Page 1

Color Television Chassis

TC8.1L

CA

H_17630_000.eps

271107

Contents Page

1. Technical Specifications, Connections, and Chassis

Overview 2

2. Safety Instructions, Warnings, and Notes 3

3. Directions for Use 4

4. Mechanical Instructions 5

5. Service Modes, Error Codes, and Fault Finding 7

6. Block Diagrams, Test Point Overview, and

Waveforms

Block Diagram Mono Carrier 13

7. Circuit Diagrams and PWB Layouts

Mono Carrier (A) 14 15-16

CRT Panel (B) 17 17

BTSC Panel (BTSC) 18 18

Side AV & I/O Panel (D) 19 19

8. Alignments 21

9. Circuit Descriptions, Abbreviation List, and IC Data

Sheets 24

Abbreviation List 30

10. Spare Parts List 31

11. Revision List 34

©

Copyright 2007 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by JY 0771 BU CD Customer Service Printed in the Netherlands Subject to modification EN 3122 785 17630

Page 2

EN 2 TC8.1L CA1.

Technical Specifications, Connections, and Chassis Overview

1. Technical Specifications, Connections, and Chassis Overview

Index of this chapter:

1.1 Technical Specifications

1.2 Side and Rear Connections

1.3 Chassis Overview

Notes:

• Figures can deviate due to the different set executions.

• Specifications are indicative (subject to change).

1.1 Technical Specifications

1.1.1 Vision

Display type : CRT, Pure Flat

Screen size : 21” (55 cm), 4:3

Tuning system : PLL

Presets/channels : 181

Tuner bands : Full-Cable

TV color systems : NTSC-M (3.58+4.5)

Video playback : NTSC, PAL

Aerial input : 75 ohm, IEC-type

1.1.2 Sound

Sound systems : Stereo BTSC

: Stereo SAP

Maximum power (W

1.1.3 Miscellaneous

Power supply:

- Mains voltage (V

- Mains frequency (Hz) : 50 / 60

Ambient conditions:

- Temperature range (°C) : +5 to +40

- Maximum humidity : 90% R.H.

):2 × 5

RMS

) : 100 - 240

AC

1.2 Side and Rear Connections

Figure 1-1 Rear and Side I/O connections

Note: The following connector color abbreviations are used

(acc. to DIN/IEC 757): Bk= Black, Bu= Blue, Gn= Green, Gy=

Grey, Rd= Red, Wh= White, and Ye= Yellow.

1.2.1 Rear I/O Connections

Cinch: Video YPbPr - In

Gn - Video Y 1 V

Bu - Video Pb 0.7 V

Rd - Video Pr 0.7 V

Cinch: Video CVBS - In, Audio - In

Ye - Video (CVBS) 1 V_pp / 75 ohm jq

Wh - Audio - L 0.5 V_rms / 10 kohm jq

Rd - Audio - R 0.5 V_rms / 10 kohm jq

Cinch: Video CVBS - Out, Audio - Out

Ye - Video (CVBS) 1 V_pp / 75 ohm kq

Wh - Audio - L 0.5 V_rms / 10 kohm kq

Rd - Audio - R 0.5 V_rms / 10 kohm kq

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 75 ohm jq

PP

OPTIONAL

H_17630_014.eps

271107

Power consumption (values are indicative)

- Normal operation (W) : ≈ 84 (/85)

: ≈ 74 (/44)

- Stand-by (W) : < 7

Dimensions (W × H × D mm) : 594 × 458 × 486

Weight (kg) : 21.6

1.3 Chassis Overview

CRT PANEL

B

SIDE AV PANEL +

D

HEADPHONE

Aerial In

- IEC-type Coax, 75 ohm D

1.2.2 Side I/O Connections (optional)

AV In

Ye - Video (CVBS) 1 V_pp / 75 ohm jq

Wh - Audio - L 0.5 V_rms / 10 kohm jq

Rd - Audio - R 0.5 V_rms / 10 kohm jq

MONO CARRIER

BTSC PANEL

BTSC

H_17130_039.eps

291107

A

Figure 1-2 PWB/CBA locations (depending on model)

Page 3

Safety Instructions, Warnings, and Notes

2. Safety Instructions, Warnings, and Notes

EN 3TC8.1L CA 2.

Index of this chapter:

2.1 Safety Instructions

2.2 Maintenance Instructions

2.3 Warnings

2.4 Notes

2.1 Safety Instructions

Safety regulations require the following during a repair:

• Connect the set to the Mains/AC Power via an isolation

transformer (> 800 VA).

• Replace safety components, indicated by the symbol h,

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

• Wear safety goggles when you replace the CRT.

Safety regulations require that after a repair, the set must be

returned in its original condition. Pay in particular attention to

the following points:

• General repair instruction: as a strict precaution, we advise

you to re-solder the solder connections through which the

horizontal deflection current flows. In particular this is valid

for the:

1. Pins of the line output transformer (LOT).

2. Fly-back capacitor(s).

3. S-correction capacitor(s).

4. Line output transistor.

5. Pins of the connector with wires to the deflection coil.

6. Other components through which the deflection current

flows.

Note: This re-soldering is advised to prevent bad connections

due to metal fatigue in solder connections, and is therefore only

necessary for television sets more than two years old.

• Route the wire trees and EHT cable correctly and secure

them with the mounted cable clamps.

• Check the insulation of the Mains/AC Power lead for

external damage.

• Check the strain relief of the Mains/AC Power cord for

proper function, to prevent the cord from touching the CRT,

hot components, or heat sinks.

• Check the electrical DC resistance between the Mains/AC

Power plug and the secondary side (only for sets that have

a Mains/AC Power isolated power supply):

1. Unplug the Mains/AC Power cord and connect a wire

between the two pins of the Mains/AC Power plug.

2. Set the Mains/AC Power switch to the “on” position

(keep the Mains/AC Power cord unplugged!).

3. Measure the resistance value between the pins of the

Mains/AC Power plug and the metal shielding of the

tuner or the aerial connection on the set. The reading

should be between 4.5 Mohm and 12 Mohm.

4. Switch “off” the set, and remove the wire between the

two pins of the Mains/AC Power plug.

• Check the cabinet for defects, to prevent touching of any

inner parts by the customer.

2.2 Maintenance Instructions

We recommend a maintenance inspection carried out by

qualified service personnel. The interval depends on the usage

conditions:

• When a customer uses the set under normal

circumstances, for example in a living room, the

recommended interval is three to five years.

• When a customer uses the set in an environment with

higher dust, grease, or moisture levels, for example in a

kitchen, the recommended interval is one year.

• The maintenance inspection includes the following actions:

1. Perform the “general repair instruction” noted above.

2. Clean the power supply and deflection circuitry on the

chassis.

3. Clean the picture tube panel and the neck of the picture

tube.

2.3 Warnings

• In order to prevent damage to ICs and transistors, avoid all

high voltage flashovers. In order to prevent damage to the

picture tube, use the method shown in figure “Discharge

picture tube”, to discharge the picture tube. Use a high

voltage probe and a multi-meter (position V

until the meter reading is 0 V (after approx. 30 s).

V

Figure 2-1 Discharge picture tube

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD w). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are connected with the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools also at this same potential.

• Be careful during measurements in the high voltage

section.

• Never replace modules or other components while the unit

is switched “on”.

• When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and prevents circuits

from becoming unstable.

2.4 Notes

2.4.1 General

• Measure the voltages and waveforms with regard to the

chassis (= tuner) ground (H), or hot ground (I), depending

on the tested area of circuitry. The voltages and waveforms

shown in the diagrams are indicative. Measure them in the

Service Default Mode (see chapter 5) with a color bar

signal and stereo sound (L: 3 kHz, R: 1 kHz unless stated

otherwise) and picture carrier at 475.25 MHz for PAL, or

61.25 MHz for NTSC (channel 3).

• Where necessary, measure the waveforms and voltages

with (D) and without (E) aerial signal. Measure the

voltages in the power supply section both in normal

operation (G) and in stand-by (F). These values are

indicated by means of the appropriate symbols.

• The semiconductors indicated in the circuit diagram and in

the parts lists, are interchangeable per position with the

semiconductors in the unit, irrespective of the type

indication on these semiconductors.

). Discharge

DC

E_06532_007.eps

250304

Page 4

EN 4 TC8.1L CA3.

Directions for Use

2.4.2 Schematic Notes

• All resistor values are in ohms, and the value multiplier is

often used to indicate the decimal point location (e.g. 2K2

indicates 2.2 kohm).

• Resistor values with no multiplier may be indicated with

either an “E” or an “R” (e.g. 220E or 220R indicates 220

ohm).

• All capacitor values are given in micro-farads (μ= × 10

nano-farads (n= × 10

-9

), or pico-farads (p= × 10

• Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

• An “asterisk” (*) indicates component usage varies. Refer

to the diversity tables for the correct values.

• The correct component values are listed in the Spare Parts

List. Therefore, always check this list when there is any

doubt.

2.4.3 Lead-free Soldering

Due to lead-free technology some rules have to be respected

by the workshop during a repair:

• Use only lead-free soldering tin Philips SAC305 with order

code 0622 149 00106. If lead-free solder paste is required,

please contact the manufacturer of your soldering

equipment. In general, use of solder paste within

workshops should be avoided because paste is not easy to

store and to handle.

• Use only adequate solder tools applicable for lead-free

soldering tin. The solder tool must be able:

– To reach a solder-tip temperature of at least 400°C.

– To stabilize the adjusted temperature at the solder-tip.

– To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature of around

360°C - 380°C is reached and stabilized at the solder joint.

Heating time of the solder-joint should not exceed ~ 4 sec.

Avoid temperatures above 400°C, otherwise wear-out of

tips will increase drastically and flux-fluid will be destroyed.

To avoid wear-out of tips, switch “off” unused equipment or

reduce heat.

• Mix of lead-free soldering tin/parts with leaded soldering

tin/parts is possible but PHILIPS recommends strongly to

avoid mixed regimes. If this cannot be avoided, carefully

clear the solder-joint from old tin and re-solder with new tin.

2.4.4 Alternative BOM identification

The third digit in the serial number (example:

BF2A0635000001) indicates the number of the alternative

-12

B.O.M. (Bill Of Materials) that has been used for producing the

specific TV set. In general, it is possible that the same TV

model on the market is produced with e.g. two different types

of displays, coming from two different suppliers. This will then

result in sets which have the same CTN (Commercial Type

Number; e.g. 28PW9515/12) but which have a different B.O.M.

number.

By looking at the third digit of the serial number, one can

-6

),

).

identify which B.O.M. is used for the TV set he is working with.

If the third digit of the serial number contains the number “1”

(example: BF1A063500001), then the TV set has been

manufactured according to B.O.M. number 1. If the third digit is

a “2” (example: BF2A0635000001), then the set has been

produced according to B.O.M. no. 2. This is important for

ordering the correct spare parts!

For the third digit, the numbers 1...9 and the characters A...Z

can be used, so in total: 9 plus 26= 35 different B.O.M.s can be

indicated by the third digit of the serial number.

