Page 1

October 1994 2

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

on histogram modification

TDA9170

FEATURES

• Picture content dependent non-linear Y and U, V

processing by histogram analysis

• Adaptive and variable gamma correction controls

• Black and white stretch capabilities

• Transparent I2C-bus control

• On-chip window generator for valid histogram

measurement and black detection.

GENERAL DESCRIPTION

The TDA9170 is a transparent analog video processor

with a YUV interface. It offers three main luminance

processing functions any combination of which can be

selected.

The luminance transfer is controlled in a non-linear

manner by the distribution (in 5 discrete histogram

sections) of the luminance values measured in a picture.

As a result, the contrast ratio of the most important parts of

the picture will be improved.

Black restoration is available in the event of a set-up in the

luminance signal. A variable gamma function, after the

histogram conversion, offers the possibility of excellent

brightness control.

To maintain a proper colour reproduction, the saturation of

the U and V colour difference signals are controlled as a

function of the actual non-linearity in the luminance

channel.

The TDA9170 concept has maximum flexibility with the

optional on-board I

2

C-bus (including hardwired address

select) and window control. The supply voltage is 8 V. The

device is mounted in a 32 pin SDIP envelope.

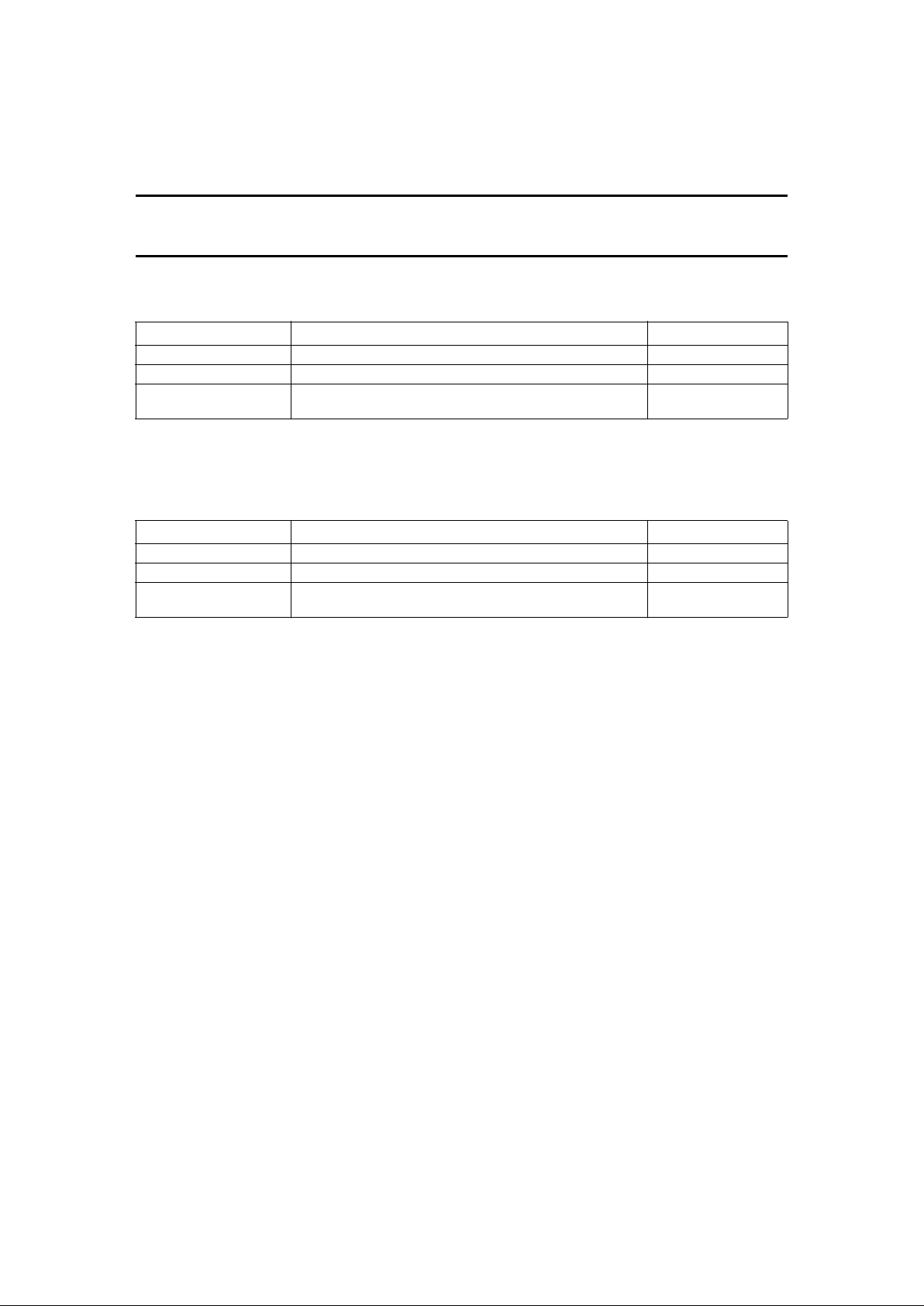

ORDERING INFORMATION

TYPE NUMBER

PACKAGE

NAME DESCRIPTION VERSION

TDA9170 SDIP32 plastic shrink in-line package; 32 leads (400 mil) SOT232-1

Page 2

October 1994 3

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

on histogram modification

TDA9170

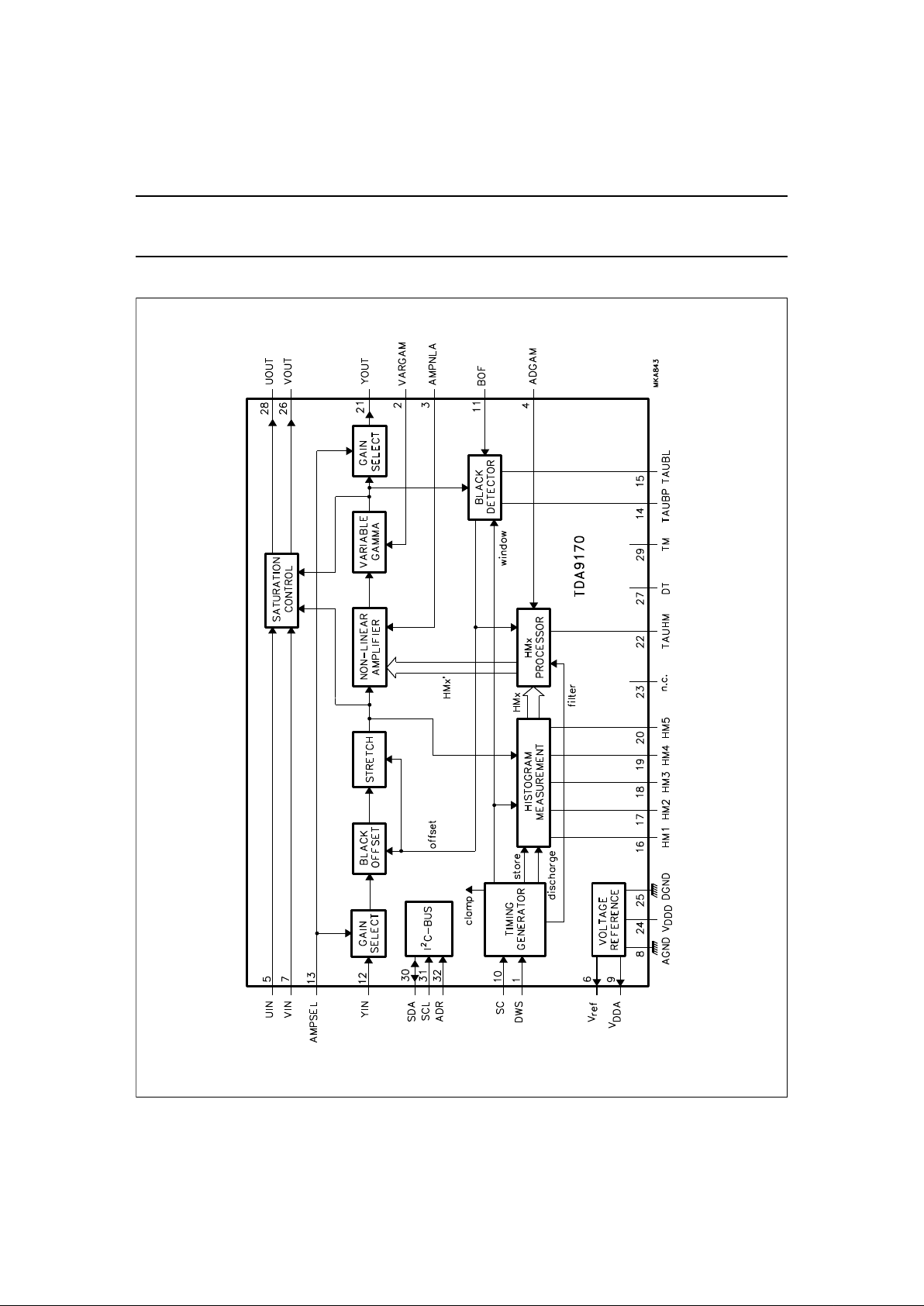

BLOCK DIAGRAM

Fig.1 Block diagram.

