Page 1

TC70/71

MICROMASTER™ – SYSTEM SUPERVISOR WITH POWER SUPPLY

MONITOR, W A TCHDOG AND BA TTER Y BACKUP

1

2

FEATURES

■ Maximum Functional Integration: Precision Power

Supply Monitor, Watchdog Timer, External RESET

Override, Threshold Detector and Battery Backup

Controller in an 8-Pin Package

■ Generates Power-on RESET and Guards Against

Unstable Processor Operation Resulting from

Power "Brown-out"

■ Automatically Halts and Restarts an Out-of-

Control Microprocessor

■ Output Can be Wire-ORed, or Hooked to Manual

RESET Pushbutton Switch

■ Watchdog Disable Pin for Easier Prototyping

(TC70)

■ Voltage Monitor for Power Fail or Low Battery

Warning (TC71)

■ Available in 8-Pin Plastic DIP or 8-Pin SOIC

Packages

■ Cost Effective

TYPICAL APPLICATIONS

■ All Microprocessor-based Systems

■ Test Equipment

■ Instrumentation

■ Set-Top Boxes

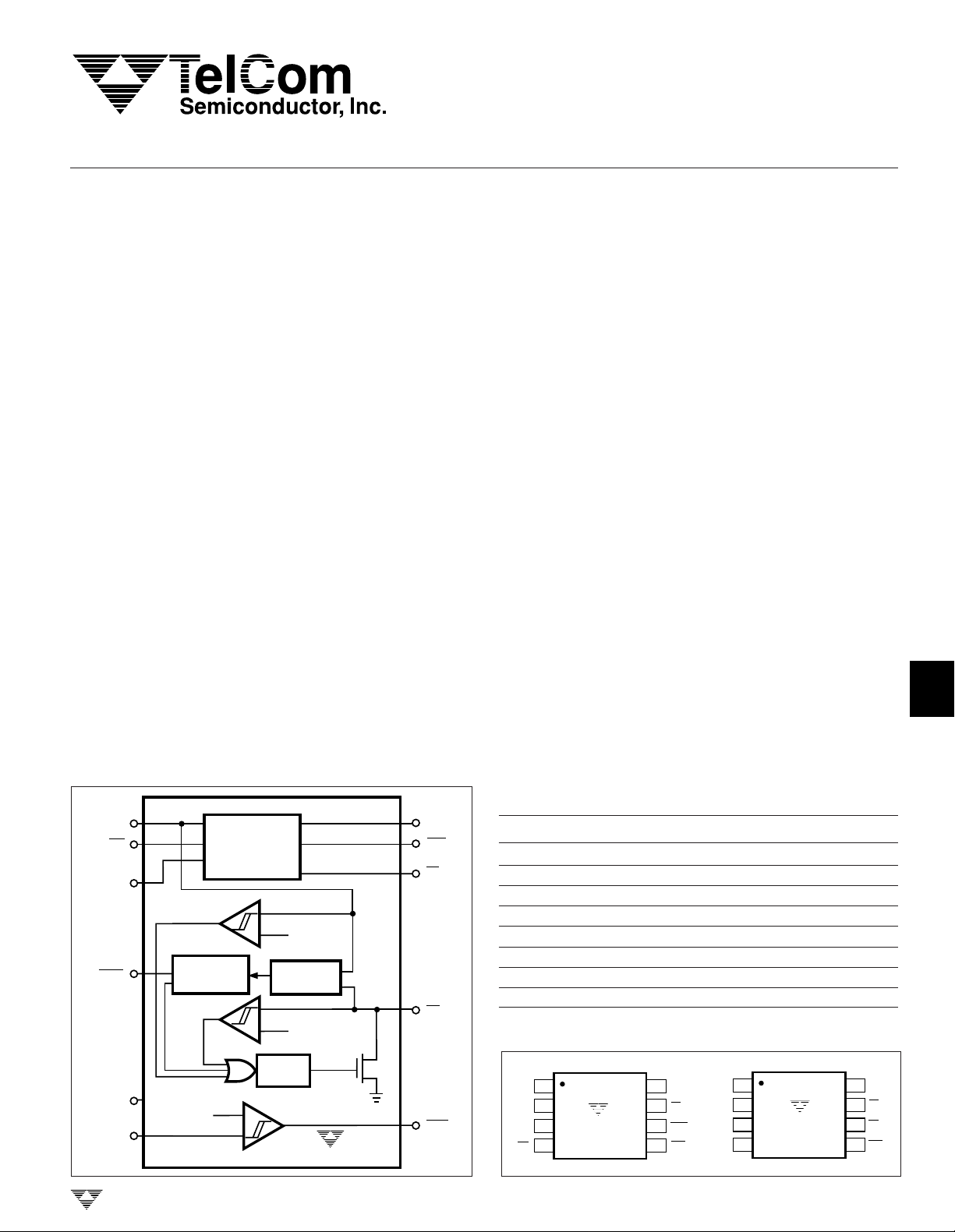

FUNCTIONAL BLOCK DIAGRAM

V

CC V

CEI

(TC70)

V

BATT

WDD

(TC70)

GND

TDI

(TC71)

WATCHDOG

V

REF3

TIMER

BATTERY

BACK-UP

CONTROL

DELAY

TIMER

V

REF1

∆V

DETECTOR

V

REF2

TC70/71

TELCOM SEMICONDUCTOR, INC.

CCO

CEO

(TC70)

PF

(TC71)

RS

TDO

(TC71)

GENERAL DESCRIPTION

The TC70/71 is a fully-integrated power supply monitor,

watchdog and battery backup circuit in a space-saving

8-pin package.

When power is initially applied, the TC70/71 holds the

processor in its reset state for a minimum of 500msec after

