Page 1

DATA SH EET

Preliminary specification

Supersedes data of June 1993

File under Integrated Circuits, IC02

July 1994

INTEGRATED CIRCUITS

Philips Semiconductors

TDA9151B

Programmable deflection controller

Page 2

July 1994 2

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

FEATURES

General

• 6.75, 13.5 and 27 MHz clock frequency

• Few external components

• Synchronous logic

• I

2

C-bus controlled

• Easy interfacing

• Low power

• ESD protection

• Flash detection with restart

• Two-level sandcastle pulse.

Vertical deflection

• 16-bit precision vertical scan

• Self adaptive or programmable fixed slope mode

• DC coupled deflection to prevent picture bounce

• Programmable fixed compression to 75%

• Programmable vertical expansion in the fixed slope

mode

• S-correction can be preset

• S-correction setting independent of the field frequency

• Differential output for high DC stability

• Current source outputs for high EMC immunity

• Programmable de-interlace phase.

East-West correction

• DC coupled EW correction to prevent picture bounce

• 2nd and 4th order geometry correction can be preset

• Trapezium correction

• Geometry correction settings are independent of field

frequency

• Self adaptive Bult generator prevents ringing of the

horizontal deflection

• Current source output for high EMC immunity.

Horizontal deflection

• Phase 2 loop with low jitter

• Internal loop filter

• Dual slicer horizontal flyback input

• Soft start by I

2

C-bus

• Over voltage protection/detection with selection and

status bit.

EHT correction

• Input selection between aquadag or EHT bleeder

• Internal filter.

GENERAL DESCRIPTION

The TDA9151B is a programmable deflection controller

contained in a 20-pin DIP package and constructed using

BIMOS technology. This high performance

synchronization and DC deflection processor has been

especially designed for use in both digital and analog

based TV receivers and monitors, and serves horizontal

and vertical deflection functions for all TV standards. The

TDA9151B uses a line-locked clock at 6.75, 13.5 or

27 MHz, depending on the line frequency and application,

and requires only a few external components. The device

can be programmed in a self-adaptive mode or in a

programmable fixed slope mode. Selection of these

modes and a large number of other functions is fully

programmable via the I

2

C-bus.

ORDERING INFORMATION

TYPE NUMBER

PACKAGE

PINS PIN POSITION MATERIAL CODE

TDA9151B 20 DIP plastic SOT146-1

Page 3

July 1994 3

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

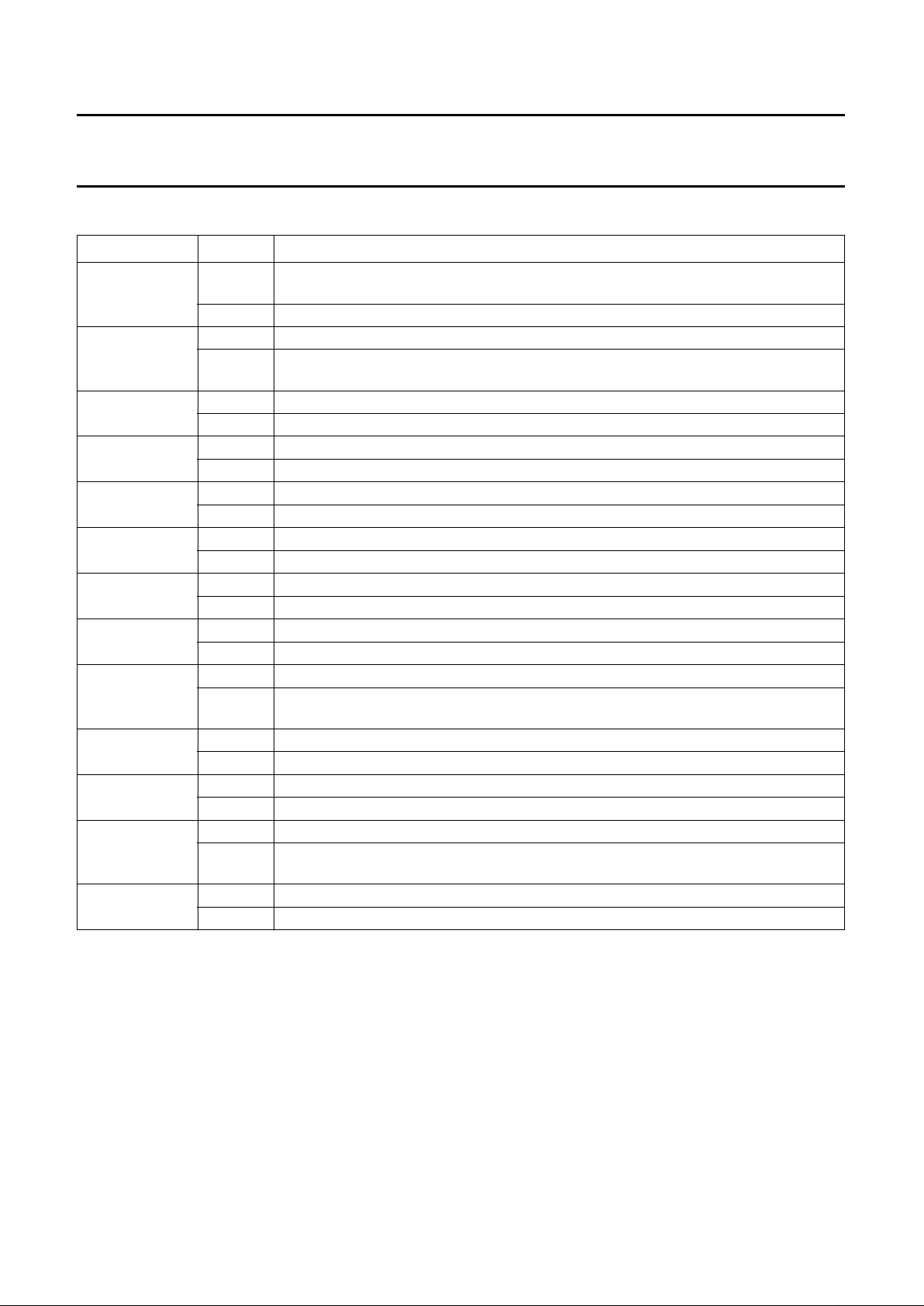

QUICK REFERENCE DATA

Notes

1. Hard wired to ground or V

CC

is highly recommended.

2. DAC values: vertical amplitude = 31; EHT = 0; SHIFT = 3; SCOR = 0.

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

CC

supply voltage 7.2 8.0 8.8 V

I

CC

supply current f

clk

= 6.75 MHz − 27 − mA

P

tot

total power dissipation − 220 − mW

T

amb

operating ambient temperature −25 − +70 °C

Inputs

V

14

line-locked clock (LLC) logic level − TTL −

V

13

horizontal sync (HA) logic level − TTL −

V

12

vertical sync (VA) logic level − TTL −

V

5

line-locked clock select (LLCS)

logic level

note 1 − CMOS 5 V −

V

18

serial clock (SCL) logic level − CMOS 5 V −

V

17

serial data input (SDA) logic level − CMOS 5 V −

V

1

horizontal flyback (HFB) phase

slicing level

FBL = logic 0 − 3.9 − V

FBL = logic 1 − 1.3 − V

V

1

horizontal flyback (HFB) blanking

slicing level

− 100 − mV

V

3

over voltage protection (PROT)

level

− 3.9 − V

V

9

EHT flash detection level − 1.5 − V

Outputs

V

20

horizontal output (HOUT) voltage

(open drain)

I20 = 10 mA −− 0.5 V

I

11−I10(M)

vertical differential (VOUT

A, B

)

output current (peak value)

vertical amplitude = 100%;

I8 = −120 µA; note 2

440 475 510 µA

V

10,11

vertical output voltage 0 − 3.9 V

I

6(M)

EW (EWOUT) total output current

(peak value)

I8 = −120 µA −− 930 µA

V

6

EW (EWOUT) output voltage 1.0 − 5.5 V

SANDCASTLE OUTPUT LEVELS (DSC)

V

2

base voltage level − 0.5 − V

V

2

horizontal and vertical blanking

voltage level

− 2.5 − V

V

2

video clamping voltage level − 4.5 − V

HORIZONTAL OFF-CENTRE SHIFT (OFCS)

