Page 1

Power Factor Controller

TDA 4817

IC for High Power Factor and

Active Harmonic Filtering

Advance Information Bipolar IC

Features

● IC for sinusoidal line-current consumption

● Power factor approaching 1

● Controls boost converter as an active harmonics filter

● Direct drive of SIPMOS transistor

● Zero crossing detector for discontinuous operation mode

with variable frequency

● 110/220 V AC operation without switchover

● Standby current consumption of 0.5 mA

P-DIP-8-1

P-DSO-8-1

Type Ordering Code Package

▼

TDA 4817 Q67000-A8298 P-DIP-8-1

▼

TDA 4817 G Q67000-A8299 P-DSO-8-1 (SMD)

▼ = New type

The TDA 4817 contains all functions for designing electronic ballasts and switched-mode power

supplies with sinusoidal line current consumption and a power factor approaching 1.

The TDA 4817 controls a boost converter as an active harmonic filter in a discontinuous (triangular

shaped current) mode with variable frequency.

A typical application is in electronic ballasts, especially when a large number of such lamps are

concentrated on one line supply point.

The output voltage of this filter is regulated with high efficiency. Therefore the device can be easily

operated on different line voltages (110/220 V

) without any switchover.

AC

The TDA 4817 is an 8-pin-economy-version of the TDA 4814 A without reference voltage output

and start/stop monitoring circuit.