VCC is in tolerance to ensure stable system start-up. After

start-up, processor sanity is monitored by the on-board

watchdog circuit. The processor must provide periodic highto-low level transitions to the TC70/71 to verify proper

execution. Should the processor fail to supply this signal

within the specified timeout period, an out-of-control processor is indicated and the TC70/71 issues a momentary

processor reset as a result. The TC70 also features a

watchdog disable pin to facilitate system test and debug.

The output of the TC70/71 can be wire-ORed to a pushbutton switch (or electronic signal) to reset the processor.

When connected to a push-button switch, the TC70/71

provides contact debounce.

The integrated battery backup circuit on-board the TC70/

71 converts CMOS RAM into nonvolatile memory by first

write-protecting, then switching the VCC line of the RAM over

to an external battery.

The TC71 incorporates an additional 1.3V threshold

detector for power fail warning, low battery detection or to

monitor power supply voltages other than +5V.

ORDERING INFORMATION

Part No. Package Temp. Range

T

C70COA 8-Pin SOIC 0°C to +70°C

TC70CPA 8-Pin Plastic DIP 0°C to +70°C

TC70EOA 8-Pin SOIC – 40°C to +85°C

TC70EPA 8-Pin Plastic DIP – 40°C to +85°C

T

C71COA 8-Pin SOIC 0°C to +70°C

TC71CPA 8-Pin Plastic DIP 0°C to +70°C

TC71EOA 8-Pin SOIC – 40°C to +85°C

TC71EPA 8-Pin Plastic DIP – 40°C to +85°C

PIN CONFIGURATIONS (DIP and SOIC)