Page 3

October 1994 4

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

on histogram modification

TDA9170

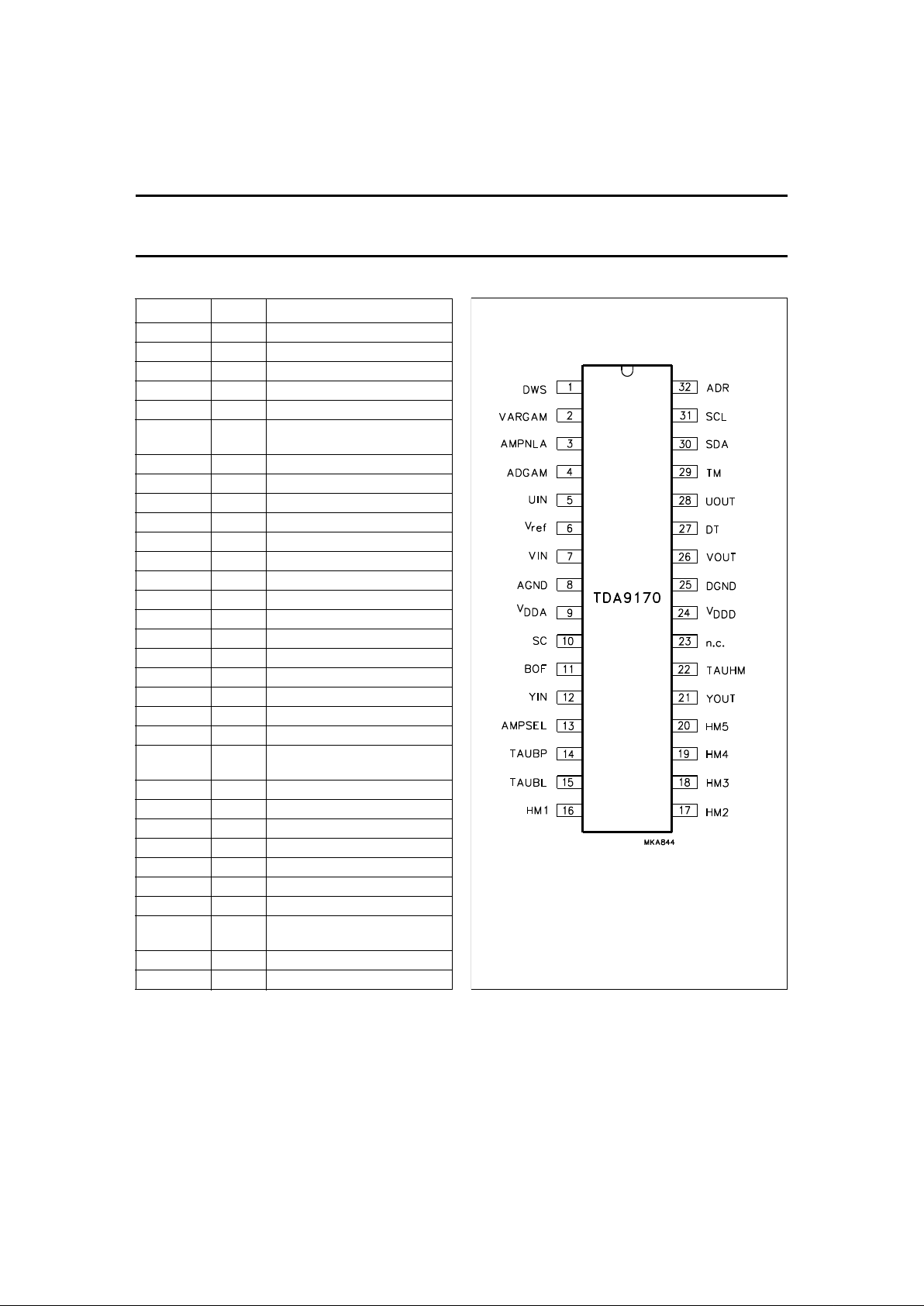

PINNING

SYMBOL PIN DESCRIPTION

DWS 1 default window select input

VARGAM 2 variable gamma input

AMPNLA 3 amplitude non-linearity input

ADGAM 4 adaptive gamma input

UIN 5 colour difference U input

V

ref

6 reference supply voltage output

(+4 V)

VIN 7 colour difference V input

AGND 8 analog ground

V

DDA

9 analog supply voltage

SC 10 sandcastle input

BOF 11 black offset on/off input

YIN 12 luminance input

AMPSEL 13 amplitude select input

TAUBP 14 time constant black peak

TAUBL 15 time constant black loop

HM1 16 histogram segment memory 1

HM2 17 histogram segment memory 2

HM3 18 histogram segment memory 3

HM4 19 histogram segment memory 4

HM5 20 histogram segment memory 5

YOUT 21 luminance output

TAUHM 22 time constant histogram

measurement loop

n.c. 23 not connected

V

DDD

24 digital supply voltage (+5 V)

DGND 25 digital ground

VOUT 26 colour difference V output

DT 27 test option

UOUT 28 colour difference U output

TM 29 test option

SDA 30 serial data input/output

(I2C-bus)

SCL 31 serial clock input (I2C-bus)

ADR 32 address select input (I2C-bus)

Fig.2 Pin configuration.

Page 4

October 1994 5

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

on histogram modification

TDA9170

FUNCTIONAL DESCRIPTION

Y input selection and amplification

The dynamic range of the luminance input amplifier can be

switched between 0.3 and 1 V (excluding sync) either

externally (pin AMPSEL) or by I2C-bus (AMPSEL bit).

Amplitudes that exceed the corresponding specified range

(e.g. the sync) will be clipped internally. The input is

clamped during the logic HIGH period of the clamp which

is defined by the sandcastle reference and should be

DC-decoupled with an external capacitor.

Black offset detection and correction

The black detector measures and stores the blackest part

of the picture within a defined window in each field. Any

difference between this value and the value measured

during the black clamp period is regarded as black offset.

In a closed loop configuration, the black offset is held until

a predefined value of the full scale (FS) value is fed back

to the input stage where it is partly compensated for.

Depending on the loop gain, 30% to 50% of the offset

value is counteracted. The loop gain is also a function of

the adaptive and variable gamma settings. The black

offset correction mechanism can be switched on and off by

the I

2

C-bus via the BON bit (see Table 6), or externally with

the black offset on/off switch (BOF pin 11).

Two external time constants are required to ensure correct

performance of the black detector; a loop filter time

constant (TAUBL) for the loop dynamics and a time

constant for memorizing the darkest parts of the picture

(TAUBP) in just one field. During the field retrace the time

constant TAUBP is first sampled and then preset to a value

that corresponds to the maximum black offset.

The corrected black offset is related to the nominal signal

amplitude which is reset to 100% FS via an amplitude

stretch function. Luminance values beyond FS are not

affected. Additionally, this offset is also used to set the

adaptive gain (see Section “Adaptive gamma”).

Histogram measurement

The histogram distribution is measured in real time over

five segments (HM1 to HM5) within a defined window

period of each field. During the window period, the video is

in one segment, a corresponding external capacitor C

HMx

is loaded via a current source. At the end of the field five

segment voltages are stored from the external capacitors

into on-board memories. The external capacitors are

discharged and the measurements are restarted.

