Page 1

3-1/2 DIGIT A/D CONVERTER WITH HOLD AND DIFFERENTIAL

REFERENCE INPUTS

1

TC811

2

FEATURES

■ Differential Reference Input

■ Display Hold Function

■ Fast Over-Range Recovery, Guaranteed Next

Reading Accuracy

■ Low Temperature Drift Internal

Reference ....................................... 35ppm/°C (Typ)

■ Guaranteed Zero Reading With Zero Input

■ Low Noise..................................................... 15µV

■ High Resolution (0.05%) and Wide Dynamic

Range (72 dB)

■ High Impedance Differential Input

■ Low Input Leakage Current .......................1pA Typ

10pA Max

■ Direct LCD Drive – No External Components

■ Precision Null Detection with True Polarity at Zero

■ Crystal Clock Oscillator

■ Available in DIP, Compact Flat Package or PLCC

■ Convenient 9V Battery Operation with

Low Power Dissipation (600µA Typical, 1mW

Maximum)

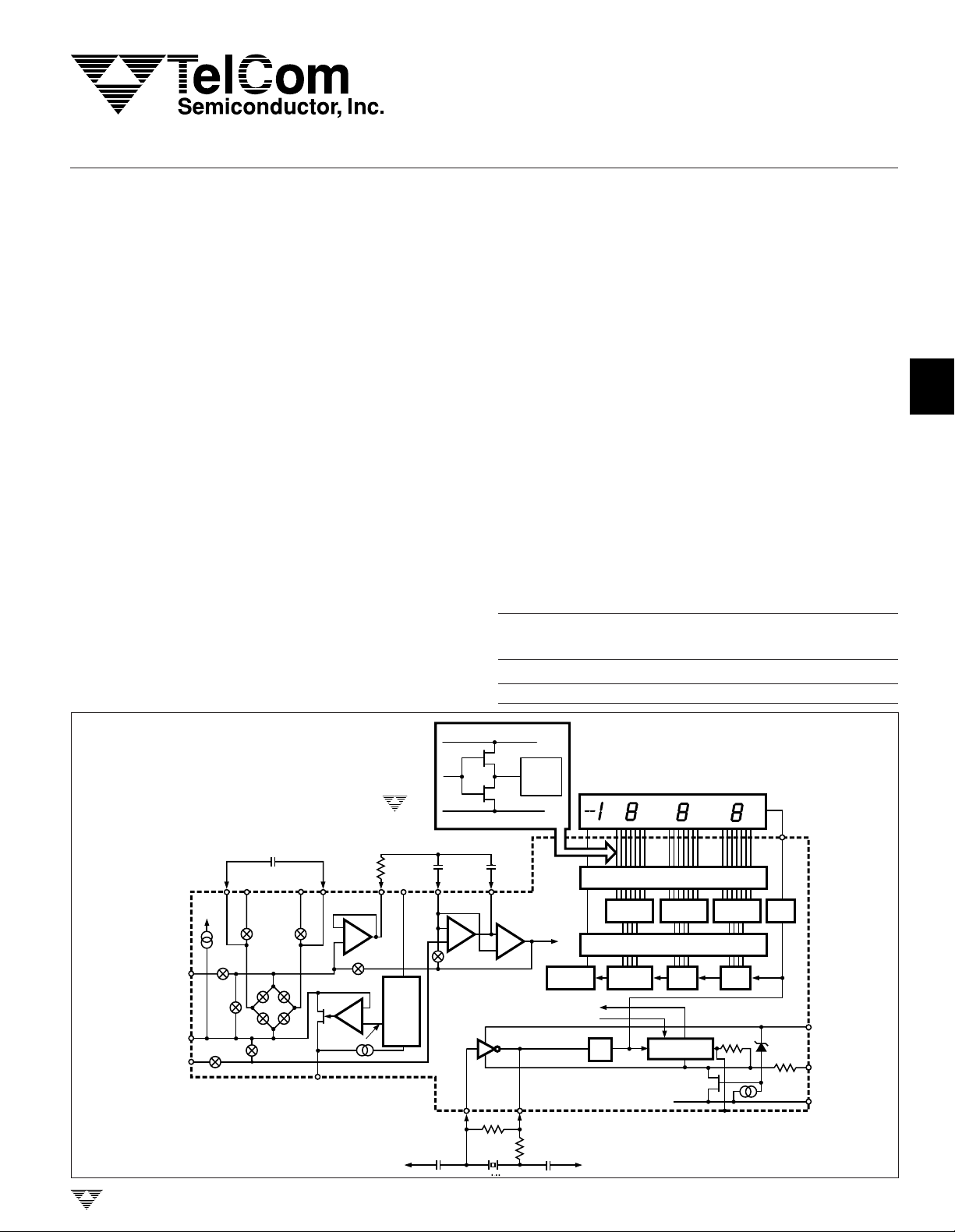

FUNCTIONAL BLOCK DIAGRAM

p-p

TYPICAL APPLICATIONS

■ Thermometry

■ Digital Meters

— Voltage/Current/Power

— pH Measurement

— Capacitance/Inductance

— Fluid Flow Rate/Viscosity

— Humidity

— Position

■ Panel Meters

■ LVDT Indicators

■ Portable Instrumentation

■ Digital Scales

■ Process Monitors

■ Gaussometers

■ Photometers

ORDERING INFORMATION

Temp. Max V

Part No. Package Range Tempco

TC811CKW 44-PQFP 0°C to +70°C 75 ppm/°C

TC811CPL

40-Pin Plastic DIP

0°C to +70°C 75 ppm/°C

REF

3

4

5

C

REF

V

ANALOG

COMMON

V

+

+

V

C

REF

REF

10

µA

31

+

IN

INT

A/Z

32

30

–

IN

DE (+)

INT

ZI & A/Z

DE

(–)DE(+)

AZ & DE (±)

V

DE (–)

–

REF

–

C

REF

33

ZI &

A/Z

V+– 3.0V

26

–

V

TELCOM SEMICONDUCTOR, INC.