Semiconductor Group 1 05.95

Page 2

TDA 4817 TDA 4817 G

TDA 4817

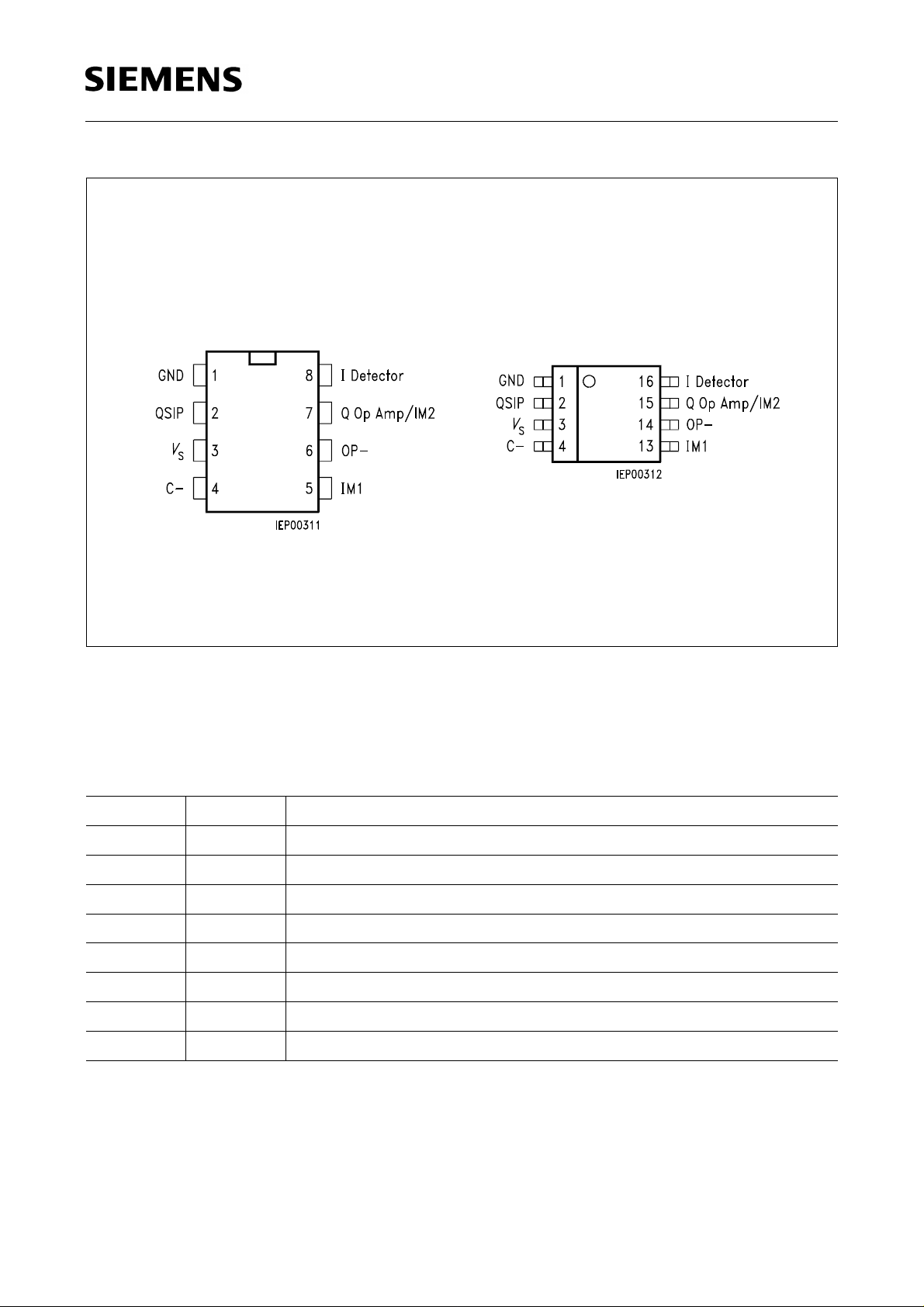

Pin Configurations

(top view)

