Page 1

15-BIT, F AST -INTEGRATING CMOS ANALOG-T O-DIGITAL

CONVERTER

1

TC850

2

FEATURES

■ 15-bit Resolution Plus Sign Bit

■ Up to 40 Conversions per Second

■ 12 Conversions per Second Guaranteed

■ Integrating ADC Technique

— Monotonic

— High Noise Immunity

— Auto-Zeroed Amplifiers Eliminate Offset

Trimming

■ Wide Dynamic Range ...................................... 96dB

■ Low Input Bias Current ................................... 30pA

■ Low Input Noise ...........................................30µV

■ Sensitivity....................................................... 100µV

■ Flexible Operational Control

— Continuous or On-Demand Conversions

— Data Valid Output

■ Bus Compatible, 3-State Data Outputs

— 8-Bit Data Bus

— Simple µP Interface

— Two Chip Enables

— Read ADC Result Like Memory

■ ± 5V Power Supply Operation ...................... 20mW

■ 40-Pin Dual-in-Line or 44-Pin PLCC Packages

FUNCTIONAL BLOCK DIAGRAM

C

R

INT

–

+

÷4

5

CONT/

DEMAND

BUF

25363439

BUFFER

INT

INT IN

TC850

7

L/H6OVR/

POL

INT OUT

–

+

INTEGRATOR

BUS INTERFACE

DECODE LOGIC

3

4RD1CS2

WR

2324

CE

22

COMPARATOR

+

–

6-BIT

UP/DOWN

COUNTER

DATA LATCH

OCTAL 2-INPUT MUX

3-STATE DATA BUS

. . . .

15

DB0

COMMON

+

REF

2

+

1

ANALOG

MUX

CONTROL

SEQUENCER

1

–

REF

A/D

18

OSC

2

REF

32

+

IN

31

–

IN

30

CLOCK

OSCILLATOR

17

OSC

+5V–5V

40

9-BIT

UP/DOWN

COUNTER

8

DB7

P-P

GENERAL DESCRIPTION

The TC850 is a monolithic CMOS analog-to-digital

converter (ADC) with resolution of 15-bits plus sign. It

combines a chopper-stabilized buffer and integrator with a

unique multiple-slope integration technique that increases

conversion speed. The result is 16 times improvement in

speed over previous 15-bit, monolithic integrating ADCs

(from 2.5 conversions per sec up to 40 per sec). Faster

conversion speed is especially welcome in systems with

human interface, such as digital scales.

The TC850 incorporates an ADC and a µP-compatible

digital interface. Only a voltage reference and a few noncritical passive components are required to form a complete 15bit plus sign ADC.

CMOS processing provides the TC850 with highimpedance differential inputs. Input bias current is typically

only 30pA, permitting direct interface to sensors. Input

sensitivity of 100µV per least significant bit (LSB) eliminates

the need for precision external amplifiers. The internal

amplifiers are auto-zeroed, guaranteeing a zero digital output

with 0V analog input. Zero adjustment potentiometers or

calibrations are not required.

The TC850 outputs data on an 8-bit, 3-state bus. Digital

inputs are CMOS compatible; outputs are TTL/CMOS compatible. Chip-enable and byte-select inputs combined with

an end-of-conversion output ensures easy interfacing to a

wide variety of microprocessors. Conversions can be performed continuously or on command. In continuous mode,

data is read as three consecutive bytes and manipulation of

address lines is not required.

Operating from ±5V supplies, the TC850 dissipates only

20mW. It is packaged in 40-pin plastic or ceramic dual-inline packages (DIPs) and in a 44-pin plastic leaded chip

carrier (PLCC), surface-mount package.

ORDERING INFORMATION

Part No. Package Temperature Range

TC850CLW 44-Pin PLCC 0°C to +70°C

TC850CPL 40-Pin Plastic DIP 0°C to +70°C

TC850IJL 40-Pin CerDIP – 25°C to +85°C

TC850ILW 44-Pin PLCC – 25°C to +85°C

3

4

5

6

7

TELCOM SEMICONDUCTOR, INC.

8

TC850-4 11/5/96

3-77

Page 2

TC850

15-BIT, FAST-INTEGRATING CMOS

ANALOG-TO-DIGITAL CONVERTER

ABSOLUTE MAXIMUM RATINGS*

Positive Supply Voltage (VDD to GND)....................... +6V

Negative Supply Voltage (VSS to GND) .....................– 9V

Analog Input voltage (IN+ or IN–) .....................VDD to V

Voltage Reference Input

Logic Input Voltage ................ V

Current Into Any Pin.................................................10mA

Ambient Operating Temperature Range

ELECTRICAL CHARACTERISTICS: V

(REF

+

1

, REF

–

, REF

1

+

)..............................VDD to V

2

+ 0.3V to GND – 0.3V

DD

While Operating................................................100µA

C Device ................................................0°C to +70°C

I Device.............................................– 25°C to +85°C

= ±5V, f

S

Lead Temperature (Soldering, 10 sec) .................+300°C

Package Power Dissipation (TA ≤ 70°C)

CerDIP..............................................................2.29W

Plastic DIP ........................................................1.23W

SS

SS

CLK

Plastic PLCC ....................................................1.23W

*Static-sensitive device. Unused devices must be stored in conductive

material. Protect devices from static discharge and static fields. Stresses

above those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings only and functional

operation of the device at these or any other conditions above those

indicated in the operational sections of the specifications is not implied.

Exposure to Absolute Maximum Rating Conditions for extended periods

may affect device reliability.

= 61.44 kHz, VFS = 3.2768V, TA = 25°C, Fig. 1 Test Circuit,

unless otherwise specified.

Symbol Parameter Test Conditions Min Typ Max Unit

Zero-Scale Error VIN = 0V ±0.25 ±0.5 LSB

End Point Linearity Error –VFS ≤ VIN ≤ +V

FS

Differential Nonlinearity — ±0.1 ±0.5 LSB

I

IN

Input Leakage Current VIN = 0V, TA = 25°C — 30 75 pA

0°C ≤ T

≤ +70°C ———

A

– 25° ≤ TA ≤ +85°C — 1.1 3 nA

V

CMR

Common-Mode Voltage Range Over Operating Temperature Range VSS + 1.5 — VDD – 1.5 V

