Page 1

INTEGRATED CIRCUITS

DATA SH EET

TDA9171

YUV picture improvement

processor based on histogram

modification and blue stretch

Preliminary specification

Supersedes data of 1995 Aug 01

File under Integrated Circuits, IC02

1996 Jun 17

Page 2

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

TDA9171

on histogram modification and blue stretch

FEATURES

• Picture content dependent non-linear Y and U,V

processing by luminance histogram analysis

• TV standard independent

• Incredible blue stretch

• Optional YC-processing.

GENERAL DESCRIPTION

The TDA9171 is a transparent analog video processor

with YUV input and output interfaces.

The luminance transfer is controlled in a non-linear way by

the distribution, in 5 discrete histogram sections, of the

luminance values measured in a picture. As a result, the

QUICK REFERENCE DATA

SYMBOL PARAMETER MIN. TYP. MAX. UNIT

V

CC

supply voltage 7.2 − 8.8 V

contrast ratio of the most important parts of the scene will

be improved.

So as to maintain a proper colour reproduction the

saturation of the −U and −V colour difference signals are

also controlled as a function of the actual non-linearity in

the luminance channel.

Optionally, the YUV blue stretch circuitry can be activated

which offsets colours near white towards blue.

The supply voltage is 8 V.

The device is contained in a 20 lead dual in-line package.

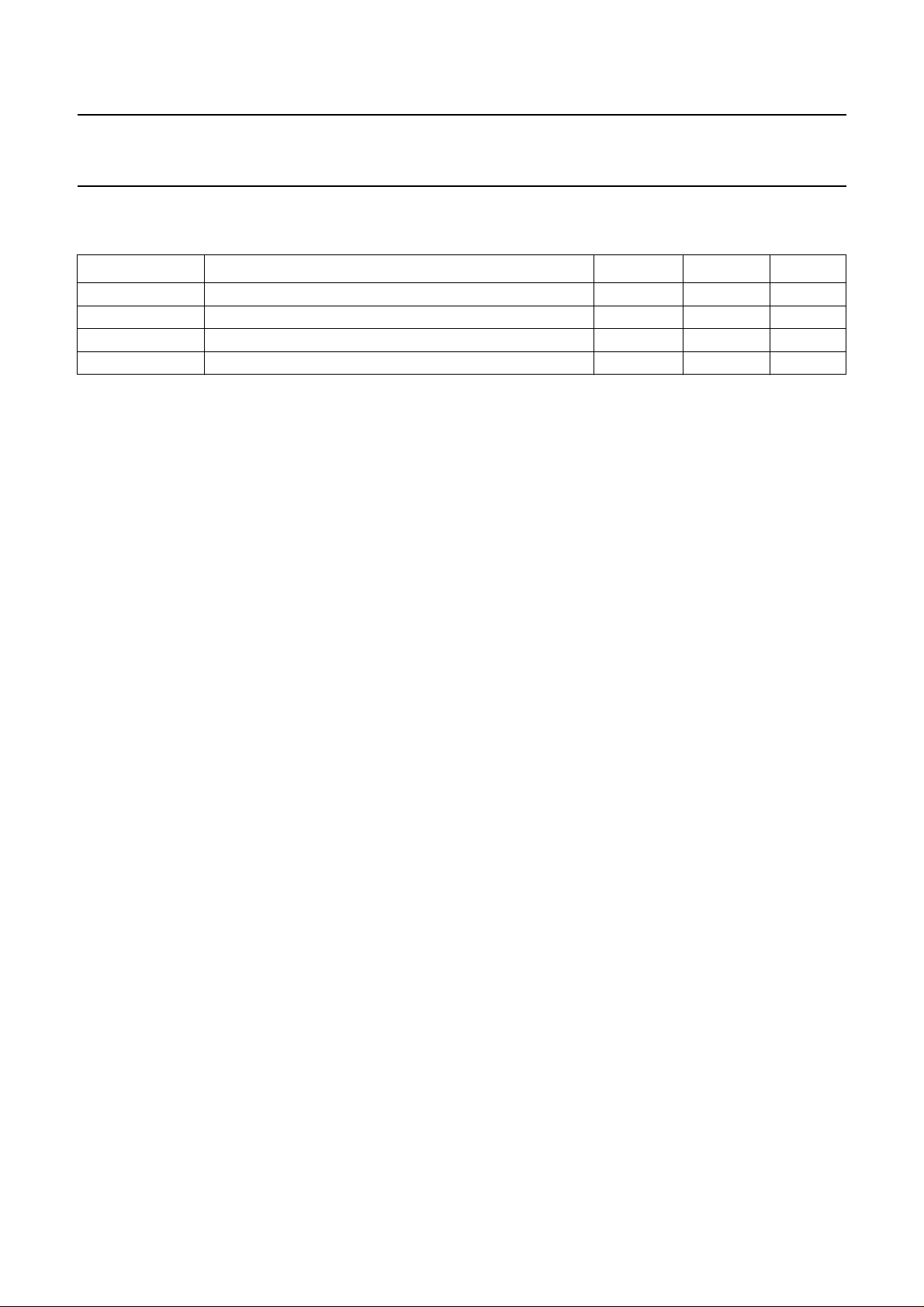

ORDERING INFORMATION

TYPE

NUMBER

TDA9171 DIP20 plastic dual in-line package; 20 leads; (300 mil); no heat spreader SOT146-1