Any part of the picture that does not contribute to the

information within the total picture should be omitted from

the histogram measurement. The miscount detector

disables measurements until it detects changing parts.

Additionally, luminance values close to FS (or white) do

not contribute sufficiently in order to maintain the absolute

light output. This procedure is allowed because the eye is

less sensitive to details in white.

As the miscount detector shortens the effective

measurement period and, because of spreads of internal

and external components, the current source is controlled

within in a closed loop so as to maintain a constant

average value of the sum of the segment voltages. The

dominant time constant of the closed loop is external and

can be tuned with an appropriate capacitor connected to

TAUHM (pin 22).

Processing of the measured histogram values

FIELD AVERAGING OF HISTOGRAM VALUES

With very rapid picture changes, also related to the field

interlace, flicker might result. The histogram values are

averaged at the field rate to reduce these flicker effects.

The time constant of the averaging process is adapted to

the speed of the histogram changes.

ADAPTIVE GAMMA

The output voltage of the first segment is fed to a variable

gain amplifier with a gain between 1 and 3. In this way

luminance values in the ‘black’ segment have a larger

weight. In our perception black parts are expanded, as

occurs with gamma control. However, the effective

contribution to the non-linear gain is only relevant for

moderate segment voltages and hence the term adaptive

gamma.

The adaptive gamma gain is amax-function of a fixed gain

part and a dynamic gain part. The fixed gain part can be

set externally with the adaptive gamma gain control

(ADGAM) or via the I2C-bus.

The dynamic part of the adaptive gamma gain is controlled

by the measured black offset value from the black

detector.

Page 5

October 1994 6

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

on histogram modification

TDA9170

ADAPTIVE WHITE-POINT STRETCHING

For dominant HM4 and HM5 voltages or large white parts

the histogram conversion procedure makes a transfer with

large gain in the white parts. However, the amount of light

being emitted from the picture is considerably reduced.

The white stretcher introduces additional overall gain for

increased light production and, as a result, violates the

principle of having a full-scale reference.

S

TANDARD DEVIATION

For pictures in which segments of the histogram

distribution are very dominant, with respect to the others,

the non-linear amplification should be reduced to

compensate for pictures with a flat histogram distribution.

The standard deviation detector measures the spread of

the histogram distribution in the segments HM1 to HM5

and modulates the user setting of the non-linear amplifier.

Non-linear amplifier

The stored segment voltages, relative to their average

value and averaged over two fields, determine the

individual gain of each segment in such a way that

continuity is guaranteed for the complete range. The

maximum and minimum gain of each segment is limited.

Apart from the adaptive white-point stretching the black

and white references are not affected by the non-linear

processing. The amount of linearity can be controlled

externally at AMPNLA (pin 3) or via the I2C-bus.

Variable gamma function

As well as the histogram conversion, a variable gamma

function can be applied to ensure excellent brightness

control. It is intended as an alternative to the DC-offset of

the classic brightness user control; it maintains the black

and white references. The gamma ranges from 0.5 to 1.5.

The gamma can be set externally at VARGAM (pin 2) or

via the I2C-bus.

Colour compensation

Non-linear luminance processing influences the colour

reproduction, mainly the colour saturation. Therefore, U

and V signals are also processed for saturation

compensation. The U and V input signals are clamped

during the logic HIGH period of the clamp which is defined

by the sandcastle reference and should be DC decoupled

with external capacitors.

Timing generator

The TDA9170 is equipped with a transparent internal

timing generator for window purposes. As a timing

reference the relevant sandcastle (SC) can be used. The

window enables the black measurement and the

histogram measurement circuitry. The internal timing

generator is basically intended for system invariant

operation. The default window handles all existing norms

and disables measurement in subtitles or logos. This

default window is preset at power-up and can be selected

with a logic HIGH level at the default window select DWS

(pin 1). If not selected the blanking of the sandcastle will

define the window borders.

However, using the I

2

C-bus and setting the WD1 and WD2

control bits (see Table 3), the window format can also be

user-programmed. The horizontal window generator

synchronizes on the rising edge of the burst key/clamp key

of the external sandcastle reference with an adjustable

window start and stop delay. The vertical window

generator synchronizes on the falling edge of the first burst

key/clamp key after a field pulse recognition.

I2C-bus specification

The I2C-bus is designed for transparent use. At power-up

all registers are preset for system invariant and external

control. All pins related to the I2C-bus can be left

open-circuit when the I2C-bus is in the standby mode. If

the sleep mode bit in the control register is set all settings

are left to bus control. For the relevant registers and

addresses see Tables 2 to 8.

