Page 1

DATA SH EET

Preliminary specification

File under Integrated Circuits, IC02

December 1991

INTEGRATED CIRCUITS

TDA9160

PAL/NTSC/SECAM decoder/sync

processor

Page 2

December 1991 2

Philips Semiconductors Preliminary specification

PAL/NTSC/SECAM decoder/sync processor TDA9160

FEATURES

• Multistandard PAL, NTSC and

SECAM

• I2C-bus controlled

• I2C-bus addresses can be selected

by hardware

• Alignment free

• Few external components

• Designed for use with baseband

delay lines

• Integrated video filters

• Horizontal and vertical drive output

• East-West correction drive output

• Two CVBS inputs

• S-VHS input

• Vertical divider system

• HA synchronization pulse

• Two level sandcastle pulse

GENERAL DESCRIPTION

The TDA9160 is an I2C-bus

controlled, alignment-free

PAL/NTSC/SECAM

decoder/processor. The device

contains horizontal and vertical drive

outputs and an east-west correction

drive circuit. The TDA9160 has been

designed for use with baseband

chrominance delay lines and

DC-coupled vertical and east-west

output circuits.

The device has three inputs, two for

CVBS and one for S-VHS. The main

signal is available at the luminance

and colour difference outputs and,

also, at the TXT output

(unprocessed). The signal at the PIP

output can be selected independently

from the main signal.

The circuit provides a drive pulse for

the horizontal output stage, a

differential sawtooth current for the

vertical output stage and an east-west

drive current for the EW output stage.

These signals can be used to provide

geometry correction of the picture. A

two level sandcastle pulse and an H

A

pulse are made available for

synchronization purposes

.The I2C-bus address of the TDA9160

can be programmed by hardware.

Fig.1 Block diagram.

Page 3

December 1991 3

Philips Semiconductors Preliminary specification

PAL/NTSC/SECAM decoder/sync processor TDA9160

QUICK REFERENCE DATA

ORDERING INFORMATION

Note

1. SOT232-1; 1996 December 2.

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

CC

positive supply voltage 7.2 8.0 8.8 V

I

CC

supply current − 50 − mA

V

24,26(p-p)

CVBS input voltage (peak-to-peak value) − 1.0 − V

V

23(p-p)

S-VHS luminance input voltage (peak-to-peak value) − 1.0 − V

V

22(p-p)

S-VHS chrominance burst input voltage (peak-to-peak

value)

− 0.3 − V

V

1(p-p)

luminance output voltage (peak-to-peak value) − 0.45 − V

V

25(p-p)

teletext output voltage (peak-to-peak value) − 1.0 − V

V

2(p-p)

chrominance output voltage −(R-Y) (peak-to-peak value) PAL/NTSC − 525 − mV

V

2(p-p)

chrominance output voltage −(R-Y) (peak-to-peak value) SECAM − 1.05 − V

V

3(p-p)

chrominance output voltage −(B-Y) (peak-to-peak value) PAL/NTSC − 665 − mV

V

3(p-p)

chrominance output voltage −(B-Y) (peak-to-peak value) SECAM − 1.33 − V

V

10

HA output voltage − 5.0 − V

I

15,16(p-p)

vertical drive output current (peak-to-peak value) − 1 − mA

I

18

horizontal drive output current −−10 mA

I

17

EW drive output current −−0.9 mA

V

6

sandcastle clamping voltage level − 4.5 − V

V

6

sandcastle blanking voltage level − 2.5 − V

EXTENDED TYPE

NUMBER

PACKAGE

PINS PIN POSITION MATERIAL CODE

TDA9160 32 SDIL plastic SOT232

(1)

Page 4

December 1991 4

Philips Semiconductors Preliminary specification

PAL/NTSC/SECAM decoder/sync processor TDA9160

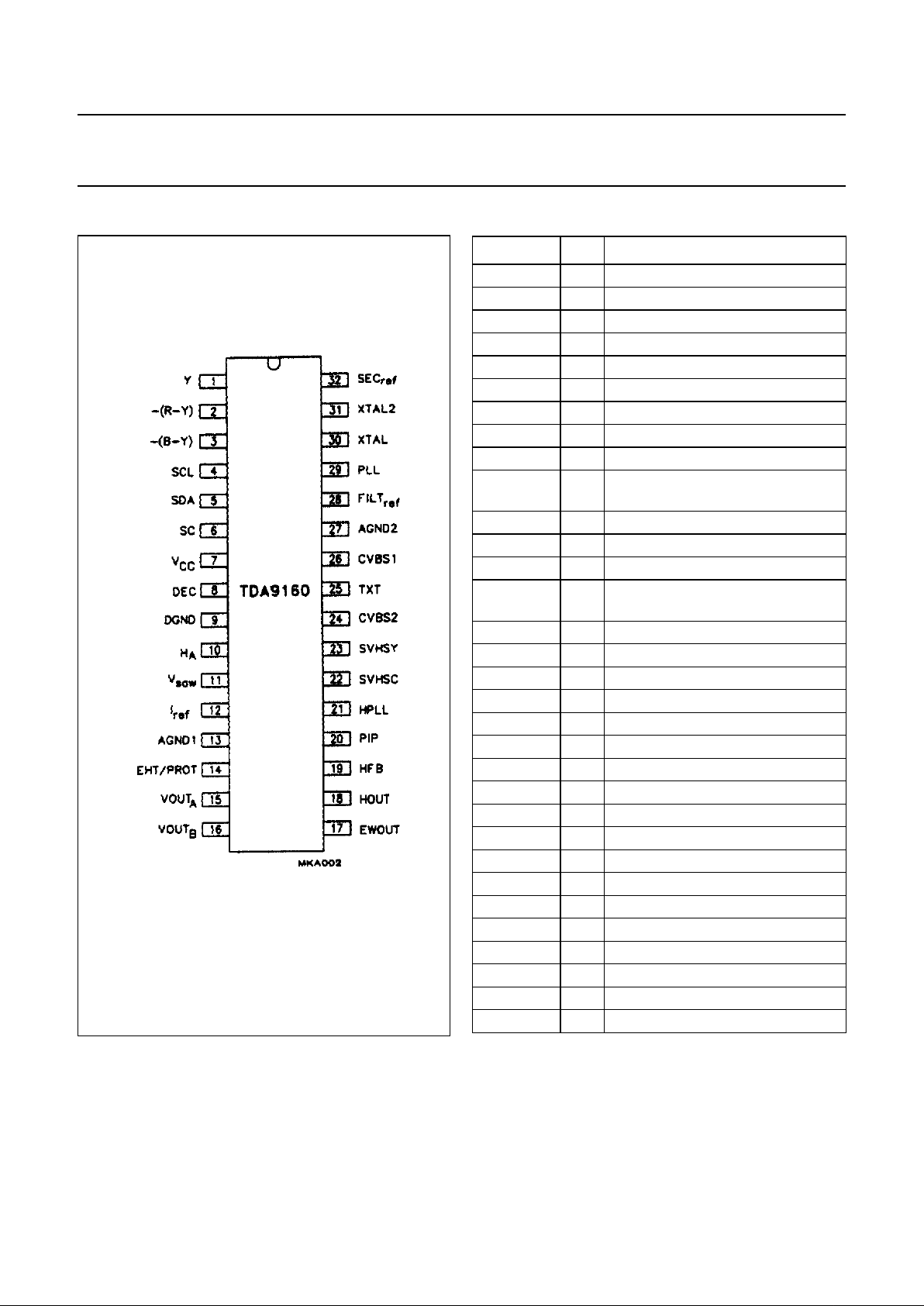

Fig.2 Pin configuration.