V

19

output voltage I19 = 2 mA 0 − V

CC

V

Page 4

July 1994 4

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

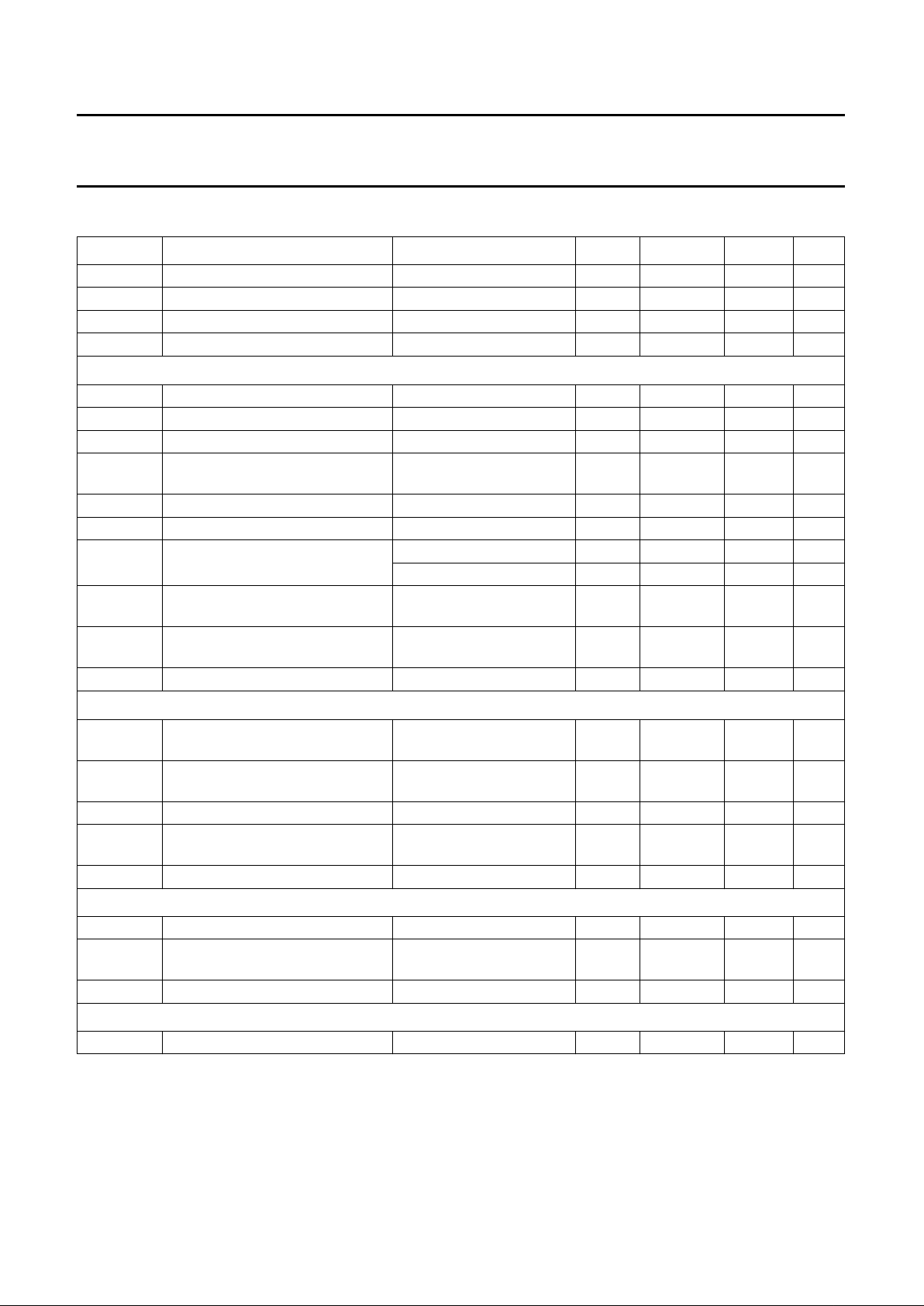

BLOCK DIAGRAM

Fig.1 Block diagram.

Page 5

July 1994 5

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

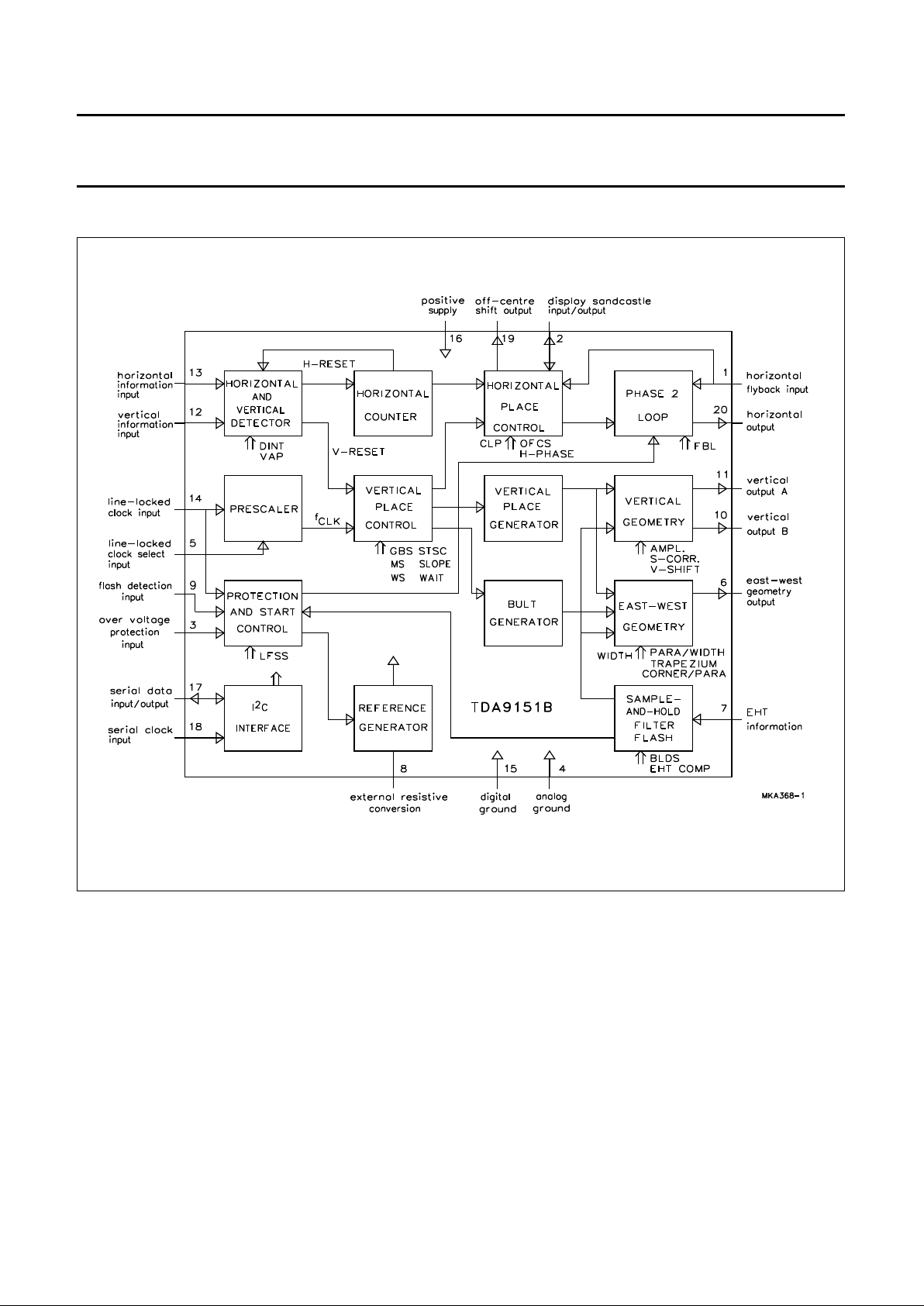

PINNING

SYMBOL PIN DESCRIPTION

HFB 1 horizontal flyback input

DSC 2 display sandcastle input/output

PROT 3 over voltage protection input

AGND 4 analog ground

LLCS 5 line-locked clock selection input

EWOUT 6 east-west geometry output

EHT 7 EHT compensation

R

CONV

8 external resistive conversion

FLASH 9 flash detection input

VOUT

B

10 vertical output B

VOUT

A

11 vertical output A

V

A

12 vertical information input

H

A

13 horizontal information input

LLC 14 line-locked clock input

DGND 15 digital ground

V

CC

16 supply input (+8 V)

SDA 17 serial data input/output

SCL 18 serial clock input

OFCS 19 off-centre shift output

HOUT 20 horizontal output

Fig.2 Pin configuration.