Page 6

October 1994 7

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

on histogram modification

TDA9170

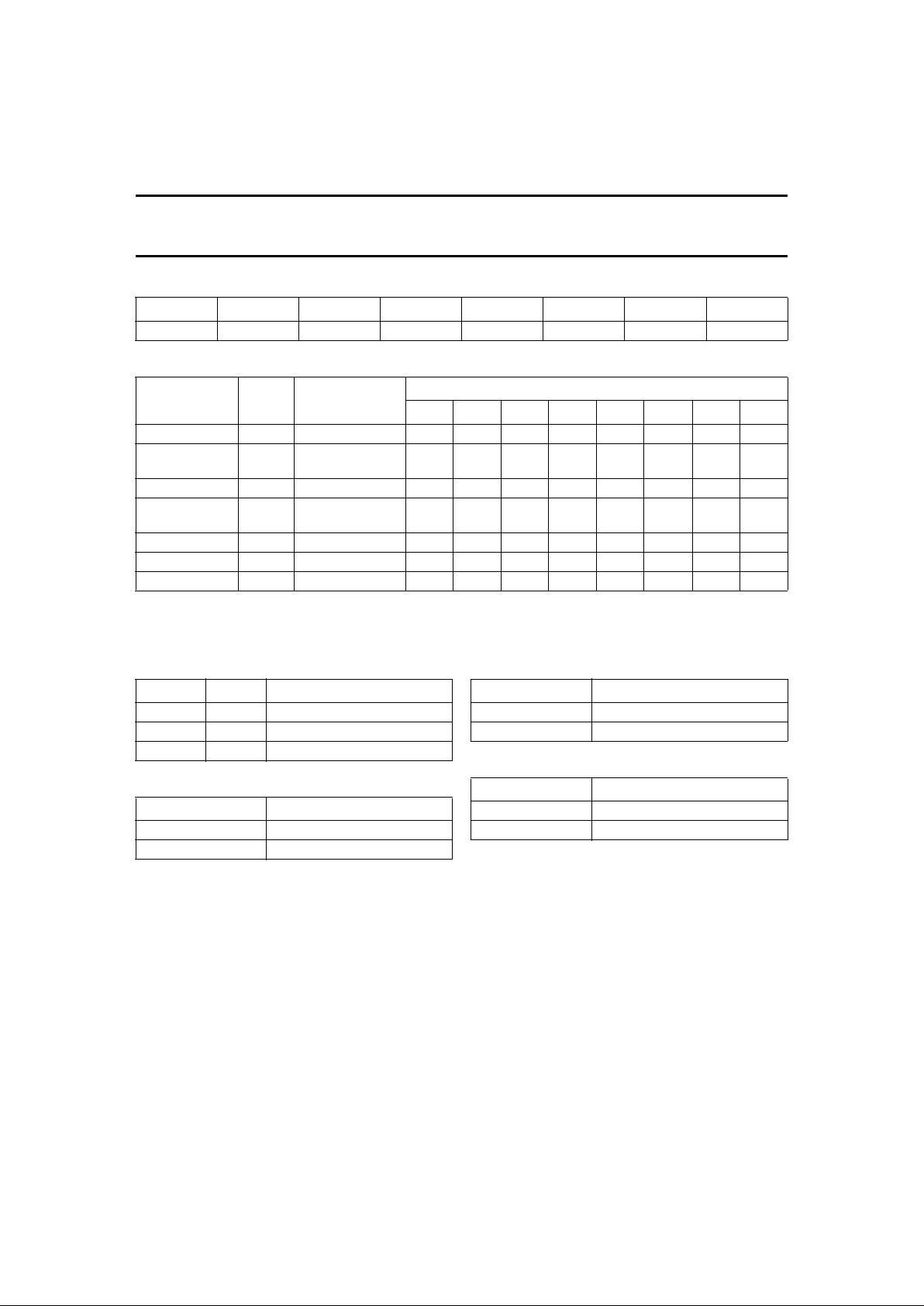

Table 1 Slave address.

Table 2 Control function.

Note

1. Valid sub-addresses: 00 to 05 (HEX); auto-increment mode available for sub-addresses.

A6 A5 A4 A3 A2 A1 A0 R/W

1 1 0 1 0 0 ADR X

CONTROL

FUNCTION

TYPE SUB-ADDRESS

(1)

DATA BYTE

D7 D6 D5 D4 D3 D2 D1 D0

Control REG 00 X X X BON WD2 WD1 AMS SLP

User variable

gamma

DAC 01 X X D5 D4 D3 D2 D1 D0

Adaptive gamma DAC 02 X X D5 D4 D3 D2 D1 D0

Non-linear

amplifier

DAC 03 X X D5 D4 D3 D2 D1 D0

Line start stop REG 04 ST3 ST2 ST1 ST0 SP3 SP2 SP1 SP0

Field start stop REG 05 ST3 ST2 ST1 ST0 SP3 SP2 SP1 SP0

Status REG − X X X X X X X POR

Table 3 Window select bits (WD1 and WD2).

Table 4 Amplitude select bit (AMS).

WD1 WD2 FUNCTION

0 0 default window

0 1 window by sandcastle blanking

1 X user window

LOGIC LEVEL FUNCTION

0 0.3 V luminance

1 1 V luminance

Table 5 Sleep mode bit (SLP).

Table 6 Black offset compensation enable bit (BON).

LOGIC LEVEL FUNCTION

0 sleep

1 I2C-bus control

LOGIC LEVEL FUNCTION

0 disabled

1 enabled

Page 7

October 1994 8

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

on histogram modification

TDA9170

Window formats

Table 7 Line frequency start stop format.

Notes

1. Start and stop events are relative to the leading edge of the BK/CLP pulse of the sandcastle.

2. fh is defined as the line frequency.

Table 8 Field frequency start stop format.

Note

1. The start event is relative to the trailing edge of the first BK/CLP pulse after a field pulse recognition. The stop event

is relative to the actual start event.

LINE WINDOW

(1)

TIMING

(2)

UNIT

Start (LWS)

4.5

⁄

64fh

+1⁄

64fh

× DEC(ST3, ST2, ST1, ST0) µs

Stop (LWP)

26.5

⁄

64fh

+2⁄

64fh

× DEC(SP3, SP2, SP1, SP0) µs

Default DEC(ST3, ST2, ST1, ST0) = 2

DEC(SP3, SP2, SP1, SP0) = 14

FIELD WINDOW

(1)

TIMING UNIT

Start (FWS) 10 + 6 × DEC(ST3, ST2, ST1, ST0) lines

Stop (FWP) 121 + 10 × DEC(SP3, SP2, SP1, SP0) lines

Default DEC(ST3, ST2, ST1, ST0) = 9

DEC(SP3, SP2, SP1, SP0) = 4

Page 8

October 1994 9

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

on histogram modification

TDA9170

LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 134).