PINNING

SYMBOL PIN DESCRIPTION

Y 1 luminance output

−(R-Y) 2 chrominance output

−(B-Y) 3 chrominance output

SCL 4 serial clock input

SDA 5 serial data input/output

SC 6 sandcastle output

V

CC

7 positive supply input

DEC 8 positive supply decoupling

DGND 9 digital ground

H

A

10 horizontal acquisition

synchronization pulse

V

saw

11 vertical sawtooth

I

ref

12 input current reference

AGND1 13 analog ground

EHT/PROT 14 EHT tracking and over-voltage

protection

VOUT

A

15 vertical drive output A

VOUT

B

16 vertical drive output B

EWOUT 17 east-west drive output

HOUT 18 horizontal drive output

HFB 19 horizontal flyback input

PIP 20 picture-in-picture output

HPLL 21 horizontal PLL filter

SVHSC 22 S-VHS chrominance input

SVHSY 23 S-VHS luminance input

CVBS2 24 CVBS2 input

TXT 25 teletext output

CVBS1 26 CVBS1 input

AGND2 27 analog ground

FILT

ref

28 filter reference decoupling

PLL 29 colour PLL filter

XTAL 30 reference crystal input

XTAL2 31 second crystal input

SEC

ref

32 SECAM reference decoupling

Page 5

December 1991 5

Philips Semiconductors Preliminary specification

PAL/NTSC/SECAM decoder/sync processor TDA9160

FUNCTIONAL DESCRIPTION

The TDA9160 is an I2C-bus

controlled, alignment free

PAL/NTSC/SECAM colour

decoder/sync processor/deflection

controller which has been designed

for use with baseband chrominance

delay lines.

In the standard operating mode the

I2C-bus address is 8A . If the TXT

output is connected to the positive rail

the address will change to 8E

The standards which the TDA9160

can decode are dependent on the

choice of external crystals. If a

4.4 MHz and a 3.6 MHz crystal are

used then SECAM, PAL 4.4/3.6 and

NTSC 4.4/3.6 can be decoded. If two

3.6 MHz crystals are used then only

PAL 3.6 and NTSC 3.6 can be

decoded. Which 3.6 MHz standards

can be decoded is dependent on the

exact frequencies of the crystal. In an

application where not all standards

are required only one crystal is

sufficient (in this instance the crystal

must be connected to the reference

crystal input (pin 30)). If a 4.4 MHz

crystal is used it must always be

connected to pin 30. Both crystals are

used to provide a reference for the

filters and the horizontal PLL,

however, only the reference crystal is

used to provide a reference for the

SECAM demodulator.

To enable the calibrating circuits to be

adjusted exactly two bits from the

I2C-bus address are used to indicate

which crystals are connected to the

IC.

The standard identification circuit is a

digital circuit without external

components; the search loop is

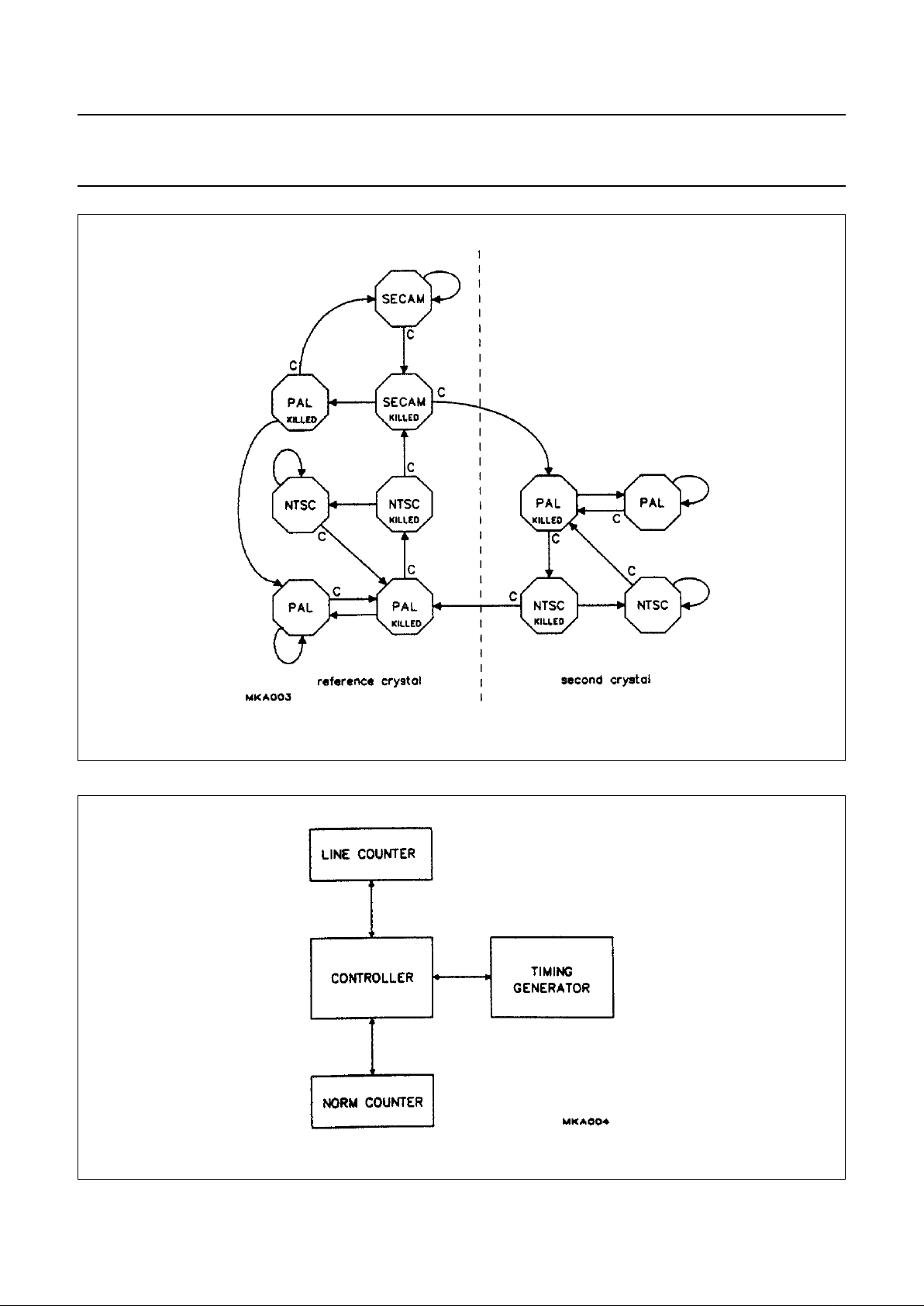

illustrated in Fig.3.