V

1

CCO

V

27

CC

GND

CEI

TC70

3

4

V

8

BATT

RS

6

WDD

5

CEO

V

1

CCO

V

27

CC

3

GND

4

TDI

TC71

TC70/71-1 11/18/96

V

8

BATT

RS

PF

6

5

TDO

5-7

3

4

5

6

7

8

Page 2

TC70/71

MICROMASTER™ – SYSTEM SUPERVISOR

WITH POWER SUPPL Y MONITOR, W A TCHDOG

AND BA TTER Y BACKUP

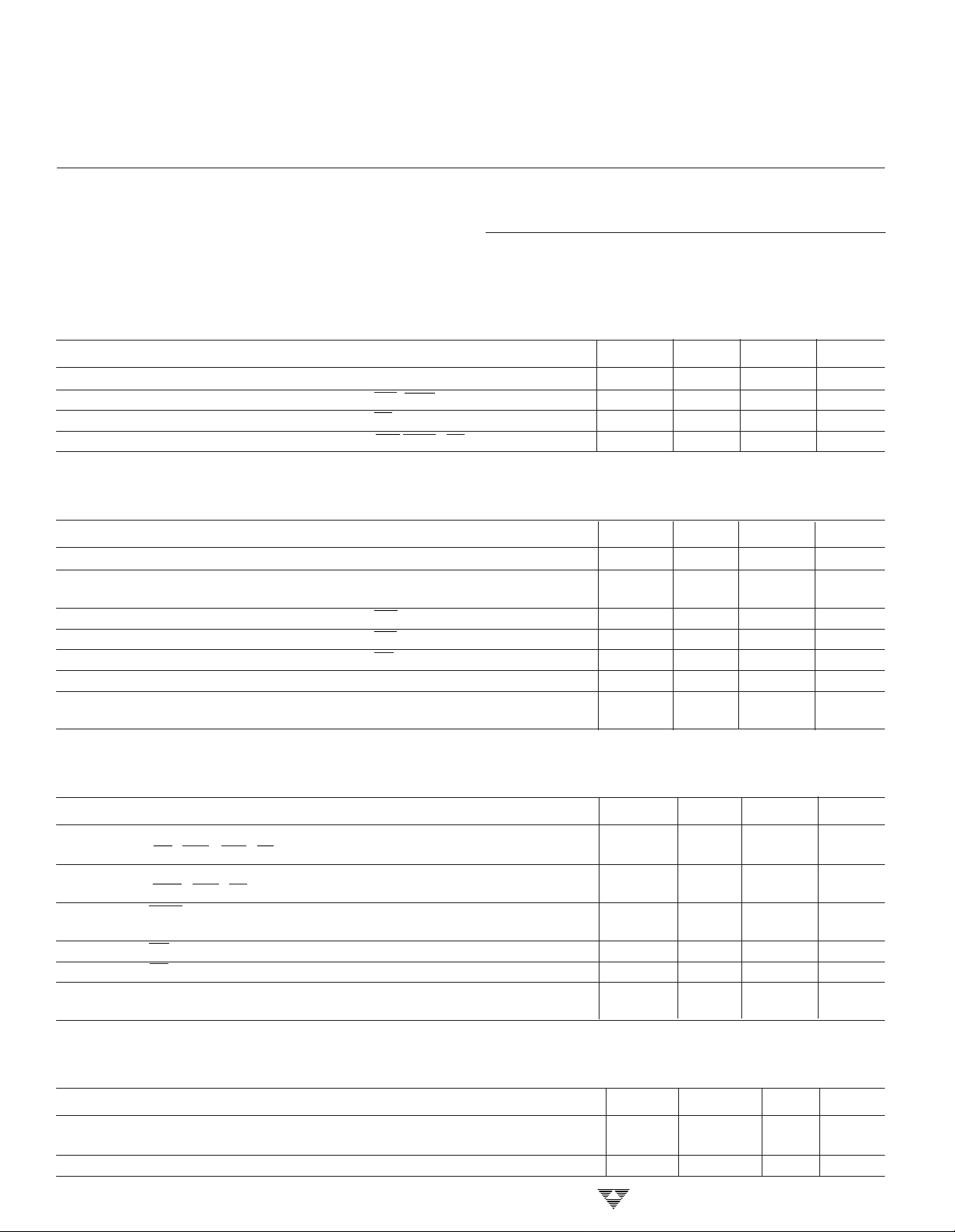

ABSOLUTE MAXIMUM RATINGS*

Voltage (Any Pin) with Respect to

Ground................................ GND – 0.3 to VCC + 0.3V

Operating Temperature Range ...............– 40°C to +85°C

ELECTRICAL CHARACTERISTICS: Recommended DC Operations: T

A

= T

MIN

to T

MAX,

Storage Temperature Range ................– 65°C to +150°C

Lead Temperature (Soldering, 10 sec) .................+300°C

*This is a stress rating only and functional operation of the device at these

or any other conditions above those indicated in the operational sections of

the specifications is not implied. Exposure to Absolute Maximum Rating

Conditions for extended periods may affect device reliability.

unless otherwise specified.