Notes

1. Human body model: equivalent to discharging a 100 pF capacitor through a 1.5 kΩ resistor.

2. Machine model: equivalent to discharging a 200 pF capacitor through a 0 Ω resistor.

QUALITY SPECIFICATION

In accordance with

“SNW-FQ-611 part E”

. The numbers of the quality specification can be found in the

“Quality

Reference Handbook”

. The Handbook can be ordered using the code 9398 510 63011. All pins are protected against

electrostatic discharge by means of clamping diodes.

Latch-up

At T

amb

= 70 °C all pins meet the specification as follows, except for pins 6 and 7 at positive trigger currents:

I

trigger

> 100 mA or V

pin

> 1.5V

DDA(max)

.

I

trigger

< −100 mA or V

pin

< −0.5V

DDA(max)

.

pin 6, V

ref

: I

trigger

> 40 mA or V

pin

> 1.5V

DDA(max)

.

pin 24, V

DDD

: I

trigger

> 70 mA or V

pin

> 1.5V

DDA(max)

.

THERMAL CHARACTERISTICS

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

V

DDA

analog supply voltage −0.5 +8.8 V

V

DDD

digital supply voltage −0.5 +5.5 V

V

ref

reference supply voltage −0.5 +5.5 V

V

n

voltage input/output on any other pin −0.5 V

DDA

+ 0.5 V

T

stg

storage temperature −55 +150 °C

T

amb

operating ambient temperature −10 +70 °C

V

es

electrostatic discharge note 1 −2000 +2000 V

note 2 −200 +200 V

SYMBOL PARAMETER VALUE UNIT

R

th j-a

thermal resistance from junction to ambient in free air 48 K/W

Page 9

October 1994 10

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

on histogram modification

TDA9170

CHARACTERISTICS

V

DDA

= 8 V; T

amb

= 25 °C; unless otherwise specified.

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supply (pins 6, 9 and 24)

V

DDA

analog supply voltage 7.2 − 8.8 V

V

DDD

digital supply voltage − 5.0 − V

V

ref

reference supply voltage − 4.0 − V

I

DDA

analog supply current − 40 − mA

Z

o(24)

output impedance − − 250 Ω

Z

o(6)

output impedance − − 250 Ω

Luminance input/output selection

LUMINANCE INPUT (PIN 12); note 1

V

i(Y)

luminance input voltage AMPSEL= 0 0.3 − − V

AMPSEL = 1 1.0 − − V

V

i(Yclamp)

input voltage level during

clamping

− 1.5 − V

I

ib(Y)

input bias current − − 0.1 µA

LUMINANCE INPUT VOLTAGE RANGE SELECTION AMPSEL (PIN 13); note 2

V

i(SEL)l

input voltage selection for lower

range

− − 1.5 V

V

i(SEL)h

input voltage selection for

higher range

3.5 − − V

I

ib(SEL)

input bias current − − 0.1 µA

LUMINANCE OUTPUT (PIN 21)

V

o(Y)

luminance output voltage AMPSEL = 0 0.3 − − V

AMPSEL = 1 1.0 − − V

V

oYclamp

output voltage level during

clamping

AMPSEL = 0 − 2.9 − V

AMPSEL = 1 − 2.0 − V

V

no

output noise voltage 52 − − dB

B

Y

luminance bandwidth transparent 7 9 − MHz

B

Y(nl)

non-linear processing

luminance bandwidth

10 − − MHz

E

bl

black level error no offset; transparent − − 1 %

E

G(n)

nominal gain error no offset; transparent − − 8 %

Black detection and correction

BLACK DETECTOR

Bl

osd(max)

maximum black offset detection

at the input

23 25 27 %

Bl

osc(max)

maximum black offset correction

at the input

8 10 12 %

Page 10

October 1994 11

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

on histogram modification

TDA9170

PICTURE AMPLITUDE STRETCH

E

G(s)

gain error after stretch maximum offset − − 1 %

BLACK OFFSET CORRECTION ON/OFF SWITCH BOF (PIN 11); note 2

V

i(blos)

input voltage level correction off − − 1.5 V

correction on 3.5 − − V

I

ib(blos)

input bias current − − 0.1 µA

TIME CONSTANT CONTROL TAUBP (PIN 4); see Fig.3

I

BP(d)

discharge current − − 3.5 mA

I

ibBP

input bias current − − 0.1 µA

V

BP(l)

control voltage lower limit − 1.0 − V

V

BP(h)

control voltage upper limit − 2.5 − V

TIME CONSTANT CONTROL TAUBL (PIN 5); see Fig.4

I

ibBL

input bias current − − 0.1 µA

V

BL(l)

control voltage lower limit − 2.0 − V

V

BL(h)

control voltage upper limit − 3.5 − V

Histogram measurement

HISTOGRAM UPDATES AT HMX (PINS 16 TO 20)