The decoder (via the I2C-bus) can be

forced to decode either SECAM or

PAL/NTSC (but not PAL or NTSC).

Crystal selection can also be forced.

Information, concerning which

standard and which crystal have been

selected and whether the colour killer

is ON or OFF is provided by the read

out. Using the forced-mode does not

affect the search loop, it does,

however, prevent the decoder from

reaching or staying in an unwanted

state. The identification circuit skips

impossible standards (e.g. SECAM

when no 4.4 MHz crystal is fitted) and

illegal standards (e.g. forced mode).

To reduce the risk of wrong

identification PAL has priority over

SECAM (only line identification is

used for SECAM).

The TDA9160 has two CVBS inputs

and one S-VHS input which can be

selected via the I

2

C-bus. The input

selector can also be switched to

enable CVBS2 to be processed,

providing that there is no S-VHS

signal present at the input. If the input

selector is set to CVBS2 it will switch

to S-VHS if an S-VHS sync pulse is

detected at the luminance input. The

S-VHS detector output can be read

via the I2C-bus.

If the voltage at either the S-VHS

luminance or the chrominance input

(pins 22 and 23) exceeds +5.5 V the

IC will revert to test mode.

The TDA9160 also provides outputs

for picture-in-picture and teletext (PIP

pin 20 and TXT pin 25). The decoder

input signal can be switched directly

to the TXT output. The PIP output

signal can be selected independently

from the TXT output. If S-VHS is

selected at the TXT output only the

luminance signal will be present; if

S-VHS is selected at the PIP output

then the luminance and chrominance

signals will be added.

All filters, including the luminance

delay line, are an integral part of the

IC. The filters are gyrator-capacitor

type filters. The resonant frequency of

the filters is controlled by a circuit that

uses the active crystal to tune the

SECAM Cloche filter during the

vertical flyback time. The remaining

filters and the delay line are matched

to this filter. The filters can be

switched to either 4.43 MHz,

4.28 MHz or 3.58 MHz irrespective of

the frequency of the active crystal.

The switching is controlled by the

identification circuit.

The S-VHS luminance signal does

not pass through the notch filter to

preserve bandwidth. The luminance

delay line delivers the Y signal to the

output 40 ns after the −(R-Y) and

−(B-Y) signals. This compensates for

the delay of the external chrominance

delay lines.

The PAL/NTSC demodulator

employs an oscillator that can operate

with either crystal (3.6 or 4.4 MHz). If

the I2C-bus indicates that only one

crystal is connected it will always

connect to the crystal at the reference

input (pin 30).

The Hue signal, which is adjustable

via the I2C-bus, is gated during the

burst for NTSC signals.

The SECAM demodulator is an

auto-calibrating PLL demodulator

which has two references. The

reference crystal, to force the PLL to

the desired free-running frequency

and the bandgap reference, to obtain

the correct absolute value of the

output signal. The VCO of the PLL is

calibrated during each vertical flyback

period, when the reference crystal is

active. When the second crystal is

active the VCO is not calibrated.

During this time the frequency of the

VCO is kept constant by applying a

constant voltage to its control input. If

the reference crystal is not 4.4 MHz

the decoder will not produce the

correct SECAM signals.

The main part of the sync circuit is a

432 × fH (6.75 MHz) oscillator the

frequency of which is divided by 432

Page 6

December 1991 6

Philips Semiconductors Preliminary specification

PAL/NTSC/SECAM decoder/sync processor TDA9160

to lock the phase 1 loop to the

incoming signal. The time constant of

the loop can be forced by the I2C-bus

(fast or slow). If required the IC can

select the time constant, depending

on the noise content of the input

signal and whether the loop is phase

locked or not (medium or slow). The

free-running frequency of the

oscillator is determined by a digital

control circuit that is locked to the

active crystal.

When a power-on-reset pulse is

detected the frequency of the

oscillator is switched to a frequency

greater than 6.75 MHz to protect the

horizontal output transistor. The

oscillator frequency is reset to

6.75 MHz when the crystal indication

bits have been loaded into the IC. To

ensure that this procedure does not

fail it is absolutely necessary to send

subaddress 00 before subaddress

01. Subaddress 00 contains the

crystal indication bits, when

subaddress 01 is received the line

oscillator calibration will be initiated.

The calibration is terminated when

the oscillator frequency reaches

6.75 MHz. The oscillator is again

calibrated when an out-of-lock

condition with the input signal is

realised by the coincidence detector.

Again the calibration will be

terminated when the oscillator

frequency reaches 6.75 MHz.

The phase 1 loop can be opened

using the I2C-bus. This is to facilitate

On Screen Display (OSD)

information. If there is no input signal

or a very noisy input signal the phase

1 loop can be opened to provide a

stable line frequency and thus a

stable picture.

The sync part provides an HA pulse

that is coupled to the processed

CVBS signal.

The horizontal drive signal can be

switched off via the I2C-bus (standby

mode). The horizontal drive is also

switched off when the over-voltage

protection circuit trips or when a POR

is detected. Should either of these

two conditions occur the IC will return

to the normal operating mode when

the appropriate command is received

via the I2C-bus. The duty cycle of the

horizontal drive signal is increased

from 2%, at start-up, to a constant

value of 55% in approximately 300

lines. The two-level sandcastle pulse

provides a combined horizontal and

vertical blanking signal and a

clamping pulse coupled to the display

section of the TV.

The vertical sawtooth generator

drives the geometry processing

circuits which provide control for the

horizontal shift, EW width, EW

parabola/width ratio, EW

corner/parabola ratio, trapezium

correction, vertical slope, vertical

shift, vertical amplitude and the

S-correction. All of these control

functions can be set via the I2C-bus.

The geometry processor has a

differential current output for the

vertical drive signal and a

single-ended output for the EW drive.

Both the vertical drive and the EW

drive outputs can be modulated for

EHT compensation. The EHT

compensation pin (pin 14) can also be

used for over-voltage protection.

De-interlace of the vertical output can

be set via the I2C-bus.

The vertical divider system has a fully

integrated vertical sync separator.

