Page 1

TC820

3-3/4 Digit A/D Converter with Frequency Counter

and Logic Probe

Features

• Multiple Analog Measurement System

- Digit A/D Converter

- Frequency Counter

- Logic Probe

• Low Noise A/D Converter:

- Differential Inputs: (1pA Bias Current)

- On-Chip 50ppm/°C Voltage Reference

• Frequency Counter:

- 4MHz Maximum Input Frequency

- Auto-RangingOver Four Decade Range

• Logic Probe:

- Two LCD Annunciators

- Buzzer Driver

• 3-3/4 Digit Display with Over Range Indicator

• LCD Display Driver with Bui lt-in Contrast Control

• Data Hold Input for Comparison Measurements

• Low Battery Detect with LCD Annunciator

• Under Range and Over Range Outputs

• On-Chip Buzzer Driver with Control Input

• 40-Pin Plastic DIP, 44-Pin Plastic Flat Pack, or

44-Pin PLCC Packages

General Description

The TC820 is a 3-3/4 digit, multi-measurement system

especiallysuitedforuse in portable instruments.It integrates a dual slope A/D converter, auto-ranging frequency counter and logic pr obe into a single 44-pin

surface mount, or 40-pin through hole package. The

TC820 operates from a single 9V input voltage (battery) and features a built-in battery low flag. Function

and decimal pointselectionareaccomplishedwithsimple logic inputs designed for direct connection to an

external microcontroller or rotary switch.

