Page 1

H-BRIDGE QUAD POWER MOSFET DRIVER

■ QUAD N-CHANNEL MOSFET DRIVE

■ INTEGRATED CHARGE PUMPFOR HIGH

SIDE MOSFET DRIVING

■ VERY LOW GROUND EMI NOISE

■ MOTOR SPEED AND DIRECTION CON-

TROL (LOW SIDE PWM)

■ INTERNAL OR EXTERNAL PWM SOURCE

■ 25kHz SWITCHING FREQUENCY ABILITY

■ SYNCHRONOUS HIGH SIDE RECTIFICA-

TION

■ REVERSED BATTERY ACTIVE PROTEC-

TION ABILITY

■ INTEGRATED 5V POWER SUPPLY FOR

MICROCONTROLLER

■ INTEGRATED SECURITY CIRCUITS:

UVLO, OVLO, WATCHDOG

■ 60V MAX RATING

DESCRIPTION

The TD340 integrated circuit allows N-Channel

Power Mosfets driving in a full H-bridge

configuration and is best suited for DC Motor

Control Applications. The four drivers outputs are

designed to allow 25kHz MOSFET switching.

The speedand direction of the motor are to be set

by twopins. Voltage across the motor is controlled

by low side Pulse Width Modulation (PWM). This

PWM feature can be made internally when the

input pinis connectedto an analog signal, or it can

be given directly from a digital source.

An internal charge pump allows proper upper

MOS driving for fullstatic operation (100% PWM).

TD340 achieves very low EMI noise thanks to its

balanced charge pump structure and its drivers

moderate slew rate.

To avoid excessive heating due to free wheeling,

appropriate synchronous rectification is achieved

on the corresponding High Side MOSFET.

Moreover, TD340 integrates a 5V voltage

regulator suitable as a power supply output forthe

microcontroller, a Reset circuit and a Watchdog

circuit.

Security functions disable the TD340 (MOS off)

when abnormal conditions occur like overvoltage,

undervoltage or CPU loss of control (watchdog).

TD340 withstands transients as met in automotive

field without special protection devices thanks to

its 60V BCD technology.

TD340

FOR DC MOTOR CONTROL

PRELIMINARY DATA

D

SO20

(Plastic Micropackage)

ORDER CODE

20

19

18

17

16

15

14

13

12

11

Package

D

OSC

CB1

H1

S1

CB2

H2

S2

L2

L1

Part Number Temperature Range

TD340ID -40°C, +125°C •

D=Small Outline Package (SO) - also available in Tape & Reel (DT)

PIN CONNECTIONS (top view)

VBATT

VOUT

RESET

CWD

WD

STBY

TEMP

IN1

IN2

1

2

3

4

5

6

7

8

9

CF GND

10

May 2000

This is preliminary information on anew product now in development or undergoing evaluation. Details are subject to change without notice.

1/21

Page 2

SYSTEM AND INTERNAL BLOCK DIAGRAM

TD340

BATT+

5V

µCONTROLLER

0V

VBATT

VOUT

SUPPLY

UVLO

OVLO

RESET

CWD

RESET

WATCHDOG

WD

STBY

TEMP

IN1

T°

PWM

LOGIC

PWM

IN2

CF GND

TD340

OSC

CB1

H1

S1

CB2

H2

S2

L2

L1

Q2H

Q2L

Q1H

M

Q1L

BATT-

PIN DESCRIPTION

Name Pin Type Function

VBATT 1 Power Input Power Supply

GND 11 Ground Ground

L1 12 Push Pull Output Low Side Drive - Gate 1

L2 13 Push Pull Output Low Side Drive - Gate 2

H1 18 Push Pull Output High Side Drive - Gate 1

H2 15 Push Pull Output High Side Drive - Gate 2

S1 17 Analog Input High Side Drive - Source 1

S2 17 Analog Input High Side Drive - Source 2

CB1 19 Analog Input High Side Drive - Bootstrap Capacitor 1

CB2 16 Analog Input High Side Drive - Bootstrap Capacitor 2

CF 10 Analog Input External Capacitor to set the PWM Switching Frequency

IN1 8 Analog or Digital Input

IN2 9 Digital Input Direction to the Motor’s Rotation

STBY 6 Digital Input Standby Mode

TEMP 7 Analog Output Analog Indicator of Temperature

VOUT 2 Power Output Regulated Power Supply Output for the Microcontroller - 5V

RESET 3 Open Drain Output Reset Signal for the Microcontroller

WD 5 Digital Input Watchdog Signal from the Μicrocontroller

CWD 4 Analog Input External Capacitor to set Watchdog Timeout

OSC 20 Digital Output Oscillator Output

Analog Level of PWM (0 to 100%) if CF connected to a capacitor,

or PWM Signal if CF connected to ground

2/21

Page 3

TD340

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

V

Batt

P

T

stg

ESD Electrostatic Discharge 2 kV

V

digital

V

lowgate

V

power

V

osc

T

R

hja

Notes:

1. The duration of the 60V voltage must be limited to 1 second if current is drained from the Vout regulator. Supply voltage in steady state

must be limited to ensure that dissipation rating is not exceeded.