CMRR Common-Mode Rejection Ratio VIN = 0V, VCM = ±1V — 80 — dB

Full-Scale Gain Temperature External Ref Temperature

Coefficient Coefficient = 0 ppm/°C — 2 5 ppm/°C

0°C ≤ TA ≤ +70°C

Zero-Scale Error V

= 0V — 0.3 2 µV/°C

IN

Temperature Coefficient 0°C ≤ TA ≤ +70°C

Full-Scale Magnitude V

= ±3.275V — 0.5 2 LSB

IN

Symmetry Error

e

I

S

I

S

V

V

I

OP

V

IL

I

PU

I

PD

I

OSC

C

C

t

CE

t

RE

t

DHC

t

DHR

t

OP

N

+

–

OH

OL

IH

IN

OUT

Input Noise Not Exceeded 95% of Time — 30 — µV

Positive Supply Current — 2 3.5 mA

Negative Supply Current — 2 3.5 mA

Output High Voltage IO = 500 µA 3.5 4.9 — V

Output Low Voltage IO = 1.6 mA — 0.15 0.4 V

Output Leakage Current Pins 8 – 15, High-Impedance State — 0.1 1 µA

Input High Voltage Note 3 3.5 2.3 — V

Input Low Voltage Note 3 — 2.1 1 V

Input Pull-Up Current Pins 2, 3, 4, 6, 7; VIN = 0V — 4 — µA

Input Pull-Down Current Pins 1, 5; VIN = 5V — 14 — µA

Oscillator Output Current Pin 18, V

= 2.5V — 140 — µA

OUT

Input Capacitance Pins 1 – 7, 17 — 1 — pF

Output Capacitance Pins 8 – 15, High-Impedance State — 15 — pF

Chip-Enable Access Time CS or CE, RD = LOW (Note 1) — 230 450 nsec

Read-Enable Access Time CS = HIGH, CE = LOW (Note 1) — 190 450 nsec

Data Hold From CS or CE RD = LOW (Note 1) — 250 450 nsec

Data Hold From RD CS = HIGH, CE = LOW (Note 1) — 210 450 nsec

OVR/POL Data Access Time CS = HIGH, CE = LOW, RD = LOW (Note 1) — 140 300 nsec

— ±1 ±2 LSB

P-P

3-78

TELCOM SEMICONDUCTOR, INC.

Page 3

15-BIT, FAST-INTEGRATING CMOS

ANALOG-TO-DIGITAL CONVERTER

ELECTRICAL CHARACTERISTICS (Cont.)

1

TC850

Symbol Parameter Test Conditions Min Typ Max Unit

t

LH

t

WRE

t

WRD

t

WWR

NOTES: 1. Demand mode, CONT/DEMAND = LOW. Figure 10 timing diagram. CL = 100pF.

Low/High Byte Access Time CS = HIGH, CE = LOW, RD = LOW (Note 1) — 140 300 nsec

Clock Setup Time Positive or Negative Pulse Width 100 — — nsec

RD Minimum Pulse Width CS = HIGH, CE = LOW (Note 2) 450 230 — nsec

RD Minimum Delay Time CS = HIGH, CE = LOW (Note 2) 150 50 — nsec

WR Minimum Pulse Width CS = HIGH, CE = LOW, Demand Mode 75 25 — nsec

Clock Setup Time Positive or Negative Pulse Width 100 — — nsec

2. Continuous mode, CONT/DEMAND = HIGH. Figure 12 timing diagram.

3. Digital inputs have CMOS logic levels and internal pull-up/pull-down resistors. For TTL compatibility, external pull-up resistors to VCC are

recommended.

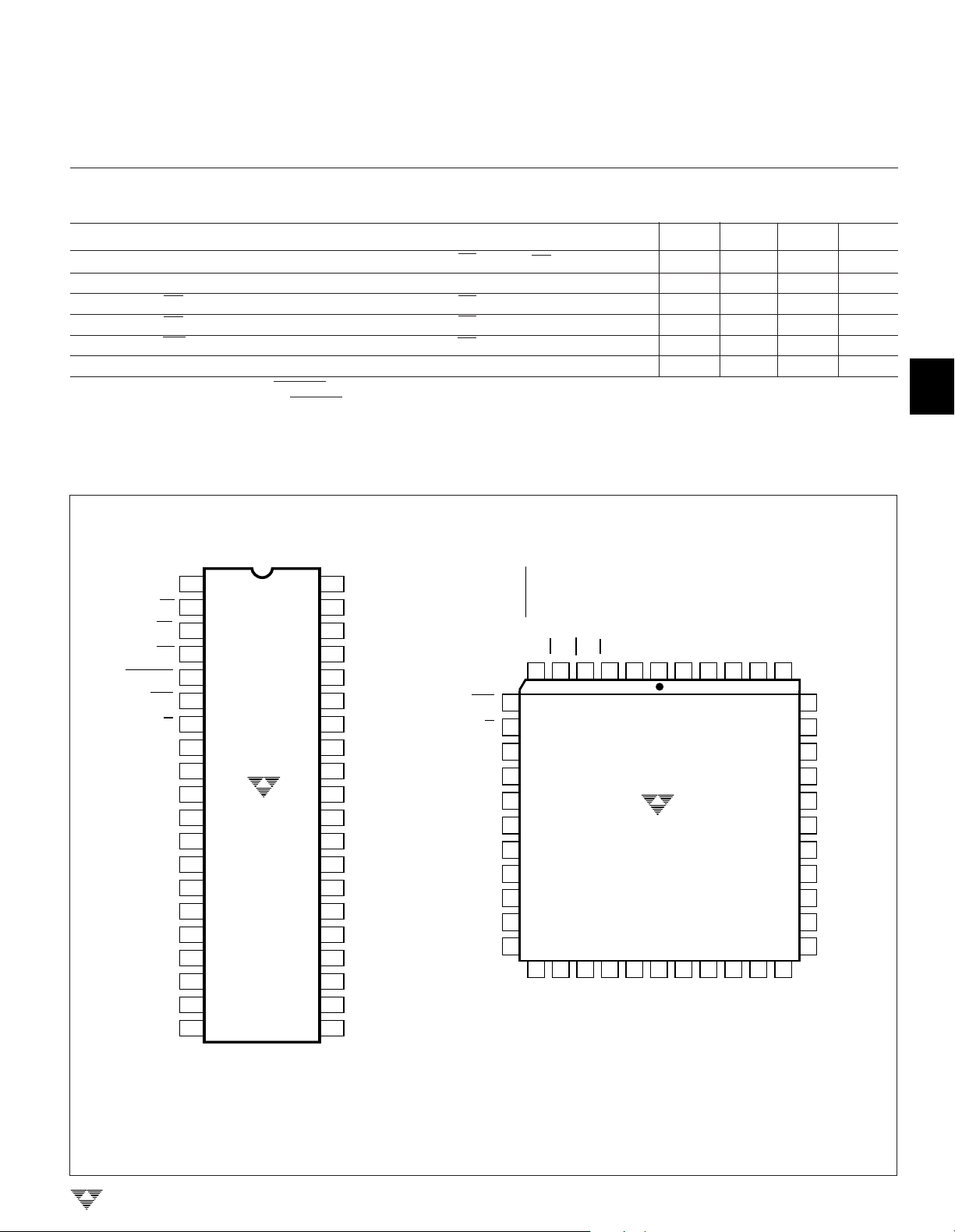

PIN CONFIGURATIONS

CS

CE

WR

RD

CONT/DEMAND

OVR/POL

L/H

DB7

DB6

DB5

DB4

DB3

DB2

DB1

DB0

BUSY

OSC

OSC

TEST

GND

1

2

3

4

5

6

7

8

9

10

TC850CPL

11

TC850IJL

12

13

14

15

16

17

1

18

2

19

20

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

V

DD

+

REF

1

+

C

REF1

–

C

REF1

–

REF

–

C

REF2

+

C

REF2

+

REF

2

+

IN

–

IN

COMMON

C

INTB

C

INTA

C

BUFA

C

BUFB

BUFFER

INT

IN

INT

OUT

V

SS

COMP

OVR/POL

L/H

DB7

DB6

DB5

NC

DB4

DB3

DB2

DB1

DB0

CONT/DEMAND

RD

6543 1442

7

8

9

10

11

12

13

18 19 20 21 23 24

OSC

BUSY

CE

WR

TC850CLW

TC850ILW

1

2

TEST

OSC

22

CS

GND

NC

NC

DD

V

COMP

1

+

43 42 41 40

25 26 27 28

REF

SS

V

+

REF1

C

OUT

INT

–

REF1

C

IN

INT

–

REF

39

38

37

36

35

34

33

3214

3115

3016

2917

BUFFER

–

C

REF2

+

C

REF2

+

REF

2

+

IN

–

IN

NC

COMMON

C

INTB

C

INTA

C

BUFA

C

BUFB

2

3

4

5

6

7

TELCOM SEMICONDUCTOR, INC.