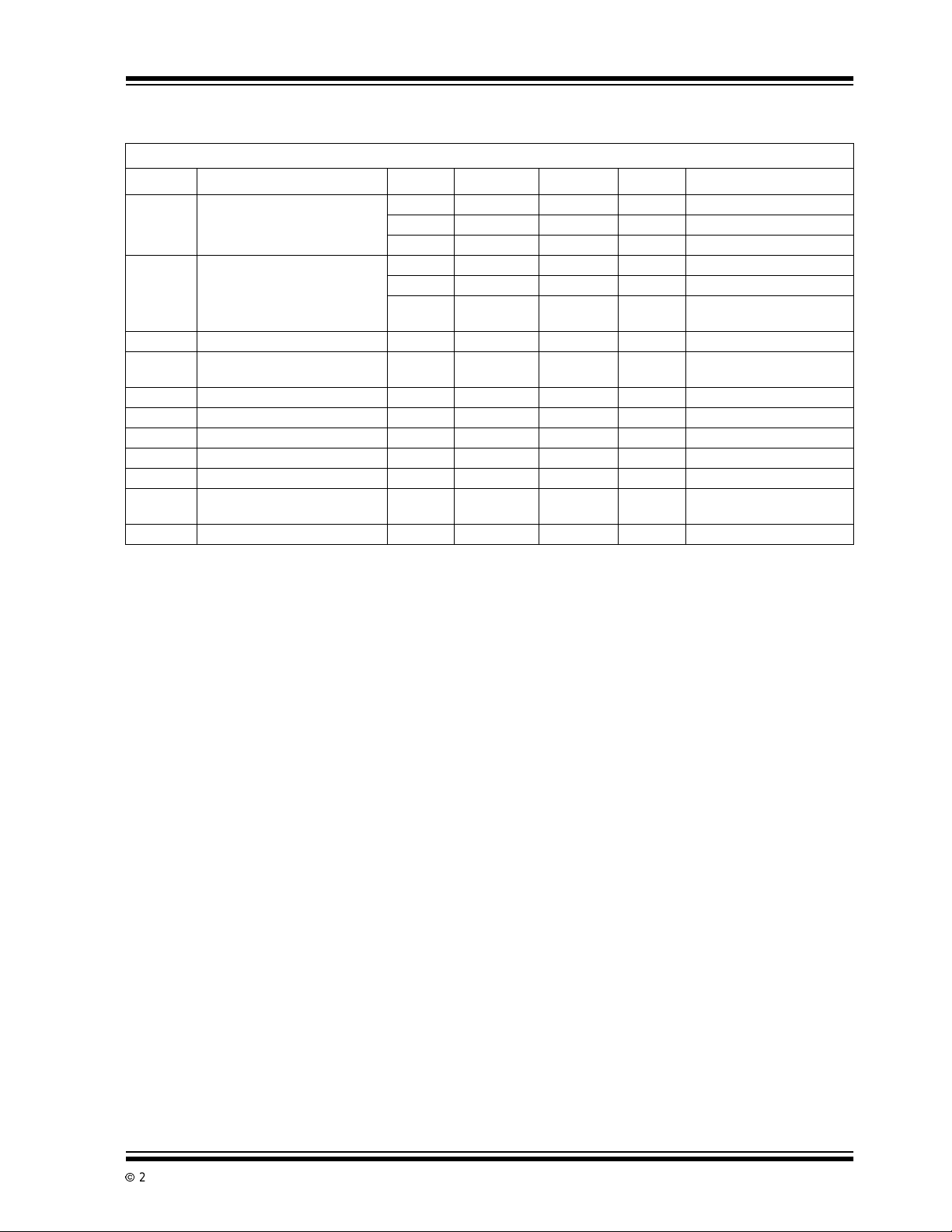

Device Selection Table

Part

Number

TC820CPL 3-3/4 Digits 40-Pin PDIP 0°Cto+70°C

TC820CKW 3-3/4Digits 44-PinPQFP 0°Cto+70°C

TC820CLW 3-3/4 Digits 44-Pin PLCC 0°Cto+70°C

2002 Microchip TechnologyInc. DS21476B-page 1

Resolution Package

Operating

Temp. Range

Page 2

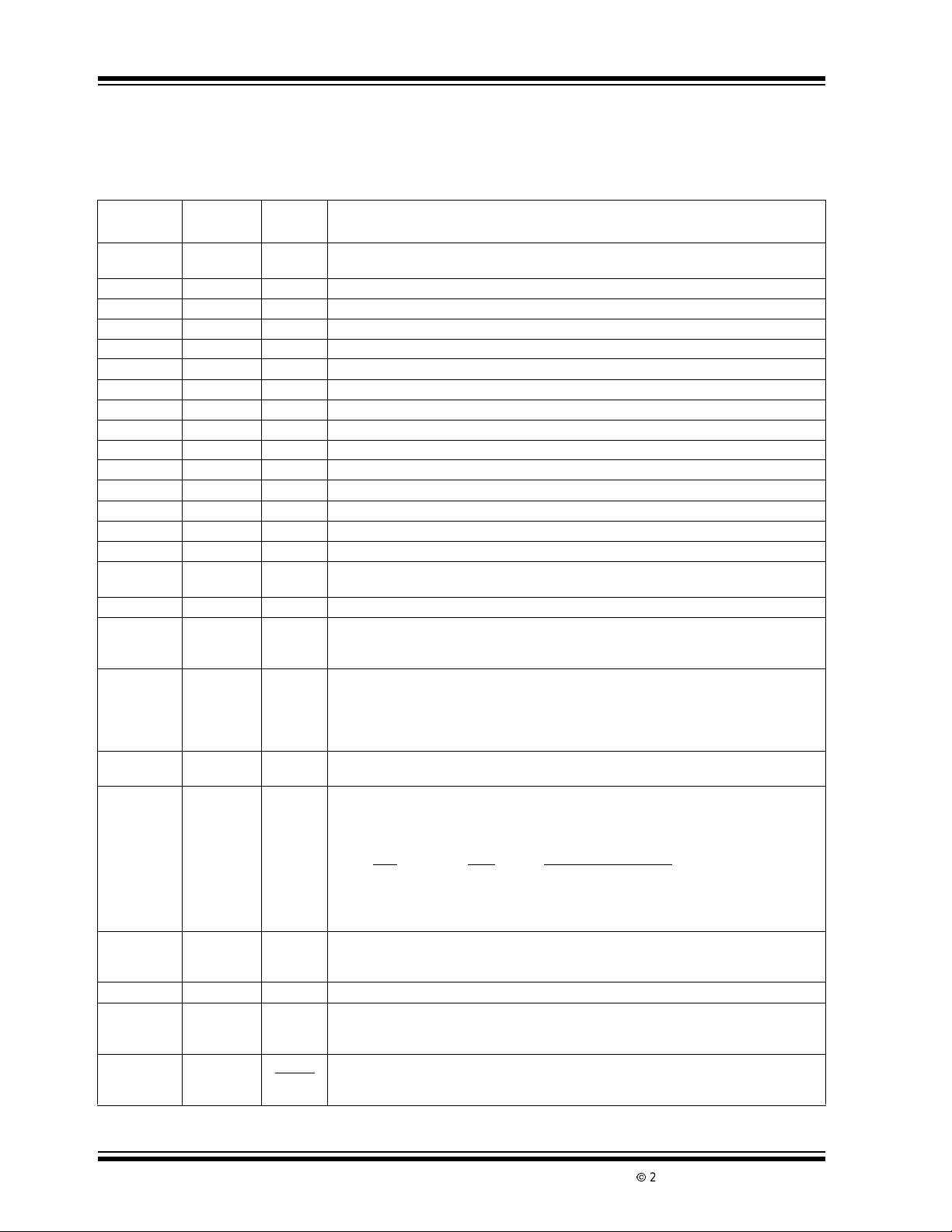

TC820

S

Package Type

44-Pin PLCC

BC3P2

OFE2

AGD2

BC2P1

PKFE1

AGD1

BP1BT

BP3

BP2

BP1

V

DISP

BC3P2

OFE2

AGD2

BC2P1

PKFE1

AGD1

BC1BT

BP3

BP2

BP1

V

DISP

AGD3

HFE3

BC4P3

6543 1442

7

8

9

10

11

12

13

14

15

16

17

18 19 20 21 23 24

DGND

AGD4

TC820CLW

LOGIC

ANNUNC

RANGE/FREQ

44-Pin PQFP

AGD3

BC4P3

HFE3

44 43 42 41 39 3840

1

2

3

4

5

6

7

8

9

10

11

12 13 14 15 17 18

DGND

AGD4

TC820CKW

LOGIC

ANNUNC

RANGE/FREQ

22

L–E4

16

DP0/LO

DD

L-E4

V

DP1/HI

DP0/LO

DD

V

DP1/HI

OSC3

OSC242OSC141EOC/HOLD

43

25

26

BUZIN

BUZOUT

FREQ/VOLTS

OSC1

OSC3

OSC2

37 36 35 34

19

20

21 22

BUZIN

BUZOUT

FREQ/VOLTS

INT

V

40

27 28

UR

PKHOLD

INT

V

EOC/HOLD

33

32

31

30

29

28

27

26

25

24

23

UR

PKHOLD

39

38

37

36

35

34

33

32

31

30

29

C

V

VIN+

V

V

V

C

C

COM

V

OR

C

AZ

V

BUFF

VIN+

V

IN

V

REF

V

REF

C

REF

C

REF

COM

V

SS

OR

AZ

BUFF

-

IN

REF

REF

REF

REF

SS

-

-

+

-

+

-

+

-

+

Segments L-E4

Segments AGD4

Segments BC4P3

Segments HFE3

Segments AGD3

Segments BC3P2

Segments OFE2

Segments AGD2

Segments BC2P1

Segments PKFE1

Segments AGD1

Segments BC1BT

BP3

BP2

BP1

DGND

ANNUNC

LOGIC

RANGE/FREQ

DP0/LO

40-Pin PDIP

1

2

3

4

5

6

7

8

9

TC820CPL

10

11

12

13

14

15

16

17

18

19

20

V

40

DD

OSC3

39

38

OSC2

OSC1

37

V

36

INT

C

35

AZ

V

34

BUFF

+

V

33

IN

-

V

32

IN

-

V

31

REF

+

V

30

REF

C

29

28

27

26

25

24

23

22

21

-

REF

+

C

REF

COM

V

SS

PKHOLD

FREQ/VOLT

BUZIN

BUZOUT

DP1/HI

DS21476B-page 2

2002 Microchip TechnologyInc.

Page 3

Typical Applications

/

TC820

Triplex LCD

EOC

Under Range

Over Range

Analog Input

Full Scale Select

Frequency Input

Logic Probe

Input

Low Drift Voltage

Differential

Reference

3-3/4 Digit A/D

Converter

Analog GND

Auto-Ranging

Frequency

Counter

Logic Probe

Digital Ground

Logic High

Logic Low

To LCD

and Buzzer

Over Range PKHold Low Batt

Clock

Oscillator

TC820

Peak Hold

Comparator

Peak

Hold

Triple LCD

Drivers

Low

Battery

Detect

+

9V

Annunciator Drive

Decimal

Point

Drivers

Buzzer

Driver

Function

Select

Volts

Frequency

Logic

Buzzer

Control

Decimal

Point

Select

Function

Select

C

REF

VIN+

VIN-

V

REF

V

REF

Common

V

DD

V

SS

+C

+

-

REF-VBUFF

DGND

C

Detect

UR OR

AZ

Low

Batt

V

INT

To LCD

A/D Control

DEINT

Under Range

Over Range

Range Frequency

Range

Input

EOC/

HOLD

EOC

÷2

TC820

PEAK

HOLD

OSC3OSC2OSC1

Logic

Low

Frequency Counter Input

A/D Counter Select

SEL

B

A

Low Batt

ANNUNC

V

÷8

DISP

BUZIN

Range

A/D Counter

(3999 Counts)

Comparator

A > B

Display

Latch

Logic

Triples

Drivers

SEG0 • • • BP3

Low

Buzzer

Driver

Range/

Frequency

Frequency

Volts

Logic

DP0/LO

15

DP1/HI

2002 Microchip TechnologyInc. DS21476B-page 3

Page 4

TC820

1.0 ELECTRICAL

CHARACTERISTICS

Absolute Maximum Ratings*

Supply Voltage (VDDto GND) ................................15V

*Stresses above those listed under "Absolute Maximum

Ratings" may cause permanent damage to the device. These

are stress ratings only and functional operation of the device

at these or any other conditions above those indicated in the

operation sections of the specifications is not implied.

Exposure to Absolute Maximum Rating conditions for

extended periods may affectdevice reliability.

Analog Input Voltage:

(Either Input) (Note 1) ............................ V

Reference Input Voltage(Either Input)....... VDDto V

DD

to V

SS

SS

Digital Inputs...........................................VDDto DGND

....................................... VDDto (DGND – 0.3V)

V

DISP

Package Power Dissipation (T

–70°C)(Note 2):

A

40-Pin Plastic DIP ......................................... 1.23W

44-Pin PLCC ..................................................1.23W

44-Pin Plastic Flat Package (PQFP) ..............1.00W

Operating Temperature Range:

"C" Devices ......................................... 0°C to +70°C

"E" Devices.......................................-40°C to +85°C

StorageTemperature Range..............-65°C to +150°C

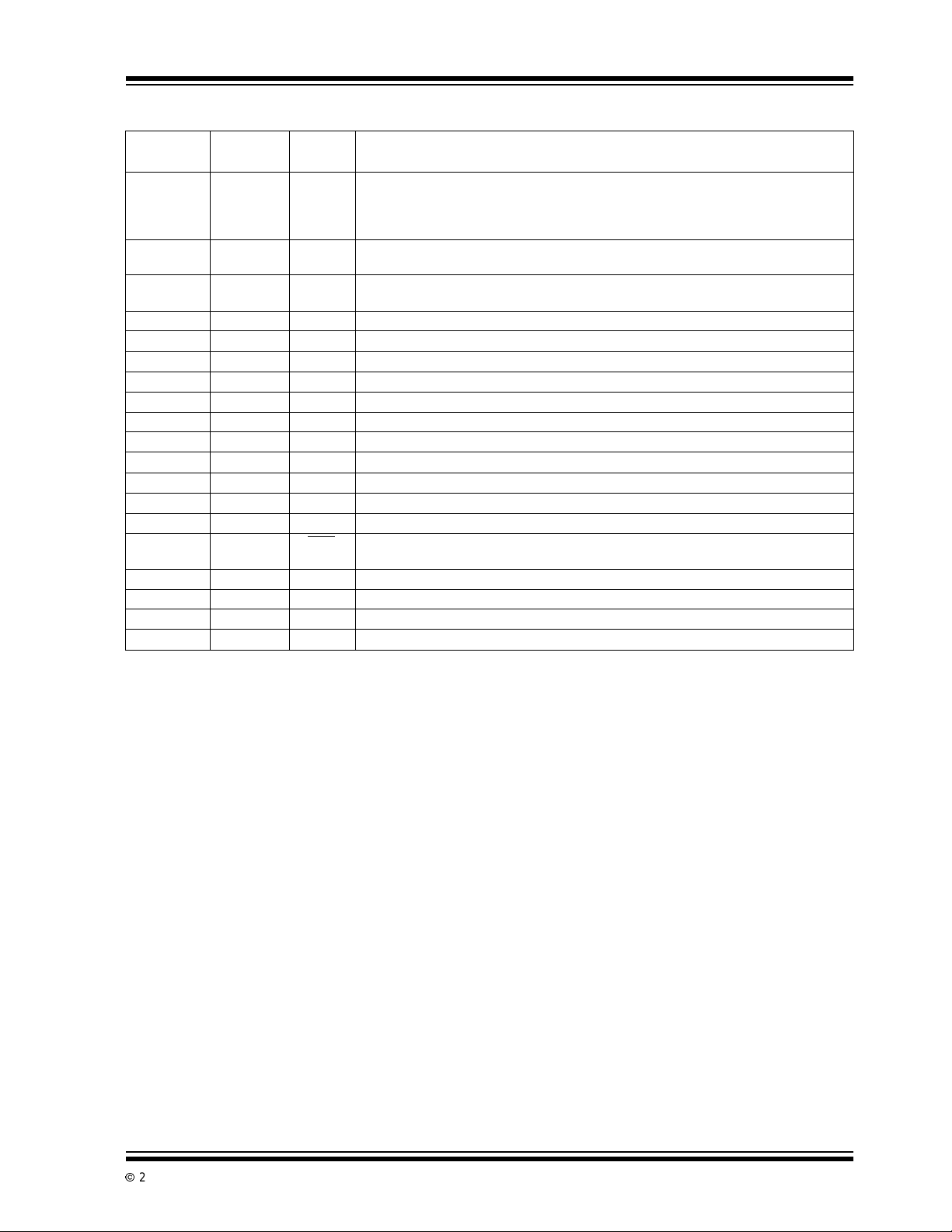

TC820 ELECTRICAL SPECIFICATIONS

Electrical Characteristics: VS=9V,TA= 25°C, unless otherwise specified.

Symbol Parameter Min Typ Max Units Test Conditions

Zero Input Reading -000 ±000 +000 Digital

Reading

RE Rollover Error -1 ±0.2 +1 Counts V

NL Nonlinearity

(Maximum Deviation From Best

Straight Line Fit)

Ratiometric Reading 1999 1999/2000 2000 — V

CMRR Common Mode Rejection Ratio — 50 — µV/V V

VCMR Common Mode Voltage Range V

e

N

I

IN

V

COM

V

CTC

Note 1: Inputvoltages may exceedthesupply voltages providedthat input currentis limited to ±100µA.Currentabove this value

Noise (P-P Value Not

Exceeded95% of Time)

Input LeakageCurrent — — — — VIN=0V

AnalogCommonVoltage 3.15 3.3 3.45 V 25kΩ between Common and

Common Voltage Temperature

Coefficient

may result in invaliddisplay readings,butwillnotdestroy the deviceif limitedt o ±1mA.

2: Dissipation ratings assumedevice is mounted with all leads solderedto printed circuit board.

-1 ±0.2 +1 Count Full Scale = 400mV

+1.5 — VDD– 1 Input High, Input Low

SS

—15 —µVVIN=0V

—1 10pAT

—20 —pA0°C≤ T

—100 —pA-40°C≤ T

—— ——25kΩ BetweenCommon and

—35 50ppm/°C0°C≤ TA≤ +70°C

—50 ——-40°C≤ T

=0V

V

IN

Full Scale= 400mV

= ±390mV

IN

Full Scale= 400mV

IN=VREF

CM

Full Scale= 400mV

(V

FS

Full Scale= 400mV

A

V

DD(VSS-VCOM

V

DD

,TC820

=±1V,VIN=0V

=200mV)

=25°C

≤ +70°C

A

≤ +85°C

A

≤ +85°C

A

)

DS21476B-page 4

2002 Microchip TechnologyInc.

Page 5

TC820

TC820 ELECTRICAL SPECIFICATIONS (CONTINUED)

Electrical Characteristics: VS=9V,TA= 25°C, unless otherwise specified.

Symbol Parameter Min Typ Max Units Test Conditions

TC

ZS

TC

FS

I

S

V

IL

V

IH

V

OL

Note 1: Inputvoltages may exceedthesupply voltages providedthat input current is limitedto±100µA. Current above thisvalue

Zero Reading Drift — — — — VIN=0V

—0.2 ——0°C≤ T

—1 ——-40°C≤ T

Scale Factor Temperature

Coefficient

—— ——V

—1 5ppm/°C0°C≤ T

— 5 — ppm/°C -40°C ≤ T

Supply Current — 1 1.5 mA VIN=0V

Peak-to-Peak Backplane

4.25 4.7 5.3 V V

Drive Voltage

Buzzer Frequency — 5 — kHz F

Counter TIme-Base Period — 1 — Second F

Low Battery Flag Voltage 6.7 7 7.3 V V

Input Low Voltage — — DGND + 1.5 V

Input High Voltage VDD–1.5 — — V

Output Low Voltage,

VDD–1.5 — DGND+0.4 V IL=50µA

UR, OR Outputs

Control Pin Pull-down Current — 5 — µAV

may result in invaliddisplay readings,butwillnotdestroy the deviceif limitedt o ±1mA.