2. The magnitude of input and output voltages must never exceed Vbatt+0.3V or 60V, whichever is less, except for H1 and H2: Vbatt+15V

or 60V, whichever is less.

OPERATING CONDITIONS

Positive Supply Voltage - Note 1 60 V

Power Dissipation 500 mW

d

Storage Temperature -55 to +150

Voltage on pins: IN1, IN2, STBY,WD, CWD, CF,TEMP,VOUT,

RESET

-0.3 to 7 V

Voltage on pins: L1, L2 -0.3 to 15 V

Voltage on pins: H1, H2, S1, S2, CB1, CB2 - Note 2 -0.3 to 60 V

Voltage on pin OSC Vbatt-6.5 to Vbatt V

Maximum Junction Temperature 150 °C

j

Thermal Resistance Junction-Ambient 85 °C/W

o

C

Symbol Parameter Value Unit

V

T

Positive Supply Voltage 6.5 to 18.5 V

batt

Operating Free Air Temperature Range -40 to +125 °C

oper

3/21

Page 4

TD340

ELECTRICAL CHARACTERISTICS

Vbatt= 12V, Tamb=-40°C to 125°C (unless otherwise specified)

Symbol Parameter Test Condition Min. Typ. Max. Unit

TotalSupply Current

I

CC

T

min.<Tamb<Tmax.

I

stdby

Standby

Standby

UVLO

OVLO

Supply Current in Standby Mode

STDBY Pin Voltage for Standby OFF 0.8 V

H

STDBY Pin Voltage for Standby ON 2 V

L

Under Voltage Lockout - when

Vbatt<UVLO all buffer outputs are low

Under Voltage Lockout - when

Vbatt>OVLO all buffer outputs are low

DRIVERS - Cbootstrap=47nF

V

V

Freq Switching Frequency of PWM Cf = 270pF 20 25 30 kHz

I

I

Static Gate-Source High Side Mosfet Volt-

gs

age (charge pump)

Dynamic Gate-Source High Side Mosfet

gsd

Voltage (bootstrap)

Dead Time for secure Synchronous

t

d

Rectification

Output Current Capability - Low Side

Source

outl

Sink

Output Current Capability - High Side

Source

outh

Sink

OSCILLATOR - Rosc=5.6k - Note 1

F

V

Frequency of internal Step up converter

osc

Oscillator

Oscillator Swing - note 7

osc

T=25°C

-40°C < T < 125°C

T=25°C

-40°C < T < 125°C

Vbatt decreasing

Hyst. = 100mV typ.

Vbatt decreasing

Hyst. = 300mV

5.8 6.2 6.5 V

18.5 20 21.5 V

4.557

10mAmA

180 300

350µAµA

No Bootstrap Cap 8 11 15 V

9V

Cf=270nF,IN1=2.4V

No Load

Cload=4nF

T=25°C

40°C < T < 125°C

T=25°C

40°C < T < 125°C

T=25°C

40°C < T < 125°C

T=25°C

40°C < T < 125°C

T=25°C

40°C < T < 125°C

Vbatt = 12V

Vbatt = 9V

Vbatt > UVLO

2.1 2.8

30

25

60

50

30

25

60

50

0.6

0.5

6.25

6.25

5.1

1.5

50

50

100

100

50

50

100

100

111.4

3.5 µs

100

100

150

150

100

100

150

150

1.5

12

12

12.5

µs

mA

mA

mA

mA

mA

mA

mA

mA

MHz

MHz

V

V

V

4/21

Page 5

TD340

ELECTRICAL CHARACTERISTICS (continued)

Vbatt= 12V, Tamb=-40°C to 125°C (unless otherwise specified)