The divider can accommodate both

50 and 60 Hz systems; it can either

locate the field frequency

automatically or it can be forced to the

desired system via the I2C-bus. A

block diagram of the vertical divider

system is illustrated in Fig.4. The

divider system operates at 432 times

the horizontal line frequency. The line

counter receives enable pulses at

twice the line frequency, thereby

counting two lines per pulse.

A state diagram of the controller is

illustrated in Fig.5. Because it is

symmetrical only the right hand part

will be described.

Depending on the previously found

field frequency, the controller will be

in one of the 'count' states. When the

line counter has counted 488 pulses

(i.e. 244 lines of the video input

signal) the controller will move to the

next state depending on the output of

the norm counter. This can be either

NORM, NEAR-NORM or NO-NORM

depending on the position of the

vertical sync pulse in the previous

fields. When the counter is in the

NORM state it generates the vertical

sync pulse (VSP) automatically and

then, when the line counter is at

LC = 626, moves to the WAIT state.

In this condition it waits for the next

pulse of the double line frequency

signal and then moves to the COUNT

state of the current field frequency.

When the controller returns to the

COUNT state the line counter will be

reset half a line after the start of the

vertical sync pulse of the video input

signal.

When the controller is in the

NEAR-NORM state it will move to the

COUNT state if it detects the vertical

sync pulse within the NEAR-NORM

window (i.e. 622 < LC < 628). If no

vertical sync pulse is detected, the

controller will move back to the

COUNT state when the line counter

reaches LC = 628. The line counter

will then be reset.

When the controller is in the

NO-NORM state it will move to the

COUNT state when it detects a

vertical sync pulse and reset the line

counter. If a sync pulse is not

detected before LC = 722 (if the

phase loop is locked in forced mode)

it will move to the COUNT state and

reset the line counter. If the phase

loop is not locked the controller will

move back to the COUNT state when

LC = 628. The forced mode option

keeps the controller in either the

left-hand side (60 Hz) or the

Page 7

December 1991 7

Philips Semiconductors Preliminary specification

PAL/NTSC/SECAM decoder/sync

processor

TDA9160

right-hand side (50 Hz) of the state

diagram.

Figure 6 illustrates the state diagram

of the 'norm' counter which is an

up/down counter that counts up if it

finds a vertical sync pulse within the

selected window. In the

NEAR-NORM and NORM states the

first correct vertical sync pulse after

one or more incorrect vertical sync

pulses is processed as an incorrect

pulse. This procedure prevents the

system from staying in the

NEAR-NORM or NORM state if the

vertical sync pulse is correct in the

first field and incorrect in the second

field. If no vertical sync pulse is found

in the selected window this will always

result in a down pulse for the 'norm'

counter.

Figure 7 illustrates the timing of the

display sandcastle (DSC) and the

reset pulse of the vertical sawtooth

with respect to the input signal

I

2

C-bus protocol

If the TXT output is connected to the

positive supply the address will

change from 8A to 8E.

Valid subaddresses = 00 to 0F

Auto-increment mode available for

subaddresses.

Subaddress 00 must always be sent

before subaddress 01 in order to

protect the horizontal output

transistor.

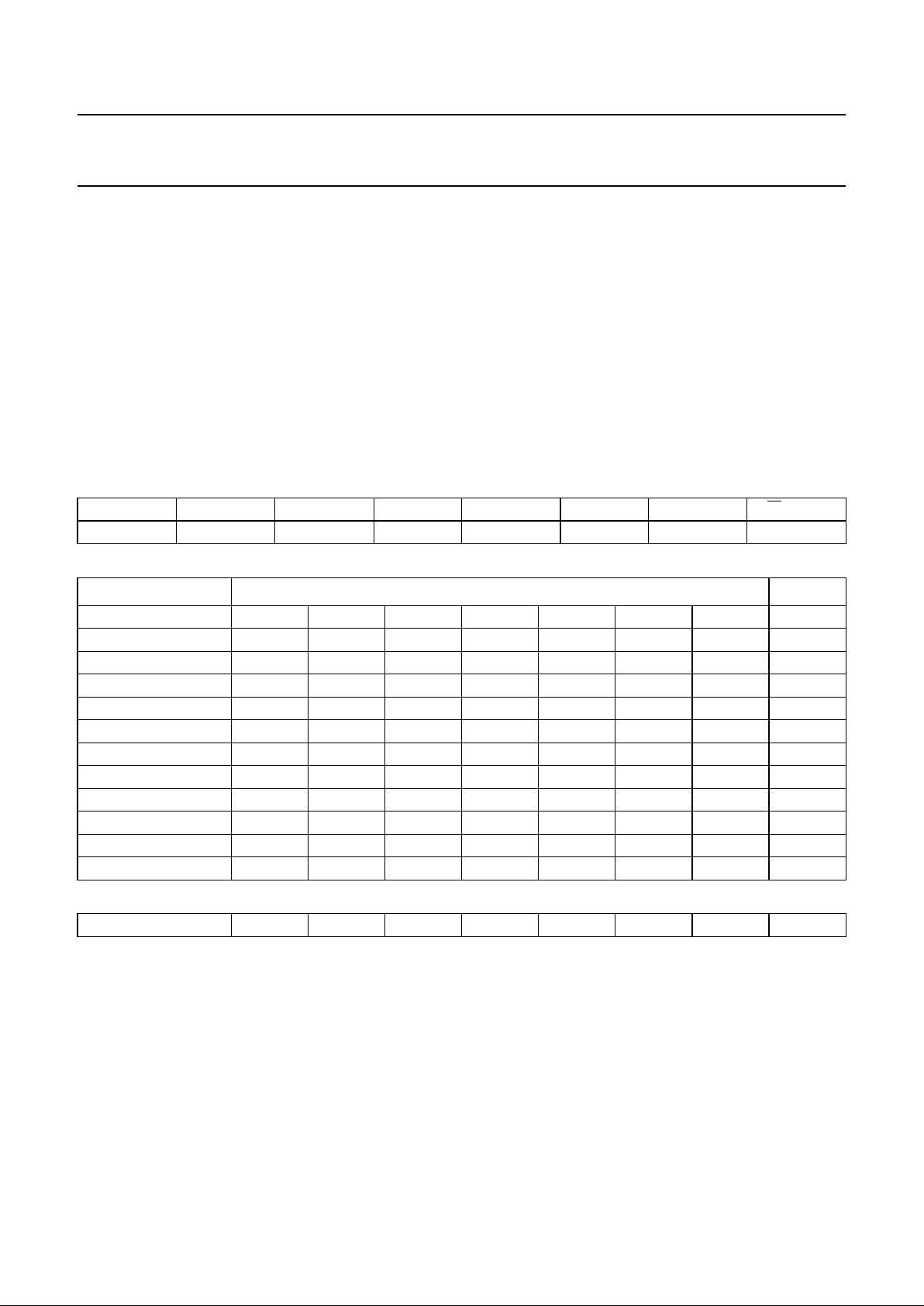

Table 1 Slave address (8A)