Identification: The bottom line of a type plate gives a 14-digit

serial number. Digits 1 and 2 refer to the production center (e.g.

AG is Bruges), digit 3 refers to the B.O.M. code, digit 4 refers

to the Service version change code, digits 5 and 6 refer to the

production year, and digits 7 and 8 refer to production week (in

example below it is 2006 week 17). The 6 last digits contain the

serial number.

MODEL :

PROD.NO:

32PF9968/10

AG 1A0617 000001

MADE IN BELGIUM

220-240V 50/60Hz

~

VHF+S+H+UHF

BJ3.0E LA

S

128W

E_06532_024.eps

130606

Figure 2-2 Serial number (example)

2.4.5 Practical Service Precautions

• It makes sense to avoid exposure to electrical shock.

While some sources are expected to have a possible

dangerous impact, others of quite high potential are of

limited current and are sometimes held in less regard.

• Always respect voltages. While some may not be

dangerous in themselves, they can cause unexpected

reactions that are best avoided. Before reaching into a

powered TV set, it is best to test the high voltage insulation.

It is easy to do, and is a good service precaution.

3. Directions for Use

You can download this information from the following websites:

http://www.philips.com/support

http://www.p4c.philips.com

Page 5

4. Mechanical Instructions

Mechanical Instructions

EN 5TC8.1L CA 4.

Index of this chapter:

4.1 Set Disassembly

4.2 Assy / Board Removal

4.3 Service Positions

4.4 Set Re-assembly

Note: Figures below can deviate slightly from the actual

situation, due to the different set executions.

4.1 Set Disassembly

Follow the disassemble instructions in described order.

4.1.1 Rear Cover Removal

Warning: disconnect the mains power cord before you remove

the rear cover.

1. Remove all the fixation screws of the rear cover [1] and [2].

2. Now, pull the rear cover backwards and remove it.

1

4.2 Assy / Board Removal

Sometimes, it can be necessary to swap a complete assy or

Printed Wiring Board (PWB). How that can be done is

explained below.

4.2.1 Side IO/Keyboard Panel Removal

1. Remove the fixation screws [3].

2. Remove the module from the TV.

1

3

1

1

1

Figure 4-1 Rear Cover removal (SL5 styling)

2

2

H_17130_036.eps

1

070507

H_17130_040.eps

Figure 4-2 Side-IO/Keyboard panel removal (SL5 styling)

070507

Page 6

EN 6 TC8.1L CA4.

s

4.2.2 Mono Carrier Removal

1. First, disconnect the strain relief of the AC power cord [4].

2. Disconnect all the necessary cables [5].

3. To remove the Mono Carrier; release the clamps [6] and

slide the whole panel backwards [7] (= away from the

front).

4. Slide the panel away from the cabinet.

Mechanical Instructions

14

4.3 Service Positions

Figure 4-6 Mono carrier removal [4/4]

H_17130_023.eps

240407

Figure 4-3 Mono carrier removal [1/4]

15

Figure 4-4 Mono carrier removal [2/4]

H_17130_025.ep

H_17130_026.eps

For easy measurements, you can use the following service

position.

4.3.1 Service Position Mono Carrier

Removing cables and repositioning the panel

For better accessibility of the Mono Carrier, do the following

(see next figure):

1. If necessary, disconnect some cables, and move the panel

somewhat to the left. Then flip it 90 degrees with its

components towards the CRT.

16

Figure 4-5 Mono carrier removal [3/4]

16

H_17130_027.eps

H_17130_024.eps

240407

Figure 4-7 Service position Mono Carrier

17

4.4 Set Re-assembly

To re-assemble the whole set, do all processes in reverse

order.

Be sure that, before the rear cover is mounted:

• The mains cord is positioned correctly in its guiding

brackets (make sure that the strain relief is replaced in its

correct position and that it will function correctly!).

• All wires/cables are returned in their original positions.

Page 7

Service Modes, Error Codes, and Fault Finding

5. Service Modes, Error Codes, and Fault Finding

EN 7TC8.1L CA 5.

Index of this chapter:

5.1 Service Modes

5.2 Error Codes

5.3 Fault Finding

5.1 Service Modes

For an explanation of the Factory Mode, see chapter 8

“Alignments”.

5.2 Error Codes

Not applicable for this chassis.

5.3 Fault Finding

5.3.1 No Picture, No Sound, No Raster, Fuse Broken

No Picture, no sound, no raster, Fuse Broken

Is D833+

(B+)

Shorted to

earth?

YES

Check

(B+)

C of Q402

NO

Is D of Q801

NO

Shorted to

to earth?

YES

Check

Q801

Figure 5-1 Flow chart “No Picture, No Sound, No Raster, Fuse Broken”.

Is D801-

D804

OK?

YES

Check

IC 801

NO

Replace

D801-D804

H_17130_010.eps

070507

Page 8

EN 8 TC8.1L CA5.

5.3.2 No Picture, No Sound, No Raster, B+ OK

No Picture, no sound, no raster, B+ OK

Service Modes, Error Codes, and Fault Finding

Check

5V supply

pin 9 of IC 201

OK?

No

Is IC201

Pin9 shorted to

earth ?

No

Check

+5V,+9V Circuit

Figure 5-2 Flow chart “No Picture, No Sound, No Raster, B+ OK”.

5.3.3 No Picture, Raster and Sound OK

Yes

Check

H out waveform

Pin 13 of IC 201

OK?

Yes

Check

waveform

C of Q401

OK?

Yes

oNoN

Yes

Replace

IC 201

Replace

Q401or R401

No Picture, Raster & Sound OK

Check

waveform

C of Q402

OK?

No

Replace

Q402

H_17130_011.eps

070507

Check RGB O/P

Pin 49,50,51,52

of IC 201 OK?

Yes

Check

RGB drive O/P

Q501, Q502 &

Q503

No

Is Pin ,50,51,52

shorted to

earth?

No

Check

9 volt Supply

& Q208

Yes

Replace

IC 201

Figure 5-3 Flow chart “No Picture, Raster and Sound OK”.

H_17130_012.eps

070507

Page 9

5.3.4 Picture OK, No Sound

Service Modes, Error Codes, and Fault Finding

Picture OK, No sound

EN 9TC8.1L CA 5.

Check Vcc

Pin 13 of IC601

OK?

Yes

Check Vol

Pin 3 & Mute Pin10 of IC601 OK?

Yes

Check audio O/P

R & L of IC 601

OK?

No

Check audio I/P

R & L of IC 601

OK?

Yes

Replace

IC 601

No

Yes

R & L speaker

No

Pin31wave of

Check IF circuit

Figure 5-4 Flow chart “Picture OK, No Sound”.

Check +22v

Circuit

Check

Check

IC201 OK?

No

or Replace

IC201

NO

Check

Q624,Q625,Q093 is

OK?

Yes

Check

Pin 59 of IC 201

Yes

Check

BTSC

Module(IC1001)

OK?

Change the damage

component

or Replace BTSC Module

No

No

Change the

damaged

component

H_17630_015.eps

271107

5.3.5 No Color

Local system

Colour

system is

Right?

No

Reset

To

Yes

Dose the TV

signal too

weak?

Check

Tuner Input

cable & antenna

Figure 5-5 Flow chart “No Color”.

No colour

YES

NO

Check

Pin 6 & 7 of

IC 201 OK?

YES

Check

Pin 47 of IC

201

NO

Check

X001, C021

& C022

H_17130_014.eps

070507

Page 10

EN 10 TC8.1L CA5.

5.3.6 One Horizontal Line

Service Modes, Error Codes, and Fault Finding

One horizontal line

Check

Deflection yoke

No

Replace

Yoke coil

Terminal OK?

Yes

Check

+24v supply

Pin 2 of IC 301

OK?

No

Check

R405 (Fuse)

D402

Yes

Check

V output

Pin 5 of IC 301

OK?

No

Check

V input

Pin 1 of IC 301

OK?

Yes

Check

R314, C301,

R317,R336, C309

Figure 5-6 Flow chart “One Horizontal Line”.

Check

V output

Pin 16 of IC 201

No

H_17130_015.eps

070507

Page 11

5.3.7 Some Waveforms:

Figure 5-7 FBP pin 12 of IC201

Service Modes, Error Codes, and Fault Finding

H_17130_016.eps

240407

Figure 5-10 Q815 drain when stand-by

EN 11TC8.1L CA 5.

H_17130_021.eps

240407

Figure 5-8 H_out pin 13 of IC201

Figure 5-9 Q402 C

H_17130_017.eps

240407

H_17130_020.eps

240407

Figure 5-11 Q815 drain

H_17130_022.eps

240407

Page 12

EN 12 TC8.1L CA5.

Personal Notes:

Service Modes, Error Codes, and Fault Finding

E_06532_012.eps

131004

Page 13

Block Diagrams, Test Point Overview, and Waveforms

6. Block Diagrams, Test Point Overview, and Waveforms

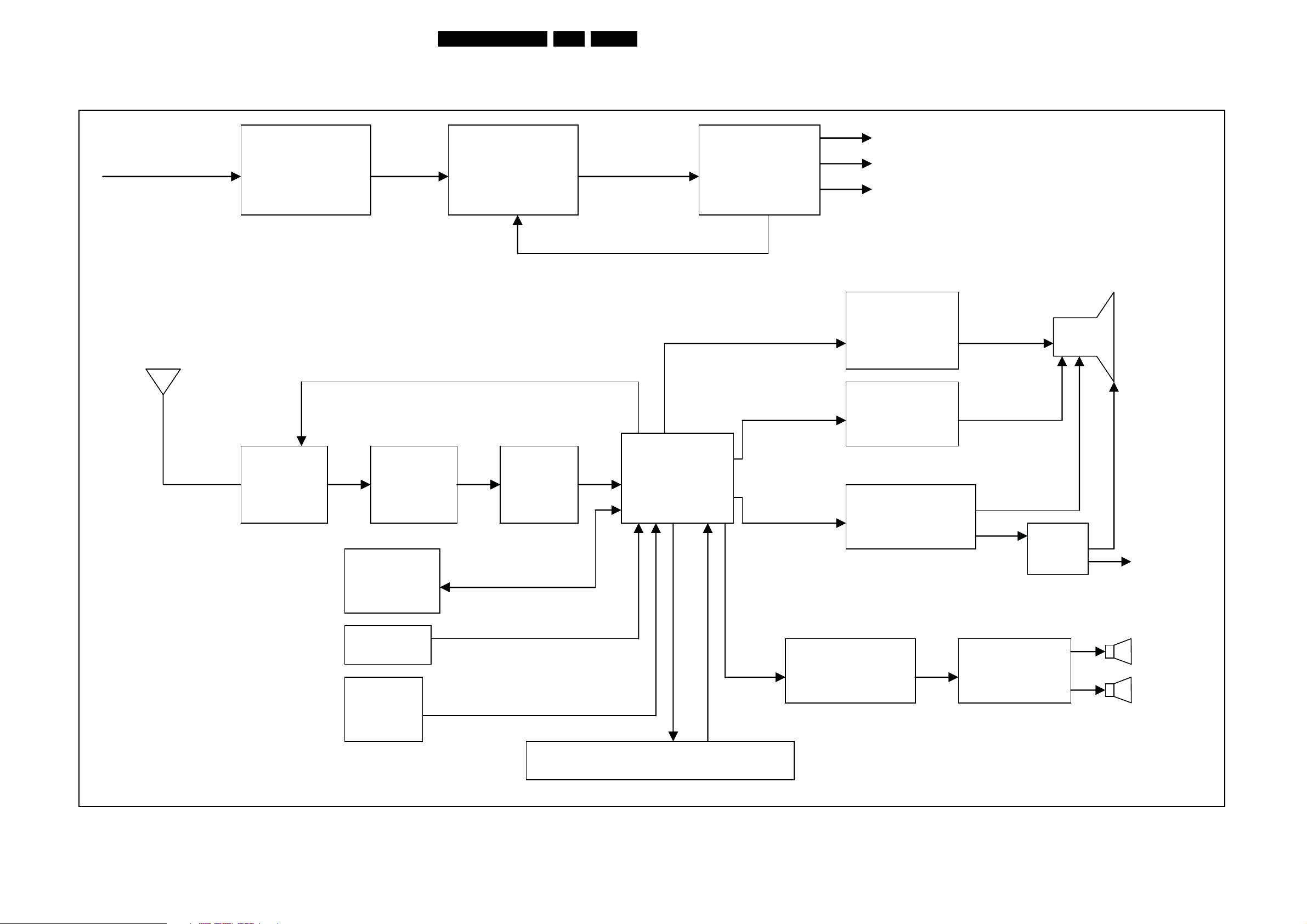

Block Diagram Mono Carrier

Q815 IC801

110 - 240V~

D801—D804

TEA1506

Power

13TC8.1L CA 6.

112V

T803

22V

Transformer

12V

Optical coupling

Video Amp.

Tuner

TU101

Signal Process

IF AMP

Q101

E2PROM

IC001

KEY

IR001

AGC

SAW

F1859

Tosh i ba

8891\8893

IC201

R/G/B

V.out

H.out

SIF

CRT Board

V. A m p .

IC301

H.Drive AMP

Q401 Q402

MSP 3425

IC1001

FBT

T402

Audio Amp.

IC601

CRT R/G/B

EHT

FOCUS

SCREEN

175V, 24V

Sensor

Interface: AV1;AV2;YUV;AV-Out

Speaker

H_17630_001.eps

291107

Page 14

Circuit Diagrams and PWB Layouts

7. Circuit Diagrams and PWB Layouts

Mono Carrier

MONO CARRIER

A A

14TC8.1L CA 7.

40-TB59PH-MAE1XG

H_17630_002.eps

201107

Page 15

Circuit Diagrams and PWB Layouts

Layout Mono Carrier (Top Side)

15TC8.1L CA 7.

40-TB59PH-MAE1XG

H_17630_003.eps

201107

Page 16

Circuit Diagrams and PWB Layouts

Layout Mono Carrier (Bottom Side)

16TC8.1L CA 7.

40-TB59PH-MAE1XG

H_17630_004.eps

221107

Page 17

Circuit Diagrams and PWB Layouts

17TC8.1L CA 7.

CRT Panel

B B

CRT PANEL

Layout CRT Panel (Top Side)

40-TB93PH-MAF1XG

H_17630_005.eps

201107

40-TB93PH-MAF1XG

H_17630_006.eps

201107

Page 18

Circuit Diagrams and PWB Layouts

18TC8.1L CA 7.

BTSC Panel

BTSC BTSC

BTSC PANEL

Layout BTSC Panel (Top Side)

40-TB59PH-MPC1XG

H_17630_005.eps

201107

40-TB59PH-MPC1XG

Layout BTSC Panel (Bottom Side)

H_17630_009.eps

201107

40-TB59PH-MPC1XG

H_17630_010.eps

201107

Page 19

Circuit Diagrams and PWB Layouts

Side AV & I/O Panel

19TC8.1L CA 7.

SIDE AV I/O PANEL

D D

Personal Notes:

40-TB93PH-SIC1XG

Layout Side AV & I/O Panel (Top Side)

H_17630_012.eps

201107

40-TB93PH-SIC1XG

H_17630_012.eps

201107

E_06532_012.eps

131004

Page 20

Personal Notes:

Circuit Diagrams and PWB Layouts

20TC8.1L CA 7.

E_06532_013.eps

131004

Page 21

8. Alignments

Alignments

EN 21TC8.1L CA 8.

8.1 How to Put the Set into Factory Mode

• Turn down the volume to “0” by pressing “VOL-” button on

the set (front panel), followed by “DISPLAY” button on the

remote control.

• Press the “OK” button on the remote control.

• Press the “CH+” or the “CH-” button to select the parameter

you want to adjust.

• Press the “VOL+” or the “VOL-” button to adjust the

selected parameter.

• To put the new values into the memory, leave the factory

mode with the “MENU” button on the remote control.

8.2 Adjustment of the B+ (BAT) voltage

1. Apply the Philips standard test pattern to the RF input.

2. Connect a DC voltmeter (range >200 V) to ground and

jumper J809 [1].

3. Adjust potentiometer VR840 [2] in STANDARD mode in

such a way the voltage reading is 120 ±2.5 V.

Note: in sets where VR840 is not present, this voltage cannot

be adjusted. In case the voltage is out of range, the defective

part(s) should be located and replaced.

12

11

H_17630_016.eps

271107

Figure 8-1 Test pin & potentiometer position

Page 22

EN 22 TC8.1L CA8.

A

Alignments

8.3 RF AGC Adjustment

1. Connect a test circuit as depicted in figure “Test circuit”.

2. Apply a color bar signal (80 dBμV).

3. Adjust the AGC data until the output of the test circuit

becomes 0.6 V (p-p) ±0.05 V.

4. Change the color bar signal to 60 dBμV.

5. The shown value of CRO should be the same as while

receiving the 80 dBμV signal. If not, repeat step 3 and 4

until the results for 60 dBμV and 80 dBμV input signal are

the same.

D2

Q101

C1

33pF

1N60

D1

1N60

C2

100pFR1100k

TO CRO

H_17480_007.eps

050707

Figure 8-2 Test circuit

8.4 Screen & Focus Voltage Adjustment

1. Apply the test pattern signal in normal status.

2. Enter the Factory mode.

3. Press the "TV/AV" button to stop the vertical scan (Note:

the RC/GC/BC is preset to 80, 80, 80-/44; 65, 80, 80-/85.

GD/BD is preset to 40).

4. Adjust the SCREEN potentiometer on the line output

transformer in such a way the horizontal line is just visible

on the screen.

5. Measure the VG2 voltage with a High Voltage Meter and a

High Voltage Test stick (1000:1). The VG2 voltage should

be 665 ±85 V for SDI tubes and 800 ±60 V for HuiFei tubes.

6. Turn on the vertical output, and adjust the "FOCUS"

potentiometer on the line output transformer in such a way

the focus is maximized. The “FOCUS” voltage should be

within the range of 6 - 8.0 kV for SDI tubes and 7 - 11.0 kV

for HuiFei tubes.

8.5 Sub-contrast, Sub-tint and Sub-color adjustment

Note: the following adjustments are only applicable in case of

a CRT exchange. Otherwise, do not adjust these values.

1. Set “Brightness”, “Contrast”, “Color” and “Tint” to 50.

2. Connect the probe of an oscilloscope to the conjunction

between R201 and P201 (B-out).

3. In STANDARD status, apply the grey-scale/color-bar

(NTSC) signal to the AV/TV input.

4. Select CNTC to adjust the contrast, until amplitude “A” is

2.0V (p-p). Refer to figure “Waveform video signal”.

5. Select COLC to adjust the color by tuning the amplitude of

“a” and “d” to the same magnitude.

6. Select TNTC to adjust the tint by tuning the amplitude “b”

and “c” to the same magnitude.

7. In STANDARD status, apply the grey-scale/color-bar (PAL)

signal to the AV input.

8. Select COLP to adjust the sub-color by tuning the

amplitude of “a”, “b”, “c” and “d” to the same magnitude.

8.6 White Balance Adjustment

8.6.1 /44 Region sets

Normal color temperature adjustment.

1. Apply the following black and white pattern in Natural

status: black side: Y = 5 ±1 Nits ( ≅ low light); white side: Y

= 80 ±10 Nits ( ≅ high light).

2. Change the color temperature to Normal Status.

3. Use a color analyzer to measure the black side of the

screen. By changing the value of RC, GC and BC, set the

reading of the color analyzer to Standard.

4. Use a color analyzer to measure the white side of the

screen. By changing the value of GD and BD, set the

reading of the color analyzer to Standard.

5. Separately, set the brightness and contrast from minimum

to maximum, and repeat step 3 and 4 until the reading of

the color analyzer is correct.

Cool color temperature adjustment.

1. Change RC-W, GC-W, BC-W, GD-W and BD-W until the

reading of the color analyzer is correct.

Warm color temperature adjustment.

1. Change RC-C, GC-C, BC-C, GD-C and BD-C until the

reading of the color analyzer is correct.

CVI color temperature adjustment.

1. Set Color Temperature to Normal status.

2. Change YUV-RC, YUV-GC, YUV-BC, YUV-GD and YUVBD until the reading of the color analyzer is correct.

8.6.2 /85 Region sets

Normal color temperature adjustment.

1. In Rich status, apply a white pattern 27 IRE (192.8 mV).

2. Measure the picture with a color analyzer and adjust RC,

GC and BC.

3. Apply a white pattern 67 IRE (478.57 mV).

4. Measure the picture with a color analyzer and adjust GD

and BD.

5. Repeat steps 1 to 4 until you get the right color temperature

on both dark and bright pictures.

Cool color temperature adjustment.

1. Adjust RC-C, GC-C, BC-C, GD-C and BD-C until the

reading of the color analyzer is correct.

Warm color temperature adjustment.

1. Adjust RC-W, GC-W, BC-W, GD-W and BD-W until the

reading of the color analyzer is correct.

CVI color temperature adjustment.

1. Adjust YUV-RC, YUV-GC, YUV-BC, YUV-GD and YUV-BD

until the reading of the color analyzer is correct.

8.6.3 Reference values

See table “Standard settings” for reference.

Table 8-1 Standard settings

Picture Mode X Y

Cool 263 ±8265 ±8

Normal 274 ±8280 ±8

Warm 291 ±8 300 ±8

a

bc

d

H_17630_017.eps

271107

Figure 8-3 Waveform video signal

Page 23

8.7 EEPROM Data:

Note: although all items are adjustable, we only recommend to

adjust the items with an asterisk (*). The other items are

adjustable as well, but we strongly discourage adjusting them.

Table 8-2 EEPROM Data

Alignments

EN 23TC8.1L CA 8.