Symbol Parameter Test Condition Min. Typ. Max. Unit

VOLTAGE REGULATOR - Co=220nF - note 2

V

Line

Reg

Load

Reg

Output Voltage

out

Line Regulation

Load Regulation

I

Maximum Output Current

o

I

Output Current Short Circuit Vout=0 100 200 mA

os

RESET SUPERVISORY CIRCUIT - note 3

Vt

V

V

Threshold Voltage Vout Increasing

hi

Threshold Voltage Vout Decreasing

thd

k

Linearity coefficient (Vthi = ki Vout) 0.86

i

k

Linearity coefficient (Vthd = kd Vout) 0.84

d

Hysteresis Threshold Voltage 50 100 200 mV

hys

t

Response Time High to Low 5 µs

phl

WATCHDOG CIRCUIT

t

Watchdog Time Out Period

wd

t

t

reset

Watchdog Input Pulse Width for Proper

ipw

Retrigger

Watchdog Input Rise Time for Proper

t

ipr

Retrigger

Reset Pulse Width 10 20 40 µs

TEMPERATURE OUTPUT

V

Output Voltage

T

∆V

Notes :

1. For proper operation, a 5.6k resistor needs to be connected between OSC and GND.

2. 220nF is the optimized value for the voltage regulator

3. The reset thresholds (Vout increasing and decreasing) are proportional to Vout, (coefficients kiand kd). ki and kd vary in the same direction with temperature.

4. Watchdog capacitor Cwd should be placed as close as possible to CWD pin.

Output Temperature Drift -7 -7.5 -7.8

T

Io=20mA

T=25°C

40°C < T < 125°C

6V < Vbatt < 16V,Io=20mA

T=25°C

40°C < T < 125°C

0 ≤ Io ≤ 40mA

T=25°C

40°C < T < 125°C

Vbatt = 12V

6V < Vbatt < 16V

T=25°C

40°C < T < 125°C

T=25°C

40°C < T < 125°C

No ext. capacitor

Cwd = 47nF - note 4

o

T= 25

C

4.6

4.5

5

5

5.4

5.5

100

150mVmV

2040mV

mV

40

20

4.0

3.9

3.9

3.8

0.5

0.7

4.3 4.5

4.2 4.4

1

1

4.6

4.5

2

1.5

mA

mA

ms

0.1 µs

0.1 µs

2.58 2.68 2.78 V

mV/oC

V

V

V

V

V

V

s

5/21

Page 6

INTERNAL ELECTRICAL SCHEMATIC AND APPLICATION ENVIRONMENT

TD340

BATT +

S1

H1

CB1

OSC

CB2

Q1H

Q2H

H2

Q1L

+

A

M

-

Q2L

L1

L2

S2

BATT -

GND

UVLO/ OVLO

OSC

filter

-

+

TD340

6/21

5V REGULATOR

VOUT

VBATT

5V

RESET

RESET

WATCHDOG

WD

CWD

STBY

STBY

T°

TEMP

1.2V

IN1

µCONTROLLER

+

-

3.6V

CF

IN2

0V

Page 7

TD340

FUNCTIONAL DESCRIPTION

Speed and Direction Control:

The TD340 IC provides the necessary interface between anH-Bridge DC-Motor Control configuration and

a micro controller. The speed and direction are given by two input signals coming from the

microprocessor.

Speed Control:

Speed control is achieved by Pulse Width Modulation (PWM).

The TD340 provides an internal PWM generator, but can accept an external PWM waveform.

IN1 can accept two different types of inputs:

- an analog input between 0 and 5V (CF must be connected to set the PWM frequency) gives an analog