NAME DESCRIPTION VERSION

PACKAGE

1996 Jun 17 2

Page 3

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

on histogram modification and blue stretch

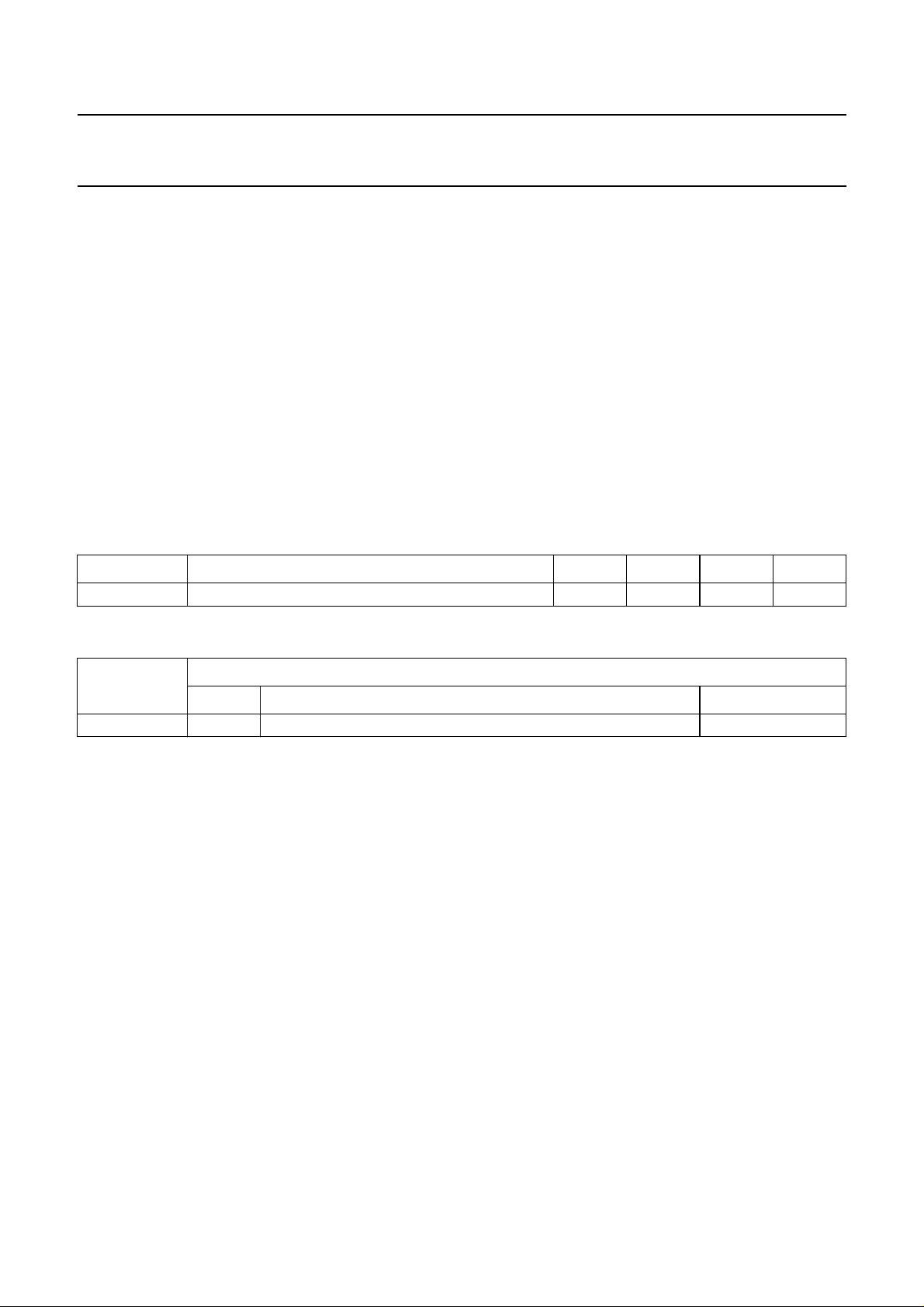

BLOCK DIAGRAM

book, full pagewidth

2

UIN

3

VIN

7

YIN

5

SC

AMPLIFIER

TIMING

CONTROL

INPUT

AND

AMPSEL

AMPSEL

TAUHM BLM BLG

68

TDA9171

HISTOGRAM

MEASUREMENT

9 10 11 12 13

SATURATION

COMPENSATION

NON-LINEAR

AMPLIFIER

HISTOGRAM

PROCESSOR

AMPLIFIER

4

20 1

BLUE

STRETCH

OUTPUT

AMPSEL

SUPPLY

AND

BIASING

16 15 17

TDA9171

19

UOUT

18

VOUT

14

YOUT

MBE990

HM1 to HM5

Fig.1 Block diagram.