2: Dissipation ratings assumedevice is mounted with all leads solderedto printed circuit board.

≤ +70°C

A

≤ +85°C

A

=399mV

IN

≤ +70°C

A

≤ +85°C

=9V

S

=DGND

DISP

=40kHz

OSC

=40kHz

OSC

to V

DD

IN=VDD

A

SS

Ext Ref = 0ppm/°C

V

2002 Microchip TechnologyInc. DS21476B-page 5

Page 6

TC820

2.0 PIN DESCRIPTIONS

ThedescriptionsofthepinsarelistedinTable2-1.

TABLE 2-1: PIN F UNCTION TABLE

Pin Number

(40-PDIP)

1 40 L-E4 LCD segment driver for L ("logic LOW"), polarity, and "e" segment of most significant

2 41 AGD4 LCD segment drive for "a," "g," and "d" segments of MSD.

3 42 BC4P3 LCD segmentdrivefor "b" and "c" segmentsof MSD and decimal point 3.

4 43 HFE3 LCD segment drive for H ("logic HIGH"), and "f" and "e" segmentsof third LSD.

5 44 AGD3 LCD segment drive for "a," "g," and "d" segments of third LSD.

6 1 BC3P2 LCD segmentdrive for "b" and "c" segmentsof third LSD and decimal point 2.

7 2 OFE2 LCD segmentdrive for "over range," and "f" and "e" segments of second LSD.

8 3 AGD2 LCD segment drive for "a," "g," and "d" segmentsof second LSD.

9 4 BC2P1 LCD segmentdrivefor "b " and "c" segmentsof second LSD and decimal point 1.

10 5 PKFE1 LCD segment drive for "hold peak reading," and "f" and "e" segmentsof LSD.

11 6 AGD1 LCD segment drive for "a," "g," and "d" segments of LSD.

12 7 BC1BT LCD segmentdrivefor"b"and "c" segments of LSD and "low battery."

13 8 BP3 LCD backplane#3.

14 9 BP2 LCD backplane#2.

15 10 BP1 LCD backplane#1.

—11V

16 12 DGND Internal logicdigital ground,thelogic "0" level. Nominally4.7VbelowV

17 13 ANNUNC Square-wave output at the backplane frequency, synchronized t o BP1. ANNUNC can be

18 14 LOGIC Logic mode control input. When connected to V

19 15 RANGE/

20 16 DP0/LO D ual purpose input. Decimalpoint select input for voltagemeasurements. In logic mode,

Pin Number

(44-PQFP)

Symbol Description

digit (MSD).

DISP

FREQ

Sets peak LCD drive signal: V

compensate for temperature variation of LCD crystal threshold voltage.

used to control display annunciators. Connecting an LCD segment to ANNUNC turns it

on; connecting it to its backplane turns it off.

LCD displays "OL"andthedecimal pointinputs controlthe HIGH and LOWannunciators.

When the "low" annunciator is on, the buzzer will also be on. When unconnectedor connected to DGND, the TC820 is in the Voltage/FrequencyMeasurementmode.Thispin

has a 5µA internal pull-down to DGND

Dual purposeinput. In Rangemode,whenconnected to VDD, the integration time

will be 200 counts instead of 2000 counts

connecting this pin to V

pull-down to DGND in Volts mode only. Decimalpoint logic:

willturn on the "low" LCD segment. Thereis an internal5µA

DD

PEAK

=(VDD)–V

.

DISP.VDISP

DD

mayalsobeusedto

DD

, the converteris in Logic mode. The

.

DP1

00 None

01 DP1

10 DP2

11 DP3

21 17 DP1/HI Dual purpose input. Decimalpoint selectinput for voltagemeasurements. In Logic mode,

22 18 BUZOUT Buzzer output. Audio frequency, 5kHz, output which drives a piezoelectric buzzer.

23 19 BUZIN Buzzercontrol input.Connecting BUZIN to V

24 20 FREQ/

VOLTS

DS21476B-page 6

connecting this pin to V

pull-down to DGND in Volts mode only.

OR’ed (internally)withthe "logiclevel low" input. There is an internal 5µApull-downto

DGND.

Voltage or frequencymeasurement selectinput. When unconnected,or connected

VOLTS to DGND, the A/D converter function is active. When connected to V

frequency counter function is active. This pin has an internal 5µA pull-down to DGND.

DPQ Decimal Point Selected

will turn on the "high" LCD segment. There is an internal 5µA

DD

turns the buzzer on. BUZIN is logically

DD

2002 Microchip TechnologyInc.

DD

,the

Page 7

TC820

TABLE 2-1: PIN FUNCTION TABLE (CONTINUED)

Pin Number

(40-PDIP)

25 21 PKHOLD Peak hold input. When connectedto VDD, the converter will only update the display if a

— 22 UR Under range output.Thisoutputwill be HIGH when the digitalreading is 380

— 23 OR Over range output. This output will be HIGH when the analog signal inputis greater

26 24 V

27 25 COM Analog circuit ground reference point. Nominally 3.3V below V

28 26 C

29 27 C

30 28 V

31 29 V

32 30 V

33 31 V

34 32 V

35 33 C

36 34 V

—35EOC

37 36 OSC1 Crystal oscillator (input)connection.

38 37 OSC2 Crystal oscillator (output) connection.

39 38 OSC3 RC oscillator connection.

40 39 V

Pin Number

(44-PQFP)

Symbol Description

new conversion value is greaterthanthepreceding value.Thus,thepeakreading will be

storedand held indefinitely. When unconnected, or connected to DGND, the converter

will operate normally. This pin has an internal 5µA pull-down to DGND.

countsor less.

than full scale. The LCD will display"OL"whenthe inputis over ranged.

Negative supply connection. Connect to negativeterminal of 9V battery.

SS

+ P ositive connection for referencecapacitor.

REF

- Negative connection for reference capacitor.

REF

+ High differential reference input connection.

REF

- Low differential reference input connection.

REF

- Low analog input signal connection.

IN

+ High analoginput signalconnection.

IN

Buffer output. Connect to integration resistor.

BUFF

Auto-zero capacitor connection.

AZ

Integrator output. Connect to integration capacitor.

INT

/

Bi-directionalpin. Pulses low (i.e., from VDDto DGND) at the end of each conversion. If

HOLD

connected to V

LCD segmentdrive for "a," "g,"and "d" segmentsof MSD.

DD

, conversions will continue,butthe displayisnot updated.

DD

DD

.

2002 Microchip TechnologyInc. DS21476B-page 7

Page 8

TC820

3.0 DETAILED DESCRIPTION

The TC820 is a 3-3/4 digit measurement system combining an integrating analog-to-digital converter, frequency counter, and logic level tester in a single

package. The TC820 supersedes the TC7106 in new

designs by improving performance and reducing system cost. The TC820 adds features that are difficult,

expensive,orimpossibleto provide with olderA/D converters (see Table 3-1). The high level of integration

permitsTC820basedinstruments to deliver higher performance and more f eatures, while actually reducing

partscount.Fabricated in low power CMOS, the TC820

directly drives a 3-3/4 digit (3999 maximum) LCD.

With a maximum range of 3999 counts,the TC820 provides 10 times greater resolution in the 200mV to

400mV range than traditional 3-1/2 digit meters. An

auto-zerocycleensuresazero reading with a 0V input.

CMOS processing reduces analog input biascurrent to

only 1pA. Rollover error (the difference in readings for

equal magnitude but opposite polarity input signals) is

less than ±1 count. Differential reference inputs permit

ratiometric measurements for ohms or bridge transducer applications.

The TC820's frequency counter option simplifies

design of an instrument well-suited to both analog and

digitaltroubleshooting: voltage,current,and resistance

measurements, plus precise frequency measurements

to 4MHz ( higher frequencies can be measured with an

external pr escaler), and a simple logic probe. The frequency counter will automatically adjust its range to

match the input frequency, over a four-decade range.

Two logic level measurement inputs permit a TC820

based meter to function as a logic probe. When combinedwithexternallevel shifters,theTC820willdisplay

logiclevelson the LCD and also turn on a piezoelectric

buzzer when the measured l ogic level is low.

Other TC820 features simplify instrument design and

reduce parts count. On-chip decimal point dr ivers are

included, as is a low battery detection annunciator. A

piezoelectricbuzzer can be controlled with an external

switch or by the logic probe inputs. Two oscillator

optionsareprovided: a crystalcanbeusedifhighaccuracy frequency measurements are desired, or a simple

RC option can be used for low-end instruments.

A "peak reading hold" input allows the TC820 to retain

the highest A/D or frequency reading. This feature is

useful in measuring motor starting current, maximum

temperature, and similar applications.

A family of instruments can be created with the TC820.

No additional design effort is required to create instruments with 3-3/4 digit resolution.

The TC820 operates from a single 9V battery, with typical power of 10mW.Packages include a 40-pin plastic

DIP, 44- pin plastic flat package (PQFP), and 44-pin

PLCC.