V

BUFF

–

+

ZI

–

+

TC811CPL

R

INT

+

V

28

LOW

TEMPCO

V

REF

+

V

TYPICAL SEGMENT OUTPUT

INTERNAL DIGITAL GROUND

C

AZ

29

38

INTEGRATOR

–

+

A/Z

COMPARATOR

40

OSC

1

10pF

+

V

0.5mA

SEGMENT

OUTPUT

2mA

C

INT

V

INT

27343635

TO

DIGITAL

SECTION

+

–

THOUSANDS

TO SWITCH DRIVERS

FROM COMPARATOR OUTPUT

CLOCK

39

22MΩ

470k

OSC

2

20pF

f

OSC

LCD DISPLAY

LCD SEGMENT DRIVERS

7 SEGMENT

DECODE

HUNDREDS

4

INTERNAL DIGITAL GOUND

+

V

7 SEGMENT

DATA LATCH

CONTROL LOGIC

7 SEGMENT

V

= 1V

DECODE

≈70kΩ

TH

1

HLDR

DECODE

TENS UNITS

BACKPLANE

21

200

6.2V

Ω

500

38

V

TEST

26

V

6

7

+

–

8

TC811-7 11/5/96

3-137

Page 2

TC811

3-1/2 DIGIT A/D CONVERTER WITH HOLD AND

DIFFERENTIAL REFERENCE INPUTS

GENERAL DESCRIPTION

The TC811 is a low power, 3-1/2 digit, LCD display

analog-to-digital converter. This device incorporates both a

display hold feature and differential reference inputs. A

crystal oscillator, which only requires two pins, permits

added features while retaining a 40-pin package. An additional feature is an "Integrator Output Zero" phase which

guarantees rapid input overrange recovery.

The TC811 display hold (HLDR) function can be used to

"freeze" the LCD display. The displayed reading will remain

indefinitely as long as HLDR is held high. Conversions

continue but the output data display latches are not updated.

The TC811 also includes a differential reference for easy

ratiometric measurements. Circuits which use the

7106/26/36 can easily be upgraded to include the hold

function with the TC811.

The TC811 has an improved internal zener reference

voltage circuit which maintains the Analog Common temperature drift to 35ppm/°C (typical) and 75ppm/°C (maximum). This represents an improvement of two to four times

over similar 3-1/2 digit converters, eliminating the need for

a costly, space consuming external reference source.

The TC811 limits linearity error to less than one count on

both the 200mV and the 2.00V full-scale ranges. Rollover

error—the difference in readings for equal magnitude but

opposite polarity input signals—is below ±1 count. High

impedance differential inputs offer 1pA leakage currents

and a 1012Ω input impedance. The 15µV

mance guarantees a “rock solid” reading. The Auto Zero

cycle guarantees a zero display readout for a zero volt input.

The single chip CMOS TC811 incorporates all the active

devices for a 3-1/2 digit analog to digital converter to directly

drive an LCD display. Onboard oscillator, precision voltage

reference and display segment and backplane drivers sim-

noise perfor-

p-p

plify system integration, reduce board space requirements

and lower total cost. A low cost, high resolution (0.05%)

indicating meter requires only a TC811, an LCD display, five

resistors, six capacitors, a crystal, and a 9V battery. Compact, hand held multimeter designs benefit from the TelCom

Semiconductor small footprint package option.

The TC811 uses a dual slope conversion technique

which will reject interference signals if the converters integration time is set to a multiple of the interference signal

period. This is especially useful in industrial measurement

environments where 50, 60 and 400Hz line frequency signals are present.

ABSOLUTE MAXIMUM RATINGS*

Supply Voltage (V+ to V–)............................................15V

Analog Input voltage (Either Input)1.....................V+ to V

Reference Input Voltage ...................................... V+ to V

Clock Input ......................................................TEST to V

Power Dissipation2 (TA ≤ 70°C)

44-Pin Flat Package .........................................1.00W

40-Pin Plastic DIP.............................................1.23W

Operating Temperature Range

Commercial Package (C) ......................0°C to +70°C

Industrial Package (I)........................– 25°C to +85°C

Storage Temperature Range ................– 65°C to +150°C

Lead Temperature (Soldering, 10 sec) .................+300°C

*Static-sensitive device. Unused devices must be stored in conductive

material. Protect devices from static discharge and static fields. Stresses

above those listed under "Absolute Maximum Ratings" may cause permanent damage to the device. These are stress ratings only and functional

operation of the device at these or any other conditions above those

indicated in the operation sections of the specifications is not implied.

Exposure to absolute maximum rating conditions for extended periods may

affect device reliability.