NLC

V

EE

CC

V

ref

V

1996 Jun 17 3

Page 4

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

on histogram modification and blue stretch

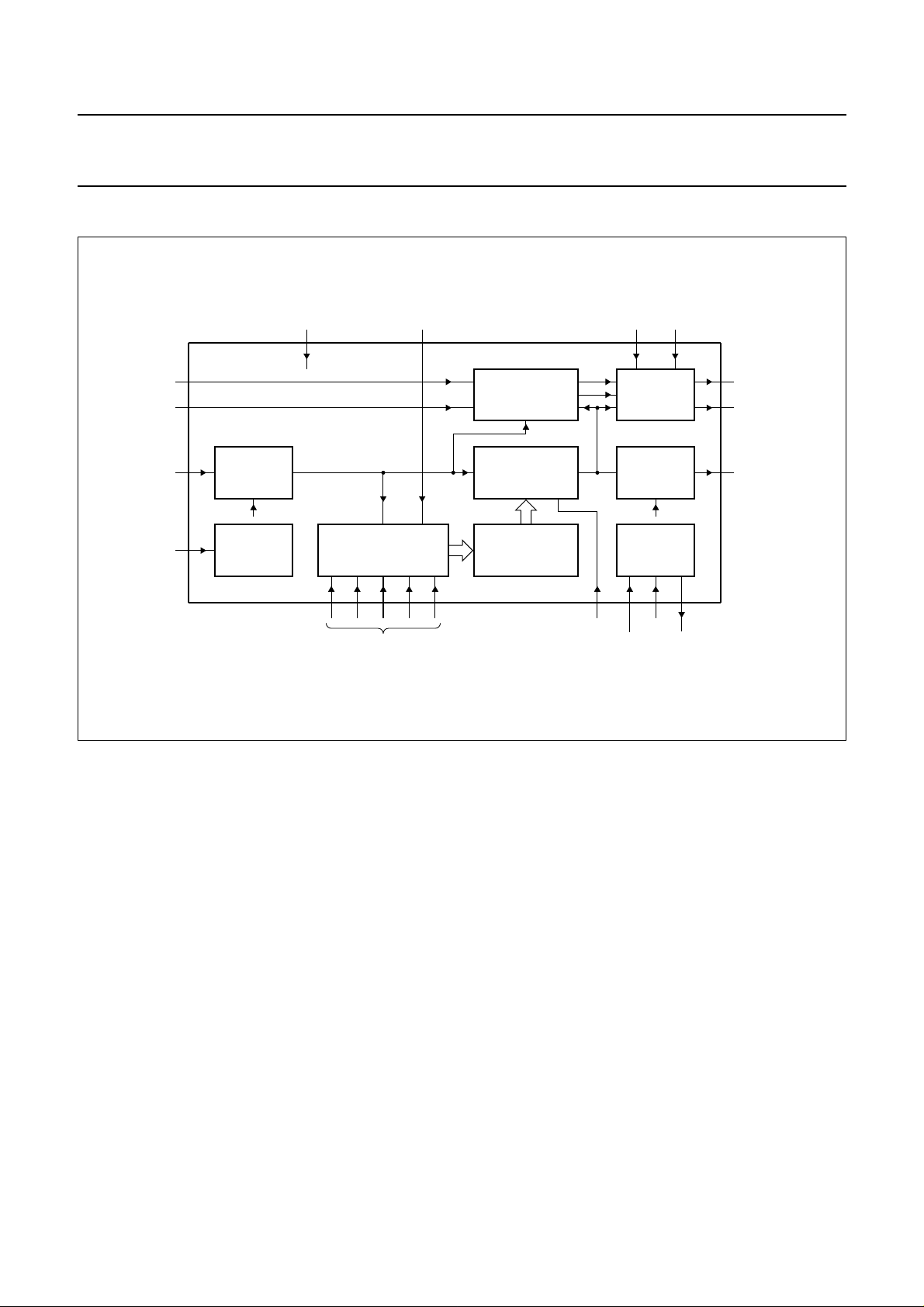

PINNING

SYMBOL PIN DESCRIPTION

BLG 1 blue stretch gain input

UIN 2 U colour difference input −UIN

VIN 3 V colour difference input −VIN

NLC 4 non-linear gain control input

SC 5 sandcastle input

AMPSEL 6 amplitude select input

YIN 7 luminance input

TAUHM 8 time constant histogram input

HM1 9 histogram segment memory 1 input

HM2 10 histogram segment memory 2 input

HM3 11 histogram segment memory 3 input

HM4 12 histogram segment memory 4 input

HM5 13 histogram segment memory 5 input

YOUT 14 luminance output

V

EE

V

CC

V

ref

VOUT 18 colour difference output −VOUT

UOUT 19 colour difference output −UOUT

BLM 20 activation level blue stretch input

15 ground

16 supply voltage

17 reference voltage output

handbook, halfpage

AMPSEL

1

BLG

2

UIN

3

VIN

4

NLC

5

SC

YIN

TAUHM

HM1

HM2

6

7

8

9

10

TDA9171

MBE989

Fig.2 Pin configuration.

TDA9171

20

BLM

19

UOUT

18

VOUT

V

17

ref

V

16

CC

V

15

EE

14

YOUT

13

HM5

12

HM4

11

HM3

FUNCTIONAL DESCRIPTION

Input selection and amplification

The dynamic range of the luminance input amplifier is

0.3 or 1 V (excluding sync) typically, depending on the

logic level at pin AMPSEL (pin 6). Amplitudes which

extend the corresponding specified range will be clipped

smoothly, however, the sync is processed to the output

transparently. The non-linear gain setting will have

minimum effect.

Optionally, in the 1 V input mode, the Y output can be

attenuated by a factor of 0.7 by means of an intermediate

level at pin AMPSEL. This option is meant for correctly

interfacing the combed CVBS signal to the video

processor in a YC-application.

The input is clamped during the logic HIGH period of the

CLP, defined by the sandcastle reference, and should be

DC-decoupled with an external capacitor.

1996 Jun 17 4

Histogram measurement

For the luminance signal the histogram distribution is

measured in real-time over five segments (HM1 to HM5) in

each field. During the period that the luminance is in one

segment, a corresponding external capacitor HMx is

loaded via a current source. At the end of the field five

segment voltages are stored from the external capacitors

into on-board memories. The external capacitors are

discharged and the measurements are repeated.

Parts in the scene that do not contribute to the information

in that scene should be omitted from the histogram

measurement. No measurements are performed during

the blanking period defined by the sandcastle.