FUNCTIONAL DESCRIPTION

Input signals (pins 12, 13, 14, 17 and 18)

The TDA9151B requires three signals for minimum

operation (apart from the supply). These signals are the

line-locked clock (LLC) and the two I

2

C-bus signals (SDA

and SCL). Without the LLC the device will not operate

because the internal synchronous logic uses the LLC as

the system clock.

I2C-bus transmissions are required to enable the device to

perform its required tasks. Once started the IC will use the

HA and/or VA inputs for synchronization. If the LLC is not

present the outputs will be switched off and all operations

discarded (if the LLC is not present the line drive will be

inhibited within 2 µs, the EW output current will drop to

zero and the vertical output current will drop to 20% of the

adjusted value within 100 µs). The SDA and SCL inputs

meet the I2C-bus specification, the other three inputs are

TTL compatible.

The LLC frequency can be divided-by-two internally by

connecting LLCS (pin 5) to ground thereby enabling the

prescaler.

The LLC timing is given in the Chapter “Characteristics”.

Page 6

July 1994 6

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

I2C-bus commands

Slave address: 8C HEX = 1000110X BIN

READ MODE

The format of the status byte is: PON PROT 000000

Where:

PON is the status bit for power-on reset (POR) and after

power failure:

• Logic 1:

– after the first POR and after power failure; also set to

1 after a severe voltage dip that may have disturbed

the various settings

– POR 1 to 0 transition, VCC = 6.25 V (typ.)

– POR 0 to 1 transition, VCC = 5.75 V (typ.)

• Logic 0:

– after a successful read of the status byte.

PROT is the over voltage detection for the scaled EHT

input:

• Logic 1:

– if the scaled EHT rises above the reference value of

3.9 V

• Logic 0:

– after a successful read of the status byte and EHT

<3.9 V.

Remark: a read action is considered successful when an

End Of Data signal has been detected (i.e. no master

acknowledge).

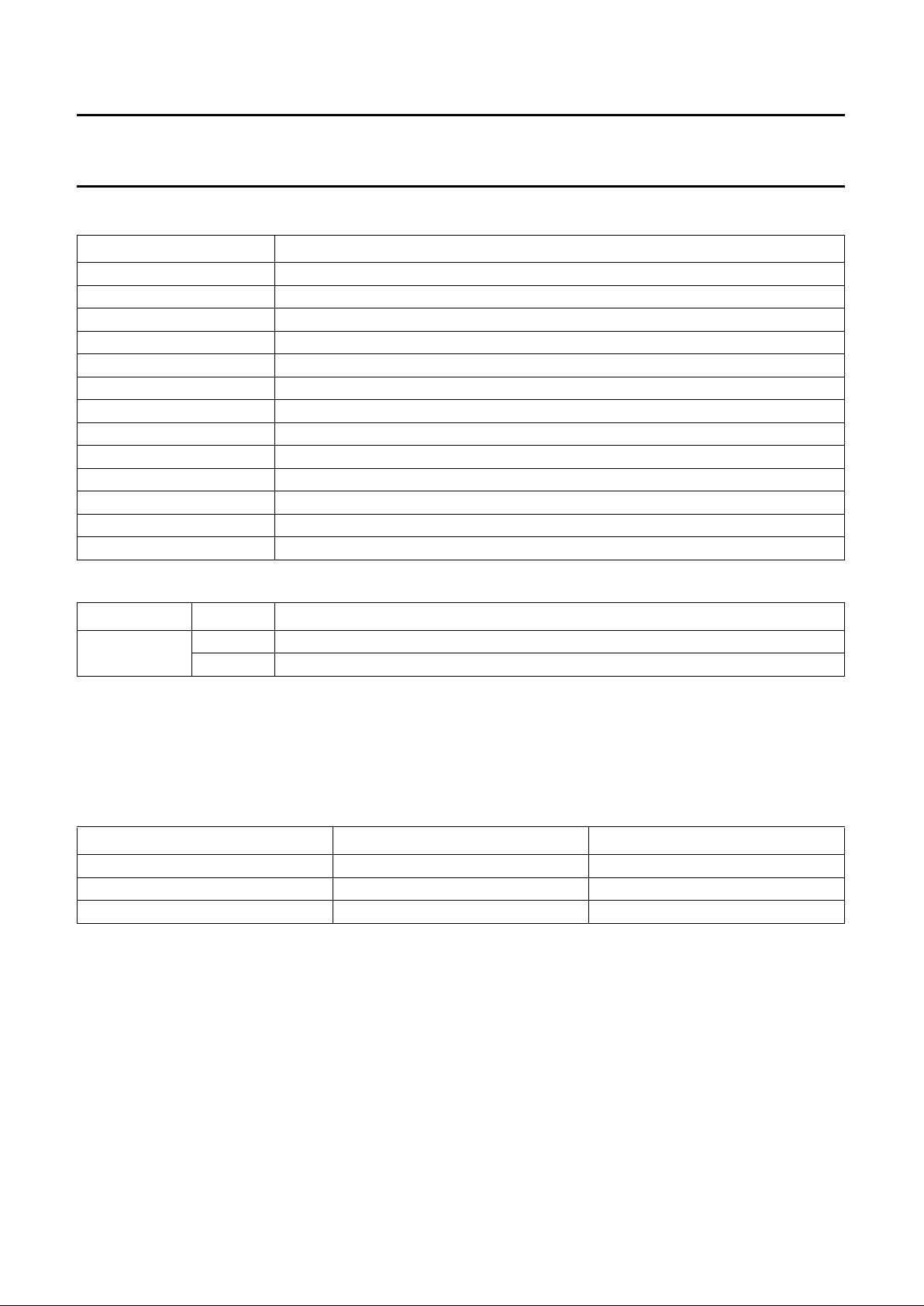

Table 1 Write mode with auto increment; subaddress and data byte format.

Notes

1. X = don’t care.

2. Data bit used in another function.

FUNCTION SUBADDRESS

DATA BYTE

D7 D6 D5 D4 D3 D2 D1 D0

Vertical amplitude 00 X

(1)

X A5A4A3A2A1A0

Vertical S-correction 01 X X A5 A4 A3 A2 A1 A0

Vertical start scan 02 X X A5 A4 A3 A2 A1 A0

Vertical off-centre shift 03 X note 2 note 2 note 2 X A2 A1 A0

EW trapezium correction 03 X A6 A5 A4 X note 2 note 2 note 2

EW width/width ratio 04 X X A5 A4 A3 A2 A1 A0

EW parabola/width ratio 05 X X A5 A4 A3 A2 A1 A0

EW corner/parabola ratio 06 X X A5 A4 A3 A2 A1 A0

EHT compensation 07 X X A5 A4 A3 A2 A1 A0

Horizontal phase 08 X X A5 A4 A3 A2 A1 A0

Horizontal off-centre shift 09 X X A5 A4 A3 A2 A1 A0

Clamp shift 0A X XXXXA2A1A0

Control 1 0B MS WS FBL VAP BLDS LFSS DINT GBS

Vertical slope MSB 0C A7 A6 A5 A4 A3 A2 A1 A0

Vertical slope LSB 0D A7 A6 A5 A4 A3 A2 A1 A0

Vertical wait 0E A7 A6 A5 A4 A3 A2 A1 A0

Control 2 0F X X X VPR CPR DIP PRD CSU

Page 7

July 1994 7

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

Table 2 Control bits.

CONTROL BIT LOGIC FUNCTION

LFSS 0 Line stop: EW output current becomes zero and the vertical output current is reduced

to 20% of the adjusted value. LFSS becomes logic 0 after a HIGH on PON.

1 Line start enabled: the soft start mechanism is now activated.

DINT 0 De-interlace on: the V

A

pulse is sampled at a position selected with control bit DIP.

1 De-interlace off: the V

A

pulse is sampled with the system clock and the detected rising

edge is used as vertical reset.

BLDS 0 Aquadag selected.

1 Bleeder selected.

GBS 0 Becomes logic 0 after power-on.

1 Guard band 48/12 lines.

VAP 0 Positive V

A

edge detection.