value of the Internal PWM duty cycle

- a digital input (CF must be grounded) gives directly the PWM

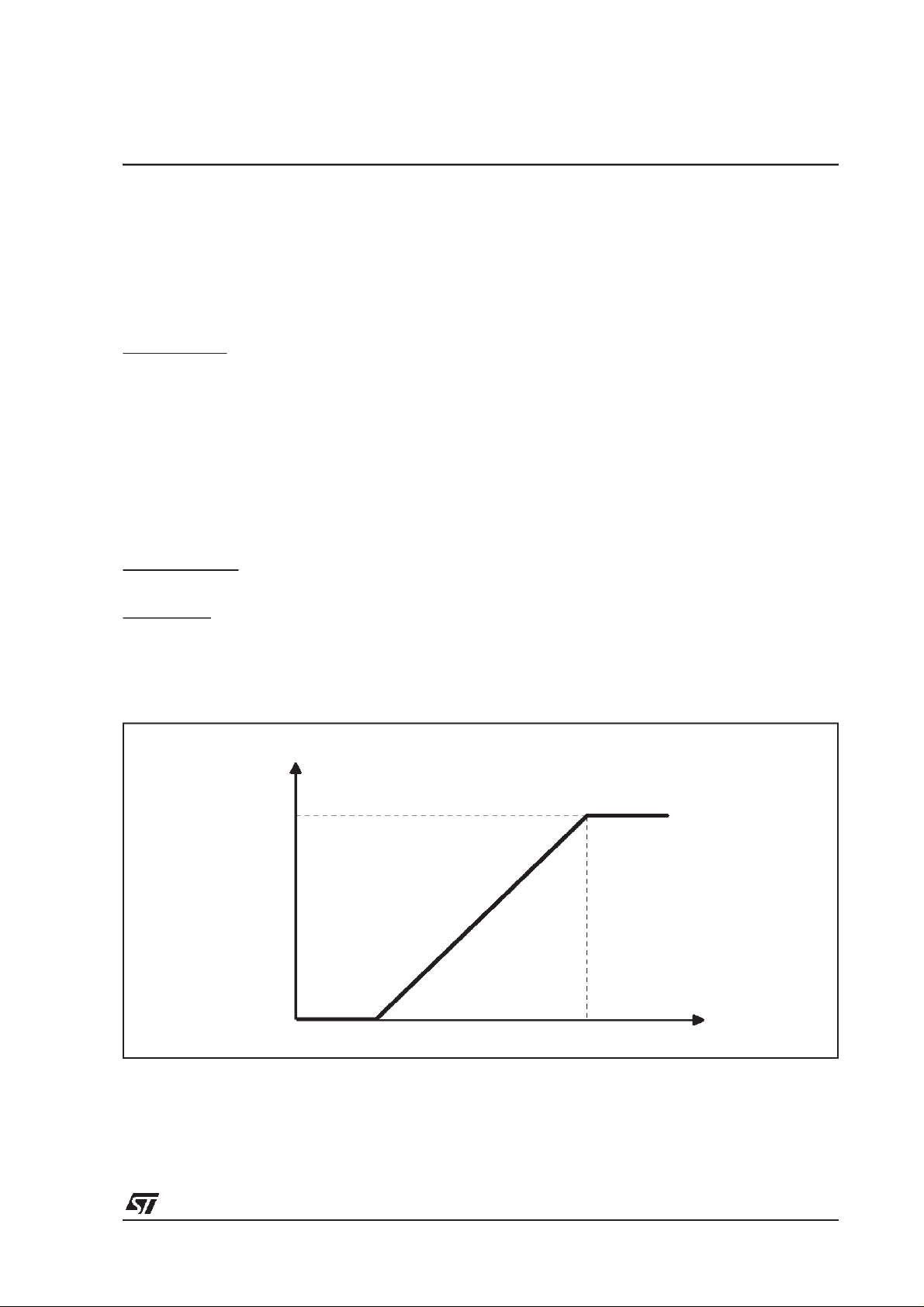

Figure 1 represents the Duty Cycle curve versus the IN1 analog voltage.

Figure 2 shows how to use the TD340 with an analog input or a digital input.

The speed control (or duty cycle) is achieved by the Low Side Drivers which impose the PWM function

while the cross-corresponding High Side MOSFETS is kept fully ON.

Direction Control:

IN2 accepts a digital value of the rotation direction.

Brake mode:

Brake mode is achieved by a zero level on the IN1 input.

The IN2 input selects low side or high side braking.

Brake mode is activated when the IN1 is at zero volt level for more than 200 us.

Figure 1 : Duty Cycle versus IN1 voltage

Duty Cycle

100%

0%

1.2V 3.6V IN1

Voltage

7/21

Page 8

Figure 2 : PWM Analog and Digital Modes

TD340

Vbatt

M

TD340

µP

5V

IN1

0V

ANALOG INPUT

+ CF (270pF)

PWM

PWM

CF

Vbatt

TD340

µP

M

PWM OUTPUT PWM OUTPUT

5V

IN1

0V

CF

DIGITALINPUT

+ CF GROUNDED

PWM

PWM

Active (synchronous) rectification for free-wheel current

A motor is an inductive load. When driven in PWM mode, motor current is switched on and off at the

25kHz frequency.When theMOS is switched off,currentcan not instantaneously dropto zero, a so-called

”free-wheel” current arises in the same direction than the power current. A path for this current must be

provided, otherwise high voltage could arise and destroy the component. The classical way to handle this

situation is to connect a diode in an anti-parallel configuration regarding to the MOS, so that current can

continue to flow through this diode, and finally vanishes by the means of ohmic dissipation, mainly in the

diode due to its 0.8V direct voltage. For high currents, dissipation can be an important issue (eg: 10A x

0.8V makes 8 W!). Furthermore, high speed diodes have to be used, and are expensive.

A more efficient way to handle this problem is to use the high side MOS as a synchronous rectifier. In this

mode, the upper MOS is switched ON when the lower one is switched OFF, and carries the free-wheel

current with much lower ohmic dissipation. Advantages are : one expensive component less (the fast

power diode), and more reliability due to the lower dissipation level.