The miscount detector disables measurements until it

detects changing parts. Additionally, luminance values

close to full scale (or white) do not contribute as well in

order to maintain the absolute light output. This procedure

is allowed because the eye is less sensitive to detail in

white.

Page 5

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

on histogram modification and blue stretch

As the miscount detector shortens the effective

measurement period and, because of spreads of internal

and external components, the current source is controlled

in a closed-loop to provide a constant value of the sum of

the segment voltages. The dominant time constant of the

closed-loop is external and can be tuned with an

appropriate capacitor value at pin TAUHM (pin 8).

Processing of the measured histogram value

FIELD AVERAGING OF HISTOGRAM VALUES

With very rapid picture changes, also related to the field

interlace, flicker might result. The histogram values are

averaged at the field rate thus reducing the flicker effects.

The time constant of the averaging process is adapted to

the speed of the histogram changes.

DAPTIVE WHITE-POINT STRETCHING

A

For dominant HM4 and HM5 voltages, or large white parts,

the histogram conversion procedure makes a transfer with

large gain in the white parts, however the amount of light

coming out of the scene is considerably reduced. The

white stretcher introduces additional overall gain for

increased light production and, as a result, violates the

principle of having a full scale reference.

S

TANDARD DEVIATION

For scenes, in which segments of the histogram

distribution are very dominant with respect to the others,

the non-linear amplification should be reduced in

comparison to scenes with a flat histogram distribution.

The standard deviation detector measures the spread of

the histogram distribution in the segments HM1 to HM5

and modulates the user setting of the non-linear amplifier.

Non-linear amplifier

The stored segment voltages relative to their average

value, averaged over two fields, determine the individual

gain of each segment in such a way that continuity is

guaranteed for the complete range. The maximum and

minimum gain of each segment is limited. Apart from the

adaptive white-point stretching the black and white

references are not affected by the non-linear processing.

The amount of linearity can be controlled externally by the

NLC pin (Non Linearity Control).

TDA9171

Colour compensation

Non-linear luminance processing influences the colour

reproduction, mainly the colour saturation. Therefore, the

U and V signals are also processed for saturation

compensation.

By convention −U and −V signals must be supplied to the

TDA9171. The −U and −V input signals are clamped

during the logic HIGH period of CLP, defined by the

sandcastle reference. In YC-applications just one colour

difference channel is required for processing the chroma

signal. However, external decoupling capacitors should be

applied to both inputs UIN and VIN. The external coupling

capacitor value should be such that the burst period of the

chroma signal is very softly clamped.

The processing is dependent on the amplitude and sign of

the colour difference signals whenever the blue stretch

circuitry is activated. Therefore, both the polarity and the

nominal amplitude of the colour difference signals are

relevant when using the blue stretch facility.

Blue stretch

The blue stretch circuit is intended to shift colours near

white, with sufficient contrast values, towards more blue

coloured white to give a brighter impression. The

chromaticity shift is proportional to the excess of the

contrast value of a white video signal with respect to a user

adjustable minimum level, defined by a voltage at

pin BLM. In this way blue shift in, for instance, human

faces can be prevented. The global amount of blue shift is

defined by the voltage level at pin BLG. The direction of

shift in the colour triangle is fixed by hardware.

It should be noted that the colour shift is different with a

wrong polarity of the colour difference signals. The

preferred BLG and BLM settings will be related to the

actual nominal amplitudes of the colour difference signals.

The blue stretch facility must be disabled in

YC-applications by setting both BLG and BLM to ground.

1996 Jun 17 5

Page 6

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

TDA9171

on histogram modification and blue stretch

LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 134); all voltages referenced to ground.

SYMBOL PARAMETER MIN. MAX. UNIT

V

CC

V

I/O

T

stg

T

amb

HANDLING

All pins are protected against ESD by means of internal clamping diodes. The protection circuit meets the following

specification:

Human body model: C = 100 pF; R = 1.5 kΩ; all pins >3000 V.

Machine model: C = 200 pF; R = 0 Ω; all pins >300 V.

At an ambient temperature of 90 °C, all pins meet the following specification:

> 100 mA or V

I

trigger

I

<−100 mA or V

trigger

Except for pins 4, 7, 8 and 17 at positive trigger currents:

Pin 4 (NLC): I

Pin 7 (YIN): I

Pin 8 (TAUHM): I

Pin 17 (V

ref

supply voltage −0.5 +8.8 V

supply voltage at any other input or output −0.5 VCC+ 0.5 V

storage temperature −55 +150 °C

operating ambient temperature −10 +70 °C

> 1.5 V

): I

trigger

trigger

trigger

pin

pin

> 90 mA or V

> 90 mA or V

> 90 mA or V

trigger

> 90 mA or V

CC(max)

<−0.5 V

CC(max)

pin

> 1.5V

pin

pin

> 1.5V

> 1.5V

pin

> 1.5V

CC(max)

CC(max)

CC(max)

CC(max)

QUALITY SPECIFICATION

In accordance with SNW-FQ-611 part E. The numbers of the quality specification can be found in the

Handbook”

. The handbook can be ordered using the code 9398 510 63011.