NC = NO INTERNAL CONNECTION

8

3-79

Page 4

15-BIT, FAST-INTEGRATING CMOS

ANALOG-TO-DIGITAL CONVERTER

TC850

PIN DESCRIPTIONS

40-Pin DIP

Pin No. Symbol Description

1 CS Chip select, active HIGH. Logically ANDed with CE to enable read and write inputs. (See

2 CE Chip enable, active LOW. (See note 5.)

3 WR Write input, active LOW. When chip is selected (CS = HIGH and CE = LOW) and in demand

4 RD Read input, active LOW. When CS = HIGH and CE = LOW, a logic LOW on RD enables the

5 CONT/DEMAND Conversion control input. When CONT/DEMAND = LOW, conversions are initiated by the WR

6 OVR/POL Overrange/polarity data-select input. When making conversions in the demand mode (CONT/

7 L/H Low/high byte-select input. When CONT/DEMAND = LOW, this input controls whether low-

8 DB7 Most significant data bit output. When reading the A/D conversion result, the polarity,

9 – 15 DB6–DB0 Data outputs DB6–DB0. 3-state, bus compatible.

16 BUSY A/D conversion status output. BUSY goes to a logic HIGH at the beginning of the deintegrate

17 OSC

18 OSC

1

2

19 TEST For factory testing purposes only. Do not make external connection to this pin.

20 DGND Digital ground connection.

21 COMP Connection for comparator auto-zero capacitor. Bypass to VSS with 0.1 µF.

22 V

23 INT

24 INT

SS

OUT

IN

25 BUFFER Output of the input buffer. Connect to R

26 C

27 C

28 C

29 C

BUFB

BUFA

INTA

INTB

30 COMMON Analog common.

31 IN

–

30 COMMON Analog common.

REF2

REF2

REF1

REF1

DD

+

2

+

–

–

–

+

+

1

33 REF

34 C

35 C

36 REF

37 C

38 C

39 REF

40 V

NOTES: 4. This pin incorporates a pull-down resistor to DGND.

5. This pin incorporates a pull-up resistor to VDD.

note 4.)

mode (CONT/DEMAND = LOW), a logic LOW on WR starts a conversion. (See note 4.)

3-state data outputs. (See note 5.)

input. When CONT/DEMAND = HIGH, conversions are performed continuously. (See note 4.)

DEMAND = LOW), OVR/POL controls the data output on DB7 when the high-order byte is

active. (See note 5.)

byte or high-byte data is enabled on DB0 through DB7. (See note 5.)

overrange, and DB7 data are output on this pin. (See text.)

phase and goes LOW when conversion is complete. The falling edge of BUSY can be used to

generate a µP interrupt.

Crystal oscillator connection or external oscillator input.

Crystal oscillator connection.

Negative power supply connection, typically – 5V.

Output of the integrator amplifier. Connect to C

Input to the integrator amplifier. Connect to summing node of R

INT

.

INT

INT

and C

INT

.

.

Connection for buffer auto-zero capacitor. Bypass to VSS with 0.1 µF.

Connection to buffer auto-zero capacitor. Bypass to VSS with 0.1 µF.

Connection for integrator auto-zero capacitor. Bypass to VSS with 0.1 µF.

Connection for integrator auto-zero capacitor. Bypass to VSS with 0.1 µF.

Negative differential analog input.

Positive input for reference voltage V

Positive connection for V

Negative connection for V

reference capacitor.

REF2

reference capacitor.

REF2

REF2

. (V

REF2

= V

REF1

/64)

Negative input for reference voltages.

Negative connection for V

Positive connection for V

Positive input for V

REF1

reference capacitor.

REF1

reference capacitor.

REF1

.

Positive power supply connection, typically +5V.

3-80

TELCOM SEMICONDUCTOR, INC.

Page 5

15-BIT, FAST-INTEGRATING CMOS

ANALOG-TO-DIGITAL CONVERTER

1

TC850

THEORY OF OPERATION

The TC850 is a multiple-slope, integrating analog-todigital converter (ADC). The multiple-slope conversion process, combined with chopper-stabilized amplifiers, results

in a significant increase in ADC speed, while maintaining

very high resolution and accuracy.

Dual-Slope Conversion Principles

The conventional dual-slope converter measurement

cycle (shown in Figure 2A) has two distinct phases:

(1) Input signal integration

(2) Reference voltage integration (deintegration)

The input signal being converted is integrated for a fixed

time period, measured by counting clock pulses. An opposite polarity constant reference voltage is then integrated

until the integrator output voltage returns to zero. The

reference integration time is directly proportional to the input

signal.

In a simple dual-slope converter, complete conversion

requires the integrator output to "ramp-up" and "rampdown." Most dual-slope converters add a third phase, autozero. During auto-zero, offset voltages of the input buffer,

integrator, and comparator are nulled, thereby eliminating

the need for zero-offset adjustments.

Dual-slope converter accuracy is unrelated to the integrating resistor and capacitor values, as long as they are

stable during a measurement cycle. By converting the

unknown analog input voltage into an easily-measured

function of time, the dual-slope converter reduces the need

for expensive, precision passive components.

Noise immunity is an inherent benefit of the integrating

conversion method. Noise spikes are integrated, or averaged, to zero during the integration period. Integrating ADCs

are immune to the large conversion errors that plague

successive approximation converters in high-noise environments.

A simple mathematical equation relates the input signal,

reference voltage, and integration time:

t

SI

1

RC

VIN(t) dt = ,

∫

0

where: VR = Reference voltage

tSI = Signal integration time (fixed)

tRI = Reference voltage integration time (variable).

VR t

RC

RI

Multiple-Slope Conversion Principles

One limitation of the dual-slope measurement technique is conversion speed. In a typical dual-slope method,

the auto-zero and integrate times are each one-half of the

deintegrate time. For a 15-bit conversion, 214+214+2

(65,536) clock pulses are required for auto-zero, integrate,

and deintegrate phases, respectively. The large number of

clock cycles effectively limits the conversion rate to about

2.5 conversions per second, when a typical analog CMOS

fabrication process is used.

The TC850 uses a multiple-slope conversion technique

to increase conversion speed (Figure 2B). This technique

makes use of a two-slope deintegration phase and permits

15-bit resolution up to 40 conversions per second.