–

–

+

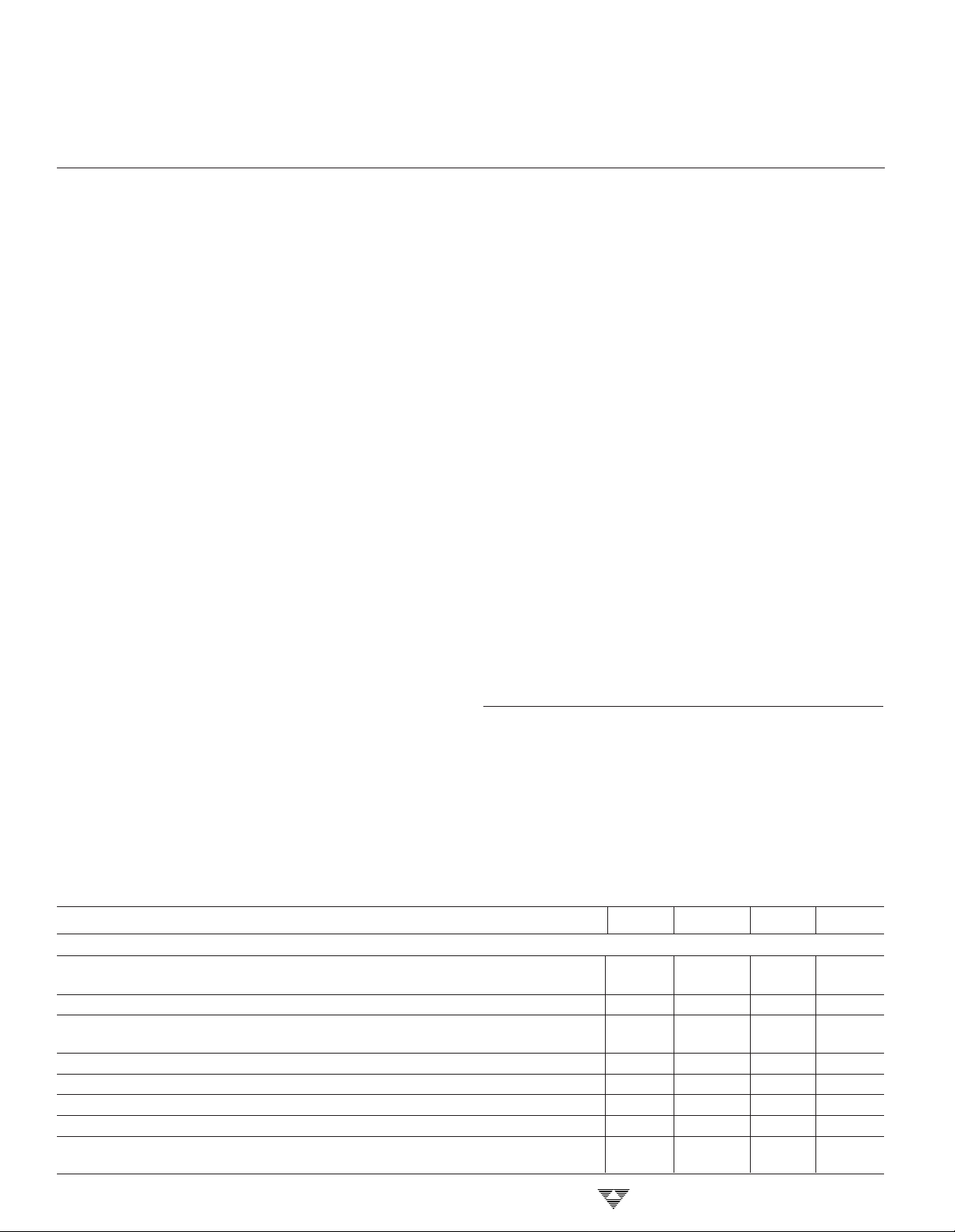

ELECTRICAL CHARACTERISTICS: V

Supply

= 9V, f

= 32.768kHz, and TA = 25°C, unless otherwise noted.

CLOCK

Symbol Parameter Test Conditions Min Typ Max Unit

Input

— Zero Input Reading VIN = 0V – 000.0 ±000.0 +000.0 Digital

VFS = 200mV Reading

— Zero Reading Drift VIN = 0V, 0°C ≤ TA ≤ 70°C — 0.2 1 µV/°C

— Ratiometric Reading VIN = V

NL Linearity Error VFS = 200mV or 2.000V – 1 ±0.2 +1 Counts

E

R

e

N

I

L

CMRR Common-Mode Rejection VCM = ±1V, VIN = 0V, — 50 — µV/V

3-138

Roll Over Error VIN– = VIN+ ≈ 200mV – 1 ±0.2 +1 Counts

Noise VIN = 0V, VFS = 200mV — 15 — µV

Input Leakage Current VIN = 0V — 1 10 pA

VFS = 200mV

REF

, V

= 100mV 999 999/1000 1000 Digital

REF

TELCOM SEMICONDUCTOR, INC.

Reading

P-P

Page 3

3-1/2 DIGIT A/D CONVERTER WITH HOLD AND

DIFFERENTIAL REFERENCE INPUTS

1

TC811

ELECTRICAL CHARACTERISTICS: V

Supply

= 9V, f

= 32.768kHz, and TA = 25°C, unless otherwise noted.

CLOCK

Symbol Parameter Test Conditions Min Typ Max Unit

TC

SF

Analog Common Section

V

CTC

V

C

Hold Pin Input Section

V

IL

V

IH

LCD Drive Section

V

SD

V

SD

Power Supply

I

SUP

NOTES: 1. Input voltages may exceed supply voltages when input current is limited to 100µA.

Scale Factor Temperature VIN = 199mV, 0°C ≤ TA ≤ 70°C — 1 5 ppm/°C

Coefficient (ext. V

tc = 0ppm)

REF

Analog Common 250KΩ from V+ to Analog Common — — — —

Temperature Coefficient 0°C ≤ T

≤ 70°C————

A

"C" Commercial — 35 75 ppm/°C

"I" Industrial — 35 100 ppm/°C

Analog Common Voltage 250kΩ from V+ to Analog Common 2.7 3.05 3.35 Volts

Input Resistance Pin 1 to Pin 37 — 70 — kΩ

Input Low Voltage Pin 1 — — Test +1.5 V

Input High Voltage Pin 1 V+ – 1.5 — — V

3

LCD Segment Drive Voltage V+ to V– = 9V 4 5 6 V

LCD Backplane Drive Voltage V+ to V– = 9V 4 5 6 V

Power Supply Current VIN = 0V, V+ to V– = 9V — — — —

f

= 16kHz — 70 100 µA

OSC

f

= 48kHz — 90 125 µA

OSC

2. Dissipation rating assumes device is mounted with all leads soldered to a printed circuit board.

3. Backplane drive is in phase with the segment drive for "segment off" 180° out of phase for "segment on." Frequency is 20 times the

conversion rate. Average DC component is less than 50mV.