1 Negative V

A

edge detection.

FBL 0 Horizontal flyback slicing level = 3.9 V.

1 Horizontal flyback slicing level = 1.3 V.

WS 0 No wait state.

1 Programmable wait state (only in constant slope mode; MS = logic 1).

MS 0 Adaptive mode with guardband amplitude control.

1 Constant slope mode (programmable).

CSU 0 No clamping suppression, standard mode of operation.

1 Clamping suppression in wait, stop and protection modes

(used in systems with e.g. TDA4680/81).

PRD 0 No defeat of HOUT, the over voltage information is only written in the PROT status bit.

1 HOUT is defeated and status bit PROT is set when over voltage is detected.

DIP 0 V

A

is sampled 42 clock pulses after the leading edge of HA.

1V

A

is sampled 258 clock pulses after the leading edge of HA.

CPR 0 Nominal amplitude.

1 Compression to 75% of adjusted amplitude, used for display of 16 : 9 standard pictures

on 4 : 3 displays.

VPR 0 Nominal amplitude (100%) during wait, stop and clipping.

1 Amplitude reduced to 20% during wait, stop and clipping.

Page 8

July 1994 8

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

Table 3 Explanation of control bits shown in Table 2.

Table 4 Clock frequency control bit (pin 5; note 1).

Note

1. Switching of the prescaler is only allowed when LFSS is LOW. It is highly recommended to hard wire LLCS to ground

or V

CC

. Active switching may damage the output power transistor due to the changing HOUT pulse. This may cause

very high currents and large flyback pulses. The permitted combinations of LLC and the prescaler are shown in

Table 5.

Table 5 Line duration with prescaler.

Note

1. Combination not allowed.

CONTROL BITS DESCRIPTION

LFSS line frame start/stop

DINT de-interlace

BLDS bleeder mode selection

GBS guard band selection

VAP polarity of V

A

edge detection

FBL flyback slicing level

WS wait state on/off

MS mode select

CSU clamping suppression mode

PRD protection/detection mode

DIP de-interlace phase

CPR compression on/off

VPR vertical power reduction mode

CONTROL BIT LOGIC FUNCTION

LLCS 0 prescaler on: the internal clock frequency f

clk

=1⁄2f

LLC

1 prescaler off (default by internal pull-up resistor): the internal clock frequency f

clk=fLLC

LLC (MHz) ON (µs) OFF (µs)

6.75 note 1 64

13.5 64 32

27 32 note 1

Page 9

July 1994 9

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

Fig.3 Timing relations between LLC, HA and line counter.

Page 10

July 1994 10

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

Horizontal part (pins 1, 2, 13, 19 and 20

S

YNCHRONIZATION PULSE

The HA input (pin 13) is a TTL-compatible CMOS input.

Pulses on this input have to fulfil the timing requirements

as illustrated in Fig.6. For correct detection the minimum

pulse width for both the HIGH and LOW periods is 2

internal clock periods.

F

LYBACK INPUT PULSE

The HFB input (pin 1) is a CMOS input. The delay of the

centre of the flyback pulse to the leading edge of the H

A

pulse can be set via the I2C-bus with the horizontal phase

byte (subaddress 08), as illustrated in Fig.7.

The resolution is 6-bit.

O

UTPUT PULSE

The HOUT pulse (pin 20) is an open-drain NMOS output.

The duty factor for this output is typically52⁄

48

(conducting/non-conducting) during normal operation. A

soft start causes the duty factor to increase linearly from 5

to 52% over a minimum period of 2000 lines in 2000 steps.

O

FF-CENTRE SHIFT

The OFCS output (pin 19) is a push-pull CMOS output

which is driven by a pulse-width modulated DAC.

By using a suitable interface, the output signal can be used

for off-centre shift correction in the horizontal output stage.

This correction is required for HDTV tubes with a 16 × 9

aspect ratio and is useful for high performance flat square

tubes to obtain the required horizontal linearity. For

applications where off-centre correction is not required,

the output can be used as an auxiliary DAC. The OFCS

signal is phase-locked with the line frequency. The

off-centre shift can be set via the I2C-bus, subaddress 09,

with a 6-bit resolution as illustrated in Fig.8.

S

ANDCASTLE

The DSC input/output (pin 2) acts as a sandcastle

generating output and a guard sensing input. As an output

it provides 2 levels (apart from the base level), one for the

horizontal and vertical blanking and the other for the video

clamping. As an input it acts as a current sensor during the

vertical blanking interval for guard detection.

C

LAMPING PULSE

The clamping pulse width is 21 internal clock periods. The

shift, with respect to HA can be varied from 35 to 49 clock

periods in 7 steps via the I2C-bus, clamp shift byte

subaddress 0A, as illustrated in Fig.9. It is possible to

suppress the clamping pulse during wait, stop and

protection modes with control bit CSU. This will avoid

unwanted reset of the TDA4680/81 (only used in those

circuits).

H

ORIZONTAL BLANKING

The start of the horizontal blanking pulse is minimum 38

and maximum 41 clock periods before the centre of the

flyback pulse, depending on the f

clk/fH

ratio K in

accordance with 41 − (432 − K).

Stop of the horizontal blanking pulse is determined by the

trailing edge of the HFB pulse at the horizontal blanking

slicing level crossing as illustrated in Fig.10.

V

ERTICAL BLANKING

The vertical blanking pulse starts two internal clock pulses

after the rising edge of the VA pulse. During this interval a

small guard pulse, generated during flyback by the vertical

power output stage, must be inserted. Stop vertical

blanking is effected at the end of the blanking interval only

when the guard pulse is present (see Section “Vertical

guard”).

The start scan setting determines the end of vertical

blanking with a 6-bit resolution in steps of one line via the

I2C-bus subaddress 02 (see Figs 11, 12 and 13).

V

ERTICAL GUARD

In the vertical blanking interval a small unblanking pulse is

inserted. This pulse must be filled-in by a blanking pulse or

guard pulse from the vertical power output stage which

was generated during the flyback period. In this condition

the sandcastle output acts as guard detection input and

requires a minimum 800 µA input current. This current is

sensed during the unblanking period. Vertical blanking is

only stopped at the end of the blanking interval when the

inserted pulse is present. In this way the picture tube is

protected against damage in the event of missing or

malfunctioning vertical deflection (see Figs 11, 12 and 13).

Page 11

July 1994 11

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

Vertical part (pins 6, 8, 10, 11 and 12)

S

YNCHRONIZATION PULSE

The VA input (pin 12) is a TTL-compatible CMOS input.

Pulses at this input have to fulfil the timing requirements as

illustrated in Fig.6. For correct detection the minimum

pulse width for both the HIGH and LOW period is 2 internal

clock periods. For further requirements on minimum pulse

width see also Section “De-interlace”.

V

ERTICAL PLACE GENERATOR

An overview of the various modes of operation of the

vertical place generator is illustrated in Fig.13.

With control bit CPR a compress to 75% of the adjusted

values is possible in all modes of operation. This control bit

is used to display 16 : 9 standard pictures on 4 : 3

displays. No new adjustment of other corrections, such as

corner and S-correction, is required.

With control bit VPR a reduction of the current during

clipping, wait and stop modes to 20% of the nominal value

can be selected, which will reduce the dissipation in the

vertical drive circuits.

Vertical place generator in adaptive mode (MS = logic 0)

The vertical start-scan data (subaddress 02) determines

the vertical placement in the total range of 64 × 432 clock

periods in 63 steps. The maximum number of

synchronized lines per scan is 910 with an equivalent field

frequency of 17.2 or 34.4 Hz for fH = 15625 or 31250 Hz

respectively.

The minimum number of synchronized lines per scan is

200 with an equivalent field frequency of 78 or 156 Hz for

fH= 15 625 or 31250 Hz respectively.

If the VA pulse is not present, the number of lines per scan

will increase to 910.2. If the LLC is not present the vertical

blanking will start within 2 µs.

Amplitude control is automatic, with a settling time of 1 to

2 new fields and an accuracy of either 16/12 or 48/12 lines

depending on the value of the GBS bit.

Differences in the number of lines per field, as can occur in

TXT or in multi-head VTR, will not affect the amplitude

setting providing the differences are less than the value

selected with GBS. This is called amplitude control

guardband. The difference sequence and the difference

sequence length are not important.