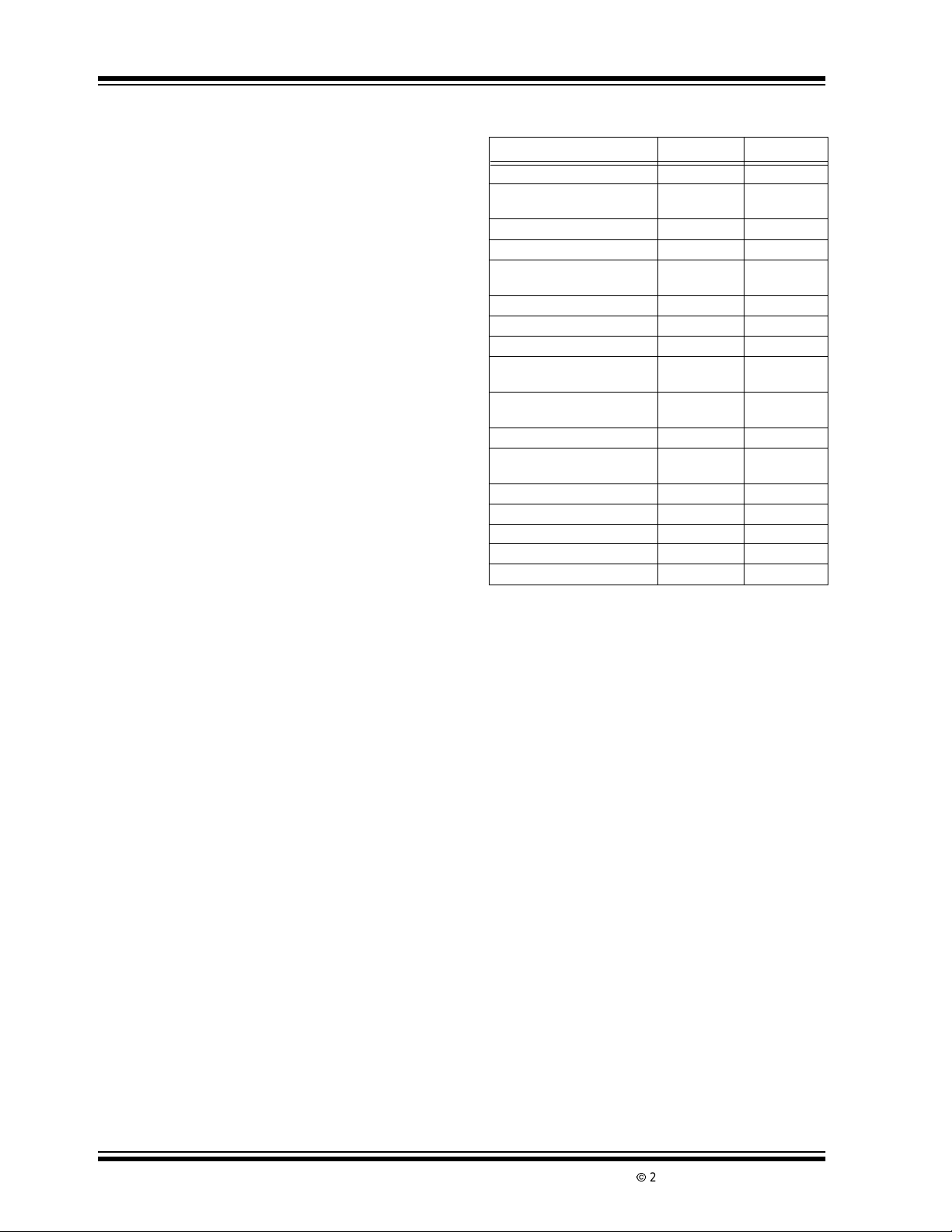

TABLE 3-1: COMPETITIVE EVALUATION

Features Comparison TC820 7106

3-3/4 Digit Resolution Yes No

Auto-Ranging Frequency

Counter

Logic Probe Yes No

Decimal Point Drive Yes No

Peak Reading Hold

(Frequency or Voltage)

Display Hold Yes No

Simple10:1RangeChange Yes No

Buzzer Drive Yes No

Low Battery Detection

withAnnunciator

Over Range Detection

withAnnunciator

Low Drift Reference Y e s No

Under Range/Over Range

Logic Output

Input Overload Display "OL" "1"

LCD Annunciator Driver Yes No

LCD Drive Type Triplexed Direct

LCD Pin Connections 15 24

LCD Elements 36 23

Yes No

Yes No

Yes No

Yes No

Yes No

3.1 General Theory of Operation

3.1.1 DUAL SLOPE CONVER SION

PRINCIPLES

The TC820 analog-to-digital converter operates on t he

principle of dual slope integration. An understanding of

the dual slope conversion technique will aid the user in

followingthedetailedTC820theoryof operationfollowing this section. A conventional dual slope converter

measurement cycle has t wo distinct phases:

1. Input Signal Integration

2. Reference Voltage Integration (De-integration)

Referring to Figure 3-1, the unknown input signal to be

convertedisintegratedfromzerofora fixedtimeperiod

(t

), measured by counting clock pulses. A constant

INT

reference voltage of the opposite polarity is then integrated until the integrator output voltage returns to

zero. The reference integration (de-integration) time

(t

) is then directly proportional to the unknown

DEINT

input voltage (V

).

IN

DS21476B-page 8

2002 Microchip TechnologyInc.

Page 9

TC820

g

T

In a simple dual slope converter, a complete conversion requires the integrator output to "ramp-up" from

zero and "ramp-down" back to zero. A simple mathematicalequationrelates the inputsignal,referencevoltage, and integration time.

EQUATION 3-1:

1

R

INTCINT

Where: V

REF

t

INT

t

DEINT

For a constant V

t

INT

V

IN

∫

0

= Ref erence Voltage

= I ntegration Time

= De- integration Time

:

INT

(t)dt =

V

REFtDEINT

R

INTCINT

EQUATION 3-2:

t

REF

DEINT

t

INT

VIN=V

FIGURE 3-1: BASIC DUAL SLOPE

CONVERTER

Analog

Input Signal

REF

Voltage

Output

Integrator

Fixed Signal

Integrate Time

R

Polarity Control

Accuracy in a dual slope converter is unrelated to the

integrating resistor and capacitor values as long as

they are stable during a measurement cycle. An inherent benefit of the dual slope technique is noise immunity. Noise spikes are integrated or averaged to zero

during the integration periods, making integrating

ADCs immune to the large conversion errors that

plague successive approximation converters in high

noise environments. Interfering signals, with frequency

components at multiples of the averaging (integrating)

period, will be attenuated (Figure 3-2). Integrating

ADCs commonly operate with the signal integration

period set to a multiple of the 50/60Hz power line

period.

C

Integrator

–

+

Switch

Driver

Phase

Control

Display

V

= V

IN

VIN = 1.2V

Variable Reference

Inte

rate Time

Comparator

–

+

Control

Logioc

REF

REF

Clock

Counter

FIGURE 3-2: NORMAL MODE

REJECTION O F DUAL

SLOPE CONVERTER

30

T = Measurement

Period

20

10

Normal Mode Rejection (dB)

0

0.1/T 1/T 10/

Input Frequency

3.2 Analog Section

In addition to the basic integrate and de-integrate dual

slope phases discussed above, the TC820 design

incorporates a "zero integrator output" phase and an

"auto-zero" phase. These additional phases ensure

thatthe integratorstartsat0V(evenaftera severe over

range conversion), and that all offset voltage errors

(buffer amplifier, integrator and comparator) are

removed f rom t he conversion. A true digital zero reading is assured without any external adjustments.

A complete conversion consists of four distinctphases:

1. Zero IntegratorOutput

2. Auto-Zero

3. Signal Integrate

4. Reference De-integrate

3.2.1 ZE RO INTEGRATOR OUTPUT

PHASE

This phase guarantees that the integrator output is at

0V before the system zero phase is entered, ensuring

that the true system offset voltages will be compensated for even after an over range conversion. The

duration of this phase is 500 counts plus the unused

de-integrate counts.

3.2.2 AUTO-ZERO PHASE

During the auto-zero phase, the differentialinputsignal

is disconnectedfrom the measurement circuit by opening internalanalogswitches,andthe internalnodesare

shortedtoAnalogCommon(0V

input condition. Additional analog switches close a

feedback loop around the integrator and comparator to

permitcomparatoroffset voltageerrorcompensation.A

voltageestablishedon C

then compensatesforinter-

AZ

nal device offset voltages during the m easurement

cycle.The auto-zerophaseresidualis typically10µVto

15µV. The auto-zero duration is 1500 counts.

)toestablishazero

REF

2002 Microchip TechnologyInc. DS21476B-page 9

Page 10

TC820

3.2.3 SIGNAL INTEGRATION PHASE

Upon completion of the auto-zero phase, the auto-zero

loop is opened and the internal differential inputs c onnect to V

+ and VIN-. The differential input signal is

IN

then integrated for a fixed time period, which is 2000

counts (4000 clock periods). The externally set clock

frequencyis divided by two before clocking the internal

counters.

The i ntegration t ime period is:

EQUATION 3-3:

4000

t

=

INT

F

OSC

The differential input voltage must be within t he

device's Common mode range when the converter and

measured system share the same power supply common (ground). If the converter and measured system

do not share the same power supply common, as in

battery powered applications, V

-shouldbetiedto

IN

analog common.

Polarity is determined at the end of signal integration

phase. The sign bit i s a "true polarity" indication, in that

signals less than 1LSB are correctly determined. This

allows precision null detection that is limited only by

device noise and auto-zero residual offsets.

3.2.4 REFERENCE INTEGRATE

(DE-INTEGRATE) PHASE

The reference capacitor,which was charged during the

auto-zero phase, is connected t o the input of the integrating amplifier. The internal sign logic ensures the

polarityof the reference voltageis always connected in

the phase opposite to that of the input voltage. This

causestheintegrator to ramp back to zero at a constant

rate, determined by the reference potential.

The amount of time required (t

) for the integrating

DEINT

amplifier to reach zero is directly proportional to the

amplitudeof the voltage that was put on the i ntegrating

capacitor(V

) during the integration phase.

INT

EQUATION 3-4:

R

t

DEINT

The digital reading displayed by the TC820 is:

Digital Count = 2000

INTCINTVINT

=

V

REF

VIN+VIN-

V

REF

The oscillator frequency is divided by 2 prior to clocking the internal decade counters. The four-phase measurement cycle takes a total of 8000 (4000) counts or

16,000clockpulses.The8000 count phaseis independent of input signal magnitude or polarity.

Each phase of the measurement cycle has the following length:

TABLE 3-2: MEASUREMENT CYCLE

PHASE LENGTH

Conversion Phase Counts

1) Auto-Zero 1500

2) Signal Integrate (Notes 1, 2) 2000

3) Reference Integrate 1 to 4001

4) IntegratorOutput Zero 499 to 4499

Note 1: This time period is fixed. The integration period for

theTC820 is:

t

(TC820) = 4000/F

INT

Where F

2: Times shown are the RANGE/FREQ at logic low (normal

operation). When RANGE/FREQ is logic high, signal

integrate times are 200 counts. See Section 3.2.7,

“10:1 Range Change”.

is the clock oscillator frequency.

OSC

= 2000 counts.

OSC

3.2.5 INPUT OVER RANGE

When the analog i nput is greater than full scale, the

LCD will di splay "OL" and the "OVER RANGE" LCD

annunciator will be on.

3.2.6 PEAK READING HOLD

The TC820 provides the capability of holding the highest (or peak) reading. Connecting the PK HOLD input

to V

each conversion, the contents of the TC820 counter

are compared to the contents of the display register. If

the new reading is higher than the reading being displayed, the higher reading is transferred to the display

register. A "higher" reading is defined as the reading

with the higher absolute value.

The peak reading is held in the display register, so the

reading will not "droop" or slowly decay with time. The

held reading will be retained until a higher r eading

occurs, the PK HOLD input is disconnected from V

or power is removed.

The peak signal to be measured must be present during the TC820 signalintegrateperiod.TheTC820 does

not performtransientpeak detectionoftheanaloginput

signal. However, in many cases, such as measuring

temperature or electric motor starting current, the

TC820 "acquisition time" will not be a limitation. If true

peak detection is required, a simple circuit will suffice.

