smaller than 0.65 mm.

6. Wave soldering is only suitable for SSOP and TSSOP packages with a pitch (e) equal to or larger than 0.65 mm; it is

definitely not suitable for packages with a pitch (e) equal to or smaller than 0.5 mm.

MOUNTING PACKAGE

SOLDERING METHOD

WAVE REFLOW

(1)

DIPPING

Through-hole mount DBS, DIP, HDIP, SDIP, SIL suitable

(2)

− suitable

Surface mount BGA, LFBGA, SQFP, TFBGA not suitable suitable −

HBCC, HLQFP, HSQFP, HSOP, HTQFP,

HTSSOP, SMS

not suitable

(3)

suitable −

PLCC

(4)

, SO, SOJ suitable suitable −

LQFP, QFP, TQFP not recommended

(4)(5)

suitable −

SSOP, TSSOP, VSO not recommended

(6)

suitable −

Page 35

1999 Sep 24 35

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

TDA9178

DEFINITIONS

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

PURCHASE OF PHILIPS I

2

C COMPONENTS

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

Purchase of Philips I

2

C components conveys a license under the Philips’ I2C patent to use the

components in the I2C system provided the system conforms to the I2C specification defined by

Philips. This specification can be ordered using the code 9398 393 40011.

Page 36

© Philips Electronics N.V. SCA

All rights are reserved. Reproduction in whole or in part is prohibited without the prior written consent of the copyright owner.

The information presented in this document does not form part of any quotation or contract, is believed to be accurate and reliable and may be changed

without notice. No liability will be accepted by the publisher for any consequence of its use. Publication thereof does not convey nor imply any license

under patent- or other industrial or intellectual property rights.

Internet: http://www.semiconductors.philips.com

1999

68

Philips Semiconductors – a w orldwide compan y

For all other countries apply to: Philips Semiconductors,

International Marketing & Sales Communications, Building BE-p, P.O. Box 218,

5600 MD EINDHOVEN, The Netherlands, Fax. +31 40 27 24825

Argentina: see South America

Australia: 3 Figtree Drive, HOMEBUSH, NSW 2140,

Tel. +61 2 9704 8141, Fax. +61 2 9704 8139

Austria: Computerstr. 6, A-1101 WIEN, P.O. Box 213,

Tel. +43 1 60 101 1248, Fax. +43 1 60 101 1210

Belarus: Hotel Minsk Business Center, Bld. 3, r. 1211, Volodarski Str. 6,

220050 MINSK, Tel. +375 172 20 0733, Fax. +375 172 20 0773

Belgium: see The Netherlands

Brazil: see South America

Bulgaria: Philips Bulgaria Ltd., Energoproject, 15th floor,

51 James Bourchier Blvd., 1407 SOFIA,

Tel. +359 2 68 9211, Fax. +359 2 68 9102

Canada: PHILIPS SEMICONDUCTORS/COMPONENTS,

Tel. +1 800 234 7381, Fax. +1 800 943 0087

China/Hong Kong: 501 Hong Kong Industrial Technology Centre,

72 Tat Chee Avenue, Kowloon Tong, HONG KONG,

Tel. +852 2319 7888, Fax. +852 2319 7700

Colombia: see South America

Czech Republic: see Austria

Denmark: Sydhavnsgade 23, 1780 COPENHAGEN V,

Tel. +45 33 29 3333, Fax. +45 33 29 3905

Finland: Sinikalliontie 3, FIN-02630 ESPOO,

Tel. +358 9 615 800, Fax. +358 9 6158 0920

France: 51 Rue Carnot, BP317, 92156 SURESNES Cedex,

Tel. +33 1 4099 6161, Fax. +33 1 4099 6427

Germany: Hammerbrookstraße 69, D-20097 HAMBURG,

Tel. +49 40 2353 60, Fax. +49 40 2353 6300

Hungary: see Austria

India: Philips INDIA Ltd, Band Box Building, 2nd floor,

254-D, Dr. Annie Besant Road, Worli, MUMBAI 400 025,

Tel. +91 22 493 8541, Fax. +91 22 493 0966

Indonesia: PT PhilipsDevelopment Corporation, Semiconductors Division,

Gedung Philips, Jl. Buncit Raya Kav.99-100, JAKARTA 12510,

Tel. +62 21 794 0040 ext. 2501, Fax. +62 21 794 0080

Ireland: Newstead, Clonskeagh, DUBLIN 14,

Tel. +353 1 7640 000, Fax. +353 1 7640 200