P-P

P-P

2

3

4

5

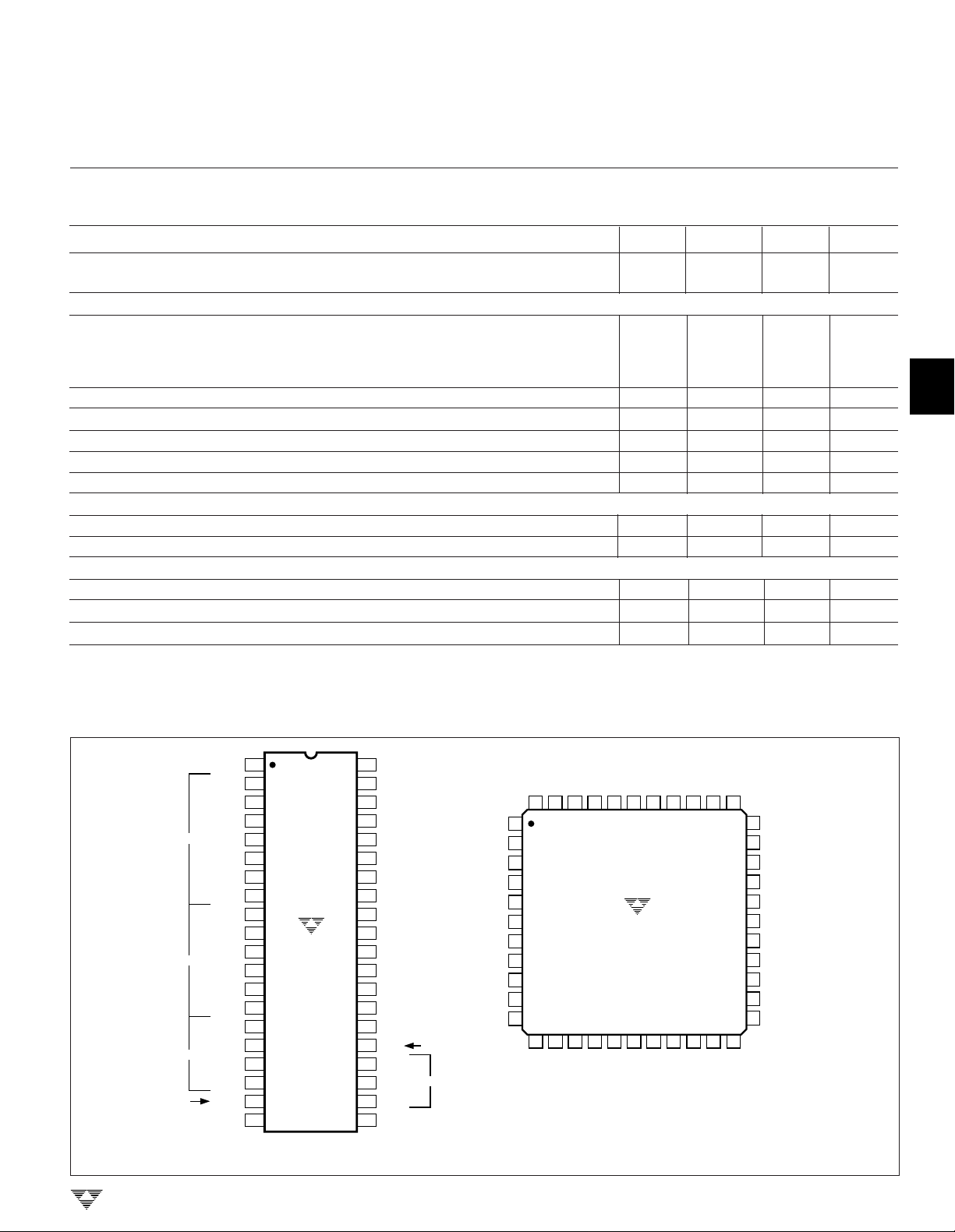

PIN CONFIGURATIONS

HLDR

D

C

B

1's

A

F

G

E

D

C

B

10's

A

F

E

D

B

100's

F

E

1000's

AB

POL

(MINUS SIGN)

28

OSC

40

OSC

39

38

37

36

35

34

33

32

31

30

29

27

26

25

24

23

22

21

1

NORMAL PIN

2

CONFIGURATION

1

3

1

4

1

5

1

6

1

7

1

8

1

9

2

10

2

2

2

2

2

3

3

3

3

4

NC = NO INTERNAL CONNECTION

11

12

13

14

15

16

17

18

19

20

TC811CPL

(40-PIN PDIP)

1

2

+

V

TEST

+

V

REF

+

C

REF

–

C

REF

–

V

REF

ANALOG

COMMON

+

V

IN

–

V

IN

C

AZ

V

BUFF

V

INT

–

V

G

10's

2

C

3

100's

A

3

G

3

BP

(BACKPLANE)

NC

NC

TEST

V

NC

OSC

OSC

HLDR

D

C

B

–

+

+

REF

REF

REF

C

C

V

44 43 42 41 39 3840

1

2

3

+

4

5

6

2

7

1

8

9

1

10

1

11

1

12 13 14 15 17 18

1F1G1E1

A

–

REF

COM

V

TC811CKW

(PQFP)

16

D2C2B2A

+

–

IN

V

BUFF35INT

IN

AZ

C

V

37

36

19 20 21 22

2F2E2

–

VVV

34

33

NC

32

G

2

C

31

3

30

A

3

29

G

3

BP

28

POL

27

26

AB

4

E

25

3

F

24

3

23

B

3

3

D

6

7

8

TELCOM SEMICONDUCTOR, INC.

3-139

Page 4

3-1/2 DIGIT A/D CONVERTER WITH HOLD AND

DIFFERENTIAL REFERENCE INPUTS

TC811

PIN DESCRIPTION

Pin No.

40-Pin Plastic DIP Symbol Description

1 HLDR Hold pin, logic 1 holds present display reading.

2D

3C

4B

5A

6F

7G

8E

9D

10 C

11 B

12 A

13 F

14 E

15 D

16 B

17 F

18 E

19 AB

1

1

1

1

1

1

1

2

2

2

2

2

2

3

3

3

3

4

20 POL Activates the negative polarity display.

21 BP Backplane drive output.

22 G

23 A

24 C

25 G

26 V

27 V

28 V

29 C

3

3

3

2

–

INT

BUFF

AZ

30 VIN– Analog input low.

31 VIN+ Analog input high.

32 COM Analog Common: Internal zero reference.

33 V

34 C

35 C

36 V

– Reference input low.

REF

– Negative connection for reference capacitor.

REF

+ Positive connection for reference capacitor.

REF

+ Reference input high.

REF

37 TEST All LCD segment test when pulled high (V+).

38 V

39 OSC

40 OSC

+

2

1

Activates the D section of the units display.

Activates the C section of the units display.

Activates the B section of the units display.

Activates the A section of the units display.

Activates the F section of the units display.

Activates the G section of the units display.

Activates the E section of the units display.

Activates the D section of the tens display.

Activates the C section of the tens display.

Activates the B section of the tens display.

Activates the A section of the tens display.

Activates the F section of the tens display.

Activates the E section of the tens display.

Activates the D section of the hundreds display.

Activates the B section of the hundreds display.

Activates the F section of the hundreds display.

Activates the E section of the hundreds display.

Activates both halves of the 1 in the thousands display.

Activates the G section of the hundreds display.