Vertical place generator in constant slope mode

(MS = logic 1)

In this mode the slope can be programmed directly with a

two byte value on subaddress 0C (MSB) and 0D (LSB).

When the actual number of lines is greater than the

programmed number of lines, the circuit will enter the stop

state in which the differential vertical output current

remains 100% or drops to 20% (programmable with

control bit VPR). The programmed value for the slope is

the required number of lines multiplied by 72. The

programming limits are; minimum 200 × 72 and maximum

910 × 72.

A vertical expansion is obtained with a combination of

slope data and a programmable wait status, at

subaddress 0E. The wait status is selected with control bit

MS and can only be activated in the constant slope mode.

The wait state is an 8-bit value, programmable from 0 to

255. The actual wait state is one line longer than the

programmed value. If blanking is applied during stop and

wait status the differential output current will be the same

with VPR selected value (20 or 100%).

D

E-INTERLACE

With de-interlace on (DINT = logic 0), the VA pulse is

sampled with LLC at a position supplied by control bit DIP

(de-interlace phase).

When DIP = logic 0 sampling takes place 42 clock pulses

after the leading edge of HA (T = T

line

× 42/432).

When DIP = logic 1 sampling takes place 258 clock pulses

after the leading edge of HA (T = T

line

× 258/432).

The distance between the two selectable sampling points

is (T

line

× (258 − 42)/432) which is exactly half a line, thus

de-interlace is possible in two directions.

The duration of the VA pulse must, therefore, be sufficient

to enable the HA pulse to caught, in this event an active

time of minimum of half a line (see Fig.14 which has an

integration time of T

line

×1⁄4 for the VA pulse).

With de-interlace off, the VA pulse is sampled with the

system clock. The leading edge is detected and used as

the vertical reset. Selection of the positive or negative

leading edge is achieved by the control bit VAP.

Page 12

July 1994 12

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

VERTICAL GEOMETRY PROCESSING

The vertical geometry processing is DC-coupled and

therefore independent of field frequency. The external

resistive conversion (R

CONV

) at pin 8 sets the reference

current for both the vertical and EW geometry processing.

A useful range is 100 to 150 µA, the recommended value

is 120 µA.

VERTICAL OUTPUTS

The vertical outputs VOUTA and VOUTB on pins 10 and 11

together form a differential current output. The vertical

amplitude can be varied over the range 80 to 120% in

63 steps via the I2C-bus (subaddress 00). Vertical

S-correction is also applied to these outputs and can be

set from 0 to 16% by subaddress 01 with a 6-bit resolution.

The vertical off-centre shift (OFCS) shifts the vertical

deflection current zero crossing with respect to the EW

parabola bottom. The control range is −1.5 to +1.5%

(±1⁄8× I8) in 7 steps set by the least significant nibble at

subaddress 03.

EW

GEOMETRY PROCESSING

The EW geometry processing is DC coupled and therefore

independent of field frequency. R

CONV

sets the reference

current for both the vertical and EW geometry processing.

The EW output is an ESD-protected single-ended current

output.

The EW width/width ratio can be set from 100 to 80% in

63 steps via subaddress 04 and the EW parabola/width

ratio from 0 to 20% via subaddress 05. The EW

corner/EW parabola ratio has a control range of−40 to 0%

in 63 steps via subaddress 06.

The EW trapezium correction can be set from

−1.5 to +1.5% in 7 steps via the most significant nibble at

subaddress 03.

BULT GENERATOR

The Bult generator makes the EW waveform continuous

(see Fig.21).

Protection input (pin 3)

The protection input (PROT) is a CMOS input.

The input voltage must be EHT scaled and has the

following characteristics:

Two modes of protection are available with the aid of

control bit PRD.

• With PRD = logic 1 the protection mode is selected,

HOUT will be defeated and the PROT bit in the status

word is set if the input voltage is above 3.9 V. Thus the

deflection stops and EW output current is zero, while the

vertical output current is reduced to 20% of the adjusted

value. A new start of the circuit is I

2

C-bus controlled with

the user software.

• With PRD = logic 0 the detection mode is selected,

HOUT will not be defeated and the over voltage

information is only written in the PROT status bit and can

be read by the I2C-bus.

All further actions, such as a write of the LFSS bit, are

achieved by the I2C-bus. They depend on the

configuration used and are defined by user software.

Flash detection/protection input (pin 9)

The FLASH input is a CMOS input with an internal pull-up

current of approximately 8 µA.

When a negative-going edge crosses the 0.75 V level a

restart will be executed with a soft start of approximately

2000 lines, such as in the soft-start mode. When the

function is not used pin 9 can be connected to ground, V

CC

or left open-circuit, the internal pull-up current source will

prevent any problems. However a hard wired connection

to VCC or ground is recommended when the function is not

used.

EHT compensation (pin 7)

The EHT input is a CMOS input.

The EHT compensation input permits scan amplitude

modulation should the EHT supply not be perfect. For

correct tracking of the vertical and horizontal deflection the

gain of the EW output stage, provided by the ratio

R

CONV-EW/RCONV

, must be1⁄16V

scan

× V

ref

(see Fig.15).

The input for EHT compensation can be derived from an

EHT bleeder or from the picture tubes aquadag

(subaddress 0B, bit BLDS).

EHT compensation can be set via subaddress 07 in

63 steps allowing a scan modulation range from

−10 to +9.7%.

Page 13

July 1994 13

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

INTERNAL CIRCUITRY

handbook, full pagewidth

300 Ω

1 2

300 Ω

3 4

300 Ω

5 6

MBD906

300 Ω

7 8

300 Ω

9 10

300 Ω

141516

300 Ω

17

300 Ω

181920

300 Ω

13

300 Ω

12 11

TDA9151B

Fig.4 Internal circuitry.

Page 14

July 1994 14

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

APPLICATION INFORMATION

Fig.5 Application diagram.

handbook, full pagewidth

MBD907

C95 C89

22 µF 100 nF

V

CC

( 8 V)

SDA

100 Ω

R75

SCL

100 Ω

R76

1 kΩ

R77

TDA9151B

V

CC

( 8 V)

HOUT OFCS

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

LLC

H

V

A

A

R99

3.3 kΩ

C97

100 nF

V

CC

( 8 V)

4.7 kΩ

39 kΩ

EHT

R87

R88

3.3 kΩ

R84

15 kΩ

R85

HFB

23 V (peak)

DSC

1

2

3

4

5

6

7

8

9

10

11

12

13

R113 R117

123

330 Ω

R113

C105

100 µF

100

nF

C105

100 µF

TDA8350

R107

82 kΩ

C110

100 nF

33 V

EW-OUT

vertical

deflection coil

LV

3 kΩ

R105

IE5

IE5

flash detection input

Zener

diode

16 V (vert)

45 V (vert)

Page 15

July 1994 15

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

TIMING DIAGRAMS

Fig.6 Timing requirements for LLC, HA and VA.

NNNNNNN

NNNNNNN

Fig.7 Horizontal phase and HOUT control range.

Page 16

July 1994 16

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

Fig.8 OFCS duty factor.

Fig.9 DSC clamping pulse.

Page 17

July 1994 17

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

Fig.10 DSC line blanking.

Fig.11 DCS vertical blanking with unblanking.

Page 18

July 1994 18

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

Fig.12 DSC with guard interval; start scan = 24.

Vertical blanking LOW period: during scan, during unblanking.

Vertical blanking HIGH period (2.5 V): during STSC, stop and wait.

Vertical blanking continuously HIGH: POR = logic 1, LFSS = logic 0, no guard detected.

Page 19

July 1994 19

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

Fig.13 Vertical deflection operating modes.

t

ub

= unblanking pulse width.

Page 20

July 1994 20

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

I = start VA for DINT = logic 1.

D = start VA for DINT = logic 0.

Fig.14 De-interlace timing.

Fig.15 Explanation of R

CONV-EW/RCONV

ratio.

Page 21

July 1994 21

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC134).