Table 2 Inputs

Table 3 Outputs

A6 A5 A4 A3 A2 A1 A0 R/

W

10001X1X

SUBADDRESS MSB LSB

00 INA INB INC IND FOA FOB XA XB

01 FORF FORS DL STB POC FM SAF FRQF

02 −−HU5 HU4 HU3 HU2 HU1 HU0

03 −−HS5 HS4 HS3 HS2 HS1 HS0

04 −−EW5 EW4 EW3 EW2 EW1 EW0

05 −−PW5 PW4 PW3 PW2 PW1 PW0

06 −−CP5 CP4 CP3 CP2 CP1 CP0

07 −−TC5 TC4 TC3 TC2 TC1 TC0

08 −−VS5 CS4 VS3 VS2 VS1 VS0

09 −−VA5VA4VA3VA2VA1VA0

0A −−SC5 SC4 SC3 SC2 SC1 SC0

0B SBL − VSH5 VSH4 VSH3 VSH2 VSH1 VSH0

ADDRESS POR FSI STS SL PROT SAK SBK FRQ

Page 8

December 1991 8

Philips Semiconductors Preliminary specification

PAL/NTSC/SECAM decoder/sync processor TDA9160

Fig.3 Search loop of the identification circuit.

Fig.4 Block diagram of the vertical divider system.

Page 9

December 1991 9

Philips Semiconductors Preliminary specification

PAL/NTSC/SECAM decoder/sync processor TDA9160

Fig.5 State diagram of the vertical divider system.

Fig.6 State diagram of the ‘norm’ counter.

Page 10

December 1991 10

Philips Semiconductors Preliminary specification

PAL/NTSC/SECAM decoder/sync processor TDA9160

Fig.7 Field timing diagram.

Page 11

December 1991 11

Philips Semiconductors Preliminary specification

PAL/NTSC/SECAM decoder/sync processor TDA9160

INPUT SIGNALS

Table 4 Source select 1

INA INB DECODER AND TXT

0 0 CVBS1

0 1 CVBS2

1 0 S-VHS

1 1 S-VHS (CVBS2)

Table 5 Source select 2

INC IND DECODER AND TXT

0 0 CVBS1

0 1 CVBS2

1 0 S-VHS

1 1 S-VHS (CVBS2)

Table 6 Phase time constant

FOA FOB MODE

0 0 auto

0 1 slow

1 − fast

Table 7 XTAL indication

XA XB CRYSTAL

0 0 2 x 3.6 MHz

0 1 1 x 3.6 MHz

1 0 1 x 4.4 MHz

1 1 3.6 and 4.4 MHz

Table 8 Forced field frequency

FORF FORS FIELD FREQUENCY

0 0 auto

0 1 60 Hz

1 0 50 Hz

1 1 auto

Table 9 Interlace

DL CONDITION

0 interlace

1 de-interlace

Table 10 Standby

STB CONDITION

0 standby

1 normal mode

Table 11 Phase loop control

POC CONDITION

0 phi one loop closed

1 phi one loop open

Table 12 Forced standard

Note to table 12

1. If XA and XB indicate that only one crystal is

connected to the IC and FM and FRQF force it to use

the second crystal the colour will be switched off.

ADD LOGIC CONDITION

FM 0 auto search

1 forced mode

SAF 0 PAL/NTSC

1 SECAM

FRQF 0 second crystal

1 reference crystal

Table 13 Service blanking

SBL CONDITION

0 service blanking OFF

1 service blanking ON

Page 12

December 1991 12

Philips Semiconductors Preliminary specification

PAL/NTSC/SECAM decoder/sync processor TDA9160

Table 14 Other input signals

Table 15 Standard read-out

FUNCTION ADDRESS DIGITAL NUMBER

hue HU5 to HU0 000000 = −45°

111111 = +45°

horizontal shift HS5 to HS0 000000 = −2.2 µs

111111 = +2.2 µs

EW width EW5 to EW0 000000 = 80%

111111 = 100%

EW parabola/width PW5 to PW0 000000 = 0%

111111 = 24%

EW corner/parabola CP5 to CP0 000000 = 0%

111111 = −44%

EW trapezium TC5 to TC0 000000 = −4%

111111 = +4%

vertical slope VS5 to VS0 000000 = −14%

111111 = +14%

vertical amplitude VA5 to VA0 000000 = −80%

111111 = +120%

S correction SC5 to SC0 000000 = 0%

111111 = 20%

vertical shift VSH5 to VSH0 000000 = −4%

111111 = +4%

SAK SBK FRQ STANDARD

0 0 0 PAL, second crystal

0 0 1 PAL, reference crystal

0 1 0 NTSC, second crystal

0 1 1 NTSC, reference crystal

1 0 0 not used

1 0 1 SECAM, reference crystal

1 1 0 colour off

1 1 1 colour off

Page 13

December 1991 13

Philips Semiconductors Preliminary specification

PAL/NTSC/SECAM decoder/sync processor TDA9160

INPUT SIGNALS

Table 16 Power-on-reset

Table 17 Field frequency indication

Table 18 S-VHS status

Table 19 Phase lock indication

Table 20 Over-voltage protection

POR CONDITION

0 normal mode

1 power-down mode

FSI CONDITION

0 50 Hz

1 60 Hz

STS CONDITION

0 no signal at input

1 signal at input

SL CONDITION

0 not locked

1 locked

PROT CONDITION

0 no over-voltage detected

1 over-voltage detected

Page 14

December 1991 14

Philips Semiconductors Preliminary specification

PAL/NTSC/SECAM decoder/sync processor TDA9160

LIMITING VALUES

In accordance with the Absolute Maximum System (IEC134)

THERMAL RESISTANCE

CHARACTERISTICS

V

CC

= 8 V; T

amb

= 25 °C; unless otherwise specified.

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

V

CC

positive supply voltage − 8.8 V

I

CC

supply current − 70 mA

P

tot

total power dissipation −−W

T

stg

storage temperature range −55 +150 °C

T

amb

operating ambient temperature range −10 +65 °C

SYMBOL PARAMETER THERMAL RESISTANCE

R

th j-a

from junction to ambient in free air t.b.f.