Activates the A section of the hundreds display.

Activates the C section of the hundreds display.

Activates the G section of the tens display.

Negative power supply voltage.

Integrator output, connection for C

Buffer output, connection for R

Integrator input, connection for CAZ.

Positive power supply voltage.

Crystal oscillator output.

Crystal oscillator input.

INT

.

INT

.

3-140

TELCOM SEMICONDUCTOR, INC.

Page 5

3-1/2 DIGIT A/D CONVERTER WITH HOLD AND

+

–

REF

VOLTAGE

ANALOG

INPUT

SIGNAL

+

–

+/–

DISPLAY

SWITCH

DRIVER

CONTROL

LOGIC

INTEGRATOR

OUTPUT

CLOCK

COUNTER

POLARITY CONTROL

PHASE

CONTROL

V

IN

V

IN

V

FULL SCALE

1.2 V

FULL SCALE

VARIABLE

REFERENCE

INTEGRATE

TIME

FIXED

SIGNAL

INTEGRATE

TIME

INTEGRATOR

C

COMPARATOR

≈

≈

DIFFERENTIAL REFERENCE INPUTS

0.1µF

33

+

ANALOG

INPUT

–

1MΩ

0.01µF

180kΩ

0.068µF

35

34

+

C

C

REF

REF

31

+

V

IN

–

30

V

IN

ANALOG

32

COMMON

28

V

BUFF

0.47

µF

29

27

20pF

+

V

TC811

C

AZ

V

INT

OSC

2

39 40

22MΩ

470k

9–19

22–25

POL

HLDR

V

V

OSC

BP

V

+

REF

–

REF

V

+

–

1

SEGMENT

DRIVE

20

MINUS SIGN

21

38

1

36

33

26

10pF

TO ANALOG COMMON

(PIN 32)

LCD

BACKPLANE

240kΩ

+

10k Ω

2 CONVERSION/SEC

+

V

9V

1

TC811

2

3

Figure 1. Typical Operating Circuit

GENERAL THEORY OF OPERATION

Dual-Slope Conversion Principles

(All Pin Designations Refer to 40-Pin DIP Package)

The TC811 is a dual slope, integrating analog-to-digital

converter. An understanding of the dual slope conversion

technique will aid the user in following the detailed TC811

theory of operation following this section. A conventional

dual slope converter measurement cycle has two distinct

phases:

1) Input Signal Integration

2) Reference Voltage Integration (Deintegration)

Referring to Figure 2, the unknown input signal to be

converted is integrated from zero for a fixed time period

(T

), measured by counting clock pulses. A constant

INT

reference voltage of the opposite polarity is then integrated

until the integrator output voltage returns to zero. The

reference integration (deintegration) time (T

directly proportional to the unknown input voltage (VIN).

In a simple dual slope converter, a complete conversion

requires the integrator output to “ramp-up” from zero and

“ramp-down” back to zero. A simple mathematical equation

relates the input signal, reference voltage and integration

time:

1 V

R

INT CINT

∫

t

INT

R

0

VIN(t) dt =

REF tDEINT

INT CINT

DEINT

) is then

Figure 2. Basic Dual Slope Converter

30

20

10

NORMAL MODE REJECTION (dB)

0

0.1/T 1/T 10/T

Figure 3. Normal-Mode Rejection of

Dual Slope Converter

For a constant V

VIN = V

REF

T = MEASUREMENT PERIOD

INPUT FREQUENCY

:

INT

t

DEINT

[

t

INT

]

4

5

6

7

where:

V

= Reference voltage

REF

t

INT

t

DEINT

TELCOM SEMICONDUCTOR, INC.

= Integration Time

= Deintegration Time

8

3-141

Page 6

3-1/2 DIGIT A/D CONVERTER WITH HOLD AND

TC811

Accuracy in a dual slope converter is unrelated to the

integrating resistor and capacitor values as long as they are

stable during a measurement cycle. An inherent benefit of

the dual slope technique is noise immunity. Noise spikes are

integrated or averaged to zero during the integration periods, making integration ADCs immune to the large conversion errors that plague successive approximation converters in high noise environments. Interfering signals, with

frequency components at multiples of the averaging (integrating) period, will be attenuated. (see Figure 3). Integrating ADCs commonly operate with the signal integration

period set to a multiple of the 50/60Hz power line period.

DIFFERENTIAL REFERENCE INPUTS

INT

DE-INT

ZI

AZ

1000

1–2000

11–140

910–2900

4000

THEORY OF OPERATION

Analog Section

In addition to the basic integrate and deintegrate dualslope cycles discussed above, the TC811 design incorporates an “Integrator Output Zero” cycle and an “Auto Zero”

cycle. These additional cycles ensure the integrator starts at

0V (even after a severe overrange conversion) and that all

offset voltage errors (buffer amplifier, integrator and comparator) are removed from the conversion. A true digital zero

reading is assured without any external adjustments.

A complete conversion consists of four distinct phases:

(1) Integrator Output Zero Cycle

(2) Auto Zero Cycle

(3) Signal Integrate Cycle

(4) Reference Deintegrate Cycle

Integrator Output Zero Cycle

This phase guarantees that the integrator output is at

zero volts before the system zero phase is entered, ensuring

that the true system offset voltages will be compensated for

even after an overrange conversion. The duration of this

phase is variable, being a function of the number of counts

(clock cycles) required for deintegration.

The Integrator Output Zero cycle will last from 11 to 140

counts for non-over-range conversions and from 31 to 640

counts for overrange conversions.

Auto Zero Cycle

During the Auto Zero cycle, the differential input signal

is disconnected from the measurement circuit by opening

internal analog switches and the internal nodes are shorted

to Analog Common (0V ref.) to establish a zero input

condition. Additional analog switches close a feedback loop

around the integrator and comparator to permit comparator

offset voltage error compensation. A voltage established on

CAZ then compensates for internal device offset voltages

Figure 4a. Conversion Timing During Normal Operation

INT

DE-INT

ZI

AZ

Figure 4b. Conversion Timing During Overrange Operation

1000

2001–2090

31–640

300–910

4000

during the measurement cycle. The Auto Zero cycle residual

is typically 10 to 15µV.

The Auto Zero duration is from 910 to 2,900 counts for

non-over-range conversions and from 300 to 910 counts for

overrange conversions.