“Quality Reference

1996 Jun 17 6

Page 7

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

TDA9171

on histogram modification and blue stretch

CHARACTERISTICS

=8V; T

V

CC

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supplies

V

CC

I

CC

V

ref

I

load

Luminance input and output selection

L

UMINANCE INPUT (PIN 7)

V

iY(es)

V

iY(cl)

I

Y(bias)

LUMINANCE INPUT VOLTAGE RANGE SELECTION (PIN 6)

V

iAMPSEL(l)

V

iAMPSEL(h)

V

iAMPSEL(m)

I

AMPSEL(bias)

LUMINANCE OUTPUT (PIN 14)

V

oY(es)

V

oY(is)

V

oY(cl)

V

oN

B

Y

B

Y(nl)

E

bl

E

G(n)

C

L

=25°C; unless otherwise specified.

amb

supply voltage 7.2 − 8.8 V

supply current − 35 − mA

reference voltage − 5.0 − V

load current −−1mA

input voltage (excluding sync) V

iAMPSEL

V

iAMPSEL

= low − 0.3 0.45 V

= middle or high − 1.0 1.5 V

input voltage level during clamping − 1.5 − V

input bias current −−0.1 µA

input voltage for lower range V

input voltage for higher range V

input voltage for higher range

iAMPSEL

iAMPSEL

V

iAMPSEL

= low −−0.5 V

= high 3.5 5.0 5.5 V

= middle 1.5 − 2.5 V

including 0.7 attenuation

input bias current −−15 µA

output voltage (excluding sync) V

output voltage (including sync) V

output voltage level during clamping V

iAMPSEL

V

iAMPSEL

iAMPSEL

iAMPSEL

V

iAMPSEL

V

iAMPSEL

output voltage noise with respect to peak

= low − 0.3 − V

= high − 1.0 − V

= middle − 1.0 − V

= low − 2.8 − V

= high − 1.7 − V

= middle − 2.2 − V

−−−52 dB

white

bandwidth minimum NLC gain 8 10 − MHz

bandwidth non-linear processing 10 −−MHz

black level error minimum NLC gain −−1.0 %

nominal gain error minimum NLC gain;

V

iAMPSEL

= low

minimum NLC gain;

V

iAMPSEL

= middle or high

−−7%

−−5%

load capacitance fi= 5 MHz −−25 pF

1996 Jun 17 7

Page 8

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

TDA9171

on histogram modification and blue stretch

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Histogram measurement

HISTOGRAM UPDATES AT HMX (PINS 9 TO 13)

Q

HMb

V

HM(av)

V

HM(min)

V

HM(max)

I

HMbias

TIME CONSTANT CONTROL TAUHM (PIN 8)

t

thmr

Q

thms

I

thm(bias)

V

thm(l)

V

thm(h)

MISCOUNT DETECTION

Q

mc(d)

t

d(mcp)

t

mcd(o)

t

mcY

Q

mc(aW)

Q

mc(dW)

Processing of measured histogram values

segment bleeder accuracy −−2%

average voltage level for 5 segments − 1.0 − V

minimum segment voltage level 0 −−V

maximum segment voltage level − 5.0 − V

input bias current −−0.1 µA

response speed see Fig.3 −−−

static error see Fig.4 −−−

input bias current −−0.1 µA

control voltage lower limit − 1.0 − V

control voltage upper limit − 2.0 − V

miscount detection level − 4 − %

miscount propagation delay 20% step − 25 − ns

miscount detection on-time each

− 0.36 −µs

event

mismatch propagation delay and

−−20 ns

luminance delay

miscount activation level at white no miscount − 90 − %

miscount deactivation level at white miscount − 87 − %

W

HITE POINT STRETCH

G

WP

maximum gain luminance for white

maximum NLC gain − 1.1 −

stretch (HM pattern = 00113)

Non-linear amplifier

ON-LINEAR GAIN SET BY HMX (PINS 9 TO 13)

N

Q

nl(b)

G

nlc(min)

segment bleeder accuracy −−3%

minimum gain segment

maximum NLC gain − 0.36 −

(HM pattern = 31100)

G

nlc(max)

maximum gain segment

maximum NLC gain − 2.28 −

(HM pattern = 31100)

NON-LINEAR SETTING NLC (PIN 4)

G

nlc

V

iNLC(l)

V

iNLC(h)

I

iNLC(bias)

non-linear control curve see Fig.5 −−−

control voltage lower limit − 0 − V

control voltage upper limit − 5.0 − V

input bias current −−0.5 µA

1996 Jun 17 8

Page 9

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

TDA9171

on histogram modification and blue stretch

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Colour difference processing

COLOUR DIFFERENCE INPUTS UIN AND VIN (PINS 2 AND 3)

V

iU(p-p)

input voltage (pin 2) (peak-to-peak

value)

V

iV(p-p)

input voltage (pin 3) (peak-to-peak

value)

I

UV(bias)

V

iUV(cl)

input bias current (pins 2 and 3) −−0.1 µA

input voltage level during clamping − 1.5 − V

COLOUR DIFFERENCE OUTPUTS UOUT AND VOUT (PINS 19 AND 18)

V

oU

V

oV

V

oUV(cl)

E

os(UV)

output voltage with respect to pin 2 150 −−%

output voltage with respect to pin 3 150 −−%

output voltage level during clamping − 2.3 − V

offset error minimum BLG and BLM;

minimum NLC gain

G

E(UV)

gain error minimum BLG and BLM;

minimum NLC gain

G

M(UV)

gain mismatch minimum BLG and BLM;

minimum NLC gain

B

UV

bandwidth minimum BLG and BLM;

minimum NLC gain

− 1.33 1.8 V

− 1.05 1.8 V

−−1%

−−10 %

−−5%

10 −−MHz

Blue stretch

C

HROMATICITY SHIFT

∆V

oU

variation of U output voltage in white

part of 100% colour bar

∆V

oV

variation of V output voltage in white

part of 100% colour bar

BLUE STRETCH ACTIVATION AREA (PIN 20)

minimum contrast level range see Fig.6 −−−

V

iBLM(l)

V

iBLM(h)