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supply

V

CC

positive supply voltage 7.2 8.0 8.8 V

I

CC

supply current − 50 − mA

P

tot

total power dissipation − 400 − mW

Input switch

CVBS1 AND CVBS2

INPUTS (PINS 26 AND 24)

V

26,24(p-p)

input voltage (peak-to-peak

value)

− 1.0 1.43 V

Z

I

input impedance 60 −−kΩ

S-VHS Y INPUT (PIN 23)

V

23(p-p)

input voltage (peak-to-peak

value)

− 1.0 1.43 V

Z

I

input impedance 60 −−kΩ

S-VHS CHROMINANCE INPUT <PIN 22>

V

22(p-p)

input voltage (peak-to-peak

value)

burst − 0.3 1.43 V

Z

I

input impedance 60 −−kΩ

LUMINANCE OUTPUT (PIN 1)

V

1(p-p)

output voltage (peak-to-peak

value)

− 450 − mV

Z

O

output impedance −−500 Ω

V

O

top sync level − 2.1 − V

S/N signal-to-noise ratio − tbf − dB

SUPP suppression of unselected

inputs

50 −−dB

Page 15

December 1991 15

Philips Semiconductors Preliminary specification

PAL/NTSC/SECAM decoder/sync processor TDA9160

TXT AND PIP OUTPUTS (PINS 25 AND 20)

V

20,25(p-p)

output voltage (peak-to-peak

value)

− 1.0 − V

Z

O

output impedance −−500 Ω

V

O

top sync level TXT output − 1.8 − V

PIP output − 2.8 − V

SUPP suppression of unselected

inputs

f = 0 to 5 MHz;

PIP output

50 −−dB

SUPP suppression of unselected

inputs

f = 0 to 5 MHz;

TXT output

35 −−dB

Bias generator

V

8

digital supply voltage − 5.0 − V

V

12

DC voltage − 3.9 − V

Subcarrier regeneration

V

ACC(p-p)

burst amplitude within ACC

range (peak-to-peak value)

25 − 500 mV

CR catching range note 1 500 −−Hz

ϕ phase shift for 400 Hz

deviation

−−5 deg

TC temperature coefficient of

oscillator

− tbf − Hz/K

Z

I

input impedance reference crystal input − 1.0 − kΩ

second crystal input − 1.5 − kΩ

V

dep

supply voltage dependency − tbf − V

Demodulators

∆2/∆3 change of −(R-Y) and −(B-Y)

signals over the ACC range

−−1dB

ratio of −(R-Y) and −(B-Y)

signals

− 1.27 −

TC temperature coefficient of

−(R-Y) and −(B-Y) amplitude

− tbf − Hz/K

spread of −(R-Y) and −(B-Y)

ratio between standards

−1 −+1dB

V

2

output level of −(R-Y) during

blanking

− 2.0 − V

V

3

output level of −(B-Y) during

blanking

− 2.0 − V

B bandwidth at −3 dB − 1 − MHz

Z

O

output impedance −−500 Ω

V

dep

supply voltage dependency − tbf − V

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Page 16

December 1991 16

Philips Semiconductors Preliminary specification

PAL/NTSC/SECAM decoder/sync processor TDA9160

PAL/NTSC DEMODULATOR

V

2(p-p)

−(R-Y) output voltage

(peak-to-peak value)

standard colour bar − 525 − mV

V

3(p-p)

−(B-Y) output voltage

(peak-to-peak value)

standard colour bar − 665 − mV

α crosstalk between −(R-Y) and

−(B-Y)

− tbf − dB

V

2,3(p-p)

8.8 MHz residue

(peak-to-peak value)

both outputs −−15 mV

V

2,3(p-p)

7.2 MHz residue

(peak-to-peak value)

both outputs −−20 mV

S/N signal-to-noise ratio 46 −−dB

PAL

DEMODULATOR

V

R(p-p)

H/2 ripple (peak-to-peak value) −−50 mV

S/N signal-to-noise ratio 46 −−dB

NTSC

DEMODULATOR

ϕ hue phase shift −45 −+45 deg

SECAM DEMODULATOR

V

2(p-p)

−(R-Y) output voltage

(peak-to-peak value)

standard colour bar − 1.05 − mV

V

3(p-p)

−(B-Y) output voltage

(peak-to-peak value)

standard colour bar − 1.33 − mV

f

OS

black level offset −−7 kHz

S/N signal-to-noise ratio − 43 − dB

V

res(p-p)

7.8 to 9.4 MHz residue

(peak-to-peak value)

−−30 mV

f

pole

pole frequency of deemphasis 77 85 93 kHz

ratio of pole and zero

frequency

− 3 −

V

cal

calibration voltage 3.0 4.0 5.0 V

NL non linearity −−3%

Filters

V

tune

tuning voltage 1.5 3.0 6.0 V

Luminance delay

t

d

delay time PAL/NTSC/BW − 430 − ns

t

d

delay time SECAM − 480 − ns

Luminance trap

f

O

notch frequency fSC = 3.6 MHz 3.53 3.58 3.63 MHz

f

SC

= 4.4 MHz 4.37 4.43 4.49 MHz

SECAM 4.23 4.29 4.35 MHz

S-VHS/BW; not active

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Page 17

December 1991 17

Philips Semiconductors Preliminary specification

PAL/NTSC/SECAM decoder/sync processor TDA9160

B bandwidth at −3 dB fSC = 3.6 MHz − 2.8 − MHz

f

SC

= 4.4 MHz − 3.4 − MHz

SECAM − 3.3 − MHz

SUPP subcarrier suppression 26 −−dB

C

HROMINANCE BANDPASS

f

res

resonant frequency fSC = 3.6 MHz − 3.58 − MHz

f

SC

= 4.4 MHz − 4.43 − MHz

B bandwidth at −3 dB f

SC

= 3.6 MHz − 1.6 − MHz

f

SC

= 4.4 MHz − 2 − MHz

Cloche filter

f

res

resonant frequency SECAM 4.26 4.29 4.31 MHz

B bandwidth at −3 dB; SECAM 241 268 295 kHz

Sync input

V

22

sync pulse amplitude CVBS 1/2; S-VHS input 50 300 600 mV

slicing level − 50 − %

t

d

delay of sync pulse due to

internal filter

0.2 0.3 0.4 µs

S/N noise detector threshold level − 20 − dB

H hysteresis − 3 − dB

t

d

delay between video signal

and internally separated

vertical sync pulse

12 18.5 27 µs

Horizontal section

H

A

OUTPUT (PIN 10)

V

OH

output voltage HIGH 2.4 5.0 5.5 V

V

OL

output voltage LOW − 0.3 0.6 V

I

sink

sink current 2 −−mA

I

source

source current 2 −−mA

t

W

pulse width 32 clock cycles − 4.7 −µs

t

d

delay between middle of

horizontal sync pulse and

middle of H

A

note 2 0.3 0.45 0.6 µs

FIRST LOOP

∆f frequency deviation when not

locked

−−1.5 %

SVRR supply voltage ripple rejection − tbf − V

TC temperature coefficient − tbf − Hz/°C

f

CR

catching range 625 −−Hz

f

HR

holding range −−1400 Hz

φ static phase shift −−0.1 µs/kHz

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Page 18

December 1991 18

Philips Semiconductors Preliminary specification

PAL/NTSC/SECAM decoder/sync processor TDA9160

SECOND LOOP

ϕ control sensitivity 300 −−µs/µs

t

CR

control range of the positive

going edge of horizontal drive

to flyback

HS = 00; note 4 13.5 −−µs

t

d

delay between second loop

reference and mid-sync of

processed video

− 3 −µs

HORIZONTAL SHIFT

SR horizontal shift range 63 steps −2.2 − +2.2 µs

HORIZONTAL DRIVE OUTPUT (PIN 18)