During the TC850's deintegration phase, the integration

capacitor is rapidly discharged to yield a resolution of 9 bits.

At this point, some charge will remain on the capacitor. This

remaining charge is then slowly deintegrated, producing an

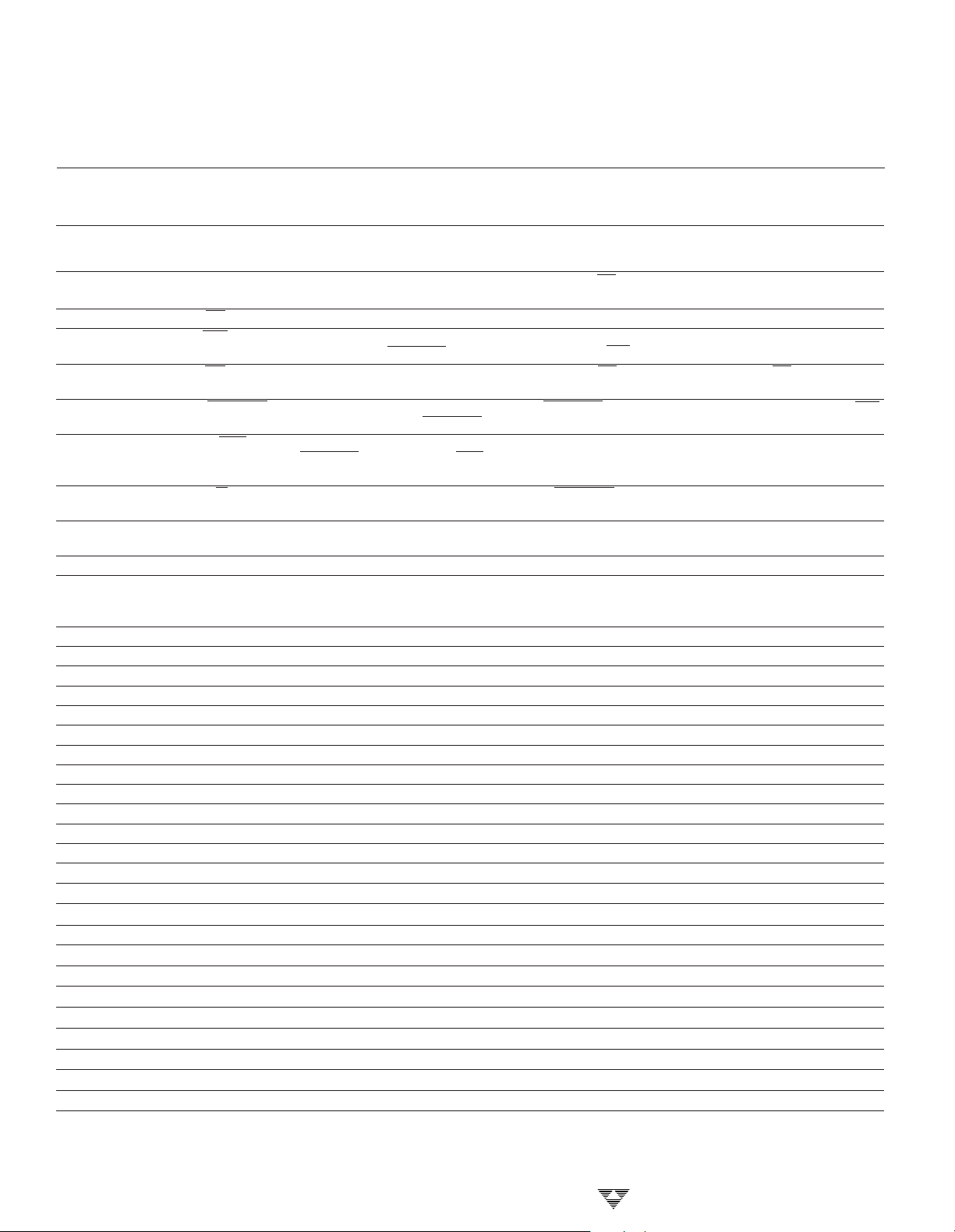

2240

V

SS

COMMON

C

C

C

C

BUFFER

INT

C

BUFACBUFB

0.1

µF

–5V

REF

REF

REF

+

REF1

–

REF1

+

REF2

–

REF2

INT

OUT

TEST

IN

26

IN

100 MΩ

32

+

0.1

µF

31

30

39

33

36

38

37

34

35

25

24

23

19

0.01 µF INPUT

+1.6384V

+0.0265V

1 µF

1 µF

120 MΩ

R

INT

0.1µF

C

INT

NC

–

+

1

+

2

–

IN

+5V

20

V

DGND

DD

16

BUSY

8

DB7

9

DB6

10

DB5

11

DB4

12

DB3

13

DB2

14

DB1

15

DB0

1

CS

2

CE

3

WR

4

RD

5

CONT/DEMAND

6

OVR/POL

7

L/H

17

**

NOTES: Unless otherwise specified, all 0.1µF capacitors are film dielectric.

61.44 kHz

**

Ceramic capacitors are not recommended.

NC = No internal capacitors

*Polypropylene capacitors.

** 100pF Mica capacitors.

OSC

18

OSC

21

COMP

C

INTA

0.1

µF

Figure 1. Standard Circuit Configuration

1

2

C

INTB

28 2729

0.1

µF

TC850

0.1

µF

15

*

*

2

3

4

5

6

7

8

TELCOM SEMICONDUCTOR, INC.

3-81

Page 6

TC850

INTEGRATOR

OUTPUT

AUTO

ZERO

TIME

SIGNAL

INTEGRATE

REFERENCE

DEINTEGRATE

END OF

CONVERSION

0V

15-BIT, FAST-INTEGRATING CMOS

ANALOG-TO-DIGITAL CONVERTER

additional 6 bits of resolution. The result is 15 bits of

resolution achieved with only 29+26 (512 + 64, or 576) clock

pulses for deintegration. A complete conversion cycle occupies only 1280 clock pulses.

In order to generate "fast-slow" integration phases, two

voltage references are required. The primary reference

(V

) is set to one-half of the full-scale voltage (typically

REF1

V

= 1.6384V, and VFS = 3.2768V). The secondary

REF1

voltage reference (V

mV). To maintain 15-bit linearity, a tolerance of 0.5% for

V

is recommended.