Pin Definitions and Functions

Pin Symbol Function

1 GND Ground

2 QSIP Driver output

3

V

S

Supply voltage

4 C – Comparator input

5 IM1 Multiplier input

6 OP – Input

7 QOP/IM2 Operational-amplifier output QOP and multiplier input M2

8 I Detector Detector input

Semiconductor Group 2

Page 3

TDA 4817

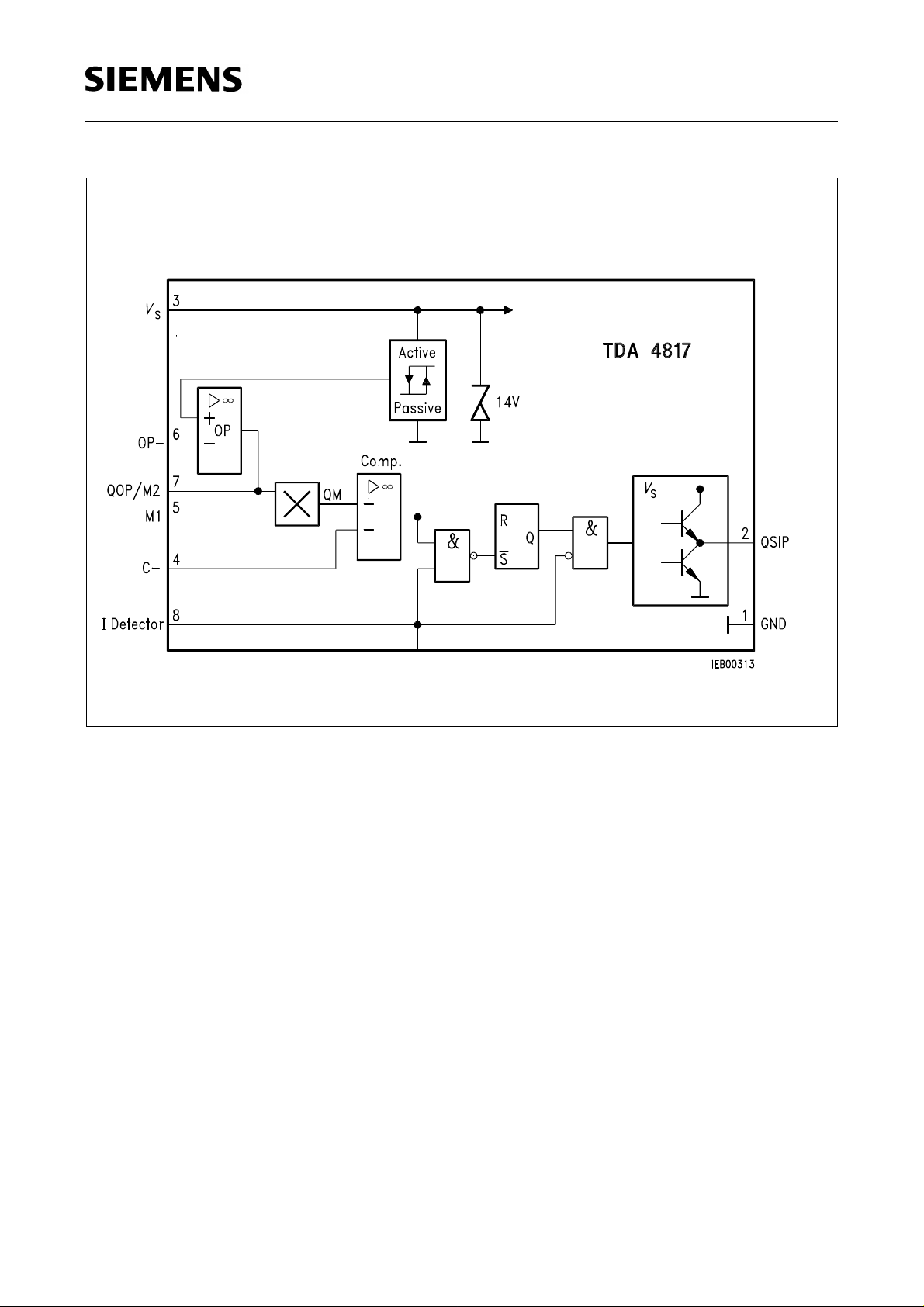

Block Diagram

Semiconductor Group 3

Page 4

TDA 4817

Circuit Description

This device has a conditioning circuit for the internal power supply. It allows standby operation with

very low current consumption (less than 0.5 mA), a hysteresis between enable and switch-off levels

and an internal voltage stabilization. An integrated Z-diode limits the voltage onVS, when impressed

current is fed.

The output driver (Q SIP) is controlled by detector input and current comparator.

The detector input (I DET) which is highly resistive in the operating state reacts on hysteresis-

determined voltage levels. To keep down the amount of circuitry required, clamping diodes are

provided which allow control by a current source.

The operating state of the boost converter choke is sensed via the detector input. H-level means

that the choke discharges and the output driver is inhibited. H-level sets a flip-flop, which stores the

switch-off instruction of the current comparator to reduce susceptibility to interference. As soon as

demagnetization is finished the choke voltage reverses and the detector input is set to L-level, thus

enabling the output driver. This ensures that the choke is always currentless when the SIPMOS

transistor switches on and that no current gaps appear.

The nominal voltage of the multiplier output is compared to the voltage derived from the actual line

current (– I COMP), thus setting the switch-off threshold of the comparator. The current comparator

blocks the output driver when the nominal peak value of the choke current given by the multiplier

output is reached.

This state is maintained in the flip-flop until H-level appears at detector input which takes over the

hold function and resets the flip-flop.

Operating states might occur without any useful detector signal. This is the case with magnetic

saturation of the choke and when the input voltage approaches or exceeds the output voltage as,

for example, during switch-on. The driver remains inhibited for the flip-flop due to the absent set

signal.

The trigger signal can be derived from the subsequent lamp generator or a SMPS control device.

The trigger signal level should be so low that with standard operation the signal from the detector

winding dominates. The multiplier delivers the preset nominal value for the current comparator by

multiplying the input voltage (IM1), which determines the nominal waveform and the output voltage

of the control amplifier.

The control amplifier stabilizes the output dc voltage of the active harmonic filter in the event of load

and input voltage changes. The control amplifier compares the actual output voltage to a

reference voltage which is provided in the IC and stable with temperature.

Output Driver

The output driver is intended to drive a SIPMOS transistor directly.

It is designed as a push-pull stage.

Both the capacitive input impedance and keeping the gate level at zero potential in standby

operation by an internal 10-kΩ-resistor are taken into account. Possible effects on the output driver

by line inductances or capacitive couplings via SIPMOS transistor Miller capacitance are limited by

diodes connected to ground and supply voltage.

Semiconductor Group 4

Page 5

Absolute Maximum Ratings

Parameter Symbol Limit Values Unit Remarks

min. typ. max.