Note

1. Equivalent to discharging a 100 pF capacitor via a 1.5 kΩ series resistor.

THERMAL CHARACTERISTICS

SYMBOL PARAMETER MIN. MAX. UNIT

V

CC

supply voltage −0.5 8.8 V

I

CC

supply current −10 +50 mA

P

tot

total power dissipation − 500 mW

T

stg

storage temperature −65 +150 °C

T

amb

operating ambient temperature −25 +70 °C

V

supply

voltage supplied to pins 1 to 3, 5 to 14 and 17 to 20 −0.5 VCC+ 0.5 V

I

I/O

current in or out of any pin except pins 4, 15 and 16 −20 +20 mA

V

ESD

electrostatic handling for all pins (note 1) −±2000 V

SYMBOL PARAMETER VALUE UNIT

R

th j-a

thermal resistance from junction to ambient in free air 70 K/W

Page 22

July 1994 22

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

CHARACTERISTICS

V

CC

= 8V;T

amb

= 25 °C; DGND = AGND = 0 V; unless otherwise specified.

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supply

V

CC

supply voltage 7.2 8.0 8.8 V

I

CC

supply current note 1;

f

clk

= 6.75 MHz

− 27 − mA

P

tot

total power dissipation − 220 − mW

V

por

power-on reset POR 1-to-0

transition

− 6.25 7.0 V

POR 0-to-1

transition

5.0 5.75 − V

SDA and SCL (pins 17 and 18)

V

17

SDA input voltage 0 − 5.5 V

V

IL

LOW level input voltage (pin 17) −−1.5 V

V

IH

HIGH level input voltage (pin 17) 3.5 −− V

I

IL

LOW level input current (pin 17) V17 = V

SSD

−−−10 µA

I

IH

HIGH level input current (pin 17) V17 = V

CC

−−10 µA

V

OL

LOW level output voltage (pin 17) IIL = 3 mA −−0.4 V

V

18

SCL input voltage 0 − 5.5 V

V

IL

LOW level input voltage (pin 18) −−1.5 V

V

IH

HIGH level input voltage (pin 18) 3.5 −− V

I

IL

LOW level input current (pin 18) V18 = V

SSD

−−−10 µA

I

IH

HIGH level input current (pin 18) V18 = V

CC

−−10 µA

Line-locked clock and line-locked clock select (pins 14 and 5)

V

IL

LOW level input voltage (pin 14) −−0.8 V

V

IH

HIGH level input voltage (pin 14) 2.0 −− V

I

14

input current V14 = <5.5 V −10 − +10 µA

t

r

rise time 0 −

1

⁄2t

LLC

t

f

fall time 0 −

1

⁄2t

LLC

δ

0

duty factor LLCS = logic 0;

at 1.4 V; note 2

40 50 60 %

δ

1

duty factor LLCS = logic 1;

at 1.4 V; note 2

25 50 75 %

TIMING (PRESCALER ON;f

clk

=1⁄2f

LLC

WHERE f

clk

= INTERNAL CLOCK)

f

LLC

line-locked clock frequency 12.4 − 29.2 MHz

K line-locked clock frequency ratio

between f

LLC

and f

H

H locked 856 864 865

H unlocked − 866 −

line-locked clock frequency ratio

between f

clk

and f

H

H locked 428 432 432.5

H unlocked − 433 −

Page 23

July 1994 23

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

TIMING (PRESCALER OFF;f

clk

=f

LLC

WHERE f

clk

= INTERNAL CLOCK)

f

LLC

line-locked clock frequency 6.2 − 15.5 MHz

K line-locked clock frequency ratio

between f

LLC

and f

H

H locked 428 432 432

H unlocked − 433 −

line-locked clock frequency ratio

between f

clk

and f

H

H locked 428 432 432

H unlocked − 433 −

V

5

LLCS input voltage 0 − 8.8 V

V

IL

LOW level input voltage (pin 5) −−1.5 V

V

IH

HIGH level input voltage (pin 5) 3.5 −− V

I

IL

LOW level input current (pin 5) V5 = V

SSD

−−−150 µA

I

IH

HIGH level input current (pin 5) V5 = V

CC

−−100 µA

Horizontal part

I

NPUT SIGNALS

HA (pin 13)

V

IL

LOW level input voltage −−0.8 V

V

IH

HIGH level input voltage 2.0 −− V

I

13

input current V13 = 5.5 V −10 − +10 µA

t

r

rise time 0 −

1

⁄2t

LLC

ns

t

f

fall time 0 −

1

⁄2t

LLC

ns

t

WH

pulse width HIGH 2 × t

clk

−−

t

WL

pulse width LOW 2 × t

clk

−−

HFB (pin 1)

V

PSL

phase slicing level; FBL = logic 0 3.7 3.9 4.1 V

FBL = logic 1 1.1 1.3 1.5 V

V

blank

blanking slicing level 0 0.1 0.2 V

I

1

input current −10 − +10 µA

Horizontal phase (delay centre flyback pulse to leading edge of HA; where N = horizontal phase data)

CR control range 0 N × t

clk

N + (432 − K)

× t

clk

number of steps − 63 −

OUTPUT SIGNALS

HOUT (pin 20)

V

20

output voltage I20 = 0 0 − V

CC

V

V

OL

LOW level output voltage I20 = 10 mA −−0.5 V

I

20

input current output off −10 − +10 µA

δ duty factor normal operation 51 52 53 %

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Page 24

July 1994 24

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

Soft start (duty factor controlled line drive)

t

W

initial pulse width soft start −−5%

CR control range 5 − 53 %

t

ss

soft start time 1500 − 3000 lines

Switch-off time to the centre of the flyback pulse

CR control range note 3 0 − 160 −

(432 − K)

× t

clk

Φ control sensitivity (loop gain) 400 1000 −µs/µs

k correction factor note 4 − 0.5 −

σ sigma value of phase jitter note 5 − 750 − ps

PSRR power supply rejection ratio −−10 ns/V

Horizontal off-centre shift (pin 19; N = off-centre shift data)

V

19

output voltage 0 − V

CC

V

V

OL

LOW level output voltage I19 = 2 mA −−0.5 V

V

OH

HIGH level output voltage I19 = −2mA VCC− 0.5 −− V

δ

(max)

maximum duty factor N <54 1/K (8N+1)/K 425/K %

δ duty factor N ≥54 − 1 − %

number of steps − 54 −

S

ANDCASTLE (PIN 2)

DSC output voltage

V

clamp

video clamping voltage 4.0 4.5 5.0 V

V

blank

horizontal and vertical blanking

voltage level

2.0 2.5 3.0 V

V

base

base voltage level 0 0.5 1.0 V

I

2

output current guard not detected −1.0 − +0.35 mA

guard detected 0.8 − 2.5 mA

t

r

rise time − 60 − ns

t

f

fall time − 60 − ns

Clamping pulse (N = clamp pulse shift data)

t

W

clamping pulse width − 21 × t

clk

−

t

clamp

clamp pulse shift w.r.t H

A

35 (2N+ 35)

× t

clk

49

number of steps − 7 −

t

start

start of horizontal blanking before

middle of flyback pulse

38 41−

(432 − K)

× t

clk

41

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Page 25

July 1994 25

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

Vertical blanking width (N = vertical start-scan data)

CR control range 1 × 432t

clk

(N + 1)

× 432t

clk

64 × 432t

clk

K = 432 1 − 64 lines

number of steps − 63 −

Guard detection (N = vertical start-scan data)

t

start

start interval w.r.t V

A

no wait {48(N+1) +2}

× t

clk

−−

t

stop

stop interval w.r.t V

A

no wait {96(N+1) +2}

× t

clk

−−

Vertical section

INPUT SIGNALS (PIN 12; V

A

)

V

IL

LOW level input voltage −−0.8 V

V

IH

HIGH level input voltage 2.0 −− V

I

12

input current V12<5.5 V −10 − +10 µA

t

r

rise time 0 −

1

⁄2t

LLC

ns

t

f

fall time 0 −

1

⁄2t

LLC

ns

t

WH

pulse width HIGH 2 × t

clk

−−

t

WL

pulse width LOW 2 × t

clk

−−

t

WH

pulse width HIGH de-interlace mode 0.5 × t

line

−−

t

WL

pulse width LOW de-interlace mode 0.5 × t

line

−−

Vertical place generator in adaptive mode (N = vertical start-scan data)

CR control range 1 × 432t

clk

(N + 1)