See t he applications section for details.

The peak reading function is also available when the

TC820 is in the Frequency Counter mode. The counter

auto-ranging feature is disabled when peak reading

hold is selected.

enables the peak hold feature. At t he end of

DD

DD

,

DS21476B-page 10

2002 Microchip TechnologyInc.

Page 11

TC820

3.2.7 10:1 RANGE CHANGE

The analog input f ull scale range can be changed with

the RANGE/FREQ input. Normally, RANGE/FREQ is

held low by an internal pull-down. Connecting this pin

to V

+ will increase the full scale voltage by a factor

S

of 10. No externalcomponent changes are required.

The RANG E/FREQ input operates by changing the

integrate period. When RANGE/FREQ is connected to

V

, the signal integration phase of the conversion is

DD

reduced by a factor of 10 (i.e.,from 2000 countsto 200

counts).

For the TC820, the 10:1range change will result in ±4V

full scale.Thisfullscalerangewill exceed the Common

mode range of the input buffer when operating f rom a

9V battery.Ifrange changing is required for the TC820,

a higher supply voltage can be provided, or t he input

voltage can be divided by 2 externally.

3.3 Frequency Counter

In addition to serving as an analog-to-digital converter,

the TC820 internal counter can also function as a frequency counter (Figure 3-3). In the Counter mode,

pulses at the RANGE/FREQ input will be counted and

displayed.

The frequency counter derives its time-base from the

clock oscillator.The counter time-base is:

EQUATION 3-5:

F

t

COUNT

=

OSC

40,000

Thus, the counter will operate with a 1-second timebase when a 40kHz oscillator is used. The frequency

counter accuracy is determined by the oscillator accuracy. For accurate frequency measurements, a crystal

oscillatoris recommended.

The frequency counter will automatically select the

proper range. Auto-range operation extends over four

decades, from 3.999kHz to 3.999MHz. Decimal points

are set automaticallyinthe Frequency mode (Figure 3-4).

The logic switching levels of the RANGE/FREQ input

are CMOS levels.For best counter operation, an external buffer is recommended. See the applications section for details.

3.4 Logic Probe

The TC820 can also function as a simple logic probe

(Figure3-5). This mode is selected when the LOGIC

input is high. Two dual purpose pins, which normally

control the decimal points, are used as logic inputs.

Connecting either input to a logic high level will turn on

the corresponding LCD annunciator. When the "low"

annunciatoris on, the buzzer will be on. As with the frequency counter input, external level shifters/buffers are

recommended for the logic probe inputs.

FIGURE 3-3: TC820 COUNTER OPERATION

TC820

From Integrator

of A/D Converter

FREQ/

VOLTS

RANGE/

FREQ

Clock

Oscillator

A/D Converter/Frequency

Counter Select

Frequency Input

÷2

÷20,000

Frequency Counter

Programmable

Divider

( ÷1, 10, 100, 1000)

A/D Converter

Comparator

To Decimal

Point Drivers

Auto-Range

Control

LCD

Data Latch, Peak Hold

Register, LCD

Decoder/Drivers

Enable

3-3/4 Digit Counter

Count Overflow

Under Range

Control

Over Range

Detect

2002 Microchip TechnologyInc. DS21476B-page 11

Page 12

TC820

FIGURE 3-4: AUTO-RANGE DECIMAL POINT SELECTION V S . FREQUENCY COUNTER INPUT

DP3 DP2 DP1

f

IN

0Hz - 3999Hz

4kHz - 39.99kHz

40kHz - 399.9kHz

400kHz

FIGURE 3-5: LOGIC PROBE SIMPLIFIED SCHEMATIC

Decimal Point

DP3

DP2

DP1

NONE

LCD

High

Low

and Pulse Stretching

Logic

Probe

Input

External Logic

Level Detection

CMOS

Logic Levels

V

DD

TC820

DP0/LO

DP1/HI

LOGIC

LCD

Drivers

NC

Disable A/D Converter

To Buzzer

DS21476B-page 12

2002 Microchip TechnologyInc.

Page 13

TC820

g

When the logic probe function is selected while FREQ/

VOLTS

is low (A/D mode), the ADC will remain in the

Auto-Zero mode. The L CD will read "OL" and all

decimal points will be off (Figure 3-6).

FIGURE 3-6:

*

High

**

Low

* "High" Annuciator will be on when DP1/HI = Logic High

** "Low" Annunciator and Buzzer will be on when DP0/LO = Lo

ic High

If the logic probe is active while FREQ/VOLTS is high

(Counter mode), the f requency counter will continue to

operate. The display will read "OL" but the decimal

pointswillbe visible. If the logicprobeinput is also connected to the RANGE/FREQ input, bringing the LOGIC

input low will immediately display the frequency at t he

logic probe input.

3.5 Analog Pin Functional Description

3.5.1 DIFFERENTIAL SIGNAL INPUTS

(V

+), (VIN-)

IN

The TC820 is designed withtrue differentialinputs, and

accepts input signals within the Input Stage Common

mode voltage (V

V

–1VtoVSS+ 1.5V. Common mode voltages are

DD

removed from the system when the TC820 operates

from a battery or floating power source (isolated from

measured system) and V

common(seeFigure3-7).

In systems where Common mode voltages exist, the

86dB Common mode rejection ratio minimizes error.

Common mode voltages do, however, affect the integrator output level. A worst case condition exists if a

large, positive V

scale, negative differential signal. The negative signal

drives the integrator output positive along with V

(Figure 3-8). For such applications, the integrator output swing can be reduced below the recommended 2V

full scale swing. The integrator output will swing within

0.3V of V

,orVDDwithout increased linearity error.

DD

3.5.2 REFERENCE (VDD,VSS)

The TC820 r eference, like the analog signal input, has

true differential inputs. In addition, the reference voltage can be generated anywhere within the power supply voltage of the converter. The differential reference

inputs permit ratiometric measurements and simplify

interfacingwith sensors, suchasloadcellsandtemperature sensors.

) r ange. The typical range is

CM

is connected to analog

SS

exists in conjunction with a full

CM

CM

To prevent rollover type errors from being induced by

large Common mode voltages, C

should be large

REF

comparedtostraynodecapacitance.A0.1µFcapacitor

is typical.

The TC820 offers a significantly improved analog common temperature coefficient, providing a very stable

voltage suitable for use as a voltage reference. The

temperature coefficient of analog common i s typically

35ppm/°C.

3.5.3 ANALOG COMMON

The analog common pin is set at a voltage potential

approximately 3.3V below V

between 3.15V and 3. 45V below V

is tied internally to an N-channel FET capable of sinking 3mA. This FET will hold the common line at 3. 3V

below V

commonlinetowardV

should an external load attempt to pull the

DD

. Analog common source cur-

DD

rent is limited to 12µA, and is, therefore,easilypulledto

a more negative voltage (i.e., below V

The TC820 connects the internal V

to analog common during the auto-zero cycle. During

the reference integrate phase, V

analog common. If V

- is not externally connected to

IN

analog common, a Common mode voltage exists.

Thisisrejectedbytheconverter's86dBCommonmode

rejection ratio. In battery powered applications, analog

common and V

- are usually connected, removing

IN

Common mode voltage concerns. In systems wher e

V

- is connected to the power supply ground or to a

IN

given voltage, analog common should be connected to

V

-.

IN

The analog common pin serves to set t he analog section reference or common point. The TC820 is specifically designed to operate from a battery, or in any

“measurement"systemwhere input signals are not referenced (float), with respect to the TC820 power

source. The analog common potential of V

gives a 7V end of battery life voltage. The analog common potential has a voltage coefficient of 0.001%.

With a sufficiently high total supply voltage

(V

DD–VSS

> 7V) , analog common is a v ery stable

potential with excellent temperature stability (typically

35ppm/°C). This potential can be used to generate the

TC820 reference voltage. An external voltage reference will be unnecessary in most cases, because of

the 35ppm/°Ctemperaturecoefficient. See the applications section for details.

. This potential is

DD

. Analog common

DD

–3.3V).

DD

+ and VIN- inputs

IN

- is connected to

IN

DD

–3.3V

2002 Microchip TechnologyInc. DS21476B-page 13

Page 14

TC820

FIGURE 3-7: COMMON MODE VOLTAGE REMOVE D IN BATTERY OPERATION WITH

V

= ANALOG COMMON

IN

V+ V-

Power

Source

Measured

System

V+

V-

GND

GND

V

BUF

+

V

IN

V

-

IN

Analog

Common

C

V

AZ

REF

V

INT

TC820

V

-

REF

Segment

Drive

+

V

DD

+

9V

BP1

V

SS

BP2

OSC1

OSC2

OSC3

LCD

BP3

NC

FIGURE 3-8: COMMON MODE VOLTAGE REDUCES AVAILABLE INT EGRATOR SWING

COM

≠ VIN)

+

Input Buffer

+

C

I

R

I

(V

–

V

IN

+

Integrator

–

V

I

–

T

I

VI =

V

CM

Where:

T

= Integration Time =

I

= Integration Capacitor

C

I

= Integration Resistor

R

I

RI C

VCM – V

[

I

IN

[

4000

F

OSC

DS21476B-page 14

2002 Microchip TechnologyInc.

Page 15

TC820

4.0 FUNCTION CONTROL INPUTS

PIN

4.1 Functional D escription

The TC820 Operating modes are selected with the

function control inputs. See the control input truth,

Table 4-1. The high logic threshold is ≥ V

the low logic level is ≤ DGND +1.5V.

TABLE 4-1: T C820 CONTROL INPUT

TRUTH TABLE

Logic Input

FREQ/

VOLTS

Note 1: Logic "0" = DGND

RANGE/

FREQ

X X 1 LogicProbe

0 0 0 A/D Converter,

0 1 0 A/D Converter,

1 Frequency

Counter

Input

2: Logic "1" = V

LOGIC

0 Frequency Counter

-

DD

TC820 Function

V

FULL SCALE

V

FULL SCALE

4.1.1 FREQ/VOLTS

This input determineswhetherthe TC820 is in the Analog-to-Digital Conversion mode, or in the Frequency

Counter mode. When FREQ/VOLTS

V

, the TC820 willmeasurefrequencyatthe RANGE/

DD

FREQ input. When unconnected, or connected to

DGND, the TC820 wi ll operate as an analog-to-digital

converter. This input has an internal 5µA pull-down to

DGND.

–1.5Vand

DD

=2xV

REF

=20xV

REF

is connected to

When the TC820 analog-to-digitalconverter function is

selected, connecting RANGE/FREQ to V

will divide

DD

the integration time by 10. Therefore, the RANGE/

FREQ input can be used to perform a 10:1 range

change without changing external components.