REF2

) is set to V

REF2

/64 (typically 25.6

REF1

Figure 2A. Dual-Slope ADC Cycle

"FAST" REFERENCE

DEINTEGRATE

(9-BIT RESOLUTION)

SIGNAL

INTERGRATE

AUTO

INTEGRATOR

OUTPUT

IN

ZERO

TIME

Figure 2B. "Fast-Slow" Reference Deintegrate Cycle

C

REF1

+

REF1

+

C

REF1

DE

+

INT

DE1

(–)

DE1

(+)

DE

REF1

–

"SLOW" REFERENCE

DEINTEGRATE

(6-BIT RESOLUTION)

END OF

CONVERSION

0V

C

DE1

(–)

REF2

REF2

–

C

REF2

–

C

REF1

DE DE

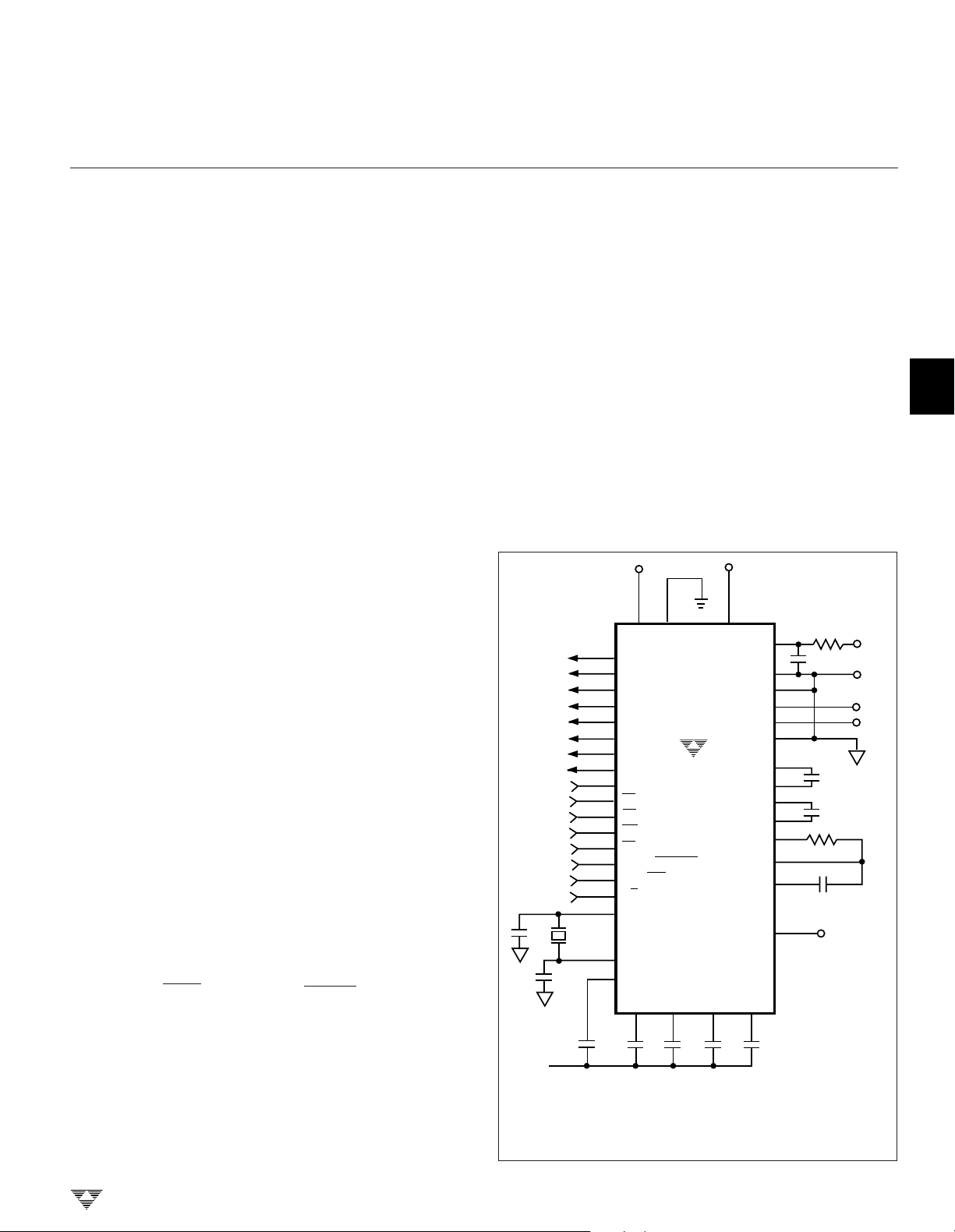

ANALOG SECTION DESCRIPTION

The TC850 analog section consists of an input buffer

amplifier, integrator amplifier, comparator, and analog

switches. A simplified block diagram is shown in Figure 3.

Conversion Timing

Each conversion consists of three phases: (1) Zero

Integrator, (2) Signal Integrate, and (3) Reference Integrate

(or Deintegrate). Each conversion cycle requires 1280 internal clock cycles (Figure 4).

C

INT

INT

IN

INTEGRATOR*

–

+

INT

OUT

–

+

COMPARATOR*

DIGITAL

SECTION

+

DE1

(+)

C

–

REF2

BUFF

–

+

BUFFER*

R

INT

TO

COMMON

3-82

DE1

(+)

INT

–

IN

INT

DE1

(–)

Figure 3. Analog Section Simplified Schematic

DE2

(+)

DE2

(–)

Z1

*AUTO-ZEROED

AMPLIFIERS

TC850

TELCOM SEMICONDUCTOR, INC.

Page 7

15-BIT, FAST-INTEGRATING CMOS

ANALOG-TO-DIGITAL CONVERTER

1

TC850

1280 CLOCK CYCLES

INTERNAL

CLOCK

CONVERSION

PHASE

. . . . . . .

246 256 778

ZERO INTEGRATOR REFERENCE INTEGRATE

SIGNAL

INTEGRATE

Figure 4. Conversion Timing

Zero-Integrator Phase

During the zero-integrator phase, the differential input

signal is disconnected from the circuit by opening internal

analog gates. The internal nodes are shorted to analog

common (ground) to establish a zero-input condition. At the

same time, a feedback loop is closed around the input buffer,

integrator, and comparator. The feedback loop ensures the

integrator output is near 0V before the signal-integrate

phase begins.

During this phase, a chopper-stabilization technique is

used to cancel offset errors in the input buffer, integrator,

and comparator. Error voltages are stored on the C

C

, and COMP capacitors. The zero-integrate phase

INT

requires 246 clock cycles.

BUFF

Signal-Integrate Phase

The zero-integrator loop is opened and the internal

differential inputs are connected to IN+ and IN–. The differential input signal is integrated for a fixed time period. The

TC850 signal-integrate period is 256 clock periods, or counts.

The crystal oscillator frequency is 44 before clocking the

internal counters.

The integration time period is:

f

OSC

4

tSI = × 256

Reference-Integrate Phase

During reference-integrate phase, the charge stored on

the integrator capacitor is discharged. The time required to

discharge the capacitor is proportional to the analog input

voltage.

The reference integrate phase is divided into three

subphases: (1) fast, (2) slow, and (3) overrange deintegrate.

During fast deintegrate, V

analog common and V

charged reference capacitor (C

tor is rapidly discharged for a maximum of 512 internal clock

pulses, yielding 9 bits of resolution.

+

is connected across the previously-

IN

–

is internally connected to

IN

). The integrator capaci-

REF1

. . . . . . . . . . . . . .

During the slow deintegrate phase, the internal V

node is now connected to the C

residual charge on the integrator capacitor is further discharged a maximum of 64 clock pulses. At this point, the

analog input voltage has been converted with 15 bits of

resolution.

If the analog input is greater than full scale, the TC850

performs up to three overrange deintegrate subphases.

Each subphase occupies a maximum of 64 clock pulses.