FAC 01 FAC 02

EEPROM data

RC GC* BC* GD* BD* HIGH5 VP50 VLIN5 VSC5 VBLK5 VCEN5

65 (/85 sets)

80 (/44 sets)

FAC 02

HIGH6* VP60* VLIN6* VSC6* VBLK6* VCEN6 HIGH5* VP50* VLIN5* VSC5* VBLK5* VCEN5

19 04 0E 19 04 17 1A 08 13 17 04 1C

FAC 03

HPOS5* U BLACK* V BLACK* STRAP F0 SIF FREQ STRAP HLQGPIF FREQ NOISE DET

4D 08 08 08 06 00 02 01

FAC 03

HPOS6* U BLACK* V BLACK* STRAP F0 SIF FREQ STRAP HLQGPIF FREQ NOISE DET

51 08 08 08 06 00 02 01

FAC 04

CNTX CNTN BRTX BRTN COLX COLN TNTX TNTN

6F 08 20 1B 7F 0E 2C 30

FAC 05

BRTC* COLC COLP SCOL SCNT* CNTC TNTCT TNTCV

30 30 (/85 sets)

FAC 06

ST3 SV3 SV4 SVD ASSH SHPX SHPN

1B 1B 1B 1B 07 1A 1A

FAC 07

MOD1 MOD2 MOD3 OPT OPTM1 OPTM2 HDCNT HSTOP

20 58 (/85 sets)

FAC 08

RFAGC* BRTS* OSD OSDF CCD OSD CCD OSDF TXCN RGCN

25 00 21 53 4A 65 10 09

FAC 09

V01 V05 V10 V25 V50 V75 V90 V100 VOLMAX

15 1F 2F 38 6C 6E 70 71 32

FAC 10

CURTCEN VOLX PWTM MODE4 MODE5 MODE6 MODE7 MODE8 MODE9

A5 75 08 12 09 1F 15 2D 0B

FAC 11

CON1 CON2 CON3 STSADJ ALI 1 ALI 2 ALI 3

06 06 02 00 0A 0A 03

FAC 12

SVM SVM1 OSD2* OSDF2 SYNC SYBBN SYBBN SYSR BBCT

10 10 28 64 02 00 00 00 04

FAC 13

CLTM CLVO CLVS ABL DCBS FLG0 FLG1

04 03 03 27 14 82 0C

FAC 14 FAC 15

HAFC AGCC NOIS ONTM NSHP PVLVL PLMT RC-C GC-C* BC-C* GD-C*

09 1C 01 08 1A 80 63 09 07 03 02

FAC 16 FAC 17

RC-W GC-W* BC-W* GD-W* BD-W* D-COL D-BRI D-CON D-SHP

0C 0B 15 FA EC 32 3A 5A 44

FAC 18 FAC 19

S-COL S-BRI S-CON S-SHP YUC-RC YUV-RC* YUV-RC* YUV-RC* YUV-RC* M-COL M-BRI M-CON M-SHP

2A 34 4E 44 00 00 00 01 01 28 36 44 26

FAC 20

SEGPOINT1

173 407 01 02 08 06 05 00 00

FAC 21 FAC 22

THEATERBAS

26 5F 2D 3E 19 2C 01 2A 75 3E 40

FAC 25

G8_FLAG00G8_FLAG01G8_FLAG02G8_FLAG03G8_FLAG04G8_FLAG05G8_FLAG0

30 06 10 02 40 00 31

80 80 40 40 1A 08 13 17 04 1C

32 (/44 sets)

78 (/44 sets)

SEGPOINT2

THEATERTRE

FF 07 05 36 45 40 (/85 sets)

08 3F C2 83 09 FF

DATA-VL DATA-VH DATA-UF SPE-POS1 SPE-DATA1 SENSI-ON SENSI -OFF

CONCERTBAS

CONCERTTRE

BROCASTBAS

BROCASTTRE

VOL_MAI GATE VOL-OUT AV GAIN OPTM3

6

42 (/44 sets)

BD-C*

0B

Page 24

EN 24 TC8.1L CA9.

Circuit Descriptions, Abbreviation List, and IC Data Sheets

9. Circuit Descriptions, Abbreviation List, and IC Data Sheets

Index of this chapter:

9.1 General

9.2 Chassis Block Diagram

9.3 Brief IC Descriptions

9.4 Abbreviation List

Notes:

• Figures can deviate slightly from the actual situation, due

to different set executions.

• For a good understanding of the following circuit

descriptions, please use the Wiring, Block (chapter 6) and

Circuit Diagrams (chapter 7). Where necessary, you will

find a separate drawing for clarification.

9.1 General

This chassis uses the Toshiba TPMA8891 processor/decoder,

and has the following key components:

Item Name of IC Function

IC201 TMPA8891CXBNG MCU & Decoder

TU101 FSBP05P-3-E Tuner

Z101 K2966M SAW Filter

IC001 AT24C08A EEPROM

IC601 TDA7496SA Audio output amplifier

IC901 HCF4053B Analog Switch

IC301 LA78040N-E Vertical Deflection Output IC

Q402 BU4508DZS Horizontal Output IC

IC801 TEA1506P Power Controller IC

IC1001 MSP3425G Multi Sound Processor

9.2 Chassis Block Diagram

Below find the chassis block diagram:

TUNER

( TU101)

SAWF

( Z101)

SDA SCL

EEPROM

4053BP

( IC901)

Video &

Audio

Decoder & MCU

TMPA8891

(IC201)

( IC001)

AV2 AV1

AV o utput

TDA7496

SA

(IC601)

Audio

MSP3425

(IC1001)

SIF

R

G

B

CRT

Board

CRT

Horizontal

Output circuit

+24V

Vertical Output

LA7804

(IC301)

Figure 9-1 Chassis block diagram

H_17630_018.eps

271107

Page 25

Circuit Descriptions, Abbreviation List, and IC Data Sheets

9.3 Brief IC Descriptions

9.3.1 IC201 (TMPA8891CXBNG)

EN 25TC8.1L CA 9.

The TMPA8891 is an integrated circuit for a PAL/ NTSC/

SECAM TV. A microcontroller (MCU) and a TV signal

processor are integrated in a 64-pin shrink DIP package.

The MCU part contains:

• 8-bit CPU.

•ROM.

•RAM.

• I/O ports.

• Timers/ counters.

• A/D converters.

• On-Screen Display controller.

• remote control interfaces.

• IIC bus interfaces.

• Closed Caption decoder.

The TV signal processor part contains:

•PIF.

•SIF.

• Video.

• Multi-standard chroma.

• Sync.

• RGB processors.

Block diagram is as follows:

Block Diagram & Pin Configuration

P63/LED2

P30/Int3/RXIN

63

62

I/O

10 I/O port

14-bit PWM x1

7-bit PWM x1

8-bit ADC Ext.x3

Int.x1

Romote preproces sor

16-bit int.timer x2

8-bit int.timer x2

Watchdog timer

Interrupt

Ext.x5 Int.x11

IIC bus interfece

Ext.x1 Int.x1

1

3

2

P60/ADC8bit

P61/LED1/ADC8bit

P31/Int4/TC3

P20/Int5/Stop

61

60

ROM: 㧠㧤 kB

RAM:2kB

ROM correction

4

uP DVss

P53/ADC8bit/TC1/Int2

P40/PWM14bit

P50/PWM7bit/T C2/Int0

P51/SCL

58

59

Font:16 x 18

Display:32C x 12L

Color:8

Character:384

Half-tone

Transparent

870X CPU core

STOP/IDLE mode

XO

65

7

Reset

8MHz

DVcc

H/L out

+

47

48

Chroma Proc.

C-BPF

PAL/NTSC/SECAM

C-Trap

Black stretch

Y gamm a

Sharpness

18

17

+

Vout

A Vcc 8V

YC Vcc 5V

TV AGND

uP MPAGND

TV Dig GND

+

P52/SDA

57

OSD R/G/B/Ys/I

8

TEST

uP AVdd 5V

P56

55

56

54

CCD

Hor.Proc.

Sync.sepa

Hor.VCO HAFC-1

HAFC-2 H-shift

11

9 15 21

10

+

uP VVss

uP DVDD 5V

TV DEF GND

Bout

53

52

Cut-off

Drive

RGB switch

Brightness

Half-tone

Transparent

Base Band Proc.

TINT

1H DL Int/Ext switch

Color Uni-color

RGB Matrix

1312

SCP

Hout

FBP

Gout

50

51

Vert.Proc.

V.C/D

V.ramp

V.geometry

V.Drive

14

+

HAFC 1

+

Rout

49

16

Vsaw

+

Y Proc.

19

IF IN

+

APC Fil

Monitor /VM out

4546

44

20

+

Y input

Cb input

SAW

AU Monitor out-1

RF AGC

Black Det

43

42

VM

IF

AGC

Video SW

22

Cr input

2423

+

EXT AU 1

C /V3 CVBS

+

IF GND

39

4041 35 33

IF GND

AGC

DET

26

25

+

+

V2 CVBS/Y

ALC filter

IF AGC

+

Audio SW

27

V1 IN 1Vpp

+

Reg.

ATT

28

ABCL

-6dB

+

S-Reg.F

363738

FM

DEMO

De-emp

(on/off)

PAL/ NTSC demod

Auto.VCO

alignment

ALC

ATT

29

AU out 1

AU out 2

+

H.correction

+

DC NF

PIF PLL

IF Vcc 5V

3464

SW

AFT

PIF Proc.

Sound

TRAP

AU Monitor

BPF

SW

31

30

32

+

/ FM radio

TVout 2Vpp

H/Lout / SIF out

/AU Monitor out-2

H_17130_035.eps

240407

/2nd SIF in

EXT AU 2

Figure 9-2 Block diagram IC201 (TMPA8891CXBNG)

Page 26

EN 26 TC8.1L CA9.

Circuit Descriptions, Abbreviation List, and IC Data Sheets

9.3.2 TU101 (FSBP05P-3-E)

Intermediate frequency:

• Picture carrier: 38.90 MHz

• Color carrier: 34.47 MHz

• Sound carrier: 33.40 MHz

Pin connection is as follows:

Pin Symbol Description

1 AGC Automatic Gain Control

2

3 AS I2C Bus Address Select

4 SCL I2C Bus Serial Clock

5 SDA I2C Bus Serial Data

6

7 BP Supply Voltage Tuner Section +5V

8 AFC Automatic Frequency Control

9 BT Supply Voltage Tuner Section +31V

10 n.c. / IF1

11 IF2 Intermediate Frequency Out

9.3.3 IC001 (AT24C08A)

It provides 8192 bits of serial electrically erasable and

programmable read-only memory (EEPROM) organized as

1024 words of 8 bits each. It needs to be pre-copied before

produced.

9.3.4 IC601 (TDA7496SA)

9.3.5 IC901 (HCF4053B)

This is an analogue switch. Its pinning diagram, pin description

and truth table are as follows:

Block Diagram

Pin Configuration

The TDA7496SA is a 2 x 5 W class AB power audio amplifier.