R

18

output resistance on-state −−50 Ω

I

18

output current −−10 mA

duty cycle of output current − 55 − %

H

ORIZONTAL FLYBACK INPUT (PIN 19)

V

HB

switching level for horizontal

blanking

− 0.3 − V

V

ϕ2

switching level for phase two

loop

− 3.8 − V

V

19

maximum input voltage −−VCCV

Z

I

input impedance 10 −−MΩ

Soft start

CR duty cycle control range 2 − 55 %

soft start time 200 300 500 lines

Vertical section (note 3)

V

ERTICAL OSCILLATOR

f

fr

free running frequency divider ratio 628 − 50 − Hz

f

LR

frequency locking range 43 − 64 Hz

LR divider locking range 488 625 722

V

ERTICAL SAWTOOTH (PIN 11)

V

11(p-p)

voltage amplitude level

(peak-to-peak value)

VS = 1F; C = 100 nF;

R = 39 kΩ

− 3.5 − V

I

dis

discharge current − 1 − mA

I

charge

charge current set by external

resistor

f = 50 Hz; VS = 1F − 19 −µA

CR vertical slope control range 63 steps −14 −+14 %

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Page 19

December 1991 19

Philips Semiconductors Preliminary specification

PAL/NTSC/SECAM decoder/sync processor TDA9160

VERTICAL DRIVE OUTPUTS (PINS 15 AND 16)

I

diff(p-p)

differential output current

(peak-to-peak value)

VA = 1F − 1 − mA

I

15,16

common mode current − 400 −µA

V

O

output voltage range 0 − 4.0 V

EHT TRACKING AND OVER-VOLTAGE PROTECTION (PIN 14)

TR tracking range 1.2 − 2.8 V

SMR scan modulation range −6 −+6%

α sensitivity − 7.5 − %/V

V

14

over-voltage protection

detection level

− 3.9 − V

DE-INTERLACE

first field delay − 0.5H −

Sandcastle (pin 6)

V

6

zero level 0 0.5 1.0 V

I

sink

sink current 0.5 −−mA

HORIZONTAL AND VERTICAL BLANKING

V

bl

blanking voltage level 2.0 2.5 3.0 V

I

source

source current 0.5 −−mA

I

ext

external current required to

force the output to the blanking

level

1 − 3mA

CLAMPING PULSE

V

clamp

clamping voltage level 4.0 4.5 5.0 V

I

source

source current 0.5 −−mA

t

W

pulse width PAL (17 LLC pulses) − 2.5 −µs

SECAM (24 LLC

pulses)

− 3.6 −µs

t

d

delay between mid sync of

input and start of clamping

pulse

3.6 3.7 3.8 µs

Geometry processing (note 3)

EW

WIDTH

CR control range 63 steps 100 − 80 %

I

eq

equivalent EW output current 0 − 400 µA

V

O

EW output voltage range 1.0 − 8.0 V

I

O

EW output current range 0 − 900 µA

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Page 20

December 1991 20

Philips Semiconductors Preliminary specification

PAL/NTSC/SECAM decoder/sync processor TDA9160

Notes to the characteristics

1. All oscillator specifications are measured with the Philips crystal series 4322 143/144. The spurious response of the

reference crystal must be less than −7 dB with respect to the fundamental frequency for a damping resistance of

1kΩ. The spurious response of the second crystal must be less than −7 dB with respect to the fundamental

frequency for a damping resistance of 1.5 kΩ.

2. This delay is caused by the low pass filter at the sync separator input.

3. All values are valid for a reference current of 100 µA (RC = 39 kΩ).

4. Valid for flyback pulse width of 12 µs at the switching level of the phase 2 loop.

EW PARABOLA/WIDTH

CR control range 63 steps 0 − 24 %

I

eq

equivalent EW output current EW = 3F 0 − 480 µA

EW CORNER/PARABOLA

CR control range 63 steps −44 − 0%

I

eq

equivalent EW output current EW = 3F; PW = 3F −210 − 0 µA

EW TRAPEZIUM

CR control range 63 steps −4 −+4%

I

eq

equivalent EW output current −80 −+80 µA

EW EHT TRACKING

TR tracking range 1.2 − 2.8 V

SMR scan modulation range −6 −+6%

I

eq

equivalent output current +120 −−120 µA

ϕ sensitivity −−7.5 − %/V

V

ERTICAL AMPLITUDE

CR control range 63 steps; SC = 00 80 − 120 %

63 steps; SC = 3F 86 − 112 %

I

eq

equivalent differential vertical

drive output current

SC = 00 800 − 1200 µA

VERTICAL SHIFT

CR control range 63 steps −4 −+4%

I

eq

equivalent differential vertical

drive output current

−40 −+40 µA

S CORRECTION

CR control range 63 steps 0 − 20 %

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Page 21

December 1991 21

Philips Semiconductors Preliminary specification

PAL/NTSC/SECAM decoder/sync processor TDA9160

QUALITY SPECIFICATION

Quality level according to URV 4-2-59/601.

Test and application information

EW output stage

In order to obtain the correct tracking

of the vertical and horizontal EHT

correction, the EW output stage

should be configured as illustrated in figure 8.

Note to Fig.8

Resistor R

ew

determines the gain of the EW output stage. Resistor Rc sets the reference current for both the vertical

sawtooth generator and the geometry processor. The preferred value of R

c

= 39 kΩ results in a reference current of 100

µA (V

ref

= 3.9 V).

The value of R

ew

is given in the following equation:

Example: If V

ref

= 3.9 kΩ, Rc= 39 kΩ and V

scan

= 120 V then Rew= 68 kΩ

SYMBOL PARAMETER RANGE A RANGE B UNIT

ESD protection circuit specification (note1) 2000 500 V

100 200 pF

1500 0 Ω

Fig.8 Configuration of the EW output stage.

R

ew

R

c

V

scan

18 V

ref

)×(

--------------------------------

×=

Page 22

December 1991 22

Philips Semiconductors Preliminary specification

PAL/NTSC/SECAM decoder/sync processor TDA9160

Control ranges of geometry control parameters

Typical case curves (Rc= 39 kΩ; C

saw

= 100 nF)

Fig.9 Control range of vertical amplitude.

VA =0, 31 and 63; VSH = 31; SC = 0

Fig.10 Control range of vertical slope.

VA = 31; VS = 0, 31 and 63; VSH = 31; SC = 0

Fig.11 Control range of vertical shift.

VA = 31; VSH = 0, 31 and 63; SC = 0

Fig.12 Control range of S correction.