× 432t

clk

64 × 432t

clk

K = 432 1 − 64 lines

number of steps − 63 −

L

max

maximum number of

synchronized lines per scan

− 910 − lines/

scan

f

eq

equivalent field frequency at 910

lines/scan

fH = 15625 Hz − 17.2 − Hz

f

H

= 31250 Hz − 34.4 − Hz

L

min

minimum number of

synchronized lines per scan

− 200 − lines/

scan

f

eq

equivalent field frequency at 200

lines/scan

fH = 15625 Hz − 78 − Hz

f

H

= 31250 Hz − 156 − Hz

CA amplitude control − automatic −

CA

g

amplitude control guardband GBS = logic 0 − 16/12 − lines

GBS = logic 1 − 48/12 − lines

settling time 1 1.5 2 new

fields

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Page 26

July 1994 26

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

Vertical place generator in constant slope mode (N = vertical wait data)

CR control range 1 × 432t

clk

(N + 1)

× 432t

clk

64 × 432t

clk

K = 432 1 − 64 lines

number of steps − 255 −

programmable slope 200 − 910 lines/

scan

programmable slope data

(number of lines × 72)

2-byte instruction; 200 × 72 − 910 × 72 lines

Vertical geometry processing

∆I

(M)

vertical differential output current

between VOUTA and VOUT

B

(peak value)

VA = 100%;

note 6;

I8= −120 µA

440 475 510 µA

D/∆T drift over temperature range −−10

−4

K

−1

amplitude error due to

S-correction setting

−−2%

1

⁄

2

(I10+I11) vertical output signal bias current I8 = −120 µA 275 325 375 µA

I

os

vertical output offset current note 7 −−1%

OS/∆T offset over temperature range −−10

−4

K

−1

V

10

vertical output voltage (pin 10) 0 − 3.9 V

V

11

vertical output voltage (pin 11) 0 − 3.9 V

CMRR common mode rejection ratio −−1 %/V

LE linearity error adjacent blocks;

note 8

−−2.0 %

non-adjacent

blocks; note 8

−−3.0 %

Vertical amplitude (N = vertical amplitude data)

CR control range note 9 81 − 119 %

number of steps − 63 −

Vertical S-correction (N = S-correction data)

CR control range note 9 0 − 15 %

number of steps − 63 −

Vertical shift

CR control range −1⁄8I

8

− +1⁄8I

8

µA

number of steps − 7 −

EW output (pin 6)

V

6

output voltage note 10 1.0 − 5.5 V

I

6

output current I8 = −120 µA;

note 11

15 − 930 µA

RR output ripple rejection − 0.15 1 %/V

D/∆T output drift over temperature

range

−−5.10

−4

K

−1

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Page 27

July 1994 27

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

EW WIDTH/WIDTH RATIO

CR control range note 9 100 − 81 %

I

eq(typ)

typical equivalent output current V6 = 3 V 15 − 440 µA

number of steps − 63 −

EW

PARABOLA/WIDTH RATIO

CR control range note 9 1 − 19 %

I

eq(typ)

typical equivalent output current width = 100% 10 − 430 µA

width = 80% 10 − 345 µA

number of steps − 63 −

EW

CORNER/EW PARABOLA RATIO

CR control range notes 9 and 12 40 − 0%

I

eq(typ)

typical equivalent output current width = 100% 0 − 200 µA

width = 80% 0 − 160 µA

number of steps − 63 −

EW

TRAPEZIUM CORRECTION

EW trapezium/width ratio note 9 −1.5 − +1.5 %

number of steps − 7 −

EHT input (pin 7)

V

ref

reference voltage BLDS = logic 1 − 3.9 − V

BLDS = logic 0 − V

CC

− V

V

I

input voltage w.r.t V

ref

BLDS = logic 1 −20 0 +20 %

V

I

input voltage w.r.t V

CC

BLDS = logic 0 0 −−2V

ref

V

m

scan

scan modulation −10 0 +9.7 %

m

GC

modulation gain control 0 − 1

number of steps − 63 −

I

I

input current −100 − +100 nA

R

CONV

input (pin 8)

V

O

output voltage I8 = −120 µA 3.7 3.9 4.1 V

I

8

current range −100 −120 −150 µA

PROT input (pin 3)

V

I

input voltage 0 − V

CC

V

V

3

voltage detection level 3.7 3.9 4.1 V

I

I

input current −10 − +10 µA

FLASH detection input (pin 9)

V

I

input voltage 0 − V

CC

V

V

9

voltage detection level falling edge 0.5 0.75 1.0 V

H detection level hysteresis 0.3 0.5 0.8 V

I

9

detection pull-up current −4 −8 −16 µA

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Page 28

July 1994 28

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

Notes to the characteristics

1. For all other frequencies the expected supply current will be as shown in Table 6 (f

clk

is the internal clock frequency,

f

LLC

is the internal clock frequency applied to pin 14).

2. When the prescaler is on, one in two LLC HIGH periods is omitted.

3. For 16 kHz operation the minimum value of the control range is 5.7 µs. With1⁄2tFB = 5.7 µs the minimum storage time

is 0 and the maximum is 18 µs.

For 32 kHz operation the minimum value of the control range is 0 µs. With1⁄2tFB = 2.85 µs the minimum storage time

is 0 and the maximum is 9 µs.

4. The k factor is defined as the amount of correction of a phase step. Thus with k = 0.5 a 50% correction of the error

takes place each line. The resulting step response now becomes kn, with n the line number after the step.

5. The sigma value (σ) of the jitter with respect to LLC (HA) at fH = 32 kHz and a storage time of 5 µs.

Measurement ofσ is carried out during 200 lines in the active scan, the resulting peak-to-peak value is approximately

6σ. The visible jitter on the screen will be higher than the peak-to-peak jitter, depending on the deflection stage.

6. DAC values: vertical amplitude = 31; EHT = 0; SHIFT = 3; SCOR = 0.

7. Value is a percentage of I10− I11.

8. The linearity error is measured without S-correction and based on the same measurement principle as used for the

screen. Measuring method: divide the output signal I10− I11 into 22 equal parts, ranging from 1 to 22 inclusive.

Measure the value of two succeeding parts called one block starting with part 2 and 3 (block 1) and ending with part

20 and 21 (block 10). Thus part 1 and 22 are unused.

Linearity error for adjacent blocks =

Linearity error for non-adjacent blocks =

Where a = amplitude, a

k

= amplitude block k and a

avg

= average amplitude.

9. Minimum available range.

10. Selection of test mode.

When the EW output is pulled above V

CC

− 0.5 V a special test mode is entered in which the prescaler and the clock

detector are disabled.

11. DAC values: vertical amplitude = 31; EHT = 0.

12. The value of −40% (typically 46%) corresponds with data 3F (hexadecimal) and implies maximum 4th order

compensation.

Table 6 Supply current with prescaler on/off.

Note

1. Combination not allowed.

LLC (MHz) ON (mA) OFF (mA)

6.75 note 1 27

13.5 27 38

27 42 note 1

aka

k1+()

–

a

avg

----------------------------- -

a

maxamin

–

a

avg

----------------------------- -

Page 29

July 1994 29

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

TEST AND APPLICATION INFORMATION

Fig.16 Control range amplitude.

I11− I10.

Fig.17 Control range S-correction.

BBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBB

Page 30

July 1994 30

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

Fig.18 Control range EW parabola/width ratio.

BBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBBBBB

Fig.19 Control range EW corner/EW parabola ratio.

Page 31

July 1994 31

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

BBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBBBBB

Fig.20 Control range EW width.

Fig.21 The BULT makes the EW waveform continuous.

BBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBB

B

BBBBBBBBBBBBBBBBBBBBBBB

Page 32

July 1994 32

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

PACKAGE OUTLINE

Fig.22 Plastic dual in-line package; 20 leads (300 mil); DIP20, SOT146-1.

Dimensions in mm.

MSA258

2.54

(9x)

0.254

M

0.53

max

seating plane

3.60

3.05

2.0

max

26.92

26.54

4.2

max

3.2

max

0.51

min

8.25

7.80

0.38 max

7.62

10.0

8.3

11

10

6.40

6.22

1.73 max

20

1

SOLDERING

Plastic dual in-line packages

B

Y DIP OR WAVE

The maximum permissible temperature of the solder is

260 °C; this temperature must not be in contact with the

joint for more than 5 s. The total contact time of successive

solder waves must not exceed 5 s.

The device may be mounted up to the seating plane, but

the temperature of the plastic body must not exceed the

specified storage maximum. If the printed-circuit board has

been pre-heated, forced cooling may be necessary

immediately after soldering to keep the temperature within

the permissible limit.