I

BLM(bias)

input control voltage lower limit − 0 − V

input control voltage upper limit − 5.0 − V

input bias current −−0.5 µA

BLUE STRETCH GAIN (PIN 1)

G

BLG

V

iBLG(l)

V

iBLG(h)

I

BLG(bias)

blue stretch gain range see Fig.7 −−−

input voltage lower limit − 0 − V

input voltage upper limit − 5.0 − V

input bias current −−0.5 µA

BLM = 4.06 V −−0.375 − V

BLG = 3.25 V − 0.150 − V

1996 Jun 17 9

Page 10

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

TDA9171

on histogram modification and blue stretch

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Timing

SANDCASTLE INPUT (PIN 5)

V

iSC

t

SC(sw)

CLP

PULSE WIDTH RESTORATION

t

CLP(diff)

Overall output performance

T

RANSPARENT MODE (NO BLUE STRETCH; NO NON-LINEAR GAIN)

t

d(YUV)

t

d(YUV)m

input voltage detection level blanking no clamp 1.0 1.25 1.5 V

with clamp 3.5 3.8 4.2 V

input sync width for no vertical sync −−15 µs

for vertical sync 35 −−µs

internal CLP pulse width difference −−30 − %

delay from input to output of YUV

signals

matching of YUV delay minimum BLG and BLM;

minimum BLG and BLM;

minimum NLC gain

− 50 100 ns

− 10 20 ns

minimum NLC gain

80

handbook, halfpage

t

thmr

(ms)

60

40

20

0

0 1000

200 400 600 800

R

= ratio of effective histogram measuring time and active video in one field

miscount

defined by the non-blanking periods of the sandcastle signal in one field.

Fig.3 Response speed of average histogram amplitude control loop as a function of C

at both 50 and 60 Hz field rate (R

miscount

60 Hz 50 Hz

= 1; C

HMx

MBE997

C

TAUHM

= 10 nF).

(nF)

TAUHM

1996 Jun 17 10

Page 11

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

on histogram modification and blue stretch

100

handbook, halfpage

Q

THMS

(%)

80

60

40

20

0

020

R

= ratio of effective histogram measuring time and active video in one field

miscount

defined by the non-blanking periods of the sandcastle signal in one field.

4 8 12 16

W

= t

eff

nonblanking_of_SC

x R

MBE995

miscount

TDA9171

(ms)

Fig.4 Static error on average histogram amplitude (pin TAUHM) as a function of effective histogram

measuring time in a field (C

handbook, halfpage

1

G

NLC

0.75

0.5

0.25

0

1.25 2.25 3.25 5.25

HMx

= 10 nF).

4.25

V

iNLC

MBE996

(V)

Fig.5 Non-linear amplifier gain as a function of input voltage at pin NLC.

1996 Jun 17 11

Page 12

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

on histogram modification and blue stretch

300

handbook, halfpage

V

(mV)

0

−300

−600

−900

1.25 2.05 5.25

∆VOUT

∆UOUT

2.85 3.65 4.45

V

MBE994

iBLM

TDA9171

(V)

UIN =VIN = 0; YIN = 100%; V

Fig.6 Blue stretch activation area as a function of input voltage at pin BLM.

= 3.25 V.

iBLG

handbook, halfpage

300

V

(mV)

0

−300

−600

−900

1.25 2.05 5.25

∆VOUT

∆UOUT

2.85 3.65 4.45

V

MBE993

iBLG

(V)

UIN = VIN = 0; YIN = 100%; V

iBLM

= 4.06 V.

Fig.7 Blue stretch gain as a function of input voltage at pin BLG.

1996 Jun 17 12

Page 13

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

TDA9171

on histogram modification and blue stretch

TEST AND APPLICATION INFORMATION

The TDA9171 is especially designed for YUV applications. A typical application diagram is shown in Fig.8. Jumpers

J1 and J2 can be used to select the appropriate luminance amplitude mode. Potentiometers BLG, BLM and NLC can be

used to apply proper blue stretch and non-linear amplifier control voltages.

The TDA9171 is also prepared for YC-processing. A typical application diagram is shown in Fig.9. Jumpers J1 and J2

can be used to select the appropriate luminance amplitude mode. Potentiometer NLC can be used to apply the proper

non-linear amplifier control voltage. For the chroma processing either the U- or V-channel can be used, however both

channels need to be DC-decoupled and the DC-decoupling capacitor value should be such that the burst period of the

chroma signal Cin is very softly clamped. The blue stretch circuitry cannot be used in YC-applications and should be

switched off by connecting both blue stretch adjustments (BLG and BLG) to ground.

handbook, full pagewidth

470 kΩ

1

UIN UOUT

VIN

SC

J1 J2

180 kΩ

YIN

220 kΩ

10 nF

10 nF

470 kΩ

100 nF

220 nF

10 nF

10 nF

2

3

4

5

TDA9171

6

7

8

9

10

MGD298

BLMBLG

470 kΩ

20

19

100 nF

VOUT

V

CC

GND

YOUT

18

17

16

100 nF

15

14

13

12

11

10 nF

10 nF

10 nF

Fig.8 YUV application.

1996 Jun 17 13

Page 14

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

on histogram modification and blue stretch

handbook, full pagewidth

1

CIN COUT

SC

J1 J2

180 kΩ

YIN

220 kΩ

100 nF

100 nF

NLC

470 kΩ

100 nF

220 nF

10 nF

10 nF

2

3

4

5

TDA9171

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

MBH500

10 nF

10 nF

10 nF

100 nF

100 nF

V

CC

GND

YOUT

TDA9171

Fig.9 YC application.