The overrange feature permits analog inputs up to 192 LSBs

greater than full scale to be correctly converted. This feature

,

permits the user to digitally null up to 192 counts of input

offset, while retaining full 15-bit resolution.

In addition to 512 counts of fast, 64 counts of slow, and

192 counts of overrange deintegrate, the reference-integrate phase uses 10 clock pulses to permit internal nodes to

settle. Therefore, the reference integrate cycle occupies 778

clock pulses.

Pin Description (Analog)

Differential Inputs (IN+ and IN–)

The analog signal to be measured is applied at the IN

and IN– inputs. The differential input voltage must be within

the common-mode range of the converter. The input common-mode range extends from VDD –1.5V to VSS +1.5V.

Within this common-mode voltage range, an 86 dB CMRR

is typical.

The integrator output also follows the common-mode

voltage. The integrator output must not be allowed to saturate. A worst-case condition exists, for example, when a

large, positive common-mode voltage with a near full-scale

negative differential input voltage is applied. The negative

input signal drives the integrator positive when most of its

available swing has been used up by the positive commonmode voltage. For applications where maximum commonmode range is critical, integrator swing can be reduced. The

integrator output can swing within 0.4V of either supply

without loss of linearity.

capacitor, and the

REF2

2

3

+

IN

4

5

6

+

7

8

TELCOM SEMICONDUCTOR, INC.

3-83

Page 8

TC850

15-BIT, FAST-INTEGRATING CMOS

ANALOG-TO-DIGITAL CONVERTER

Differential Reference (V

REF

)

The TC850 requires two reference voltage sources in

order to generate the "fast-slow" deintegrate phases. The

main voltage reference (V

and REF– pins. The secondary reference (V

between the REF

+

and REF– pins.

2

) is applied between the REF

REF1

REF2

) is applied

The reference voltage inputs are fully differential, and

the reference voltage can be generated anywhere within the

power supply voltage of the converter. However, to minimize

roll-over error, especially at high conversion rates, keep the

reference common-mode voltage (i.e., REF–) near or at the

analog common potential. All voltage reference inputs are

high impedance. Average reference input current is typically

only 30pA.

Analog Common (COMMON)

Analog common is used as the IN– return during the

zero-integrator and deintegrate phases of each conversion.

If IN– is at a different potential than analog common, a

common-mode voltage exists in the system. This signal is

rejected by the 86 dB CMRR of the converter. However, in

most applications, IN– will be set at a fixed, known voltage

(power supply common, for instance). In this case, analog

common should be tied to the same point so that the

common-mode voltage is eliminated.

DIGITAL SECTION DESCRIPTION

+

1

The TC850 digital section consists of two sets of conversion counters, control and sequencing logic, clock oscillator

and divider, data latches, and an 8-bit, 3-state interface bus.

A simplified schematic of the bus interface logic is shown in

Figure 5.

Clock Oscillator

The TC850 includes a crystal oscillator on-chip. All that

is required is to connect a crystal across OSC1 and OSC

pins, and to add two inexpensive capacitors (Figure 1). The

oscillator output is ÷ 4 prior to clocking the A/D internal

counters. For example, a 100kHz crystal produces a system

clock frequency of 25kHz. Since each conversion requires

1280 clock periods, in this case the conversion rate will be

25,000/1280, or 19.5 conversions per second.

In most applications, however, an external clock is

divided down from the microprocessor clock. In this case,

the OSC1 pin is used as the external oscillator input and

OSC2 is left unconnected. The external clock driver should

swing from digital ground to VDD. The ÷4 function is active for

both external clock and crystal oscillator operations.

2

DBO–DB7

L/H

RD

CE

CS

POL/OVR

WR

CONT/

DEMAND

3-STATE

BUFFER

8

OUTPUT

ENABLE

OCTAL

2-INPUT

8 7

MUX

SELECT

TC850

8

SELECT

2-INPUT

MUX

START

CONVERSION

END OF

CONVERSION

LOW-BYTE

UP/DOWN

COUNTER

HIGH-BYTE

UP/DOWN

COUNTER

TO A/D

CONTROL

LOGIC

POLARITY

OVERANGE

3-84

Figure 5. Bus Interface Simplified Schematic

TELCOM SEMICONDUCTOR, INC.

Page 9

15-BIT, FAST-INTEGRATING CMOS

ANALOG-TO-DIGITAL CONVERTER

1

TC850

Digital Operating Modes

Two modes of operation are available with the TC850,

continuous conversions and on-demand. The operating

mode is controlled by the CONT/DEMAND input. The bus

interface method is different for continuous and demand

modes of operation.

Demand Mode Operation

When CONT/DEMAND is low, the TC850 performs one

conversion each time the chip is selected and the WR input

is pulsed low. Data is valid on the falling edge of the BUSY

output and can be accessed using the interface truth table

(Table 1).

Table 1. Bus Interface Truth Table

CE•CS RD CONT/DEMAND L/H OVR/POL DB7 DB6–DB0

Pins 1 and 2 Pin 4 Pin 5 Pin 7 Pin 6 Pin 8 Pin 9-Pin 15 (Note 1)

0 0 0 0 0 "1" = Input Positive Data Bits 14 – 8

0 0 0 0 1 "1" = Input Overrange Data Bits 14 – 8

0 0 0 1 X Data Bit 7 Data Bits 6 – 0

0 0 1 X X Note 3

0 1 X X X High-Impedance State

1 X X X X High-Impedance State

NOTES: 1. Pin numbers refer to 40-pin DIP.

2. Extended overrange operation: Although rated at 15 bits (±32,767 counts) of resolution, the TC850 provides an additional 191 counts

above full scale. For example, with a full-scale input of 3.2768V, the maximum analog input voltage which will be properly converted is

3.2958V. The extended resolution is signified by the overrange bit being high and the low-order byte contents being between 0 and 190.

For example, with a full-scale voltage of 3.2768V:

V

IN

3.2767V Low 255

3.2768V High 000

3.2769V High 001

3.2867V High 099

3. Continuous mode data transfer:

a. In continuous mode, data MUST be read in three sequential bytes after the BUSY output goes low:

(1) The first byte read will be the high-order byte, with DB7 = polarity.

(2) The second byte read will contain the low-order byte.

(3) The third byte read will again be the high-order byte, but with DB7 = overrange.

b. All three data bytes must be read within 443-1/2 clock cycles after the falling edge of BUSY.

c. The RD input must go high after each byte is read, so that the internal byte counter will be incremented. However, the CS and CE

inputs can remain enabled through the entire data transfer sequence.

Overrange Bit Low Byte Data Bits 14–8

10

10

10

10

Continuous Mode Operation

When CONT/DEMAND is high, the TC850 continuously

performs conversions. Data will be valid on the falling edge

of the BUSY output, and remains valid for 443-1/2 clock

cycles.

The low/high (L/H) byte-select and overrange/polarity

(OVR/POL) inputs are disabled during continuous mode

operation. Data must be read in three consecutive bytes, as

shown in Table I.

NOTE: In continuous mode, the conversion result must be read within 4431/2 clock cycles of the BUSY output falling edge. After this time (i.e., 1/2

clock cycle before BUSY goes high) the internal counters are reset and the

data is lost.