Signal Integration Cycle

Upon completion of the Auto Zero cycle, the Auto Zero

loop is opened and the internal differential inputs connect to

+

V

and V

IN

for a fixed time period which, in the TC811 is 1000 counts

(4000 clock periods). The externally set clock frequency is

divided by four before clocking the internal counters. The

integration time period is:

T

The differential input voltage must be within the device

common-mode range when the converter and measured

system share the same power supply common (ground).

INT

–

. The differential input signal is then integrated

IN

4000

=

f

OSC

3-142

TELCOM SEMICONDUCTOR, INC.

Page 7

3-1/2 DIGIT A/D CONVERTER WITH HOLD AND

DIFFERENTIAL REFERENCE INPUTS

1

TC811

If the converter and measured system do not share the same

power supply common, as in battery powered applications,

–

V

should be tied to Analog Common.

IN

Polarity is determined at the end of signal integration

phase. The sign bit is a “true polarity” indication in that

signals less than 1 LSB are correctly determined. This

allows precision null detection which is limited only by device

noise and Auto Zero residual offsets.

Reference Integrate (Deintegrate) Cycle

The reference capacitor, which was charged during the

Auto Zero cycle, is connected to the input of the integrating

amplifier. The internal sign logic insures that the polarity of

the reference voltage is always connected in the phase

which is opposite to that of the input voltage. This causes the

integrator to ramp back to zero at a constant rate which is

determined by the reference potential.

The amount of time required (T

amplifier to reach zero is directly proportional to the amplitude of the voltage that was put on the integrating capacitor

(V

) during the integration cycle:

INT

R

T

DEINT

The digital reading displayed Is:

Digital Count = 1000

The oscillator frequency is divided by 4 prior to clocking

the internal decade counters. The four phase measurement

cycle takes a total of 4000 counts or 16000 clock pulses. The

4000 count cycle is independent of input signal magnitude

or polarity.

Each phase of the measurement cycle has the following

length:

1) Auto Zero: 300 to 2900 Counts

2) Signal Integrate: 1000 Counts

INT CINT VINT

=

V

REF

+

V

– V

IN

V

REF

) for the integrating

DEINT

–

IN

the need for an external reference. Some minor component

changes are required to upgrade existing designs, reduce

power dissipation, and improve the overall performance.

(see Oscillator Components)

Digital Section

The TC811 contains all the segment drivers necessary

to directly drive a 3-1/2 digit liquid crystal display (LCD). An

LCD backplane driver is included. The backplane frequency

is the external clock frequency divided by 800. For three

conversions/second the backplane frequency is 60Hz with

a 5V nominal amplitude. When a segment driver is in phase

with the backplane signal the segment of “OFF”. An out of

phase segment drive signal causes the segment to be “ON”

or visible. This AC drive configuration results in negligible

DC voltage across each LCD segment. This insures long

LCD display life. The polarity segment driver is “ON” for

negative analog inputs. If VIN+ and VIN– are reversed then

this indicator would reverse.

TEST Function (TEST)

On the TC811, when TEST is pulled to a logical “HIGH”,

all segments are turned “ON”. The display will read “-1888”.

During this mode the LCD segments have a constant DC

voltage impressed. Do not leave the display in this mode for

more than several minutes. LCD displays may be destroyed

if operated with DC levels for extended periods.

The display FONT and segment drive assignment are

shown in Figure 5.

DISPLAY FONT

1000's 100's 10's 1's

2

3

4

5

6

This time period is fixed. The integration period is:

T

INT

Where f

3) Reference Integrate: 0 to 2000 Counts

4) Integrator Output Zero: 11 to 640 Counts

The TC811 can replace the ICL7106/26/36 in circuits

which require both the hold function and a differential

reference. The TC811 offers a greatly improved internal

reference temperature coefficient, which can often eliminate

TELCOM SEMICONDUCTOR, INC.

4000

= = 1000 Counts

f

OSC

is the crystal oscillator frequency.

OSC

Figure 5. Display FONT and Segment Assignment

HOLD Reading Input (HLDR)

When HLDR is at a logic “HI” the latch will not be

updated. Conversions will continue but will not be updated

until HLDR is returned to “LOW”. To continuously update the

display, connect HLDR to ground or leave it open. This input

is CMOS compatible and has an internal resistance of 70kΩ

(typical) tied to TEST.

3-143

7

8

Page 8

TC811

3-1/2 DIGIT A/D CONVERTER WITH HOLD AND

DIFFERENTIAL REFERENCE INPUTS

COMPONENT VALUE SELECTION

Auto Zero Capacitor - C

The value of the Auto Zero capacitor (CAZ) has some

influence on system noise. A 0.47µF capacitor is recommended for 200mV full-scale applications where 1LSB is

100µV. A 0.10µF capacitor should be used for 2.0V fullscale applications. A capacitor with low dielectric absorption

(Mylar) is required.

Reference Voltage Capacitor -C

The reference voltage used to ramp the integrator

output voltage back to zero during the reference integrate

cycle is stored on C

. A 0.1µF capacitor is typical. If the

REF

application requires a sensitivity of 200mV full-scale, increase C

to 1.0µF. Rollover error will be held to less than

REF

1/2 count. A good quality, low leakage capacitor, such as

Mylar, should be used.

Integrating Capacitor - C

CINT should be selected to maximize integrator output

voltage swing without causing output saturation. Analog

common will normally supply the differential voltage reference. For this case a ±2V integrator output swing is optimum

when the analog input is near full-scale. For 2 or 2.5 reading/

second (f

value is suggested. If a different oscillator frequency is used,

C

must be changed in inverse proportion to maintain the

INT

nominal ±2V integrator swing. An exact expression for C

is :

C

INT

where:

f

= Clock frequency at Pin 39

OSC

VFS = Full-scale input voltage

R

= Integrating resistor

INT

V

= Desired full-scale integrator output swing

INT

= 32kHz or 40kHz) and VFS = 200mV, a .068µF

OSC

=

V

INT RINT fOSC

4000 V

FS

AZ

REF

INT

INT

Oscillator Components

The internal oscillator has been designed to operate

with a quartz crystal, such as the Statek CX-1V series. Such

crystals are very small and are available in a variety of

standard frequencies. Note that f

generate the TC811 internal control clock. The backplane

drive signal is derived by dividing f

To achieve maximum rejection of ac-line noise pickup,

a 40kHz crystal should be used. This frequency will yield an

integration period of 100msec and will reject both 50Hz and

60Hz noise. For prototyping or cost-sensitive applications a

32.768kHz watch crystal can be used, and will produce

about 25dB of line-noise rejection. Other crystal frequencies, from 16kHz to 48kHz, can also be used.