The pinning is as follows:

Block Diagram

V

INR

INL

470µF

PW_GND

470nF

S_GND

470nF

SVR 7

11

1

8

5

VOLUME

VAROUT_R

VOLUME

30K

VOLUME

34

100nF

VAROUT_L

300K

2

+

-

OP AMP

MUTE/STBY

PROTECTIONS

+

-30K

OP AMP

+5V

S

13

PW_GND

15

1000µF

14

OUTR

1000µF

S1 ST-BY

10K

1µF

S_GND

S2 MUTE

9

STBY

10

MUTE

60K

12

OUTL

Pin Configuration (Top View)

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

PW_GND

OUTR

V

S

OUTL

PW_GND

MUTE

STBY

S_GND

SVR

N.C.

INL

VAROUT_L

VOLUME

VAROUT_R

INR

H_17130_029.eps

240407

E_06532_040.eps

040507

Figure 9-4 Block diagram and pinning of IC901 (HCF4053)

Table 9-1 Pin Configuration

PIN No SYMBOL NAME AND FUNCTION

11, 10, 9 A, B, C Binary Control Inputs

+5V

+5V

6 INH Inhibit Inputs

12, 13, 2, 1, 5, 3 IN/OUT ax,ay,bx,by,cx,cy Input/Output

14 OUT/IN ax or ay

15 OUT/IN bx or by

4 OUT/IN cx or cy

7 VEE Supply Voltage

8 VSS Negative Supply Voltage

16 VDD Positive Supply Voltage

Table 9-2 Truth Table

INHIBIT C or B or A

0 0 ax or bx or cx

0 1 ay or by or cy

1 X NONE

X : Don’t Care

Figure 9-3 Block diagram and pinning of IC601 (TDA7496SA)

Page 27

Circuit Descriptions, Abbreviation List, and IC Data Sheets

s

7

EN 27TC8.1L CA 9.

9.3.6 IC301 (LA78040N-E)

IC301 is a vertical deflection output IC.

Its block diagram and pin connection are as follows:

Block Diagram

Pin Configuration

17

9.3.7 Q402 (BU4508DZS)

Q402 is a high speed switching, high voltage PNP power

transistor with a built-in damper diode, designed for use in

horizontal deflection circuits.

The pinning is as follows:

PIN CONFIGURATION

case

123

PINNING SOT186A

c

b

Rbe

e

SYMBOL

PIN DESCRIPTION

1 base

2 collector

3 emitter

case isolated

H_17130_031.ep

Figure 9-5 Block diagram and pinning of IC301 (LA78040N-E)

24040

H_17130_033.eps

240407

Figure 9-6 Pinning of Q402 (BU4508DZS)

Page 28

EN 28 TC8.1L CA9.

9.3.8 IC801 (TEA1506P)

IC801 is a switched mode power supply control IC.

Its block diagram and pinning are as follows:

Block Diagram

Circuit Descriptions, Abbreviation List, and IC Data Sheets

Pin Configuration

H_17130_032.eps

240407

Figure 9-7 Block diagram of IC801 (TEA1506P)

Page 29

Circuit Descriptions, Abbreviation List, and IC Data Sheets

EN 29TC8.1L CA 9.

9.3.9 IC1001 (MSP3425)

The SIF signal is sent out from Pin31 of IC201. It passes

through Q241, R241 and X241.

SIF will be finally sent into Pin2 of IC1001. An analog automatic

gain control circuit (AGC) allows a wide range of input levels.

The analog-to-digital conversion of the IF sound signal is done

by an A/D-converter. The high pass filter, formed by a coupling

capacitor at SIF_IN1+ suppresses video components.

IC1001 is controlled via the I2C bus slave interface.

The (analog) sound signal will go from Pin26/27 of IC1001 to

Pin1/5 of IC601. IC601 is a class AB power audio amplifier. The

output voltage of IC601 drives the speakers. The volume is

adjusted via the I2C bus.

Table 9-3 Sound Processor

Pin No. Pin Name Type Short Description

1 AVSUP Analog power supply

+5V

2 ANA_IN+ IN IF Input 1

3 ANA_IN- IN IF common

4 TESTEN IN Test pin

5 XTAL_IN IN Crystal oscillator

6 XTAL_OUT OUT Crystal oscillator

7 TP Test pin

8 D_CTR_I/O_1 IN/OUT D_CTR_I/O_1

9 D_CTR_I/O_0 IN/OUT D_CTR_I/O_0

10 ADR_SEL IN I2C BUS address select

11 STANDBYQ IN Stand-by (Low-active)

12 I2C_CL IN/OUT I2C clock

13 I2C_DA IN/OUT I2C data

14 I2S_CL I2S clock

15 I2S_WS I2S word strobe

16 I2S_DA_OUT I2S data output

17 I2S_DA_IN1 I2S1 data input

18 ADR_CL ADR clock

19 DVSUP Digital power supply +5

V

20 DVSS Digital ground

21 I2S_DA_IN2 I2S2 data input

22 RESETQ IN Power-on-reset

23 NC Not connected

24 NC Not connected

25 VREF2 Reference ground 2

High-voltage part

26 DACM_R OUT Loudspeaker out, right

27 DACM_L OUT Loudspeaker out, left

28 NC Not connected

29 VREF1 Reference Ground 1

High voltage part

30 SC1_OUT_R OUT Audio 1 output, right

31 SC1_OUT_L OUT Audio 1 output, left

32 NC Not connected

33 AHVSUP Analog power supply

8.0V

34 CAPL_M Volume capacitor MAIN

35 AHVSS Analog ground

36 AGNDC Analog reference voltage

High-voltage part

37 SC2_IN_L IN Audio 2 input, left

38 SC2_IN_R IN Audio 2 input, right

39 ASG Analog shield Ground

40 SC1_IN_L IN Audio 1 input, left

41 SC1_IN_R IN Audio 1 input, right

Pin No. Pin Name Type Short Description

42 VREFTOP Reference voltage IF A/D

converter

43 MONO_IN IN Mono input

44 AVSS Analog ground

Page 30

EN 30 TC8.1L CA9.

Circuit Descriptions, Abbreviation List, and IC Data Sheets

9.4 Abbreviation List

1080i 1080 visible lines, interlaced

1080p 1080 visible lines, progressive scan

ADC Analogue to Digital Converter

AFC Automatic Frequency Control: control

signal used to tune to the correct

frequency

AGC Automatic Gain Control: algorithm that

controls the video input of the feature

box

AM Amplitude Modulation

AR Aspect Ratio: 4 by 3 or 16 by 9

AV Audio Video

B/G Monochrome TV system. Sound

carrier distance is 5.5 MHz

BTSC Broadcast Television System

Committee

CBA Circuit Board Assembly (or PWB)

CVBS Composite Video Blanking and

Synchronization

CVI Component Video Input

DAC Digital to analogue Converter

DFU Directions For Use: owner's manual

DNR Dynamic Noise Reduction

DRAM Dynamic RAM

DSP Digital Signal Processing

DVD Digital Versatile Disc

EEPROM Electrically Erasable and

Programmable Read Only Memory

EXT EXTernal (source), entering the set by

SCART or by cinches (jacks)

FBL Fast Blanking: DC signal

accompanying RGB signals

FM Field Memory / Frequency Modulation

HH_sync

HD High Definition: 720p, 1080i, 1080p

HP Head Phone

I Monochrome TV system. Sound

carrier distance is 6.0 MHz

I2C Integrated IC bus

IC Integrated Circuit

IF Intermediate Frequency

IR Infra Red

IRQ Interrupt ReQuest

Last Status The settings last chosen by the

customer and read and stored in RAM

or in the NVM. They are called at start-

up of the set to configure it according

the customers wishes

LATAM LATin AMerica

LED Light Emitting Diode

LS Loud Speaker

M/N Monochrome TV system. Sound

carrier distance is 4.5 MHz

MOSFET Metal Oxide Semiconductor Field

Effect Transistor

MUTE MUTE Line

NAFTA North American Free Trade

Association: Trade agreement

between Canada, USA and Mexico

NC Not Connected

NTSC National Television Standard

Committee. Color system used mainly

in North America and Japan. Color

carrier NTSC M/N = 3.579545 MHz,

NTSC 4.43 = 4.433619 MHz (this is a

VCR norm, it is not transmitted off-air)

NVM Non Volatile Memory: IC containing

TV related data (for example, options)

O/C Open Circuit

OSD On Screen Display

PAL Phase Alternating Line. Color system

used mainly in Western Europe (color

carrier = 4.433619 MHz) and South

America (color carrier PAL M =

3.575612 MHz and PAL N = 3.582056

MHz)

PCB Printed Circuit Board (or PWB)

PIP Picture In Picture

PLL Phase Locked Loop. Used, for

example, in FST tuning systems. The

customer can directly provide the

desired frequency

PSU Power Supply Unit

PWB Printed Wiring Board (or PCB)

RAM Random Access Memory

RC Remote Control transmitter

RC5 (6) Remote Control system 5 (6), the

signal from the remote control receiver

RF Radio Frequency

RGB Red, Green, and Blue. The primary

color signals for TV. By mixing levels

of R, G, and B, all colors (Y/C) are

reproduced.

RGBHV Red, Green, Blue, Horizontal sync,

and Vertical sync

ROM Read Only Memory

SC SandCastle: two-level pulse derived

from sync signals

S/C Short Circuit

SCL Clock signal on I2C bus

SD Standard Definition: 480i, 576i

SDA Data signal on I2C bus

SDRAM Synchronous DRAM

SECAM SEequence Couleur Avec Memoire.

Color system used mainly in France

and Eastern Europe. Color carriers =

4.406250 MHz and 4.250000 MHz

SIF Sound Intermediate Frequency

SMPS Switch Mode Power Supply

SND SouND

SOPS Self Oscillating Power Supply

SRAM Static RAM

SSB Small Signal Board

STBY Stand-by

SVHS Super Video Home System

SW Sub Woofer / SoftWare / Switch

THD Total Harmonic Distortion

TXT TeleteXT

uP Microprocessor

VL Variable Level out: processed audio

output toward external amplifier

VCR Video Cassette Recorder

VGA Video Graphics Array

WYSIWYR What You See Is What You Record:

record selection that follows main

picture and sound

XTAL Quartz crystal

YPbPr Component video (Y= Luminance, Pb/

Pr= Color difference signals B-Y and

R-Y, other amplitudes w.r.t. to YUV)

Y/C Video related signals: Y consists of

luminance signal, blanking level and

sync; C consists of color signal.

Y-OUT Luminance-signal

YUV Baseband component video (Y=

Luminance, U/V= Color difference

signals)

Page 31

10. Spare Parts List

Spare Parts List

EN 31TC8.1L CA 10.