1996 Jun 17 14

Page 15

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

on histogram modification and blue stretch

PACKAGE OUTLINE

DIP20: plastic dual in-line package; 20 leads (300 mil)

D

seating plane

L

Z

20

e

b

TDA9171

SOT146-1

M

E

A

2

A

A

1

w M

b

1

11

c

(e )

1

M

H

pin 1 index

1

0 5 10 mm

scale

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

A

A

A

UNIT

inches

Note

1. Plastic or metal protrusions of 0.25 mm maximum per side are not included.

max.

mm

OUTLINE

VERSION

SOT146-1

1 2

min.

max.

1.73

1.30

0.068

0.051

IEC JEDEC EIAJ

b

b

1

0.53

0.38

0.021

0.015

0.014

0.009

REFERENCES

cD E e M

0.36

0.23

(1) (1)

26.92

26.54

1.060

1.045

SC603

6.40

6.22

0.25

0.24

E

10

(1)

M

e

L

1

3.60

8.25

3.05

7.80

0.14

0.32

0.12

0.31

EUROPEAN

PROJECTION

H

E

10.0

0.2542.54 7.62

8.3

0.39

0.010.10 0.30

0.33

ISSUE DATE

w

92-11-17

95-05-24

Z

max.

2.04.2 0.51 3.2

0.0780.17 0.020 0.13

1996 Jun 17 15

Page 16

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

on histogram modification and blue stretch

SOLDERING DIP, SDIP, HDIP, DBS and SIL

Introduction

There is no soldering method that is ideal for all IC

packages. Wave soldering is often preferred when

through-hole and surface mounted components are mixed

on one printed-circuit board. However, wave soldering is

not always suitable for surface mounted ICs, or for

printed-circuits with high population densities. In these

cases reflow soldering is often used.

This text gives a very brief insight to a complex technology.

A more in-depth account of soldering ICs can be found in

“IC Package Databook”

our

Soldering by dip or wave

The maximum permissible temperature of the solder is

260 °C; solder at this temperature must not be in contact

with the joint for more than 5 seconds.

(order code 9398 652 90011).

TDA9171

The total contact time of successive solder waves must not

exceed 5 seconds.

The device may be mounted to the seating plane, but the

temperature of the plastic body must not exceed the

specified storage maximum. If the printed-circuit board has

been pre-heated, forced cooling may be necessary

immediately after soldering to keep the temperature within

the permissible limit.

Repairing soldered joints

Apply a low voltage soldering iron (less than 24 V) to the

lead(s) of the package, below the seating plane or not

more than 2 mm above it. If the temperature of the

soldering iron bit is less than 300 °C it may remain in

contact for up to 10 seconds. If the bit temperature is

between 300 and 400 °C, contact may be up to 5 seconds.

DEFINITIONS

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

1996 Jun 17 16

Page 17

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

on histogram modification and blue stretch

NOTES

TDA9171

1996 Jun 17 17

Page 18

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

on histogram modification and blue stretch

NOTES

TDA9171

1996 Jun 17 18

Page 19

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

on histogram modification and blue stretch

NOTES

TDA9171

1996 Jun 17 19

Page 20

Philips Semiconductors – a worldwide company

Argentina: see South America

Australia: 34 Waterloo Road, NORTH RYDE, NSW 2113,

Tel. +61 2 805 4455, Fax. +61 2 805 4466

Austria: Computerstr. 6, A-1101 WIEN, P.O. Box 213,

Tel. +43 1 60 101, Fax. +43 1 60 101 1210

Belarus: Hotel Minsk Business Center, Bld. 3, r. 1211, Volodarski Str. 6,

220050 MINSK, Tel. +375 172 200 733, Fax. +375 172 200 773

Belgium: see The Netherlands

Brazil: see South America

Bulgaria: Philips Bulgaria Ltd., Energoproject, 15thfloor,

51 James Bourchier Blvd., 1407 SOFIA,

Tel. +359 2 689 211, Fax. +359 2 689 102

Canada: PHILIPS SEMICONDUCTORS/COMPONENTS,

Tel. +1 800 234 7381, Fax. +1 708 296 8556

China/Hong Kong: 501 Hong Kong Industrial Technology Centre,

72 Tat Chee Avenue, Kowloon Tong, HONG KONG,

Tel. +852 2319 7888, Fax. +852 2319 7700

Colombia: see South America

Czech Republic: see Austria

Denmark: Prags Boulevard 80, PB 1919, DK-2300 COPENHAGEN S,

Tel. +45 32 88 2636, Fax. +45 31 57 1949

Finland: Sinikalliontie 3, FIN-02630 ESPOO,

Tel. +358 615 800, Fax. +358 615 80920

France: 4 Rue du Port-aux-Vins, BP317, 92156 SURESNES Cedex,

Tel. +33 1 40 99 6161, Fax. +33 1 40 99 6427

Germany: Hammerbrookstraße 69, D-20097 HAMBURG,

Tel. +49 40 23 52 60, Fax. +49 40 23 536 300

Greece: No. 15, 25th March Street, GR 17778 TAVROS,

Tel. +30 1 4894 339/911, Fax. +30 1 4814 240

Hungary: see Austria

India: Philips INDIA Ltd, Shivsagar Estate, A Block, Dr. Annie Besant Rd.