4.1.4 DP0/LO, DP1 /HI

The function of these dual purpose pins is determined

by the LOGIC input. W hen the TC820 is in the Analogto-Digital Converter mode, these inputs control the

LCD decimal points. See the decimal point truth,

Table 4-2. These inputs have internal 5µA pull-downs

to DGND when the Voltage/Frequency Measurement

mode i s active.

TABLE 4-2: TC820 DECIMAL POINT

TRUTH TABLE

DP1 DP0 LCD

0 0 3999

0 1 399.9

10 39.99

11 3.999

Connecting the L OGIC input to V

in the Logic Probe mode. In thismode,theDP0/LO and

DP1/HI inputs control the LCD "low" and "high" annunciators directly. When DP1/HI is connected to V

"high" annunciator will turn on. When DP0/LO is connectedtoV

, the "low" annunciator and the buzzer

DD

will turn on. The internal pull-downs on these pins ar e

disabled when the logic probe function is selected.

These inputs have CMOS logic switching thresholds.

For optimum per formance as a logic probe, external

level shifters are recommended. See the applications

section for details.

places the TC820

DD

DD

,the

4.1.2 LOGIC

The LOGIC input is used to activate the logic probe

function.When connected to V

the Logic Probe mode. The LCD will show "OL" and all

decimal points will be off. The decimal point inputs

directly control "high" and "low" display annunciators.

When LOGIC is unconnected, or connected to DGND,

the TC820 will perform analog-to-digital or frequency

, the TC820 will enter

DD

4.1.5 BUZIN

This input controls the TC820 on-chip buzzer driver.

Connecting BUZIN to V

will turn the buzzer on.

DD

Thereis an external pull-downto DGND. BUZIN can be

used with external circuitry to provide additional functions, such as a fast, audible continuity indication.

4.2 Additional Features

measurements, as selected by the FREQ/VOLTS

input. The LOGIC input has an internal 5µA pull-down

to DGND.

The TC820 is available in 40-pin and 44-pin packages.

Several additional features are available in the 44-pin

package.

4.1.3 RANGE/FREQ

The function of this dual purpose pin is determined by

the FREQ/VOLTS

nectedtoV

DD

quency counter function. Pulses at this input are

counted with a time-base equal to F

this input has CMOS input levels (V

DGND +1.5V), an external buffer is recommended.

2002 Microchip TechnologyInc. DS21476B-page 15

input. When FREQ/VOLTS is con-

, RANGE/FREQ is the input for the fre-

/40,000. Since

OSC

–1.5Vand

DD

Page 16

TC820

4.2.1 EOC/HOLD

EOC/HOLD is a dual purpose, bi-directionalpin. As an

output, this pin goes low for 10 clock cycles at the end

of each conversion. This pulse latches the conversion

data into the display driver section of the TC820.

EOC

/HOLD can be used to hold(or "FREEZE") the dis-

play. Connecting this pin to V

inhibits the display

DD

update process. Conversions will continue, but the display wi ll not change. EOC

/HOLD will hold the display

reading for either analog-to-digital, or frequency

measurements.

The input/output structure of the EOC

/HOLD pin is

shown i n Figure 4-1. The output drive current is only a

few microAmps, so EOC

/HOLD can easily be overdrivenby an open collector logic gate, as well as a FET,

bipolar transistor, or mechanical switch. When used as

an output, EOC

/HOLD will have a slow rise and fall

time due to the limited output current drive. A CMOS

Schmitt trigger buffer is recommended.

FIGURE 4-1: EOC/HOLD PIN

EOC/HOLD

4

Display

Update

4.2.2 OVER RANGE (OR),

UNDER RANGE (UR)

The OR output will be high when the analog input signal is greater than full scale (3999 counts).The UR output w ill be high when the display reading is 380 counts

or less.

The OR and UR outputs can be used to provide an

auto-rangingmeter function.By logically ANDing these

outputs with the inverted EOC

/HOLD output, a single

pulse will be generated each time an under ranged or

over ranged conversion occurs (Figure 4-2).

FIGURE 4-2: GENERATING UNDER

RANGE AND OVER

RANGE PULSES

EOC/HOLD

UR

OR

*

*

*

*74HC132

TC820

TC820

≈ 500kΩ

EOC

4.2.3 V

The V

age. In the 40-pin package, V

DISP

input sets the peak-to-peak LCD drive volt-

DISP

is connected inter-

DISP

nally to DGND, providing a typical LCD drive voltage of

5V

. The 44-pin package includes a separate V

P-P

DISP

input f or applications requiring a variable or temperature compensated LCD drive voltage. See the applications information for suggested circuits.

DS21476B-page 16

2002 Microchip TechnologyInc.

Page 17

TC820

–

5.0 TYPICAL APPLICATIONS

5.1 Power Supplies

The TC820 is designed to operate from a single power

supplysuchas a 9V battery(Figure 5-1). The converter

will operateovera range of 7V to 15V. For battery operation, analog common (COM) provides a Common

mode bias voltage (see analog common discussion in

the theory of operation section). However, measurementscannotbereferencedto battery ground. To do so

will exceed the Negative Com mon mode voltage limit.

FIGURE 5-1: POWERING THE TC820

FROM A SINGLE 9V

BATTERY

TC820

V

DD

V

+

REF

+

9V

–

V

-

REF

COM

V

+

IN

V

-

IN

V

SS

+

V

IN

5.2 Digital Ground (DGND)

Digital ground is generated from an internal zener

diode (Figure 5-3). The voltage between V

DGND is the internal supply voltage for the digital section of the TC820. DGND will sink a minimum of 3mA.

DGND establishes the low logic level reference for the

TC820 mode select inputs, and for the frequency and

logic probe inputs. The DGND pin can be used as t he

negative supply for external logic gates, such as the

logic probe buffers. To ensure correct counter operation at high frequency, connect a 1µF capacitor from

DGND to V

DD

.

DGND also provides the drive voltage for the LCD. The

TC820 40-pin package internally connects the LCD

V

pin to DGND, and providesan LCD drivevoltage

DISP

of about 5V

V

pinto DGND will provide a 5V LCD drive voltage.

DISP

. In the 44-pin package, connecting the

P-P

FIGURE 5-3: DGND AND CO M

OUTPUTS

3.2V

5V

–

+

12µA

N

Logic

Section

DD

V

DD

COM

and

A battery with voltage between 3.5V and 7V can be

used to power the TC820, when used with a voltage

doubler, as shown in Figure 5-2. The voltage doubler

uses the TC7660 and two externalcapacitors. With this

configuration,measurements can be referenced either

to analog common or to battery ground.

FIGURE 5-2: POWERING THE TC820

FROM A LOW VOLTAGE

BATTERY

V

DD

V

+

+

3.5V to 6V

REF

V

REF

COM

-

TC820

+

10µF

2

4

8

TC7660

3

5

10µF

+

VIN+

V

-

IN

V

SS

+

V

IN

–

DGND

V

SS

TC820

P

N

5.3 Digital Input Logic Levels

Logic levels for the TC820 digital inputs are referenced

to V

V

DD

and DGND. The high level threshold i s

DD

– 1.5V, and the low l ogic level is DGND + 1.5V. In

most cases, digital inputs will be connected directly to

V

with a mechanical switch. CMOS gates can also

DD

be usedto controlthelogicinputs,as showninthelogic

probe inputs section.

5.4 Clock Oscillator

The TC820 oscillator can b e controlled with either a

crystal, or with an inexpensive resistor capacitor combination.Thecrystalcircuit, shown in Figure 5-4, is recommended when high accuracy is required in the

Frequency Counter mode. The 40kHz crystal is a standard frequency for ultrasonic alarms, and will provide a

1-second time-base for the counter or 2.5 analog-todigital conversions per second. Consult the crystal

manufacturerfor detailed applications information.

2002 Microchip TechnologyInc. DS21476B-page 17

Page 18

TC820

FIGURE 5-4: SUGGESTED CRYSTAL

OSCILLATOR CIRCUIT

TC820

5pF

37

40kHz

22MΩ

Where low cost is important, the RC circuit of Figure 5-5

can be used. The frequency of this circuit will be

approximately:

10pF

38 39

470kΩ

EQUATION 5-1:

T

OSC

0.3

=

RC

FIGURE 5-5: RCOSCILLATOR CIRCUIT

FIGURE 5-6: SYSTEM CLOCK

GENERATION

TC820

RC

Oscillator

Components

XTAL

Oscillator

Components

OSC1 OSC2 OSC3

A/D

Counter

Buzzer

LCD

Backplane

Driver

÷

2

÷

8

÷

240

TC820

110kΩ

10pF

75pF

5pF

37 38 39

Typical values are R = 10kΩ and C = 68pF. The resistor value should be ≥ 100kΩ. For accurate frequency

measurement, an R C oscillator frequency of 40kHz is

required.

5.5 System Timing

All system timing is derived from the clock oscillator.

The clock oscillator is divided by 2 prior to clocking the

A/D counters.The clock is also divided by 8 to drive the

buzzer, by 240 t o generate the LCD backplane frequency, and by 40,000 for the frequency counter timebase. A simplified diagram of the system clock is

shown in Figure 5-6.

Counter

Time-Base

÷

40,000

5.6 Component Value Selection

5.6.1 AUTO-ZERO CAPACITOR - C

The value of the auto-zero capacitor (CAZ)hassome

influence on system noise. A 0.47µF capacitor is recommended; a low dielectric absorption capacitor

(Mylar) is required.

5.6.2 REFERENCE VOLTAGE

CAPACITOR - C

The r eference voltage capacitor used to ramp the integrator output voltage back to zero during the reference

integrate cycle is stored on C

typical. A good quality, low leakage capacitor (such as

Mylar) should be used.

REF

.A0.1µF capacitor is

REF

AZ

DS21476B-page 18

2002 Microchip TechnologyInc.

Page 19

TC820

5.6.3 INTEGRATING CAPACITOR - C

C

should be selected to maximize integrator output

INT

INT

voltage swing without causing output saturation. Analog

common will normally supply the differential voltage reference. For this case, a ±2V integrator output swing is

optimum when the analog input is near full scale. For 2.5

readings/second (F

= 40kHz) and VFS= 400mV, a

OSC

0.22µF value is suggested. If a different oscillator frequency is used, C

must be changed in inverse pro-

INT

portion to maintain t he nominal ±2V integrator swing.

An exact expression for C

INT

is:

EQUATION 5-2:

4000 V

C

=

INT

V

INTRINTFOSC

Where: F

= Clock Frequency

OSC

= Full Scale Input Voltage

V

FS

= Integrating Resistor

R

INT

= Desired Full Scale Integrator

V

INT

Output Swing

C

must have low dielectric absorption to minimize

INT

rollover error. A polypropylene capacitor is

recommended.