Sets Listed by Model Number (CTN)

21PT4207/44

Canceled

21PT6437/44

0001 9965 100 04136 HS 4p 400/13 TJC1/4Y

CHASSIS 9965 200 32673 Main Chassis assy [A]

CRT 9965 100 09385 A51ERF135X90 assy [B]

IR001 9965 000 27288 IR Receiver assy [J]

P601 9965 100 04134 HS 2p 2468 S11/2Y

SPL 9965 000 36789 Loudsp. 8Ω 5W

SPR 9965 000 36789 Loudsp. 8Ω 5W

21PT6447/85

Not available yet

21PT6457/44

Not available yet

21PT6457/85

Not available yet

Main Chassis [A]

Various

F801 9965 000 35264 Fuse 3.15AT 250VAC

IR001 9965 000 27288 IR Receiver Module

P1101 9965 100 04139 RCA Socket AV

P201 9965 100 04137 HS 5p24 500

P402 9965 100 04138 HS 4p24 460

P904 9965 100 09399 HS 5p LCSAP001TL0579

TU101 9965 000 34483 Tuner FSNA05T-4-E

g

C001 9965 000 34503 100pF 5% 50V

C002 9965 000 34503 100pF 5% 50V

C003 9965 000 27860 10μF /-20% 16V

C004 9965 000 27860 10μF /-20% 16V

C005 9965 100 07896 10nF +80% -20% 50V

C006 9965 000 17966 0.01μF +80-20% 50V

C008 9965 000 31199 470pF 5% 50V

C008A 9965 000 28015 22μF 20% 50V

C009 9965 000 14069 100μF 20% 16V

C011 9965 000 35328 27pF 5% 50V

C016 9965 000 14069 100μF 20% 16V

C017 9965 100 07896 10nF +80% -20% 50V

C019 9965 100 07896 10nF +80% -20% 50V

C020 9965 000 17966 0.01μF +80-20% 50V

C020A 9965 000 17966 0.01μF +80-20% 50V

C021 9965 000 34507 47pF 5% 50V

C022 9965 000 34507 47pF 5% 50V

C023 9965 000 27860 10μF /-20% 16V

C024 9965 000 17966 0.01μF +80-20% 50V

C030 9965 000 14039 4.7μF 20% 50V

C081 9965 000 13961 47μF 20% 16V

C082 9965 100 07896 10nF +80% -20% 50V

C086 9965 000 15084 22μF 20% 16V

C091 9965 000 28015 22μF 20% 50V

C095 9965 000 14075 10μF 20% 50V

C097 9965 000 14075 10μF 20% 50V

C1001 9965 000 30782 3.3pF 50V

C1002 9965 000 30782 3.3pF 50V

C1004 9965 000 27330 56pF 5% 50V 0603

C1005 9965 000 27330 56pF 5% 50V 0603

C1006 9965 000 15112 0.1μF 5% 50V

C1008 9965 000 15112 0.1μF 5% 50V

C1009 9965 000 27860 10μF /-20% 16V

C101 9965 000 14039 4.7μF 20% 50V

C1010 9965 000 15719 3.3µF 20% 50V

C1011 9965 000 15112 0.1μF 5% 50V

C1012 9965 000 20357 1000pF 50V 5% 0603

C1013 9965 000 27860 10μF /-20% 16V

C1015 9965 000 27860 10μF /-20% 16V

C1016 9965 000 27860 10μF /-20% 16V

C1018 9965 000 20357 1000pF 50V 5% 0603

C1019 9965 000 20357 1000pF 50V 5% 0603

C1025 9965 000 14012 470pF 5% 50V 0603

C1031 9965 000 20344 10nF 50V +80-20% 0603

C1033 9965 000 20344 10nF 50V +80-20% 0603

C1034 9965 000 20344 10nF 50V +80-20% 0603

C1035 9965 000 14011 22pF 5% 50V

C1036 9965 000 14011 22pF 5% 50V

C1037 9965 000 15112 0.1μF 5% 50V

C1038 9965 000 13961 47μF 20% 16V

C1039 9965 000 15114 0.47μF 5% 50V

C103A 9965 000 14039 4.7μF 20% 50V

C1040 9965 000 20357 1000pF 50V 5% 0603

C1041 9965 000 20357 1000pF 50V 5% 0603

C1042 9965 000 15084 22

C1043 9965 000 14008 0.1uF 50V +80%~-20%

C1044 9965 000 20349 220pF 5% 50V 0603

C1045 9965 000 20349 220pF 5% 50V 0603

C108 9965 000 13961 47μF 20% 16V

C109 9965 100 07896 10nF +80% -20% 50V

C110 9965 000 17966 0.01μF +80-20% 50V

C112 9965 000 30711 1000pF 20% 50V

C114 9965 000 17966 0.01μF +80-20% 50V

C121 9965 000 34503 100pF 5% 50V

C122 9965 000 34503 100pF 5% 50V

C135A 9965 100 07896 10nF +80% -20% 50V

C201 9965 000 17966 0.01μF +80-20% 50V

C202 9965 000 13961 47μF 20% 16V

C203 9965 000 14037 1μF 20% 50V

C204 9965 000 15115 2200pF 5% 50V

C205 9965 000 34500 0.22μF 10% 50V

C211 9965 000 14069 100μF 20% 16V

C212 9965 100 07896 10nF +80% -20% 50V

C213 9965 000 30713 2.2nF 10% 50V

C214 9965 000 28015 22μF 20% 50V

C216 9965 000 14039 4.7μF 20% 50V

C217 9965 000 14599 470μF 20% 16V

C218 9965 000 15088 0.47μF 20% 50V

C219 9965 000 30711 1000pF 20% 50V

C220 9965 000 27860 10μF /-20% 16V

C224 9965 100 07896 10nF +80% -20% 50V

C227 9965 000 27860 10μF /-20% 16V

C228 9965 100 07896 10nF +80% -20% 50V

C230 9965 100 03106 1MΩ 1/6W

C231 9965 000 27860 10μF /-20% 16V

C232 9965 000 14070 220μF 20% 16V

C233 9965 000 17966 0.01μF +80-20% 50V

C234 9965 000 27872 0.1μF 5% 100V

C235 9965 000 17886 0.0082μF 5% 63V

C236 9965 000 34501 0.47μF 10%

C239 9965 000 17966 0.01μF +80-20% 50V

C242 9965 000 27860 10μF /-20% 16V

C243 9965 000 34518 1500pF 10% 50V

C245 9965 000 14037 1μF 20% 50V

C246 9965 000 13961 47μF 20% 16V

C248 9965 100 07896 10nF +80% -20% 50V

C273 9965 000 13961 47μF 20% 16V

C301 9965 000 15112 0.1μF 5% 50V

C302 9965 100 03161 220μF 20% 35V

C303 9965 000 14598 100μF 20% 35V

C304 9965 000 35325 10pF 5% 50V

C305 9965 000 15084 22μF 20% 16V

C306 9965 000 30711 1000pF 20% 50V

C307 9965 000 14039 4.7μF 20% 50V

C308 9965 000 22932 1000pμF 20% 25V

C309 9965 000 15112 0.1μF 5% 50V

C310 9965 000 14039 4.7μF 20% 50V

C311 9965 000 14069 100μF 20% 16V

C401 9965 000 22811 1000pF 10% 50V

C402 9965 000 23812 0.012μF 1.6KV 5%

C404 9965 100 03127 47Ω 5% 1/6W

C405 9965 000 14036 100μF 20% 25V

C407 9965 000 17521 22nF 5% 63V

C408 9965 000 14921 10μF 20% 250V

C409 9965 000 15096 390pF 10% 500V

C410 9965 100 03162 CAP. M.PP 0.1μF 250V

C411 9965 000 17512 47μF 20% 160V

C412 9965 000 15096 390pF 10% 500V

C413 9965 000 14073 470μF 20% 35V

C414 9965 000 14039 4.7μF 20% 50V

C417 9965 100 07896 10nF +80% -20% 50V

C418 9965 000 14070 220μF 20% 16V

C420 9965 000 24353 1μF 20% 160V

C421 9965 000 17879 0.39μF 5% 250V

C422 9965 000 14081 5600pF 5% 50V

C423 9965 000 13961 47μF 20% 16V

C425 9965 100 07896 10nF +80% -20% 50V

C441 9965 000 14039 4.7μF 20% 50V

C501 9965 000 31199 470pF 5% 50V

C502 9965 000 31199 470pF 5% 50V

C503 9965 000 31199 470pF 5% 50V

μF 20% 16V

C504 9965 000 44381 10nF 10% 500V

C505 9965 000 44382 1000pF 10% 2kV

C507 9965 100 07896 10nF +80% -20% 50V

C508 9965 000 14070 220μF 20% 16V

C514 9965 000 14925 Bead BF60 for C508

C514 9965 000 35317 10nF 20/80%

C601 9965 000 15113 220nF 5% 50V

C602 9965 000 15113 220nF 5% 50V

C603 9965 000 15117 4700pF 5% 50V

C604 9965 000 15117 4700pF 5% 50V

C605 9965 000 14599 470μF 20% 16V

C606 9965 000 14599 470μF 20% 16V

C607 9965 000 14599 470μF 20% 16V

C608 9965 000 14599 470μF 20% 16V

C609 9965 000 14599 470μF 20% 16V

C618 9965 100 03088 22μF 20% 50V

C619 9965 000 14073 470μF 20% 35V

C624 9965 000 28015 22μF 20% 50V

C625 9965 000 14069 100μF 20% 16V

C626 9965 000 35326 0.1μF 80%/20% 50V

C801 9965 000 35331 0.22μF 20% 250V

C802 9965 100 03199 0.1μF 10% 400V

C803 9965 000 17914 470pF 10% 400V

C804 9965 000 17914 470pF 10% 400V

C805 9965 000 44381 10nF 10% 500V

C806 9965 100 09397 220μF 20% 450V

C807 9965 000 15188 4700pF 250Vac +80-20%

C808 9965 000 15188 4700pF 250Vac +80-20%

C809 9965 000 23786 220pF 10% 1KV

C810 9965 100 03198 CAP.M.PP.10NF/400V

C811 9965 100 09395 0.047μF 63V +/-5%

C813 9965 000 31199 470pF 5% 50V

C814 9965 000 15806 0.1μF +80-20% 50V

C815 9965 000 37248 560pF 10% 2kV

C818 9965 000 15113 220nF 5% 50V

C820 9965 100 03193 22μF 20% 25V

C821 9965 000 31455 220pF 5% 50V

C826 9965 000 44381 10nF 10% 500V

C829 9965 100 03195 2200pF 20% 400VAC

C830 9965 000 15183 220pF 500V 10%

C831 9965 100 07896 10nF +80% -20% 50V

C832 9965 000 14073 470μF 20% 35V

C833 9965 000 23786 220pF 10% 1KV

C834 9965 100 03194 1UμF 50V

C835 9965 000 31230 100μF 20% 160V

C837 9965 000 15806 0.1μF +80-20% 50V

C839 9965 000 30711 1000pF 20% 50V

C841 9965 000 15183 220pF 500V 10%

C842 9965 100 07896 10nF +80% -20% 50V

C843 9965 000 17510 1000μF 16V 20%

C844 9965 000 33957 10nF 5% 50V

C845 9965 000 14067 1000μF 20% 16V

C850 9965 000 15182 47μF 20% 25V

C852 9965 000 14039 4.7μF 20% 50V

C903 9965 000 15084 22μF 20% 16V

C904 9965 000 27860 10μF /-20% 16V

C905 9965 000 27860 10μF /-20% 16V

C906 9965 000 15084 22μF 20% 16V

C907 9965 000 27860 10μF /-20% 16V

C908 9965 000 27860 10μF /-20% 16V

C909 9965 000 15084 22μF 20% 16V

C910 9965 100 07896 10nF +80% -20% 50V

C911 9965 000 14037 1μF 20% 50V

C912 9965 100 07896 10nF +80% -20% 50V

C913 9965 000 35329 330pF 50V /-5%

C914 9965 000 35329 330pF 50V /-5%

C916 9965 000 14037 1μF 20% 50V

C918 9965 000 35329 330pF 50V /-5%

C919 9965 000 35329 330pF 50V /-5%

C931 9965 000 17966 0.01μF +80-20% 50V

C963 9965 000 14037 1μF 20% 50V

C964 9965 000 14037 1μF 20% 50V

f

R0010 9965 100 03127 47Ω 5% 1/6W

R002 9965 100 03127 47Ω 5% 1/6W

R003 9965 000 15057 4.7k 5% 0.16W

R004 9965 000 15057 4.7k 5% 0.16W

R005 9965 000 14050 10k 5% 0.16W

R006 9965 000 31774 3.3kΩ 5% 0.16W

R007 9965 000 31774 3.3kΩ 5% 0.16W

R008 9965 000 14049 100Ω 5% 0.16W

R012 9965 000 14049 100Ω 5% 0.16W

R013 9965 100 02999 1kΩ 5% 1/6W

R015 9965 100 03121 2.7kΩ 5% 1/6W

R016 9965 100 03107 1.2kΩ 5% 1/6W

R017 9965 000 13957 2.2kΩ 5% 1/6W

R020 9965 000 13960 470Ω 5% 0.16W

Page 32

EN 32 TC8.1L CA10.