However, we have to take care not to drive the two MOS simultaneously. To avoid transient problems

when the MOSare switched, a deadtime is inserted between the opening of one MOS, and the closing of

the otherone. In theTD340 device, the deadtimeis fixed to about 2.5 microseconds. Thisvalue is the time

between the commands of the gate drivers, not the deadtime between the actual MOS states because of

the rising and falling times of the gate voltages (due to capacitance), and the MOS characteristics. The

actual value of the deadtime for a typical configuration is about 1.5 microseconds.

Figure 3 shows the synchronous rectification principle

Table 1 summarizes the status of the Mosfets (and the speed and direction ofthe motor) according to the

Inputs (IN1 and IN2) status in analog and logic modes.

8/21

Page 9

TD340

Figure 3 : Synchronous Rectification Principle

ex1:

Speed: PWM=x%

No synchronousrectification

1-x%

FULL

OFF

PWM

M

x%

FULL

ON

FULL

OFF

HIGH DISSIPATION

THROUGH FREE WHEEL DIODE!

Table 1 : Function Table in Digital and Analog Modes

Stby

State

Disable

State

IN1 (V)

IN2

(V)

digital analog Q1L Q1H Q2L Q2H

Mosfets Status

ex2:

Speed: PWM=x%

With synchronousrectification - TD340

1-x%

PWM

FULL

ON

M

PWM

x%

LOW DISSIPATION

THROUGH LOW Rdson!

Comments

FULL

OFF

1 X X X X OFF OFF OFF OFF Motor Off in Standby Mode

X 1 X X X OFF OFF OFF OFF Motor Off in Disable Mode

0 0 0 idle 0 to 1.2 0 ON OFF ON OFF Motor Brake Low

0 0 0 idle 0 to 1.2 5 OFF ON OFF ON Motor Brake High

0 0 PWM 1.2 to 3.6 0 OFF ON PWM !PWM Motor x% Forward

0 0 PWM 1.2 to 3.6 5 PWM !PWM OFF ON Motor x% Backward

0 0 5 idle 3.6 to 5 0 OFF ON ON OFF Motor 100% Forward

0 0 5 idle 3.6 to 5 5 ON OFF OFF ON Motor 100% Backward

Notes:

- Standby state is active when STBY pin is pulled low

- Disable state is active when one of the following conditions is met: UVLO, OVLO, Reset, Watchdog Timeout.

9/21

Page 10

TD340

MOS drivers

Output drivers are designed to drive MOS with gate capacitance of up to 4 nF. A small resistor in serial

with gateinput is recommended to prevent spurious oscillations due to parasitic inductance inconjunction

with gate capacitance. Typical value of these resistors are from 10 to 100 ohms, depending on the MOS

characteristics.

Charge pump

To drivethehigh side MOS, theTD340 has to provide a voltage of about 10V higher that the power supply

voltage. The TD340 provides an internal charge pump which acts as a voltage tripling generator clamped

to 12V and allows the output of correct gate voltage with power voltage level as low as 6.5V. Its double

balanced structure ensures low EMI Ground Noise. The internal charge pump is used to achieve correct

voltage level at startup or static states.

An 5.6k resistor needs to be connected between OSC and GND for proper operation.

Bootstrap capacitors

To achieve dynamic driving up to 25kHz, it is necessary to support the internal charge pump with

bootstrap capacitors.

Bootstrap capacitorsare charged from Vbat when thelower MOS is ON. When the lower MOS isswitched

off and the upper one is switched ON, the bootstrap capacitor provides thenecessary current to the driver

in order to charge the gate capacitor to the right voltage level.

A design rule to select the bootstrap capacitor value is to choose ten times the gate capacitance.

For example, MOS with 4 nF gate capacitance will require bootstrap capacitors of about 47nF.

MOS gate discharge

The high side MOS are switched off with internal Gate to Source discharge (not Gate to Ground

discharge) to prevent the Gates from negative transient voltages.

Figure 4 : Typical waveforms on low and high side MOS gates.

Upper trace : High side MOS gate

Lower trace : Low side MOS gate

10/21

Page 11

TD340

Reversed battery active protection

In full H-bridge configuration, there is a risk in case of power voltage reversal due to the intrinsic diodes

inside the MOS. A passive protection solution is to wire a diode between the H-bridge and the power

supply. Disadvantages are voltage drop and power dissipation.

The TD340 provides support for reversed battery active protection.

An oscillator OSC output is available to allow proper command of a 5th MOS connected upside down.