Symbol Parameter Test Conditions Min Typ Max Unit

V

CC

V

IH

V

IH

V

IL

Supply Voltage Note 1 4.5 5.0 5.5 V

Input HIGH Level CEI, WDD (Note 1) 2.5 — — V

Input HIGH Level RS (Note 1) 2.2 — — V

Input LOW Level CEI, WDD, RS (Note 1) — — 0.8 V

ELECTRICAL CHARACTERISTICS: DC: T

Symbol Parameter Test Conditions Min Typ Max Unit

I

CC1

I

CC2

I

IH

I

IL

I

IH

I

STBY

I

STBY

A

= T

MIN

to T

, VCC = 4.5V to 5.5V, unless otherwise specified.

MAX

Operating Current Notes 2, 3 — 5 6.5 mA

Operating Current in VCC = 0; V

= 2.8V; (Note 3) — 0.01 0.20 µA

BATT

Battery Backup Mode

Input Leakage CEI — 4 7 µA

Input Leakage CEI — 1 — µA

Input Leakage RS — 1 — µA

Battery Standby Current 5.5V > VCC > V

Battery Standby Current 5.5V > VCC > V

+ 0.2V – 1.0 — 0.02 µA

BATT

+ 0.2V – 0.1 — 0.02 µA

BATT

TA = 25°C

ELECTRICAL CHARACTERISTICS:

DC: Power Supply Monitor, EXT. RESET and Watchdog:

Symbol Parameter Test Conditions Min Typ Max Unit

I

OL

I

OH

WDD

I

V

STH

V

STL

V

CCTRIP

Output Current 0.4V VOL = 0.4V 2 5 — mA

(RS, TDO, CEO, PF Pins)

Output Current 2.4V VOH = 2.4V 2 3 — mA

(TDO, CEO, PF Pins)

WDD Input Current WDD = GND – 120 — — µA

WDD = V

RS Strobe (HIGH) Level Figure 3 (Note 1) VDD – 0.5 — — V

RS Strobe (LOW) Level Figure 3 (Note 1) 2.2 — VDD – 1.8 V

VCC Trip Point (Note 1) 0°C ≤ TA ≤ 70°C 4.25 — 4.49

– 40°C ≤ TA ≤ 85°C 4.20 4.49

CC

TA = T

MIN

to T

, VCC = 4.5V to 5.5V,

MAX

——25

unless otherwise specified.

ELECTRICAL CHARACTERISTICS:

DC: Battery Backup and Threshold Detector:

Symbol Parameter Test Conditions Min Typ Max Unit

V

V

5-8

OUT1

OUT2

V

Output Voltage I

CCO

V

in Battery Backup Mode

OUT

TA = T

= 1mA VCC – 0.3 VCC – 0.1 — V

OUT

I

= 50mA VCC – 0.5 VCC – 0.20 —

OUT

I

= 250µA, VCC < V

OUT

MIN

to T

, VCC = 4.5V to 5.5V, unless otherwise specified.

MAX

BATT

– 0.2, V

BATT

= 2.8V

V

BATT

– 0.1 V

BATT

– 0.02

— V

TELCOM SEMICONDUCTOR, INC.