Spare Parts List

R021A 9965 100 03110 150Ω 5% 1/6W

R022A 9965 000 13960 470Ω 5% 0.16W

R023A 9965 000 17864 820Ω 5% 0.16W

R024A 9965 000 15062 7.5kΩ 50% 1/6W

R025A 9965 100 03121 2.7kΩ 5% 1/6W

R026A 9965 100 03126 430Ω 50% 1/6W

R027 9965 000 15066 10Ω 5% 0.25W

R027A 9965 000 15050 270Ω 5% 0.16W

R028 9965 100 03000 680Ω 5% 1/6W

R029 9965 100 02999 1kΩ 5% 1/6W

R030 9965 000 14050 10k 5% 0.16W

R031 9965 000 15041 100k 5% 0.16W

R035 9965 100 02999 1kΩ 5% 1/6W

R041 9965 000 15057 4.7k 5% 0.16W

R042 9965 000 14050 10k 5% 0.16W

R046 9965 100 03123 30kΩ 5% 1/6W

R091 9965 000 14050 10k 5% 0.16W

R092 9965 000 15057 4.7k 5% 0.16W

R093 9965 000 15057 4.7k 5% 0.16W

R094 9965 000 15044 1.5k 5% 0.16W

R095 9965 000 14050 10k 5% 0.16W

R097 9965 000 31684 Resistor fixed carbon

R099 9965 000 31773 150W 5% 0.16W

R1001 9965 000 32037 100Ω 1/10W 0603

R1002 9965 000 32037 100Ω 1/10W 0603

R1003 9965 000 27226 100kΩ 1/10W 0603

R1005 9965 000 32051 3.3kΩ 1/10W 0603

R1006 9965 000 30773 47Ω 1/10W 5% 0603

R1007 9965 000 32042 1.5kΩ 5% 1/10W

R1008 9965 000 27226 100kΩ 1/10W 0603

R1014 9965 000 32038 1kΩ 1/10W 0603

R1015 9965 000 32038 1kΩ 1/10W 0603

R1016 9965 000 32038 1kΩ 1/10W 0603

R1017 9965 000 32038 1kΩ 1/10W 0603

R114 9965 100 03140 56Ω 5% 1/6W

R115 9965 100 03110 150Ω 5% 1/6W

R116 9965 100 02999 1kΩ 5% 1/6W

R117 9965 100 03110 150Ω 5% 1/6W

R118 9965 000 17864 820Ω 5% 0.16W

R119 9965 000 13960 470Ω 5% 0.16W

R201 9965 100 03114 220Ω 5% 1/6W

R202 9965 100 03114 220Ω 5% 1/6W

R203 9965 100 03114 220

R205 9965 100 03123 30kΩ 5% 1/6W

R206 9965 100 03120 220kΩ 5% 1/6W

R216 9965 000 27858 27kΩ 5% 1/6W

R217 9965 100 03114 220Ω 5% 1/6W

R218 9965 000 15044 1.5kΩ 5% 0.16W

R218A 9965 000 15044 1.5kΩ 5% 0.16W

R228 9965 000 13959 330Ω 5% 1/6W

R232 9965 000 15041 100k 5% 0.16W

R237 9965 100 03146 8.2kΩ 5% 1/6W

R238 9965 000 13960 470Ω 5% 0.16W

R241 9965 100 02999 1kΩ 5% 1/6W

R242 9965 000 14049 100Ω 5% 0.16W

R243 9965 000 13960 470Ω 5% 0.16W

R244 9965 000 15057 4.7k 5% 0.16W

R245 9965 000 23744 150kΩ 5% 0.17W

R246 9965 000 14055 33kΩ 5% 1/6W

R247 9965 000 27858 27kΩ 5% 1/6W

R248 9965 000 13960 470Ω 5% 0.16W

R250 9965 000 14056 390Ω 5% 0.17W

R298 9965 100 03152 330Ω 1/2W

R307 9965 100 03113 18kΩ 5% 1/6W

R308 9965 000 15057 4.7k 5% 0.16W

R309 9965 000 14050 10k 5% 0.16W

R310 9965 100 03109 12kΩ 5% 1/6W

R311 9965 000 15044 1.5k 5% 0.16W

R312 9965 100 03139 51kΩ 1/6W

R313 9965 100 03159 1.5Ω 1W

R314 9965 100 03147 2.2Ω 1/4W

R315 9965 100 09390 1kΩ 1W +/-5%

R317 9965 100 03153 56Ω 1/2W

R318 9965 100 03107 1.2kΩ 5% 1/6W

R336 9965 100 03149 220Ω 1/2W

R401 9965 000 17494 120Ω 5% 1/6W

R402 9965 100 03148 5.6Ω 5% 1/2W

R403 9965 000 24352 0.47Ω 5% 1W

R404 9965 000 22919 15kΩ 5% 3W 5%

R405 9965 100 03155 1.5Ω 5% 1W

R406 9965 000 15057 4.7k 5% 0.16W

R407 9965 100 09391 5.6Ω 2W +/-5%

R407A 9965 000 32031 6.8Ω 2W /-5%

R408 9965 000 17869 12k 5% 1W

R409 9965 100 03149 220Ω 1/2W

R410 9965 100 03151 22kΩ 1/2W

R411 9965 100 03158 1.8kΩ 5% 1W

R413 9965 000 14048 10Ω 5% 1/6W

R414 9965 000 15049 24kΩ 5% 1/6W

R415 9965 100 02999 1kΩ 5% 1/6W

R416 9965 100 03142 6.8kΩ 5% 1/6W

R417 9965 100 03157 1.2kΩ 5% 1/2W

R418 9965 100 03156 1kΩ 5% 1/2W

R419 9965 100 03154 2.2Ω 5% 1/2W

Ω 5% 1/6W

R440 9965 100 03147 2.2Ω 1/4W

R441 9965 000 31773 150W 5% 0.16W

R442 9965 000 17494 120Ω 5% 1/6W

R443 9965 100 03141 620Ω 5% 1/6W

R501 9965 000 14049 100Ω 5% 0.16W

R502 9965 000 15057 4.7k 5% 0.16W

R503 9965 000 17938 750Ω 5% 0.16W

R504 9965 000 14049 100Ω 5% 0.16W

R505 9965 000 15057 4.7k 5% 0.16W

R506 9965 000 17938 750Ω 5% 0.16W

R507 9965 000 14049 100Ω 5% 0.16W

R508 9965 000 15057 4.7k 5% 0.16W

R509 9965 000 17938 750Ω 5% 0.16W

R510 9965 000 15409 15k 5% 2W

R511 9965 000 15409 15k 5% 2W

R512 9965 000 15409 15k 5% 2W

R514 9965 100 03001 2.7kΩ 5% 1/2W

R515 9965 100 03001 2.7kΩ 5% 1/2W

R518 9965 100 03001 2.7kΩ 5% 1/2W

R521 9965 000 17939 100k 5% 0.25W

R522 9965 100 02999 1kΩ 5% 1/6W

R523 9965 100 03000 680Ω 5% 1/6W

R524 9965 100 03086 5.1kΩ 1/6

R525 9965 100 03000 680Ω 5% 1/6W

R526 9965 100 03000 680Ω 5% 1/6W

R527 9965 100 03000 680Ω 5% 1/6W

R601 9965 000 15057 4.7k 5% 0.16W

R602 9965 000 15057 4.7k 5% 0.16W

R603 9965 000 14050 10k 5% 0.16W

R604 9965 000 14050 10k 5% 0.16W

R607 9965 000 14050 10k 5% 0.16W

R608 9965 000 14050 10k 5% 0.16W

R619 9965 000 22921 0.22Ω

R624 9965 000 31773 150W 5% 0.16W

R625 9965 000 31773 150W 5% 0.16W

R802 9965 000 15177 1MΩ 1/2W

R803 9965 000 15782 NTC 4.7Ω 18%

R804 9965 100 08476 100kΩ

R806 9965 000 17557 DSP-301M-A

R807 9965 000 25987 220Ω 10% 1/2W

R810 9965 000 30822 68kΩ 5% 2W

R811 9965 100 03107 1.2kΩ 5% 1/6W

R812 9965 000 31774 3.3kΩ 5% 0.16W

R813 9965 100 03187 100Ω 5% 1/4W

R814 9965 000 14048 10Ω 5% 1/6W

R815 9965 100 03191 0.08Ω 5% 2W

R816 9965 000 24348 22kΩ 5% 1/4W

R817 9965 000 15664 2.2kΩ 5% 1/4W

R818 9965 000 14055 33kΩ 5% 1/6W

R819 9965 100 03184 330kΩ 5% 1/6W

R820 9965 000 14059 22Ω 5% 0.25W

R821 9965 000 13960 470Ω 5% 0.16W

R822 9965 100 03185 390kΩ 1/6W

R829 9965 000 15781 8.2MΩ 1W

R835 9965 100 03000 680Ω 5% 1/6W

R836 9965 000 13957 2.2kΩ 5% 1/6W

R837 9965 000 14055 33kΩ 5% 1/6W

R838 9965 100 03188 3.6kΩ 1/6

R839 9965 100 08314 82kΩ 1/2W +/-1%

R840 9965 000 14050 10k 5% 0.16W

R841 9965 000 14585 47kΩ 5% 1/6W

R842 9965 000 44690 3.9kΩ 1% 1/6W

R843 9965 100 03189 1Ω 5% 1W

R844 9965 100 02999 1kΩ 5% 1/6W

R845 9965 000 15771 1KΩ 1/4W 5% Carb. Film

R846 9965 000 31773 150Ω 5% 0.16W

R847 9965 000 31773 150Ω 5% 0.16W

R851 9965 000 14050 10k 5% 0.16W

R853 9965 000 31684 Resistor fixed carbon

R902 9965 000 31773 150Ω 5% 0.16W

R903 9965 100 02999 1kΩ 5% 1/6W

R904 9965 000 27873 33Ω

R905 9965 100 02999 1kΩ 5% 1/6W

R906 9965 100 03144 82Ω 5% 1/6W

R907 9965 100 02999 1kΩ 5% 1/6W

R908 9965 100 02999 1kΩ 5% 1/6W

R911 9965 100 03144 82Ω 5% 1/6W

R912 9965 100 02999 1kΩ 5% 1/6W

R913 9965 100 03144 82Ω 5% 1/6W

R914 9965 100 03144 82Ω 5% 1/6W

R915 9965 000 14049 100Ω 5% 0.16W

R916 9965 000 14049 100Ω 5% 0.16W