5.6.4 INTEG RATING RESISTOR - R

The input buffer amplifier and integrator are designed

with class A output stages. The integrator and buffer

can supply 40µA drive currents with negligible linearity

errors. R

ear drive region, but not so large that printed circuit

board leakage currents induce er rors. For a 400mV full

scale, R

is chosen to remain in the output stage l in-

INT

should be about 100kΩ.

INT

FS

INT

In some applications, a scale factor other t han unity

may exist between a transducer output voltage and the

required digital reading. Assume, for example, that a

pressure transducer output is 800mV for 4000 l b/in

Rather than dividing the input voltageby two, the reference voltage should be set t o 400mV. This permits the

transducer input t o be used directly.

The internal voltage reference potential available at analog common will normally be used to supply the converter's reference voltage. This potential is stable

whenever the supply potential is greater than approximately 7V. The low battery detection circuit and analog

common operate from the same internal reference. This

ensures that the low battery annunciator will turn on at

the time the internalreferencebeginstoloseregulation.

The TC820 can also operate with an external reference.Figure 5-7 shows internal and externalreference

applications.

FIGURE 5-7: REFERENCE VOLTAGE

CONNECTIONS

9V

+

22kΩ

V

V

DD

SS

2kΩ

V

+

REF

TC820

SET V

(a) Internal Reference (b) External Reference

V

REF

Analog

Common

= 1/2 V

REF

V

REF

-

FULL SCALE

V

TC820

Common

DD

V

REF

V

REF

Analog

MCP1525

+

-

V

1µF

V+

V

OUT

V

IN

SS

2

.

5.7 Reference Voltage Selection

A full scale reading (4000 counts for TC820) requires

the input signal be t wice the reference voltage. See

Reference Voltage Selection, Table 5-1 below.

5.8 Ratiometric Resistance

Measurements

The TC820 true differential input and differential reference make ratiometric readings possible. In ratiometric

operation, an unknown resistance is measured with

TABLE 5-1: REF ERENCE VOLTAGE

SELECTION

Full Scale Input Voltage

(V

)(Note1)

FS

V

REF

200mV (Note 2) —

400mV 200mV 10µV

1V 500mV 250µV

2V (Notes 3, 4) 1V 500µV

Note 1: TC820 in A/D Converter mode, RANGE/FREQ =

logic low.

2: Not recommended.

3: V

4: Fullscale voltage valuesare not limitedtothe val-

2002 Microchip TechnologyInc. DS21476B-page 19

> 2V may exceedthe Input Common mode

FS

range. See Section 3.2.7, "10:1 Range Change".

ues shown. For example, TC820 V

value from 400mV to 2V.

Resolution

can be any

FS

respect to a known standard resistance. No accurately

defined reference voltage is needed.

The unknown resistance is put in series with a known

standard and a current is passed through the pair

(Figure 5-8). The voltage developed across the unknown

is applied to the input and voltages across the known

resistor applied to the reference input. If the unknown

equals the standard, the input voltage will equal the referencevoltageandthedisplaywillread2000. The displayed

reading can bedetermined from thefollowing expression:

EQUATION 5-3:

R

Displayed Reading =

The display wi ll over range for values of R

2xR

STANDARD

.

UNKNOWN

R

STANDARD

UNKNOWN

≥

Page 20

TC820

g

FIGURE 5-8: LOW PARTS COUNT

RATIOMETRIC

RESISTANCE

MEASUREMENT

V

DD

V

+

R

R

UNKNOWN

STANDARD

REF

-

V

REF

V

+

IN

TC820

-

V

IN

Analog

Common

LCD

5.9 Buffering the FREQ Input

When the FREQ/VOLTS input is high and the LOGIC

inputis low,theTC820 will count pulses at the RANGE/

FREQ input. The time-base will be F

1 second with a 40kHz clock. The signal to be measured should swing from V

to DGND. The RANGE/

DD

FREQ input has CMOS input levels without hysteresis.

For best results, especially with low frequency s inewave inputs, an external buffer with hysteresis should

be added. A typical circuit is shown in Figure 5-9.

FIGURE 5-9: FREQUENCY COUNTER

EXTERNAL BUFFER

+9V

+

1µF

V

DD

/40,000, or

OSC

TC820

FIGURE 5-10: SIMPLE EXTERNAL

LOGIC PROBE BUFFER

TC820

+9V

V

DD

LOGIC

Logic

Probe

Input

**

*74HC14

If carefully controlled logic thresholds are required, a

window comparator can be used. Figure 5-11 shows a

typical circuit. This circuit will turn on the high or low

annunciators when the logic thresholds are exceeded,

but the resistors connected from DP0/LO and DP1/HI

to DGND will turn both annunciators off when the logic

probe is unconnected.

The TC820 logic inputs are not latched internally, so

pulsesofshortdur ation willusuallybedifficultorimpossible to see. To display short pulses properly, the input

pulse should be "stretched." The circuit of Figure 5-11

shows capacitors added across the input pull-down

resistors to stretch the input pulse and permit viewing

short duration input pulses.

FIGURE 5-11: WINDOW COMPARATOR

LOGIC PROBE

DP1/HI

DP0/LO

DGND

FREQ/VOLTS

RANGE/FREQ

DGND

Frequency

Input

GND

DGND

74HC14

5.10 Logic Probe Inputs

The DP0/LO and DP1/HI inputs provide the logic probe

inputs when the LOGIC input is high. Driving either

DP0/LO or DP1/HI to a logic high w ill turn on the appropriate LCD annunciator. W hen DP0/LO is high, the

buzzer will be on.

To providea"singleinput"logic probe function,external

buffers should be used. A simple circuit is shown in

Figure 5-10. This circuitwillturntheappropriate annunciator on for high and l ow level inputs.

R1

V

H

–

1MΩ

Logic

Probe Input

1MΩ

Note: Select R1, R2, R3 for desired lo

R2

R3

+

–

V

L

+

+9V

TC820

1N4148

1N4148

ic thresholds.

V

DD

LOGIC

DP1/HI

DP0/LO

DGND

DS21476B-page 20

2002 Microchip TechnologyInc.

Page 21

TC820

5.11 External Peak Detection

The TC820 wi ll hold the highest A/D conversion or frequency reading indefinitely when the PKHOLD input is

connected to V

must be present during the A/D converter's signal i ntegrateperiod. For slowly changing signals,such as temperature, the peak reading will be pr operly converted

and held.

If rapidly changing analog signals must be held, an

external peak detector should be added. An inexpensive

circuit can be made from an op amp and a few discrete

components,asshown in Figure5-12.Thedrooprateof

theexternalpeakdetectorshouldbeadjustedso thatthe

held voltage will not decay below the desired accuracy

level during the converter's 400msec conversion time.

FIGURE 5-12: EXTERNAL PEAK

10kΩ

–

TL061

V

+

IN

. However, the analog peak input

DD

DETECTOR

+9V

V

DD

PKHOLD

1N4148

0.01µF

Offset Null

TC820

VIN+

V

SS

Other display output lines have waveforms that vary

dependingon the displaysvalues.Figure 5-13 shows a

set of waveforms for the a, g, d outputs of one digit for

several combinations of "on" segments.

FIGURE 5-14: TYPICAL DISPLAY

OUTPUT WAVEFORMS

V

DD

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

H

L

DISP

DD

H

L

DISP

DD

H

L

DISP

DD

H

L

DISP

Segment

Line

All OFF

a Segment

ON

d, g OFF

a, g ON

d OFF

All ON

TABLE 5-2: LCD BACKPLANE A ND

SEGMENT ASSIGN MENTS

0V

5.12 Liquid Crystal Display (LCD)

The TC820 drives a triplex (multiplexed 3:1) LCD with

threebackplanes.TheLCDcanincludedecimalpoints,

polarity sign, and annunciators for over range, peak

hold, high and low logic levels, and low battery.

Table 5-2 shows the assignment of the display segments to the backplanes and segment drive lines. The

backplane drive frequency is obtained by dividing the

oscillator frequency by 240.

Backplanewaveforms are shown in Figure 5-13.These

appearonoutputsBP1,BP2,andBP3. They remainthe

same, regardlessof the segmentsbeing driven.

FIGURE 5-13: BACKPLANE

WAVEFORMS

BP1

BP2

BP3

40-Pin

(PDIP)

44-Pin

(PQFP)

LCD Display

Pin Number

BP1 BP2 BP3

140 3 LOW

241 4 A4"—"

3 42 5 B4 G4 E4

4 43 6 HIGH C4 D4

544 7 A3F3DP3

61 8 B3G3E3

7 2 9 OVER C3 D3

83 10 A2F2DP2

9 4 11 B2 G2 E2

10 5 12 PEAK C2 D2

11 6 13 A1 F1 DP1

12 7 14 B1 G1 E1

13 8 2,16* — C1 D1

14 9 1 BP1 — BATT

15 10 15 LOW BP2 BP3

*Connect both pins 2 and 16 of LCD to TC820 BP3 of output.

2002 Microchip TechnologyInc. DS21476B-page 21

Page 22

TC820

5.13 LCD Source

Althoughmost users will design their own custom LCD,

a standarddisplayfortheTC820(Figure 5-15),Part No.

ST-1355-M1, is available from the followingsources:

Crystaloid (USA)

Crystaloid Electronics

P.O. Box 628

5282 Hudson Drive

Hudson, OH 44238

Phone: 216-655-2429

Crystaloid (Europe)

Rep. France

102, rue des Nouvelles

F92150 Suresnes France

Phone: 33-1-42-04-29-25

Fax: 33-1-45-06-46-99

FIGURE 5-15 : TYPICAL TC820 LCD

HIGH

LOW

OVER PEAK

PIN 1

BATT

5.15 LCD Drive Voltage (V

DISP

)

The peak-to-peak LCD drive voltage is equal to (VDD–

V

). In the 40-pin dual in-line package (DIP), V

DISP

DISP

is i nternally connected to DGND, providing a typical

LCD drive voltage of 5V

P-P

.

For applications with a wide temperature range, some

LCDs require that the drive levels vary with temperature

to maintain good viewing angle and display contrast. In

this case, the TC820 44-pin package provides a pin connection for V

. Figure 5-16 shows TC820 circuits that

DISP

can be adjusted to give a temperature compensation of

about 10mV/°C between V

between GND and V

age because V

DISP

cannot exceed 0.3V below GND.

DISP

DD

and V

. The diode

DISP

shouldhave a low turn on volt-

5.16 Crystal Source

Two sources o f the 40kHz crystal are:

Statek Corp.

512 N. Main St.

Orange, CA 92668

Phone: 714-639-7810

Fax: 714-997-1256

Part #: CX-1V-40.0

SPK Electronics

2F-1, No. 312, Sec, 4, Jen Ai Rd.

Taipei, Taiwan R.O.C.