The MOS must have low threshold voltage

In normal conditions, the MOS intrinsic diode supplies power to the driver at startup. When the TD340 is

started, the OSC output enables the MOS to switch on, providing lower voltage drop and lower power

dissipation.

In caseof reversed battery, the 5th MOS remains off, and no dangerous voltages can reach the driver nor

the power MOS.

The OSC oscillator can only supply a few mA. It must be loaded with a large impedance, typically 100pF

and 680k.

Figure 5 : Reversed Battery Active Protection Principle

because the oscillator output swing is about 6.5V.

Normal Conditions

Vbatt+6V

VbattOsc

1

2

3

TD340

4

VBATT

~Vbatt

2

M

3

REVERSED BATTERY

5

Driver isnot supplied

Vbatt

Osc

1

2

3

TD340

4

GND

MOSFET5

REMAINS

OFF

2

M

3

VBATT

GND

ALLMOSFETSAND DRIVERARE PROTECTED

UVLO and OVLO protections

The TD340 includes protections again overvoltage and undervoltage conditions.

Overvoltage is dangerous for the MOS and for the load due to possible excessive currents and power

dissipation.

Undervoltage is dangerous because MOS driving is no more reliable. MOS could be in linear mode with

high ohmic dissipation.

TD340 Under Voltage LockOut and Over Voltage LockOut features protect the system from no

operational power voltage. UVLO and OVLO thresholds are 6.2V and 20V. Hysteresis provides reliable

behavior near the thresholds.

During UVLO and OVLO, MOS are switched off (TD340 in disable state).

11/21

Page 12

TD340

Microcontroller support

For easy system integration, the TD340 provides the following functions:

- 5V regulator,

- reset circuit,

- watchdog circuit,

- standby mode,

- temperature indicator.

5V regulator

The TD340 provides a 5V regulated voltage at VOUT pin with amaximum current of 20mAover thewhole

Vbatt range (6.5 to 16V). Current can be up to 40 mA with nominal 12V Vbatt.

It is mandatory to connecta 220nF capacitor to the 5V output, even if the 5V output is not used, because

the 5V is internally used by the device. 220nF is the optimized value for the voltage regulator.

Reset circuit

The integratedsupervisor circuit resets themicro controller as soon as the voltage ofthe Micro Controller

decreases below 4.2V, and until the voltage of the micro controller has not passed above 4.3V.

RESET output is active low. It features an open drain with a internal 75k pull up resistor to internal 5V

which allows hardwired OR configuration.

Figure 6 : Reset Waveforms

Vout

Vthi

Vthd

Vccmin

Vreset

1V

zoom

tph l

t

t

12/21

Page 13

TD340

Watchdog circuit

An integrated Watchdog circuit resets the microcontroller when a periodic signal coming from the

microcontroller is missing after an externally adjustable Time out delay.

Watchdog timeout is adjustable by means of a capacitor Cwdbetween CWD pin and GND. This capacitor

should be placed as close as possible to the CWD pin.

Watchdog function can be inhibited by tying the CWD pin to ground.

Timeout range is from about 1ms to 1s, approximate value is given by:

Twd = 1 + (20 x Cwd) (Twd in ms, and Cwd in nF).

When the watchdog timeout triggers, the reset output is pulsed once low for 20 microseconds, and the

driver outputs are set to ground (MOS switched off). TD340 stays in disable state (MOS off) until pulses

appear again on WD pin.

Figure 7 : Watchdog waveforms

WDRESET

tip w

twd

treset

t

t

t

H1,H2,L1,L2

Temperature output

The TD340 provides a temperature indicator with the TEMP output.

TEMP voltage is 2.68V at 25°C with a temperature coefficient of -7.5mV/°C.

The goal of this function is to provide a rough temperature indication to the uP. It allows the system

designer to adapt the behavior of the application to the ambient temperature.

The TEMP output must be connected to a high impedance input. Maximum available current is 1uA.

13/21

Page 14

TD340

Standby mode

The TD340 can be put in standby mode under software control. When the STBY pin is driven low, the

MOS drivers are switched off and internal charge pump oscillator is stopped. The 5V regulator, the

watchdog and reset circuits are still active.

There is no pull up/down resistor on the STBY pin. STBY must not be left open.

Power consumption (not including the current drained from the 5V regulator) is reduced to about 200uA.

To achieve this standby current, the 5.6k resistor on the OSC pin has to be disconnected withan external

low power MOS controlled by the STBY signal (see figure 10 for an application example)

Standby mode should be only activated when IN1=IN2=0V and after that the motor is actually stopped

because thefour MOS are switched off. On exit from the standby mode, a delay of up to 20ms (depending

upon the bootstrap capacitor value) must be given before applying signals to the IN1 and IN2 inputs to

allow proper startup of the charge pump (it is also true for power-up). Figure 8 shows the voltage across

the Cb bootstrap capacitor at powerup or at standby exit as a function of time.