R

EPAIRING SOLDERED JOINTS

Apply a low voltage soldering iron below the seating plane

(or not more than 2 mm above it). If its temperature is

below 300 °C, it must not be in contact for more than 10 s;

if between 300 and 400 °C, for not more than 5 s.

Page 33

July 1994 33

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

DEFINITIONS

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

PURCHASE OF PHILIPS I2C COMPONENTS

Purchase of Philips I2C components conveys a license under the Philips’ I2C patent to use the

components in the I2C system provided the system conforms to the I2C specification defined by

Philips. This specification can be ordered using the code 9398 393 40011.

Page 34

July 1994 34

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

NOTES

Page 35

July 1994 35

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9151B

NOTES

Page 36

Philips Semiconductors

Philips Semiconductors – a worldwide company

Argentina: IEROD, Av. Juramento 1992 - 14.b, (1428)

BUENOS AIRES, Tel. (541)786 7633, Fax. (541)786 9367

Australia: 34 Waterloo Road, NORTH RYDE, NSW 2113,

Tel. (02)805 4455, Fax. (02)805 4466

Austria: Triester Str. 64, A-1101 WIEN, P.O. Box 213,

Tel. (01)60 101-1236, Fax. (01)60 101-1211

Belgium: Postbus 90050, 5600 PB EINDHOVEN, The Netherlands,

Tel. (31)40 783 749, Fax. (31)40 788 399

Brazil: Rua do Rocio 220 - 5

th

floor, Suite 51,

CEP: 04552-903-SÃO PAULO-SP, Brazil.

P.O. Box 7383 (01064-970).

Tel. (011)821-2333, Fax. (011)829-1849

Canada: PHILIPS SEMICONDUCTORS/COMPONENTS:

Tel. (800) 234-7381, Fax. (708) 296-8556

Chile: Av. Santa Maria 0760, SANTIAGO,

Tel. (02)773 816, Fax. (02)777 6730

Colombia: IPRELENSO LTDA, Carrera 21 No. 56-17,

77621 BOGOTA, Tel. (571)249 7624/(571)217 4609,

Fax. (571)217 4549

Denmark: Prags Boulevard 80, PB 1919, DK-2300 COPENHAGEN S,

Tel. (032)88 2636, Fax. (031)57 1949

Finland: Sinikalliontie 3, FIN-02630 ESPOO,

Tel. (9)0-50261, Fax. (9)0-520971

France: 4 Rue du Port-aux-Vins, BP317,

92156 SURESNES Cedex,

Tel. (01)4099 6161, Fax. (01)4099 6427

Germany: PHILIPS COMPONENTS UB der Philips G.m.b.H.,

P.O. Box 10 63 23, 20043 HAMBURG,

Tel. (040)3296-0, Fax. (040)3296 213.

Greece: No. 15, 25th March Street, GR 17778 TAVROS,

Tel. (01)4894 339/4894 911, Fax. (01)4814 240

Hong Kong: PHILIPS HONG KONG Ltd., Components Div.,

6/F Philips Ind. Bldg., 24-28 Kung Yip St., KWAI CHUNG, N.T.,

Tel. (852)424 5121, Fax. (852)428 6729

India: Philips INDIA Ltd, Components Dept,

Shivsagar Estate, A Block ,

Dr. Annie Besant Rd. Worli, Bombay 400 018

Tel. (022)4938 541, Fax. (022)4938 722

Indonesia: Philips House, Jalan H.R. Rasuna Said Kav. 3-4,

P.O. Box 4252, JAKARTA 12950,

Tel. (021)5201 122, Fax. (021)5205 189

Ireland: Newstead, Clonskeagh, DUBLIN 14,

Tel. (01)640 000, Fax. (01)640 200

Italy: PHILIPS COMPONENTS S.r.l.,

Viale F. Testi, 327, 20162 MILANO,

Tel. (02)6752.3302, Fax. (02)6752 3300.

Japan: Philips Bldg13-37, Kohnan 2-chome, Minato-ku, TOKYO 108,

Tel. (03)3740 5028, Fax. (03)3740 0580

Korea: (Republic of) Philips House, 260-199 Itaewon-dong,

Yongsan-ku, SEOUL, Tel. (02)794-5011, Fax. (02)798-8022

Malaysia: No. 76 Jalan Universiti, 46200 PETALING JAYA,

SELANGOR, Tel. (03)750 5214, Fax. (03)757 4880

Mexico: Philips Components, 5900 Gateway East, Suite 200,

EL PASO, TX 79905, Tel. 9-5(800)234-7381, Fax. (708)296-8556

Netherlands: Postbus 90050, 5600 PB EINDHOVEN, Bldg. VB

Tel. (040)783749, Fax. (040)788399

New Zealand: 2 Wagener Place, C.P.O. Box 1041, AUCKLAND,

Tel. (09)849-4160, Fax. (09)849-7811

Norway: Box 1, Manglerud 0612, OSLO,

Tel. (022)74 8000, Fax. (022)74 8341

Pakistan: Philips Electrical Industries of Pakistan Ltd.,

Exchange Bldg. ST-2/A, Block 9, KDA Scheme 5, Clifton,

KARACHI 75600, Tel. (021)587 4641-49,

Fax. (021)577035/5874546.

Philippines: PHILIPS SEMICONDUCTORS PHILIPPINES Inc,

106 Valero St. Salcedo Village, P.O. Box 2108 MCC, MAKATI,

Metro MANILA, Tel. (02)810 0161, Fax. (02)817 3474

Portugal: PHILIPS PORTUGUESA, S.A.,

Rua dr. António Loureiro Borges 5, Arquiparque - Miraflores,

Apartado 300, 2795 LINDA-A-VELHA,

Tel. (01)14163160/4163333, Fax. (01)14163174/4163366.

Singapore: Lorong 1, Toa Payoh, SINGAPORE 1231,

Tel. (65)350 2000, Fax. (65)251 6500

South Africa: S.A. PHILIPS Pty Ltd., Components Division,

195-215 Main Road Martindale, 2092 JOHANNESBURG,

P.O. Box 7430 Johannesburg 2000,

Tel. (011)470-5911, Fax. (011)470-5494.

Spain: Balmes 22, 08007 BARCELONA,

Tel. (03)301 6312, Fax. (03)301 42 43

Sweden: Kottbygatan 7, Akalla. S-164 85 STOCKHOLM,

Tel. (0)8-632 2000, Fax. (0)8-632 2745

Switzerland: Allmendstrasse 140, CH-8027 ZÜRICH,

Tel. (01)488 2211, Fax. (01)481 77 30

Taiwan: PHILIPS TAIWAN Ltd., 23-30F, 66, Chung Hsiao West

Road, Sec. 1. Taipeh, Taiwan ROC, P.O. Box 22978,

TAIPEI 100, Tel. (02)388 7666, Fax. (02)382 4382.

Thailand: PHILIPS ELECTRONICS (THAILAND) Ltd.,

209/2 Sanpavuth-Bangna Road Prakanong,

Bangkok 10260, THAILAND,

Tel. (662)398-0141, Fax. (662)398-3319.

Turkey:Talatpasa Cad. No. 5, 80640 GÜLTEPE/ISTANBUL,

Tel. (0212)279 2770, Fax. (0212)269 3094

United Kingdom: Philips Semiconductors LTD.,

276 Bath road, Hayes, MIDDLESEX UB3 5BX,

Tel. (081)73050000, Fax. (081)7548421

United States:811 East Arques Avenue, SUNNYVALE,

CA 94088-3409, Tel. (800)234-7381, Fax. (708)296-8556

Uruguay: Coronel Mora 433, MONTEVIDEO,

Tel. (02)70-4044, Fax. (02)92 0601

For all other countries apply to: Philips Semiconductors,

International Marketing and Sales, Building BE-p,

P.O. Box 218, 5600 MD, EINDHOVEN, The Netherlands,

Telex 35000 phtcnl, Fax. +31-40-724825

SCD33 © Philips Electronics N.V. 1994

All rights are reserved. Reproduction in whole or in part is prohibited without the

prior written consent of the copyright owner.

The information presented in this document does not form part of any quotation

or contract, is believed to be accurate and reliable and may be changed without

notice. No liability will be accepted by the publisher for any consequence of its

use. Publication thereof does not convey nor imply any license under patent- or

other industrial or intellectual property rights.

Printed in The Netherlands

533061/1500/02/pp36 Date of release: July 1994

Document order number: 9397 737 90011

Loading...

Loading...