TDA 4817

Supply voltage V

Inputs

Comparator

Operational amplifier

Multiplier

Output OP

Z-current V

-GND I

S

Driver output QSIP V

QSIP clamping diodes

Detector input

Detector clamping diodes

Junction temperature

Storage temperature

Thermal resistance

system-air TDA 4817

TDA 4817 G

V

V

V

V

I

V

I

T

T

R

R

S

C

OP

M1

QOP

Z

QSIP

QSIP

Det

Det

j

stg

th SA

th SA

–

–

– 0.3 V

– 0.3

– 0.3

– 0.3

Z

20

20

20

V VZ = Z-voltage

V

V

V

– 0.3 6 V

0 100 mA Observe P

– 0.3 V

S

– 10 10 mA V

V

> VS or

QSIP

V

< – 0.3 V

QSIP

0.9 6 V

– 10 10 mA V

Det

V

Det

> 6 V or

< 0.9 V

150 ˚C

– 55 125 ˚C

100

170

K/W

K/W

P-DIP-8 package

P-DSO-8 package

max

Operating Range

Supply voltage V

Z-current I

Driver current I

Ambient temperature T

S

Z

QSIP

A

V

Son

V

Z

V

1)

0 100 mA Observe P

– 500 500 mA Observe P

– 25 85 ˚C

max

max

Semiconductor Group 5

Page 6

TDA 4817

Characteristics

V

< VS < VZ; TA = – 25 to 85 ˚C

SON

Parameter Symbol Limit Values Unit Test Condition

min. typ. max.

Current Consumption

Without load on driver

(QSIP) and

Load on QSIP with

SIPMOS gate;

dynamic operation

V

; QSIP low

REF

I

S

I

S

I

S

5

0.5

10

15

mA

mA

mA

0 V < VS < V

V

< VS < V

SON

V

= 12 V;

S

f

= 50 kHz;

switch

SON

Z

load QSIP = 10 nF

Hysteresis on

V

S

Turn-ON threshold for

V

rising

S

Switching hysteresis

Comparator

Input offset voltage

Input current

Common-mode input

voltage

Operational Amplifier

Open-loop voltage gain

Input offset voltage

Input current

Common-mode input

voltage

Output current

Output voltage

Gain-bandwidth product

Transition phase

Voltage Feedback

Threshold

Temperature response

V

SH

V

Shy

V

IO

– I

I

V

ICM

G

VO

V

IO

– I

I

V

IC

I

Q

V

Q

f

r

Φ

T

V

FB

∆VFB/∆T

9.6

1.0

– 10

0

60

– 10

0

– 3

1.2

1.96

– 0.3

10.4 11.2

1.7

10

2

3.5

80

10

2

3.5

1.5

4

2

120

2

2.04

0.3

V

V

mV

µA

V

dB

mV

µA

V

mA

V

MHz

deg

V

mV/K

T

= 25 ˚C

j

Pin 6 connected to

Pin 7

Output Driver

H-output voltage

L-output voltage

Output current rising edge

falling edge

V

V

– I

I

QSIP

QSIPH

QSIPL

QSIP

5

200

250

Semiconductor Group 6

300

350

1

400

450

V

V

mA

mA

I

= – 10 mA

QSIP

I

= 10 mA

QSIP

C

= 10 nF

L

C

= 10 nF

L

Page 7

TDA 4817

Characteristics (cont’d)

V

< VS < VZ; TA = – 25 to 85 ˚C

SON

Parameter Symbol Limit Values Unit Test Condition

min. typ. max.

Z-Diode (VS)

P

Z-voltage (observe

Multiplier

max

) V

Z

13 15.5 17 V IZ = 200 mA

Quadrant for input

voltages

Input voltage M1

Reference level for M1

Input voltage M2

Reference level for M2

Input current M1, M2

Max. output voltage

Multiplier gain

Multiplier gain

Temperature response

of coefficient

Delay Times

Input comparator-QSIP

Detector

Upper switching voltage

for voltage rising (H)

Lower switching voltage

for voltage falling (L)

Input current

Clamping-diode

level positive

negative

Switching hysteresis

Calculation of output voltage

V

M1

V

REF M1

V

M2

V

REF M2

– I

I

V

QM max

C

Q25

C

Q

∆TC/C

t

I

V

DetH

V

DetL

– I

Det

V

+

Det

V

–

Det

V

Dethy

V

: VQM = C x VM1 x VM2 in V.