Q

HMb

segment bleeder accuracy − − 2 %

V

HM(av)

average voltage level for

5 segments

− 1.0 − V

V

HM(min)

minimum segment voltage level 0 − − V

V

HM(max)

maximum segment voltage level − 5.0 − V

I

ibHM

input bias current − − 0.1 µA

TIME CONSTANT CONTROL TAUHM (PIN 22); see Figs 5, 6 and 7

I

ibTHM

input bias current − − 0.1 µA

V

THM(l)

control voltage lower limit − 1.0 − V

V

THM(h)

control voltage upper limit − 2.0 − V

MISCOUNT DETECTION

Q

mc(d)

miscount detection level − 5 − %

t

p(mc)

miscount propagation delay 20% step − 25 − ns

t

o(mc)

miscount detection on-time for

each event

0.31 0.36 0.41 µs

t

Y(mc)

mismatch propagation and

luminance delay

− − 20 ns

Q

mc(aW)

miscount activation level at

white

no miscount − 90 − %

Q

mc(dW)

miscount de-activation level at

white

miscount − 87 − %

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Page 11

October 1994 12

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

on histogram modification

TDA9170

Processing of measured histogram values

ADAPTIVE GAMMA CONTROL RANGE

G

adg(min)

minimum gain for HM1 − 1 −

G

adg(max)

maximum gain for HM1 − 3 −

ADAPTIVE GAMMA SETTING ADGAM (PIN 4); note 3; see Fig.8

V

adg(l)

control voltage lower limit − 1.75 − V

V

adg(h)

control voltage upper limit − 3.25 − V

I

ibADG

input bias current − − 0.1 µA

G

adp(min)

minimum gain for HM1 no offset; G

VAR

= 1 − 1 −

G

adp(max)

maximum gain for HM1 no offset; G

VAR

= 1 − 3 −

ADAPTIVE GAMMA BY BLACK OFFSET

G

adb(min)

minimum gain for HM1 no offset; G

VAR

= 1 − 1 −

G

adb(max)

maximum gain for HM1 maximum offset;

G

VAR

= 1

− 2.5 −

WHITE-POINT STRETCH

G

wp

maximum gain luminance for

white stretch

HM-pattern = 01103:

Gnl= 1

− 1.09 −

Non-linear amplifier

N

ON-LINEAR GAIN SET BY HMX (PINS 16 TO 20)

Q

nl(b)

segment bleeder accuracy − − 2 %

G

nl(min)

minimum gain segment HM-pattern= 31100:

Gnl= 1

− 0.36 −

G

nl(max)

maximum gain segment HM-pattern = 31100:

Gnl= 1

− 2.28 −

NON-LINEARITY SETTING AMPNLA (PIN 3); note 3

V

nl(l)

control voltage lower limit − 1.75 − V

V

nl(h)

control voltage upper limit − 3.25 − V

I

ib(nl)

input bias current − − 0.1 µA

DYNAMICS

t

d(nl)

delay between linear and

non-linear path

− − 20 ns

Variable gamma

V

ARIABLE GAMMA CONTROL RANGE

G

VAR(min)

minimum variable gamma

setting

− 0.5 −

G

VAR(max)

maximum variable gamma

setting

− 1.5 −

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Page 12

October 1994 13

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

on histogram modification

TDA9170

VARIABLE GAMMA SETTING VARGAM(PIN 2);note3

V

VAR(l)

control voltage lower limit − 1.75 − V

V

VAR(h)

control voltage upper limit − 3.25 − V

V

VAR(lt)

control voltage for linear transfer − 2.5 − V

I

ibVAR

input bias current − − 0.1 µA

Colour difference processing

COLOUR DIFFERENCE INPUTS UIN AND VIN (PINS 5 AND 7)

V

i(UIN)

input voltage 1.8 − − V

V

i(VIN)

input voltage 1.8 − − V

I

ib

input bias current (pins 5 and 7) − − 0.1 µA

V

i(cl)

input voltage level during

clamping

− 1.5 − V

COLOUR DIFFERENCE OUTPUTS (PINS 28 AND 26)

∆V

o28

output voltage range with

respect to the input (pin 28)

150 − − %

∆V

o26

output voltage range with

respect to the input (pin 26)

150 − − %

V

o(cl)

output voltage level during

clamping

− 2.3 − V

E

off

offset error transparent − − 1 %

E

G

gain error transparent − − 5 %

B bandwidth transparent 20 30 − MHz

Timing

H

ORIZONTAL WINDOW GENERATION

fh line frequency 15 − 16 kHz

Default window setting (with respect to start BK/CLP pulse)

t

dh(ws)

default start window −

6.5

⁄

64fh

−

t

dhd(wp)

default window stop −

54.5

⁄

64fh

−

User window generation with I2C-bus (with respect to start BK/CLP pulse)

t

hws(min)

minimum start window −

4.5

⁄

64fh

−

t

hws(max)

maximum start window −

19.5

⁄

64fh

−

t

hwp(min)

minimum window stop −

26.5

⁄

64fh

−

t

hwp(max)

maximum window stop −

56.5

⁄

64fh

−

VERTICAL WINDOW GENERATION

fv vertical frequency 45 − 65 Hz

Default window setting (start event with respect to start detected field blanking, stop event with respect to start event)

t

dvws

default window start − 64 − lines

t

dvdwp

default window stop − 161 − lines

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Page 13

October 1994 14

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

on histogram modification

TDA9170

Notes

1. Input amplitude values greater than the minimum specified range are still processed. However, the gain will slowly

saturate. Amplitudes up to +4 dB are permitted without significant clipping.