Phone: (02) 754-2677

Fax: 886-2-708-4124

Part #: QRT-38-40.0kHz

5.14 Annunciator Output

The annunciator output is a square wave running

at the backplane frequency (for example, 167Hz when

F

= 40kHz).Thepeak-to-peakamplitude is equalto

OSC

(V

DD–VDISP

to the annunciator output turns it on; connectingit to i ts

backplane turns it off.

FIGURE 5-16: TEMPERATURE COMPENSATING CIRCUITS

). Connecting an annunciator of the LCD

1N4148

5kΩ

75kΩ

Note: Pin numbers shown are for 44-pin flat package.

39kΩ

200kΩ

–

+

1N5817 1N5817

TL071

11

12

TC820

V

DISP

DGND

V+

V-

39

24

20kΩ

18k Ω

39kΩ

2N2222

11

12

TC820

V

DISP

DGND

V+

39

24

V-

DS21476B-page 22

2002 Microchip TechnologyInc.

Page 23

6.0 PACKAGING INFORMATION

6.1 Package Marking Information

Package marking data not available at this time.

6.2 Taping Forms

Component Taping Orientation for 44-Pin PLCC Devices

User Direction of Feed

PIN 1

TC820

W

P

Standard Reel Component Orientation

for TR Suffix Device

Carrier Tape, Number of Components Per Reel and Reel Size

Package Carrier Width (W) Pitch (P) Part Per Full Reel Reel Size

44-Pin PLCC 32 mm 24 mm 500 13 in

Note: Drawing does not represent total number of pins.

Component Taping Orientation for 44-Pin PQFP Devices

User Direction of Feed

PIN 1

W

P

Standard Reel Component Orientation

for TR Suffix Device

Carrier Tape, Number of Components Per Reel and Reel Size

Package Carrier Width (W) Pitch (P) Part Per Full Reel Reel Size

44-Pin PQFP 24 mm 16 mm 500 13 in

Note: Drawing does not represent total number of pins.

2002 Microchip TechnologyInc. DS21476B-page 23

Page 24

TC820

(

)

6.3 Package Dimensions

40-Pin PDIP (Wide)

.200 (5.08)

.140 (3.56)

.150 (3.81)

.115 (2.92)

.110 (2.79)

.090 (2.29)

44-Pin PLCC

2.065 (52.45)

2.027 (51.49)

.070 (1.78)

.045 (1.14)

.022 (0.56)

.015

0.38

PIN 1

PIN 1

.555 (14.10)

.530 (13.46)

.040 (1.02)

.020 (0.51)

.015 (0.38)

.008 (0.20)

.610 (15.49)

.590 (14.99)

3° MIN.

.700 (17.78)

.610 (15.50)

Dimensions: inches (mm)

.695 (17.65)

.685 (17.40)

.656 (16.66)

.650 (16.51)

.656 (16.66)

.650 (16.51)

.695 (17.65)

.685 (17.40)

.050 (1.27) TYP.

.021 (0.53)

.013 (0.33)

.630 (16.00)

.591 (15.00)

.032 (0.81)

.026 (0.66)

.020 (0.51) MIN.

.120 (3.05)

.090 (2.29)

.180 (4.57)

.165 (4.19)

Dimensions: inches (mm)

DS21476B-page 24

2002 Microchip TechnologyInc.

Page 25

6.3 Package Dimensions (Continued)

(

TC820

44-Pin PQFP

PIN 1

.018 (0.45)

.012 (0.30)

.031 (0.80) TYP.

.398 (10.10)

.390 (9.90)

.557 (14.15)

.537 (13.65)

.398 (10.10)

.390 (9.90)

.557 (14.15)

.537 (13.65)

.009 (0.23)

.005 (0.13)

.096

7° MAX.

.041 (1.03)

.026 (0.65)

.010 (0.25) TYP.

.083 (2.10)

.075 (1.90)

2.45) MAX.

Dimensions: inches (mm)

2002 Microchip TechnologyInc. DS21476B-page 25

Page 26

TC820

SALES AND SUPPORT

Data Sheets

Products supportedby a preliminary DataSheetmayhave an erratasheetdescribing minor operational differences and recommendedworkarounds.To determine if an errata sheetexists for a particular device, please contact one of the following:

1. Your local Microchip sales office

2. TheMicrochip CorporateLiteratureCenter U.S. FAX:(480)792-7277

3. The Microchip Worldwide Site (www.microchip.com)

Pleasespecify which device, revision of silicon and Data Sheet (includeLiterature#) you are using.

New Customer Notification System

Register on our web site (www.microchip.com/cn)toreceive the most currentinformation on our products.

DS21476B-page 26

2002 Microchip TechnologyInc.

Page 27

TC820

Information contained in this publication regarding device

applications and the like is intended through suggestion only

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

No representation or warranty is given and no liability is

assumed by Microchip Technology Incorporated with respect

to the accuracy or use of such information, or infringement of

patents or other intellectual property rights arising from such

use or otherwise. Use of Microchip’s products as critical components in life support systems is not authorized except with

express written approval by Microchip. No licenses are conveyed, implicitly or otherwise, under any intellectual property

rights.

Trademarks

The Microchip name and logo, the Microchip logo, FilterLa b,

K

EELOQ,microID,MPLAB,PIC,PICmicro,PICMASTER,

PICSTART, PRO MATE, SEEVAL and The Embedded Control

SolutionsCompany areregiste red trademarksof MicrochipTechnologyIncorp or ated in the U.S.A. and other countries .

dsPIC, ECONOMONI TOR, FanSense, FlexROM, fuz z yLA B,

In-Circuit Serial Programming, ICSP, ICEPIC, microPort,

Migratable Memory, MPA SM, MPLIB, MPLINK, MPSIM,

MXDEV, PI CC, PICDEM, PICDEM.net, rfPIC, Select Mode

and Total Enduranceare trademarksofMicrochip Technology

Incorporated in the U.S.A.

Serialized Quick Turn Programming (SQTP) is a service mark

of Microchip TechnologyIncorporated in t he U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2002, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received QS-9000 quality system

certification for its worldwide headquarters,

design and wafer fabrication facilities in

Chandler and Tempe, Arizona in July 1999

and Mountain View, California in March 2002.

The Company’s quality system processes and

procedures are QS-9000 compliant for its

®

PICmicro

devices, Serial EEPROMs, microperipherals,

non-volatile memory and analog products. In

addition, Microchip’s quality system for the

design and manufacture of development

systemsisISO 9001certified.

2002 Microchip TechnologyInc. DS21476B-page 27

8-bit MCUs, KEELOQ®code hopping

Page 28

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200 Fax: 480-792-7277

Technical Support: 480-792-7627

Web Address: http://www.microchip.com

Rocky Mountain

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7966 Fax: 480-792-7456

Atlanta

500 Sugar Mill Road, Suite 200B

Atlanta, GA 30350

Tel: 770-640-0034 Fax: 770-640-0307

Boston

2 Lan Drive, Suite 120

Westford, MA 01886

Tel: 978-692-3848 Fax: 978-692-3821

Chicago

333 Pierce Road, Suite 180

Itasca, IL 60143

Tel: 630-285-0071 Fax: 630-285-0075

Dallas

4570 Westgrove Drive, Suite 160

Addison, TX 75001

Tel: 972-818-7423 Fax: 972-818-2924

Detroit

Tri-Atria Office Building

32255 Northwestern Highway, Suite 190

Farmington Hills, MI 48334

Tel: 248-538-2250 Fax: 248-538-2260

Kokomo

2767 S. Albright Road

Kokomo, Indiana 46902

Tel: 765-864-8360 Fax: 765-864-8387

Los Angeles

18201 Von Karman, Suite 1090

Irvine, CA 92612

Tel: 949-263-1888 Fax: 949-263-1338

New York

150 Motor Parkway, Suite 202

Hauppauge, NY 11788

Tel: 631-273-5305 Fax: 631-273-5335

San Jose

Microchip Technology Inc.

2107 North First Street, Suite 590

San Jose, CA 95131

Tel: 408-436-7950 Fax: 408-436-7955

Toronto

6285 Northam Drive, Suite 108

Mississauga, Ontario L4V 1X5, Canada

Tel: 905-673-0699 Fax: 905-673-6509

ASIA/PACIFIC

Australia

Microchip Technology Australia Pty Ltd

Suite 22, 41 Rawson Street

Epping 2121, NSW

Australia

Tel: 61-2-9868-6733 Fax: 61-2-9868-6755

China - Beijing

Microchip Technology Consulting (Shanghai)

Co., Ltd., Beijing Liaison Office

Unit 915

Bei Hai Wan Tai Bldg.

No. 6 Chaoyangmen Beidajie

Beijing, 100027, No. China

Tel: 86-10-85282100 Fax: 86-10-85282104

China - Chengdu

Microchip Technology Consulting (Shanghai)

Co., Ltd., Chengdu Liaison Office

Rm. 2401, 24th Floor,

Ming Xing Financial Tower

No. 88 TIDU Street

Chengdu 610016, China

Tel: 86-28-6766200 Fax: 86-28-6766599

China - Fuzhou

Microchip Technology Consulting (Shanghai)

Co., Ltd., Fuzhou Liaison Office

Unit 28F, World Trade Plaza

No. 71 Wusi Road

Fuzhou 350001, China

Tel: 86-591-7503506 Fax: 86-591-7503521

China - Shanghai

Microchip Technology Consulting (Shanghai)

Co., Ltd.

Room 701, Bldg. B

Far East International Plaza

No. 317 Xian Xia Road

Shanghai, 200051

Tel: 86-21-6275-5700 Fax: 86-21-6275-5060

China - Shenzhen

Microchip Technology Consulting (Shanghai)

Co., Ltd., Shenzhen Liaison Office

Rm. 1315, 13/F , Shenzhen Kerry Centre,

Renminnan Lu

Shenzhen 518001, China

Tel: 86-755-2350361 Fax: 86-755-2366086

Hong Kong

Microchip Technology Hongkong Ltd.

Unit 901-6, Tower2, Metroplaza

223 Hing Fong Road

Kwai Fong, N.T., Hong Kong

Tel: 852-2401-1200 Fax: 852-2401-3431

India

Microchip Technology Inc.

India Liaison Office

Divyasree Chambers

1 Floor, Wing A (A3/A4)

No. 11, O’Shaugnessey Road

Bangalore, 560 025, India

Tel: 91-80-2290061 Fax: 91-80-2290062

Japan

Microchip Technology Japan K.K.

Benex S-1 6F

3-18-20, Shinyokohama

Kohoku-Ku, Yokohama-shi

Kanagawa, 222-0033, Japan

Tel: 81-45-471- 6166 Fax: 81-45-471-6122

Korea

Microchip Technology Korea

168-1, Youngbo Bldg. 3 Floor

Samsung-Dong, Kangnam-Ku

Seoul, Korea 135-882