QM

0

V

REF

0

0.62

0.55

– 0.3

Q

1.0

0.95

50

I.

0

V

REF

1.6

0.67

– 0.1

2

V

REF

2

0.72

0.77

0.1

+ 1

qu

V

V

V

V

µA

V

V

V

%/K

500 700 ns

1.3

1.6

V

V

10

6.9

µA

V

0.6

300

mV

– 1

– 1

T

= 25 ˚C

j

1)

2)

0.9 V < V

I

= 3 mA

Det

I

= 3 mA

Det

1)

< 6 V

Det

1) V

= 1 V

M1

V

= V

M2

2) Step function on comparator input ∆V

REF

+ 1 V

from – 100 mV to + 100 mV.

Comp

Semiconductor Group 7

Page 8

Multiplier Characteristics

TDA 4817

Semiconductor Group 8

Page 9

TDA 4817

Discontinuous Operation Mode with Variable Frequency

The TDA 4817 works in a discontinuous operation mode with variable frequency.

The principle of a freely oscillating controller exploits the physical relationship between current and

voltage at the boost converter choke. The current in the semiconductors flows in a triangular shape.

This is only when the current in the boost converter diode has gone to zero that the transistor goes

conductive. This arrangement does away with the diode’s power-squandering reverse currents.

If triangular currents flow continuously through the boost converter choke the input current

averaged over a high-frequency period is exactly half the peak of the high-frequency choke current.

If the peak values of the choke current are located along an envelope curve that is proportional to

a sinusoidal low- frequency input voltage, the input current available after smoothing in an RFI filter

is sinusoidal.

Semiconductor Group 9

Page 10

TDA 4817

Application Circuit: Electronic Ballast

Semiconductor Group 10

Page 11

TDA 4817

The TDA 4817 controls a boost converter as an active harmonic filter, drawing a sinusoidal line

current and providing a regulated DC voltage at the converter output.

The active harmonic filter improves the power factor in electronic ballasts for fluorescent lamps and

in switched-mode power supplies, reducing the harmonic content of the incoming, non rectified

mains current and if suitably dimensioned permitting operation at input voltages between 90 V and

270 V.

Benefits of TDA 4817 in Electronic Ballasts and SMPS

● Sinusoidal line current consumption

● Power factor approaching 1 increases the power available from the AC line by more than 35 %

compared to conventional rectifier circuits. Circuit breakers and connectors become more

reliable because of the lower peak currents.

● Active harmonic filtering reduces harmonic content in line current to meet VDE/IEC/EN-

standards.

● Wide-range power supplies are easier to implement for AC input voltages of 90 to 250 V without

switch-over.

● Preregulated DC output voltage provides optimal operating conditions for a subsequent

converter.

● Reduced smoothing capacitance:

For a given amplitude of the 100/120 Hz ripple voltage the smoothing capacitance can be

reduced by 50 % in comparison to a conventional rectifier circuit.

Reduced choke size:

Rectifier circuits capable of more than 200 W usually employ chokes to decrease the charging

current ot the capacitor. These chokes are larger than those used in a preregulator with powerfactor control.

● Higher efficiency:

A preregulator does cause some additional losses, but these are more than compensated for by

the cut in losses created by the rectifier configuration and the optimum operating conditions that

are produced for a subsequent converter, even in the event of supply-voltage fluctuations.

Semiconductor Group 11

Page 12

Summary of Effects of DC-Voltage Preregulation with Power-Factor Control

TDA 4817

Parameter Conventional

Power

Rectification

Mean DC supply voltage 280 V 340 V

Maximum DC supply voltage with line overvoltage 350 V 350 V

Minimurn DC supply voltage with line undervoltage 230 V 330 V

Relative reverse voltage of diodes with line overvoltage 1 0.7

Relative forward resistance of SIPMOS transistors with

sustained conducting-state power loss and line undervoltage

Relative forward resistance of SIPMOS transistors with

sustained conducting-state power loss and rated supply

voltage

Relative input capacitance with sustained ripple voltage 1 0.3 to 0.5

Power factor 0.5 to 0.7 0.99

1 2.06

1 1.74

Power

Rectification with

Preregulator and

Power-Factor

Control

Semiconductor Group 12

Loading...

Loading...