2. This select is valid provided the sleep mode bit is not set.

3. This control is valid provided the sleep mode bit is not set.

User window generation with I2C-bus

t

vsw(min)

minimum window start − 10 − lines

t

vsw(max)

maximum window start − 100 − lines

t

vwp(min)

minimum window stop − 121 − lines

t

vwp(max)

maximum window stop − 271 − lines

Default window select DWS; (pin 1): note 2

V

isc(DWS)

voltage input level for window

by SC blanking

− − 1.5 V

V

id(DWS)

voltage input level for default

window

3.5 − 5.5 V

I

ibDWS

input bias current V

DWS

= V

DDA

− − 10 µA

Sandcastle input SC; (pin 10)

V

i(SC)

voltage input level no blanking; no clamp − 0 1.0 V

with blanking; no clamp 1.2 1.5 1.8 V

with blanking and clamp 3.1 3.5 3.9 V

t

i(sw)

input sync width no vertical sync − − 15 µs

with vertical sync 35 − − µs

CLP PULSE WIDTH RESTORATION

t

d(clp)

internal CLP pulse width

difference

− −100 − ns

I

2

C-bus specification

ADDRESS SELECT ADR (PIN 32)

V

iADR

input voltage level A0 = 0 − − 1.5 V

A1 = 1 3.5 − 5.5 V

I

ibADR

input bias current − − 0.1 µA

TEST PINS TM AND DT (PINS 29 AND 27)

V

i(test)

input voltage level − − 0.5 V

Overall output performance

t

d(YUV)

delay from input to output of

YUV

transparent − 50 100 ns

t

dm(YUV)

delay of matching YUV transparent − 10 20 ns

α

w(YUV)

crosstalk from window any channel − − −60 dB

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Page 14

October 1994 15

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

on histogram modification

TDA9170

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

Fig.3 Black occurrence detection time constant as a function of C

TAUBP

.

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

Fig.4 Response time constant black level loop as a function of C

TAUBL

.

The dashed line =625 lines/frame.

The full line =525 lines/frame.

Page 15

October 1994 16

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

on histogram modification

TDA9170

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

Fig.5 Response speed of average histogram amplitude control loop as a function of C

TAUHM

at 60 Hz field-rate.

(1) Minimum user window.

(2) Default window.

(3) Maximum user window, window by sandcastle blanking.

Rmc= 1.

W

eff

= thw× Nvw× Rmc.

Where:

thw= horizontal window width (µs).

Nvw= vertical window height (lines).

Rmc= effective histogram measuring time within window due to miscount in percentage of thw× Nvw.

Page 16

October 1994 17

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

on histogram modification

TDA9170

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

Fig.6 Response speed of average histogram amplitude control loop as a function of C

TAUHM

at 50 Hz field-rate.

(1) Minimum user window.

(2) Default window.

(3) Maximum user window.

(4) window by sandcastle blanking.

Rmc= 1.

W

eff

= thw× Nvw× Rmc.

Where:

thw= horizontal window width (µs).

Nvw= vertical window height (lines).

Rmc= effective histogram measuring time within window due to miscount in percentage of thw× Nvw.

Page 17

October 1994 18

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

on histogram modification

TDA9170

Fig.7 Static error on average histogram amplitude (pin TAUHM) as a function of effective histogram measuring

time in a field.

W

eff

= thw× Nvw× Rmc.

Where:

thw= horizontal window width (µs).

Nvw= vertical window height (lines).

Rmc= effective histogram measuring time within window due to miscount in

percentage of t

hw

× Nvw.

Page 18

October 1994 19

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

on histogram modification

TDA9170

Fig.8 Adaptive gamma gain setting as a function of ADGAM setting in sleep mode.

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

Fig.9 Non-linear amplifier non-linearity setting as a function of AMPNLA setting in sleep mode.

Page 19

October 1994 20

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

on histogram modification

TDA9170

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

Fig.10 Variable gamma setting as a function of VARGAM setting in sleep mode.

Page 20

October 1994 21

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

on histogram modification

TDA9170

APPLICATION INFORMATION (BUS-MODE)

Fig.11 Application diagram.

Page 21

October 1994 22

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

on histogram modification

TDA9170

PACKAGE OUTLINE

Fig.12 Plastic shrink dual in-line package; 32 leads (400 mil) SDIP32; SOT232-1.

17

16

1.3 max

9.1

8.7

29.4

28.5

3.8

max

4.7

max

0.51

min

0.18

M

0.53

max

1.778

(15x)

3.2

2.8

seating plane

1.6

max

10.7

10.2

0.32 max

10.16

12.2

10.5

MSA270

32

1

Dimensions in mm.

Page 22

October 1994 23

Philips Semiconductors Preliminary specification

YUV picture improvement processor based

on histogram modification

TDA9170

SOLDERING

Plastic dual in-line packages

B

Y DIP OR WAVE

The maximum permissible temperature of the solder is

260 °C; this temperature must not be in contact with the

joint for more than 5 s. The total contact time of successive

solder waves must not exceed 5 s.

The device may be mounted up to the seating plane, but

the temperature of the plastic body must not exceed the

specified storage maximum.

If the printed-circuit board has been pre-heated, forced

cooling may be necessary immediately after soldering to

keep the temperature within the permissible limit.

R

EPAIRING SOLDERED JOINTS

Apply a low voltage soldering iron below the seating plane

(or not more than 2 mm above it). If its temperature is

below 300 °C, it must not be in contact for more than 10 s;

if between 300 and 400 °C, for not more than 5 s.

DEFINITIONS

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

PURCHASE OF PHILIPS I

2

C COMPONENTS

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

Purchase of Philips I

2

C components conveys a license under the Philips’ I2C patent to use the

components in the I2C system provided the system conforms to the I2C specification defined by

Philips. This specification can be ordered using the code 9398 393 40011.

Loading...

Loading...