Page 3

MICROMASTER™ – SYSTEM SUPERVISOR

WITH POWER SUPPL Y MONITOR, W A TCHDOG

AND BA TTER Y BACKUP

TC70/71

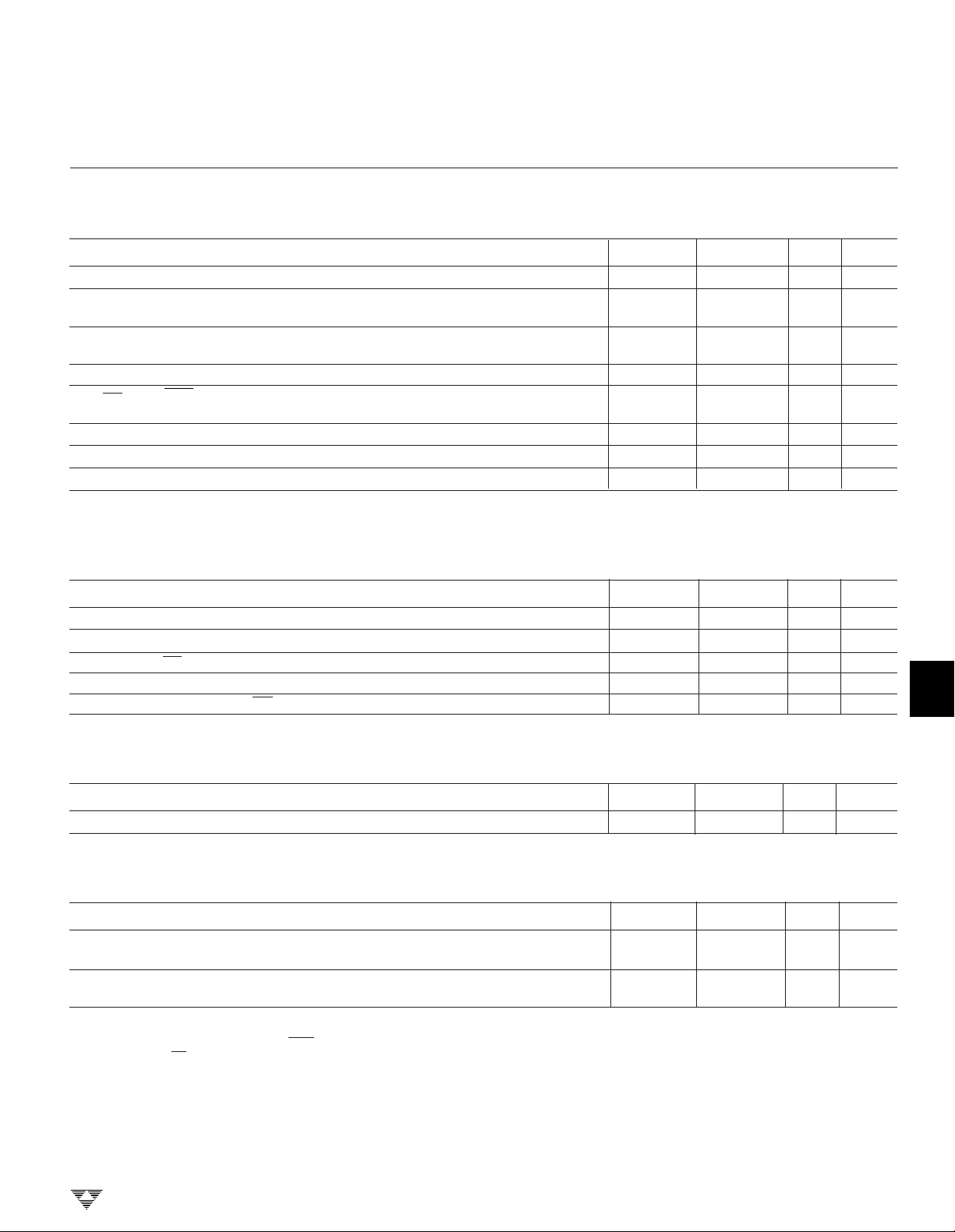

ELECTRICAL CHARACTERISTICS: (Cont.)