Pins 39 and 40 make up the oscillator section of the

TC811. Figures 6a and 6b show some typical conversion

rate component values.

The LCD backplane frequency is derived by dividing the

oscillator frequency by 800. Capacitive loading of the LCD

may compromise display performance if the oscillator is run

much over 48kHz.

Reference Voltage (V

REF

A full-scale reading (2000 counts) requires the input

signal be twice the reference voltage.

In some applications a scale factor other than unity may

exist, such as between a transducer output voltage and the

required digital reading. Assume, for example, a pressure

transducer output is 400mV for 2000lb/in2. Rather than

dividing the input voltage by two, the reference voltage

should be set to 200mV. This permits the transducer input to

be used directly.

TC811

is divided by four to

OSC

by 800.

OSC

)

C

must have low dielectric absorption to minimize

INT

roll-over error. A polypropylene capacitor is recommended.

Integrating Resistor -R

INT

The input buffer amplifier and integrator are designed

with class A output stages which have idling currents of 6µA.

The integrator and buffer can supply 1µA drive currents with

negligible linearity errors. R

is chosen to remain in the

INT

output stage linear drive region but not so large that printed

circuit board leakage currents induce errors. For a 200mV

full-scale, R

should be about 180kΩ. A 2.0V full-scale

INT

requires abut 1.8MΩ.

3-144

OSC1

40

22MΩ

40.0 kHz

10pF

Figure 6a. TC811 Oscillator

TELCOM SEMICONDUCTOR, INC.

OSC2

470k

20pF

+

V

3839

9V

+

Page 9

3-1/2 DIGIT A/D CONVERTER WITH HOLD AND

DIFFERENTIAL REFERENCE INPUTS

1

TC811

Oscillator Full-Scale Voltage (VFS)

Freq. (kHz) 200mV 2.0V

RINT CINT RINT CINT

32.768 180k 0.068µF 1.8M 0.068µF

40 150k 0.068µF 1.5M 0.068µF

Figure 6b.

DEVICE PIN FUNCTIONAL DESCRIPTION

Differential Signal Inputs (V

–

V

(Pin 30))

IN

The TC811 is designed with true differential inputs and

accepts input signals within the input stage common mode

voltage range (VCM). The typical range is V+ – 1.0 to V– +

1.5V. Common-mode voltages are removed from the system when the TC811 operates from a battery or floating

power source (isolated from measured system) and V

connected to Analog Common. (see Figure 8)

In systems where common-mode voltages exist, the

86dB common-mode rejection ratio minimizes error. Common-mode voltages do, however, affect the integrator output level. A worse case condition exists if a large positive

VCM exists in conjunction with a full-scale negative differential signal. The negative signal drives the integrator output

positive along with VCM (Figure 8). For such applications the

integrator output swing can be reduced below the recommended 2.0V full-scale swing. The integrator output will

swing within 0.3V of V+ or V– without increased linearity

error.

+

(Pin 31),

IN

–

is

IN

inputs permit ratiometric measurements and simplify interfacing with sensors such as load cells and temperature

sensors. The TC811 is ideally suited to applications in handheld multimeters, panel meters, and portable instrumentation. The reference voltage can be generated anywhere

within the V+ to V– power supply range.

To prevent rollover type errors from being induced by

large common-mode voltages, C

pared to stray node capacitance. A 0.1µF capacitor is a

typical value.

The TC811 offers a significantly improved Analog Common temperature coefficient. This provides a very stable

voltage suitable for use as a voltage reference. The temperature coefficient of Analog Common is typically

35ppm/°C.

INPUT

BUFFER

+

V

IN

–

V

CM

+

–

Where:

R

I

T

V

=

I

RI C

INTEGRATION TIMET

==

I

C

INTEGRATION CAPACITOR

=

I

INTEGRATION RESISTOR

=

R

I

should be large com-

REF

C

I

–

+

INTEGRATOR

I

V

–

[

CMVIN

I

V

I

[

4000

f

OSC

2

3

4

5

GND

–

REF

(Pin 33)

V

V

V

ANALOG

COMMON

+

–

BUF

V

Reference (V

Unlike the ICL7116, the TC811 has a differential refer-

ence as well as the “hold” function. The differential reference

TELCOM SEMICONDUCTOR, INC.

+

REF

+

V

V

POWER

SOURCE

(Pin 36), V

MEASURED

SYSTEM

+

V

–

V

–

GND

Figure 7. Common-Mode Voltage Removed in Battery Operation With V

CAZV

TC811

–

V

REF

Figure 8. Common-Mode Voltage Reduces Available

SEGMENT

INT

+

+

V

REF

+

Integrator Swing. (V

DRIVE

BPPOL

OSC

1

OSC

2

–

V

9V

LCD DISPLAY

20MΩ

470k

–

= Analog Common

IN

COM

≠ VIN)

10pF

40kHZ

20 pF

6

+

V

7

+

V

8

3-145

Page 10

TC811

TC811

BP

TEST

V

+

V

+

GND

TO LCD

DECIMAL

POINT

TO LCD

BACKPLANE

4049

TC811

DECIMAL

POINT

SELECT

V

+

V

+

TEST

GND

4030

TO LCD

DECIMAL

POINTS

BP

HDLR

TO "HOLD"

ANNUNCIATOR

3-1/2 DIGIT A/D CONVERTER WITH HOLD AND

DIFFERENTIAL REFERENCE INPUTS

Analog Common (Pin 32)

The Analog Common pin is set at a voltage potential

approximately 3.0V below V+. This potential is guaranteed

to be between 2.70V and 3.35V below V+. Analog common

is tied internally to an N channel FET capable of sinking

100µA. This FET will hold the common line at 3.0V below V

should an external load attempt to pull the common line

toward V+. Analog common source current is limited to 1µA.

Analog common is therefore easily pulled to a more negative

voltage (i.e. below V+– 3.0V).