(Note 2)

127

10

0

10

0

10

0

10

2

3

4

5

6

TELCOM SEMICONDUCTOR, INC.

7

8

3-85

Page 10

TC850

15-BIT, FAST-INTEGRATING CMOS

ANALOG-TO-DIGITAL CONVERTER

Pin Description (Digital)

Chip Select and Chip Enable (CS and CE)

The CS and CE inputs permit easy interfacing to a

variety of digital bus systems. CE is active LOW while CS is

active HIGH. These inputs are logically ANDed internally

and are used to enable the RD and WR inputs.

Write Enable Input (WR)

The write input is used to initiate a conversion when the

TC850 is in demand mode. CS and CE must be active for the

WR input to be recognized. The status of the data bus is

meaningless during the WR pulse, because no data is

actually written into the TC850.

Read Enable Input (RD)

The read input, combined with CS and CE, enables the

3-state data bus outputs. Also, in continuous mode, the

rising edge of the RD input activates an internal byte counter

to sequentially read the three data bytes.

Low/High Byte Select (L/H)

The L/H input determines whether the low (least significant) byte or high (most significant) byte of data is placed on

the 3-state data bus. This input is meaningful only when the

TC850 is in the demand mode. In the continuous mode, data

must be read in three predetermined bytes, so the L/H input

is ignored.

Overrange/Polarity Bit Select (OVR/POL)

The TC850 provides 15 bits of resolution, plus polarity

and overrange bits. Thus, 17 bits of information must be

transferred on an 8-bit data bus. To accomplish this, the

overrange and polarity bits are multiplexed onto data bit DB7

of the most significant byte. When OVR/POL is HIGH, DB7

of the high byte contains the overrange status (HIGH =

analog input overrange, LOW = input within full scale). When

OVR/POL is LOW, DB7 is HIGH for positive analog input

polarity and LOW for negative polarity. The OVR/POL input

is meaningful only when CS, CE, and RD are active, and L/

H is LOW (i.e., the most significant byte is selected). OVR/

POL is ignored when the TC850 is in continuous mode.

Continuous/Demand Mode Input (CONT/DEMAND)

This input controls the TC850 operating mode. When

CONT/DEMAND is HIGH, the TC850 performs conversions

continuously. In continuous mode, data must be read in the

prescribed sequence shown in Table I. Also, all three data

bytes must be read within 443-1/2 internal clock cycles after

the BUSY output goes low. After 443-1/2 clock cycles data

will be lost.

When CONT/DEMAND is LOW, the TC850 begins a

conversion each time CS and CE are active and WR is

pulsed LOW. The conversion is complete and data can be

read after the falling edge of the BUSY output. In demand

mode, data can be read in any sequence, and remains valid

until WR is again pulsed LOW.

Busy Output (BUSY)

The BUSY output is used to convey an end-of-conversion to external logic. BUSY goes HIGH at the beginning of

the deintegrate phase and goes LOW at the end of the

conversion cycle. Data is valid on the falling edge of BUSY.

The output-high period is fixed at 836 clock periods, regardless of the analog input value. BUSY is active during

continuous and demand mode operation.

This output can also be used to generate an end-ofconversion interrupt in µP-based systems. Noninterruptdriven systems can poll BUSY to determine when data is

valid.

ANALOG SECTION APPLICATIONS

Component Selection

Reference Voltage

The typical value for reference voltage V

This value yields a full-scale voltage of 3.2768V and resolution of 100µV per step. The V

V

by 64. Thus, typical V

REF1

25.6mV. The V

value should be adjusted within ±1% to

REF2

value is derived by dividing

REF2

value is 1.6384V/64, or

REF2

maintain 15-bit accuracy for the total conversion process;

i.e.,

V

V

REF2

REF1

= ±1%.

64

The reference voltage is not limited to exactly 1.6384V,

however, because the TC850 performs a ratiometric conversion. Therefore, the conversion result will be:

V

Digital counts = • 16384.

V

IN

REF1

The full-scale voltage can range from 3.2V to 3.5V. Fullscale voltages of less than 3.2V will result in increased noise

in the least significant bits, while a full-scale above 3.5V will

exceed the input common-mode range.

Integration Resistor

The TC850 buffer supplies 25µA of integrator charging

current with minimal linearity error. R

V

R

INT

FULL SCALE

= .

25 µA

is easily calculated:

INT

For a full-scale voltage of 3.2768V, values of R

between 120kΩ and 150kΩ are acceptable.

is 1.6384V.

REF1

INT

3-86

TELCOM SEMICONDUCTOR, INC.

Page 11

15-BIT, FAST-INTEGRATING CMOS

ANALOG-TO-DIGITAL CONVERTER

1

TC850

Integration Capacitor

The integration capacitor should be selected to produce

an integrator swing of ≈4V at full scale. The capacitor value

is easily calculated:

V

FS

C = • ,

R

INT

where f

and VFS is the maximum input voltage.

The integration capacitor should be selected for low

dielectric absorption to prevent roll-over errors. A polypropylene, polyester or polycarbonate dielectric capacitor is

recommended.

Reference Capacitors

The reference capacitors require a low leakage dielectric, such as polypropylene, polyester or polycarbonate. A

value of 1µF is recommended for operation over the temperature range. If high-temperature operation is not required, the C

Auto-Zero Capacitors

Five capacitors are required to auto-zero the input

buffer, integrator amplifier, and comparator. Recommended

capacitors are 0.1µF film dielectric (such as polyester or

polypropylene). Ceramic capacitors are not recommended.

is the crystal or external oscillator frequency

CLOCK

values can be reduced.

REF

4 • 256

4V • f

CLOCK

f

= f

CLOCK

where f

sents the clock divider, and 256 is the number of integrate

cycles.

For example, 60Hz noise will be rejected with a clock

frequency of 61.44kHz, giving a conversion rate of 12

conversions/sec. Integer submultiples of 61.44kHz (such as

30.72kHz, etc.) will also reject 60Hz noise. For 50Hz noise

rejection, a 51.2kHz frequency is recommended.

If noise rejection is not important, other clock frequencies can be used. The TC850 will typically operate at

conversion rates ranging from 3 to 40 conversions/sec,

corresponding to oscillator frequencies from 15.36kHz to

204.8kHz.

is the noise frequency to be rejected, 4 repre-

NOISE

10 MΩ

TC850

17

61.44 kHz

100 pF 100 pF

NOISE

× 4 × 256,

÷

4

18

SYSTEM

CLOCK

2

3

4

5

DIGITAL SECTION APPLICATION

Oscillator

The TC850 may operate with a crystal oscillator. The

crystal selected should be designed for a Pierce oscillator,

such as an AT-cut quartz crystal. The crystal oscillator

schematic is shown in Figure 6.

Since low frequency crystals are very large and ceramic

resonators are too lossy, the TC850 clock should be derived

from an external source, such as a microprocessor clock.

The clock should be input on the OSC1 pin and no connection should be made to the OSC2 pin. The external clock

should swing between DGND and VDD.