Figure 8 : Charge pump voltage at startup

Fig. 8a : Cb = 10nF

Fig. 8c : Cb = 100nF

Fig. 8b : Cb = 47nF

14/21

Page 15

TD340

PERFORMANCE CURVES

5V Regulator Voltage vs Output Current

5.1

5.0

Vbatt=16V

4.9

4.8

Vout(V)

4.7

Cout=22 0nF

4.6

4.5

0 102030405060

Vbatt=12V

Vbatt=8V

Vbatt= 6 V

Iout(mA)

Charge Pump Voltage vs Current

40

Vbatt=24 V

Vbatt=16V

Vbatt=12 V

Vcb (V)

35

30

25

20

5V Regulator Voltage vs Vbatt

5.1

5.0

4.9

4.8

Vout(V)

4.7

4.6

4.5

0 5 10 15 20 25

Vba tt (V)

Charge Pump Voltage vs Vbatt

40

35

30

25

ICb=0

Vcb (V)

20

Iload=20mA

Cout=220nF

15

10

Cb=10nF

5

0 20406080100120

Icb(µA)

High Side MOS Static Vgs vs Vbatt

13

12

11

10

Vgs (V)

9

8

7

6 8 10 12 14 16 18 20 22

Vbatt (V)

Vbatt= 6 .5V

15

10

5

5 10152025

ICb=60uA

Cb=10nF

Vbatt(V)

High Side MOS Static Vgs vs Temperature

12

11.5

11

Vgs (V)

10.5

10

-50 0 50 100 15 0

T(°C)

Vbatt=12V

15/21

Page 16

PERFORMANCE CURVES (continued) Vbatt= 12V, unless otherwise specified

TD340

Supply current

5

4.5

4

Icc (mA)

3.5

3

2.5

-50 0 50 100 150

T(°C)

Reset Threshold (decreasing)

4.4

4.3

4.2

Standby current

350

300

250

Istby(µA)

200

150

100

-50 0 50 100 15 0

T(°C)

Reset Threshold (increasing)

4.4

4.3

4.2

Vthd (V)

4.1

4.0

3.9

-50 0 50 100 150

Under Voltage Lockout

6.5

6.4

6.3

6.2

6.1

UVLO(V)

6.0

5.9

5.8

-50 0 50 100 150

T(°C)

T(°C)

Vthi (V)

4.1

4.0

3.9

-50 0 50 100 150

Over Voltage Lockout

22

21

20

OVLO(V)

19

18

-50 0 50 100 150

T(°C)

T(°C)

16/21

Page 17

TD340

PERFORMANCE CURVES (continued) Vbatt= 12V, unless otherwise specified

OSC Output Frequency

1.4

1.2

1.0

Fosc (MHz)

0.8

0.6

-50 0 50 100 150

T(°C)

High Side Driver output Current (source)

100

80

Deadtime between High and Low Drivers

3.8

3.6

3.4

no load

3.2

td (µs)

3

2.8

2.6

2.4

-50 0 50 100 150

T(°C)

Low Side Driver output Current (source)

100

80

60

Iouth_src (mA)

40

20

-50 0 50 100 150

T(°C)

High Side Driver output Current (sink)

14 0

12 0

10 0

Iouth_sink(mA)

80

60

-50 0 50 100 150

T(°C)

60

Ioutl_src (mA)

40

20

-50 0 50 100 15 0

T(°C)

Low Side Driver output Current (sink)

140

120

100

Ioutl_sink (mA)

80

60

-50 0 50 10 0 15 0

T(°C)

17/21

Page 18

TD340

APPLICATION CIRCUIT DIAGRAMS

The following schematics show typical application circuits. The first one is a simple,standalone system,

while the other one is µC driven and includes advanced features like standby mode and reversed battery

active protection.

Simple standalone system

Figure 9 shows a basic use of the TD340. The speed is controlled with a simple adjustable resistor.

Direction is controlled with a switch.

Internal PWM generator is used, frequency is set by the capacitor C3.

Note that the C2 capacitor (220nF) is included because it is needed by the internal TD340 circuit.

Interface lines for microcontroller are not used:

Standby is tied to 5V (Vout),

WD and CWD are tied to ground,

Reset and Temperature outputs are left unconnected.

Reversed battery protection is provided by the means of the diode D2.