DC: Battery Backup and Threshold Detector:

Symbol Parameter Test Conditions Min Typ Max Unit

I

OUT1

I

OUT2

V

SW

V

HYST

VOH

CEO

V

TDI

I

TDI

V

TDI (HYST)

V

Output Current VCC = 4.5V, V

CCO

V

Output Current in V

CCO

Battery Backup Mode V

Battery Switchover Threshold —

(VCC Falling)

Battery Switchover Hysteresis — 20 — mV

CEO Output Voltage in VCC < V

Battery Backup Mode IOH = 10µA

Threshold Detector Trip Voltage 1.2 — 1.4 V

Threshold Detector Input Current TA = 25°C –25 — +25 nA

Threshold Detector Hysteresis — 10 — mV

CCO

BATT

TA = T

= V

= 2.8V

BATT

to T

MIN

CCO

– 0.3V 500 — — µA

BATT

– 0.2, V

, VCC = 4.5V to 5.5V, unless otherwise specified.

MAX

= 3.5V 50 100 — mA

V

= 2.8V V

BATT

– 0.01

BATT

– 0.2 — — V

BATT

—V

1

2

3

ELECTRICAL CHARACTERISTICS: AC: Power Supply Monitor, EXT. RESET and Watchdog:

Symbol Parameter Test Conditions Min Typ Max Unit

t

PBH

t

RST

t

ST

t

TD

t

RPD

PB Hold Time Figure 4 (Note 4) 20 — — msec

Reset Active Time Figure 6 500 — 900 msec

RS STROBE Pulsewidth Figure 3 500 — — nsec

Watchdog Timeout Period Figure 3 500 700 900 msec

VCC Detect to RS LOW Figure 6 — — 100 nsec

TA = T

MIN

specified.

to T

, VCC = 4.5V to 5.5V, unless otherwise

MAX

ELECTRICAL CHARACTERISTICS:

AC: Battery Backup and Threshold Detector:

Symbol Parameter Test Conditions Min Typ Max Unit

t

PD

CE Propagational Delay Figure 7 — — 50 nsec

TA = T

MIN

to T

, VCC = 4.5V to 5.5V, unless otherwise specified.

MAX

ELECTRICAL CHARACTERISTICS:

AC:

TA = T

Symbol Parameter Test Conditions Min Typ Max Unit

t

F

t

R

NOTES: 1. All voltages referenced to ground.

to T

MIN

VCC Fall Time From Figure 5 (Note 1) 10 — — µsec

4.25V to 3.0V

VCC Rise Time From Figure 5 (Note 1) 0 — — µsec

3.0V to 4.25V

2. No output load.

3 Measured with V

4. The RS output must be held low for a minimum of 20msec to guarantee a reset.

MAX

.

CCO

and CEO open.

4

5

6

7

TELCOM SEMICONDUCTOR, INC.

8

5-9

Page 4

TC70

TC71

PIN DESCRIPTION

Pin No Pin No

(TC70) (TC71) Symbol Description

11V

22 VCCV

3 3 GND GND Input. Ground.

4 – CEI Chip enable input. Chip enable to static RAM or other device to be battery

– 4 TDI Threshold detector input. When the voltage on threshold detector input (TDI) is

5 – CEO Chip enable output. This line goes low only when CEI is low and VCC is above

– 5 TDO Threshold detector output. TDO goes low when TDI is less than 1.3V and VCC is

6 – WDD Watchdog disable input. Grounding this line disables the watchdog timer (no

– 6 PF Power fail output. This line goes low when V

7 7 RS RESET/STORE (Bidirectional). An open drain with pull-up (in output mode) that

88V

CCO

BATT

V

CC

Connect to VCC if V

CC

backed-up. Connect to ground if V

less than 1.3V, threshold detector output (TDO) goes low.

the RESET threshold.

greater than V

V

BATT

RESET pulses are generated after the watchdog timer times out). This input is

provided to facilitate system debug. This input is internally pulled-up and can be

left open, or tied to VCC for normal watchdog operation.

to write-protect the external device to be battery backed.

goes active if:

1. V

2. If pulled low by an external electronic signal or switch closure

3. If the watchdog is not strobed within the minimum watchdog timeout period

4. During power-up and power down

In the input mode, RS is a negative edge triggered input that resets the

watchdog timer when pulled to ground through a 10kΩ, 5% tolerance resistor.

Backup battery input. Connect to ground if battery backup is not used.