SC = 0, 31 and 63; VA = 31; VSH = 31. The picture height does not

change with the setting of S correction for nominal setting of vertical

amplitude (VA = 31).

Page 23

December 1991 23

Philips Semiconductors Preliminary specification

PAL/NTSC/SECAM decoder/sync processor TDA9160

Fig.13 Control range of EW width.

EW = 0, 31 and 63; PW = 31; CP = 31

Fig.14 Control range of EW parabola/width ratio.

EW = 0, 31 and 63; PW = 31; CP = 31

Fig.15 Control range of EW corner/parabola ratio.

CP = 0, 31 and 63; EW = 31; PW = 63

Fig.16 Control range of EW trapezium correction.

TC = 0, 31 and 63; EW = 31; PW = 31; CP = 0

Page 24

December 1991 24

Philips Semiconductors Preliminary specification

PAL/NTSC/SECAM decoder/sync processor TDA9160

Adjustment of geometry control

parameters

The deflection processor of the

TDA9160 offers nine control

parameters for picture alignment:

• S-correction, vertical amplitude,

vertical slope and vertical shift for

the vertical picture alignment

• Horizontal shift, EW width, EW

parabola/width, EW

corner/parabola and EW trapezium

correction for the horizontal picture

alignment

The required values for the settings of

S-correction, EW parabola/width ratio

and EW corner/parabola ratio are

determined for a particular

combination of picture tube type,

vertical output stage and EW output

stage. These parameters can be

preset via the I

2

C-bus and do not

require any additional adjustment.

The remainder of the parameters are

preset to the mid value of their control

range (i.e. 1F), or to values that have

obtained from previous TV set

adjustments.

After the vertical S-correction has

been preset the vertical picture

alignment could, in theory, be

completed by positioning the top of

the picture using the vertical

amplitude adjustment and the bottom

of the picture using the vertical slope

adjustment (see note). It can be

shown, however, that without

compensation offsets in the external

vertical output stage or in the picture

tube would result in a certain linearity

error especially with picture tubes that

need large S-correction. The total

linearity error is in first order

approximation proportional to the

offset and to the square of the

required S-correction. A vertical shift

control is available for offset

compensation.

For adjustment of the vertical shift,

independent of the vertical slope, a

special vertical shift alignment is

provided. This mode is entered by

setting the SBL bit HIGH. In this mode

the −(R-Y) and −(B-Y) outputs are

blanked during the second half of the

picture. The first line in which the

colours are blanked must be

positioned in the middle of the screen.

The necessity to use the vertical shift

alignment depends on the expected

offsets in the vertical output stage and

picture tube, on the required value of

the S-correction and on the demands

upon the vertical linearity. If the

vertical shift alignment is not used

VSH should be set to its mid value

(i.e. VSH = 1F).

The actual factory adjustments of the

picture consist of the following steps:

• The vertical shift is adjusted as

previously described (if required).

• The top of the picture is positioned

by adjusting the vertical amplitude

and the bottom of the picture by

adjusting the vertical slope

• The picture is positioned in the

horizontal direction by adjusting the

EW width and horizontal shift

• The left and right hand sides of the

picture are aligned in parallel by

adjusting the EW trapezium

correction (if required).

Note

The value of the vertical slope

determines the charge current of the

vertical sawtooth capacitor (C

saw

as

shown in Fig.8) and thus the

amplitude of the sawtooth voltage at

pin 11. This voltage serves as the

input voltage for the geometry

processor. Consequently the setting

of the vertical slope will affect both the

vertical and EW output currents.

Page 25

December 1991 25

Philips Semiconductors Preliminary specification

PAL/NTSC/SECAM decoder/sync

processor

TDA9160

Notes to figure 17

1. Pins 31 and 32 are sensitive to leakage current.

2. The analog and digital ground currents should be well separated.

3. The decoupling capacitor connected between pins 8 and 9 must be placed as close to the IC as possible.

Fig.17 Application diagram.

Page 26

December 1991 26

Philips Semiconductors Preliminary specification

PAL/NTSC/SECAM decoder/sync processor TDA9160

PACKAGE OUTLINE

UNIT b

1

cEe M

H

L

REFERENCES

OUTLINE

VERSION

EUROPEAN

PROJECTION

ISSUE DATE

IEC JEDEC EIAJ

mm

DIMENSIONS (mm are the original dimensions)

SOT232-1

92-11-17

95-02-04

b

max.

w

M

E

e

1

1.3

0.8

0.53

0.40

0.32

0.23

29.4

28.5

9.1

8.7

3.2

2.8

0.181.778 10.16

10.7

10.2

12.2

10.5

1.6

4.7 0.51 3.8

M

H

c

(e )

1

M

E

A

L

seating plane

A

1

w M

b

1

e

D

A

2

Z

32

1

17

16

b

E

pin 1 index

0 5 10 mm

scale

Note

1. Plastic or metal protrusions of 0.25 mm maximum per side are not included.

(1) (1)

D

(1)

Z

A

max.

12

A

min.

A

max.

SDIP32: plastic shrink dual in-line package; 32 leads (400 mil)

SOT232-1

Page 27

December 1991 27

Philips Semiconductors Preliminary specification

PAL/NTSC/SECAM decoder/sync processor TDA9160

SOLDERING

Introduction

There is no soldering method that is ideal for all IC

packages. Wave soldering is often preferred when

through-hole and surface mounted components are mixed

on one printed-circuit board. However, wave soldering is

not always suitable for surface mounted ICs, or for

printed-circuits with high population densities. In these

situations reflow soldering is often used.

This text gives a very brief insight to a complex technology.

A more in-depth account of soldering ICs can be found in

our

“IC Package Databook”

(order code 9398 652 90011).

Soldering by dipping or by wave

The maximum permissible temperature of the solder is

260 °C; solder at this temperature must not be in contact

with the joint for more than 5 seconds. The total contact

time of successive solder waves must not exceed

5 seconds.

The device may be mounted up to the seating plane, but

the temperature of the plastic body must not exceed the

specified maximum storage temperature (T

stg max

). If the

printed-circuit board has been pre-heated, forced cooling

may be necessary immediately after soldering to keep the

temperature within the permissible limit.

Repairing soldered joints

Apply a low voltage soldering iron (less than 24 V) to the

lead(s) of the package, below the seating plane or not

more than 2 mm above it. If the temperature of the

soldering iron bit is less than 300 °C it may remain in

contact for up to 10 seconds. If the bit temperature is

between 300 and 400 °C, contact may be up to 5 seconds.

DEFINITIONS

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

PURCHASE OF PHILIPS I

2

C COMPONENTS

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

Purchase of Philips I

2

C components conveys a license under the Philips’ I2C patent to use the

components in the I2C system provided the system conforms to the I2C specification defined by

Philips. This specification can be ordered using the code 9398 393 40011.

Loading...

Loading...