Transistors Q1H, Q1L, Q2H, Q2L are to be chosen depending on the motor characteristics.

For example, STP30NE03L are 30V, 30A devices with gate capacitance of about 1nF. For these MOS,

22nF bootstrap capacitors are adequate.

Resistors R1 to R4 are used to control the rise and fall times on the MOS gates, and are also useful to

avoid oscillation of the gate voltage due to the parasitic inductance of lines in conjunction with the gate

capacitance. Typical values for resistors R1 to R4 are from 10 to 100 ohms.

Capacitor C6 is used to store energy and to filter the voltage across the bridge.

Applications:

Small domestic motorized equipments, battery-powered electrical tools, ...

Complete, µC driven system

The next schematic (figure 10) shows a complete system driven by a µC.

The auto-reload timer feature of ST6 µC family is used to easily generate the PWM command signal

(TD340 internal generator is not used, CF pin is connected to ground).

Transil diode D3 can be added as a security to avoid overvoltage transients if the MOS are all driven off

when the motor is running. For example, it can happen if TD340 is put in standby or disable state while

motor is running.

Applications:

- Automotive: advanced window lift systems, wiper systems, ...

- Industrial: battery-powered motor systems, electric door opening, ...

18/21

Page 19

TD340

Figure 9: Simple Standalone System

.

C6

470uF

+

+12V

Q1H

D1

MOSFET N

Load

Q2H

MOSFET N

C4 22nF

C5 22nF

R1 22

R2 22

Q1L

MOSFET N

GND

Q2L

MOSFET N

R3 22

R4 22

Q1L, Q1H, Q2L, Q2H: STP30NE03L

R5

5.6k

121113

14

15

16

17

18

19

20

Cb1

Osc

TD340

Vbat

Vout

12435

H1

Reset

S1

Cwd

H2

Cb2

Stby

Wd

6

7910

S2

Temp

8

L2

In1

L1

In2

Cf Gnd

U1

C3

270pF

C2

220nF

C1

+

10uF

S1

P1

10k

19/21

Page 20

Figure 10: Complete, µC Driven System

TD340

+Vbatt

Optionnal

R6

D1

680k

1N4148

Optionnal

Q3

MOSFET NC9

D2

1N4148

100pF

C4 47nF

D3

C6

470uF

+

Q1H

MOSFET N

Q2H

MOSFET N

C5 47nF

R1 100

R2 100

Motor

R3 100

Q1L

MOSFET N

GND

Q2L

MOSFET N

Q4

R4 100

5.6k

R5

BS170

Optionnal

Q3: STP60NE06L

Q1L, Q1H, Q2L, Q2H: STP60NE06

SW1

OPEN

SW2

CLOSE

121113

14151617181920

S1

H1

Cb1

Osc

TD340

Vbat

Vout

Reset

Cwd

12435

C1

10uF

+

Cb2

Stby

Wd

6

XT1

L1

L2S2H2

In1

In2

Temp

7910

8

Cf Gnd

U1

C3

100pF

C2

220nF

C8C7

XT1, C7, C8: see ST6252 datasheet

12111379

10

141516

NMI

PC3

PC2

ST6252

PB0

12435

Vpp/Test

PB2

Reset

PB3

OSCin

OSCout

PB7

PB6

6

PA5

Vdd

U2

Vss PA4

8

20/21

Page 21

TD340

PACKAGE MECHANICAL DATA

20 PINS - PLASTIC MICROPACKAGE (SO)

Dim.

Millimeters Inches

Min. Typ. Max. Min. Typ. Max.

a1 0.254 0.010

B 1.39 1.65 0.055 0.065

b 0.45 0.018

b1 0.25 0.010

D 25.4 1.000

E 8.5 0.335

e 2.54 0.100

e3 22.86 0.900

F 7.1 0.280

I 3.93 0.155

L 3.3 0.130

Z 1.34 0.053

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the

consequences of use of such information nor for any infringement of patents or other rights of third parties which may result from

its use. No license is granted by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications

mentioned in this publication are subject to change without notice. This publication supersedes and replaces all information

previously supplied. STMicroelectronics products are not authorized for use as critical components in life suppo rt devices or

systems withoutexpress written approval of STMicroelectronics.

Australia - Brazil - China - Finland - France - Germany - Hong Kong - India - Italy - Japan - Malaysia - Malta - Morocco

The ST logo is a registered trademark of STMicroelectronics

2000 STMicroelectronics - Printed in Italy - All Rights Reserved

STMicroelectronics GROUP OF COMPANIES

Singapore - Spain - Sweden - Switzerland - United Kingdom

http://www.st.com

21/21

Loading...

Loading...