R922 9965 000 27858 27kΩ 5% 1/6W

R922A 9965 000 14055 33kΩ 5% 1/6W

R923 9965 000 13960 470Ω 5% 0.16W

R940 9965 000 15062 7.5kΩ 50% 1/6W

R941 9965 000 14049 100Ω 5% 0.16W

R942 9965 000 14049 100Ω 5% 0.16W

R963 9965 100 02999 1kΩ 5% 1/6W

R964 9965 100 02999 1kΩ 5% 1/6W

RT801 9965 000 25706 PTC 9Ω

VR801 9965 000 24388 Varistor Res Myg-14k300

1W

5% 1/6W

b

0030 9965 100 03164 COIL. 12uH +/-5%

L002 9965 000 15123 10μH 5%

L080 9965 000 15126 33μH 5%

L1001 9965 000 15124 22μH 5%

L1002 9965 000 15124 22μH 5%

L103 9965 000 15121 1μH 10%

L108 9965 000 15124 22μH 5%

L202 9965 000 15126 33μH 5%

L203 9965 100 03165 Bead BF-I35050R-730

L208 9965 000 15124 22μH 5%

L411 9965 000 15448 COIL WIDTH 64 UH

L412 9965 000 15129 Linearity coil 50μH

L815 9965 000 24357 Bead H75 (3.5X1X5)

L830 9965 000 24357 Bead H75 (3.5X1X5)

L833 9965 100 03165 Bead BF-I35050R-730

L834 9965 000 15193 100μH 10%

L835 9965 100 03165 Bead BF-I35050R-730

L840 9965 000 24357 Bead H75 (3.5X1X5)

L843 9965 000 15193 100μH 10%

T401 9965 100 03166 Transf. Hor. BCT-101

T402 9965 100 09393 FBT BSC25-0220w

T801 9965 100 09396 Filter LCL-ET2823-TCL

T803 9965 100 03203 Transf. Conv. BCK4035

X001 9965 000 15136 Xtal 8.0MHz

X1001 9965 000 26861 Xtal 18.432MHz (12pF)

X241 9965 000 34511 CER.FILTER LT4.5MH

Z101 9965 000 22820 SAW FILTER F1859

d

D001 9965 100 03096 Zener 5% 4V7 1/2W

D001B 9965 000 32018 LED 932205099682

D002 9965 100 02996 1N4148 (Switching)

D005 9965 100 02996 1N4148 (Switching)

D006 9965 100 02996 1N4148 (Switching)

D007 9965 100 02996 1N4148 (Switching)

D008 9965 000 13957 2.2kΩ 5% 1/6W

D009 9965 000 15818 BZX79-C6V2

D010 9965 000 15818 BZX79-C6V2

D011 9965 000 15818 BZX79-C6V2

D012 9965 000 15818 BZX79-C6V2

D020A 9965 100 03090 BAT85 (Switch.)

D090 9965 000 15817 3V9 1/2W 5%

D091 9965 100 02996 1N4148 (Switching)

D092 9965 100 02996 1N4148 (Switching)

D093 9965 100 02996 1N4148 (Switching)

D094 9965 100 02996 1N4148 (Switching)

D1001 9965 100 09400 10V/500MW

D102 9965 100 03098 CW574CD

D206 9965 100 02996 1N4148 (Switching)

D207 9965 000 15818 BZX79-C6V2

D301 9965 100 03094 1N4001 (Rectifier)

D302 9965 100 02996 1N4148 (Switching)

D303 9965 100 02996 1N4148 (Switching)

D304 9965 000 15817 3V9 1/2W 5%

D305 9965 100 02996 1N4148 (Switching)

D306 9965 100 02996 1N4148 (Switching)

D307 9965 100 02996 1N4148 (Switching)

D401 9965 100 03091 FR104 (Fast Rectifier)

D402 9965 100 03091 FR104 (Fast Rectifier)

D403 9965 100 02996 1N4148 (Switching)

D404 9965 000 15818 BZX79-C6V2

D405 9965 100 03091 FR104 (Fast Rectifier)

D406 9965 100 02996 1N4148 (Switching)

D440 9965 100 02996 1N4148 (Switching)

D442 9965 100 09387 500mW 15HSCST

D501 9965 100 02996 1N4148 (Switching)

D502 9965 100 02996 1N4148 (Switching)

D625 9965 100 02996 1N4148 (Switching)

D626 9965 100 02996 1N4148 (Switching)

D801 9965 000 15164 RL255

D802 9965 000 15164 RL255

D803 9965 000 15164 RL255

D804 9965 000 15164 RL255

D809 9965 000 20421 1H8

D814 9965 100 02996 1N4148 (Switching)

D819 9965 100 02996 1N4148 (Switching)

D820 9965 100 03091 FR104 (Fast Rectifier)

D821 9965 100 03172 18V 1/2W 5%

D822 9965 100 09394 20V 1/2W 5%

D823 9965 100 03172 18V 1/2W 5%

D830 9965 100 03174 GRU3ZX R=N

D833 9965 000 44366 RU3A

D840 9965 100 02996 1N4148 (Switching)

D841 9965 000 44714 RU3YX

D844 9965 100 03173 7V5 1/2W 5%

D902 9965 000 15818 BZX79-C6V2

D903 9965 000 15818 BZX79-C6V2

D904 9965 000 15818 BZX79-C6V2

D905 9965 000 15818 BZX79-C6V2

Page 33

ce

IC001 9965 000 17857 M24C08

IC1001 9965 000 25711 MSP3425G

IC201 9965 100 09392 TMPA8893CSCNG

IC301 9965 000 33275 STV9302B

IC402 9965 100 09389 CW7805CS

IC601 9965 100 03004 TDA7496SA R=N

IC801 9965 100 03179 TEA1506P R=N

IC802 9965 100 03178 HPC922-C

IC803 9965 100 03177 TL431ACLP

Q002 9965 100 03003 2SC1815-Y

Q003 9965 100 02997 ST2SA1015Y (PNP)

Q005 9965 100 02997 ST2SA1015Y (PNP)

Q093 9965 100 03003 2SC1815-Y

Q095 9965 100 03003 2SC1815-Y

Q097 9965 100 03003 2SC1815-Y

Q1003 9965 100 03003 2SC1815-Y

Q1005 9965 100 08485 BC847A (NPN)

Q1006 9965 100 08485 BC847A (NPN)

Q101 9965 000 14974 2SC3779D

Q208 9965 100 03003 2SC1815-Y

Q210 9965 100 02997 ST2SA1015Y (PNP)

Q241 9965 100 03003 2SC1815-Y

Q245 9965 100 03003 2SC1815-Y

Q401 9965 100 09388 2SC2235Y

Q402 9965 100 03099 BU450DZ

Q405 9965 100 02997 ST2SA1015Y (PNP)

Q501 9965 100 02998 2SC2482

Q502 9965 100 02998 2SC2482

Q503 9965 100 02998 2SC2482

Q510 9965 100 02997 ST2SA1015Y (PNP)

Q624 9965 100 03003 2SC1815-Y

Q625 9965 100 02997 ST2SA1015Y (PNP)

Q801 9965 100 02997 ST2SA1015Y (PNP)

Q802 9965 100 03003 2SC1815-Y

Q815 9965 100 03176 2SK2645-01MR

Q841 9965 100 03003 2SC1815-Y

Q842 9965 100 03003 2SC1815-Y

Q843 9965 100 03175 2SD2012

Q844 9965 100 03003 2SC1815-Y

Q845 9965 100 03003 2SC1815-Y

Q903 9965 100 03003 2SC1815-Y

Q905 9965 100 03003 2SC1815-Y

J012 9965 100 01107 Audio Cable 1500mm

J018 9965 100 01107 Audio Cable 1500mm

J019 9965 100 01107 Audio Cable 1500mm

J1001 9965 000 27224 0Ω 5% 1/10W 0603

J1002 9965 000 27224 0Ω 5% 1/10W 0603

J1003 9965 000 27224 0Ω 5% 1/10W 0603

J1007 9965 100 01107 Audio Cable 1500mm

J1010 9965 000 27224 0Ω 5% 1/10W 0603

J1011 9965 000 27224 0Ω 5% 1/10W 0603

J1012 9965 000 27224 0Ω 5% 1/10W 0603

J1013 9965 000 27224 0Ω 5% 1/10W 0603

J1014 9965 000 27224 0Ω 5% 1/10W 0603

J103 9965 000 14049 100Ω 5% 0.16W

J223 9965 100 01107 Audio Cable 1500mm

J238 9965 100 01107 Audio Cable 1500mm

J405 9965 100 01107 Audio Cable 1500mm

J803 9965 100 01107 Audio Cable 1500mm

J819 9965 100 01107 Audio Cable 1500mm

J830 9965 100 01107 Audio Cable 1500mm

J914 9965 100 01107 Audio Cable 1500mm

J922 9965 100 01107 Audio Cable 1500mm

J924 9965 100 01107 Audio Cable 1500mm

J925 9965 100 01107 Audio Cable 1500mm

K001 9965 000 17540 Switch

K002 9965 000 17540 Switch

K003 9965 000 17540 Switch

K004 9965 000 17540 Switch

Spare Parts List

EN 33TC8.1L CA 10.

Page 34

EN 34 TC8.1L CA11.

11. Revision List

Manual xxxx xxx xxxx.0

• First release.

Revision List

Loading...

Loading...