The TC811 connects the internal V

Analog Common during the Auto Zero cycle. During the

reference integrate phase V

Common. If V

–

is not externally connected to Analog

IN

–

is connected to Analog

IN

Common, a common-mode voltage exists. This is rejected

by the converter’s 86dB common-mode rejection ratio. In

battery powered applications, Analog Common and V

usually connected, removing common-mode voltage concerns. In systems where V

supply ground or to a given voltage, Analog Common should

be connected to V

–

.

IN

–

is connected to the power

IN

The Analog Common pin serves to set the analog

section reference or common point. The TC811 is specifically designed to operate from a battery or in any measurement system where input signals are not referenced (float)

with respect to the TC811 power source. The Analog Common potential of V+ – 3.0V gives a 7V end of battery life

voltage. The analog common potential has a voltage coefficient of 0.001%/%.

With a sufficiently high total supply voltage (V+ – V– >

7.0V), Analog Common is a very stable potential with

excellent temperature stability (typically 35ppm/°C). This

potential can be used to generate the TC811 reference

voltage. An external voltage reference will be unnecessary

in most cases because of the 35ppm/°C temperature coefficient. See TC811 Internal Voltage Reference discussion.

TEST (Pin 37)

The TEST pin potential is 5V less the V+. TEST may be

used as the negative power supply connection when interfacing the TC811 to external CMOS logic. The TEST pin is

tied to the internally generated negative logic supply through

a 500Ω resistor. The TEST pin may be used to sink up to

1mA. See the applications section for additional information

on using TEST as a negative digital logic supply.

If TEST is pulled “HIGH” (V+), all segments plus the

minus sign will be activated. Do not operate in this mode for

more than several minutes, because when TEST is pulled to

V+, the LCD Segments are impressed with a DC voltage

which may cause damage to the LCD.

3-146

+

and V

IN

–

inputs to

IN

–

IN

are

APPLICATIONS INFORMATION

Decimal Point and Annunciator Drive

The TEST pin is connected to the internally generated

digital logic supply ground through a 500Ω resistor. The

TEST pin may be used as the negative supply for external

+

CMOS gate segment drivers. LCD display annunciators for

decimal points, low battery indication, or function indication

may be added without adding an additional supply. No more

than 1mA should be supplied by the TEST pin. The TEST pin

potential is approximately 5V below V+.

Internal Voltage Reference

The TC811 Analog Common voltage temperature stability has been significantly improved. This improved device

can be used to upgrade old systems and design new

systems without external voltage references. External R and

C values do not need to be changed, however, noise

performance will be improved by increasing CAZ (See Auto

Zero Capacitor section). Figure 10 shows Analog Common

supplying the necessary voltage reference for the TC811.

Figure 9. Display Annunciator Drivers

TELCOM SEMICONDUCTOR, INC.

Page 11

3-1/2 DIGIT A/D CONVERTER WITH HOLD AND

DIFFERENTIAL REFERENCE INPUTS

Liquid Crystal Display Sources

Several LCD manufactures supply standard LCD displays to interface with the TC811 3-1/2 digit analog-to-digital

converter.

Representative

Manufacturer Address/Phone Part Numbers

Crystaloid 5282 Hudson Dr., C5335, H5535,

Electronics Hudson, OH 44236 T5135, SX440

216-655-2429

AND 770 Airport Blvd., FE 0801,

Burlingame, CA 94010 FE 0203

415-347-9916

EPSON 3415 Kashikawa St., LD-B709BZ

Torrence, CA 90505 LD-H7992AZ

212-534-0360

Hamlin, Inc. 612 E. Lake St., 3902, 3933, 3903

Lake Mills, WI 53551

414-648-2361

*

NOTE:

Contact LCD manufacturer for full product listing/specifications.

*

TC811

9V

+

26

–

V

TC811

ANALOG

COMMON

SET V

Figure 10. TC811 Internal Voltage Reference Connection

REF

V

+

V

REF

–

V

REF

= 1/2 V

38

+

36

V

REF

33

32

FULL SCALE

240kΩ

10kΩ

1

2

3

4

Oscillator Crystal Source

Representative

Manufacturer Address/Phone Part Numbers

STATEK 512 N-Main CX-1V 40.0

Orange, CA 92668

714-639-7810

Ratiometric Resistance Measurements

The TC811 true differential input and differential reference make ratiometric readings possible. In ratiometric

operation, an unknown resistance is measured with respect

to a known standard resistance. No accurately defined

reference voltage is needed.

The unknown resistance is put in series with a known

standard and a current is passed through the pair (Figure

11). The voltage developed across the unknown is applied

to the input and the voltage across the known resistor

applied to the reference input. If the unknown equals the

standard, the input voltage will equal the reference voltage

and the display will read 1000. The displayed reading can be

determined from the following expression:

R

Displayed reading = x 1000

The display will overrange for R

R

STANDARD

.

UNKNOWN

R

STANDARD

UNKNOWN

≥ 2 X

V

REF

–

R

STANDARD

R

UNKNOWN

Figure 11. Low Parts Count Ratio Metric Resistance Measurement

V

REF

+

V

IN

–

V

IN

ANALOG

COMMON

HLDR

LCD

TC811

+

+

V

5

6

7

8

TELCOM SEMICONDUCTOR, INC.

3-147

Page 12

TC811

3-1/2 DIGIT A/D CONVERTER WITH HOLD AND

DIFFERENTIAL REFERENCE INPUTS

+

9V

9V

+

160 kΩ 300 kΩ 300 kΩ

1N4148

SENSOR

50 kΩ

R

2

50 kΩ

R

1

Figure 12. Temperature Sensor

+

V

–

V

IN

+

V

IN

VFS = 200 MV

+

V

REF

–

V

REF

COMMON

–

V

TC811

HLDR V

5.6 kΩ 160 kΩ

1N914

0.7%/°C

PTC

+

R

R

1

20 kΩ

R

20 kΩ

2

3

+

V

–

V

IN

+

V

IN

+

V

REF

–

V

REF

COMMON

–

V

TC811

HLDR V

+

Figure 13. Positive Temperature Coefficient

Resistor Temperature Sensor

3-148

TELCOM SEMICONDUCTOR, INC.

Loading...

Loading...