Worli, MUMBAI 400 018, Tel. +91 22 4938 541, Fax. +91 22 4938 722

Indonesia: see Singapore

Ireland: Newstead, Clonskeagh, DUBLIN 14,

Tel. +353 1 7640 000, Fax. +353 1 7640 200

Israel: RAPAC Electronics, 7 Kehilat Saloniki St, TEL AVIV 61180,

Tel. +972 3 645 0444, Fax. +972 3 648 1007

Italy: PHILIPS SEMICONDUCTORS, Piazza IV Novembre 3,

20124 MILANO, Tel. +39 2 6752 2531, Fax. +39 2 6752 2557

Japan: Philips Bldg 13-37, Kohnan 2-chome, Minato-ku, TOKYO 108,

Tel. +81 3 3740 5130, Fax. +81 3 3740 5077

Korea: Philips House, 260-199 Itaewon-dong, Yongsan-ku, SEOUL,

Tel. +82 2 709 1412, Fax. +82 2 709 1415

Malaysia: No. 76 Jalan Universiti, 46200 PETALING JAYA, SELANGOR,

Tel. +60 3 750 5214, Fax. +60 3 757 4880

Mexico: 5900 Gateway East, Suite 200, EL PASO, TEXAS 79905,

Tel. +1 800 234 7381, Fax. +1 708 296 8556

Middle East: see Italy

Netherlands: Postbus 90050, 5600 PB EINDHOVEN, Bldg. VB,

Tel. +31 40 27 83749, Fax. +31 40 27 88399

New Zealand: 2 Wagener Place, C.P.O. Box 1041, AUCKLAND,

Tel. +64 9 849 4160, Fax. +64 9 849 7811

Norway: Box 1, Manglerud 0612, OSLO,

Tel. +47 22 74 8000, Fax. +47 22 74 8341

Philippines: Philips Semiconductors Philippines Inc.,

106 Valero St. Salcedo Village, P.O. Box 2108 MCC, MAKATI,

Metro MANILA, Tel. +63 2 816 6380, Fax. +63 2 817 3474

Poland: Ul. Lukiska 10, PL 04-123 WARSZAWA,

Tel. +48 22 612 2831, Fax. +48 22 612 2327

Portugal: see Spain

Romania: see Italy

Russia: Philips Russia, Ul. Usatcheva 35A, 119048 MOSCOW,

Tel. +7 095 926 5361, Fax. +7 095 564 8323

Singapore: Lorong 1, Toa Payoh, SINGAPORE 1231,

Tel. +65 350 2538, Fax. +65 251 6500

Slovakia: see Austria

Slovenia: see Italy

South Africa: S.A. PHILIPS Pty Ltd., 195-215 Main Road Martindale,

2092 JOHANNESBURG, P.O. Box 7430 Johannesburg 2000,

Tel. +27 11 470 5911, Fax. +27 11 470 5494

South America: Rua do Rocio 220 - 5th floor, Suite 51,

CEP: 04552-903-SÃO PAULO-SP, Brazil, P.O. Box 7383 (01064-970),

Tel. +55 11 821 2333, Fax. +55 11 829 1849

Spain: Balmes 22, 08007 BARCELONA,

Tel. +34 3 301 6312, Fax. +34 3 301 4107

Sweden: Kottbygatan 7, Akalla, S-16485 STOCKHOLM,

Tel. +46 8 632 2000, Fax. +46 8 632 2745

Switzerland: Allmendstrasse 140, CH-8027 ZÜRICH,

Tel. +41 1 488 2686, Fax. +41 1 481 7730

Taiwan: PHILIPS TAIWAN Ltd., 23-30F, 66,

Chung Hsiao West Road, Sec. 1, P.O. Box 22978,

TAIPEI 100, Tel. +886 2 382 4443, Fax. +886 2 382 4444

Thailand: PHILIPS ELECTRONICS (THAILAND) Ltd.,

209/2 Sanpavuth-Bangna Road Prakanong, BANGKOK 10260,

Tel. +66 2 745 4090, Fax. +66 2 398 0793

Turkey: Talatpasa Cad. No. 5, 80640 GÜLTEPE/ISTANBUL,

Tel. +90 212 279 2770, Fax. +90 212 282 6707

Ukraine: PHILIPS UKRAINE, 2A Akademika Koroleva str., Office 165,

252148 KIEV, Tel. +380 44 476 0297/1642, Fax. +380 44 476 6991

United Kingdom: Philips Semiconductors Ltd., 276 Bath Road, Hayes,

MIDDLESEX UB3 5BX, Tel. +44 181 730 5000, Fax. +44 181 754 8421

United States: 811 East Arques Avenue, SUNNYVALE, CA 94088-3409,

Tel. +1 800 234 7381, Fax. +1 708 296 8556

Uruguay: see South America

Vietnam: see Singapore

Yugoslavia: PHILIPS, Trg N. Pasica 5/v, 11000 BEOGRAD,

Tel. +381 11 825 344, Fax.+381 11 635 777

For all other countries apply to: Philips Semiconductors, Marketing & Sales Communications,

Building BE-p, P.O. Box 218, 5600 MD EINDHOVEN, The Netherlands, Fax. +31 40 27 24825

© Philips Electronics N.V. 1996 SCA49

All rights are reserved. Reproduction in whole or in part is prohibited without the prior written consent of the copyright owner.

The information presented in this document does not form part of any quotation or contract, is believed to be accurate and reliable and may be changed

without notice. No liability will be accepted by the publisher for any consequence of its use. Publication thereof does not convey nor imply any license

under patent- or other industrial or intellectual property rights.

Printed in The Netherlands 537021/50/02/pp20 Date of release: 1996 Jun 17 Document order number: 9397 750 00911

Internet: http://www.semiconductors.philips.com/ps/

(1) ADDRESS CONTENT SOURCE June 17, 1996

Loading...

Loading...