Since oscillator frequency is ÷ 4 internally and each

conversion requires 1280 internal clock cycles, the conversion time will be:

Conversion time = f

An important advantage of the integrating ADC is the

ability to reject periodic noise. This feature is most often

used to reject line frequency (50Hz or 60Hz) noise. Noise

rejection is accomplished by selecting the integration period

equal to one or more line frequency cycles. The desired

clock frequency is selected as follows:

CLOCK

× 4 × 1280.

Figure 6. Crystal Oscillator Schematic

Data Bus Interfacing

The TC850 provides an easy and flexible digital interface. A 3-state data bus and six control inputs permit the

TC850 to be treated as a memory device, in most applications. The conversion result can be accessed over an 8-bit

bus or via a µP I/O port.

A typical µP bus interface for the TC850 is shown in

Figure 7. In this example, the TC850 operates in the demand

mode, and conversion begins when a write operation is

performed to any decoded address space. The BUSY

output interrupts the µP at the end-of-conversion.

The A/D conversion result is read as three memory

bytes. The two LSBs of the address bus select high/low byte

and overrange/polarity bit data, while high-order address

lines enable the CE input.

Figure 8 shows a typical interface to a µP I/O port or

single-chip µC. The TC850 operates in the continuous

mode, and can either interrupt the µC/µP or be polled with an

input pin.

6

7

8

TELCOM SEMICONDUCTOR, INC.

3-87

Page 12

TC850

TC850

CONT/DEMAND

TC850

DB0

DB1

DB2

DB3

DB4

DB5

DB6

DB7

CS

L/H

OVR/POL

RD

WR

BUSY

CS

ADDRESS

X00

X01

X10

Figure 7. Interface to Typical µP Data Bus

DB0

DB1

DB2

DB3

DB4

DB5

DB6

DB7

ADDRESS

DECODE

+5V

DATA BUS

HIGH BYTE AND POLARITY

LOW BYTE

HIGH BYTE AND OVERRANGE

DB0

DB1

DB2

DB3

DB4

DB5

DB6

DB7

A2

. . .

A15

A0

A1

RD

WR

INTERRUPT

PA0

PA1

PA2

PA3

PA4

PA5

PA6

PA7

µP

µC OR µP

I/O PORT

15-BIT, FAST-INTEGRATING CMOS

ANALOG-TO-DIGITAL CONVERTER

Since the PA0–PA7 inputs are dedicated to reading

A/D data, the A/D CS/CE inputs can be enabled continuously. In continuous mode, data must be read in 3 bytes, as

shown in Table I. The required RD pulses are provided by a

µC/µP output pin.

The circuit of Figure 8 can also operate in the demand

mode, with the start-up conversion strobe generated by a

µC/µP output pin. In this case, the L/H and CONT/DEMAND

inputs can be controlled by I/O pins and the RD input

connected to digital ground.

Demand Mode Interface Timing

When CONT/DEMAND input is LOW, the TC850 performs a conversion each time CE and CS are active and WR

is strobed LOW.

The demand mode conversion timing is shown in Figure

9. BUSY goes LOW and data is valid 1155 clock pulses after

WR goes LOW. After BUSY goes low, 125 additional clock

cycles are required before the next conversion cycle will

begin.

Once conversion is started, WR is ignored for 1100

internal clock cycles. After 1100 clock cycles, another WR

pulse is recognized and initiates a new conversion when the

present conversion is complete. A negative edge on WR is

required to begin conversion. If WR is held LOW, conversions will not occur continuously.

The A/D conversion data is valid on the falling edge of

BUSY, and remains valid until one-half internal clock cycle

before BUSY goes HIGH on the succeeding conversion.

BUSY can be monitored with an I/O pin to determine end of

conversion, or to generate a µP interrupt.

In demand mode, the three data bytes can be read in

any desired order. The TC850 is simply regarded as three

bytes of memory and accessed accordingly. The bus output

timing is shown in Figure 10.

BUSY

RD

CONT/DEMAND

CS

CS WR

NC

Figure 8. Interface to Typical µP I/O Port or Single-Chip µC

3-88

+5V

INTERRUPT

PB0

Continuous Mode Interface Timing

When the CONT/DEMAND input is HIGH, the TC850

performs conversions continuously. Data will be valid on the

falling edge of BUSY, and all three bytes must be read within

443-1/2 internal clock cycles of BUSY going LOW. The

timing diagram is shown in Figure 11.

In continuous mode, OVR/POL and L/H byte-select

inputs are ignored. The TC850 automatically cycles through

three data bytes, as shown in Table I. Bus output timing in

the continuous mode is shown in Figure 12.

TELCOM SEMICONDUCTOR, INC.

Page 13

15-BIT, FAST-INTEGRATING CMOS

ANALOG-TO-DIGITAL CONVERTER

1

TC850

CS

.

CE

INTERNAL

CLOCK

.

CS

CE

WR

BUSY

DB0-DB7

. . . .

319 CLOCK

CYCLES

PREVIOUS CONVERSION

DATA VALID

t

CE

t

RE

. . . . . . . .

1100 CLOCK CYCLES

WR PULSES ARE IGNORED

836 CLOCK CYCLES

DATA MEANINGLESS

Figure 9. Conversion Timing, Demand Mode

NEXT CONVERT

COMMAND WILL

BE RECOGNIZED

125 CLOCK

CYCLES

NEW CONVERSION DATA VALID

t

DHC

t

DHR

NEXT

CONVERSION

CAN BEGIN

2

3

4

RD

DB0-DB6

DB7

OVR/POL

L/H

*

HI-Z

HI-Z

NOTE: CONT/DEMAND = LOW

*RD (as well as CS and CE) can go HIGH after each byte is read (i.e., in a µP bus interface)

or remain LOW during the entire DATA-READ sequence (i.e., µP I/O port interface).

DATA BITS 8 TO 14 HIGH IMPEDANCE

"1"= INPUT

OVERRANGE

t

OP

Figure 10. Bus Output Timing, Demand Mode

"1"= POSITIVE

POLARITY

t

LH

DATA BITS

0 T0 6

DATA BIT 7

5

6

HIGH IMPEDANCE

DONT' CARE

7

DONT' CARE

8

TELCOM SEMICONDUCTOR, INC.

3-89

Page 14

TC850

15-BIT, FAST -INTEGRATING CMOS

ANALOG-TO-DIGITAL CONVERTER

INTERNAL

CLOCK

BUSY

DB0-DB7

CONT/DEMAND

BUSY

RD

. . . . . . .

836 CLOCK CYCLES

DATA MEANINGLESS

Figure 11. Conversion Timing, Continuous Mode

t

WRE

t

RE

1280 INTERNAL CLOCK CYCLES

t

WRD

. . . . . . . . . .

443-1/2 CLOCK

CYCLES

DATA VALID

1/2 CLOCK CYCLE

DATA

MEANINGLESS

3-90

DB0-DB7

HI-Z

NOTES: CS = HIGH; CE = LOW

DATA BITS 8-14

POLARITY

DATA BITS 0-7

Figure 12. Bus Output Timing, Continuous Mode

DATA BITS 8-14

OVERRANGE

HIGH IMPEDANCE

STATE

TELCOM SEMICONDUCTOR, INC.

Loading...

Loading...