MICROMASTER™ – SYSTEM SUPERVISOR

WITH POWER SUPPL Y MONITOR, W A TCHDOG

AND BA TTER Y BACKUP

Output. The higher of VCC or V

and V

BATT

Input. +5V power supply.

. (The threshold detector is turned off when VCC is less than

.

CC

BATT

falls below 4.5V nominal

CCO

is internally switched to this output.

BATT

are not used.

is not used.

CCO

is below 4.5V nominal. It is used

CC

DETAILED DESCRIPTION

Precision Power Supply Monitor

The RS pin is immediately driven low any time VCC is

below 4.5V nominal. The processor is held in its reset state

during power-up and power-down. RS remains low for a

minimum of 500msec after VCC is within tolerance to allow

the power supply and processor to stabilize.

Watchdog Timer

The processor drives the RS pin with an input/output

(I/O) line in series with a voltage divider to VDD. Pulling the

bottom of this divider low results in an internal voltage

change (strobe) sufficient to reset the watchdog timer, but

above the VIL input threshold of the processor RESET input.

The processor must continuously apply strobes in this

manner within a set period to verify proper software execution. A momentary reset (500msec minimum) is generated

if a hardware or software failure keeps RS from being

5-10

strobed within the watchdog timeout period. This action

typically initiates the processor's power-up routine. If the

interruption persists, new reset pulses are generated each

timeout period until RS is strobed. The timeout period is

typically 700msec.

It is often difficult to debug a system while the watchdog

is continuously generating reset pulses. For example, the

watchdog must be disabled when the system is operated

with an in-circuit emulator (ICE). The watchdog disable input

(TC70) is provided for system debugging, (or if the watchdog

timer on-board the processor is to be used). Grounding

WDD disables the watchdog (all other functions remain

intact). For normal watchdog operation, WDD can be tied to

VDD.

The software routine that drives the RS strobe must be

in a section of the program that executes frequently enough

so the time between toggles is less than one watchdog

timeout period. The strobe signal can be derived from

microprocessor address, data and/or control signals. Typical circuit examples are shown in Figure 1.

TELCOM SEMICONDUCTOR, INC.

Page 5

MICROMASTER™ – SYSTEM SUPERVISOR

WITH POWER SUPPL Y MONITOR, W A TCHDOG

AND BA TTER Y BACKUP

1

TC70

TC71

Resistor Value Selection

The values of R1 and R2 must be chosen to ensure a

valid low strobe level (V

line is low. The use of 10kΩ, ±5% tolerance resistors are

recommended. These values result in a nominal strobe level

of 2.83V on RS (min/max of 2.43V/3.24V, assuming

V

= 5.0V ±10%). Other resistor values can be used, so

DD

long as the additive tolerances of the power supply and

resistor values result in a strobe that falls within V

V

under all additive tolerance conditions.

STL

) on RS when the processor I/O

STL

STH

and

External Override Reset Control

A built-in debounce circuit allows a pushbutton switch

(or other electronic reset signal) to be wire-ORed to RS as

an external reset override (Figure 4). The external reset

signal is required to be an active low signal of at least

20msec in duration. Internally, this input is timed to provide

a minimum reset pulse width output of 500msec.

Threshold Detector

The TC71 issues a low-true output on the TDO pin any

time the TDI pin is less than 1.3V and VCC is greater than

V

. The voltage to be monitored is connected to the TDI

BATT

input through a simple resistor divider. The threshold detector can be used to generate an early power fail warning if the

unregulated DC input to the +5V regulator is available for

monitoring.

data corruption during power up and power down. The

battery switchover circuit compares VCC to the V

and connects VCCO to whichever is higher. Switchover

(VSW) occurs when VCC is 10mV below V

and when VCC is 10mV more than V

battery switchover comparator has 20mV of hysteresis to

prevent switch chattering if VCC falls very slowly.

BATT

as VCC falls,

BATT

as VCC rises. The

BATT

input

Integrated Battery Backup (TC71)

The TC71 differs from the TC70 in that it has a Power

Fail (PF) output instead of a gated chip enable (CEI, CEO).

PF must be externally gated with the decode for the CMOS

RAM or other device to be battery-backed. (Many CMOS

RAMs have both CE and CE enables. In this case, the PF

output can be connected directly to the CE input of the RAM).

PF is high as long as VCC is greater than 4.5V nominal.

When VCC falls below 4.5V nominal, PF is driven low.

Battery switchover for the TC71 is otherwise identical to that

of the TC70.

Supply Monitor Noise Sensitivity

The TC70/71 is optimized for fast response to negativegoing changes in VDD. Systems with an inordinate amount

of electrical noise on VDD (such as systems using relays),

may require a 0.1µF bypass capacitor to reduce detection

sensitivity. This capacitor should be installed as close to the

TC70/71 as possible to keep the capacitor lead length short.

2

3

4

5

Integrated Battery Backup (TC70)

The CEO line (TC70) drives the CE input of a CMOS

RAM or other device to be battery-backed. CEO follows CEI

as long as VCC is greater than 4.5V nominal. If VCC falls

below 4.5V nominal, CEO is driven to the potential of VCCO

thus write protecting the RAM and preventing accidental

VCCO

CEO

CEI

RS

Figure 1. TC70 Typical Application

+5V

+3V L

I

BATTERY

WDD

V

CC

V

BATT

GND

TC70

TYPICAL APPLICATIONS

Figure 1 shows a full feature implementation of the

TC70; Figure 2 shows the TC71. Resistors R1 and R2 of

Figure 2 set the trip point voltage for the early power fail

warning circuit using the TC71 threshold detector.

V

CC

CMOS

RAM

CE

+5V

R1

10K

ADDRESS

DECODER

R2

13K

RESET

ADDRESS

I/O

RESET

PROCESSOR

6

7

8

TELCOM SEMICONDUCTOR, INC.

5-11

Page 6

TC70

TC71

MICROMASTER™ – SYSTEM SUPERVISOR

WITH POWER SUPPL Y MONITOR, W A TCHDOG

AND BA TTER Y BACKUP

REGULATOR

R3

R4

FILTER CAP

TC55RP

RECTIFIER

V

CC

3V L

I

WDD

V

CC

TDI

V

BATT

GND

AC I

N

VCCO

PF

V

CE

CC

CE

TC71

TDO

V

R3

10K

RS

Figure 2. TC71 Typical Application

CC

RESET

CMOS

RAM

ADDRESS

DECODER

R4

13K

ADDRESS

NMI

I/O

RESET

PROCESSOR

t

ST

RS

V

(MIN)

STH

V

(MAX)

STL

(MIN)

V

STL

t

TD

Note: t

will keep the watchdog timer from forcing RS LOW.

(A

is the maximum elapsed time between strobes which

TD

STROBE

is defined as a high-to-low transition from V

Figure 3. Watchdog Strobe

STH

to V

STL

PB CLOSED

t

RS

)

.

PBH

V

IL

PB OPEN

t

RST

V

IH

Figure 4. RS Override Reset

5-12

TELCOM SEMICONDUCTOR, INC.

Page 7

MICROMASTER™ – SYSTEM SUPERVISOR

WITH POWER SUPPL Y MONITOR, W A TCHDOG

AND BA TTER Y BACKUP

1

TC70

TC71

V

CEI

t

R

t

F

CC

4.25V

3.0V

Figure 5. Power Up/Down Slew Rate Figure 6. Power Up/Down Reset Timing

V

IH

V

CC

4.25V

CEI

RS

V

t

RPD

V

IL

OL

t

RST

2

3

V

OH

4

5

V

BATT- 0.2V

CEO

V

CC

V

IH

t

PD

4.25V

3.0V

t

R

Figure 7. Battery Backup (Power-Up)

CEO

V

t

PD

CC

Figure 8. Battery Backup (Power-Down)

4.25V

3.0V

t

F

V

BATT-0.2V

6

7

8

TELCOM SEMICONDUCTOR, INC.

5-13

Loading...

Loading...